fanuc 15iA, 150i- A User Manual

Computer Numerical Control Products

GE Fanuc Automation

Series 15i / 150i – Model A

Remote Buffer

Descriptions Manual

B-6322EN-1/01 1999

Warnings and notices for

this publication

GFLE-003

Warning

In this manual we have tried as much as possible to describe all the various

matters. However, we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this

manual should be regarded as “impossible”.

Notice

This document is based on information available at the time of its publication. While efforts have

been made to be accurate, the information contained herein does not purport to cover all details or

variations in hardware or software, nor to provide every contingency in connection with

installation, operation, or maintenance. Features may be described herein which are not present in

all hardware and software systems. GE Fanuc Automation assumes no obligation of notice to

holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall

apply.

The following are Registered Trademarks of GE Fanuc Automation

CIMPLICITY® Genius®

The following are Trademarks of GE Fanuc Automation

Alarm Master

CIMSTAR

Field Control

Genet

Helpmate

LogicMaster

Modelmaster

PowerMotion

ProLoop

PROMACRO

Series Five

Series 90

Series One

Series Six

Series Three

VuMaster

Workmaster

© Copyright 1998 FANUC Ltd.

Authorized Reproduction GE Fanuc Automation Europe S.A.

All Rights Reserved

No part of this manual may be reproduced in any form.

All specifications and designs are subject to change without notice.

B-63322EN-1/01 PREFACE

p-1

PREFACE

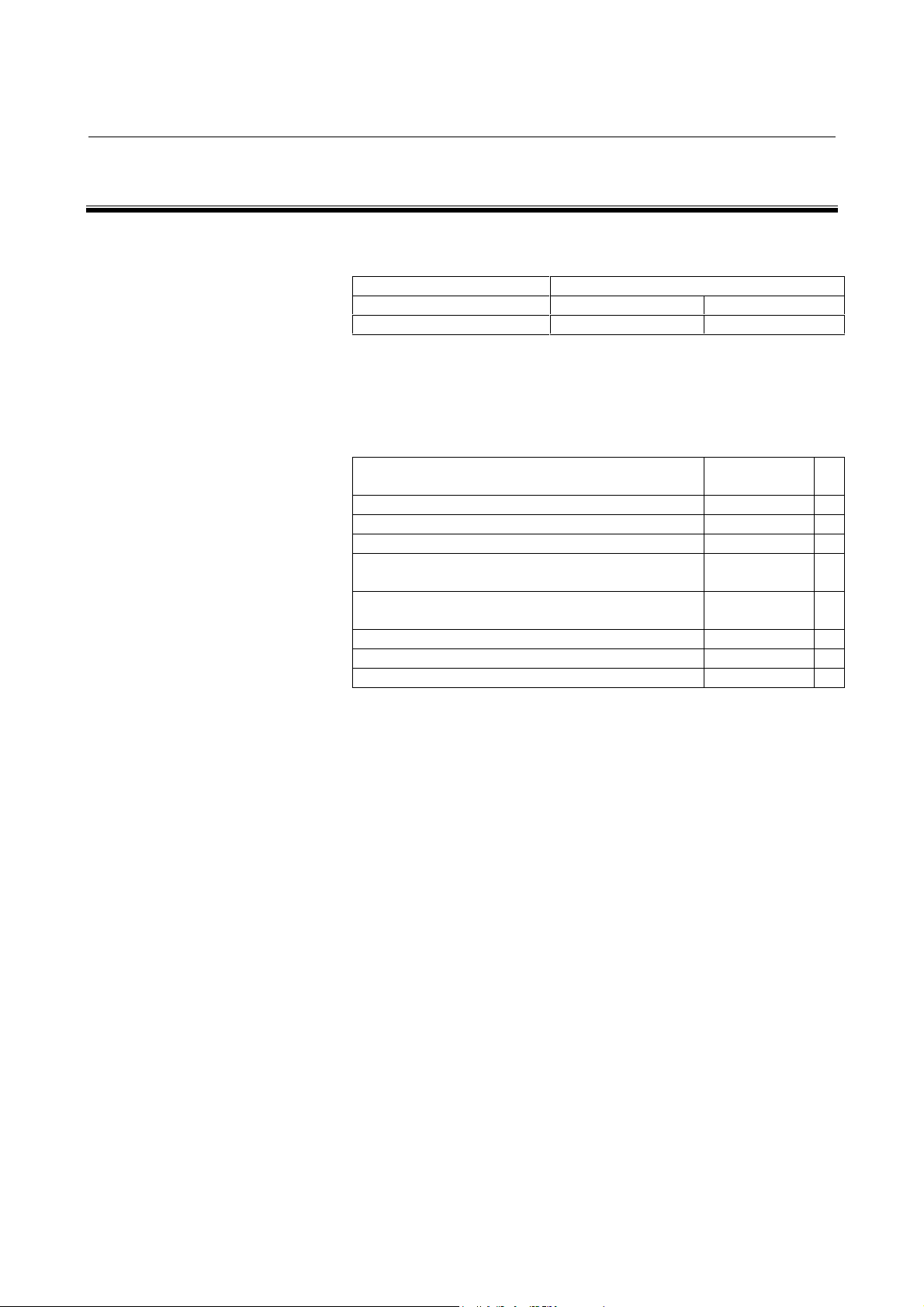

Applicable product name

The models covered by this manual, and their abbreviations are:

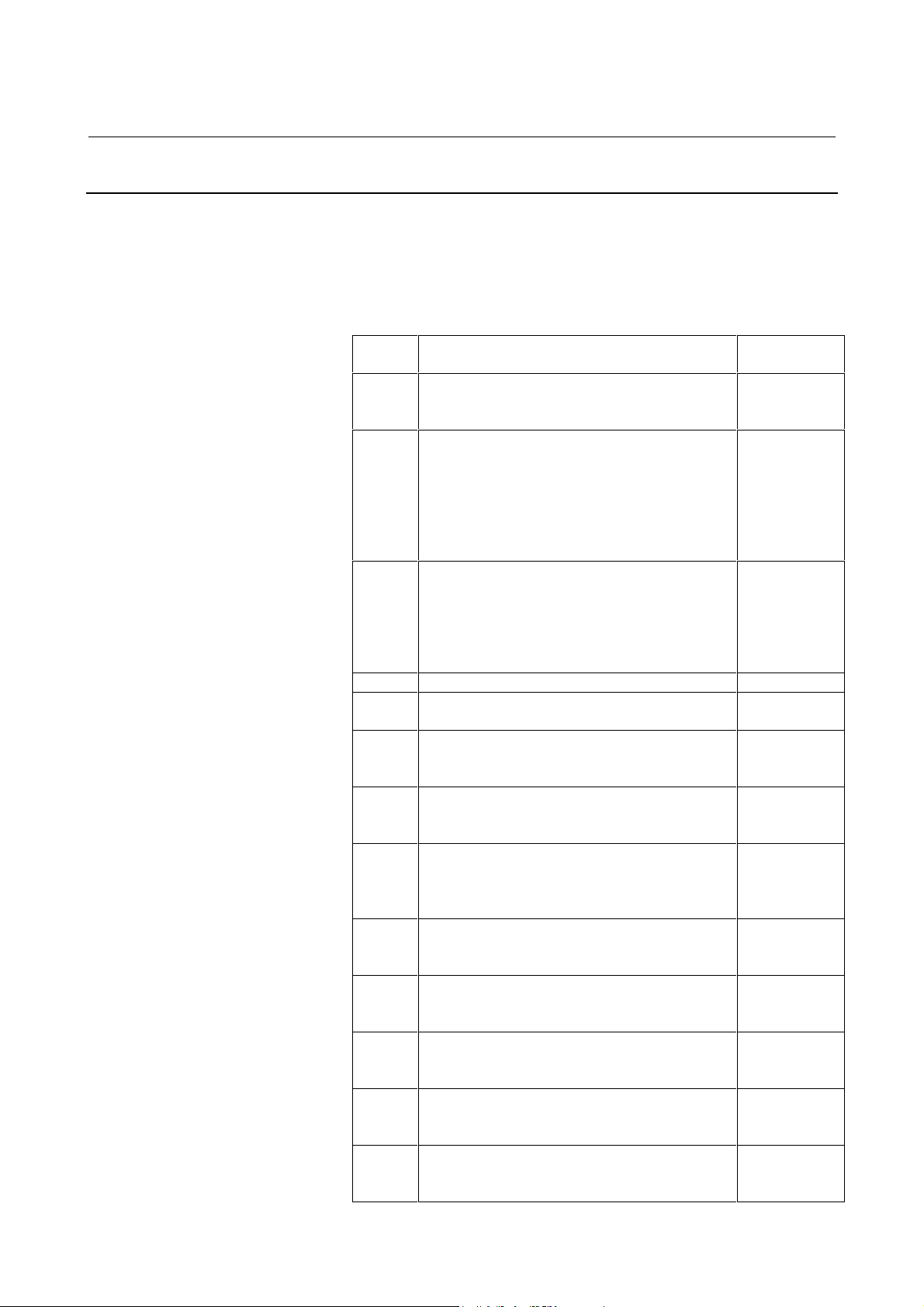

Product name Abbreviations

FANUC Series 15i-MA 15i-MA Series 15i

FANUC Series 150i-MA 150i-MA Series 150i

Related manuals

The table below lists manuals related to MODEL A of Series 15i, and

Series 150i. In the table, this manual is marked with an asterisk (*).

Table 1 (a) Related manuals

Manual name

Specification

number

DESCRIPTIONS B-63322EN

CONNECTION MANUAL (Hardware) B-63323EN

CONNECTION MANUAL (Function) B-63323EN-1

OPERATOR’S MANUAL (PROGRAMMING)

for Machining Center

B-63324EN

OPERATOR’S MANUAL (OPERATION)

for Machining Center

B-63324EN-1

MAINTENANCE MANUAL B-63325EN

PARAMETER MANUAL B-63330EN

DESCRIPTIONS (Supplement for Remote Buffer) B-63322EN-1 *

B-63322EN-1/01

c-1

CONTENTS

PREFACE ................................................................................................................ p-1

1. GENERAL.............................................................................................................1

2. INTERFACE BETWEEN REMOTE BUFFER AND

HOST COMPUTER.............................................................................................2

2.1 ELECTRICAL INTERFACE ..................................................................................................... 3

2.2 SOFTWARE INTERFACE........................................................................................................ 4

3. ELECTRICAL INTERFACE.............................................................................5

3.1 TRANSMISSION SYSTEM....................................................................................................... 6

3.2 RS-232-C INTERFACE.............................................................................................................. 7

3.3 RS-422 INTERFACE................................................................................................................ 10

4. PROTOCOL A....................................................................................................13

4.1 MESSAGE FORMAT .............................................................................................................. 14

4.2 CODE SYSTEM....................................................................................................................... 14

4.3 COMMUNICATION SYSTEM............................................................................................... 15

4.4 COMMAND ............................................................................................................................. 17

4.4.1 Command Table.............................................................................................................................17

4.4.2 Description of Data Part.................................................................................................................19

4.5 PARAMETER TABLE............................................................................................................. 23

4.6 ERROR PROCESS................................................................................................................... 24

4.7 STATUS TRANSITION........................................................................................................... 25

5. EXPANSION PROTOCOL A...........................................................................26

5.1 COMMUNICATION SYSTEM............................................................................................... 27

5.2 DATA PACKET FORMAT ..................................................................................................... 28

5.3 MONITOR PACKET FORMAT.............................................................................................. 30

5.4 COMMUNICATION EXAMPLE............................................................................................ 32

6. PROTOCOL B....................................................................................................41

6.1 COMMUNICATION SYSTEM............................................................................................... 42

6.1.1 When the CNC Alarm/Reset is not Posted to the Host...................................................................42

6.1.2 When the CNC Alarm/Reset is Posted to the Host.........................................................................44

6.2 CONTROL CODE.................................................................................................................... 48

6.3 BUFFER CONTROL................................................................................................................ 48

6.4 ALARM AND RESET OF CNC.............................................................................................. 49

7. EXPANSION PROTOCOL B (RS-422)...........................................................50

CONTENTS B-63322EN-1/01

c-2

8. DATA INTERFACE ..........................................................................................51

8.1 DATA PART ............................................................................................................................ 52

8.2 INTERFACE OF DATA PART ............................................................................................... 52

9. BINARY INPUT OPERATION FUNCTION .................................................53

9.1 FUNCTION EXPLANATION ................................................................................................. 54

9.2 TRANSFER RATE................................................................................................................... 57

9.3 NOTES......................................................................................................................................58

10. PARAMETER.....................................................................................................59

10.1 INPUT DEVICE NUMBER..................................................................................................... 60

10.2 EXCLUSIVE PARAMETER FOR REMOTE BUFFER......................................................... 61

10.3 PARAMETERS RELATED TO BINARY INPUT OPERATION.......................................... 67

11. ALARM ...............................................................................................................70

12. MAINTENANCE................................................................................................71

12.1 LED INDICATIONS ................................................................................................................ 71

12.1.1 Normal State ..................................................................................................................................71

12.1.2 System Errors.................................................................................................................................72

12.2 MATERIAL FOR REMOTE BUFFER TROUBLESHOOTING............................................ 74

12.3 DETERMINING THE LOGICAL SLOT NUMBER OF

THE REMOTE BUFFER BOARD .......................................................................................... 76

12.3.1 Determining the Logical Slot Number on the Screen Displayed

at the Time a System Alarm Occurs......................................................................................76

12.3.2 Determining the Logical Slot Number on the System Configuration Screen.........................77

B-63322EN-1/01 1. GENERAL

-1-

1 GENERAL

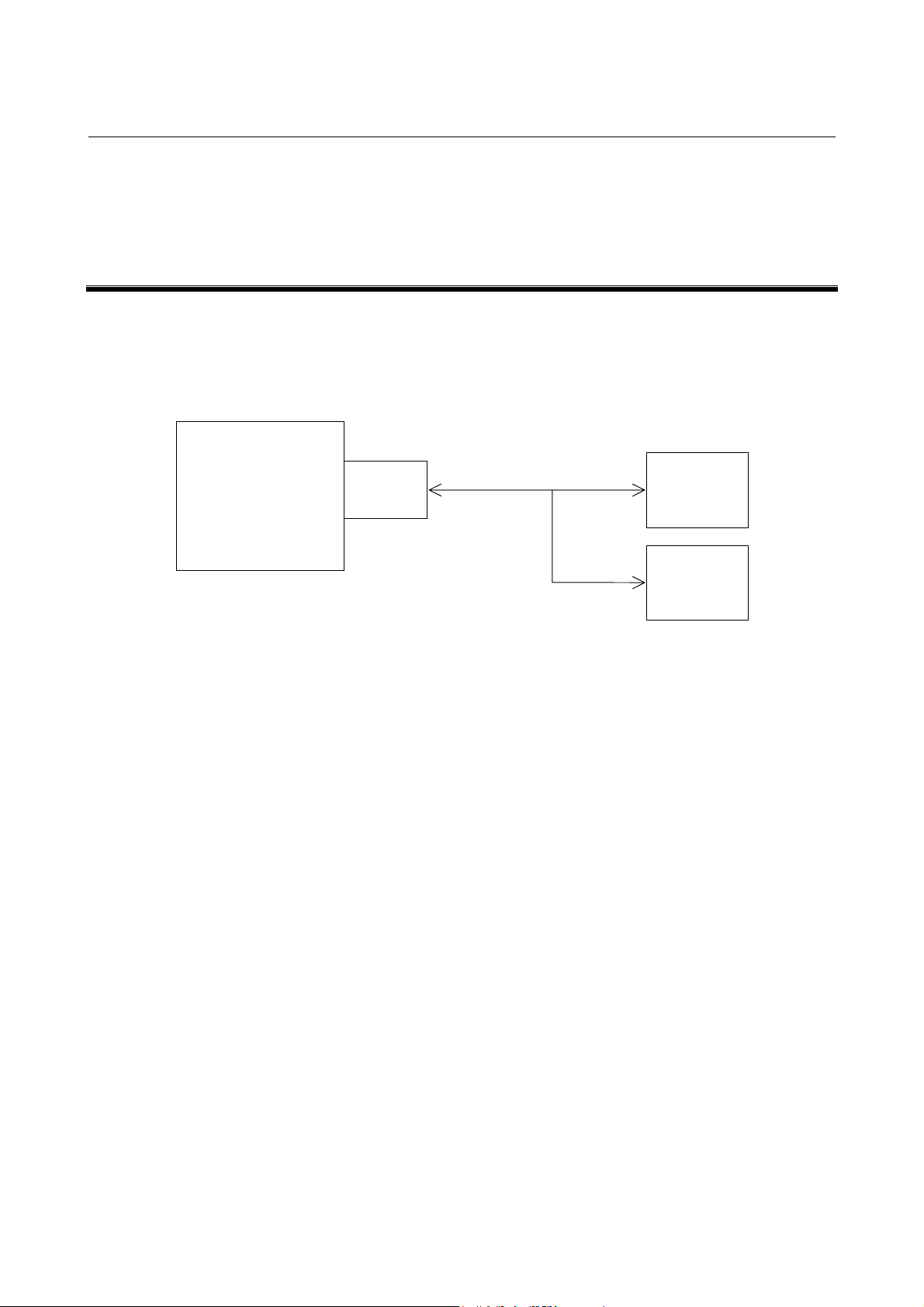

The remote buffer for FANUC Series 15i/150i-MODEL A is an

option and is used to allow a large number of data to be continuously

supplied to the CNC at high speed by connecting it to the host

computer or I/O device through a serial interface.

The followings can be performed by the remote buffer.

1) It is used to perform DNC operation at high speed and with high

reliability by performing on-line connection to the host

computer.

2) It is used to download the NC program and parameters from the

host computer. When protocol B or expansion protocol B is

used, NC programs and parameters can also be uploaded to the

host computer.

3) It is used to perform DNC operation and download various kinds

of data by connecting to the I/O device. The following I/O

devices can be connected.

(1) FANUC PROGRAM FILE Mate

(2) FANUC HANDY FILE

Hereafter, the destination where the remote buffer is connected to is

called “Host computer” for ease of explanation.

RS-232-C/RS-422

15i/150i-MA

Remote

buffer

Host

computer

I/O device

2. INTERFACE BETWEEN REMOTE BUFFER AND HOST COMPUTER B-63322EN-1/01

-2-

2 INTERFACE BETWEEN REMOTE BUFFER

AND HOST COMPUTER

B-63322EN-1/01 2. INTERFACE BETWEEN REMOTE BUFFER AND HOST COMPUTER

-3-

2.1

ELECTRICAL INTERFACE

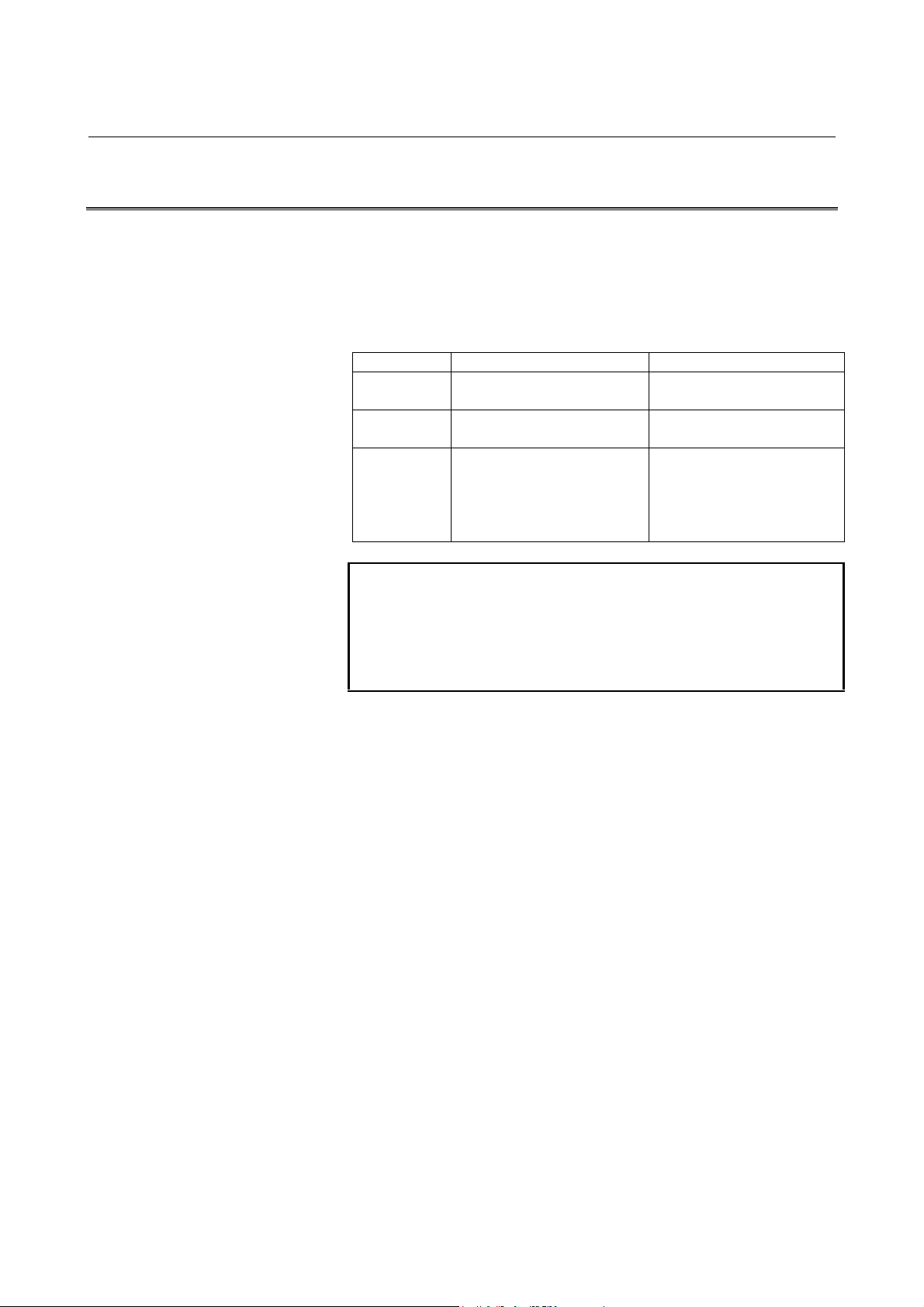

The following which interfaces are provided as standard

specifications.

1) RS-232-C interface

2) RS-422 interface (Note 1)

RS-232-C RS-422

Interface Serial voltage interface

(start-stop system)

Balance transmission serial

interface (start-stop system)

Baud rate 50 – 19200 baud rate

(Note 2)

50 – 86400 baud rate

(Note 1)

Cable length

(MAX.)

100m (4800 baud or less)

50m (9600 baud)

15m (19200 baud)

It differs depending on I/O

devices.

Approximately 800m

(9600 baud or less)

50m (19200 baud or more)

NOTE

1 When the baud rate exceeding 38400 BPS is used, the

synchronization of reception clock is required. Prepare

the TT (*TT ) and RT (*RT) signals.

2 When t he baud r at e used is 19200 baud or more, use the

RS-422 interface.

2. INTERFACE BETWEEN REMOTE BUFFER AND HOST COMPUTER B-63322EN-1/01

-4-

2.2

SOFTWARE INTERFACE

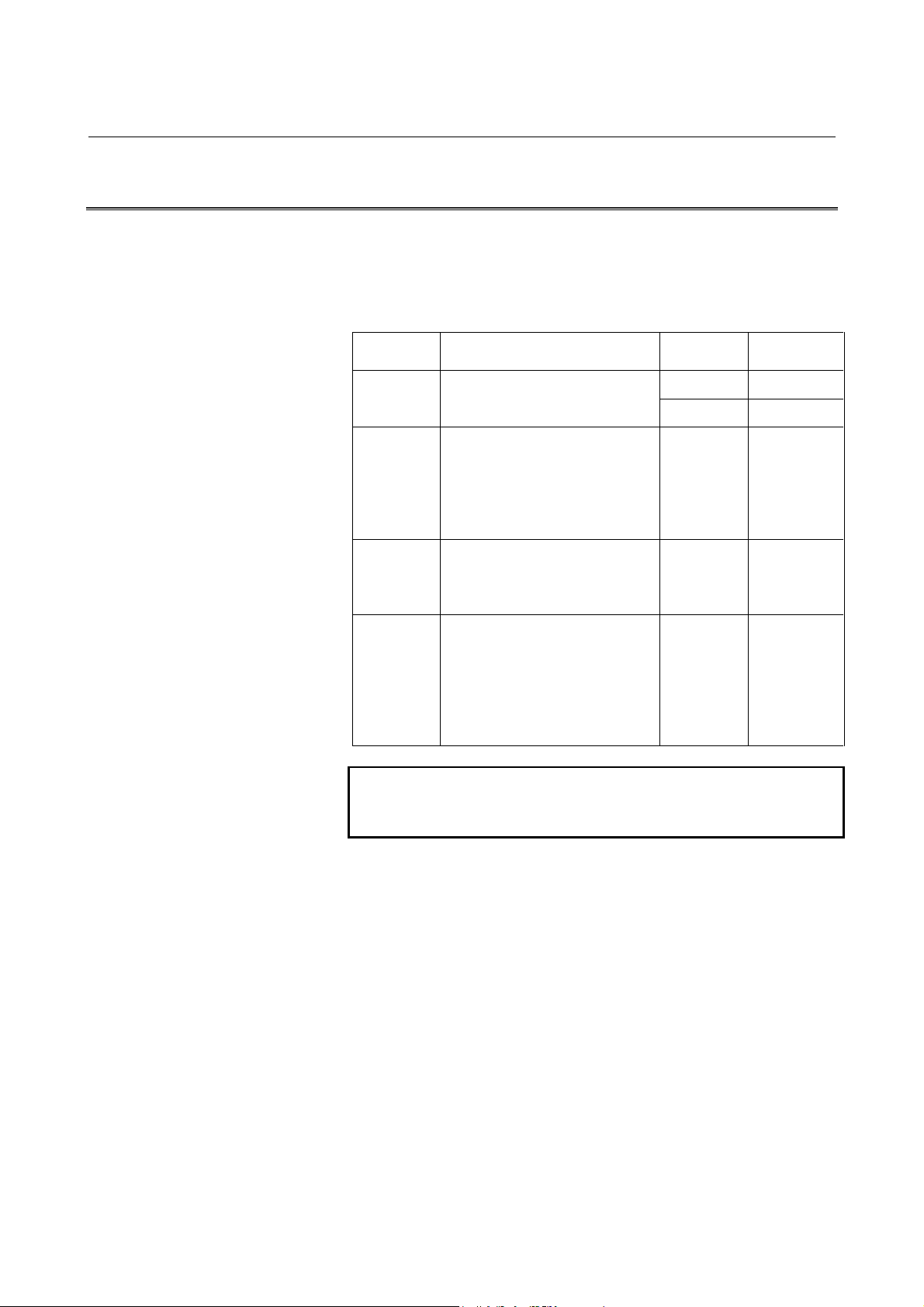

The following four protocols for communication between the remote

buffer and host computer are provided. The protocol meeting the

requirement of specifications of connection device can be selected by

setting a parameter.

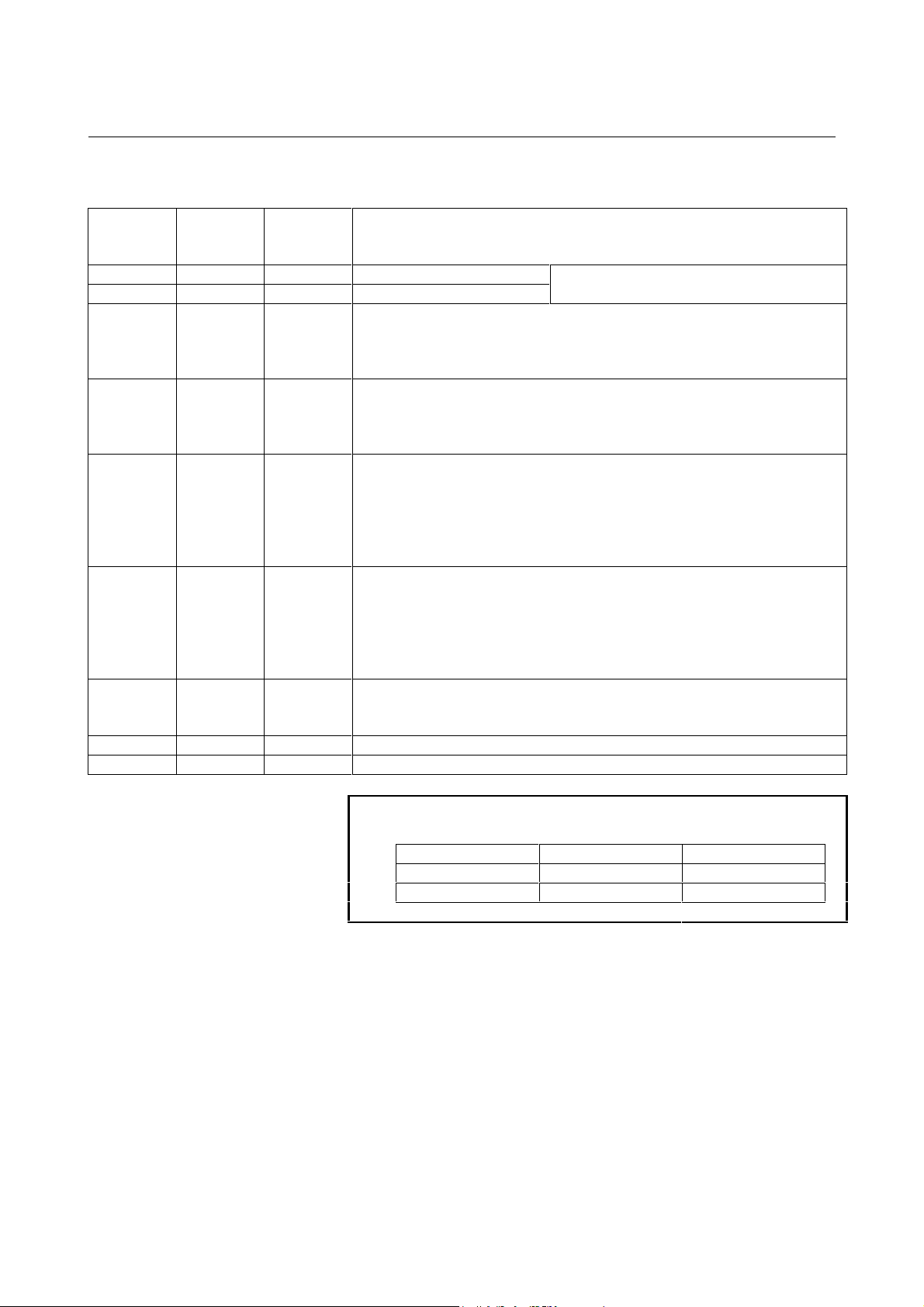

Protocol Features of protocol

Interface

used

Transfer

rate (Max.)

RS-232-C 19200 BPSProtocol

A

It is the handshake system

where transmit/receive is

repeated between the both.

RS-422 86400 BPS

Expansion

protocol

A

It is nearly the same as the

protocol A. However, the NC

program can be transferred at

high-speed so that it can be

applied to the high-speed DNC

operation.

RS-422 86400 BPS

Protocol

B

It is the system for controlling

the communication between the

both by the control code output

from the remote buffer.

RS-232-C 19200 BPS

Expansion

protocol

B

The control system is the same

as that of protocol B. However,

it allows the transmission speed

to be increased. In this case, it

is required to receive the

reception synchronization clock

from the source.

RS-422 86400 BPS

NOTE

The average data transfer speed becomes smaller than

the maximum transfer speed.

B-63322EN-1/01 3. ELECTRICAL INTERFACE

-5-

3 ELECTRICAL INTERFACE

3. ELECTRICAL INTERFACE B-63322EN-1/01

-6-

3.1

TRANSMISSION SYSTEM

It is the start-stop system for adding the start bit before and stop bit

after the information bits, respectively.

The format for adding one parity bit to each byte of data to be

transmitted is also allowed.

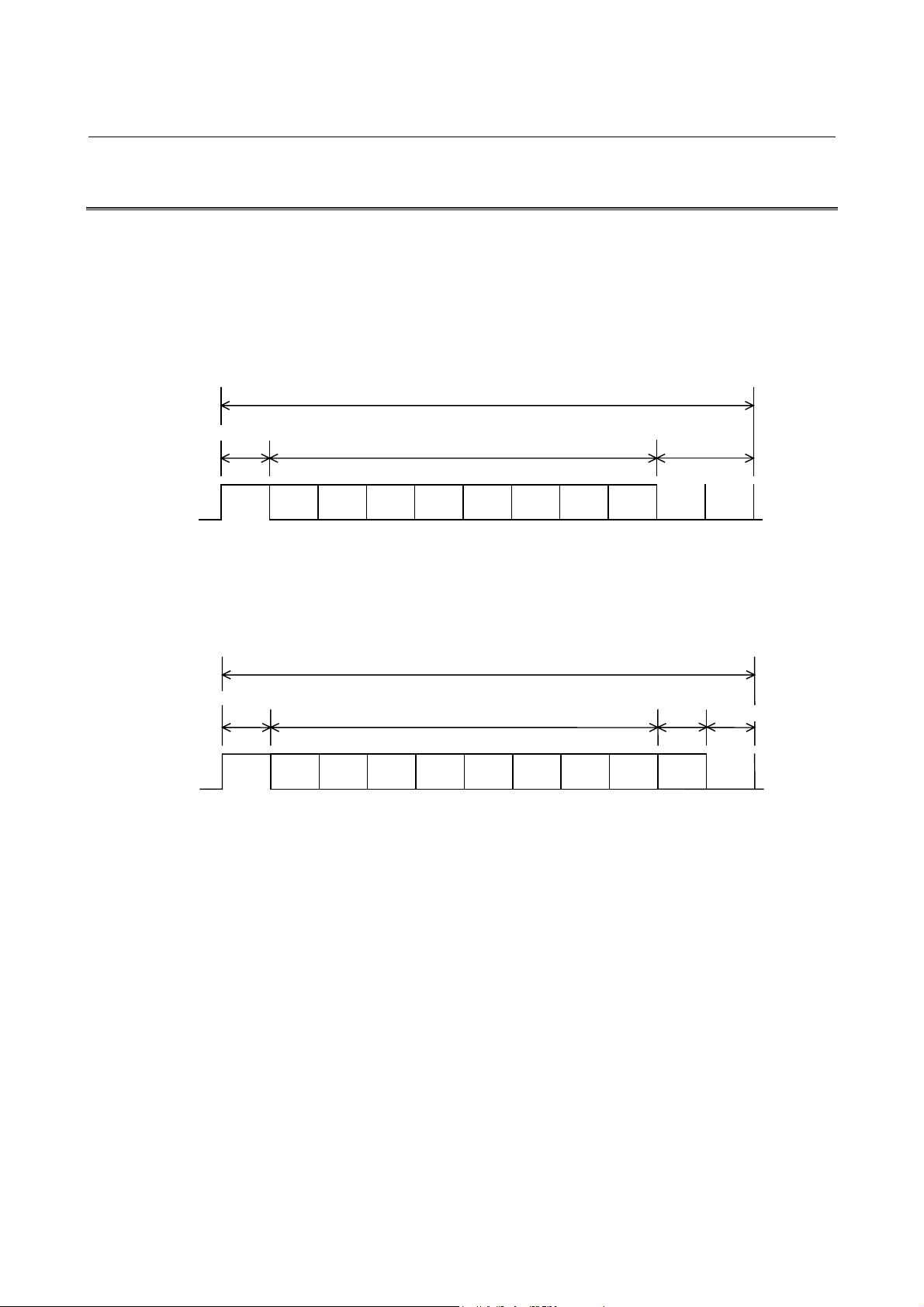

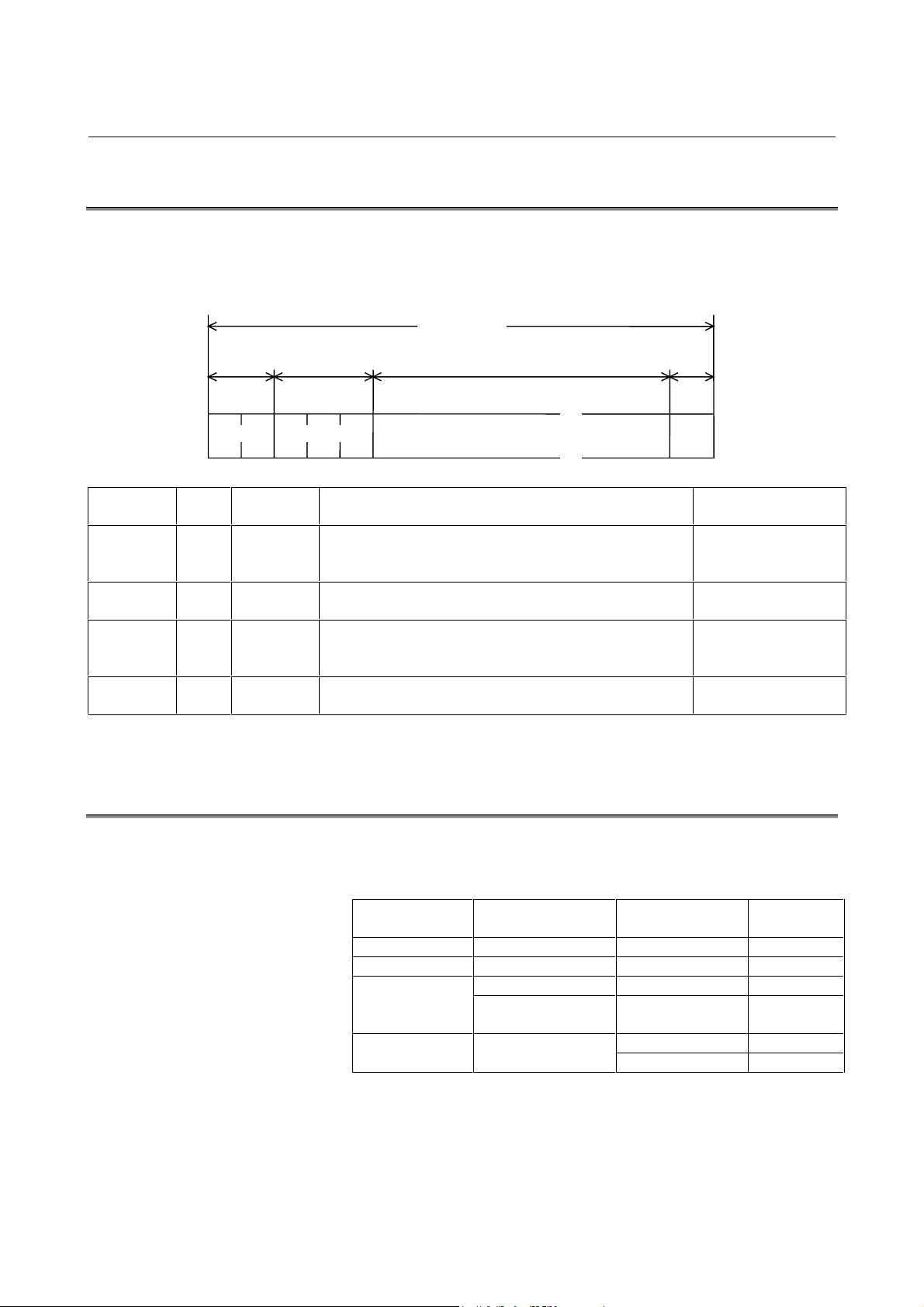

1) Format with no parity bit

Data bit is sent starting from the LSB.

2) Format with parity bit

Data bit is sent starting from the LSB.

The format with parity bit becomes the even parity including a

parity bit. The number of stop bits of parameter determines

whether there is a parity bit or not.

Stop bit 1 → With parity bit

Stop bit 2 → With no parity bit

b1 b2 b5b4b3 b8b7b6

1 character

Start bit Stop bit

Data bit

ON

OFF

LSB MSB

pb1 b2 b5b4b3 b8b7b6

1 character

Start bit

Data bit

ON

OFF

LSB MSB

Stop bit

Parity bit

B-63322EN-1/01 3. ELECTRICAL INTERFACE

-7-

3.2

RS-232-C INTERFACE

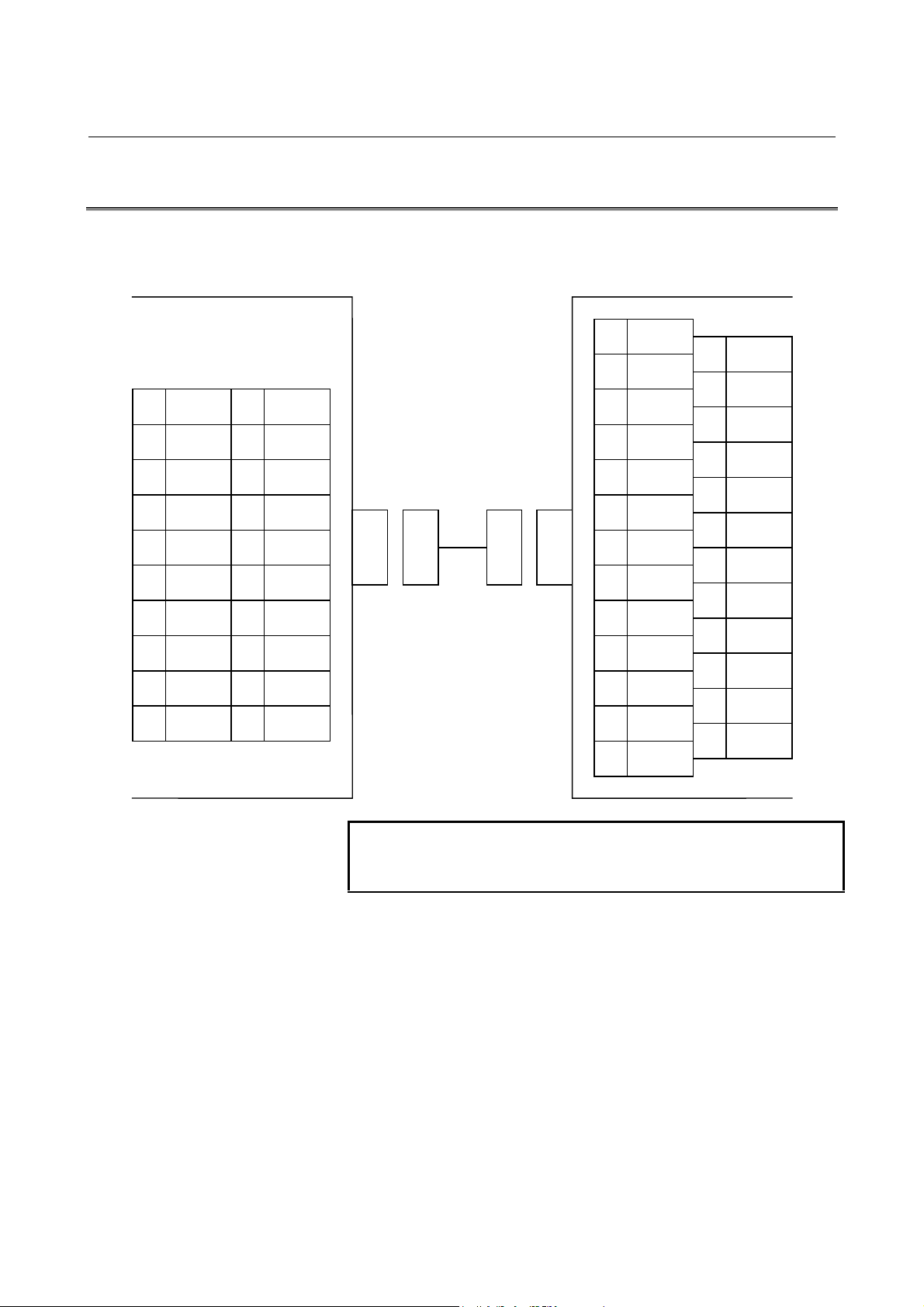

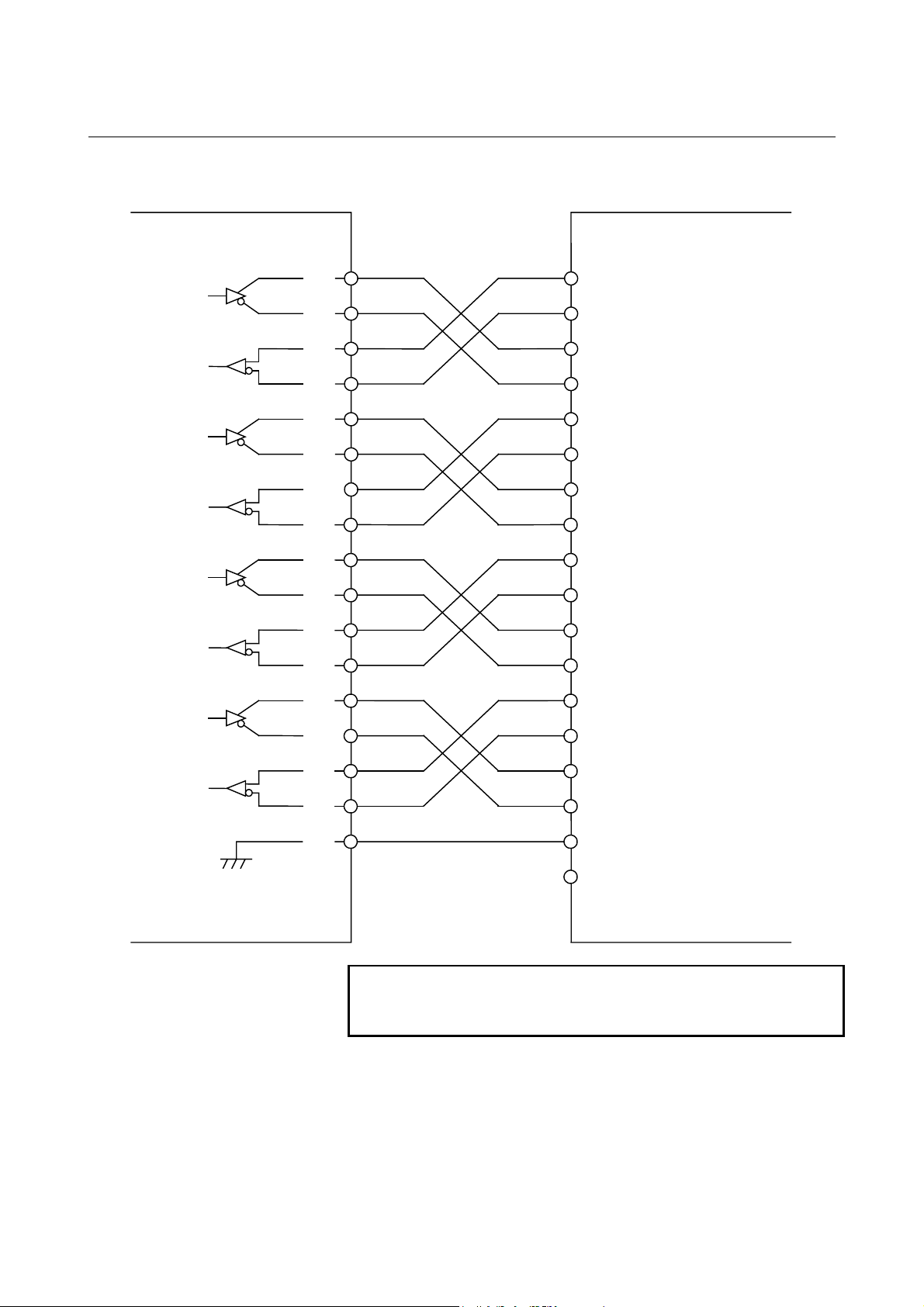

1) Connection between devices

NOTE

(+24V) is used as the power to FANUC RS-232-C

devices.

JD5L

(PCR-E20LMDETZ-SL)

(DBM-25S)

Host compute r (e xample)

1 RD

2 0V

3 DR

4 0V

5 CS

6 0V

7 CD

8 0V

9

10 (+24V)

11 SD

12 0V

13 ER

14 0V

15 RS

16 0V

17

18

19 (+24V)

20

1 FG

2 SD

3 RD

4 RS

5 CS

6 DR

7 SG

8 CD

9

10

11

12

13

14

15

16

17

18

19

20 ER

21

22

23

24

25

CNC

remote buffer board

3. ELECTRICAL INTERFACE B-63322EN-1/01

-8-

2) General diagram of signal connection

When no CS is used, short-circuit it with the RS. However,

when the protocol A or expansion protocol A is used, perform

connecting as shown in the figure above for use as busy control.

When DR is not used, short-circuit it with ER.

Always short-circuit CD to ER.

NOTE

Connect the FG pin to the FG pin of the relay connector

or to the protective grounding pin inside t he locker.

Host compute r

CNC

Output

Input

SD

RD

RS

CS

ER

DR

CD

0V

11

1

15

5

13

3

7

SD

RD

RS

CS

ER

DR

CD

SG

FG Note)

B-63322EN-1/01 3. ELECTRICAL INTERFACE

-9-

3) Signal description

Signal

name

RS-232-C

circuit

number

Input/

output

Description

SD 103 Output Send data

RD 104 Input Receive data

See “3.1” for the bit configuration.

RS 105 Output Request to send

It is used to inform whether the remote buffer is ready to receive data or not.

When the ER signal is on and this signal is on, the remote buffer is ready to

receive data.

CS 106 Input Clear to send

It is used to know the busy status at the host computer. When the DR signal

is on and this signal is on, the host computer is regarded as being ready to

receive data.

DR 107 Input Data set ready

When this signal is on, it is considered that the preparation at the host

computer has been completed. Generally, it is connected to the ER signal of

the host computer. When this signal is off during data transmission, an

alarm occurs.

Always connect it to the ER signal of CNC side when this signal is not used.

ER 108.2 Output Data terminal ready

When this signal is on, it is considered that the remote buffer is in ready

condition.

In general, it is connected to the ER signal at the host computer. If it is

turned off during transmission of data, an alarm occurs. If this signal is not

used, always connect this to the ER signal at the CNC side.

CD 109 Input Received line signal detector

This signal is not used for connection to the host computer. Thus, connect it

to the ER signal of remote buffer side.

SG 102 Grounding for signal

FG 101 Grounding for protection

NOTE

Turn on or off signal according to the following:

-3 V or less +3 V or more

Function OFF ON

Signal Condition Marking Spacing

3. ELECTRICAL INTERFACE B-63322EN-1/01

-10-

3.3

RS-422 INTERFACE

1) Connection between devices

NOTE

Do not connect anything to the (+24V) pin.

JD6L

(PCR-E20LMDETZ-SL)

Host compute r (e xample)

1 RD

2 *RD

3 RT

4 *RT

5 CS

6 *CS

7 RR

8 0V

9 *RR

10 (+24V )

11 SD

12 *SD

13 TT

14 *TT

15 RS

16 *RS

17 TR

18 *TR

19 (+24V)

20

1 FG

2

3

4 SD

5

6 RD

7 RS

8 RT

9 CS

10

11 RR

12 TR

13

20

21

22 *SD

23

24 *RD

25 *RS

26 *RT

27 *CS

28

29 *RR

30 *TR

31

CNC

remote buffer board

14

15

16

17 TT

18

19 SG

33

34

35 *TT

36

37

32

B-63322EN-1/01 3. ELECTRICAL INTERFACE

-11-

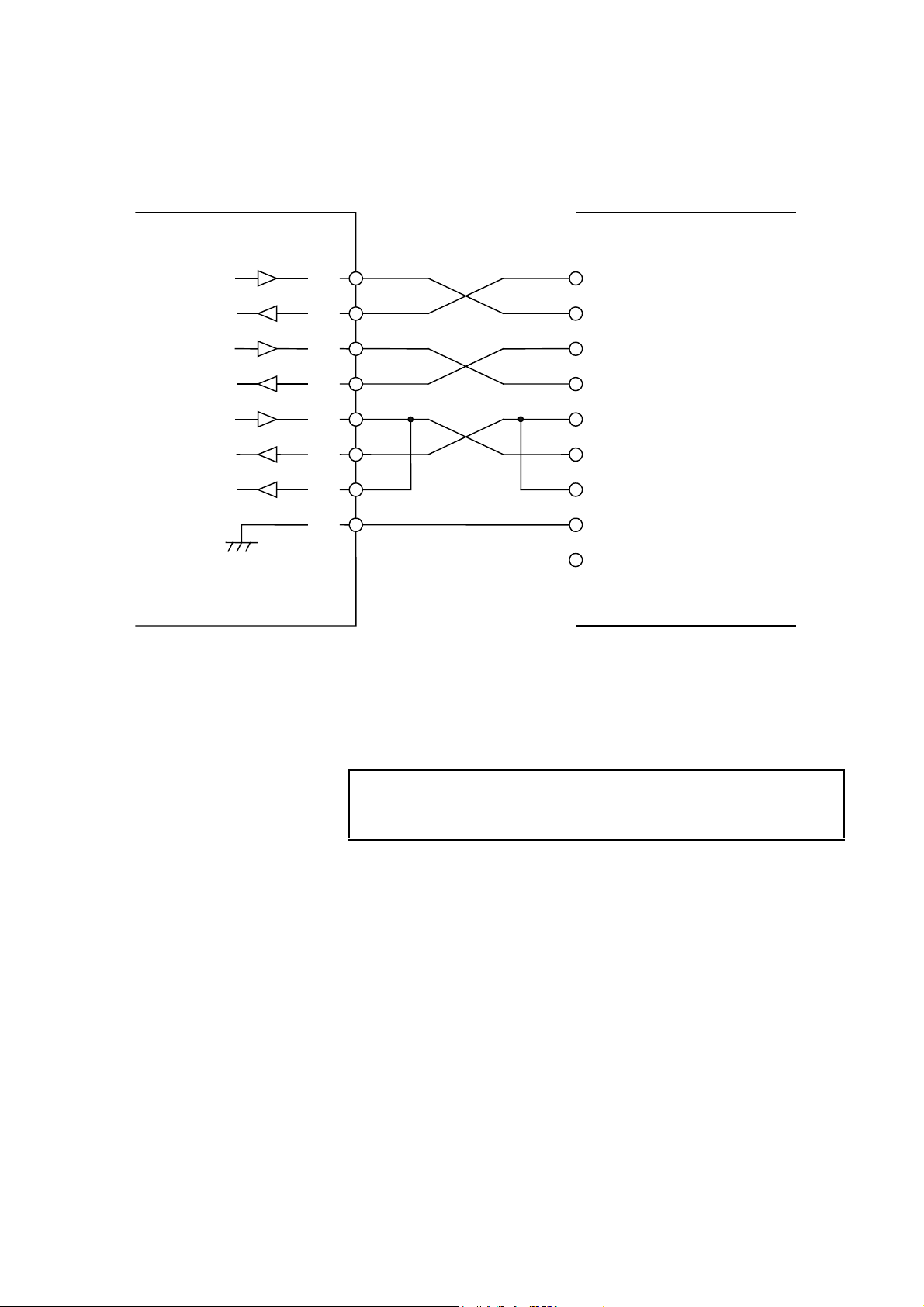

2) General diagram of signal connection

NOTE

Connect the FG pin to the FG pin of the relay connector

or to the protective grounding pin inside t he locker.

Host compute r

CNC

Output

Input

SD

*SD

RD

*RD

RS

*RS

CS

0V

11

12

1

2

15

16

5

SD

*SD

RD

*RD

RS

*RS

CS

SG

FG Note)

*CS

TR

*TR

RR

*RR

TT

*TT

6

17

18

7

9

13

14

*CS

TR

*TR

RR

*RR

TT

*TT

RT

*RT

4

8

RT

*RT

3

3. ELECTRICAL INTERFACE B-63322EN-1/01

-12-

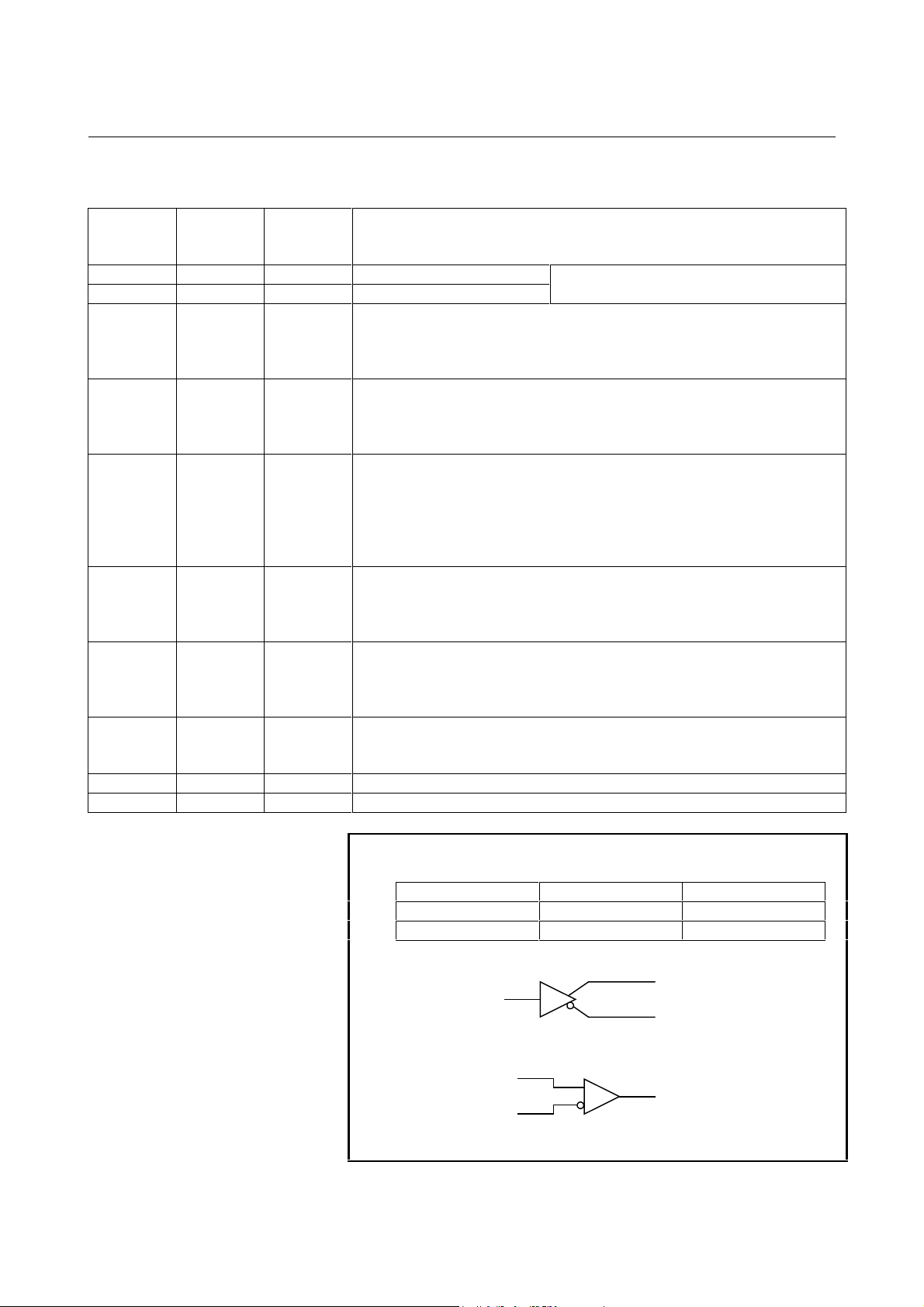

3) Signal description

Signal

name

RS-232-C

circuit

number

Input/

output

Description

SD 103 Output Transmission data

RD 104 Input Reception data

See “3.1” for the bit configuration.

RS 105 Output Transmission request

It is used to inform whether the remote buffer is ready to receive data or not.

When the TR signal is on and this signal is on, the remote buffer is ready to

receive data.

CS 106 Input Clear to send

It is used to know the busy status at the host computer. When the RR signal

is on and this signal is on, the host computer is regarded as being ready to

receive data.

TR

(ER)

108.2 Output Terminal Ready

When this signal is on, it is considered that the operation of remote buffer

has been completed.

In general, it is connected to the ER signal at the host computer. If it is

turned off during transmission of data, an alarm results. If this signal is not

used, always connect this to the ER signal at the CNC side.

RR

(DR)

109 Input Receiver Ready

When this signal is on, it indicates that the host computer is ready to transmit

data to the remote buffer. If this signal is not used, always connect it to the

TR signal at the remote buffer side.

TT 113 Output Transmission timing

Transmission clock transmission terminal at the remote buffer side. When

38400 baud or more is used, always connect it to the RT signal at the host

computer side.

RT 115 Input Reception timing

Reception clock input terminal at the remote buffer side. When 38400 baud

or more is used, always connect it to the TT signal at the host computer side.

SG 102 Grounding for signal

FG 101 Grounding for protection

NOTE

The signal turn on/of f according to the following:

A < B A > B

Function OFF ON

Signal Condition Marking Spacing

Driver

Receiver

A

A

B

B

B-63322EN-1/01 4. PROTOCOL A

-13-

4 PROTOCOL A

It is used for the handshake system where the communication between

the remote buffer and host computer repeats transmission/reception

each other.

4. PROTOCOL A B-63322EN-1/01

-14-

4.1

MESSAGE FORMAT

The information (character-string) exchanged between the remote

buffer and host computer is called “message”. The general type of

message is shown as below:

Field

Byte

length

Abbreviation Meaning Remarks

Checksum 2 No It is used to indicate the lower 8 bits of binary sum of all

bytes from the command field to end code by two-digit

hexadecimal number (0 – 9 and A – F).

Transmit the MSB

before the LSB.

Command 3 No It is used to display the type of message (functions) and

to specify the operation and response of the partner.

Data 0 – n Yes It is the data part corresponding to a command.

Abbreviate it when a command without data part is used.

Details are described later.

SAT, SET, DAT, RTY

SDI, SDO

End code

(ETX)

1 No It indicates the end of message. Not transmit a code

which is the same as an end code to data part.

4.2

CODE SYSTEM

The communication codes between the remote buffer and host

computer are described below:

Field Command Code

Related

parameters

Checksum --- ISO/ASCII 5000#2

Command name --- ISO/ASCII 5000#2

DAT ISO/ASCII/EIA/Bin 0000#2Data part

Commands other

than DAT

ISO/ASCII 5000#2

ISO/ASCII 5000#2End code ---

CR/ETX 5000#3

Sum Command Data part

/

/

ETX

1 byte

Variable length (it can be omitted.)3 byte2 byte

Message

B-63322EN-1/01 4. PROTOCOL A

-15-

4.3

COMMUNICATION SYSTEM

It is used to perform communication between the remote buffer and

host computer. When the both are ready to operate after power on,

the communication starts from the transmission of remote buffer and

reception of host computer and then the transmission/reception is

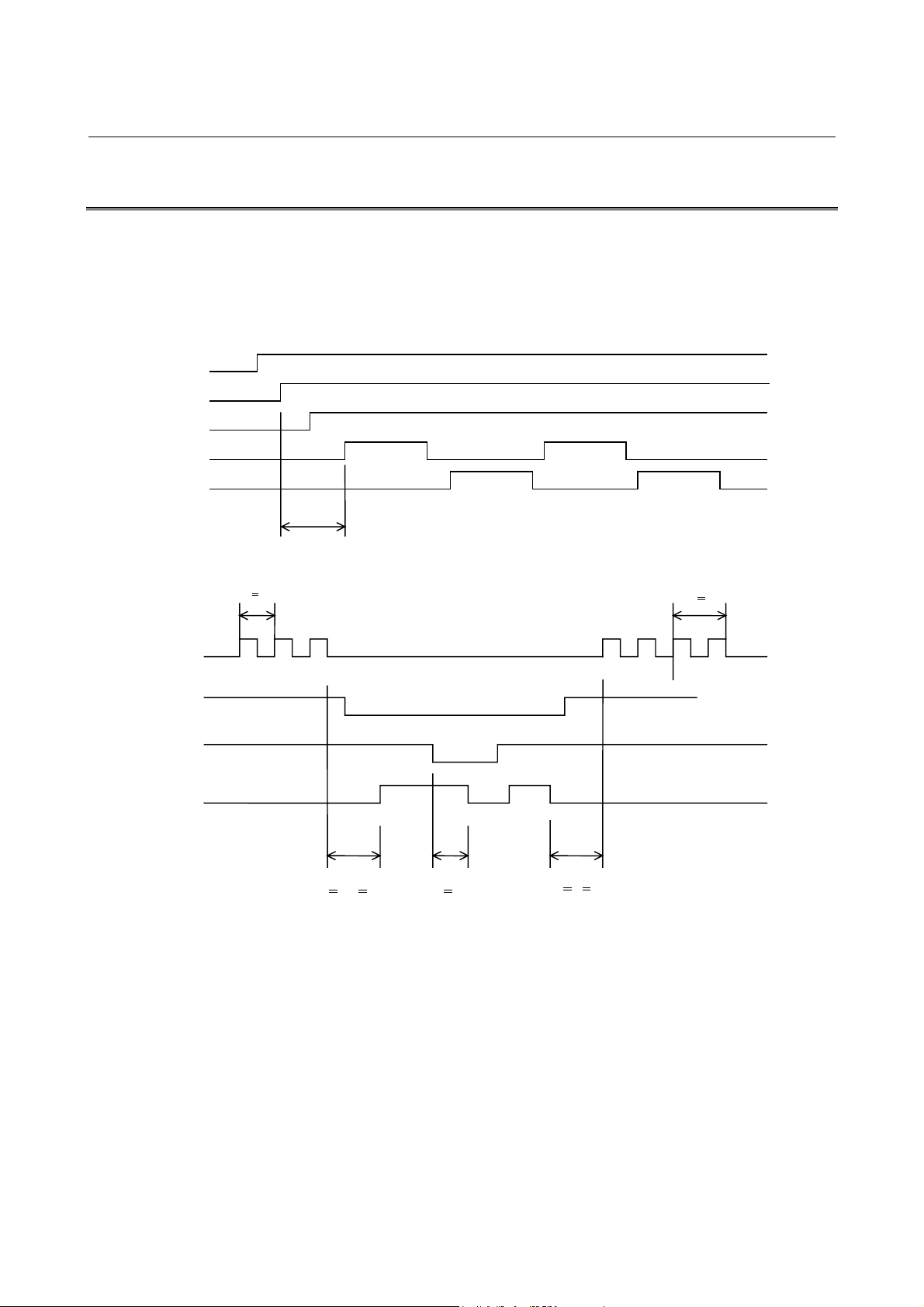

repeated.

(1) Approximately two seconds are required for the first request

after both of remote buffer and host computer are ready.

However, when the CS signal is off, the first transmission is

performed after turning on the CS signal.

(2) The minimum time period between bytes is determined by the

parameter Ti (msec) of SET command. There is no prescription

of minimum time period between reception bytes.

(3) Switching from transmission to reception

Immediately the remote buffer side can be ready to receive

signal. Start transmission within the parameter setting time (To

sec) at the host computer side. When no response is obtained for

the time period (To or more), an error occurs in the host

computer. (Overtime)

ER

RS

CS

SD

RD

Approximately 2 seconds

0 < t2 < To n2 < No

Tx<t3<tp

n2t2 t3

t1 > ti

n1 < 3

SD

CS

RS

RD

4. PROTOCOL A B-63322EN-1/01

-16-

(4) Switching from reception to transmission

The remote buffer waits for Tx msec (parameter setting time)

and moves to the transmission process after completion of

reception. When there is no transmission after waiting another

parameter (Tp seconds), it is considered that an error occurred in

the remote buffer.

(5) Overrun on reception

When the RS signal is turned off by the remote buffer on

reception of signal, stop the transmission within the overrun

parameter number bytes by the host computer.

(6) Overrun on transmission

When the CS is turned off on transmission of remote buffer, the

transmission is suspended within 3 bytes including that which is

currently being transmitted.

B-63322EN-1/01 4. PROTOCOL A

-17-

4.4

COMMAND

4.4.1

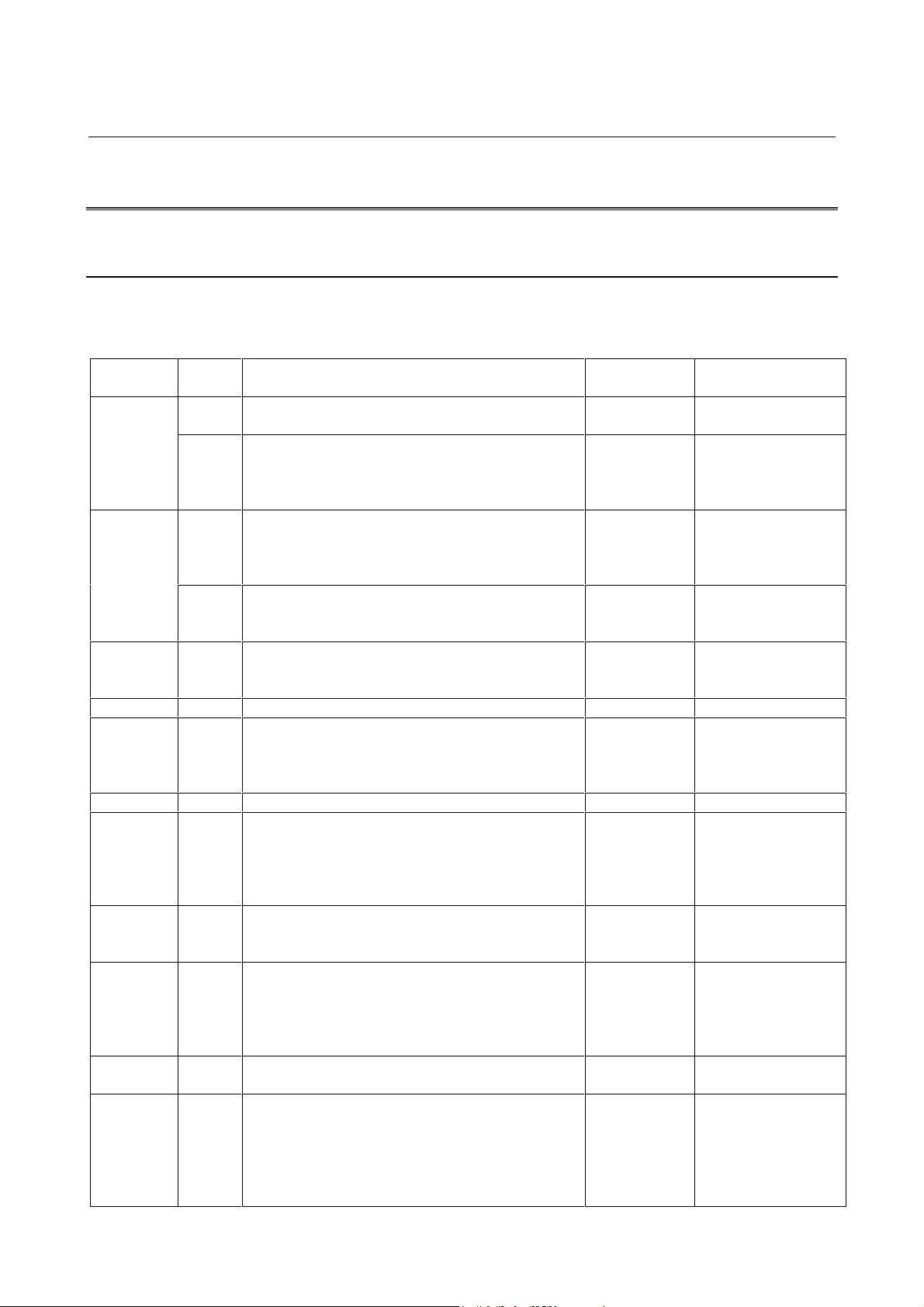

Command Table

Commands used in the protocol A are described below:

Origin station R: Remote buffer H: Hoast computer

Command

Origin

station

Functions Data part

Executed command

at CNC side

R Initialization command

It is used to command the initialization of host.

Meaningless SYNSYN

H Response of SYN

Response when the initialization does not end yet

Initialization command

It is command to initialize the remote buffer.

Meaningless

R Notice of initialization end

The host should respond the RDY in the case of end

of initialization or the SYN when the initialization has

not ended.

Meaningless RDY, SYN

RDY

H Notice of initialization end

It is used to notice that the initialization of host has

ended.

Meaningless

RST R Notice of CNC reset

Immediately after the CNC is res et, transmit this

command when it is possible to transmit signal.

Meaningless ARS

ARS H Response corresponding to the RST Meaningless

ALM R Notice of CNC alarm occurrence

When an alarm occurs in CNC, trans mit this

command when it is possible to transmit immediately

after that.

Meaningless AAL

AAL H Response corresponding to the ALM Meaningless

SAT R Notice of remote buffer status

It is used to notice the status of remote buffer by

transmitting it when there is no data to be especially

transmitted while the Tp sec has passed after

receiving the command.

Status SET......... Normal

CLB

RDI

SDO

SYN

SET H Response corresponding to the SAT

It is used to modify the setting parameter of remote

buffer by specifying the data part.

Modification

parameter

GTD R Transmit command of NC data

Transmit this command when the space of remote

buffer exceeds Nb bytes of parameter setting value

in the remote operation status.

Meaningless DAT ........ Normal

EOB........ End

WAT ....... Busy

RDI

SDO

DAT H Response corresponding to the GTD

Transmit this command with the NC data.

NC data

WAT H Response corresponding tot he GTD

Transmit this command if the NC data cannot be

transmitted within To when the GTD has been

received.

The GTD is transmitted again by the remote buffer

after a parameter setting time of Tw.

Meaningless

4. PROTOCOL A B-63322EN-1/01

-18-

Command

Origin

station

Functions Data part

Executed command

at CNC side

EOD H Response corresponding to GTD

Transmit this command when the GTD has been

received while the transmission of NC data has

been completed.

Meaningless

CLB H Buffer clear

It can be transmitted as the response of SAT when

the buffer at the remote buffer side is to be cleared.

Meaningless

RDI H DI reading request

It is used to request transmission of image of

specified 8-bit DI.

The DI image at that time is responded by the SDI

command in the remote buffer.

This command can be transmitted as responses of

SAT and GTD.

Meaningless

SDI R Notice of DI

It is used to transmit the signal status of DI as the

response of RDI command.

The host should transmit the response of command

received immediately before transmitting the RDI

after receiving this command.

DI image Response

corresponding to the

GTD/SAT

SDO H DO output request

It is used to command that the 8-bit image of data

part should be output to the DO.

It can be transmitted as responses of SAT, GTD,

and SDI.

DO image

RTY R/H Request of retransmission

It is used to request the retransmission of the same

message as before.

Immediately transmit this command when a

transmit error is detected during reception of

messages.

Reason for

retransmission

Command

transmitted

immediately before

B-63322EN-1/01 4. PROTOCOL A

-19-

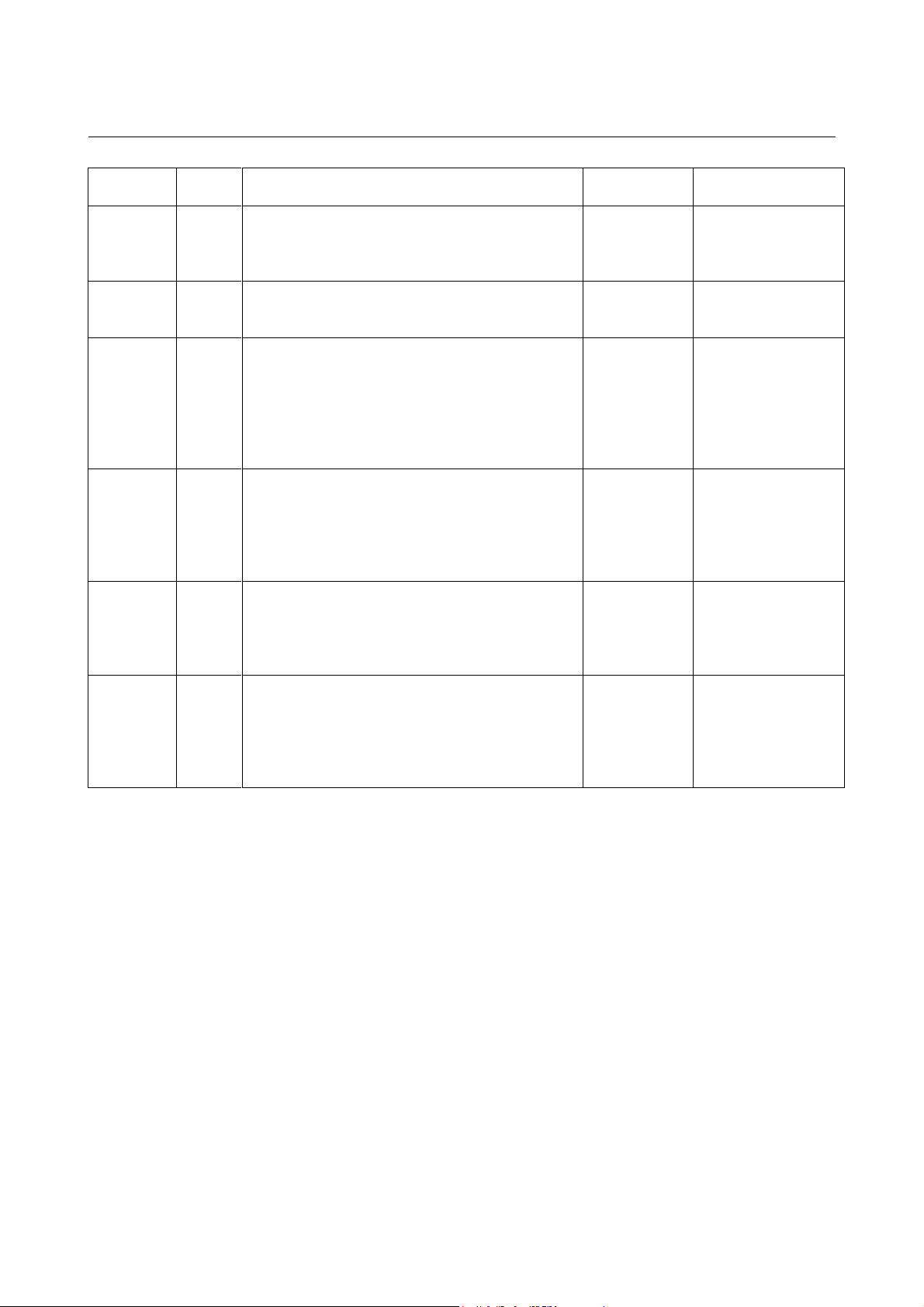

4.4.2

Description of Data Part

Data part of message is of variable length. Up to 4096 and 72 bytes

can be received/transmitted in the case of <DAT> and the others,

respectively.

1) Data part of SAT

Byte

position

Meaning and code

Default value

(hexadecimal)

1 Switching of remote/tape operations

According to parameter (Data No. 5000, #1)

setting. (*C)

0

2 Status of remote buffer

0: Non-completion status of operation

preparation

1: Reset status

2: Operation status

3: Alarm status

4: Open line

0

3 Causes of shift to alarm status

0: NC alarm

1: Checksum error (retry over)

6: Reception of unexpected response

(command error)

A: Overrun error (retry over)

0

4 Not used ---

5 - 8 Number of bytes currently stored in the buffer

(Four-digit hexadecimal number)

0000

9 - 12 Current value of parameter Nb

Empty area limit of buffer

(Four-digit hexadecimal number)

07D0

13 - 16 Current value of parameter No

Amount of maximum overrun on reception

(Four-digit hexadecimal number)

0032

17 - 20 Current value of parameter No

Number of times of retry on detecting a

transmission error (Four-digit hexadecimal

number)

000A

21 - 24 Current value of parameter Tp

Polling time interval (second)

(Four-digit hexadecimal number)

0005

25 - 28 Current value of parameter To

Time-out time (second)

(Four-digit hexadecimal number)

0014

29 - 32 Current value of parameter Ti

Minimum time interval between bytes

transmitted (Four-digit hexadecimal number)

000A

33 - 36 Current value of parameter Tx

Minimum switching time from reception to

transmission (Four-digit hexadecimal number)

0064

37 - 40 Current value of parameter Tw

Waiting time on reception of (WAT)

(Four-digit hexadecimal number)

0005

4. PROTOCOL A B-63322EN-1/01

-20-

Byte

position

Meaning and code

Default value

(hexadecimal)

41 - 44 Unit for the boring time (four digits in

hexadecimal)

Setting parameter P

2

to 1 sets the unit for the

boring time to 0.1 seconds.

0000

45 - 46 Note)

Code to be converted (two-digit hexadecimal

number)

00

47 - 78 Note)

Code after conversion (two-digit hexadecimal

number)

00

49 - 54 Rese rve ---

55 - 56 Packet length parameter n of expansion

protocol A (two-digit hexadecimal number)

00: Normal protocol A

01: Expansion protocol A

NC data length = 256 bytes

Packet length = 260 bytes

02: Expansion protocol A

NC data length = 512 bytes

Packet length = 516 bytes

04: Expansion protocol A

NC data length = 1024 bytes

Packet length = 1028 bytes

00

57 - 72 Not used ---

NOTE

Bytes 45, 46, 47, and 48 of SAT

These bytes contain the parameters necessary for the

remote buffer t o convert the protocol A <DAT > command

data and expansion protocol A data in the specified

section. Specify the code to be converted in bytes 45

and 46. Specify the code to which conversion is to be

performed in bytes 47 and 48. For details, refer to

Section 4.4.2 (3).

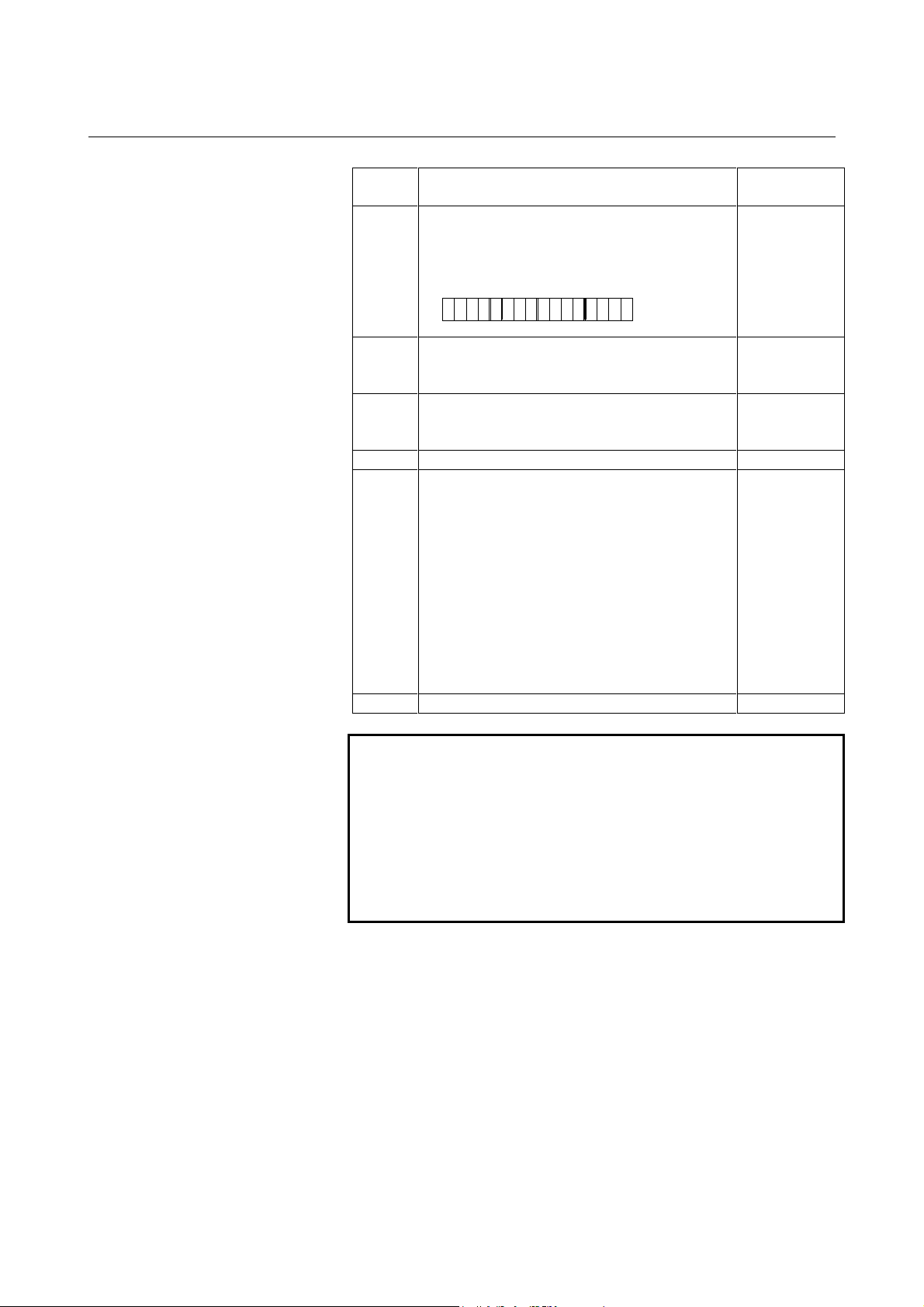

15 0

0000000000000P

2

00

Loading...

Loading...