fanuc 0-MD, 0-GSD Parameter Manual

FANUC Series 0-MD/0-GSD

Parameter Manual

B-62580EN/01

•No part of this manual may be reproduced in any form.

•All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters. However, we cannot describe all the matters which must not be done, or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of which are registered trademarks of respective owners. However, these names are not followed by or in the main body.

B±62580EN/01 |

PREFACE |

|

|

The models covered by this manual, and their abbreviations are:

Product name |

Abbreviations |

||

|

|

|

|

FANUC Series 0±MD |

0±MD |

Series 0±D |

|

|

|

||

FANUC Series 0±GSD |

0±GSD |

||

|

|||

|

|

|

|

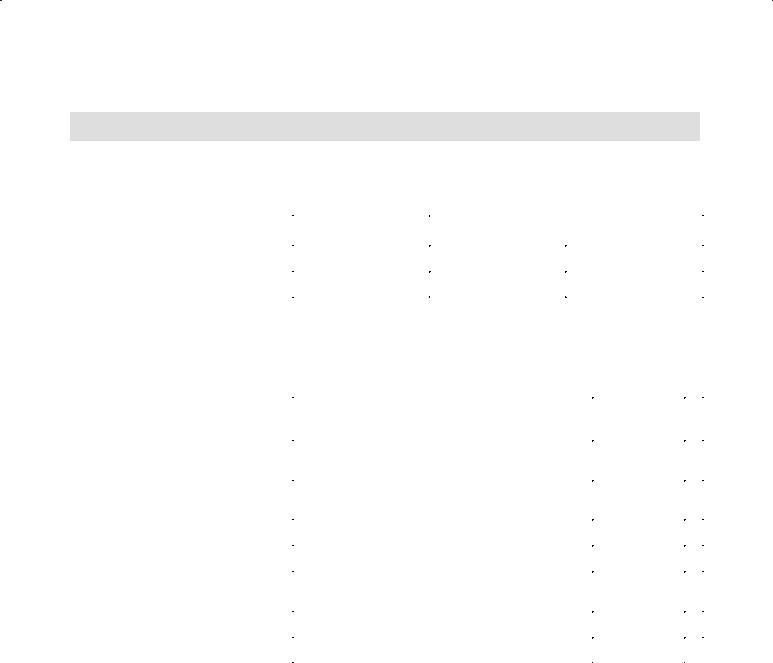

The table below lists manuals related to the FANUC Series 0±D.

In the table, this manual is marked with an asterisk (*).

Table 1 Manuals related to the FANUC Series 0±D

Manuals name |

Specification |

|

number |

|

|

|

|

|

|

|

|

FANUC Series 0±TD/MD/GCD/GSD |

B±62543EN |

|

CONNECTION MANUAL (HARDWARE) |

|

|

|

|

|

|

|

|

FANUC Series 0±TD/MD/GCD/GSD |

B±62543EN±1 |

|

CONNECTION MANUAL (FUNCTION) |

|

|

|

|

|

|

|

|

FANUC Series 0±TD/GCD OPERATOR'S MANUAL |

B±62544EN |

|

|

|

|

FANUC Series 0±MD/GSD OPERATOR'S MANUAL |

B±62574EN |

|

|

|

|

FANUC Series 0±TD/MD/GCD/GSD MAINTENANCE |

B±62545EN |

|

MANUAL |

|

|

|

|

|

|

|

|

FANUC Series 0±TD/GCD PARAMETER MANUAL |

B±62550EN |

|

|

|

|

FANUC Series 0±MD/GSD PARAMETER MANUAL |

B±62580EN |

* |

|

|

|

p±1

B±62580EN/01 |

Table of Contents |

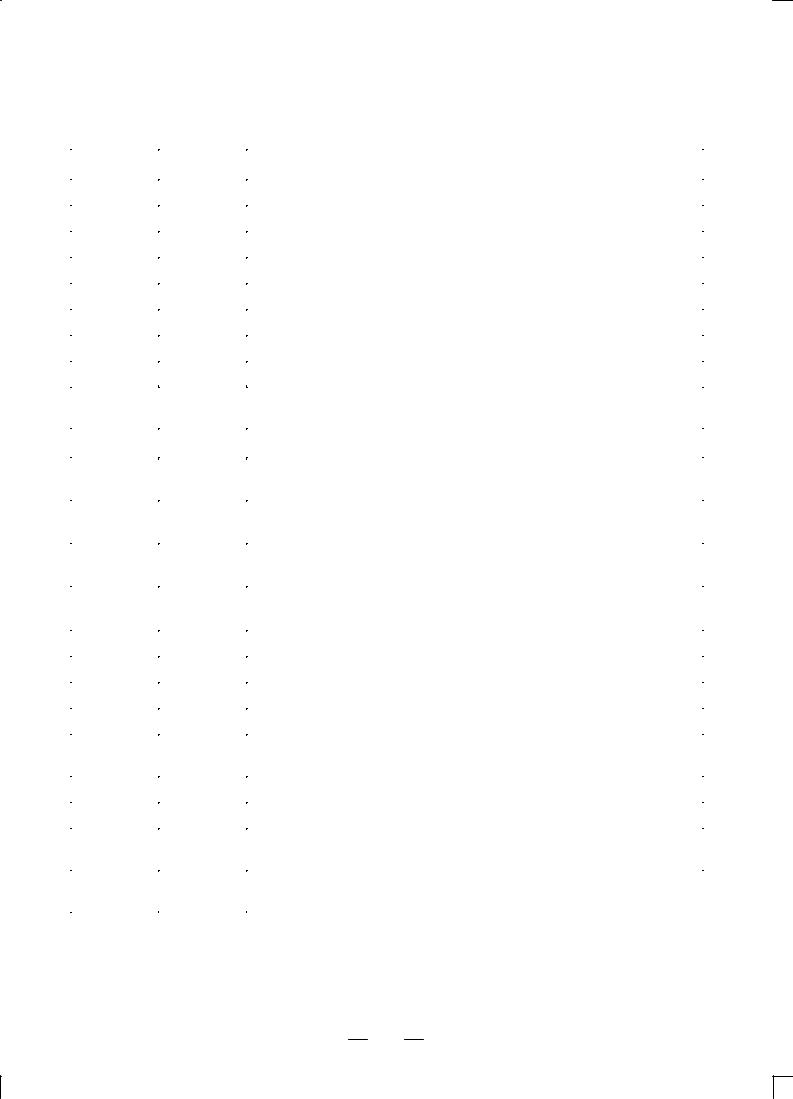

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p±1

1. FUNCTION PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

(1) |

Setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2 |

(2) |

Parameters related to the reader/punch interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

(3) |

Parameters related to controlled axes and the increment system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

(4) |

Parameters related to coordinate systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

(5) |

Parameters related to the stroke limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

(6) |

Parameters related to the feedrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

(7) |

Parameters related to acceleration/deceleration control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

(8) |

Parameters related to servo motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

(9) |

Parameters related to DI/DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

(10) |

Parameters related to the CRT/MDI, display, and editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

(11) |

Parameters related to programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

(12) |

Parameters related to pitch error compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

(13) |

Parameters related to spindle control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

(14) |

Parameters related to tool compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

(15) |

Parameters related to canned cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

(16) |

Parameters related to rigid tapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

(17) |

Parameters related to unidirectional positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

(18) |

Parameters related to control in the normal direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

(19) |

Parameters related to custom macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

(20) |

Parameters related to the display of operation time and number of parts . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

(21) |

Parameters related to manual handle feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

(22) |

Parameters related to the software operator's panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

(23) |

Parameters related to PMC axis control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

(24) |

Parameters related to the surface grinding machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

(25) |

Parameters related to the PMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

2. PARAMETER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

3. SETTING PARAMETER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

4. DESCRIPTION OF PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

c±1

B±62580EN/01 |

1. FUNCTION PARAMETERS |

|

|

1 FUNCTION PARAMETERS

(1)Setting parameters

(2)Parameters related to the reader/punch interface

(3)Parameters related to controlled axes and the increment system

(4)Parameters related to coordinate systems

(5)Parameters related to the stroke limit

(6)Parameters related to the feedrate

(7)Parameters related to acceleration/deceleration control

(8)Parameters related to servo motors

(9)Parameters related to DI/DO

(10)Parameters related to the CRT/MDI, display, and editing

(11)Parameters related to programming

(12)Parameters related to pitch error compensation

(13)Parameters related to spindle control

(14)Parameters related to tool compensation

(15)Parameters related to canned cycles

(16)Parameters related to rigid tapping

(17)Parameters related to unidirectional positioning

(18)Parameters related to control in the normal direction

(19)Parameters related to custom macro

(20)Parameters related to the display of operation time and number of parts

(21)Parameters related to manual handle feed

(22)Parameters related to the software operator's panel

(23)Parameters related to PMC axis control

(24)Parameters related to the surface grinding machines

(25)Parameters related to the PMC

NOTE

1A bit parameter has two meanings, each described on the left and right of |. The meaning on the left applies when the bit is set to 0 and the meaning on the right applies when it is set to 1.

(Example)The current value is 0/1.

2For details, refer to ªDescription of Parametersº.

1

1. FUNCTION PARAMETERS |

B±62580EN/01 |

|||

|

|

|

|

|

(1) Setting parameters (1/1) |

|

|

||

|

|

|

|

|

No. |

Symbol |

|

|

Description |

|

|

|

|

|

0000 |

REVX, Y, 4 |

|

The mirror image of each axis is disabled/enabled. |

|

|

|

|

|

|

0000 |

TVON |

|

When a program is registered, a TV check is not executed/is executed. |

|

|

|

|

|

|

0000 |

ISO |

|

The code system used to output a program is EIA/ISO. |

|

|

|

|

|

|

0000 |

INCH |

|

The least input increment (input unit) of a program is one millimeter/one inch. |

|

|

|

|

|

|

0000 |

I/O |

|

Input/output unit on the reader/punch interface |

|

|

|

|

|

|

0000 |

ABS |

|

In the MDI mode, commands are specified with incremental values/absolute values. |

|

|

|

|

|

|

0000 |

SEQ |

|

Sequence numbers are not automatically inserted/are automatically inserted. |

|

|

|

|

|

|

0000 |

PWE |

|

Parameters cannot be written/can be written. |

|

|

|

|

||

(2) Parameters related to the reader/punch interface (1/1) |

||||

|

|

|

|

|

No. |

Symbol |

|

|

Description |

|

|

|

|

|

0002#0 |

STP2 |

|

(I/O=0) |

The stop bit is 1/2. |

0012#0 |

STP2 |

|

(I/O=1) |

|

|

|

|

|

|

0002#2 |

ASR33 |

|

(I/O=0) |

FANUC PPR etc./20±mA current interface |

0012#0 |

ASR33 |

|

(I/O=1) |

|

|

|

|

|

|

0002#3 |

RSASCI |

|

(I/O=0) |

The input/output code is ISO or EIA/ASCII. |

0012#3 |

RSASCI |

|

(I/O=1) |

|

|

|

|

|

|

0002#7 |

NFED |

|

(I/O=0) |

Beforehand and afterwards, a feed character is output/is not output. |

0012#7 |

NFED |

|

(I/O=1) |

|

|

|

|

|

|

0015#5 |

PRWD |

|

The rewind signal is not output/is output to the portable tape reader. |

|

|

|

|

|

|

0018#6 |

TVC |

|

In the comment section of a program, a TV check is not executed/is executed. |

|

|

|

|

|

|

0038#6, #7 |

, |

|

(I/O=0, 1) Setting the input/output unit |

|

|

|

|

|

|

0070#7 |

ICR |

|

If data is output in ISO code, the EOB code is LF, CR, or CR/LF. |

|

|

|

|

|

|

0075#7 |

IONUL |

|

If a null character is detected while EIA codes are read, an alarm does not occur/oc- |

|

|

|

|

curs. |

|

|

|

|

|

|

0391#6 |

RS23BN |

|

On the RS±232C interface, the DC code is used/is not used. |

|

|

|

|

|

|

0396#0 |

NCKER |

|

The ER (RS±232C) or TR (RS±422) signal is checked/is not checked. |

|

|

|

|

|

|

0399#6 |

FEDNUL |

|

A feed character in a significant information section is output as a space character/null |

|

|

|

|

character. |

|

|

|

|

|

|

0552 |

± ± ± ± ± ± |

|

(I/O=0) |

Baud rate |

0553 |

± ± ± ± ± ± |

|

(I/O=1) |

|

|

|

|

|

|

2

B±62580EN/01 |

1. FUNCTION PARAMETERS |

|

|

(3) Parameters related to controlled axes and the increment system (1/1)

No. |

Symbol |

|

Description |

|

|

|

|

0001#0 |

SCW |

The least command increment (output unit) for a linear axis is one millimeter/inch. |

|

|

|

|

|

0003#0 to #3 |

ZM: |

(X to 4) |

The direction of a reference position return and initial direction are positive/ |

|

|

|

negative. |

|

|

|

|

0008#2 to #4 |

ADW: |

(4) |

Axis name |

0280 |

± ± ± ± ± ± |

(4) |

|

|

|

||

|

|

|

|

0011#2 |

ADLN |

(4) |

Rotation axis/linear axis |

|

|

|

|

0024#1 |

LII10 |

The input/output unit is IS±B/IS±A. |

|

|

|

|

|

0049#4 |

S3JOG |

The number of axes that can be simultaneously controlled in manual operation is one/ |

|

|

|

up to three. |

|

|

|

|

|

0057#3 |

MIC |

If a decimal point is omitted, the least input increment is not multiplied/is multiplied by |

|

|

|

ten. |

|

|

|

|

|

0074#0 to #3 |

CRF: |

If a reference position return is not made and a movement command other than G28 is |

|

|

|

specified, an alarm does not occur/occurs. |

|

|

|

|

|

0076#1 |

JZRN |

The function for setting the reference position without dogs is disabled/enabled. |

|

|

|

|

|

0391#0 to #5 |

JZRN: |

The function for setting the reference position without dogs is enabled/disabled. |

|

|

|

|

|

0398#1 |

ROAX |

The roll±over function is disabled/enabled. |

|

|

|

|

|

0398#2 |

RODRC |

The direction of rotation specified in ABS mode is determined so that the distance of |

|

|

|

rotation is minimized/determined according to the sign of the specified value. |

|

|

|

|

|

0398#3 |

ROCNT |

Relative coordinates which are not multiples of the travel distance per rotation are not |

|

|

|

rounded/are rounded. |

|

|

|

|

|

0399#7 |

OUTZRN |

If the remaining travel distance or active miscellaneous function is found at a manual |

|

|

|

return to the reference position, an alarm occurs/does not occur. |

|

|

|

|

|

0269 to 0272 |

± ± ± ± ± ± |

Number of a servo axis |

|

|

|

|

|

0279 |

± ± ± ± ± ± |

Attribute of the fourth axis |

|

|

|

|

|

3

1. FUNCTION PARAMETERS |

B±62580EN/01 |

||

|

|

|

|

(4) Parameters related to coordinate systems (1/1) |

|

||

|

|

|

|

No. |

Symbol |

Description |

|

|

|

|

|

0010#7 |

APRS |

At a manual reference position return, automatic coordinate system setting is not |

|

|

|

executed/is executed. |

|

|

|

|

|

0024#6 |

CLCL |

At a manual reference position return, the local coordinate system is not canceled/is |

|

|

|

canceled. |

|

|

|

|

|

0028#5 |

EX10D |

When an external workpiece coordinate system shift is executed, the offset value is |

|

|

|

the input value/ten±times the input value. |

|

|

|

|

|

0708 to 0711 |

± ± ± ± ± ± |

(X to 4) Coordinates of the reference position for automatic coordinate system setting |

|

0815 to 0818 |

± ± ± ± ± ± |

(X to 4) |

|

|

|

|

|

0735 to 0738 |

± ± ± ± ± ± |

(X to 4) Distance from the first reference position to the second reference position |

|

|

|

|

|

0751 to 0754 |

± ± ± ± ± ± |

Offset from the external workpiece reference point on each axis |

|

|

|

|

|

0755 to 0758 |

± ± ± ± ± ± |

Offset from the first workpiece reference point on each axis (G54) |

|

|

|

|

|

0759 to 0762 |

± ± ± ± ± ± |

Offset from the second workpiece reference point on each axis (G55) |

|

|

|

|

|

0763 to 0766 |

± ± ± ± ± ± |

Offset from the third workpiece reference point on each axis (G56) |

|

|

|

|

|

0767 to 0770 |

± ± ± ± ± ± |

Offset from the fourth workpiece reference point on each axis (G57) |

|

|

|

|

|

0771 to 0774 |

± ± ± ± ± ± |

Offset from the fifth workpiece reference point on each axis (G58) |

|

|

|

|

|

0775 to 0778 |

± ± ± ± ± ± |

Offset from the sixth workpiece reference point on each axis (G59) |

|

|

|

|

|

0860 |

± ± ± ± ± ± |

Travel distance per revolution about the rotation axis |

|

|

|

|

|

(5) Parameters related to the stroke limit (1/1) |

|

||

|

|

|

|

No. |

Symbol |

Description |

|

|

|

|

|

0008#6 |

OTZN |

A Z±axis stored stroke check is executed/is not executed. |

|

|

|

|

|

0015#4 |

LM2 |

The signal for switching the second stored stroke limit is disabled/enabled. |

|

|

|

|

|

0057#5 |

HOT3 |

The hardware OT signals :+LX to :±LZ (X020, #0 to #5) are disabled/enabled. |

|

|

|

|

|

0065#3 |

PSOT |

Before a reference position return is made, the stored stroke limit is checked/is not |

|

|

|

checked. |

|

|

|

|

|

0076#7 |

OTRF0M |

An alarm occurs after the stroke limit is exceeded/before the stroke limit is exceeded. |

|

|

|

|

|

0700 to 0703 |

± ± ± ± ± ± |

(X to 4) First stored stroke limit in the positive direction on each axis |

|

|

|

|

|

0704 to 0707 |

± ± ± ± ± ± |

(X to 4) First stored stroke limit in the negative direction on each axis |

|

|

|

|

|

0743 to 0746 |

± ± ± ± ± ± |

Second stored stroke limit in the positive direction on each axis |

|

|

|

|

|

0747 to 0750 |

± ± ± ± ± ± |

Second stored stroke limit in the negative direction on each axis |

|

|

|

|

|

4

B±62580EN/01 |

|

1. FUNCTION PARAMETERS |

|

|

|

(6) Parameters related to the feedrate (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0001#6 |

RDRN |

For the rapid traverse command, a dry run is disabled/enabled. |

|

|

|

0008#5 |

ROVE |

The rapid traverse override signal ROV2 (G117, #7) is enabled/disabled. |

|

|

|

0010#0 |

ISOT |

When a reference position is not established, manual rapid traverse is disabled/en- |

|

|

abled. |

|

|

|

0011#3 |

ADNW |

Feedrate specification A/B |

|

|

|

0015#3 |

SKPF |

With G31, a dry run, override, or automatic acceleration/deceleration is disabled/en- |

|

|

abled. |

|

|

|

0049#6 |

NPRV |

When a position coder is not used, the command of feed per rotation is disabled/en- |

|

|

abled. |

|

|

|

0049#7 |

FML10 |

The unit of parameters in which the rapid traverse rate and cutting feedrate are speci- |

|

|

fied is not multiplied/is multiplied by ten. |

|

|

|

0393#1 |

COVOUT |

The function for changing the speed of outer arc machining is disable/enabled. |

|

|

|

0393#5 |

STOV0 |

If the cutting feedrate override is 0% in rapid traverse, a stop does not occur/occurs. |

|

|

|

0397#2 |

OVR255 |

The signal of feedrate override in 1% steps is disable/enabled. |

|

|

|

0518 to 0521 |

± ± ± ± ± ± |

(X to 4) Rapid traverse feedrate for each axis |

|

|

|

0527 |

± ± ± ± ± ± |

Maximum cutting feedrate |

|

|

|

0530 |

± ± ± ± ± ± |

(X to 4) FL speed in exponential acceleration/deceleration of cutting feed |

|

|

|

0533 |

± ± ± ± ± ± |

(X to 4) F0 speed of rapid traverse override |

|

|

|

0534 |

± ± ± ± ± ± |

(X to 4) FL speed at a reference position return |

|

|

|

0548 |

± ± ± ± ± ± |

FL speed in exponential acceleration/deceleration of manual feed |

|

|

|

0549 |

± ± ± ± ± ± |

Cutting feedrate in the automatic mode at power±on |

|

|

|

0559 to 0562 |

± ± ± ± ± ± |

Jog rapid traverse rate for each axis |

|

|

|

0565, 0566 |

± ± ± ± ± ± |

Jog feedrate when the rotary switch is set to position 10 |

|

|

|

0567 |

± ± ± ± ± ± |

Maximum cutting feedrate with feedrate specification B |

|

|

|

0568 |

± ± ± ± ± ± |

F0 speed of rapid traverse override on an additional axis with feedrate specification B |

|

|

|

0569 |

± ± ± ± ± ± |

FL speed at a reference position return on an additional axis with feedrate specifica- |

|

|

tion B |

|

|

|

0605 to 0608 |

± ± ± ± ± ± |

FL speed of exponential acceleration/deceleration for manual feed on each axis |

|

|

|

0684 |

± ± ± ± ± ± |

Feedrate with which the error detect function assumes that deceleration is completed |

|

|

|

5

1. FUNCTION PARAMETERS |

B±62580EN/01 |

||

|

|

|

|

(7) Parameters related to acceleration/deceleration control (1/1) |

|||

|

|

|

|

No. |

Symbol |

|

Description |

|

|

|

|

0020#5 |

NCIPS |

A position check is executed/is not executed. |

|

|

|

|

|

0045#4 |

CCINP |

The in±position width for cutting feed is specified with the same parameters as those |

|

|

|

used for rapid traverse (No. 0500 to 0503)/with different parameters (No. 0609 to |

|

|

|

0612). |

|

|

|

|

|

0048#4 |

SMZCT |

Rapid traverse block overlap is disabled/enabled. |

|

|

|

|

|

0076#0 |

ERDT |

The error detect function is disable/enabled. |

|

|

|

|

|

0379 |

± ± ± ± ± ± |

Feedrate ratio at which the next block is started for block overlap |

|

|

|

|

|

0399#2 |

RPDFF |

Feed forward control is applied only to cutting feed/applied to both cutting feed and |

|

|

|

rapid traverse. |

|

|

|

|

|

0399#4 |

CINPS |

For feed±type±based in±position check (CCINP: bit 4 of parameter 0045), the in±posi- |

|

|

|

tion width for cutting feed is specified using parameters other than those for rapid tra- |

|

|

|

verse, only when the next block also specifies cutting feed/regardless of the type of |

|

|

|

feed specified in the next block. |

|

|

|

|

|

0522 to 0525 |

± ± ± ± ± ± |

(X to 4) |

Time constant of linear acceleration/deceleration in rapid traverse on each axis |

|

|

|

|

0529 |

± ± ± ± ± ± |

Time constant of exponential acceleration/deceleration in cutting feed or manual feed |

|

|

|

|

|

0601 to 0604 |

± ± ± ± ± ± |

(X to 4) Time constant of exponential acceleration/deceleration in manual feed on |

|

|

|

|

each axis |

|

|

|

|

0635 |

± ± ± ± ± ± |

Time constant of linear acceleration/deceleration after interpolation in cutting feed |

|

|

|

|

|

0651 to 0654 |

± ± ± ± ± ± |

(X to 4) Time constant of exponential acceleration/deceleration in cutting feed on a |

|

|

|

|

PMC axis |

|

|

|

|

6

B±62580EN/01 |

|

1. FUNCTION PARAMETERS |

|

|

|

(8) Parameters related to servo motors (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0004 to 0007 |

GRD: |

(X to 4) Capacity of the reference counter of each axis |

0570 to 0573 |

± ± ± ± ± ± |

(X to 4) |

|

|

|

0004 to 0007 |

DMR: |

(X to 4) Detection multiplication of each axis (DMR) |

|

|

|

0010#2 |

OFFVY |

If VRDY is set to 1 before PRDY is set to 1, an alarm occurs/does not occur. |

|

|

|

0021#0 to #3 |

APC: |

(X to 4) For each axis, an absolute±position detector is not used/is used. |

|

|

|

0021#6 |

NOFLUP |

At power±on before the reference position is established by the absolute±position de- |

|

|

tector, a follow±up is executed/is not executed. |

|

|

|

0022#0 to #3 |

ABS: |

(X to 4) The reference position has not yet been established/has already been estab- |

|

|

lished by the absolute±position detector. |

|

|

|

0035#7 |

ACMR |

(X to 4) An optional CMR is not used/is used. |

|

|

|

0037#0 to #5 |

SPTP: |

(X to 4) As a position detector, a separate pulse coder is not used/is used. |

|

|

|

0037#7 |

PLC01 |

(X to 8) A high±resolution pulse coder is not used/is used. |

|

|

|

0076#4 |

ADBLS |

Cutting feed and rapid traverse separate backlash is disabled/enabled. |

|

|

|

0390#0 to #5 |

NREQ: |

If an absolute pulse coder is used for each axis and the zero point is not established |

|

|

before power±on, an alarm requesting a return to the reference position does not oc- |

|

|

cur/occurs. |

|

|

|

0399#5 |

FUNO |

If a servo alarm is detected by the CNC, a follow±up is executed/is not executed. |

|

|

|

0100 to 0103 |

± ± ± ± ± ± |

(X to 4) Command multiplication of each axis (CMR) |

|

|

|

0265 |

± ± ± ± ± ± |

Time interval for leveling the current value display on the servo adjustment screen |

|

|

|

0452 to 0455 |

± ± ± ± ± ± |

(X to 4 3RD WORD) Count at the zero point of the APC |

0739 to 0742 |

± ± ± ± ± ± |

(X to 4 LOWER 2 WORD) |

|

|

|

0500 to 0503 |

± ± ± ± ± ± |

(X to 4) Effective area on each axis |

|

|

|

0504, 0507 |

± ± ± ± ± ± |

(X to 4) Limit on position error for each axis during traveling |

|

|

|

0508 to 0511 |

± ± ± ± ± ± |

(X to 4) Grid shift amount for each axis |

|

|

|

0512 to 0515 |

± ± ± ± ± ± |

(X to 4) Loop gain of position control for each axis |

|

|

|

0517 |

± ± ± ± ± ± |

(X to 4) Loop gain of position control common to all axes |

|

|

|

0535 to 0538 |

± ± ± ± ± ± |

(X to 4) Backlash compensation for each axis |

|

|

|

0593 to 0596 |

± ± ± ± ± ± |

(X to 4) Limit on position error for each axis during a stop |

|

|

|

0609 to 0612 |

± ± ± ± ± ± |

(X to 4th) In±position width for cutting feed for each axis |

|

|

|

7

1. FUNCTION PARAMETERS |

B±62580EN/01 |

||

|

|

|

|

(9) Parameters related to DI/DO (1/1) |

|

||

|

|

|

|

No. |

Symbol |

Description |

|

|

|

|

|

0001#2 |

DCS |

The START key on the MDI panel is connected through the machine/is not connected |

|

|

|

through the machine. |

|

|

|

|

|

0001#5 |

DECI |

(X to 4) At a reference position return, deceleration occurs when the deceleration |

|

|

|

signal is set to 0/1. |

|

|

|

|

|

0003#4 |

OVRI |

(X to 4) Acceleration occurs when the override signal or rapid traverse override signal |

|

|

|

is set to 0/1. |

|

|

|

|

|

0008#7 |

EILK |

Interlock occurs on all axes or Z±axis only/on an individual axis. |

|

|

|

|

|

0009#0 to #3 |

TFIN |

(X to 4) Time period in which the signal (FIN, bit 3 of G120) indicating that the miscel- |

|

|

|

laneous function, spindle±speed function, or tool function has been com- |

|

|

|

pleted is accepted |

|

|

|

|

|

0009#4 to #7 |

TMF |

(X to 4) Period up to the time when the signal indicating that the code of the miscella- |

|

|

|

neous function, spindle±speed function, or tool function is read is sent |

|

|

|

|

|

0012#1 |

ZILK |

Interlock occurs on all axes/Z±axis only. |

|

|

|

|

|

0015#2 |

RIKL |

The high±speed interlock signal *RILK (X008, #5) is disabled/enabled. |

|

|

|

|

|

0019#1 |

C4NG |

The signal to ignore the fourth axis 4NG (X004, #7) is disabled/enabled. |

|

|

|

|

|

0020#4 |

BCD3 |

For the B code, six digits/three digits are output. |

|

|

|

|

|

0045#2 |

RWDOUT |

The rewind signal RWD (F164, #6) is output only when the tape reader is rewinding/is |

|

|

|

output while a program in memory is rewound. |

|

|

|

|

|

0045#7 |

HSIF |

For processing the M, S, T, and B codes, the standard interface is used/the high± |

|

|

|

speed interface is used. |

|

|

|

|

|

0049#0 |

DILK |

The signal for separate interlock in the direction of each axis is disabled/enabled. |

|

|

|

|

|

0049#1 |

RDIK |

The high±speed interlock signal is always enabled/is disabled when the signal for sep- |

|

|

|

arate interlock in the direction of each axis is set to 1. |

|

|

|

|

|

0070#4 |

DSTBGE |

When output is started in background editing, the signal for starting manual data input |

|

|

|

DST (F150, #5) is not output/is output. |

|

|

|

|

|

0252 |

± ± ± ± ± ± |

Extension time for the reset signal |

|

|

|

|

|

8

B±62580EN/01 |

1. FUNCTION PARAMETERS |

|

|

(10) Parameters related to the CRT/MDI, display, and editing (1/2)

No. |

Symbol |

Description |

|

|

|

0001#1 |

PROD |

In the relative coordinate display, tool length compensation is included/is not included. |

|

|

|

0001#4 |

IOF |

An offset value is input from the MID panel in the ABS mode/INC mode. |

|

|

|

0002#1 |

PPD |

Coordinate system setting does not cause relative coordinates to be pre±set/causes |

7002#1 |

PPDS |

relative coordinates to be pre±set. |

|

||

|

|

|

0010#1 |

EBCL |

When a program in memory is displayed, the EOB code is displayed as ;/:. |

|

|

|

0011#7 |

MCINP |

By MINP (G120, #0), a program is not registered/is registered in memory. |

|

|

|

0015#0 |

CBLNK |

The cursor blinks/does not blink. |

|

|

|

0015#6 |

REP |

If a program registered from the reader/punch interface has the same number as |

|

|

another program registered in memory, an alarm occurs/the program is replaced. |

|

|

|

0018#5 |

PROAD |

In the absolute coordinate display, tool length compensation is included/is not in- |

|

|

cluded. |

|

|

|

0018#7 |

EDITB |

With the standard keyboard, editing A is executed/editing B is executed. |

|

|

|

0019#6 |

NEOP |

M02, M30, or M99 terminates program registration/does not terminate program regis- |

|

|

tration. |

|

|

|

0019#7 |

DBCD |

On the diagnostic screen, the data of a timer counter is displayed in binary/decimal. |

|

|

|

0023#0 to #6 |

:::: |

Setting of the language to be used on the display |

|

|

|

0028#0 |

PRCPOS |

On the program check screen, relative coordinates are displayed/absolute coordinates |

|

|

are displayed. |

|

|

|

0028#2 |

DACTF |

The actual speed is not displayed/is displayed. |

|

|

|

0035#0 to #3 |

NDSP: |

The current position on each axis is displayed/is not displayed. |

|

|

|

0040#0 |

NAMPR |

On the program directory screen, program names are not displayed/are displayed. |

|

|

|

0040#4 |

SORT |

On the program directory screen, programs are arranged in the order in which they are |

|

|

registered/in the ascending order of program numbers. |

|

|

|

0045#0 |

RDL |

Under I/O unit external control, reading depends on the REP bit (bit 6 of parameter |

|

|

0015)/a program is registered after all programs are deleted. |

|

|

|

0045#1 |

RAL |

Reading on the reader/punch interface causes all programs to be registered/only the |

|

|

first program to be registered. |

|

|

|

0048#7 |

SFFDSP |

The soft±key display and control depend on the configuration of additional functions/ |

|

|

are executed regardless of additional functions. |

|

|

|

0050#1 |

NOFMK |

When a sequence number is searched for, the format is checked/is not checked. |

|

|

|

0056#0 |

NOCND |

When the length of part program storage is 120 or 320 m, or if the background editing |

|

|

function is provided, memory is automatically compressed/is not automatically com- |

|

|

pressed. |

|

|

|

0060#0 |

DADRDP |

On the diagnostic screen, addresses are not displayed/are displayed. |

|

|

|

0060#2 |

LDDSPG |

Dynamic ladder display is not executed/is executed. |

|

|

|

9

1. FUNCTION PARAMETERS |

B±62580EN/01 |

|

|

(10) Parameters related to the CRT/MDI, display, and editing (2/2)

No. |

Symbol |

Description |

|

|

|

0060#5 |

OPMNDP |

Operating monitor display is invalid/valid. |

|

|

|

0060#6 |

EXTSP |

The function to search for or display a protected program is disabled/enabled. |

|

|

|

0063#0 |

MTDSPI |

Machine coordinates are not displayed according to the input system/are displayed |

|

|

according to the input system. |

|

|

|

0063#1 |

PRSTIN |

Automatic coordinate system setting in the inch input mode is specified in parameter |

|

|

0708 and subsequent parameters/in parameter 0815 and subsequent parameters. |

|

|

|

0064#0 |

SETREL |

Pre±setting relative coordinates causes clearing to zero/optional values to be used. |

|

|

|

0064#1 |

ALLPRE |

For pre±setting relative coordinates, the standard specification is selected/axes are |

|

|

selected by numeric keys. |

|

|

|

0064#5 |

NPA |

If an alarm occurs or an operator message is input, the alarm or message screen is |

|

|

displayed instead/is not displayed. |

|

|

|

0076#2 |

IOP |

Input or output of an NC program can be stopped by an NC reset/only by pressing the |

|

|

[STOP] soft key. |

|

|

|

0077#6 |

HLKEY |

The MDI keys are not processed in the high±speed mode/are processed in the high± |

|

|

speed mode. |

|

|

|

0078#0 |

NOINOW |

The amount of tool compensation can be input with the MDI keys/cannot be input with |

|

|

the MDI keys. |

|

|

|

0078#2 |

NOINMV |

A macro variable can be input with the MDI keys/cannot be input with the MDI keys. |

|

|

|

0078#3 |

NOINWZ |

An offset from the workpiece reference point can be input with the MDI keys/cannot be |

|

|

input with the MDI keys. |

|

|

|

0389#0 |

SRVSET |

The servo setting screen is displayed/is not displayed. |

|

|

|

0393#2 |

WKNMDI |

If the automatic operation is started or halted, an offset from the workpiece reference |

|

|

point can be input with the MDI keys/cannot be input with the MDI keys. |

|

|

|

0393#7 |

DGNWEB |

If PWE is set to 0, a PMC parameter cannot be input/can be input. |

|

|

|

0395#1 |

TLSCUR |

On the offset screen, the cursor position is not retained/is retained. |

|

|

|

0397#7 |

SERNAI |

The contents of alarm 409 are not displayed/are displayed. |

|

|

|

0398#0 |

WKINC |

With the MDI keys, an offset from the workpiece reference point is input in the ABS |

|

|

mode/INC mode. |

|

|

|

0337 to 0346 |

± ± ± ± ± ± |

Character codes of the title |

|

|

|

0351 to 0355 |

± ± ± ± ± ± |

Character codes of the NC name |

|

|

|

0550 |

± ± ± ± ± ± |

Increment used when the sequence number is automatically inserted |

|

|

|

0797 |

± ± ± ± ± ± |

Encryption |

|

|

|

0798 |

± ± ± ± ± ± |

Key |

|

|

|

10

B±62580EN/01 |

|

1. FUNCTION PARAMETERS |

|

|

|

(11) Parameters related to programming (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0010#4 |

PRG9 |

Editing of subprograms from O9000 to O9999 is not inhibited/is inhibited. |

|

|

|

0011#6 |

G01 |

The mode selected at power±on is G00/G01. |

|

|

|

0015#7 |

CPRD |

If a decimal point is omitted, the selected unit is the least input increment/mm, inch, |

|

|

deg, and sec. |

|

|

|

0016#3 |

NPRD |

Decimal point input or display is used/is not used. |

|

|

|

0019#5 |

M02NR |

After M02 is executed, a return to the beginning of the program is made/is not made. |

|

|

|

0028#4 |

EXTS |

External program number search is invalid/valid. |

|

|

|

0030#7 |

G91 |

The mode selected at power±on is G90/G91. |

|

|

|

0045#6 |

CLER |

Pressing the RESET key, setting the external reset signal or an emergency stop sets |

|

|

the system in the reset state/clear state. |

|

|

|

0065#7 |

M3B |

A single block can contain only one M code/up to three M codes. |

|

|

|

0389#2 |

PRG8 |

Editing of programs from O8000 to 8999 is not inhibited/is inhibited. |

|

|

|

0391#7 |

NOCLR |

In the clear state, a specific G code is cleared/is not cleared. |

|

|

|

0393#3 |

M3PQNG |

An M code specified with three digits is valid/invalid. |

|

|

|

0393#6 |

RADCHK |

When circular interpolation is specified, the difference between the radius values at the |

|

|

start point and end point is not checked/is checked. |

|

|

|

0394#6 |

WKZRST |

In workpiece coordinate system setting, an NC reset does not cause a return to |

|

|

G54/causes a return to G54. |

|

|

|

0394#7 |

CAKEY |

On the parameter, diagnostic, or offset screen, pressing the CAN key does not erase a |

|

|

single character/erases a single character. |

|

|

|

0396#7 |

EORRE |

If EOR is read without the program end command, an alarm occurs/a reset occurs. |

|

|

|

0111, 0112 |

± ± ± ± ± ± |

M code which is not buffered |

|

|

|

0212 |

± ± ± ± ± ± |

Plane selected at power±on |

|

|

|

0876 |

± ± ± ± ± ± |

Limit of arc radius error |

|

|

|

(12) Parameters related to pitch error compensation (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0011#0, #1 |

PML: |

(X to 4) Magnification of pitch error compensation |

|

|

|

0712 to 0715 |

± ± ± ± ± ± |

(X to 4) Interval of pitch error compensation for each axis |

|

|

|

1000 to 6000 |

± ± ± ± ± ± |

Reference position of pitch error compensation for each axis |

|

|

|

1001 to 6128 |

± ± ± ± ± ± |

Pitch error compensation for each axis |

|

|

|

11

1. FUNCTION PARAMETERS |

B±62580EN/01 |

||

|

|

|

|

(13) Parameters related to spindle control (1/2) |

|

||

|

|

|

|

No. |

Symbol |

Description |

|

|

|

|

|

0003#5 |

GST |

By SOR (G120, #5), spindle orientation is executed/a gear±change is executed. |

|

|

|

|

|

0012#6 |

G84S |

If the G74 or G84 cycle is specified, the gear is changed at a point specified through S |

|

|

|

analog output gear±change method A or B/at a point specified in parameters 0540 and |

|

|

|

0556. |

|

|

|

|

|

0013#5 |

ORCW |

In spindle orientation, S analog output is positive/negative. |

|

|

|

|

|

0013#6, #7 |

TCW, CWM |

Sign output in S analog output |

|

|

|

|

|

0014#0 |

SCTA |

The spindle speed arrival signal is checked conditionally/always. |

|

|

|

|

|

0020#7 |

SFOUT |

SF (F150, #2) is output when a gear±change is made/even if a gear±change is not |

|

|

|

made. |

|

|

|

|

|

0024#2 |

SCTO |

The spindle speed arrival signal SAR (G120, #4) is not checked/is checked. |

|

|

|

|

|

0028#6, #7 |

PSG: |

Gear ratio between the spindle and position coder |

|

|

|

|

|

0035#6 |

LGCM |

The gear±change speed is the maximum speed of each gear (method A)/is deter- |

|

|

|

mined by parameters 0585 and 0586 (method B). |

|

|

|

|

|

0062#3 |

SPMRPM |

Parameters of spindle speed control are specified in units of 1 RPM/10 RPM. |

|

|

|

|

|

0071#0 |

ISRLPC |

When the serial interface spindle is used, the position coder signal is fetched from the |

|

|

|

optical fiber cable/connector M27. |

|

|

|

|

|

0071#4 |

SRL2SP |

The number of serial interface spindles connected is one/two. |

|

|

|

|

|

0071#7 |

FSRSP |

The serial interface spindle is not used/is used. |

|

|

|

|

|

0080#2 |

MORCM: |

For the first spindle motor, the spindle orientation function with the stop position set |

|

|

|

externally is not used/is used. |

|

|

|

|

|

0108 |

± ± ± ± ± ± |

Spindle speed in stable spindle rotation |

|

|

|

|

|

0108 |

± ± ± ± ± ± |

Spindle motor speed at a gear±change |

|

|

|

|

|

0110 |

± ± ± ± ± ± |

Delay timer if the spindle speed arrival signal SAR (G120, #4) is checked |

|

|

|

|

|

0539 |

± ± ± ± ± ± |

[Neutral gear] Maximum spindle speed |

|

0541 |

± ± ± ± ± ± |

[Low gear] |

|

[High gear] |

|

||

0555 |

± ± ± ± ± ± |

|

|

|

|

||

|

|

|

|

0540 to 0543 |

± ± ± ± ± ± |

Spindle speed when the voltage for specifying the spindle speed of each gear is 10 V |

|

|

|

|

|

0540 |

± ± ± ± ± ± |

[Neutral gear] Minimum spindle speed in a tapping cycle |

|

0556 |

± ± ± ± ± ± |

[High gear] |

|

|

|

||

|

|

|

|

0542 |

± ± ± ± ± ± |

Upper limit of the value output to the spindle motor |

|

|

|

|

|

0543 |

± ± ± ± ± ± |

Lower limit of the value output to the spindle motor |

|

|

|

|

|

0577 |

± ± ± ± ± ± |

Spindle speed offset compensation |

|

|

|

|

|

0585, 0586 |

± ± ± ± ± ± |

Gear±change point in S analog switching method B |

|

|

|

|

|

0957 to 0959 |

± ± ± ± ± ± |

Limit of position error during spindle rotation at the maximum spindle speed |

|

|

|

|

|

12

B±62580EN/01 |

|

1. FUNCTION PARAMETERS |

|

|

|

(13) Parameters related to spindle control (2/2) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

7516 |

± ± ± ± ± ± |

Data for adjusting the gain under sub±spindle control by the S command specified with |

|

|

four or five digits |

|

|

|

7539 |

± ± ± ± ± ± |

Sub±spindle speed offset compensation |

|

|

|

(14) Parameters related to tool compensation (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0001#3 |

RS43 |

When a reset occurs, the vector of tool length compensation is cleared/is not cleared. |

|

|

|

0003#6 |

TSLT |

Tool length compensation is executed on the Z±axis (type A)/an axis vertical to the |

|

|

specified plane (type B). |

|

|

|

0016#2 |

SUPM |

In cutter compensation C, start±up and cancellation are executed through the method |

|

|

of type A/B. |

|

|

|

0019#3 |

TLCD |

Tool length compensation A or B/C |

|

|

|

0030#2 |

OFCDH |

Tool compensation memory C is disable/enabled. |

|

|

|

0036#5 |

TLCDOK |

In tool length compensation of type C, offset of two or more axes is disabled/enabled. |

|

|

|

0036#6 |

OFRD |

Tool length compensation and cutter compensation are specified with the H code./Tool |

|

|

length compensation and cutter compensation C are specified with the H code and D |

|

|

code, respectively. |

|

|

|

0062#2 |

G40V |

Operation by a single command (G40, G41, or G42) |

|

|

|

0557 |

± ± ± ± ± ± |

Maximum travel distance that can be ignored on the outside of a corner in cutter com- |

|

|

pensation C |

|

|

|

(15) Parameters related to canned cycles (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0002#4, #5 |

PMXY1, 2 |

Axis and direction on and in which the tool is retracted in canned cycle G76 or G87 |

|

|

|

0011#4 |

MCF |

When positioning of G81 terminates, the signal to specify an external operation func- |

|

|

tion is not output/is output. |

|

|

|

0012#4 |

FXCS |

In canned cycle G74 or G84, reverse and forward spindle rotations are executed after |

|

|

M05 is output/even if M05 is not output. |

|

|

|

0012#5 |

FXCO |

In canned cycle G76 or G87, an oriented spindle stop is executed after M05 is output/ |

|

|

even if M05 is not output. |

|

|

|

0057#6 |

FXY |

The drilling axis in a canned cycle is always the Z±axis/is a programmed axis. |

|

|

|

0403 |

± ± ± ± ± ± |

Clearance/cutting start point in a peck tapping cycle |

|

|

|

0531 |

± ± ± ± ± ± |

Clearance in canned cycle G73 (high±speed peck drilling cycle) |

|

|

|

0532 |

± ± ± ± ± ± |

Cutting start point in canned cycle G83 (peck drilling cycle) |

|

|

|

13

1. FUNCTION PARAMETERS |

B±62580EN/01 |

||

|

|

|

|

(16) Parameters related to rigid tapping (1/2) |

|||

|

|

|

|

No. |

Symbol |

|

Description |

|

|

|

|

0019#4 |

SRGTP |

The rigid tapping selection signal (RGTAP) is G123, #1/G135, #0. |

|

|

|

|

|

0035#5 |

RGCTO |

When the tool is retracted in rigid tapping, the time constant of acceleration/decelera- |

|

|

|

tion on the spindle and tapping axis is the same parameter as that for starting cutting/is |

|

|

|

a different parameter from that for starting cutting. |

|

|

|

|

|

0037#6 |

VALT |

In rigid tapping, the variable time constant switching function is not used/is used. |

|

|

|

|

|

0040#2 |

RGTPE |

In rigid tapping, the rigid mode is canceled after the rigid DI signal is turned off/even |

|

|

|

before the rigid DI signal is turned off. |

|

|

|

|

|

0063#3 |

VSLPC |

An optional gear ratio between the spindle and position coder is not used/is used. |

|

|

|

|

|

0063#4 |

RGDOV |

When the tool is retracted, an override is disabled/enabled. |

|

|

|

|

|

0065#5 |

TAPDRN |

During tapping, a dry run is enabled/disabled. |

|

|

|

|

|

0076#3 |

G84RGD |

G84 and G74 are not handled as G codes for rigid tapping/are handled as G codes for |

|

|

|

rigid tapping. |

|

|

|

|

|

0077#1 |

CT3G |

Three±stage time constant switching is disabled/enabled. |

|

|

|

|

|

0388#0 |

PCTPH |

A peck tapping cycle is handled as a high±speed peck tapping cycle. |

|

|

|

|

|

0388#2 |

RGMFH |

A feed hold and single±block operation are enabled/disabled. |

|

|

|

|

|

0388#3 |

RGORT |

When rigid tapping is started, a spindle reference position return is not made/is made. |

|

|

|

|

|

0388#5 |

SIG |

At a gear±change, the SIND signal is disabled/enabled. |

|

|

|

|

|

0388#6 |

CHKERC |

During spindle rotation, the position error is checked according to the maximum |

|

|

|

spindle speed/specified spindle speed. |

|

|

|

|

|

0254 |

± ± ± ± ± ± |

Type of acceleration/deceleration for the spindle and tapping axis |

|

|

|

|

|

0255 |

± ± ± ± ± ± |

Spindle backlash amount in rigid tapping |

|

|

|

|

|

0256 |

± ± ± ± ± ± |

M code for specifying the rigid tapping mode |

|

|

|

|

|

0258 |

± ± ± ± ± ± |

Override value when the tool is retracted in rigid tapping |

|

|

|

|

|

0378 |

± ± ± ± ± ± |

Override for rigid tapping return |

|

|

|

|

|

0400 to 0402 |

± ± ± ± ± ± |

Time constant of acceleration/deceleration on the spindle and tapping axis when the |

|

|

|

tool is retracted |

|

|

|

|

|

0613 |

± ± ± ± ± ± |

Time constant of acceleration/deceleration on the spindle and tapping axis |

|

|

|

|

|

0614 |

± ± ± ± ± ± |

FL speed of exponential acceleration/deceleration on the spindle and tapping axis |

|

|

|

|

|

0615 |

± ± ± ± ± ± |

Loop gain of position control on the spindle and tapping axis |

|

|

|

|

|

0616 |

± ± ± ± ± ± |

(Low gear) |

Multiplier of loop gain on the spindle |

0624 |

± ± ± ± ± ± |

(Neutral gear) |

|

0625 |

± ± ± ± ± ± |

(High gear) |

|

|

|

|

|

0617 |

± ± ± ± ± ± |

Allowable maximum spindle speed in rigid tapping |

|

|

|

|

|

0618 |

± ± ± ± ± ± |

Effective area on the tapping axis in rigid tapping |

|

|

|

|

|

14

B±62580EN/01 |

|

1. FUNCTION PARAMETERS |

|

|

|

(16) Parameters related to rigid tapping (2/2) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0619 |

± ± ± ± ± ± |

Effective area on the spindle in rigid tapping |

|

|

|

0620 |

± ± ± ± ± ± |

Limit of position error on the tapping axis during traveling |

|

|

|

0621 |

± ± ± ± ± ± |

Limit of position error on the spindle during traveling |

|

|

|

0622 |

± ± ± ± ± ± |

Limit of position error on the tapping axis under a stop |

|

|

|

0623 |

± ± ± ± ± ± |

Limit of position error on the spindle under a stop |

|

|

|

0626 |

± ± ± ± ± ± |

Feedrate for defining the reference lead in rigid tapping |

|

|

|

0627 |

± ± ± ± ± ± |

Position error on the spindle in rigid tapping |

|

|

|

0628 |

± ± ± ± ± ± |

Spindle pulse distribution in rigid tapping |

|

|

|

0663 to 0665 |

± ± ± ± ± ± |

Number of teeth on the spindle when an optional gear ratio is selected |

|

|

|

0666 to 0668 |

± ± ± ± ± ± |

Number of teeth on the position coder when an optional gear ratio is selected |

|

|

|

0669 to 0671 |

± ± ± ± ± ± |

Loop gain of position control |

|

|

|

0692 |

± ± ± ± ± ± |

(Low gear) Time constant of acceleration/deceleration on the spindle and tapping axis |

0693 |

± ± ± ± ± ± |

(Neutral gear) |

|

|

|

0694 |

± ± ± ± ± ± |

(Low gear) Maximum spindle speed in rigid tapping |

0695 |

± ± ± ± ± ± |

(Neutral gear) |

|

|

|

0696 |

± ± ± ± ± ± |

Instantaneous difference between errors on the spindle and tapping axis |

|

|

|

0697 |

± ± ± ± ± ± |

Maximum difference between errors on the spindle and tapping axis |

|

|

|

0799 |

± ± ± ± ± ± |

Integrated spindle pulse distribution in rigid tapping |

|

|

|

0960 |

± ± ± ± ± ± |

Amount of return for rigid tapping return |

|

|

|

(17) Parameters related to unidirectional positioning (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0029#0 to #3 |

G60: |

In unidirectional positioning (G60) for each axis, the direction of approach is positive/ |

|

|

negative. |

|

|

|

0204 to 0207 |

± ± ± ± ± ± |

Distance of approach in unidirectional positioning for each axis |

|

|

|

(18) Parameters related to control in the normal direction (1/1)

No. |

Symbol |

Description |

|

|

|

0683 |

± ± ± ± ± ± |

Rotation speed around a controlled axis in the normal direction |

|

|

|

0832 |

± ± ± ± ± ± |

Limit up to which an inserted rotation around a controlled axis in the normal direction |

|

|

can be ignored |

|

|

|

0833 |

± ± ± ± ± ± |

Limit on travel distance that can be executed with the angle in the normal direction of |

|

|

the previous block |

|

|

|

15

1. FUNCTION PARAMETERS |

B±62580EN/01 |

||

|

|

|

|

(19) Parameters related to custom macro (1/1) |

|

||

|

|

|

|

No. |

Symbol |

Description |

|

|

|

|

|

0011#5 |

SBKM |

By a macro statement, a single±block stop is not made/is made. |

|

|

|

|

|

0040#1 |

DPOSUP |

If data is output by the DPRINT command, leading zeros are output as space charac- |

|

|

|

ters/as they are. |

|

|

|

|

|

0040#5 |

TMCR |

A T code is processed as the code of the tool function/code for calling O9000. |

|

|

|

|

|

0040#6 |

COMC |

When a reset occurs, common variables (#100 to #149) are made null/are not made |

|

|

|

null. |

|

|

|

|

|

0040#7 |

LOCC |

When a reset occurs, local variables (#01 to #33) are made null/are not made null. |

|

|

|

|

|

0042 |

ASTCD |

Hole pattern of the EIA code of an asterisk (*) |

|

|

|

|

|

0043 |

EQCD |

Hole pattern of the EIA code of an equal sign (=) |

|

|

|

|

|

0044 |

SHPCD |

Hole pattern of the EIA code of a sharp (#) |

|

|

|

|

|

0053 |

LBLCD |

Hole pattern of the EIA code of a square bracket ([) |

|

|

|

|

|

0054 |

RBLCD |

Hole pattern of the EIA code of a square bracket (]) |

|

|

|

|

|

0056#1 |

MSKT |

At an interrupt, absolute coordinates are not set as skip coordinates/are set as skip |

|

|

|

coordinates. |

|

|

|

|

|

0056#2 |

MBLK |

Custom macro interrupt of type I/type II |

|

|

|

|

|

0056#3 |

MSTE |

The interrupt signal uses the edge trigger method/status trigger method. |

|

|

|

|

|

0056#4 |

MPRM |

The M codes for enabling and disabling an interrupt are M96 and M97 respectively/are |

|

|

|

specified in parameters. |

|

|

|

|

|

0056#5 |

MSUB |

When an interrupt occurs, local variables are of the macro type/subprogram type. |

|

|

|

|

|

0056#6 |

MCYL |

During a cycle operation, a custom macro interrupt is disabled/enabled. |

|

|

|

|

|

0056#7 |

MUSR |

The custom macro interrupt function is disabled/enabled. |

|

|

|

|

|

0057#4 |

CROUT |

After data output in ISO code is completed with B/D PRINT, LF is output/CR/LF is out- |

|

|

|

put. |

|

|

|

|

|

0220 to 0229 |

± ± ± ± ± ± |

G code for calling custom macro from O9010 to O9019 |

|

|

|

|

|

0230 to 0239 |

± ± ± ± ± ± |

M code for calling a custom macro from O9020 to O9029 |

|

|

|

|

|

0240 to 0242 |

± ± ± ± ± ± |

M code for calling a subprogram from O9001 to O9003 |

|

|

|

|

|

0246 |

± ± ± ± ± ± |

M code for enabling a custom macro interrupt |

|

|

|

|

|

0247 |

± ± ± ± ± ± |

M code for disabling a custom macro interrupt |

|

|

|

|

|

0248 |

± ± ± ± ± ± |

M code for calling a program registered in a file |

|

|

|

|

|

16

B±62580EN/01 |

1. FUNCTION PARAMETERS |

|

|

(20) Parameters related to the display of operation time and number of parts (1/1)

No. |

Symbol |

Description |

|

|

|

0040#3 |

RWCNT |

With M02 or M30, the total number of parts to be machined and the number of parts |

|

|

machined are counted/are not counted. |

|

|

|

0219 |

± ± ± ± ± ± |

M code for counting the total number of parts to be machined and the number of parts |

|

|

machined |

|

|

|

0600 |

± ± ± ± ± ± |

Number of parts required |

|

|

|

0779 |

± ± ± ± ± ± |

Total number of parts to be machined |

|

|

|

(21) Parameters related to manual handle feed (1/1)

No. |

Symbol |

Description |

|

|

|

0002#6 |

TJHD |

During teaching in jog mode, the manual pulse generator is disabled/enabled. |

|

|

|

0013#0 |

JHD |

In the jog mode, the manual pulse generator is disable/enabled. |

|

|

|

0018#0 to #3 |

N:MP2 |

For each axis, the magnification of handle feed (x 100) is enabled/disabled. |

|

|

|

0060#4 |

HDLPM |

If the handle of the manual pulse generator is rotated quickly, the reading and travel |

|

|

distance may not agree/the travel distance depends on the reading. |

|

|

|

0386#4 to #7 |

HDPIG: |

For each axis, the magnification of manual handle feed (x 1000) is enabled/disabled. |

|

|

|

0121 |

± ± ± ± ± ± |

Magnification of manual handle feed (M) |

|

|

|

0699 |

± ± ± ± ± ± |

Magnification of manual handle feed (N) |

|

|

|

(22) Parameters related to the software operator's panel (1/1)

No. |

Symbol |

Description |

|

|

|

0017#0 |

OPG1 |

On the software operator's panel, the mode is not selected/is selected. |

|

|

|

0017#1 |

OPG2 |

On the software operator's panel, the selection of a jog feed axis or rapid traverse is |

|

|

not executed/is executed. |

|

|

|

0017#2 |

OPG3 |

On the software operator's panel, the selection of the manual pulse generator axis |

|

|

switch or magnification switch is not executed/is executed. |

|

|

|

0017#3 |

OPG4 |

On the software operator's panel, jog feedrate override switch is not executed/is |

|

|

executed. |

|

|

|

0017#4 |

OPG5 |

On the software operator's panel, BDT, SBK, MLK, or DRN switch is not executed/is |

|

|

executed. |

|

|

|

0017#5 |

OPG6 |

On the software operator's panel, protect switch is not executed/is executed. |

|

|

|

0017#6 |

OPG7 |

On the software operator's panel, feed hold switch is not executed/is executed. |

|

|

|

0130 to 0137 |

± ± ± ± ± ± |

Axis and direction of jog feed corresponding to keys on the software operator's panel |

|

|

|

0140 to 0203 |

± ± ± ± ± ± |

Character code of general±purpose switches on the software operator's panel |

|

|

|

17

1. FUNCTION PARAMETERS |

B±62580EN/01 |

||

|

|

|

|

(23) Parameters related to PMC axis control (1/1) |

|

||

|

|

|

|

No. |

Symbol |

Description |

|

|

|

|

|

0030#0, #1 |

EAC: |

Axis setting for executing PMC axis control (specification A) |

|

|

|

|

|

0032#4 |

PNGMLK |

On a PMC axis, a machine lock is enabled/disabled. |

|

|

|

|

|

0032#6 |

EACSB |

PMC axis control of specification A/specification B |

|

|

|

|

|

0049#5 |

EFML10 |

Under PMC axis control, the specified feedrate (cutting feed) is multiplied by one/ten. |

|

|

|

|

|

0052#0 to #7 |

NODIC: |

Under PMC axis control, the current position display |

depends on the position of the |

|

|

decimal point with increment system 1 or 10/depends on the standard specifications. |

|

|

|

|

|

0061#0 to #5 |

EBC: |

Under PMC axis control (specification B), DI and DO used for each axis are of group |

|

|

|

A/B. |

|

|

|

|

|

0062#6 |

AXPCF |

To the actual speed display, traveling along a PMC controlled axis is added/is not add- |

|

|

|

ed. |

|

|

|

|

|

0063#5 |

EAXOV |

On a PMC axis, a dry run and override are disabled/enabled. |

|

|

|

|

|

0066#3 |

EPMSKP |

The skip signal used under PMC axis control is the same as the corresponding signal |

|

|

|

of the CNC/is a unique signal. |

|

|

|

|

|

0078#4 |

OVRIE |

Under PMC axis control, the speed increases when the override signal is set to 0/1. |

|

|

|

|

|

0078#6 |

RDRNE |

Under PMC axis control, a dry run for the rapid traverse command is disable/enabled. |

|

|

|

|

|

0078#7 |

EAXOVE |

The dry run signal and override signal used under PMC axis control are the same as |

|

|

|

the corresponding signals of the CNC/are unique signals. |

|

|

|

|

|

0387#7 |

EFERPD |

Under PMC axis control, the parameter of the rapid traverse rate is the same as that of |

|

|

|

the CNC/the rapid traverse rate is determined by the feedrate data specified with the |

|

|

|

axis control command. |

|

|

|

|

|

0350 |

± ± ± ± ± ± |

Axis for which the velocity command is executed under PMC axis control |

|

|

|

|

|

0462 |

± ± ± ± ± ± |

Time constant of linear acceleration/deceleration for the velocity specified with the ve- |

|

|

|

locity command |

|

|

|

|

|

0657 to 0662 |

± ± ± ± ± ± |

(X to 4) FL speed of exponential acceleration/deceleration on a PMC axis during cut- |

|

|

|

ting feed |

|

|

|

|

|

0672 |

± ± ± ± ± ± |

FL speed on a PMC controlled axis during reference position return |

|

|

|

|

|

0685 |

± ± ± ± ± ± |

F0 speed of independent rapid traverse override on a PMC controlled axis |

|

|

|

|

|

(24) Parameters related to the surface grinding machine (1/1) |

|

||

|

|

|

|

No. |

Symbol |

Description |

|

|

|

|

|

0838 |

± ± ± ± ± ± |

Minimum diameter of the grinding wheel when the diameter is checked |

|

|

|

|

|

18

B±62580EN/01 |

|

1. FUNCTION PARAMETERS |

|

|

|

(25) Parameters related to the PMC (1/1) |

||

|

|

|

No. |

Symbol |

Description |

|

|

|

0024#0 |

IGNPMC |

PMC control is enabled/disabled. |

|

|

|

0028#1 |

PRCMSG |

On the program check screen, the remaining travel distance is displayed/a message |

|

|

from the PMC is displayed. |

|

|

|

0060#1 |

PCLDB |

The baud rate during ladder loading is 4800 bps/9600 bps. |

|

|

|

0356 to 0359 |

± ± ± ± ± ± |

Number of characters that can be displayed in the remaining travel distance field on |

|

|

the program check screen |

|

|

|

0476 to 0479 |

± ± ± ± ± ± |

First PMC address at which the characters in the remaining travel distance field are set |

|

|

|

19

2. PARAMETER DESCRIPTION |

B±62580EN/01 |

|

|

2 PARAMETER DESCRIPTION

[01. Setting method] |

1) Preparation |

||

|

(A) |

Select the MDI mode. |

|

|

(B) |

Press the function button [DGNOS/PARAM] to display the |

|

|

|

parameter setting screen. |

|

|

(C) Key in address ªNo.º and value ª0º in the stated order, then press |

||

|

|

the [INPUT] button; the setting parameter screen will appear. Set |

|

|

|

PWE = 1. |

|

|

(D) Executing the above steps enables parameter input. |

||

|

2) Setting |

|

|

|

(A) |

On the parameter setting screen, key in address ªNo.º and the |

|

|

|

desired parameter number in the stated order, then press the |

|

|

|

[INPUT] button. The desired number will be searched for. Using |

|

|

|

the cursor/page key can also switch the screen sequentially. |

|

|

(B±1) |

Bit±type parameter |

|

|

|

|

Specify 0 or 1 in the 8 bits of the parameter. One parameter |

|

|

|

consists of 8 bits. Bit 7 is the highest bit, and bit 0 is the lowest. |

|

|

|

It is impossible to set or reset an individual bit separately from |

|

|

|

another bit. All bits must be manipulated simultaneously. |

|

|

|

Example) |

|

|

|

If you want to change ª00001000º to ª10001000º, key in |

|

|

|

ª10001000º [INPUT]. |

|

|

|

The highest bit must be entered first, then the next highest, |

|

|

|

and so on. The lowest bit must be entered last. If only less |

|

|

|

than 8 bits are entered, any bit left unspecified is regarded |

|

|

|

as 0. |

|

|

|

ª1001[INPUT]º is equivalent to ª0001001[INPUT]º. |

|

(B±2) |

Nonbit±type parameter |

|

|

|

|

Key in a value within the valid data range, and press the |

|

|

|

[INPUT] button. |

|

3) Resume the setting that was changed in item 1). |

|

|

|

|

|

NOTE |

|

|