JLG 4017 Service Manual

An Oshkosh Corporation Company

Model

4017

3121858

Revised

September 3, 2010

Service Manual

EFFECTIV IT Y PAGE

June 10, 2005 - A - Original Issue Of Manual

January 6, 2006 - B - Revision Of Manual

September 3, 2010 - C - Revised pages 2.8, 3.25 thru 3.27, 6.5 & 6.6

31261858 4017 i

EFFECTIV IT Y PAGE

4017 3121858-ii

SECTION CONTENTS

Section Subject Page

Section 1

Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.2 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3 Operator & Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.4 Accident Prevention Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.5 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.6 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.7 Emergency Exit Rear Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.8 Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

Section 2

General Information and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.1 Replacement Parts and Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2

2.2 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3

2.3 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.4 Fluids, Lubricants and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9

2.5 Service and Maintenance Schedules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10

2.6 Lubrication Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11

Section 3

Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.1 Boom System Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

3.2 Boom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.3 Boom Assembly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.4 Boom Extend and Retract Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.14

3.5 Boom Section Separation Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.17

3.6 Hose Carrier Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.18

3.7 Boom Wear Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.21

3.8 Quick Switch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.23

3.9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25

Section 4

Cab and Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.1 Operator’s Cab and Covers Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . 4.2

4.2 Operator’s Cab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.3

4.3 Cab Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

4.4 Cab Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7

4.5 Cab Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8

Section 5

Axles, Drive Shafts, Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.1 Axle, Drive Shaft and Wheel Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

5.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

5.3 Axle Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

5.4 Drive Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.10

5.5 Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.12

5.6 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.13

5.7 Towing a Disabled machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.14

4017

JLG Industries, Inc.

i

Section Subject Page

Section 6

Transmission: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.1

6.1 Transmission Assembly Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2

6.2 Transmission Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.3 Transmission Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.4 Transmission Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.5 Transmission Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.6 Transmission Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7

Section 7

Engine: Perkins 1004-40T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2

7.2 Engine Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4

7.3 Specifications and Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4

7.4 Engine Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4

7.5 Engine Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6

7.6 Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.6

7.7 Engine Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8

7.8 Air Cleaner Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9

7.9 Engine Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9

7.10 Engine Drive Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.13

7.11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.14

Section 8

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1

8.1 Hydraulic Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.2

8.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3

8.3 Hydraulic Pressure Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3

8.4 Hydraulic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.4

8.5 Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.7

8.6 Engine Implement Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.8

8.7 Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.10

8.8 Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.16

Section 9

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1

9.1 Electrical Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.3

9.2 Service Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.4

9.3 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.4

9.4 Fuses and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.4

9.5 Electrical System Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.7

9.6 Circuit Breakdowns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.12

9.7 Engine Start Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.15

9.8 Charging Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.16

9.9 Window Wiper/Washer Windshield Wiper Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.17

9.10 Cab Heater and Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.19

9.11 Solenoids and Senders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.20

9.12 Display Monitor and Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.27

9.13 Joystick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.28

9.14 Dash Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.28

9.15 Transmission Control Lever / Accessory Control Lever. . . . . . . . . . . . . . . . . . . . . . . . . 9.29

ii

4017

Section 1

Safety Practices

Contents

PARAGRAPH TITLE PAGE

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3 Operator & Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.4 Accident Prevention Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.5 Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.5.1 Safety Alert System and Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.6 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.6.1 Personal Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.6.2 Equipment Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.6.4 Operational Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.7 Emergency Exit Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.8 Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

4017

1.1

Safety Practices

1.1 INTRODUCTION

This service manual provides general directions for

accomplishing servic e and re pai r proc edu res. Fo ll owi ng

the procedures in this manual will help assure safety and

equipment reliability.

Read, understand and follow the information in this

manual, and obey all locally appro ved safe ty p r actices,

procedures, rules, codes, regulations and laws.

These instructions cannot cover all details or variations in

the equipment, procedures, or processes described, nor

provide directions for meeting every possible contingency

during opera tion, maintenance, or testing. When additi onal

information is desired consult the local JLG distributor.

Many factors contribute to unsafe conditions: carelessness,

fatigue, overload, inattentiveness, unfamiliarity, even

drugs and alcohol, among others. For optimal safety,

encourage everyone to think, and to act, safely.

Appropriate service methods and proper repair

procedures are essential for the safety of the individual

doing the work, for the safety of the operator, and for the

safe, reliable operation of the machine. All references to

the right side, left side, front and rear are given from the

operator’s seat looking in a for ward direction.

Supplementary information is available from JLG in the

form of Service Bulletins, Service Campaigns, Service

Training Schools, the JLG website, other literature, and

through updates to the manual itself.

1.2 DISCLAIMER

All information in this manual is based on the latest

product information available at the time of publication.

JLG reserves the right to make changes and

improvements to its products, and to discontinue the

manufacture of any product, at its discretion at any time

without public notice or obligation.

1.3 OPERATOR & SAFETY MANUAL

The mechanic must not operate the machine until the

Operator & Safety Manual has been read & understood,

training has been accomplished and operation of the

machine has been completed under the supervision of an

experienced and qualified operator.

An Operator & Safety Manual is supplied with each

machine and must be kept in the cab. In the event that the

Operator & Safety Manual is missing, consult the local

JLG distributor before proceeding.

1.4 ACCIDENT PREVENTION TAGS

Place Accident Prevention Tags on the ignition key

switch and the steering wheel before attempting to

perform any service or maintenance. Remove key and

disconnect battery leads.

1.2

4017

Safety Practices

1.5 SAFETY INFORMATION

To avoid possible death or injury, carefully read,

understand and comply with all safety messages.

In the event of an accident, know where to obtain medical

assistance and how to use a first-aid kit and fire

extinguisher/fire suppression system. Keep emergency

telephone numbers (fire department, ambulance, rescue

squad/paramedics, police department, etc.) nearby. If

working alone, check with another person routinely to

help assure personal safety.

1.5.1 Safety Alert System and Signal Words

DANGER

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

1.6 SAFETY INSTRUCTIONS

Following are general safety statements to consider before

performing maintenance procedures on the telehandler.

Additional statements related to specific tasks and

procedures are located throughout this manual and are

listed prior to any work instructions to provide safety

information before the potential of a hazard occurs.

For all safety messages, carefully read, understand and

follow the instructions before

1.6.1 Personal Hazards

PERSONAL SAFETY GEAR: Wear all the protective

clothing and personal safety gear necessary to perform

the job safely. This might include heavy gloves, safety

glasses or goggles, filter mask or respirator, safety shoes

or a hard hat.

LIFTING: NEVER lift a heavy object without the help of at

least one assistant or a suitable sling and hoist.

1.6.2 Equipment Hazards

LIFTING OF EQUIPMENT: Before using any lifting

equipment (chains, slings, brackets, hooks, etc.), verify

that it is of the proper capacity, in good working order, and

is properly attached.

NEVER stand or otherwise become positioned under a

suspended load or under raised equipment. The load or

equipment could fall or tip.

DO NOT use a hoist, jack or jack stands only to support

equipment. Always support equipment with the proper

capacity blocks or stands properly rated for the load.

HAND TOOLS: Always use the proper tool for the job;

keep tools clean and in good working order, and use

special service tools only as recommended.

proceeding.

4017

1.3

Safety Practices

1.6.3 General Hazards

SOLVENTS: Only use approved solvents that are known

to be safe for use.

HOUSEKEEPING: Keep the work area and operator’s

cab clean, and remove all hazards (debris, oil, tools, etc.).

FIRST AID: Imme diately clean, dress and report all inj uries

(cuts, abrasions, burns, etc.), no matter how minor the

injury may seem. Know the location of a First Aid Kit, and

know how to use it.

CLEANLINESS: Wear eye protection, and clean all

components with a high-pressure or steam cleaner

before attempting service.

When removing hydraulic components, plug hose ends

and connections to prevent excess leakage and

contamination. Place a suitable catch basin beneath the

machine to capture fluid run-off.

Check and obey all Federal, State and/or Local

regulations regarding waste storage, disposal and

recycling.

1.6.4 Operational Hazards

ENGINE: Stop the engine before performing any service

unless specificall y instr uc ted othe rw is e.

VENTILATION: Avoid prolonged engine operation in

enclosed areas without adequate ventilation.

SOFT SURFACES AND SLOPES: NEVER work on a

machine that is parked on a soft surface or slope. The

machine must b e on a hard leve l surfa ce, wit h th e wh eel s

blocked before performing any service.

FLUID TEMPERATURE: NEVER work on a machine

when the engine, cooling or hydraulic systems are hot.

Hot components and fluids can cause severe burns.

Allow systems to cool before proceeding.

FLUID PRESSURE: Before loosenin g any hydr aul ic or

diesel fuel component, hose or tube, turn the engine

OFF. Wear heavy, protective gloves and eye protection.

NEVER check for leaks using any part of your body; use

a piece of cardboard or wood instead. If injured, seek

medical attention immediately. Diesel fluid leaking under

pressure can explode. Hydraulic fluid and diesel fuel

leaking under pressure can penetrate the skin, cause

infection, gangrene and other serious personal injury.

Relieve all pressure before disconnecting any

component, part, line or hose. Slowly loosen parts and

allow release of residual pressure before removing any

part or component. Before starting the engine or applying

pressure, use components, parts, hoses and pipes that

are in good condition, connected properly and are

tightened to the proper torque. Capture fluid in an

appropriate container and dispose of in accordance with

prevailing environmental regulations.

RADIATOR CAP: Always wear steam-resistant, heat

protective gloves when opening the radiator cap. Cover

the cap with a clean, thick cloth and turn slowly to the first

stop to relieve pressure.

FLUID FLAMABILTITY: DO NOT service the fuel or

hydraulic systems near an open flame, sparks or smoking

materials.

NEVER drain or store fluids in an open container. Engine

fuel and hydraulic fluid are flammable and can cause a

fire and/or explosion.

DO NOT mix gasoline or alcohol with diesel fuel. The

mixture can cause an explosion.

PRESSURE TESTING: When conducting any test, only

use test equipment that is correctly calibrated and in good

condition. Use the correct equipment in the pr ope r

manner, and make changes or repairs as indicated by the

test procedure to achieve the desired result.

LEAVING MACHINE: Lower the forks or attachment to

the ground before leaving the machine.

TIRES: Always keep tires inflated to the proper pressure

to help prevent tipover. DO NOT over-inflate tires.

NEVER use mismatched tire types, sizes or ply ratings.

Always use matched sets according to machine

specifications.

MAJOR COMPONENTS: Never alter, remove, or

substitute any items such as counterweights, tires,

batteries or other items that may reduce or affect the

overall weight or stability of the machine.

BATTERY: DO NOT charge a frozen battery.Charging a

frozen battery may cause it to explode. Allow the battery

to thaw before jump-starting or connecting a battery

charger.

1.4

4017

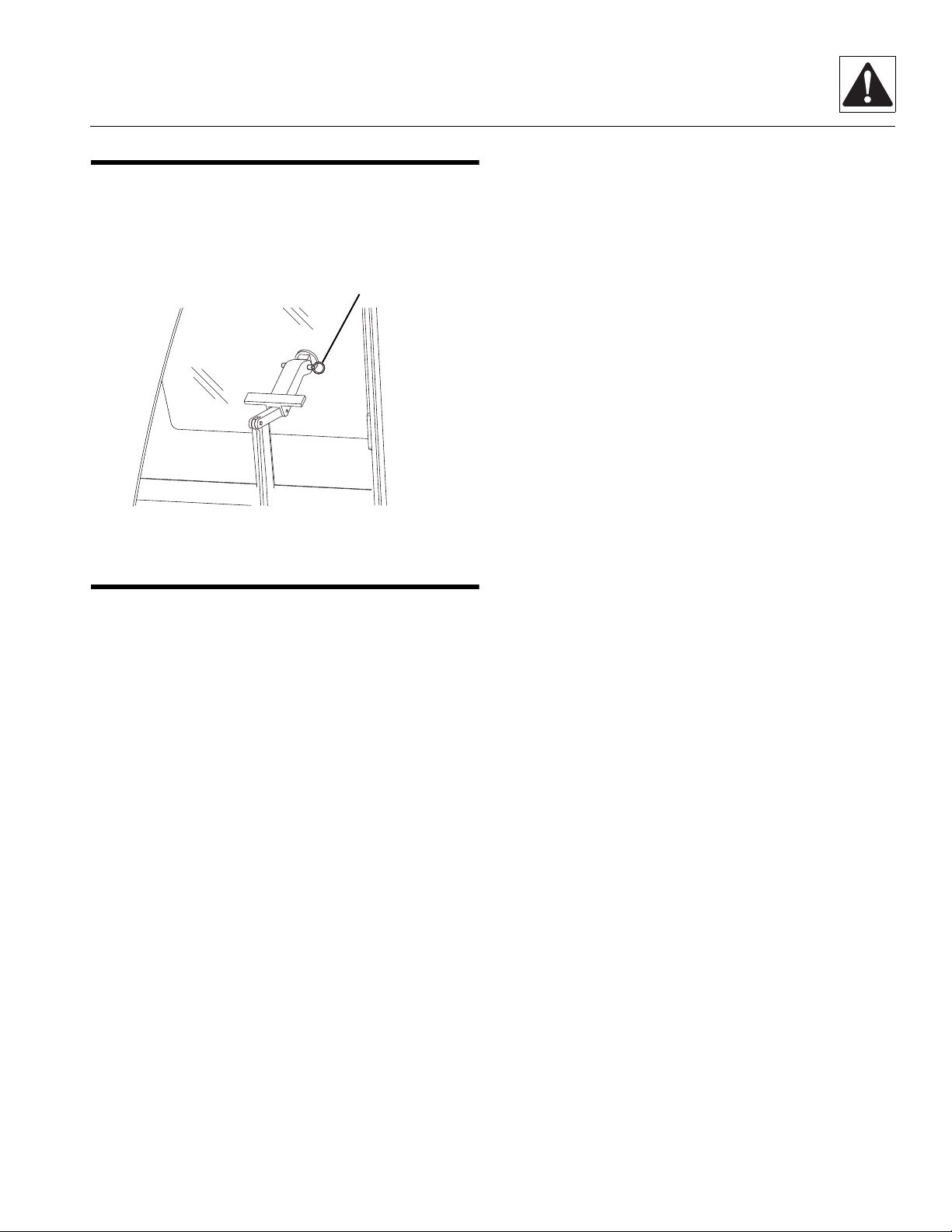

1.7 EMERGENCY EXIT REAR WINDOW

MZ1400

1

The rear window in the enclosed cab can be used as an

emergency exit by removing the latch pin (1) located on

the window latch. Once the latch pin is removed, the

window is free to swing open.

Safety Practices

1.8 SAFETY DECALS

Check that all safety decals are present and readable on

the machine. Refer to the Operator & Safety Manual

supplied with machine for information.

4017

1.5

Safety Practices

This Page Intentionally Left Blank

1.6

4017

Section 2

General Information and Specifications

PARAGRAPH TITLE PAGE

2.1 Replacement Parts and Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2

2.2 T orques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3

2.2.1 ASTM Fastener Torque Chart (English) . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3

2.2.2 ASTM Fastener Torque Chart (Metric) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4

2.2.3 Metric Fastener Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

2.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.1 Travel Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.2 Engine Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.3 Hydraulic Cylinder Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3.4 Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

2.3.5 Axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

2.3.6 Electrical System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8

2.4 Fluids, Lubricants and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9

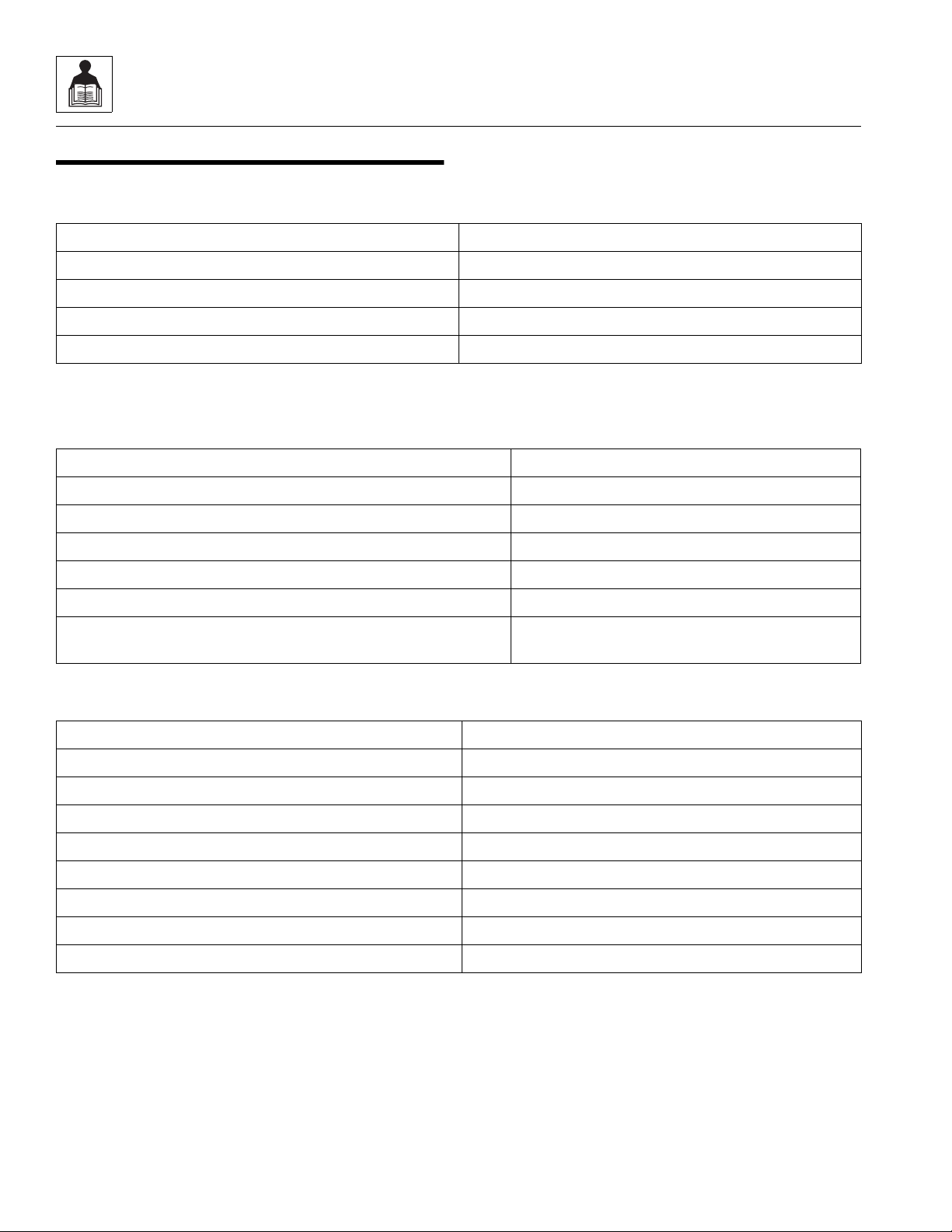

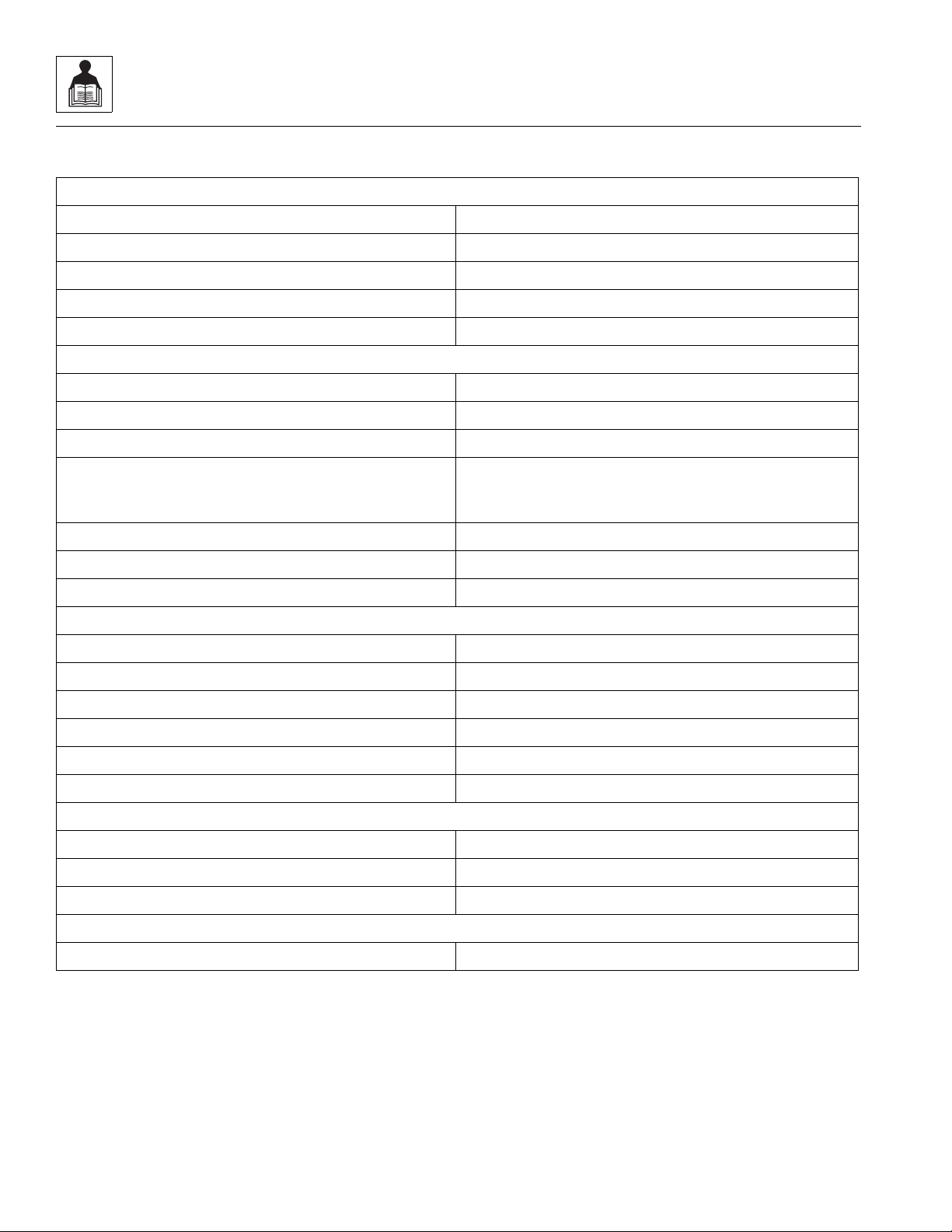

2.5 Service and Maintenance Schedules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10

2.5.1 8 & 1st 50 Hour Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10

2.5.2 50, 250 & 500 Hour Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . 2.10

2.5.3 1000 & 1500 Hour Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . 2.11

2.6 Lubrication Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11

2.6.1 8 Hour Lube Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11

2.6.2 50 Hour Lube Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.11

4017

2.1

General Information and Specifications

35

MZ1462

1

2.1 REPLACEMENT PARTS AND WARRANTY INFORMATION

Before ordering parts or initiating service inquiries, make

note of the machine serial number. The machine serial

number plate (1) is located as indicated in the figure

below.

IMPORTANT: The replacement of any part on this

machine with any other than JLG authorized

replacement parts can adversely affect the performance,

durability, or safety of the machine, and will void the

warranty. JLG disclaims liability for any claims or

damages, whether regarding property damage, personal

injury or death arising out of the use of unauthorized

replacement parts.

A warranty registration form must be filled out by the JLG

distributor, signed by the purchaser and returned to JLG

when the machine is sold and/or put into use.

Registration activates the warranty period and helps to

assure that warranty claims are promptly processed. To

guarantee full warranty service, verify that the distributor

has returned the business reply card of the warranty

registration form to JLG.

2.2

4017

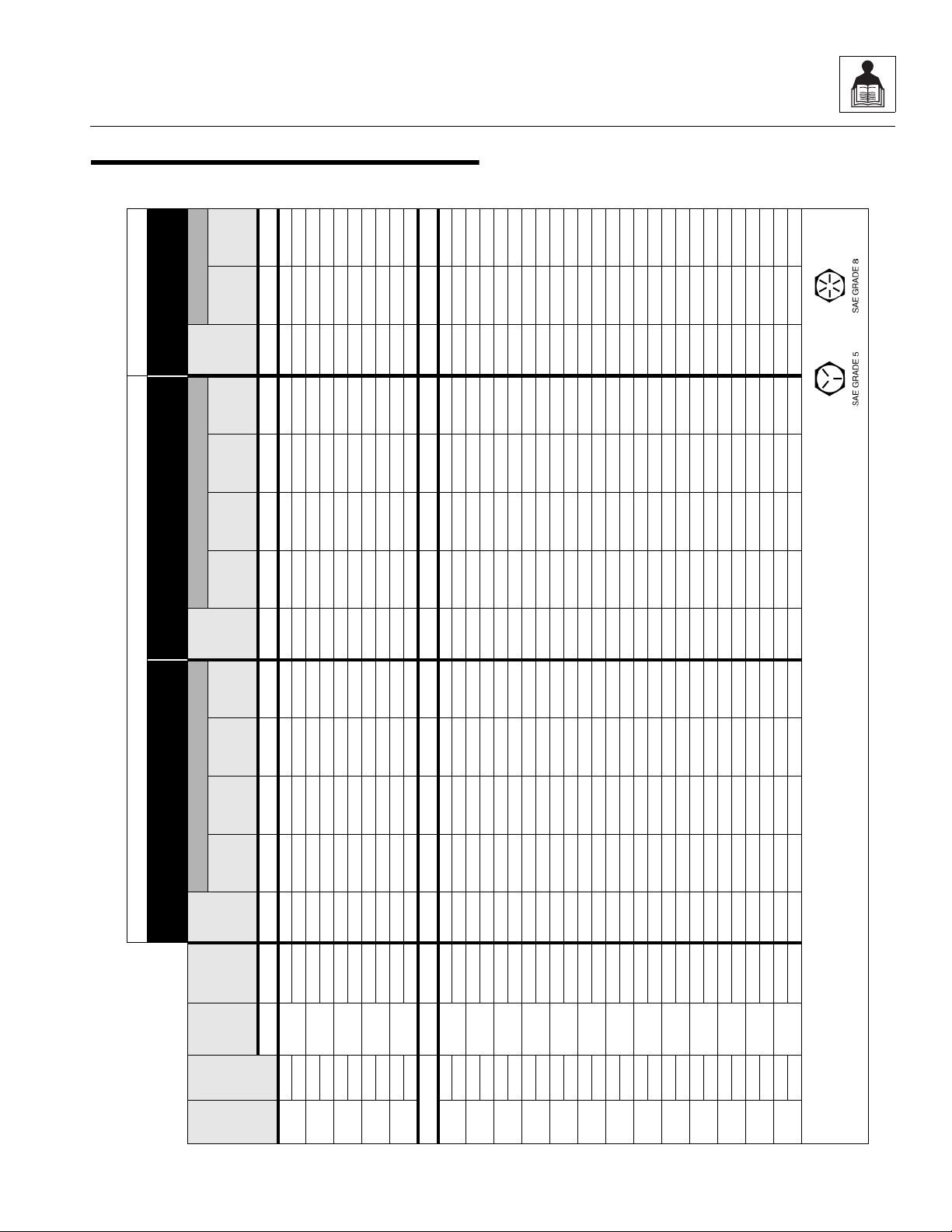

2.2 TORQUES

VALUES FOR ZINC PLATED / YELLOW CHROMATE FASTENERS ONLY UNPLATED CAP SCREWS

SAE GRADE 5 BOLTS &

GRADE 2 NUTS

SAE GRADE 8 BOLTS & GRADE 8 NUTS

& SOCKET HEAD CAP SCREWS

UNBRAKO 1960 SERIES

SOCKET HEAD

SIZE

THDS.

PER

INCH

BOLT

DIA.

TENSILE

STRESS

AREA

CLAMP

LOAD

TORQUE

CLAMP

LOAD

TORQUE

CLAMP

LOAD

TORQUE

DRY OR

LOCTITE

263

LUB

LOCT ITE

262

LOCTITE

242 OR

271

DRY OR

LOCTITE

263

LUB

LOCTITE

262

LOCTITE

242 OR

271

WITHOUT

LOC-WEL

PATCH

WITH

LOC-WEL

PATCH

IN SQ. IN. LB. IN-LB IN-LB IN-LB IN-LB LB. IN-LB. IN-LB IN-LB IN-LB LB. IN-LB IN-LB

4

40

0.1120

0.00604 380 8 6 — — 540 12 9 — — — — —

48 0.00661 420 9 7 — — 600 13 10 — — — — —632

0.1380

0.00909 580 16 12 — — 820 23 17 — — — — —

40 0.01015 610 18 13 — — 920 25 19 — — — — —832

0.1640

0.01400 900 30 22 — — 1260 41 31 — — — — —

36 0.01474 940 31 23 — — 1320 43 32 — — — — —1024

0.1900

0.01750 1120 43 32 — — 1580 60 45 — — — — —

32 0.02000 1285 49 36 — — 1800 68 51 — — — — —

1/4

20

0.2500

0.0318 2020 96 75 — 105 2860 144 108 — 160 3180 160 168

28 0.0364 2320 120 86 — 135 3280 168 120 — 185 3640 168 178

5/16

18

0.3125

0.0524 3340 17 13 16 19 4720 25 18 22 30 5240 25 28

24 0.0580 3700 19 14 17 21 5220 25 20 25 30 5800 27 30

3/8

16

0.3750

0.0775 4940 30 23 28 35 7000 45 35 40 50 7750 45 50

24 0.0878 5600 35 25 32 40 7900 50 35 45 55 8780 50 55

7/16

14

0.4375

0.1063 6800 50 35 45 55 9550 70 55 63 80 10630 70 77

20 0.1187 7550 55 40 50 60 10700 80 60 70 90 11870 75 82

1/2

13

0.5000

0.1419 9050 75 55 68 85 12750 110 80 96 120 14190 110 120

20 0.1599 10700 90 65 80 100 14400 120 90 108 130 15990 115 127

9/16

12

0.5625

0.1820 11600 110 80 98 120 16400 150 110 139 165 18200 155 170

18 0.2030 12950 120 90 109 135 18250 170 130 154 190 20300 165 182

5/8

11

0.6250

0.2260 14400 150 110 135 165 20350 220 170 180 240 22600 210 231

18 0.2560 16300 170 130 153 190 23000 240 180 204 265 25600 220 242

3/4

10

0.7500

0.3340 21300 260 200 240 285 30100 380 280 301 420 33400 365 400

16 0.3730 23800 300 220 268 330 33600 420 320 336 465 37300 400 440

7/8

9

0.8750

0.4620 29400 430 320 386 475 41600 600 460 485 660 46200 585 645

14 0.5090 32400 470 350 425 520 45800 660 500 534 725 50900 635 700

1

8

1.0000

0.6060 38600 640 480 579 675 51500 900 680 687 990 60600 865 950

12 0.6630 42200 700 530 633 735 59700 1000 740 796 1100 66300 915 1000

1-1/8

7

1.1250

0.7630 42300 800 600 714 840 68700 1280 960 1030 1400 76300 1240 1365

12 0.8560 47500 880 660 802 925 77000 1440 1080 1155 1575 85600 1380 1520

1-1/4

7

1.2500

0.9690 53800 1120 840 1009 1175 87200 1820 1360 1453 2000 96900 1750 1925

12 1.0730 59600 1240 920 1118 1300 96600 2000 1500 1610 2200 107300 1880 2070

1-3/8

6

1.3750

1.1550 64100 1460 1100 1322 1525 104000 2380 1780 1907 2625 115500 2320 2550

12 1.3150 73000 1680 1260 1506 1750 118100 2720 2040 2165 3000 131500 2440 2685

1-1/2

6

1.5000

1.4050 78000 1940 1460 1755 2025 126500 3160 2360 2530 3475 140500 3040 3345

12 1.5800 87700 2200 1640 1974 2300 142200 3560 2660 2844 3925 158000 3270 3600

ote: These torque values do not apply to cadmium plated fasteners.

2.2.1 ASTM Fastener Torque Chart (English)

General Information and Specifications

4017

2.3

General Information and Specifications

VALUES FOR ZINC PLATED / YELLOW CHROMATE FASTENERS ONLY UNPLATED CAP SCREWS

SAE GRADE 5 BOLTS &

GRADE 2 NUTS

SAE GRADE 8 BOLTS & GRADE 8 NUTS

& SOCKET HEAD CAP SCREWS

UNBRAKO 1960 SERIES

SOCKET HEAD

SIZE

THDS.

PER

INCH

BOLT

DIA.

TENSILE

STRESS

AREA

CLAMP

LOAD

TORQUE

CLAMP

LOAD

TORQUE

CLAMP

LOAD

TORQUE

DRY OR

LOCTITE

263

LUB

LOCTITE

262

LOCTITE

242 OR

271

DRY OR

LOCTITE

263

LUB

LOCTITE

262

LOCTITE

242 OR

271

WITHOUT

LOC-WEL

PATCH

WITH

LOC-WEL

PATCH

IN SQ. IN. LB. N, m N, m N, m N, m LB. N, m N, m N, m N, m LB. N, m N, m

IN SQ. IN. LB. N, m N, m N, m N, m LB. N, m N, m N, m N, m LB. N, m N, m

Note: These torque values do not apply to cadmium plated fasteners.

2.2.2 ASTM Fastener Torque Chart (Metric)

2.4

4017

General Information and Specifications

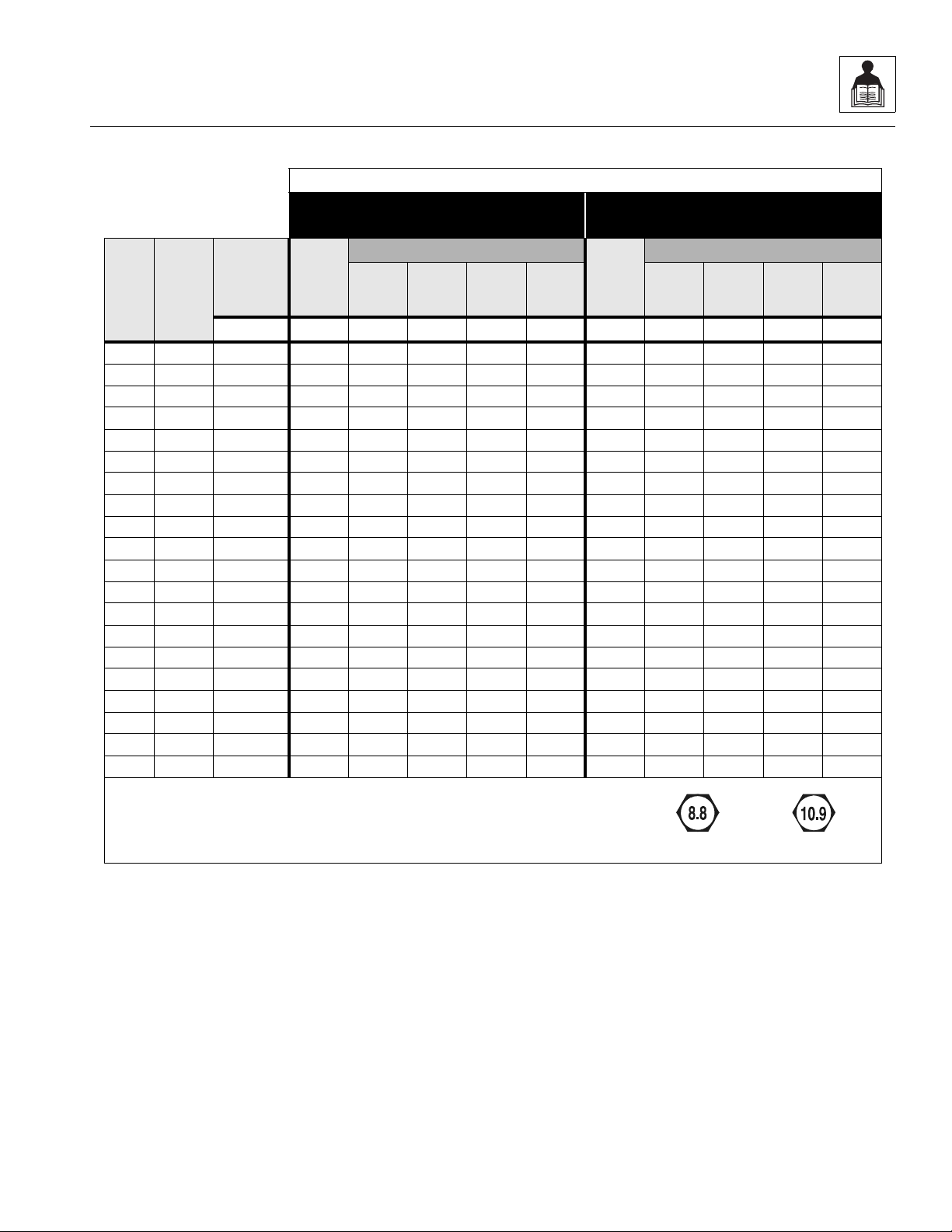

METRIC CLASS 8.8 METRIC CLASS 10.9

2.2.3 Metric Fastener Torque Chart

VALUES FOR ZINC PLATED / YELLOW CHROMATE FASTENERS ONLY

CLASS 8.8 METRIC BOLTS &

CLASS 8 METRIC NUTS

TORQUE

LUB

LOCTITE

262

LOCTITE

242 OR

271

CLAMP

SIZE PITCH

TENSILE

STRESS

AREA

CLAMP

LOAD

DRY OR

LOCTITE

263

sq. mm KN N, m N, m N, m N, m KN N, m N, m N, m N, m

3 .5 5.03 2.19 1.3 1.0 1.2 1.4 3.13 1.9 1.4 1.5 2.1

3.5 .6 6.78 2.95 2.1 1.6 1.9 2.3 4.22 3.0 2.2 2.4 3.3

4 .7 8.78 3.82 3.1 2.3 2.8 3.4 5.47 4.4 3.3 3.5 4.8

5 .8 14.2 6.18 6.2 4.6 5.6 6.8 8.85 8.9 6.6 7.1 9.7

6 1 20.1 8.74 11 7.9 9.4 12 12.5 15 11 12 17

7 1 28.9 12.6 18 13 16 19 18 25 19 20 28

81.2536.615.92519232822.837272940

10 1.5 58.0 25.2 50 38 45 55 36.1 72 54 58 79

12 1.75 84.3 36.7 88 66 79 97 52.5 126 95 101 139

14 2 115 50.0 140 105 126 154 71.6 200 150 160 220

16 2 157 68.3 219 164 197 241 97.8 313 235 250 344

18 2.5 192 83.5 301 226 271 331 119.5 430 323 344 473

20 2.5 245 106.5 426 320 383 469 152.5 610 458 488 671

22 2.5 303 132.0 581 436 523 639 189.0 832 624 665 915

24 3 353 153.5 737 553 663 811 220.0 1060 792 845 1170

27 3 459 199.5 1080 810 970 1130 286.0 1540 1160 1240 1690

30 3.5 561 244.0 1460 1100 1320 1530 349.5 2100 1570 1680 2310

33 3.5 694 302.0 1990 1490 1790 2090 432.5 2600 2140 2280 2860

36 4 817 355.0 2560 1920 2300 2690 509.0 3660 2750 2930 4020

42 4.5 1120 487.0 4090 3070 3680 4290 698.0 5860 4400 4690 6440

CLASS 10.9 METRIC BOLTS &

CLASS 10 METRIC NUTS

LOAD

DRY OR

LOCT ITE

263

LUB

TORQUE

LOCTITE

262

LOCTITE

242 OR

271

Note: These torque values do not apply to cadmium plated fasteners.

4017

2.5

General Information and Specifications

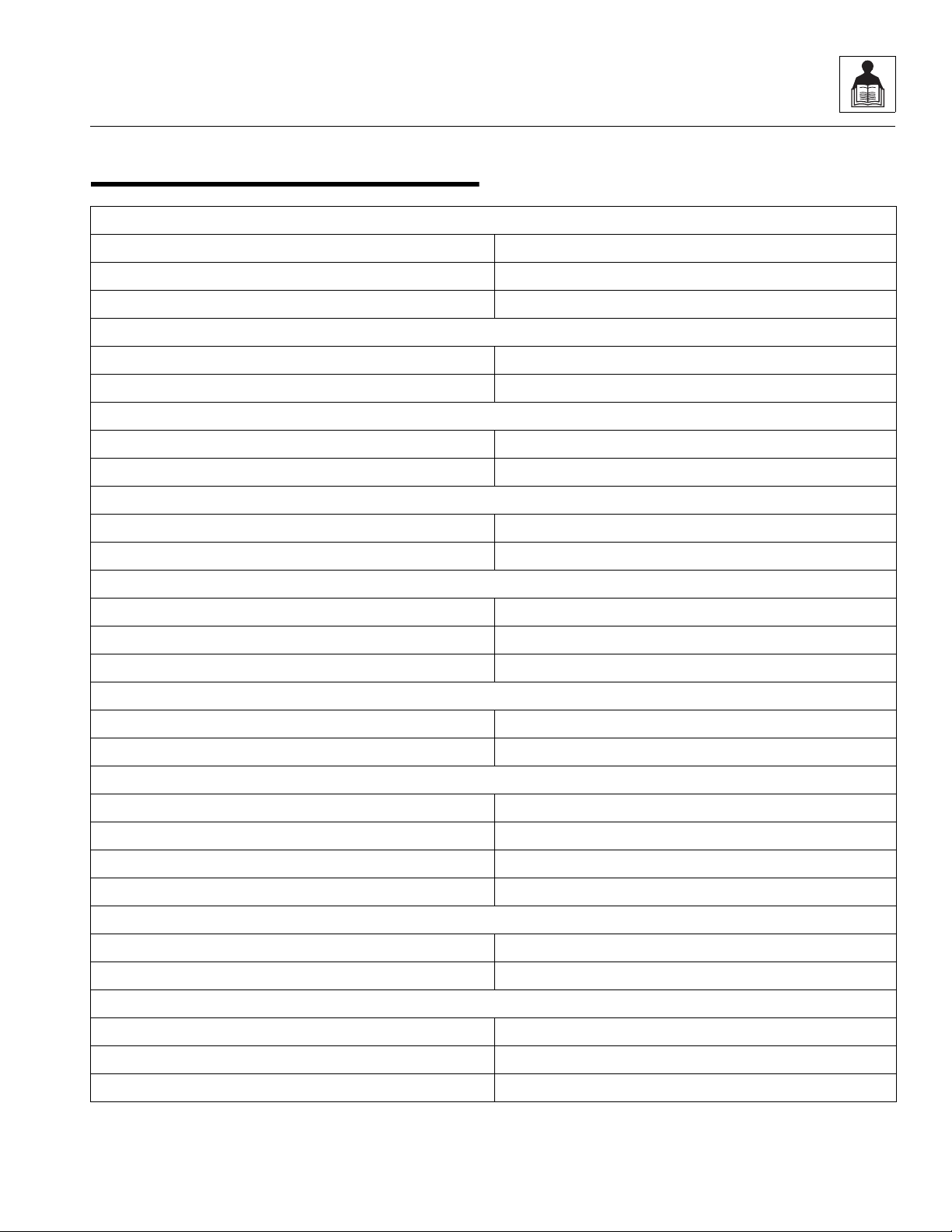

2.3 SPECIFICATIONS

2.3.1 Travel Speeds

Description

First Gear 5,2 km/h (3.2 mph)

Second Gear 11 km/h (6.9 mph)

Third Gear 22,5 km/h (14 mph)

Fourth Gear 35 km/h (21.7 mph)

2.3.2 Engine Performance Specifications

Note: Engine manufacturer's maximum “high idle” setting is lockwired and sealed. DO NOT disturb this setting.

Description

Engine Make/Model Perkins 1004-40T

Low Idle 925 ±50 rpm

High Idle 2200 ±50 rpm

Horsepower 99.5 BHP / 74.5 kW @ 2200 rpm

Fuel Delivery Fuel Injection

Air Cleaner Dry Type, Replaceable Pr im ar y and Safety

Elements

2.3.3 Hydraulic Cylinder Performance

Function Approximate Times (seconds)

Extend Cylinder Extend 23.0

Extend Cylinder Retract 18.0

Lift Retracted 15.5

Lower Retracted 10.0

Attachment Tilt - UP 4.5

Attachment Tilt - DOWN 9.8

Outrigger - Left and Right, DOWN 8.7

Outrigger - Left and Right, UP 6.4

2.6

4017

General Information and Specifications

2.3.4 Tires

Description

Wheel Lug Nut Torque 550-600 Nm (405-445 lb-ft)

Standard Tire Size 405/70-24 14PR MPT-04 TBL

Standard Tire Air Pressure (Minimum) 450 kPa (65 psi)

Optional Tires

Opti on al Tir e Size 405/70-24 14PR MPT-01 TBL

Opti o nal Tire Air P ressu re (Mi n i mum) 450 kPa (65 psi)

2.3.5 Axles

Dana Spicer

Model

212-531 FRONT 1:20.667 0280173

212-190-002 REAR 1:20.667 4803383

Axle JLG P/N

4017

2.7

General Information and Specifications

2.3.6 Electrical System

Battery:

Type, Rating 12 VDC, Negative (-) Ground, Maintenance Free

Quantity 1

Reserve Capacity 1,000 Cold Cranking Amps @ 0° F (-18° C)

Group/Series Series 31

Alternator 12V, 85 Amps

Fuses - Standard Blade Style:

5 Amps Radio

7.5 Amps Headlights and Tail Lights, ESX Ignition and Sensors

10 Amps Brake Lights, Cold Start, Beacon

15 Amps Rear Work Lights, Cab Heater, Aux Power Socket,

Battery Ind. Light, Dome Light, Spare, Ignition, Front

Work Lights, Boom Work Lights,

20 Amps Rear Wiper, Front Wiper

25 Amps ESX Battery, Air Conditioning

30 Amps Key Switch

Relays:

Key (power) K1

Start Interlock K2

Flasher K3

Wiper K4

Work Lights K5

Fuel Solenoid K6

Relays in Engine Compartment:

Starter

Lift pump

Glow Plug

Inline Fuse:

Lift Pump and Glow Plug

2.8

4017

General Information and Specifications

2.4 FLUIDS, LUBRICANTS AND CAPACITIES

Engine Crankcase Oil

Capacity w/Filter Change 8,5 liters (9 quarts)

Filter Capacity 1,0 liter (0.26 quarts)

Type of Oil 15W-40 CE/SE

Fuel Filters

Primary Fuel Filter Capacity Approx. 1,0 liter (0.26 quarts)

Fuel Filter Capacity 0,6 liters (0.16 quarts)

Fuel Tank

Capacity 140 liters (37 gallons)

Type of Fuel U.S.A. #2 Diesel

Cooling System

System Capacity w/o Heater 19,7 liters (20.8 quarts)

Type of Fluid 50/50 mix of ethylene glycol & water

Transmission Fluid

Capacity w/filter change 12,9 liter (13.6 quarts)

Filter Capacity 1,4 liters (1.5 quarts)

Type of Fluid Mobilfluid 424

®

Tractor Hydraulic Fluid (ISO 46)

Transmission Transfer Case (Drop Box)

Capacity 1,4 liter (1.5 quarts)

Type of Fluid Mobilfluid 424

®

Tractor Hydraulic Fluid (ISO 46)

Axles

Differential Housing Capacity - Front 6,9 liters (1.3 quarts)

Differential Housing Capacity - Rear 6,9 liters (1.3 quarts)

Wheel End Capacity 1,25 liters (1.3 quarts)

Type of Fluid Mobilfluid 424

®

Tractor Hydraulic Fluid (ISO 46)

Brakes

Master Cylinder Capacity 0,7 liters (0.7 quarts)

Type of Fluid ATF Dexron II

Hydraulic System

System Capacity 246 liters (65 gallons)

Reservoir Capacity to FULL Mark 160 liters (42.3 gallons)

Type of Fluid Mobilfluid 424

4017

®

Tractor Hydraulic Fluid (ISO 46)

2.9

General Information and Specifications

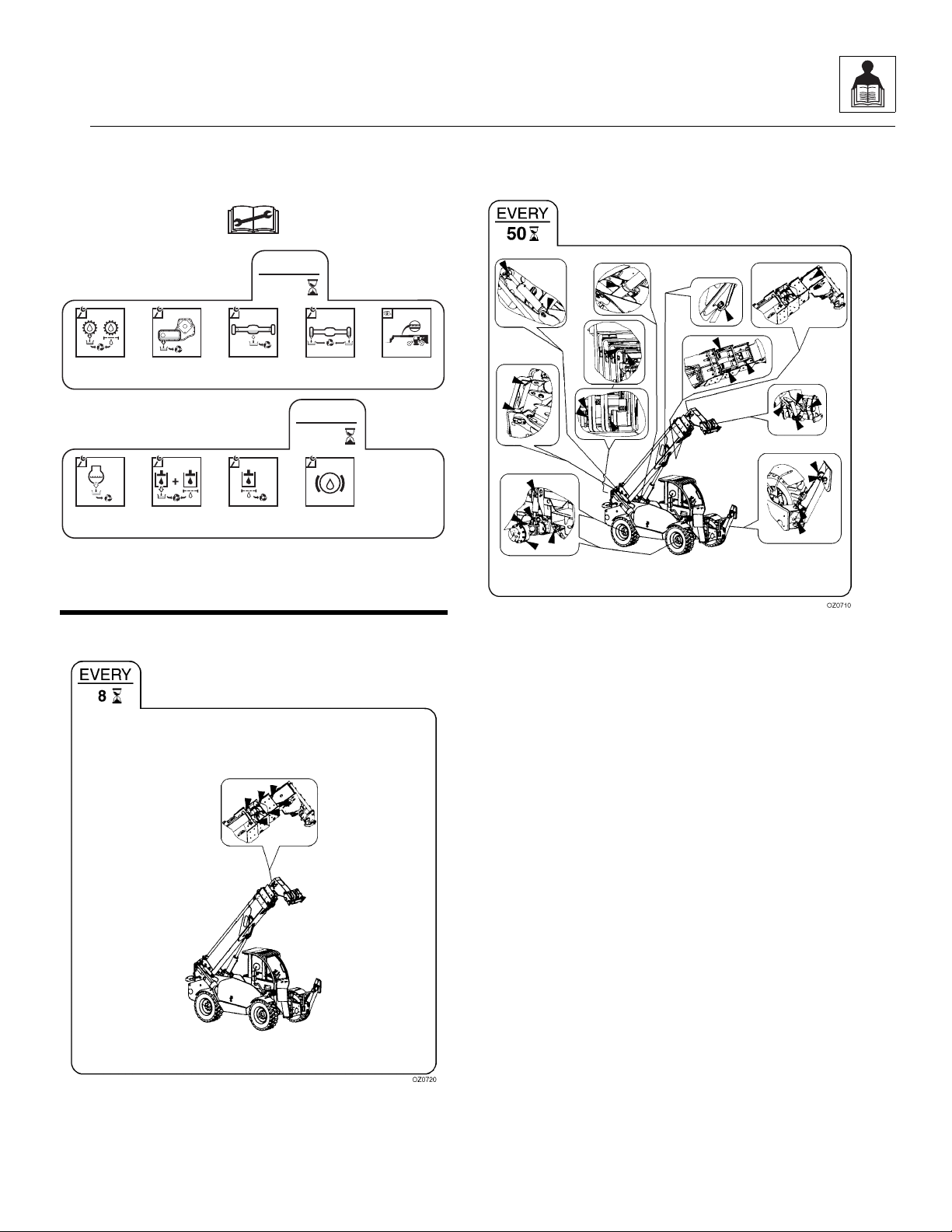

OZ0300

Check Wheel

Lug Nut

Torque

LB/FT (Nm)

Change

Axle Oil

Change Wheel

End Oil

50

1

st

Check Boom

Chain Tension

Change Engine

Oil & Filter

Change

Transmission

Oil & Filter

Air Filter

Restriction

Indicator

Check Fuel

Level

Check Engine

Oil Level

Check Tire

Pressure

8

EVERY

Check Brake

Fluid Level

Check

Transmission

Oil Level

Test Load

Moment

Indicator

Check Hydraulic

Oil Level

OZ0320

500

EVERY

Check Wheel

Lug Nut

Torque

LB/FT (Nm)

Change Fuel

Filter

50

EVERY

Drain Fuel/

Water

Separator

Check Engine

Coolant Level

Check

Battery

Follow Lubrication

Schedule

250

EVERY

Check Axle

Oil Level

Check Wheel

End Oil Levels

Air Filter

Vacuator

Valve

Check

Fan Belt

Check Boom

Chain

Tension

Check Boom

Bearing

Pads

Check Transfer

Case Oil Level

Change Engine

Oil and

Filter

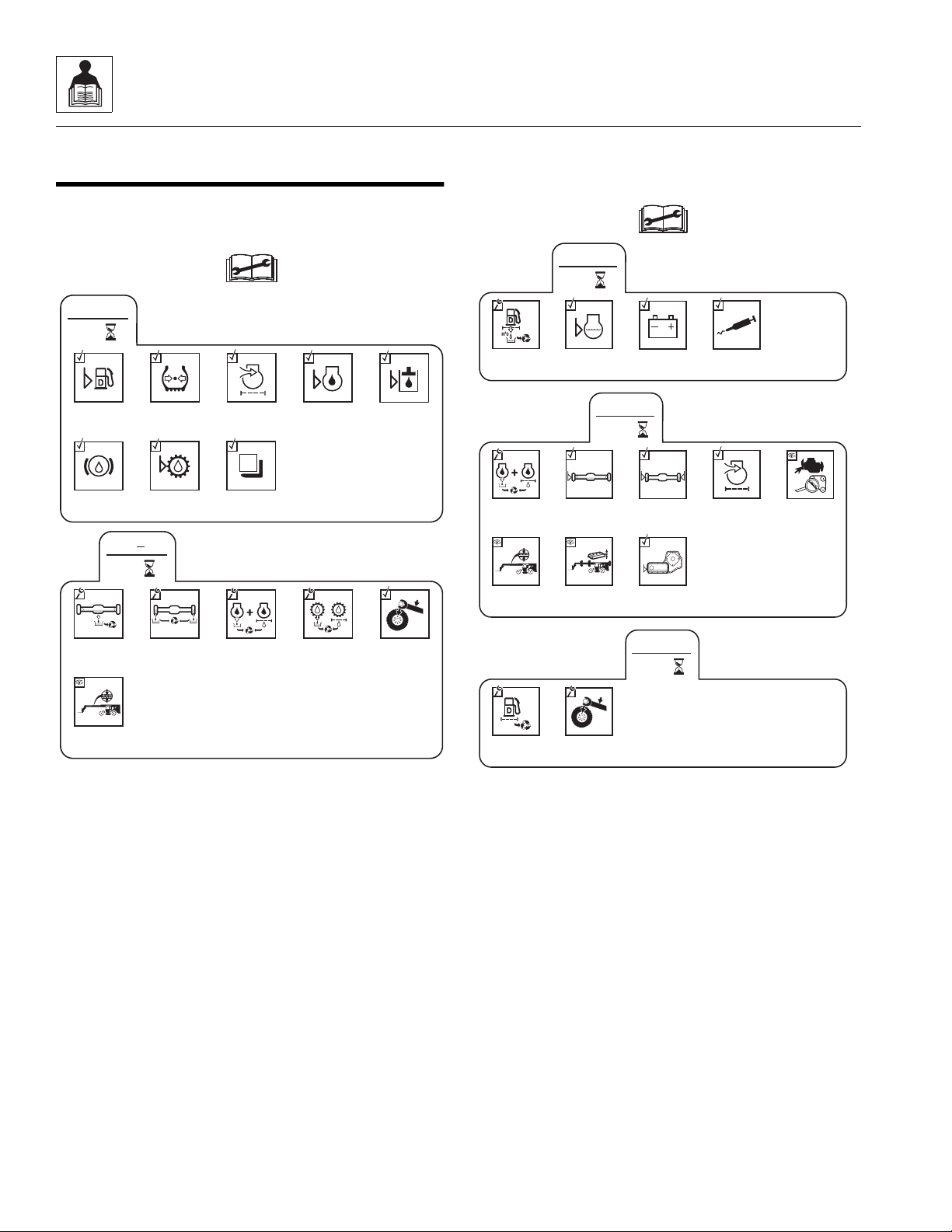

2.5 SERVICE AND MAINTENANCE SCHEDULES

2.5.1 8 & 1st 50 Hour Maintenance Schedule

2.5.2 50, 250 & 500 Hour Maintenance Schedule

2.10

4017

General Information and Specifications

OZO891

1500

EVERY

Change

Engine Coolant

Change

Hydraulic

Fluid & Filters

Change

Hydraulic Tank

Breather

Change

Brake Fluid

1000

EVERY

Change

Axle Oil

Change Wheel

End Oil

Change

Transmission

Oil & Filter

Change

Transfer Case

Oil

Check Boom

Chain

(4017 only)

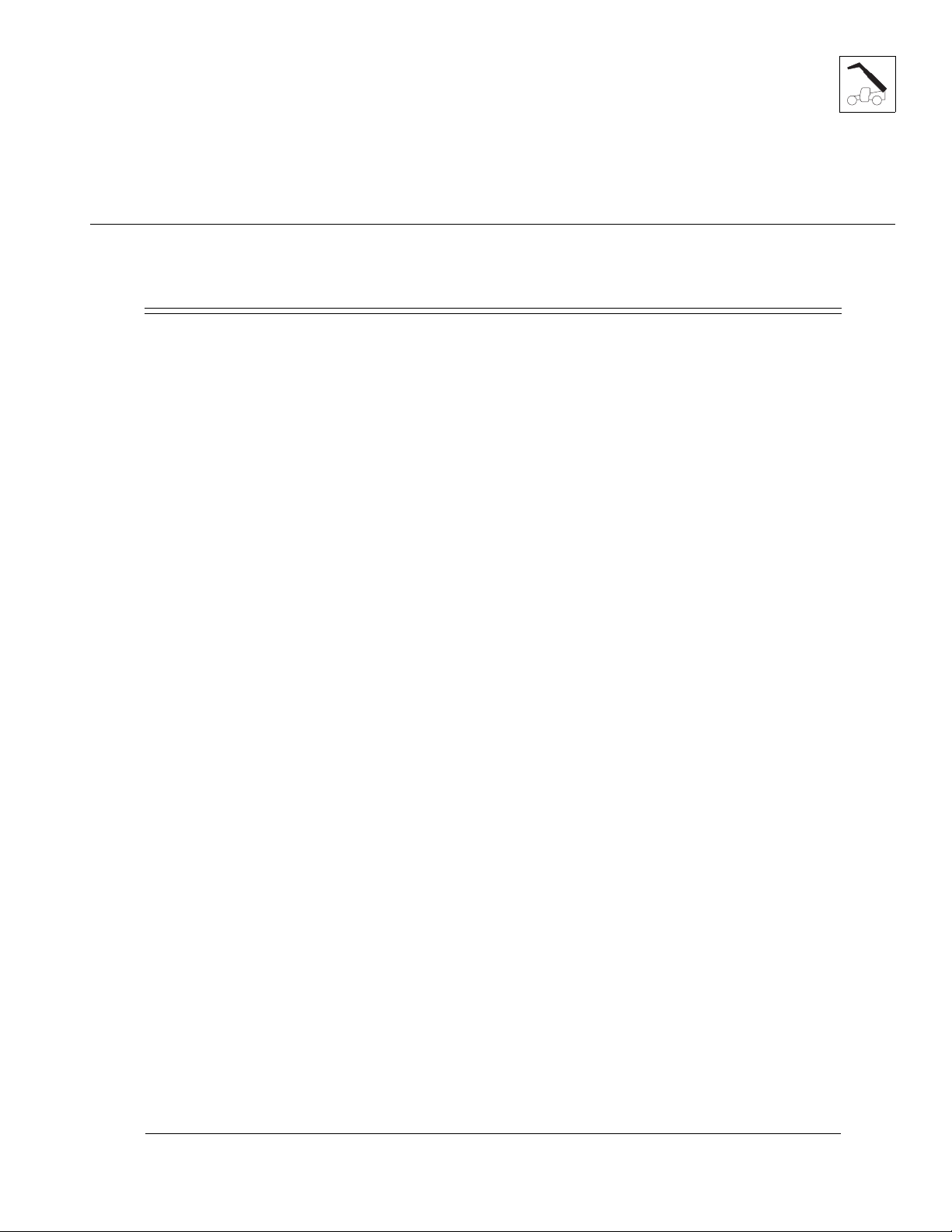

Mystik T e trimo ly

(NLGI 2 GC-LB)

Mystik Tetrimoly

(NLGI 2 GC-LB)

2.5.3 1000 & 1500 Hour Maintenance Schedule

2.6 LUBRICATION SCHEDULES

2.6.2 50 Hour Lube Schedule

2.6.1 8 Hour Lube Schedule

4017

2.11

General Information and Specifications

This Page Intentionally Left Blank

2.12

4017

Section 3

Boom

Contents

PARAGRAPH TITLE PAGE

3.1 Boom System Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

3.2 Boom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.2.1 Boom System Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.3 Boom Assembly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.3.1 Boom Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

3.3.2 Second, Third & Fourth Boom Section Removal . . . . . . . . . . . . . . . . . . . 3.4

3.3.3 Third & Fourth Boom Section Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6

3.3.4 Fourth Boom Section Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6

3.3.5 Hose Carrier Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.7

3.3.6 Hose Carrier Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.7

3.3.7 Fourth Boom Section Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.8

3.3.8 Third & Fourth Boom Section Installation . . . . . . . . . . . . . . . . . . . . . . . . . 3.9

3.3.9 Second, Third & Fourth Boom Section Installation . . . . . . . . . . . . . . . . . . 3.10

3.3.10 Boom Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.13

3.4 Boom Extend and Retract Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.14

3.4.1 Boom Chain Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.14

3.5 Boom Section Separation Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.17

3.6 Hose Carrier Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.18

3.6.1 Hose Carrier Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.18

3.6.2 Hose Carrier Assembly Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.19

3.7 Boom Wear Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.21

3.7.1 Wear Pad Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.21

3.7.2 Boom Wear Pad Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.21

3.7.3 Boom Wear Pad Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.23

3.8 Quick Switch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.23

3.8.1 Connecting with a Mechanical Quick Switch Device. . . . . . . . . . . . . . . . . 3.23

3.8.2 Connecting with a Hydraulic Quick Switch Device . . . . . . . . . . . . . . . . . . 3.23

3.8.3 Connecting with a Quick Switch to a Hydraulic Operated Attachment . . . 3.24

3.8.4 Quick Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.24

3.8.5 Quick Switch Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.24

3.9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25

4017

3.1

Boom

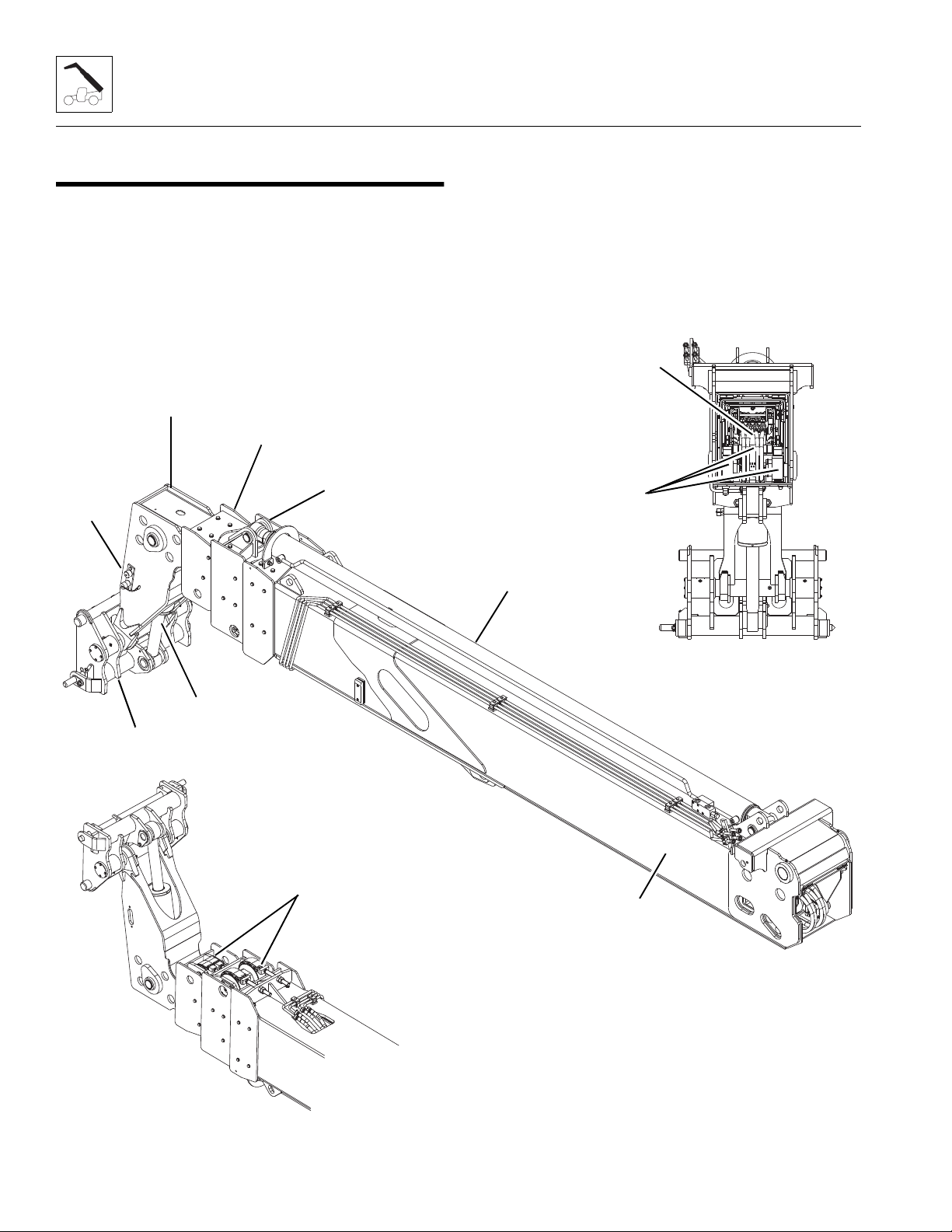

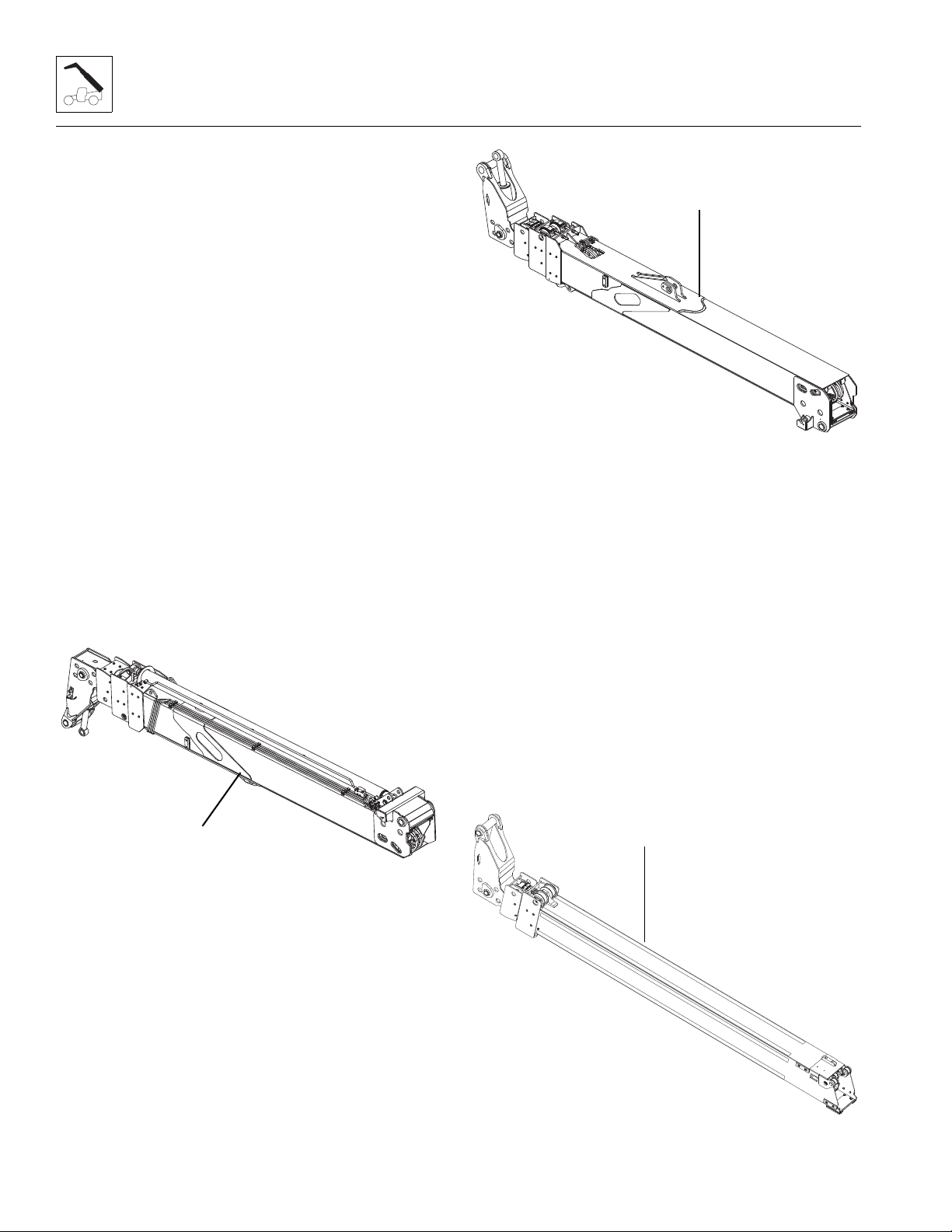

MZ0800

MZ0810

MZ0830

Extend/Retract

Cylinder

First Boom

Section

Auxiliary

Quick

Connects

Tilt Cylinder

Second Boom

Section

Third Boom

Section

Fourth Boom

Section

Hose Carrier

Extend Chains

(two pair)

Bottom View

Quick Switch Assembly

Rear View

Retract Chains

(three)

3.1 BOOM SYSTEM COMPONENT TERMINOLOGY

To understand the safety, operation and maintenance

information presented in this section, it is necessary that

the operator/mechanic be familiar with the name and

location of the major assemblies of the boom system. The

following illustration identifies the components that are

referred to throughout this section.

3.2

4017

Boom

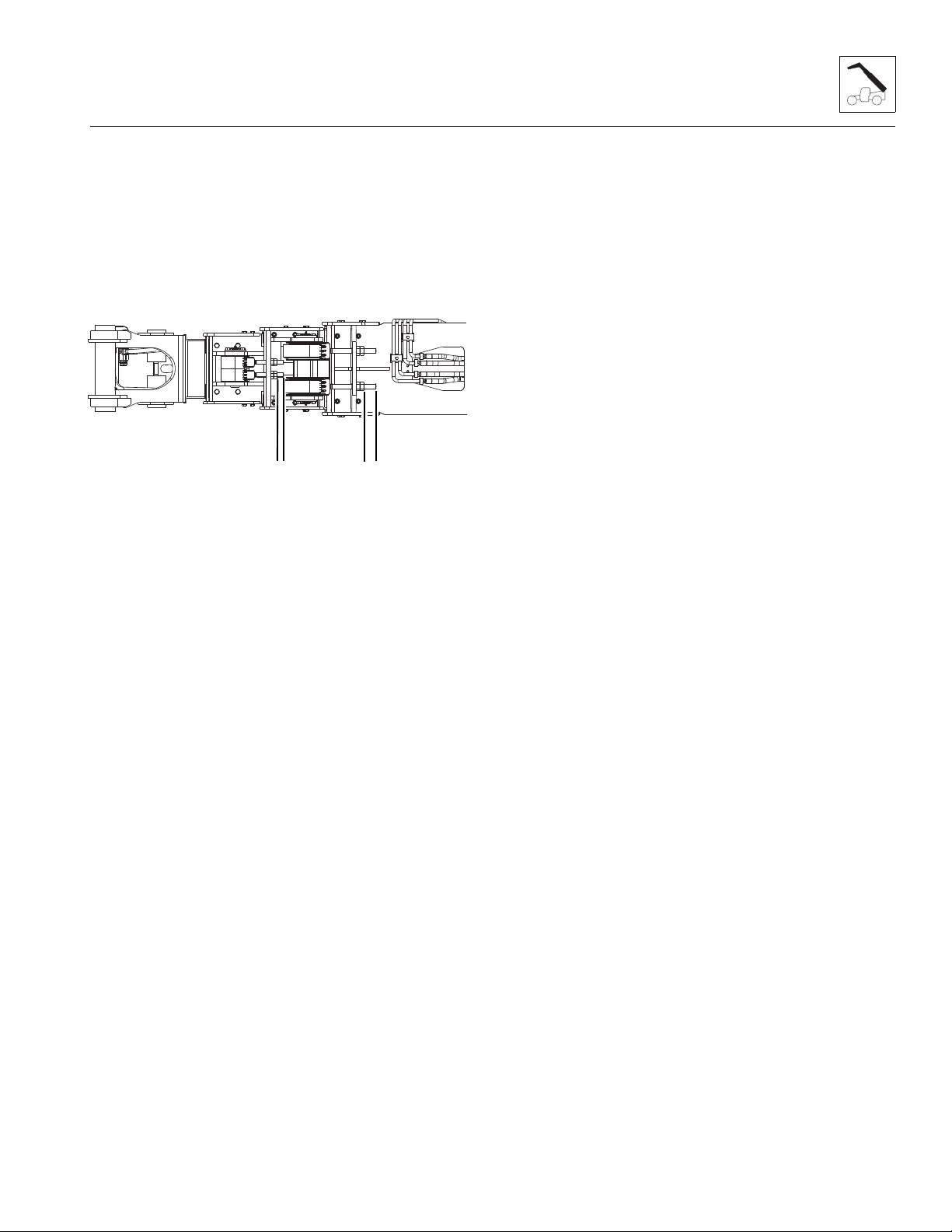

MZ0420

EXT/RET

LIFT

TILT

AUX

SWAY

L. O/R

R. O/R

FRONT OF

MACHINE

1

3.2 BOOM SYSTEM

3.2.1 Boom System Operation

The four section boom consists of the first, second, third

and fourth assemblies with double third and fourth

section extend chains, a double third section retract

chains and a single fourth section retract chain.

As the extend/retract cylinder, which is anchored at the

front of the second boom section, and the rear of the first

boom section begins to extend, it forces the second boom

section out of the first boom section.

The first, second, third and fourth boom sections are

connected by extend and retract chains. These chains

are routed around sheaves on the second and third boom

sections. As the second and third boom sections are

forced out, the extend chain pulls the fourth boom section

out of the third boom section.

As hydraulic pressure is applied to the retract port on the

extend/retract cylinder, the second boom section is pulled

back into the first boom section, and the retract chain

pulls the third and fourth boom sections back into the

second boom section.

This mechanical linkage formed by the chains and

supporting hardware, extends and retracts the third and

fourth boom sections at the same rate.

The first boom section does not extend or retract, but lifts

and lowers via action of the lift cylinder.

3.3.1 Boom Removal

1. Remove any attachment from the quick switch

assembly. (Refer to Section 3.8.1, “Connecting with

a Mechanical Quick Switch Device.”)

2. Set the quick attach assembly in a vertical position

and set on a hard level surface. Refer to Section

3.8.4, “Quick Switch Removal,” for disassembly

instructions.

3. Park the machine on a firm, level surface. Be sure

there is enough room in front of the machine to allow

the boom sections to be removed. Fully retract the

boom then raise the boom to access the rod end pin

of lift cylinder. Place the transmission control lever in

(N) NEUTRAL, engage the park brake and shut the

engine OFF.

4. Open the engine cover. Allow the system fluids to

cool.

5. Place an Accident Prevention Tag on both the

ignition key switch and the steering wheel, stating

that the machine should not be operated.

3.3 BOOM ASSEMBLY MAINTENANCE

The boom assembly consists of the first, second, third

and fourth boom sections and supporting hardware.

IMPORTANT: Before removing the boom, the carriage

or any other attachment must be removed from the quick

switch assembly.

These instructions must be completed in sequence. The

second, third and fourth boom sections are removed from

the first boom section.The third and fourth boom sections

are removed from the second boom section.The fourth

boom section is removed from the third boom section.

Before beginning, conduct a visual inspection of the

machine and work area, and review the task about to be

undertaken. Read, understa nd and follow thes e

instructions.

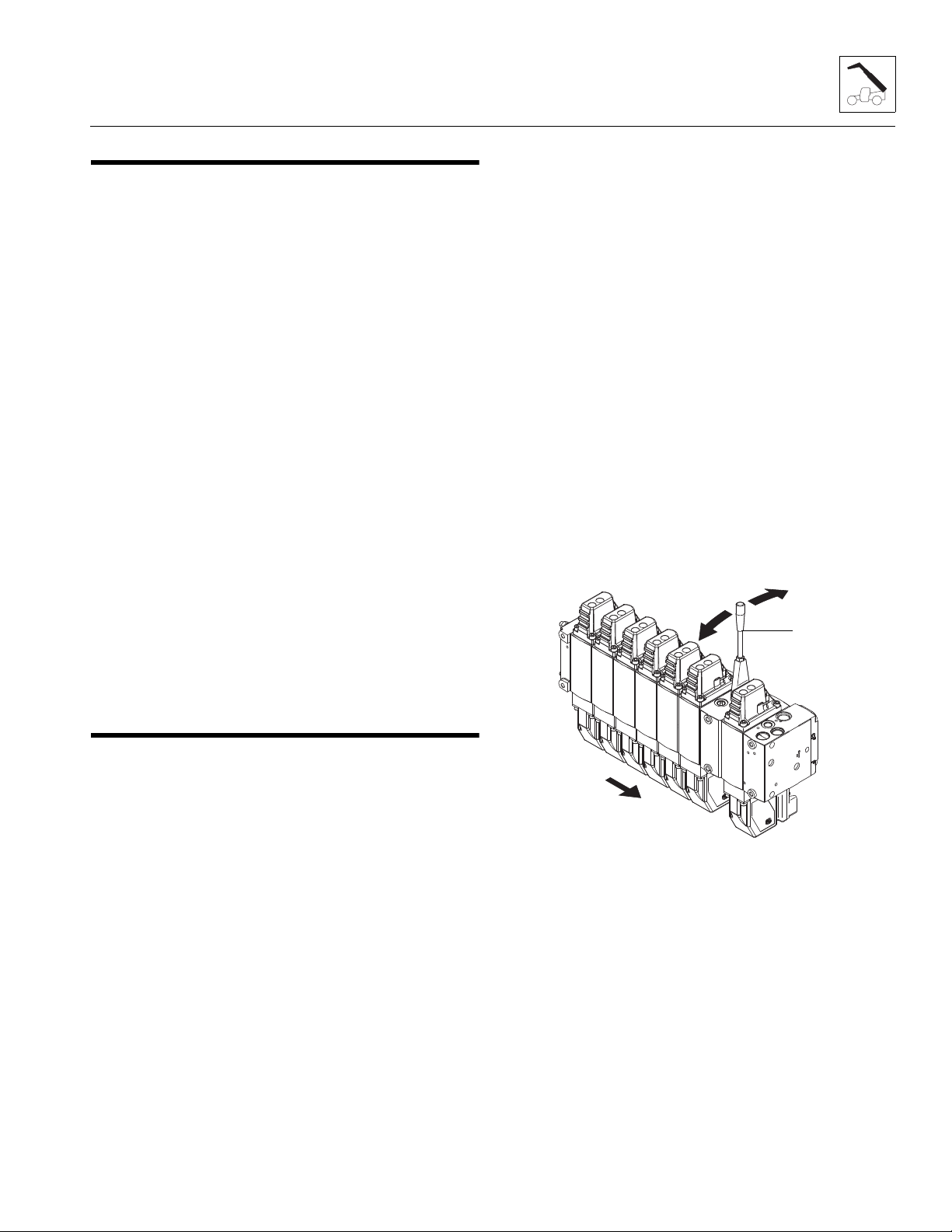

4017

6. Relieve any trapped pressure in the tilt hydraulic

system by installing the handle (1) (located in the

toolbox) or using an 9mm wrench and move the

double nut on the side of the actuator module on the

tilt valve section back and forth. Repeat on the

auxiliary valve section and on the extend/retract

valve section.

7. Disconnect, label and cap both hoses from the

extend/retract cylinder, tilt hoses and both auxiliary

hoses from tubes at left rear corner of first boom

section to prevent dirt and debris from entering

hydraulic system.

8. Remove the extend/retract cylinder support at the

top front of the first boom section.

3.3

Boom

MZ0820

1

(before being turned over)

MZ0740

2

(after being turned over)

MZ0750

3

9. Support the extend/retract cylinder and remove the

clip and pin from rod end of extend/retract cylinder.

Remove the clip and pin from barrel end of extend/

retract cylinder and remove the extend/retract

cylinder.

10. Disconnect the boom angle indicator rod from switch

at the inside left rear corner of the main boom

section and frame. Refer to Section 9.11.9, “Boom

Angle Sensor,” for adjustment information.

11. Support the front of the boom by placing a sling

behind the boom head. Support the lift/lower cylinder

and remove the lock bolt and then the rod end pin.

Lower the lift/lower cylinder onto the frame rails.

12. Remove the lock bolt and pin from compensation

cylinder on each side of first boom section. Remove

the lock bolt and pivot pin from rear of first boom

section.

13. Lower the boom to a level position and place a

suitable support under the boom head. Reposition

the slings to each end of the boom.

14. Lift the complete boom (1) off machine and set on

level ground or supports being careful not to damage

the tubes on the left side of boom.

3.3.2 Second, Third & Fourth Boom Sectio n Removal

1. Set the complete boom on level ground and by

repositioning the slings turn boom over on to the top

side. Set the complete boom (2) on suitable stands

to begin tear down.

Note: With the complete boom setting upside down, the

removal and replacing of each boom section, tilt cylinder,

hoses, extend and retract chains and hose carrier are

made much easier.

Note: In the following sections the individual boom

sections are removed as follows:

1. Remove second, third and fourth boom sections as

one unit from the first boom section.

2. Remove third and fourth boom sections as one unit

from the second boom section.

3. Remove fourth boom section from the third boom

section.

4. Remove hose carrier from fourth boom section.

2. At the boom head attach a sling through rod end of

tilt cylinder. Remove both hoses from tilt cylinder.

Plug the hose ends and cap the tilt cylinder fittings to

prevent dirt and debris from entering the hydraulic

system. Remove the clip from barrel end of tilt

cylinder pin. Remove the tilt cylinder pin and lift the

tilt cylinder out of the boomhead.

3.4

4017

Boom

MZ0790

1

1

3. Use a suitable sling around the third section boom to

take any pressure off of wear pads to make pad

removal easier.

Note: Before removing the extend chains, measure the

distance (1) between the face of the jam nut to the end of

the chain clevis on all four extend chains. This

measurement will be used when reassembling the

boom.

4. At the bottom front of the first section boom remove

the jam nuts and nuts and washers from the two

extend chain clevises. Remove clips and pins from

the two clevises and remove clevis from each chain.

5. At the bottom front of the second section boom

remove the jam nuts and nuts and washers from the

two extend chain clevises. Remove clips and pins

from the two clevises and remove clevis from each

chain.

6. At the rear of boom, loosen and unscrew both tilt

hoses and both auxiliary hoses from bulkhead on

hose carrier. Plug the hose ends and cap the

bulkhead fittings to prevent dirt and debris from

entering the hydraulic system.

7. Remove the clip and pin from both retract chain

clevises that are attached to the rear of the third

section boom. The pins can be removed through the

access holes at t h e b ot to m le f t an d right sides of t h e

first section boom. Do not remove the clev ises

8. Remove the clip and pin from the retract chain clevis

that is attached to the rear of the fourth boom

section. Do not remove the clevis.

9. Pull the second section boom out

152 mm to 203 mm (6 in to 8 in) to be able to loosen

and remove all the bolts and remove all the wear

pads, backing plates and shims from the front inside

of the first section boom. Tag each pad, backing

plate, shim and bolts from each location.

10. Pull the third boom section out 152 mm to 203 mm

(6 in to 8 in) to be able to access the wear pad bolts

on the rear of the second section boom. Remove the

top left and right side wear pads, backing plates and

shims (one on each side) from the second boom

section. Loosen the bottom rear wear pad bolts and

remove the shims from the second boom section to

gain the necessary clearance to be able to remove

the second boom section from the first boom

section. Tag each pad, backing plate, shim and bolts

from each location.

11. Using a sling around the front of the second boom

section, lift and slide the three boom sections 3/4 of

the way out of the first boom section. Set the boom

head down on a suitable support, then center the

sling to be able to balance the three boom sections

being removed. Carefully pull the three boom

sections (3) the remainder of the way out of the first

boom section and set the three boom sections down

on suitable supports.

12. Remove the clip and pin holding each retract chain

from the inside of the first boom section. Clean and

inspect chains. Replace if damaged.

13. Unscrew the tilt and auxiliary hoses from tubes at

bottom front of first boom section. Plug the tilt and

auxiliary hoses and cap the tubes to prevent dirt and

debris from entering hydraulic system. Clean and

inspect the hoses. Replace if damaged.

14. Inspect the boom and welds. Consult the local JLG

distributor or the JLG Service Department i f stru ctural

damage is detected.

15. Inspect hoses, hardware, wear pads, mounting

points, chains and other components visible with the

first boom section. Replace any item if damaged.

(Refer to Section 3.4.1, 3.4.1. “Boom Chain

Inspection,” and Section 3.7.1, 3.7.1. “Wear Pad

Inspection.”)

Note: It is recommended that if any chain or hose is

damaged that ALL chains or hoses are replaced.

4017

3.5

Boom

MZ0760

1

3.3.3 Third & Fourth Boom Section Removal

1. With the three boom sections setting on suitable

supports remove bolts, keeper and pin from both

sheaves on the bottom front of the second boom

section. Remove sheaves. Remove all the wear

pads, backing plates and shims from the front inside

of the second boom section. Tag each pad, backing

plate, shim and bolts from each location.

2. Remove the bolts, keeper and pin from center

sheave on the bottom rear of the third boom section.

Remove the sheave.

3. Remove the top left and right side rear wear pads,

backing plates and shims (one on each side) from

the third boom section. Loosen the bottom rear wear

pad bolts and remove the shims from the third boom

section to gain the necessary clearance to remove

the third boom section from the second boom

section. Tag each pad, backing plate, shim and bolts

from each location.

4. Place a sling around the front of the third boom

section. Lift and slid the two boom sections 3/4 of the

way out of the second boom section.Set the boom

head down on a suitable support, then center the

sling to be able to balance the two boom sections

being removed. Carefully pull the two boom sections

(1) the remainder of the way out of the second boom

section and set the two boom sections down on

suitable supports.

5. Remove the lock bolts, keeper and pin from both

sheaves at bottom rear of the second section boom.

Remove the sheave’s.

6. Remove the clip and pin holding retract chain from

bottom front of second boom section. Clean and

inspect chain. Replace if damaged.

7. Inspect the boom and welds. Consult the local JLG

distributor or the JLG Service Department if structural

damage is detected.

8. Inspect hoses, hardware, wear pads, mounting

points, chains and other components visible with the

first boom section. Replace any item if damaged.

(Refer to Section 3.4.1, 3.4.1. “Boom Chain

Inspection,” and Section 3.7.1, 3.7.1. “Wear Pad

Inspection.”)

Note: It is recommended that if any chain or hose is

damaged that ALL chains or hoses are replaced.

3.3.4 Fourth Boom Section Removal

1. With the two boom sections setting on suitable

supports remove the bolts, keeper and pin from

sheave on the front of the third boom section.

Remove the sheaves. Remove all the wear pads,

backing plates and shims from the front inside of the

third boom section. Tag each pad, backing plate,

shim and bolts from each location.

2. Remove the top left and right side rear wear pads,

backing plates and shims (one on each side) from

the fourth boom section. Loosen the bottom rear

wear pad bolts and remove the shims from the fourth

boom section to gain the necessary clearance to be

able to remove the fourth boom section from the

third boom section.Tag each pad, backing plate,

shim and bolts from each location.

3. Loosen and remove the two bolts holding the rear of

the catrack to the top of the third boom section. Lift

and push rear of hose carrier into the fourth boom

section.

4. Place a sling around the front of the fourth boom

section (2). Lift and slid the fourth boom section 3/4

of the way out of the third boom section. Set the

boom head down on a suitable support, then center

the sling to be able to balance the fourth boom

section being removed. Carefully pull the fourth

boom section the remainder of the way out of the

third boom section and set the fourth boom section

down on suitable supports.

5. Remove the clip and pin holding both extend chains

from bottom of third and fourth boom sections. Clean

and inspect chains. Replace if damaged.

3.6

4017

Loading...

Loading...