JLG 600SC-660SJC Service Manual

Service and Maintenance Manual

Model 600SC 600SJC 660SJC

3120794

April 9, 2002

ANSI

JLG Industries (Australia) |

JLG Industries (UK) |

JLG Deutschland GmbH |

P.O. Box 5119 |

Unit 12, Southside |

Max Planck Strasse 21 |

11 Bolwarra Road |

Bredbury Park Industrial Estate |

D-27721 Ritterhude/lhlpohl |

Port Macquarie |

Bredbury |

Bei Bremen |

N.S.W. 2444 |

Stockport |

Germany |

Australia |

SK6 2sP |

Phone: (49) 421 693 500 |

Phone: (61) 2 65 811111 |

England |

Fax: (49) 421 693 5035 |

Fax: (61) 2 65 810122 |

Phone: (44) 870 200 7700 |

|

|

Fax: (44) 870 200 7711 |

|

JLG Latino Americana Ltda. |

JLG Europe B.V. |

JLG Industries (Norge AS) |

Rua Eng. Carlos Stevenson, |

Jupiterstraat 234 |

Sofeimyrveien 12 |

80-Suite 71 |

2132 HJ Foofddorp |

N-1412 Sofienyr |

13092-310 Campinas-SP |

The Netherlands |

Norway |

Brazil |

Phone: (31) 23 565 5665 |

Phone: (47) 6682 2000 |

Phone: (55) 19 3295 0407 |

Fax: (31) 23 557 2493 |

Fax: (47) 6682 2001 |

Fax: (55) 19 3295 1025 |

|

|

JLG Industries (Europe) |

JLG Industries (Pty) Ltd. |

Plataformas Elevadoras |

Kilmartin Place, |

Unit 1, 24 Industrial Complex |

JLG Iberica, S.L. |

Tannochside Park |

Herman Street |

Trapadella, 2 |

Uddingston G71 5PH |

Meadowdale |

P.I. Castellbisbal Sur |

Scotland |

Germiston |

08755Castellbisbal |

Phone: (44) 1 698 811005 |

South Africa |

Spain |

Fax: (44) 1 698 811055 |

Phone: (27) 11 453 1334 |

Phone: (34) 93 77 24700 |

|

Fax: (27) 11 453 1342 |

Fax: (34) 93 77 11762 |

JLG Industries (Italia)

Via Po. 22

20010 Pregnana Milanese - MI

Italy

Phone: (39) 02 9359 5210

Fax: (39) 02 9359 5845

JLG Polska

UI. Krolewska

00-060 Warsawa

Poland

Phone: (48) 91 4320 245

Fax: (48) 91 4358 200

JLG Industries (Sweden)

Enkopingsvagen 150

Box 704

SE - 175 27 Jarfalla

Sweden

Phone: (46) 8 506 59500

Fax: (46) 8 506 59534

INTRODUCTION

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A GENERAL

This section contains the general safety precautions which must be observed during maintenance of the aerial platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves or others, or damage to the equipment. A maintenance program must be followed to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST AS SAFE AS ORIGINALLY MANUFACTURED, IS A SAFETY VIOLA-

TION.

The specific precautions to be observed during maintenance are inserted at the appropriate point in the manual. These precautions are, for the most part, those that apply when servicing hydraulic and larger machine component parts.

Your safety, and that of others, is the first consideration when engaging in the maintenance of equipment. Always be conscious of weight. Never attempt to move heavy parts without the aid of a mechanical device. Do not allow heavy objects to rest in an unstable position. When raising a portion of the equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CON-

TROL OVER THE FIELD INSPECTION AND MAINTENANCE, SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPER-

ATOR.

feed lines to system components can then be disconnected with minimal fluid loss.

C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN THIS SECTION MAY RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY VIOLATION.

•NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL CAP IS CLOSED AND SECURE AT ALL OTHER TIMES.

•REMOVE ALL RINGS, WATCHES AND JEWELRY WHEN PERFORMING ANY MAINTENANCE.

•DO NOT WEAR LONG HAIR UNRESTRAINED, OR LOOSE-FITTING CLOTHING AND NECKTIES WHICH ARE APT TO BECOME CAUGHT ON OR ENTANGLED IN EQUIPMENT.

•OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICEMANUAL.

•KEEP OIL, GREASE, WATER, ETC. WIPED FROM STANDING SURFACES AND HAND HOLDS.

•USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

•NEVER WORK UNDER AN ELEVATED BOOM UNTIL BOOM HAS BEEN SAFELY RESTRAINED FROM ANY MOVEMENT BY BLOCKING OR OVERHEAD SLING, OR BOOM SAFETY PROP HAS BEEN ENGAGED.

•BEFORE MAKING ADJUSTMENTS, LUBRICATING OR PERFORMING ANY OTHER MAINTENANCE, SHUT OFF ALL POWER CONTROLS.

•BATTERY SHOULD ALWAYS BE DISCONNECTEDDURING REPLACEMENT OF ELECTRICAL COMPONENTS.

B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems operate at extremely high potentially dangerous pressures. Every effort should be made to relieve any system pressure prior to disconnecting or removing any portion of the system.

Relieve system pressure by cycling the applicable control several times with the engine stopped and ignition on, to direct any line pressure back into the reservoir. Pressure

•KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

•USE ONLY APPROVED, NONFLAMMABLE CLEANING SOLVENTS.

3120794 |

– JLG Lift – |

A-1 |

INTRODUCTION

|

REVISON LOG |

Original Issue |

- January 25, 2000 |

Revised |

- July 28, 2000 |

Revised |

- April 9, 2002 |

A-2 |

– JLG Lift – |

3120794 |

TABLE OF CONTENTS

TABLE OF CONTENTS |

|

SUBJECT - SECTION, PARAGRAPH |

PAGE NO. |

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS |

|

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

SECTION 1 - SPECIFICATIONS

1.1 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Hydraulic Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Hydraulic System (Including Tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Engine Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Component Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 Engine - Diesel (Liquid-Cooled) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Swing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Auxiliary Power Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2 Turning Radius (Outside) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Turning Radius (Inside) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Boom Elevation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Machine Weight approximately . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Machine Height (Stowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Machine Length (Stowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Machine Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Function Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2 Machine Orientation When Doing Speed Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Test Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3 1.6 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3 Deutz F4M1011F Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.7 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4 1.8 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5 1.9 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5 1.10 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5 1.11 Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

SECTION 2 - GENERAL

2.1 Machine Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Delivery Inspection and Frequent Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Annual Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Service and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety and Workmanship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Components Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Component Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Pressure-Fit Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3120794 |

– JLG Lift – |

i |

TABLE OF CONTENTS (Continued)

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH |

PAGE NO. |

Bolt Usage and Torque Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic Lines and Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Lubrication and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Changing Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Cylinder Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Platform Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Cylinder Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5 Pins and Composite Bearing Repair Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

SECTION 3 - TURNTABLE

3.1 Tilt Alarm Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Manual Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Throttle Checks and Adjustments - Deutz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Controller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Failure Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Swing Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Swing Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Turntable Bearing Mounting Bolt Condition Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wear Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Swing Bearing Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Swing Bearing Torque Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5 Swing Brake - Mico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

SECTION 4 - BOOM & PLATFORM

4.1 Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Platform Sections Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Boom Rope Torquing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Torque Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Main Boom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Wire Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Three Month Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Five Year Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Replacement Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5 Boom Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Disassembly of Boom Sections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

ii |

– JLG Lift – |

3120794 |

TABLE OF CONTENTS

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH |

PAGE NO. |

4.6 Articulating Jib Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14 Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.7 Limit Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15 4.8 Rotator - Helac. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17 Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.9 Foot Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20 4.10 SUPERFLEX Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20 System Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21 SUPERFLEX Terminal Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22 SUPERFLEX Terminal Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22 Setup and Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23 How to Perform the Normal-Active Tuning Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24 How to make Bench-Static Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27 How To Troubleshoot the SUPERFLEX Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27 How to Troubleshoot the Digisensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27 Important Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31 Crawler Tracking Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32 Drive & Steer Function Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32 Superflex Inputs And Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

SECTION 5 - HYDRAULICS

5.1 Cylinders - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1 Systems Incorporating Double Acting Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Systems Incorporating Holding Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Valves - Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1 Solenoid Control Valve - Rexroth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Relief Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Cylinder Checking Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1 Cylinders Without Counterbalance Valves - Master Cylinder and Steer Cylinder . . . . . . . . 5-1 Cylinders With Single Counterbalance Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Cylinders With Dual Counterbalance Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3 Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.5 Cylinder Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9 Main Boom Telescope Cylinder Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9 Main Boom Telescope Cylinder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9 Main Boom Lift Cylinder Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10 Main Boom Lift Cylinder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.6 Pressure Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11 Main Relief, Steer, Swing and Lift Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11 Platform Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11 Articulating Jib Boom (If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.7 Hydraulic Pump W/hayes Pump Drive Coupling Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16 5.8 Hydraulic Component Start-Up Procedures and recommendations . . . . . . . . . . . . . . . . . . . . . . .5-16

3120794 |

– JLG Lift – |

iii |

TABLE OF CONTENTS (Continued)

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH PAGE NO. SECTION 6 - UNDERCARRIAGE

6.1 Track Carrier Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.2 Track Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.3 Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Separate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.4 Front Idler and Recoil Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Front Idler Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Front Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Recoil Spring Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Recoil Spring Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.5 Track Adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.6 Final Drive Sprocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-30

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

6.7 Travel Brake Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.8 Travel Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.9 Travel Brake Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

6.10 Travel Brake Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

6.11 Travel Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

6.12 Final Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-50

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

Final Drive Oil - Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

Final Drive Oil Level Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-58

6.13 Swivel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-58

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-58

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-61

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-61

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-61

iv |

– JLG Lift – |

3120794 |

TABLE OF CONTENTS

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH |

PAGE NO. |

6.14 Towing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-62

Towing the Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-62

Final Drive Sun Gear Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-63

6.15 Track Adjustment - Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-63

Measuring Track Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

Tightening the Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

Loosening the Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

Track Adjustment - Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

6.16 Undercarriage- Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-64

SECTION 7 - SCHEMATICS

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.3 Hydraulic Circuit Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

LIST OF FIGURES

FIGURE NO. |

TITLE |

PAGE NO. |

1-1. Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6 1-2. Lubrication Point Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 1-3. Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10 3-1. Tilt Switch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 3-2. Addco Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 3-3. Swing Torque Hub Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4 3-4. Swing Bearing Bolt Feeler Gauge Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5 3-5. Swing Bearing Tolerance Measuring Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5 3-6. Swing Bearing Tolerance Boom Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6 3-7. Swing Bearing Torque Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8 3-8. Swing Brake Assembly (Mico) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9 4-1. Platform Section Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1 4-2. Dimensions of Boom Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1 4-3. Clamping Wire Ropes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1 4-4. Location and Thickness of Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2 4-5. Location of Components - Platform Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4 4-6. Location of Components - Rotator and Leveling Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4 4-7. Location of Components - Boom Powertrack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4 4-8. Boom Assembly Cutaway - S Models - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6 4-9. Boom Assembly Cutaway - S Models - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7 4-10. Boom Assembly Cutaway - S Models - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8 4-11. Disassembly of Sheave Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8 4-12. Disassembly Wire Rope Routing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9 4-13. Dimension of Sheaves When New . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10 4-14. Routing Installation of Retract Wire Ropes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11 4-15. Reassembly of Components - Boom Powertrack Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12 4-16. Boom Powertrack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13 4-17. Location of Components - Articulating Jib Boom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14 4-18. Limit Switches Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16 4-20. Removing Portion of End Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17 4-21. Heating Setscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17 4-22. Removing Setscrew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17 4-23. Removing End Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17 4-19. Rotator Assembly (Helac) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18 4-24. Removing Shaft from Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19 4-25. Removing Sleeve from Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

3120794 |

– JLG Lift – |

v |

TABLE OF CONTENTS (Continued)

LIST OF FIGURES (continued)

FIGURE NO. |

TITLE |

PAGE NO. |

4-26. Actuator Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20 4-27. SUPERFLEX Terminal Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22 4-28. Wiring Diagram - Single Coil Uni-Directional Flow Control Valve - 1 Axis. . . . . . . . . . . . . . . . . . .4-22 4-29. Controller Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23 4-30. Calibration Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26 4-31. Testing the SUPERFLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27 4-32. Digisensor Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28 4-33. Typical SUPERFLEX System Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29 4-34. OPTIMIZER Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30 5-1. Cylinder Barrel Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3 5-2. Cap Screw Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3 5-3. Cylinder Rod Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3 5-4. Tapered Bushing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4 5-5. Gar-Max Bearing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4 5-6. Rod Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5 5-7. Poly-Pak Piston Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5 5-8. Wiper Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5 5-9. Installation of Head Seal Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6 5-10. Piston Seal Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6 5-11. Tapered Bushing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7 5-12. Seating the Tapered Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7 5-13. Rod Assembly Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8 5-14. Boom Positioning and Support, Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9 5-15. Articulating Jib Boom Pressure Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11 5-16. Main Control Valve Pressure Adjustments - Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12 5-17. Main Control Valve Pressure Adjustments - Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13 5-18. Location of Components - Main Control Valve (Sheet 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14 5-19. Location of Components - Main Control Valve (Sheet 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15 6-1. Undercarriage Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1 6-2. Track Carrier Roller - Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3 6-3. Track Carrier Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4 6-4. Track Roller - Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9 6-5. Track Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10 6-6. Track Link Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16 6-7. Track Shoe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16 6-8. Front Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19 6-9. Recoil Spring Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22 6-10. Track Adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28 6-11. Travel Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33 6-12. Final Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-43 6-13. Tooling (J) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-56 6-14. Swivel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-60 7-1. Electrical Components Installation - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2 7-2. Electrical Components Installation - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3 7-3. Electrical Schematic - Deutz or Isuzu - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4 7-4. Electrical Schematic - Deutz or Isuzu - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5 7-5. Hydraulic Schematic - Sheet 1 of 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6 7-6. Hydraulic Schematic - Sheet 2 of 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7 7-7. Hydraulic Schematic - Sheet 3 of 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8 7-8. Hydraulic Schematic - Sheet 4 of 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9 7-9. Hydraulic Schematic w/GFT24 Drive - Sheet 1 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10 7-10. Hydraulic Schematic w/GFT24 Drive - Sheet 2 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11 7-11. Hydraulic Schematic w/GFT24 Drive - Sheet 3 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12 7-12. Hydraulic Schematic w/GFT24 Drive - Sheet 4 of 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

vi |

– JLG Lift – |

3120794 |

TABLE OF CONTENTS

LIST OF TABLES

TABLE NO. |

TITLE |

PAGE NO. |

1-1 Function Speeds (In Seconds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-2 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-3 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-4 Mobil DTE 13M Specs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-5 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-6 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-7 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-8 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-9 Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

2-1 Inspection and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 Cylinder Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-3 Inspection and Preventive Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

3-1 Position Controller Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

4-1 Adjusting Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

4-2 Adjustment Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4-3 Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

5-1 Cylinder Head and Tapered Bushing Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5-2 Holding Valve Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

6-1 Track Carrier Roller Required Tools - Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6-2 Track Carrier Roller Required Tools - Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6-3 Track Roller Required Tools - Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6-4 Track Roller Required Tools - Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-5 Track Roller Required Tools - Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6-6 Track Required Tools - Separate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6-7 Track Required Tools - Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6-8 Front Idler Required Tools - Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

6-9 Recoil Spring Required Tools - Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

6-10 Recoil Spring Required Tools - Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

6-11 Track Adjuster Required Tools - Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-29

6-12 Final Drive Sprocket Required Tools - Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-30

6-13 Final Drive Sprocket Required Tools - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-31

6-14 Travel Motor Required Tools - Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

6-15 Travel Motor Required Tools - Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

6-16 Travel Motor Required Tools - Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

6-17 Travel Motor Required Tools - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-40

6-18 Final Drive Required Tools - Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

6-19 Final Drive Required Tools - Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-42

6-20 Final Drive Required Tools - Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-50

6-21 Final Drive Required Tools - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-56

3120794 |

– JLG Lift – |

vii |

TABLE OF CONTENTS (Continued)

This page left blank intentionally.

viii |

– JLG Lift – |

3120794 |

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

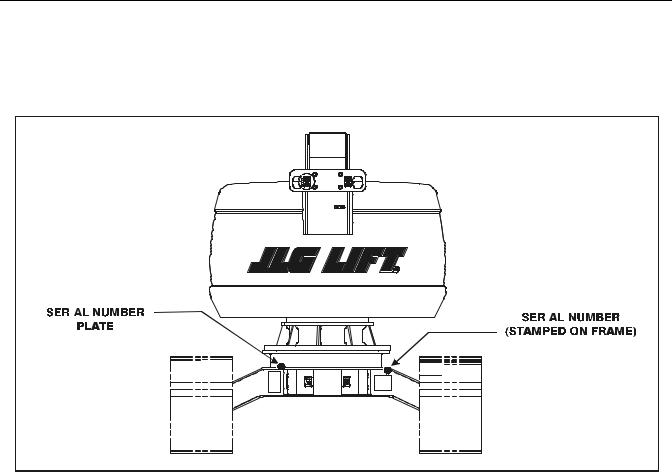

1.1CAPACITIES

Fuel Tank

39 US. Gallons (147.6 l)

Hydraulic Oil Tank

31 U.S. Gallons (117.3 l) with 10% air space

Hydraulic System (Including Tank)

37.2 U.S. Gallons (140.8 l)

Engine Crankcase

Deutz F4M1011F Diesel w/Filter - 11 quarts (10.5 l)

1.2COMPONENT DATA

Engine - Diesel (Liquid-Cooled)

Manufacturer/ModelDeutz F4M1011F.

Oil Capacity.

5 Quarts (4.5 l) Cooling System.

11 Quarts (10.5 l) w/Filter.

16 Quarts (15 l) Total Capacity. Low RPM - 1800.

High RPM - 2800.

Alternator - 60 Amp, belt drive.

Battery - 1000 Cold Cranking Amps, 210 Minutes

ReserveCapacity, 12 VDC.

Fuel Consumption.

Low RPM - 1.90 GPH (7.19 lph).

High RPM - 2.50 GPH (9.46 lph).

Horsepower - 65 @ 3000 RPM, full load. Engine - Diesel. (Water-Cooled)

Swing System

Swing Motor Displacement - 4.62 cu. in. (75 cm3]).

Swing Brake - Automatic spring applied hydraulically released disc brakes.

Swing Hub Ratio - 50:1.

Hydraulic Gear Pump. (at 1800 RPM) 7.9 GPM (29.90 lpm).

Pump Displacement - 1.02 cu. in. (16 cm3]). Clockwise Rotation.

Auxiliary Power Pump

2.6 GPM (9.84 lpm) @ 1200 PSI. (82.7 BAR. Pump Displacement - .244 cu. in. (14 cm3]). DC Motor.

Clockwise Rotation.

Hydraulic Filter - In-line.

Return - Bypass Type.

10 Microns Absolute.

Charge.

10 Microns Absolute.

Hydraulic Strainers (In Tank).

30 Microns.

3120794 |

– JLG Lift – |

1-1 |

SECTION 1 - SPECIFICATIONS

1.3 PERFORMANCE DATA |

1.4 FUNCTION SPEEDS |

Travel Speed

Table 1-1. Function Speeds (In Seconds)

1.6 MPH (2.6 Km/hr.)

Travel Speed - Out of Transport

0.4 MPH (0.6 Km/hr.)

Gradeability.

55%

Turning Radius (Outside)

8 ft. (2.4 m)

Turning Radius (Inside)

0

Boom Elevation

600SC - +60 ft. 2 13/16 in. (18.36 m) -6 ft. 1 11/16 in. (1.87 m)

600SCJ - +60 ft. 5 3/4 in. (18.43 m) -9 ft. 9 3/16 in. (2.98 m)

660SCJ - +66 ft. 7 5/8 in. (20.31 m) -11 ft. 5 1/4 in. (3.49 m)

Machine Weight approximately

Steel Track - 25,900 lbs. (11,748 kg)

Rubber Track - 26,860 lbs. (12,184 kg)

Machine Height (Stowed)

Steel Track - 8’4" (2.54 m)

Rubber Track - 8’6" (2.59 m)

Machine Length (Stowed)

35’ 6" (10.8 m)

Machine Width

8 ft. (2.4 m)

Function |

Speed |

|

|

Lift Up |

46-60 |

|

|

Lift Down |

33-43 |

|

|

Swing Right & Left* |

79-101 |

|

|

Telescope In |

22-33 |

|

|

Telescope Out |

50-67 |

|

|

Platform Rotate Right & Left** |

16-25 |

|

|

Jib Up |

22-34 |

|

|

Jib Down |

16-26 |

|

|

Drive (Forward & Reverse) |

85-90 |

|

|

Drive Out of Transport (Forward & Reverse) |

80-85 |

|

|

*Max 10% Difference Between Left & Right |

|

**Max 15% Difference Between Left & Right |

|

|

|

Machine Orientation When Doing Speed

Tests

Lift: Telescope Retracted. Lift Up, Record Time, Lift Down,

Record Time.

Swing: Boom at Full Elevation. Telescope Retracted. Swing the Turntable off center and stop. Swing the opposite direction ana start the test wen the turntable is centered up. This eliminates ramp up and down on the controller affecting times.

Telescope: Boom at Full Elevation; Telescope Retracted; Telescope Out, Record Time. Telescope In, Record Time.

Tracking: Test to be done on a gravelled level surface. Position the machine driving at high speed at a reference point. (No steer correction). Results should be 4 to 6 ft.(1.2 to 1.8 m) tracking error at 200 ft. (60.9 m).

Drive: Test should be done on a graveled level surface. Drive select switch should be set at High Speed. Start approx. 10 ft. from starting point so that the unit is at maximum speed when starting the test. Results should be recorded for a 200 ft. (60.9 m) course. Drive Forward, Record Time. Drive Reverse, Record Time.

Drive (Out of Transport): Test should be done on a graveled level surface. Drive select switch should be set at Low Engine, Low Drive (The platform speed knob control, if equipped, could be selected to the creep speed to simulate the boom above horizontal). Results should be recorded for a 50 ft. (15.2 m) course. Drive Forward, Record Time. Drive Reverse, Record Time.

1-2 |

– JLG Lift – |

3120794 |

SECTION 1 - SPECIFICATIONS

Platform Rotate: Platform level and completely rotated one direction. Rotate the opposite direction, Record Time. Rotate the other direction, Record Time.

Articulating Jib: Platform level and centered with the boom. Start with the Jib down. Jib Up, Record Time. Jib Down, Record Time.

Test Notes

1.Stop watch should be started with the function, not with the controller or switch.

2.All speed tests are run from the platform. These speeds do not reflect the ground control operation.

3.The platform speed knob control must be at full speed (turned clockwise completely).

4.Function speeds may vary due to cold, thick hydraulic oil. Test should be run with the oil temperature above 100° F (38° C).

5.Some flow control functions may not work with the speed knob clicked into the creep position.

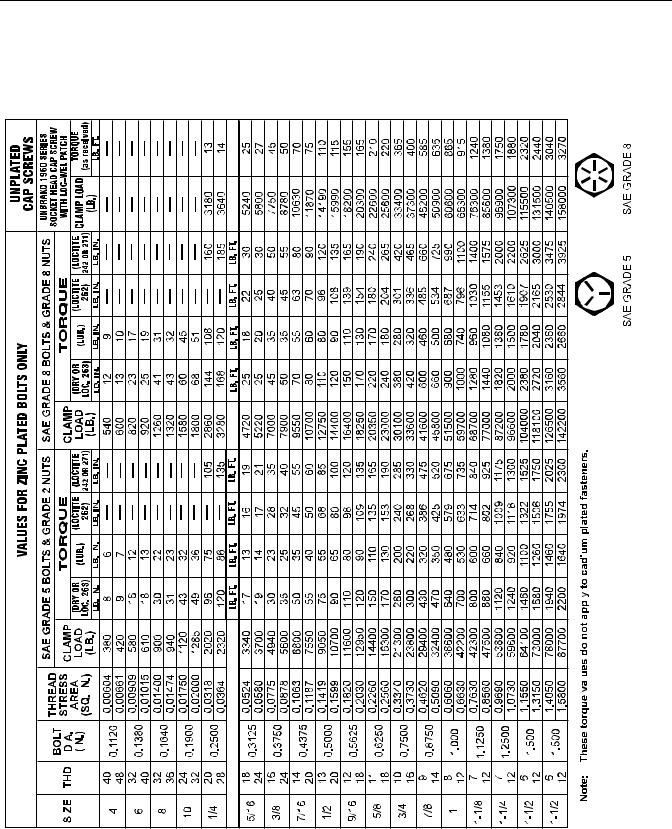

1.5TORQUE REQUIREMENTS

Table 1-2. Torque Requirements

Description |

Torque Value |

Interval |

|

(Dry) |

Hours |

||

|

|||

|

|

|

|

|

|

|

|

Bearing To Chassis |

See Note |

50/600* |

|

|

|

|

|

Bearing To Turntable |

See Note |

50/600* |

|

|

|

|

|

Wire Rope |

15 ft.lbs. |

150 |

|

|

(20 Nm) |

|

|

|

|

|

|

M16 Travel motor |

175 ±30 ft.lbs. |

As |

|

mounting bolts |

(240±40 Nm) |

required |

|

|

|

|

|

M20 Final Drive |

390 ±50 ft.lbs. |

As |

|

mounting bolts |

(530±70 Nm) |

required |

|

|

|

|

|

M20 Track roller |

340 ±44 ft.lbs. |

As |

|

mounting bolts |

(460±60 Nm) |

required |

|

|

|

|

|

M24 Carrier roller |

600 ±70 ft.lbs. |

As |

|

mounting bolts |

(800±100 Nm) |

required |

|

|

|

|

*Check swing bearing bolts for security after first 50 hours of operation and every 600 hours thereafter. (See paragraph on Swing Bearing in Section 2.)

NOTE: When maintenance becomes necessary or a fastener has loosened, refer to the Torque Chart to determine proper torque value.

1.6LUBRICATION

Deutz F4M1011F Engine

Single Viscosity Oil (CD-SE, CD-SF).

When Outside Temperature is |

Use SAE Viscosity |

Consistently |

Number |

-20°F. to +25°F. (-29°C. to +4°C.) |

*10W |

+5°F. to +50°F. (+15°C. to +10°C.) |

20W-20 |

+40°F. to +85°F. (+4°C. to +30°C.) |

30 |

Above 75°F. (24°C.) |

40 |

Multi Viscosity Oil (CD-SE, CD-SF)

*This viscosity can be used at colder temperatures with engine oil preheating.

When Outside |

|

Temperature is |

Use SAE Viscosity Number |

Consistently |

|

-40°F. to +75°F. (-40°C. to |

*5W-30 (Synthetic) |

+24°C.) |

|

-15°F. to +70°F. (-26°C. to |

10W-30 |

+21°C.) |

|

-15°F. to +85°F. (-26°C. to |

10W-40 |

+30°C.) |

|

Above -5°F. (-21°C.) |

15W-40 |

-5°F. to +75°F. (-21°C. to |

15W-30 |

+24°C.) |

|

*This viscosity can be used at colder temperatures with engine oil preheating.

NOTE: Crankcase oil should be MIL-L2104B/MIL-L2104C or have properties of API classification CC/CD grades.

3120794 |

– JLG Lift – |

1-3 |

SECTION 1 - SPECIFICATIONS

Hydraulic Oil

Table 1-3. Hydraulic Oil

HYDRAULIC SYSTEM |

|

OPERATING |

SAE VISCOSITY GRADE |

TEMPERATURE RANGE |

|

|

|

+0° to +180° F (-18° C to |

10W |

+83° C) |

|

|

|

+0° F to +210° F (-18° C to |

10W-20, 10W-30 |

+99° C) |

|

|

|

+50° F to +210° F (+10° C to |

20W-20 |

+210° C) |

|

|

|

Lubrication Specifications

Table 1-5. Lubrication Specifications

KEY |

SPECIFICATIONS |

MPG |

Multipurpose Grease having a mini- |

|

mum dripping point of 350° F. Excel- |

|

lent water resistance and adhesive |

|

qualities, and being of extreme pres- |

|

sure type. |

|

(Timken OK 40 pounds minimum.) |

EPGL |

Extreme Pressure Gear Lube (oil) |

|

meeting API service classification |

|

GL-5 or MIL-Spec MIL-L-2105 |

NOTE: Hydraulic oils must have anti-wear qualities at least to API Service Classification GL-3, and sufficient chemical stability for mobile hydraulic system service. JLG Industries recommends Mobilfluid 424 hydraulic oil, which has an SAE viscosity index of 152 .

NOTE: When temperatures remain below 20° F (-7 degrees C), JLG Industries recommends the use of Mobil DTE 13M.

Table 1-4. Mobil DTE 13M Specs

ISO Viscosity Grade |

|

#32 |

|

|

|

Specific Gravity |

|

0.877 |

|

|

|

Pour Point, Max |

|

-40 F (-40 C) |

|

|

|

Flash Point, Min. |

|

330 F (166 C) |

|

|

|

|

Viscosity |

|

at 40° C |

|

33cSt |

|

|

|

at 100° C |

|

6.6 cSt |

at 100° F |

|

169 SUS |

at 210° F |

|

48 SUS |

cp at -20° F |

|

6,200 |

Viscosity Index |

|

140 |

|

|

|

HO |

Hydraulic Oil. API service classifica- |

|

tion GL-3, e.g. Mobilfluid 424. |

EO |

Engine (crankcase) Oil. Gas - API SF, |

|

SH, SG class, MIL-L-2104. Diesel - |

|

API CC/CD class, MIL-L-2104B/MIL- |

|

L-2104C. |

NOTE: Refer to Lubrication Chart, for specific lubrication procedures.

1.7PRESSURE SETTINGS

Main Relief - 3000 PSI (206.85 Bar).

Upper Boom Lift Down - 1500 PSI (103.4 Bar). Swing - 1700 PSI (117.2 Bar).

Platform Level Forward - 2800 PSI (193.06 Bar).

Backward - 1800 PSI (124.11 Bar).

Articulating Jib Boom Up - 1500 PSI (103 Bar). Down - 1200 PSI (82.7 Bar).

Aside from JLG recommendations, it is not advisable to mix oils of different brands or types, as they may not contain the same required additives or be of comparable viscosities. If use of hydraulic oil other than Mobilfluid 424 is desired, contact JLG Industries for proper recommendations.

1-4 |

– JLG Lift – |

3120794 |

SECTION 1 - SPECIFICATIONS

1.8CYLINDER SPECIFICATIONS

Table 1-6. Cylinder Specifications

DESRIPTON |

|

BORE |

|

|

STROKE |

|

|

ROD DIA. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

600SJ |

660SJ |

600S |

600SJ |

660SJ |

600S |

600SJ |

660SJ |

600S |

|

|

|

|

|

|

|

|

|

|

Lift |

6.00 |

6.00 |

6.00 |

44.6875 |

44.6875 |

44.6875 |

3 |

3 |

3 |

|

(152.4) |

(152.4) |

(152.4) |

(1135.1) |

(1135.1) |

(1135.1) |

(76.2) |

(76.2) |

(76.2) |

|

|

|

|

|

|

|

|

|

|

Telescope |

3.5 |

3.5 |

3.5 |

143.1875 |

168.4375 |

177.75 |

2.5 |

2.5 |

2.5 |

|

(88.9) |

(88.9) |

(88.9) |

(3637) |

(4278.3) |

(4514.9) |

(63.5) |

(63.5) |

(63.5) |

|

|

|

|

|

|

|

|

|

|

Master |

3.5 |

3.5 |

3 |

13.0625 |

13.0625 |

8.5 |

1.5 |

1.5 |

1.5 |

|

(88.9) |

(88.9) |

(76.2) |

(331.8) |

(331.8) |

(215.9) |

(38.1) |

(38.1) |

(38.1) |

|

|

|

|

|

|

|

|

|

|

Slave Level |

3.5 |

3.5 |

3 |

13.0625 |

13.0625 |

8.5 |

1.5 |

1.5 |

1.5 |

|

(88.9) |

(88.9) |

(76.2) |

(331.8) |

(331.8) |

(215.9) |

(38.1) |

(38.1) |

(38.1) |

|

|

|

|

|

|

|

|

|

|

Lift (Articulating Jib |

3 |

3 |

N/A |

25.5 |

25.5 |

N/A |

1.5 |

1.5 |

N/A |

Boom) |

(76.2) |

(76.2) |

|

(647.7) |

(647.7) |

|

(38.1) |

(38.1) |

|

|

|

|

|

|

|

|

|

|

|

1.9MAJOR COMPONENT WEIGHTS

Table 1-7. Major Component Weights

|

600SJ |

|

660SJ |

|

|

600S |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LB. |

|

KG. |

LB. |

|

KG. |

LB. |

|

KG. |

|

|

|

|

|

|

|

|

|

|

Platform Control Console |

250 |

|

113 |

250 |

|

113 |

250 |

|

113 |

|

|

|

|

|

|

|

|

|

|

Platform Level Cylinder |

60 |

|

27 |

60 |

|

27 |

46 |

|

21 |

|

|

|

|

|

|

|

|

|

|

Main Boom (Includes Lift Cyl., Rotator, and Support) |

3483 |

|

1580 |

3783 |

|

1716 |

3527 |

|

1600 |

|

|

|

|

|

|

|

|

|

|

Turntable Complete (including engine) |

7915 |

|

3590 |

9065 |

|

4112 |

7315 |

|

3318 |

|

|

|

|

|

|

|

|

|

|

1.10 CRITICAL STABILITY WEIGHTS

DO NOT REPLACE ITEMS CRITICAL TO STABILITY WITH ITEMS

OF DIFFERENT WEIGHT OR SPECIFICATION (FOR EXAMPLE:

BATTERIES, FILLED TIRES, COUNTERWEIGHT, ENGINE & PLAT-

FORM) DO NOT MODIFY UNIT IN ANY WAY TO AFFECT STABIL-

ITY.

Table 1-8. Critical Stability Weights

|

|

|

600SJ |

660SJ |

|

|

600S |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LB. |

|

KG. |

LB. |

|

KG. |

LB. |

|

KG. |

|

|

|

|

|

|

|

|

|

|

|

Engine |

Ford |

460 |

|

209 |

460 |

|

209 |

460 |

|

209 |

|

|

|

|

|

|

|

|

|

|

|

Platform |

6 ft. (1.83 M) |

205 |

|

93 |

205 |

|

93 |

205 |

|

93 |

|

|

|

|

|

|

|

|

|

|

|

|

8 ft. (2.44 M) |

230 |

|

105 |

230 |

|

105 |

230 |

|

105 |

|

|

|

|

|

|

|

|

|

|

|

3120794 |

– JLG Lift – |

1-5 |

SECTION 1 - SPECIFICATIONS

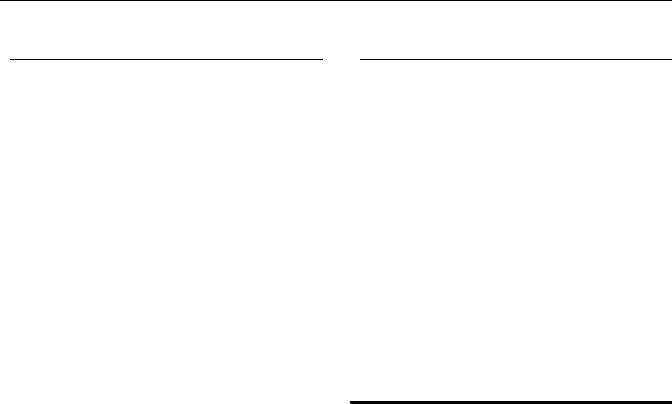

1.11 SERIAL NUMBER LOCATIONS |

|

the machine serial number is stamped on the left side of |

|||||||||||||||||||||||

the frame. |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

A serial number plate is affixed to the left rear side of the |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

frame. If the serial number plate is damaged or missing, |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|