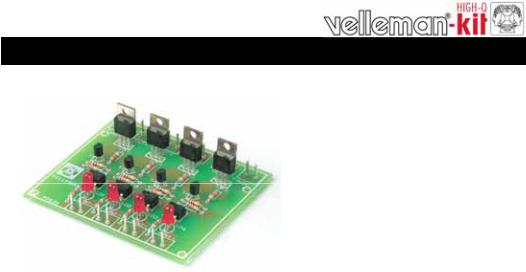

Velleman K2634 Assembly instructions

Total solder points: 108 |

|

|

|

Difficulty level: beginner 1 |

2 |

3 |

4 5 advanced |

QUAD TRIAC SWITCH CARD

K2634

|

|

|

|

|

|

|

|

|

|

|

|

|

|

its |

|

|

|

|

|

|

|

|

|

|

|

|

|

cu |

|

|

|

|

|

|

|

|

|

|

|

|

|

ercir |

|

|

|

|

|

|

|

|

|

|

|

|

|

w |

|

|

|

|

|

|

|

|

|

|

|

|

po |

|

|

|

||

|

|

|

|

|

|

|

h- |

|

|

|

|

|

||

|

|

|

|

to |

4 |

hig |

|

|

|

|

|

|

it. |

|

|

|

|

p |

|

|

|

|

|

|

|

|

cu |

||

|

|

lu |

|

|

|

|

|

|

|

|

e |

|

|

|

|

tro |

|

|

|

|

|

|

|

riv |

|

|

|||

on |

|

|

|

|

|

|

rd |

|

|

|

|

|||

C |

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

|

|

|

|

ow |

|

|

|

|

|

|

|

|

|

|

|

|

|

-p |

|

|

|

|

|

|

|

|

|

|

|

|

|

w |

|

|

|

|

|

|

|

|

|

|

|

|

m |

a lo |

|

|

|

|

|

|

|

|

|

|

|

|

fro |

|

|

|

|

|

|

|

|

|

|

|

|

|

ILLUSTRATED ASSEMBLY MANUAL |

H2634IP-1 1 |

Features & Specifications

Applying relays is the most usual way to switch an alternating current (AC) with an electronic control, because of its simplicity and its security, as the switching and switched voltage are completely separated. The low speed (esp. for illuminated advertisements ) and the short life of the contacts are however major disadvantages. In order to avoid the disadvantages of the relay without losing the advantages, optocoupler controlled triacs are used. Because of the fact that the outputs are controlled by current instead of voltage, they are less sensitive to input interferences, so that the triac card can easily be mounted near the load and relatively far from the control circuit (e.g. for score boards etc.).

This kit can immediately be connected to cards like: K8000, K8050, K8023, K8055, K8046, K8055 or other cards with open collector output. Circuits which can deliver a control current of 10mA or higher can also be used.

Features:

Four triac outputs

Inputs galvanically isolated by optocouplers. 4 control LED's are provided

Specifications:

Load : 24 to 240V AC, 0,5 A not cooled (max. 4A) per output. Control current : 10 to 20mA DC.

9V DC/200mA ISOLATED FROM THE MAIN VOLTAGE (isolated winding or another transformer). Dimensions : 78 x 90 x 29 mm

2

Assembly hints

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project successful. Read them carefully.

1.1 Make sure you have the right tools:

• A good quality soldering iron (25-40W) with a small tip.

•Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to the tip, to give it a wet look. This is called ‘thinning’ and will protect the tip, and enables you to make good connections. When solder rolls off the tip, it needs cleaning.

• Thin raisin-core solder. Do not use any flux or grease.

• A diagonal cutter to trim excess wires. To avoid injury when cutting excess leads, hold the lead so they cannot fly towards the eyes.

•Needle nose pliers, for bending leads, or to hold components in place.

• Small blade and Phillips screwdrivers. A basic range is fine.

0. 000

For some projects, a basic multi-meter is required, or might be handy

.2 Assembly Hints :

Make sure the skill level matches your experience, to avoid disappointments.

Follow the instructions carefully. Read and understand the entire step before you perform each operation.

Perform the assembly in the correct order as stated in this manual

Position all parts on the PCB (Printed Circuit Board) as shown on the drawings.

Values on the circuit diagram are subject to changes.

Values in this assembly guide are correct*

Use the check-boxes to mark your progress.

Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute manual updates, indicated as ‘NOTE’ on a separate leaflet.

3

Assembly hints

1.3 Soldering Hints :

1- Mount the component against the PCB surface and carefully solder the leads

2- Make sure the solder joints are cone-shaped and shiny

3- Trim excess leads as close as possible to the solder joint

REMOVE THEM FROM THE TAPE ONE AT A TIME !

AXIAL COMPONENTS ARE TAPED IN THE COR-

RECT MOUNTING SEQUENCE !

4

Loading...

Loading...