JLG 20VP Service Manual

Service and Maintenance Manual

ANSI

Model

10VP

15VP

20VP

3120728

June 14 2001

FOREWORD

The purpose of this manual is to provide users with the operating procedures essential for the promotion of

proper machine operation for its intended purpose. It is important to over-stress proper machine usage. All

information in this manual should be READ and UNDERSTOOD before any attempt is made to operate the

machine. YOUR OPERATING MANUAL IS YOUR MOST IMPORTANT TOOL - Keep it with the machine.

REMEMBER ANY EQUIPMENT IS ONLY AS SAFE AS THE OPERATOR.

BECAUSE THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND

OPERATION, PROPER SAFETY PRACTICES ARE THE RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

ALL INSTRUCTIONS IN THIS MANUAL ARE BASED ON THE USE OF THE MACHINE UNDER PROPER

OPERATING CONDITIONS, WITH NO DEVIATIONS FROM THE ORIGINAL DESIGN. ALTERATION AND/

OR MODIFICATION OF THE MACHINE IS STRICTLY FORBIDDEN, WITHOUT WRITTEN APPROVAL

FROM JLG INDUSTRIES, PER OSHA REGULATIONS.

THIS "SAFETY ALERT SYMBOL" IS USED TO CALL ATTENTION TO POTENTIAL HAZARDS

WHICH MAY LEAD TO SERIOUS INJURY OR DEATH IF IGNORED.

Safety of personnel and proper use of the machine are of primary concern, DANGER, WARNING, CAUTION,

IMPORTANT, INSTRUCTIONS and NOTE are inserted throughout this manual to emphasize these areas.

They are defined as follows:

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED WILL RESULT IN SERIOUS

INJURY OR DEATH.

CAUTION INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR

MODERATE INJURY. IT MAY ALSO BE USED TO ALERT

AGAINST UNSAFE PRACTICES.

Also in this Manual "Notes:" are used to provide information of special interest.

JLG INDUSTRIES, INC. MAY HAVE ISSUED SAFETY RELATED BULLETINS FOR YOUR JLG PRODUCT. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG DISTRIBUTOR FOR INFORMATION CONCERNING SAFETY RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR YOUR JLG PRODUCT. ALL ITEMS REQUIRED BY THE SAFETY RELATED

BULLETINS MUST BE COMPLETED ON THE AFFECTED JLG PRODUCT.

WARNING INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED COULD RESULT IN SERIOUS INJURY OR DEATH.

IMPORTANT OR INSTRUCTIONS PROCEDURES ESSENTIAL

FOR SAFE OPERATION AND WHICH, IF NOT FOLLOWED

MAY RESULT IN A MALFUNCTION OR DAMAGE TO THE

MACHINE.

Due to the continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes without

prior notification. Contact JLG Industries, Inc. for updated information.

This page left intentionally blank.

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A. GENERAL

This section contains the general safety precautions

which must be observed during maintenance of the aerial

platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves or others or

damage to the equipment. A maintenance program must

be established by a qualified person and must be followed

to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED IS A SAFETY VIOLATION.

The specific precautions to be observed during machine

maintenance are inserted at the appropriate point in the

manual. These precautions are, for the most part, those

that apply when servicing hydraulic and larger machine

component parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of component weight and never attempt to

move heavy parts without the aid of a mechanical device.

Do not allow heavy objects to rest in an unstable position.

When raising a portion of the equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA IS THE RESPONSIBILITY OF THE OWNER/

OPERATOR.

C. MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION COULD RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY VIOLATION.

• REMOVE ALL RINGS, WATCHES, AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL DANGER, WARNING, CAUTION AND OTHER INSTRUCTIONS ON MACHINE

AND IN SERVICE MANUAL.

• KEEP STANDING SURFACES AND HAND HOLDS

FREE OF OIL, GREASE, WATER, ETC.

• NEVER WORK UNDER AN ELEVATED PLATFORM

UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED

FROM ANY MOVEMENT BY BLOCKING OR OVERHEAD SLING.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

•BATTERY SHOULD ALWAYS BE DISCONNECTED

DURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

B. HYDRAULIC SYSTEM SAFETY

1. It should be particularly noted that the machines

hydraulic systems operate at extremely high and

potentially dangerous pressures. Every effort should

be made to relieve any system pressure prior to disconnecting or removing any portion of the system.

2. Relieve system pressure by activating the lift DOWN

control with the platform completely lowered to

direct any line pressure back into the return line to

the reservoir. Pressure feed lines to system components can then be disconnected with minimal fluid

loss.

3120728 – JLG Lift – a

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

This page intentionally left blank

b – JLG Lift – 3120728

EFFECTIVITY CHANGES

September 15, 1997 – Original Issue of Manual

January 10, 1998 – Change 1– Pages Affected: Revision Log - Page c

Table of Contents - Page ii

Section 3 - Pages 3-8 & 3-9

February 7, 2000 – Revised – Pages Affected: Section-1, Page 1-5, Table 1-5.

Section-2, Page 2-18, Table 2-3.

(removed lube check requirement for drive wheel gear box)

March 22, 2000– Revised – Added 20VP UL-EE Option.

September 8, 2000 – Revised Complete Manual

EFFECTIVITY PAGE

October 19, 2000 – Revised – Pages Affected:Section-2, Pages 2-20 thru 2-22 also 2-32 and 2-33.

Section-3, Page 3-16, added Table 3-3.

November 15, 2000 – Revised – Pages Affected:Section-1, Page 1-1

Section-2, Pages 2-33 & 2-34.

June 14, 2001 – Revised – Pages Affected:Section-2, Pages 2-23 thru 2-25

3120728 – JLG Lift – c

EFFECTIVITY PAGE

This page intentionally left blank

d – JLG Lift – 3120728

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION INTRODUCTION - - MAINTENANCE SAFETY PRECAUTIONS

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a

B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a

Effectivity Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c

SECTION 1 - SPECIFICATIONS

1.1 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Component Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.5 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6 Hydraulic Pressure Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.8 Serial Number Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

SECTION 2 - SERVICE PROCEDURES

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Servicing And Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Lubrication Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.4 Positioning Lift For Access To Components Located Under The Base Frame . . . . . . . . . . . . . . .2-4

2.5 Drive Motor Component Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.6 Platform Control Box Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.7 Battery Charger Assembly And Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.8 Hydraulic Lift Cylinder - Removal, Inspection And Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.9 Mast Assembly And Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2.10 Mast To Base Frame Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

2.11 Mast Chains/cables And Sequencing Cables Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

2.12 Sequence Cable Replacement Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

2.13 Preventive Maintenance And Inspection Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

SECTION 3 - TROUBLESHOOTING

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Troubleshooting Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Hydraulic Circuit Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.4 Electrical Circuit Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.5 Troubleshooting Section - Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3.6 Ohm Ratings For Various Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.7 Main Power Circuit Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.8 Drive Train Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.9 Mast Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

3.10 Hydraulic Leak Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

3.11 Base Frame Components Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

3120728 – JLG Lift – i

TABLE OF CONTENTS

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. Hydraulic Pressure Setting - Adjustment Screw Located at Base of Pump Motor . . . . . . . . . . . .1-3

1-2. Hydraulic Pressure Gauge Installation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

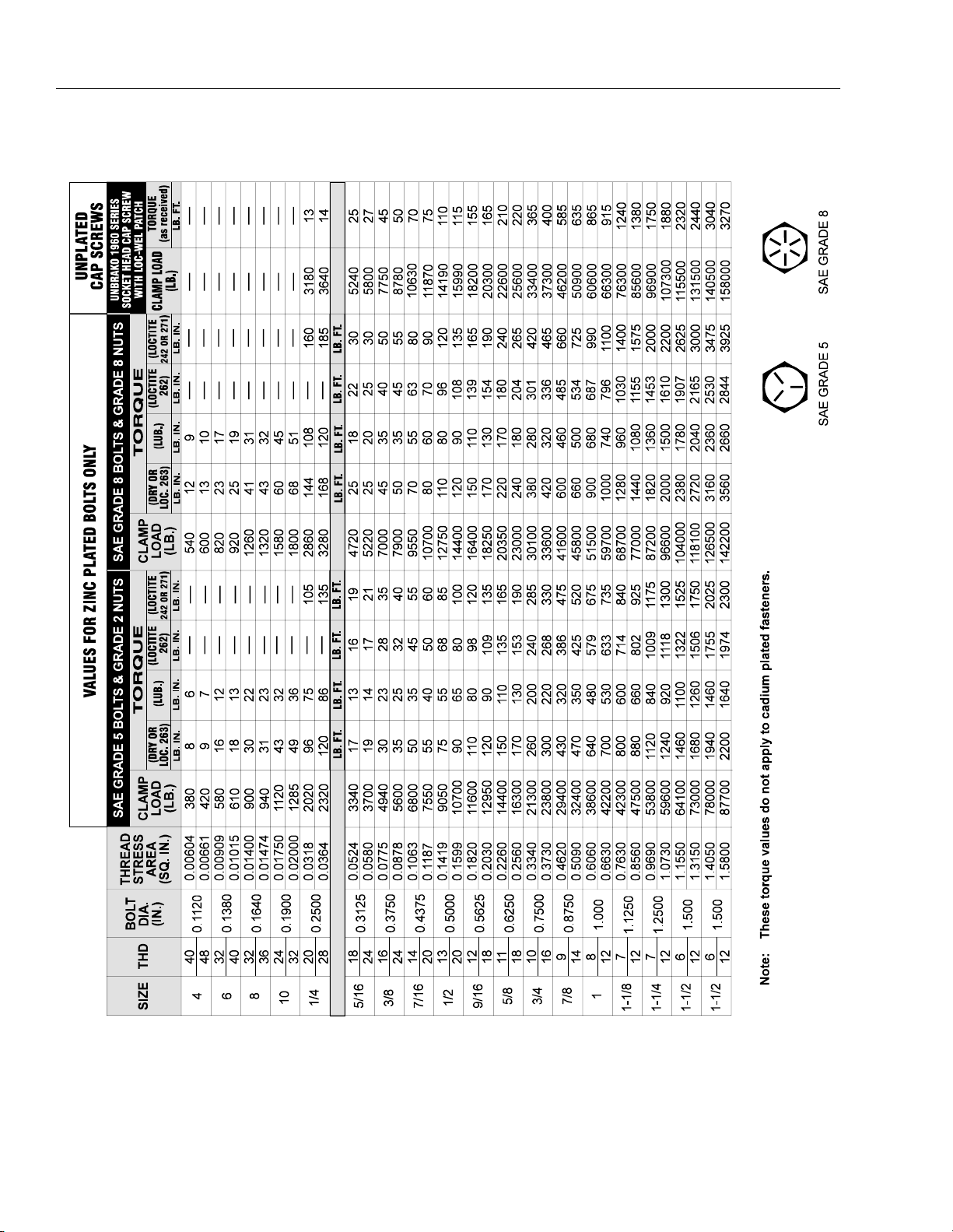

1-3. Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-4. Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

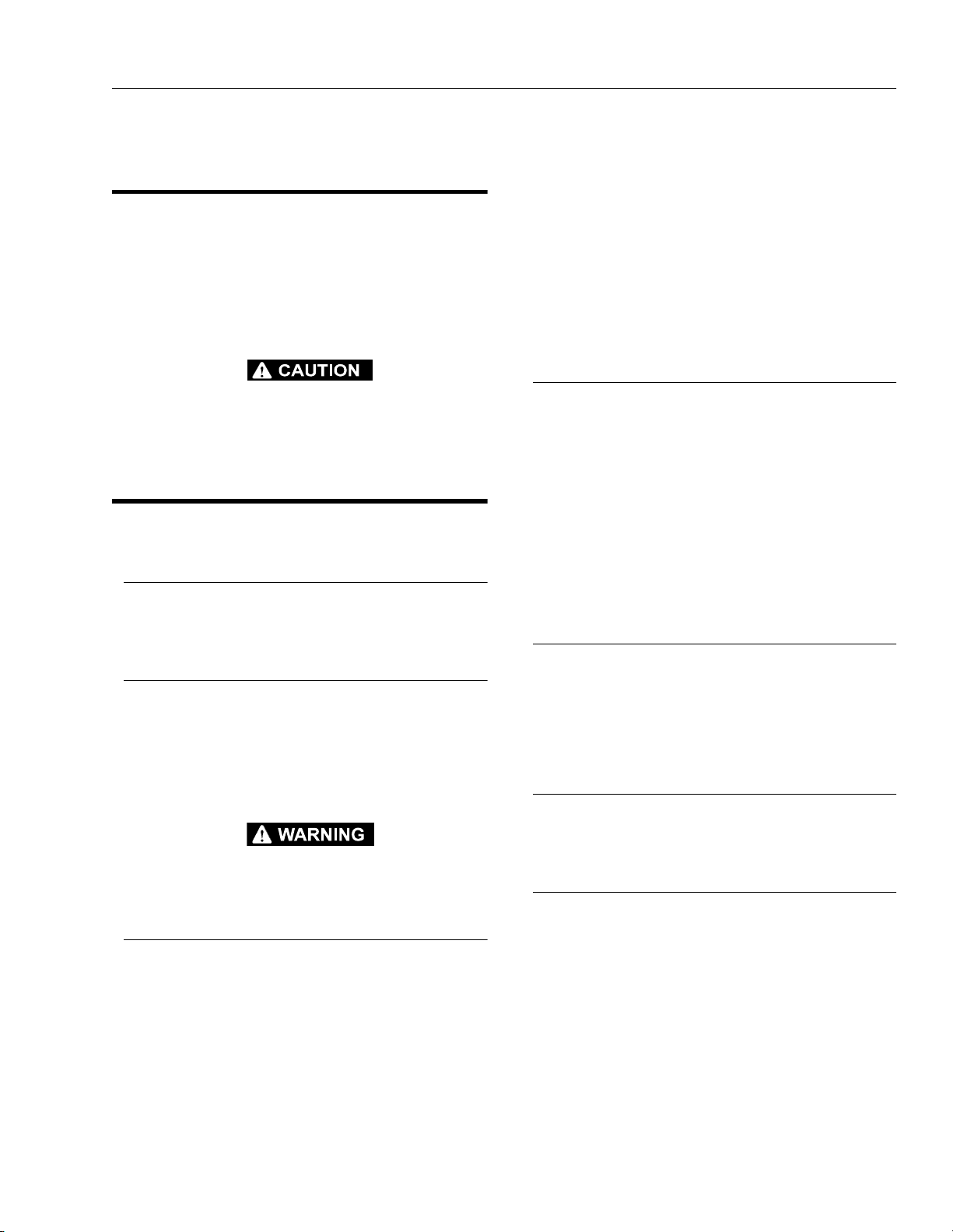

2-1. Accessing Machine Underside Components by Lifting with a Fork Truck. . . . . . . . . . . . . . . . . . .2-4

2-2. Check Torque Limit Clutch - Torque Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-3. Torque Limit Clutch - Adjustment Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-4. Brake Assembly Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-5. Brake Armature Plate & Brake Disk Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-6. Manual Release Brake Cable Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-7. Drive Motor Assembly Removal.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-8. Drive Motor Gear Box Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-9. Gear/Pinion Shaft Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-10. Drive Shaft Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-11. Drive Motor Brush Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-12. Drive Motor Brush Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-13. Correct/Incorrect Brush Spring Bracket Positions.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2-14. Platform Control Box Assembly (Exploded View). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2-15. Platform Control - Circuit Board Component Wiring Connections. . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2-16. Machine Positioned for Cylinder Removal.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2-17. Lift Cylinder Internal Component Assembly Cross-Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

2-18. Mast Section - Assembly Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2-19. 10VP Mast Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2-20. 15VP Mast Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2-21. 20VP Mast Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2-22. Mast Chain/Cable/Sequence Cable Adjustment Components. . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

3-1. LED Battery/Fault Code Indicator Strip on Platform Controller Box. . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2. Overview of Standard Electrical System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3-3. VP Electrical Diagram. (VP Series - Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-4. Overview of VP UL-EE Approved Optional Electrical System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-5. VP Electrical Diagram. (with UL-EE Approved Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3-6. Hydraulic Diagram. (VP Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1. Machine GVW and Wheel Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-2. Hydraulic Oil Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3. Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-4 Machine Interlock Switch Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-5. Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-6 Lubrication Intervals for Various Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2-1 Chain Stretch Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 VP Series Mast Component Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2-3 Preventive Maintenance & Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

3-1 MC-1 WARNING CODES (Indicated by 3 beeps, then slow flashing LED’s). . . . . . . . . . . . . . . . .3-3

3-2 MC-1 ERROR CODES (Indicated by rapid LED flashing and periodic beep) . . . . . . . . . . . . . . . . 3-4

3-3 Ohm Ratings for Various Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3-4 Unit will not Power Up From Ground Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-5 No Power At Platform Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3-6 Won’t Drive. (Platform Lowered or Elevated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3-7 Elevation Switch Circuit Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3-8 Brake Limit Switch Circuit Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

ii – JLG Lift – 3120728

TABLE OF CONTENTS

3-9 Drive Motor/Circuit Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3-10 Brake Switch/Circuit Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3-11 Won’t Drive with Platform Elevated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-12 Tilt Sensor Circuit Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-13 PHP Limit Switch Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3-14 Won’t Climb Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3-15 Drives In Opposite Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3-16 Only Drives A Short Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3-17 E-Stop and Key Switch Circuit Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3-18 Won’t Drive Straight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3-19 Noise from Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

3-20 Platform Will Not Lift Up Using Platform Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

3-21 Pump Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

3-22 Pump Valves Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3-23 Platform Will Not Lower Using Platform Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

3-24 Unit Will Not Lift Up From Ground Control Toggle Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

3-25 Unit Will Not Lower From Ground Control Toggle Switch.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

3-26 Platform Will Not Lower Manually. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

3-27 Platform Lift Up and Down Jerky. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

3-28 Mast Noisy when Lifting and Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

3-29 Platform (Mast) Won’t Stay Elevated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

3-30 Platform (Mast) Descends Too Slowly.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3-31 Hydraulic Leak Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

3-32 Caster Wheels Not Operating Freely. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

3-33 Pot Hole Protection (PHP) Bars Will Not Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

3120728 – JLG Lift – iii

TABLE OF CONTENTS

This page intentionally left blank

iv – JLG Lift – 3120728

SECTION 1. SPECIFICATIONS

SECTION 1 - SPECIFICATIONS

1.1 CAPACITIES

System Voltage

All VP Models –24 Volt DC (2 - 12 volt DC batteries)

Hydraulic Oil Reservoir

All VP Models – 5 qts. U.S. (4.7 ltr.)

1.2 COMPONENT DATA

Hydraulic Pump/Pump Motor Assembly

Pump Motor - 24 Volt DC motor

Pump Displacement –

10 & 15VP – .098 cu. in./rev. (1.6cc/rev.)

20VP – .049 cu. in./rev. (0.8cc/rev )

Pump Output (Max.) –

10 & 15VP - 1.20 gpm @ 2200 psi

20VP – 0.65 gpm @ 2200 psi

Hydraulic System Pressure Setting –

10 & 15VP - 1000 psi (68.95 bar)

20VP - 2500 psi (172.3 bar)

Rear Wheel Drive Motors

DriveMotors -

24 Volt DC w/perm. magnet

Right angle gear

Maintenance free sealed gear

Brake shaft and drive shaft,Integral to Motor

Parking Brake (must be released for pushing)

Batteries/Battery Charger

Batteries (2) – 12 Volt / 80 Amp Hour –

Deep CycleMarine - RV

Battery Charger –

U.S.A./CAN. –120 Volt A.C. / 60 Hz input

Brazil - 220 Volt A.C./ 60 Hz input

24 volt, 10 amp output -

with 2 amp finish

Reset Circuit Breaker

Automatic Charge Circuit

Plug Interlock Circuit

1.3 PERFORMANCE DATA

Platform Capacity(All Platforms except

Extendible)

10VP –350 lbs. (160 kg)

15VP –350 lbs. (160 kg)

20VP –350 lbs. (160 kg)

Extendible Platform Capacity

ANSI (U.S.) – 300 lbs. (136 kg)

CSA (CAN.) – 250 lbs. (114 kg)

Platform Size

Standard Platform – 26 in. x 26 in.

(66cm) x (66cm)

Machine Height (In Stowed Position)

VP Series - 79 in. (201cm) height

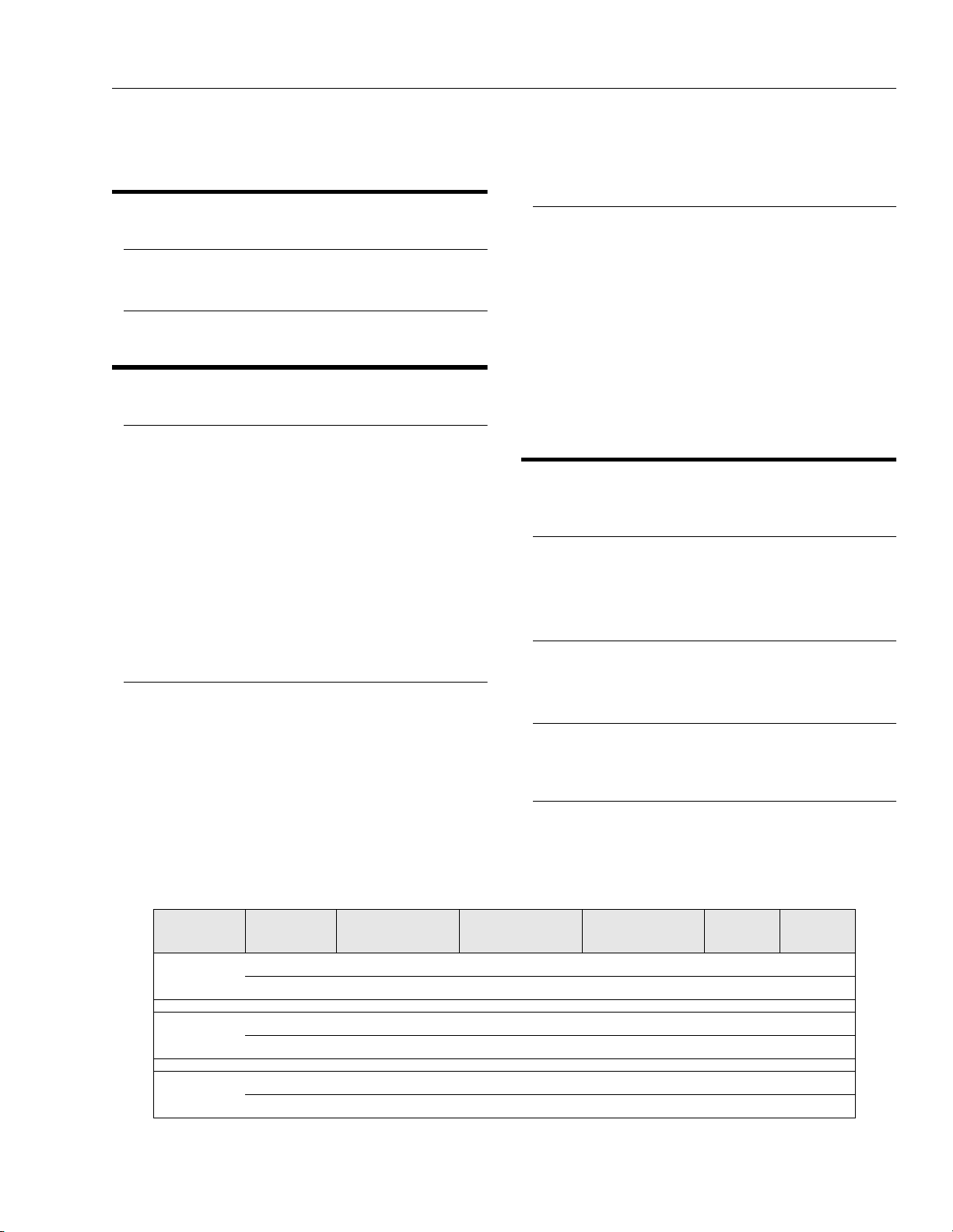

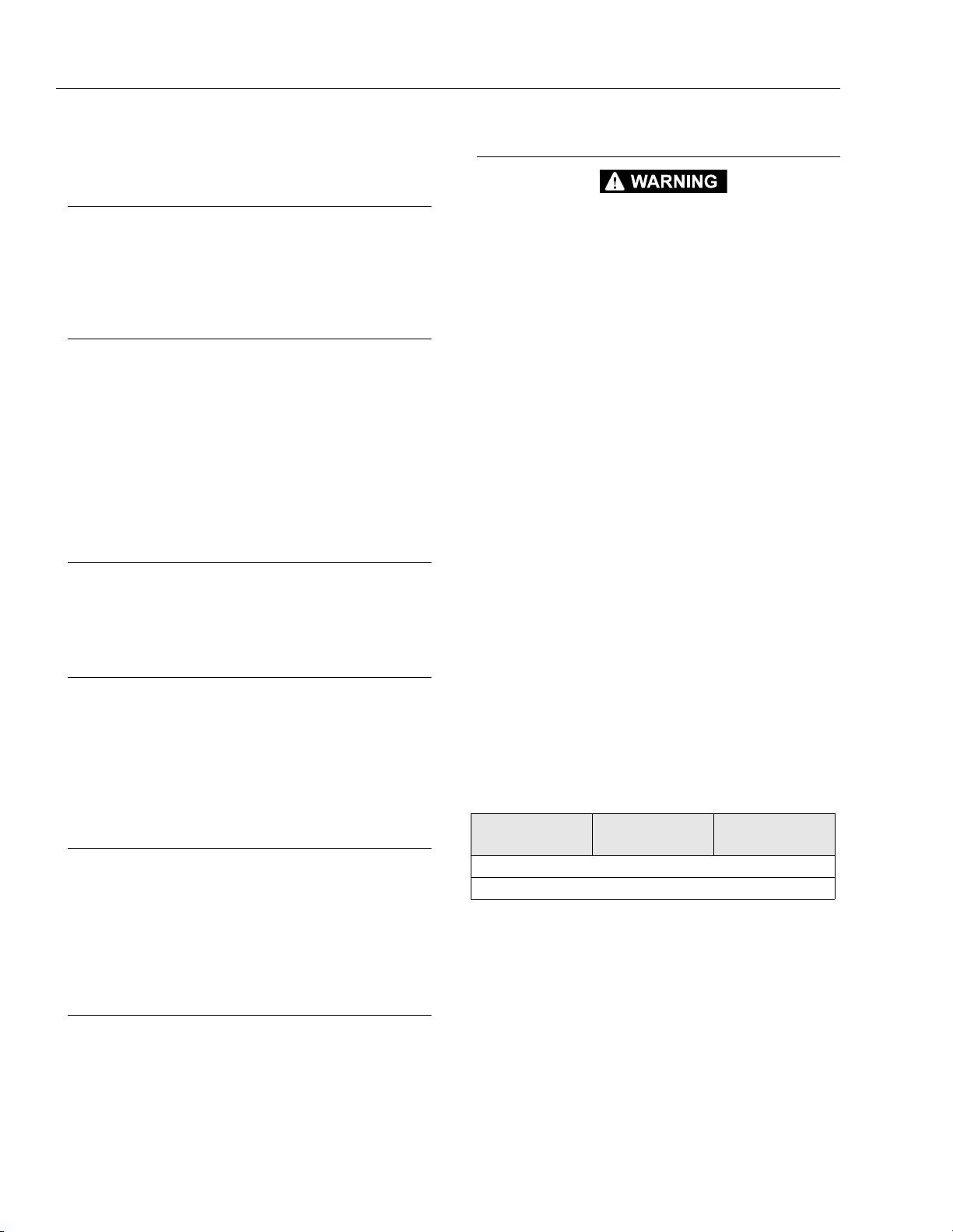

Tab le 1 - 1 .

Machine GVW and Wheel Loads

VP MODEL CONFIG. GVW (no load)

10VP ANSI (U.S.) 930 lb. (422 kg) 424 lb. 216 lb. 76 psi 102 psi

CSA (CAN.) 930 lb. (422 kg) 424 lb. 216 lb. 76 psi 102 psi

15VP ANSI (U.S.) 1,355 lb. (615 kg) 604 lb. 249 lb. 108 psi 117 psi

CSA (CAN.) 1,425 lb. (647 kg) 630 lb. 257 lb. 113 psi 121 psi

20VP ANSI (U.S.) 1,910 l b. (867 kg) 750 lb. 400 lb. 134 psi 188 psi

CSA (CAN.) 2,100 lb. (953 kg) 774 lb. 470 lb. 140 psi 220 psi

DRIVE WHEEL

(ea) w/rated load

CASTER

(ea) w/rated load

PSI

(Drive)

PSI

(Caster)

3120728 – JLG Lift – 1-1

SECTION 1 - SPECIFICATIONS

Base Footprint

VP Series - 32 in. (81cm) width 56 in. (1.42m) length

Max. Platform Height (mast extended)

10VP – 10 ft. 6 in.(3.2m)

15VP – 15 ft.(4.5m)

20VP – 19 ft. 9 in.(5.9m)

Platform Working Height (average)

10VP –16 ft. 6 in.(4.8m)

15VP –21 ft.(6.4m)

20VP –25 ft. 9 in.(7.6m)

Machine Drive Speed (max.)*

Platform Lowered - 2 mph (3.22 kph)

Platform Elevated - 0.5 mph (.81 kph)

(reduced by limit switch)

* Variable to maximum with speed cut back.

Amperage Draw (average)

Lift - 12 amps.Drive - 20 amps.

Interlock Switch Operating Conditions

Table 1-4. shown, lists machine response to various interlock switch positions.

1.5 LUBRICATION

Hydraulic Oil

Hydraulic oils must have anti-wear qualities at least to API

Service Classification GL-3, and sufficient chemical stability for mobile hydraulic system service. JLG Industries,

recommends Mobilfluid 424 hydraulic oil, which has an

SAE viscosity of 10W-30 and a viscosity index of 152.

For cold weather applications, i.e. when temperatures

remain consistently below +20°F (–7°C) JLG recommends using Mobil DTE 13 hydraulic oil.

Aside from JLG recommendations, it is not advisable to

mix oils of different brands or types, as they may not contain the same required additives or be of comparable viscosities. If use of hydraulic oil other than Mobilfluid 424 is

desired, contact JLG Industries for proper recommendations.

Table 1-2. Hydraulic Oil Operating Range

HYDRAULIC SYSTEM OPERATING

TEMPERATURE RANGE

0 ° F t o +2 3 ° F

(-18° C to -5° C)

0° F to +210° F

( -1 8 ° C t o +9 9 ° C )

50° F to 210° F

(+10° C to +210° C)

SAE VISCOSITY

GRADE

10W

10W-20, 10W-30

20W-20

Lubrication Specifications

1.4 TORQUE REQUIREMENTS

When maintenance becomes necessary or a fastener has

loosened, refer to the Torque Chart, Figure 1-3., Torque

Chart. to determine proper torque value.

Table 1-4. Machine Interlock Switch Operating Conditions.

Mast Elevation

mast retracted bars raised (not tilted) engaged Full Dr ive and Lift

mast retracted bars raised (not tilted) disengaged Drive and Lift Disabled

mast extended bars lowered (not tilted) engaged Drive 25% maximum

mast extended bars raised (blocked) (not tilted) engaged Drive Disable d

mast extended bars lowered (tilt) engaged Drive and Lift disabled

mast retracted bars raised (tilt) engaged Lift Disabled

mast retracted

Drive Cutout

(PHP System)

bars raised/battery charger

plugged-in

Tilt Status Brake Status Controller Response

(not tilted) engaged Drive Disable d

Table 1-3. Lubrication Specifications

KEY SPECIFICATIONS

Multipurpose Grease having a minimum dripping point

MPG -

EPGL -

HO - Hydraulic Oil. ISO-Vg grade 32, 46.

of 350° F. Excellen t water resistance and adhe sive qualities, and being of extreme pressure type. (Timken OK

40 poun ds minimum.)

Extreme Pressure Gear Lube (oil) meeting API service

classification GL-5 or MIL-Spec MIL-L-2105.

1-2 – JLG Lift – 3120728

1.6 HYDRAULIC PRESSURE ADJUSTMENT

RETURN

SECTION 1 - SPECIFICATIONS

Adjust system pressure so that platform will raise with

rated capacity in platform.

The following are recommended factory pressure settings;

VP10,VP15 –1000 psi

VP20 – 2500 psi

Turning adjustment screw clockwise increases system

pressure, turning screw counterclockwise decreases

system pressure.

Make pressure adjustment with oil at normal operating

temperature. If pressure is set when oil is cold, platform

may not raise rated load after oil has warmed.

PRESSURE

ADJUSTMENT

SCREW

ADJUSTMENT

SCREW CAP

LINE

REPLACE ELBOW

WITH A T-FITTING

TO CONNECT

PRESSURE GAUGE

HERE

EXTEND

LINE

PRESSURE

GAUGE

Figure 1-2. Hydraulic Pressure Gauge Installation.

1.7 CYLINDER SPECIFICATIONS

NOTE: All dimensions are given in inches (in), with the met-

ric equivalent, centimeters (cm), given in parentheses.

Table 1-5. Cylinder Specifications

Figure 1-1. Hydraulic Pressure Setting - Adjustment

Screw Located at Base of Pump Motor

(Remove Hex Head Cap as Shown)

ONLY OPEN HYDRAULIC SYSTEM LINES WITH THE MAST LOW-

DESCRIPTION

Lift Cylinder 10VP

Lift Cylinder 15VP

Lift Cylinder 20VP

BORE

in./(cm)

1.50

(3.81)

1.50

(3.81)

1.50

(3.81)

STROKE

in./(cm)

54.50

(138.43)

54.50

(138.43)

54.50

(138.43)

ROD DIA.

in./(cm)

1.125

(2.86)

1.125

(2.86)

1.125

(2.86)

ERED TO RELIEVE PRESSURE IN THE SYSTEM. CAREFULLY

LOOSEN REQUIRED FITTINGS, WEAR SAFETY PROTECTION

EQUIPMENT WHEN WORKING WITH HYDRAULIC SYSTEMS.

Connect pressure gauge as shown in Figure 1-2., Hydraulic Pressure Gauge Installation.

1.8 SERIAL NUMBER LOCATION

For machine identification, a serial number plate is affixed

to the machine. The plate is located on the back of the

mast, just above the mast support bracket.

Select a T-Fitting to exactly match the thread size of the

pump (.562 x 18 THD), pressure line (.562 x 18 THD) and

gauge fitting as required.

3120728 – JLG Lift – 1-3

SECTION 1 - SPECIFICATIONS

Figure 1-3. Torque Chart.

1-4 – JLG Lift – 3120728

SECTION 1 - SPECIFICATIONS

6

1

2

3

Figure 1-4. Lubrication Chart.

Table 1-6.Lubrication Intervals for Various Components

ITEM COMPONTENT

1Hydraulic Oil

Drive Wheel

2

Bearings

Drive Wheel

3

Gear Box

4 Caster Axle s 2 - Grease Fitt ing MPG - Pressure Gun

5 Swivel Raceways 2 - Front Casters MPG - Pressure Gun

6 Mast Chains * 2 - Per Section

* Ap p li e s On l y t o Ma s t Se c ti o ns w i th C ha i ns .

Key to Lubricants: MPG - Multipurpose Grease

NO/TYPE

LUBE POINTS

F il l To Li n e o n

Reservoir

5 Qt. Reservoir

4 - Grease Fittings MPG- Pressure Gun

2 - Gear Box Gear Oil

HO - Hydra ulic Oil - See Sectio n 1.5, "Lubrication" in Service Manua l.

GEAR OIL - Good Quality Worm Gear Oil - SAE 90 - AGMA#5 - EP Compounded

LUBE/METHOD

HO - Check Hyd. Oil

L e ve l

HO - Change Hyd. Oil

Chain Lube - Brush or

Spray

3

MONTHS

150 Hrs.

✔

✔

✔

✔

4, 5

INTERVAL HOURS

6

MONTHS

300 Hrs.

1

YEAR

600 Hrs.

2

YEARS

1200 Hrs.

✔

COMMENTS

Check Hydraulic Oil every 10 hrs.

Change Hydr aulic Oil every 1 200

hrs.

Change only when serviced

requires 6 oz. (175 cc ’s) to fill.

Inspect, lubricate if dry or rusting.

Notes: 1. Be certain t o lubricate like items on each side of the machine.

2. Recommended lubricating intervals are based on nor mal use. If machine is subjected to severe operating conditions,

such as a high number of cycles, location, corrosive/dir ty environment, etc., user must adjust lubricating requirements accordingly.

3. Prior to checking hydraulic oil level, operate machine through one complete cycle of lift function (full up and down). Failure t o do s o wi l l

result in incorrect oil level reading on the hydraulic reservoir.

3120728 – JLG Lift – 1-5

SECTION 1 - SPECIFICATIONS

This page intentionally left blank

1-6 – JLG Lift – 3120728

SECTION 2 - SERVICE PROCEDURES

SECTION 2. SERVICE PROCEDURES

2.1 GENERAL

This section provides general information to assist in the

performance of maintenance on the personnel lift.

Descriptions, techniques and specific procedures are

designed to provide the safest and most efficient maintenance for use by personnel responsible for ensuring the

correct installation and operation of machine components

and systems.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

2.2 SERVICING AND MAINTENANCE

GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this chapter.

selves. As soon as a line or component is disconnected,

cap or cover all openings to prevent entry of foreign matter.

Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings are

unobstructed. Cover all parts to keep them clean. Be sure

all parts are clean before they are installed. New parts

should remain in their containers until they are ready to be

used.

Components Removal and Installation

Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as near

perpendicular as possible to top of part being lifted.

Should it be necessary to remove a component on an

angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between the supporting

structure and the component becomes less than 90

degrees.

If a part resists removal, check to see whether all nuts,

bolts, cables, brackets, wiring, etc., have been removed

and that no adjacent parts are interfering.

Component Disassembly and Reassembly

Safety and Workmanship

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of component weight. Never attempt to

move heavy parts without the aid of a mechanical device.

Do not allow heavy objects to rest in an unstable position.

When raising a portion of the equipment, ensure that adequate support is provided.

NEVER WORK UNDER AN ELEVATED PLATFORM UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED FROM ANY MOVEMENT

BY BLOCKING OR OVERHEAD SLING.

Cleanliness

The most important single item in preserving the long service life of a machine is to keep dirt and foreign materials

out of the vital components. Precautions have been taken

to safeguard against this. Shields, covers, seals, and filters are provided to keep the wheel bearings, mast sections and oil supply clean; however, these items must be

maintained on a scheduled basis in order to function

properly.

At any time when oil lines are disconnected, clear adjacent areas as well as the openings and fittings them-

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts

When assembling pressure-fit parts, use an “anti-seize” or

molybdenum disulfide base compound to lubricate the

mating surface.

Bearings

When a bearing is removed, cover it to keep out dirt and

abrasives. Clean bearings in nonflammable cleaning solvent and allow to drip dry. Compressed air can be used

but do not spin the bearing.

Discard bearings if the races and balls (or rollers) are pitted, scored, or burned.

If bearing is found to be serviceable, apply a light coat of

oil and wrap it in clean (waxed) paper. Do not unwrap

reusable or new bearings until they are ready to install.

Lubricate new or used serviceable bearings before installation. When pressing a bearing into a retainer or bore,

3120728 – JLG Lift – 2-1

SECTION 2 - SERVICE PROCEDURES

apply pressure to the outer race. If the bearing is to be

installed on a shaft, apply pressure to the inner race.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

Use bolts of proper length. A bolt which is too long will

bottom before the head is tight against its related part. If a

bolt is too short, there will not be enough thread area to

engage and hold the part properly. When replacing bolts,

use only those having the same specifications of the original, or one which is equivalent.

Unless specific torque requirements are given within the

text, standard torque values should be used on heattreated bolts, studs, and steel nuts, in accordance with

recommended shop practices. (See Figure 1-1.)

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System

Keep the system clean. If evidence of metal or rubber particles is found in the hydraulic system, drain and flush the

entire system.

Disassemble and reassemble parts on clean work surface. Clean all metal parts with non-flammable cleaning

solvent. Lubricate components, as required, to aid assembly.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in the Lubrication Chart, (See Figure

1-2.). Service applicable components with the amount,

type, and grade of lubricant recommended in this manual,

at the specified intervals. When recommended lubricants

are not available, consult your local supplier for an equivalent that meets or exceeds the specifications listed.

Batteries

Clean batteries, using a non-metallic brush and a solution

of baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry batteries and coat terminals with

an anti-corrosion compound.

Mast Chain Inspection Procedure

MAST CHAINS TO BE INSPECTED AND LUBRICATED EVERY

THREE MONTHS.

Inspect mast chains for the following conditions:

Wear: Always inspect that segment of chain that operates

over a sheave. As the chain flexes over the sheaves, joints

and plate edges very gradually wear. Chain “stretch” can

be measured using a manufacturers wear scale or steel

tape. When chains have elongated 3% they must be

removed and replaced. Refer to Table 2-1 for proper chain

specifications and allowable stretch tolerances. Peening

and wear of chain plate edges are caused by sliding over

a chain worn contact face of a sheave, or unusually heavy

loads. All of the above require replacement of the chain

and correction of the cause. Chain side wear, noticeable

when pin heads and outside plates show a definite wear

pattern, is caused by misalignment of the sheave/chain

anchors and must be corrected promptly. Do not repair

chains; if a section of chain is damaged, replace the entire

chain set.

Rust and Corrosion: Rust and corrosion will cause a

major reduction in the load carrying capacity of the chain,

because these are primary reasons for side plate cracking. The initial lubrication at the factory is applied in a hot

dip tank to assure full penetration into the joint. Do not

steam clean or degrease chains. At time of chain installation, factory lube must be supplemented by a maintenance program to provide a film of oil on the chains at all

times. If chains are corroded, they must be inspected,

especially the outside plates, for cracks in-line with the

pins. If cracks are found, replace the chain; if no cracks

are discovered, lubricate the chains by dipping in heated

oil, and reinstall on the machine. Keep chains lubricated.

Table 2-1. Chain Stretch Tolerance

Chain Size

.50" pitch 12" or 24 pitches . 24 in./12 in. span

.625 pitch 15" or 24 pitches .30 in./1 5 in. span

Fatigue Cracks: Fatigue is a phenomenon that affects

most metals, and is the most common cause of chain

plate failures. Fatigue cracks are found through the link

holes, perpendicular (90 degrees) from the pin in-line

position. Inspect chains carefully after long time use and

heavy loading for this type of crack. If any cracks are discovered, replace all chains, as seemingly sound plates

are on the verge of cracking. Fatigue and ultimate

strength failures on JLG Lifts are incurred as a result of

severe abuse as design specs are well within the rated lifting capacity of these chains.

Pin to Pin

Measurement

Allowable Stretch

2-2 – JLG Lift – 3120728

SECTION 2 - SERVICE PROCEDURES

Tight Joints: All joints in the leaf chain should flex freely.

On leaf chain, tight joints are usually caused by rust/corrosion, or the inside plates “walking” off the bushing. Limber

up rusty/corroded chains (after inspecting care fully) with

a heavy application of oil (preferably a hot oil dip). Tap

inside “ walking” plates inward; if “walking” persists,

replace the chain. This type of problem is accelerated by

poor lubrication maintenance practice, and most tight

joint chains have been operated with little or no lubrication. Tight joints on leaf chain are generally caused by:

a. Bent pins or plates.

b. Rusty joints.

c. Peened plate edges.

Oil rusty chains, and replace chains with bent or peened

chain components. Keep chains lubricated.

Protruding or Turned Pins: Chains operating with inadequate lube generate tremendous friction between the pin

and plates (pin and bushing on leaf chain). In extreme

cases, this frictional torque can actually turn the pins in

the outside press-fit plates. Inspect for turned pins, which

can be easily spotted as the “V” flats on the pin heads are

no longer in line. Replace all chains showing evidence of

turned or protruding pins. Keep chains lubricated.

Chain Anchors and Sheaves: An inspection of the chain

must include a close examination of chain anchors and

sheaves. Check chain anchors for wear breakage and

misalignment. Anchors with worn or broken fingers should

be replaced. They should also be adjusted to eliminate

twisting the chain for an even load distribution.

Inspect the sheaves, sheave bearings, sheave grooves

and pins for extreme wear, replace as necessary. A worn

sheave can mean several problems, as follows:

a. Chains too tight.

b. Sheave bearings/pin bad.

c. Bent/misaligned chains.

Mast Cable Inspection Procedure

Inspection should be more frequent as cables approach

the end of their useful lives.

Only the surface wires of the cable require inspection, do

not attempt to open the cable. Any deterioration resulting

in any loss of original strength, such as described below,

shall be noted, and then a determination made if further

use would constitute a hazard.

Mast cables must be replaced after machine has been in

service for five (5) years, regardless of cable condition, or

sooner if conditions dictate.

Conditions such as the following shall be sufficient reason

for questioning continual use of the [cable] or increasing

the frequency of inspection:

1. In running ropes, six randomly distributed broken

wires in one lay or three broken wires in one strand

in one lay.

2. One outer wire broken at the point of contact with

the core of the rope which has worked its way out of

the rope structure and protrudes or loops out from

the rope structure. Additional inspection of this section is required.

3. Wear of one-third the original diameter of outside

individual wires.

4. Kinking, crushing, birdcaging or any other damage

resulting in distortion of the rope structure.

5. Evidence of any heat damage from any cause.

6. Reductions from nominal diameter of more than;

a. 1/64th in. (0.4mm) for diameters up to and

including 5/16th in. (8mm);

NOTE: A good indicator of a stretched extend/retract cable

is if the adjusting nuts are bottomed out. If no adjustment remains the cables have stretched and need

replacement.

Also check for cracked, bent, worn, severely corroded, or

improperly installed cable ends.

Inspect sheaves, sheave grooves, and sheave pins for

excessive wear, replace as necessary.

MAST CABLES ARE TO BE INSPECTED EVERY THREE MONTHS

OR MORE FREQUENTLY AS DESCRIBED FOLLOWING.

2.3 LUBRICATION INFORMATION

Hydraulic System

WEAR PROTECTIVE GLOVES TO PROTECT HANDS WHEN HANDLING CABLE.

The periodic inspection shall cover the entire length of the

cable. The inspection frequency shall be based on such

factors as expected cable life as determined by experience on the particular application or similar installations,

severity of environment, percentage of capacity lifts, frequency rates of operation, and exposure to shock loads.

3120728 – JLG Lift – 2-3

The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various means,

e.g., using inadequate hydraulic oil, allowing moisture,

grease, filings, sealing components, sand, etc., to enter

when performing maintenance, or by permitting the pump

to cavitate due to insufficient system warm-up or leaks in

the pump supply.

The design and manufacturing tolerances of the component working parts are very close, therefore, even the

smallest amount of dirt or foreign matter entering a system

SECTION 2 - SERVICE PROCEDURES

can cause wear or damage to the components and generally results in faulty operation. Every precaution must be

taken to keep hydraulic oil clean, including reserve oil in

storage.

Cloudy oils indicate a high moisture content which permits organic growth, resulting in oxidation or corrosion. If

this condition occurs, the system must be drained,

flushed, and refilled with clean oil.

It is not advisable to mix oils of different brands or types,

as they may not contain the same required additives or be

of comparable viscosities. Good grade mineral oils, with

viscosities suited to the ambient temperatures in which

the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil of new

machines due to the wear-in of meshing components.

Hydraulic Oil

For best performance, JLG recommends the use of ISOVg grade 32, 46 oil with a viscosity range between 15-250

SUS at 100 degrees F (32-54 cST at 40 degrees C). Refer

to Section 1-5 of this Service Manual for recommended

hydraulic oils.

Changing Hydraulic Oil

Use of any of the recommended hydraulic oils eliminates

the need for changing the oil on a regular basis. If it is necessary to change the oil, use only those oils meeting or

exceeding the specifications appearing in this manual. If

unable to obtain the same type of oil supplied with the

machine, consult local supplier for assistance in selecting

the proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG Industries recommends changing the

hydraulic oil annually.

Use every precaution to keep the hydraulic oil clean. If the

oil must be poured from the original container into

another, be sure to clean all possible contaminants from

the service container.

While the unit is shut down, a good preventive maintenance measure is to make a thorough inspection of all

hydraulic components, lines, fittings, etc., as well as a

functional check of each system, before placing the

machine back in service.

Lubrication Specifications

Specified lubricants, as recommended by the component

manufacturers, are always the best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose grease requirements.

Should any question arise regarding the use of greases in

maintenance stock, consult your local supplier for evaluation. Refer to Table 1-3 in this Service Manual for an explanation of the lubricant key designations appearing in the

Lubrication Chart.

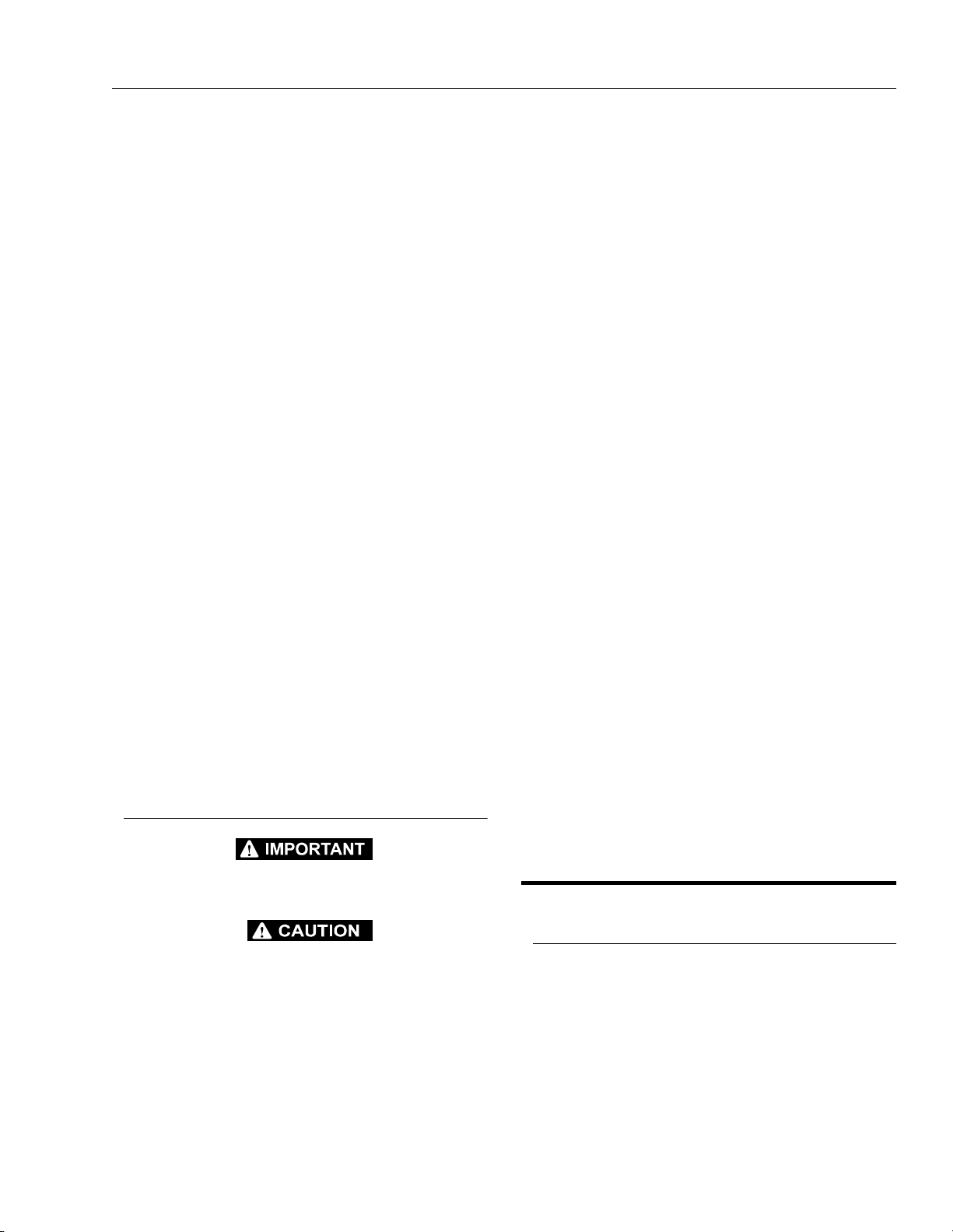

2.4 POSITIONING LIFT FOR ACCESS TO

COMPONENTS LOCATED UNDER THE

BASE FRAME

Access to the underside of the VP lift can be obtained by

lifting the machine with a fork lift truck, using the fork lift

pockets in the base frame.

Lifting with a Fork Truck (See Figure 2-1.)

1. Choose a fork lift truck capable of safely handling

the full weight of the machine.

2. Locate work area on a firm, level surface.

KEEP MACHINE LEVEL OR SLIGHTLY TILTED TOWARD FORKLIFT

TRUCK WHEN LIFTING TO PREVENT MACHINE FROM SLIDING

OFF LIFTING TINES.

3. When lifting with a fork truck, lift only using the fork

lift-truck pockets running the length of the machine’s

base frame from rear to front.

4. After lifting machine to desired work height, place

support stands under the machine. The support

stands must reach from the floor to the bottom of the

machine and be capable of safely handling the

weight of the machine.

LIFT USING ONLY THE

FORK LIFT POCKETS

RUNNING THE LENGTH

OF THE BASE FRAME

PLACE

SUPPORT

STAND

BETWEEN

MACHINE

AND

FLOOR

Figure 2-1. Accessing Machine Underside

Components by Lifting with a Fork Truck.

2-4 – JLG Lift – 3120728

SECTION 2 - SERVICE PROCEDURES

2.5 DRIVE MOTOR COMPONENT SERVICE

PROCEDURES

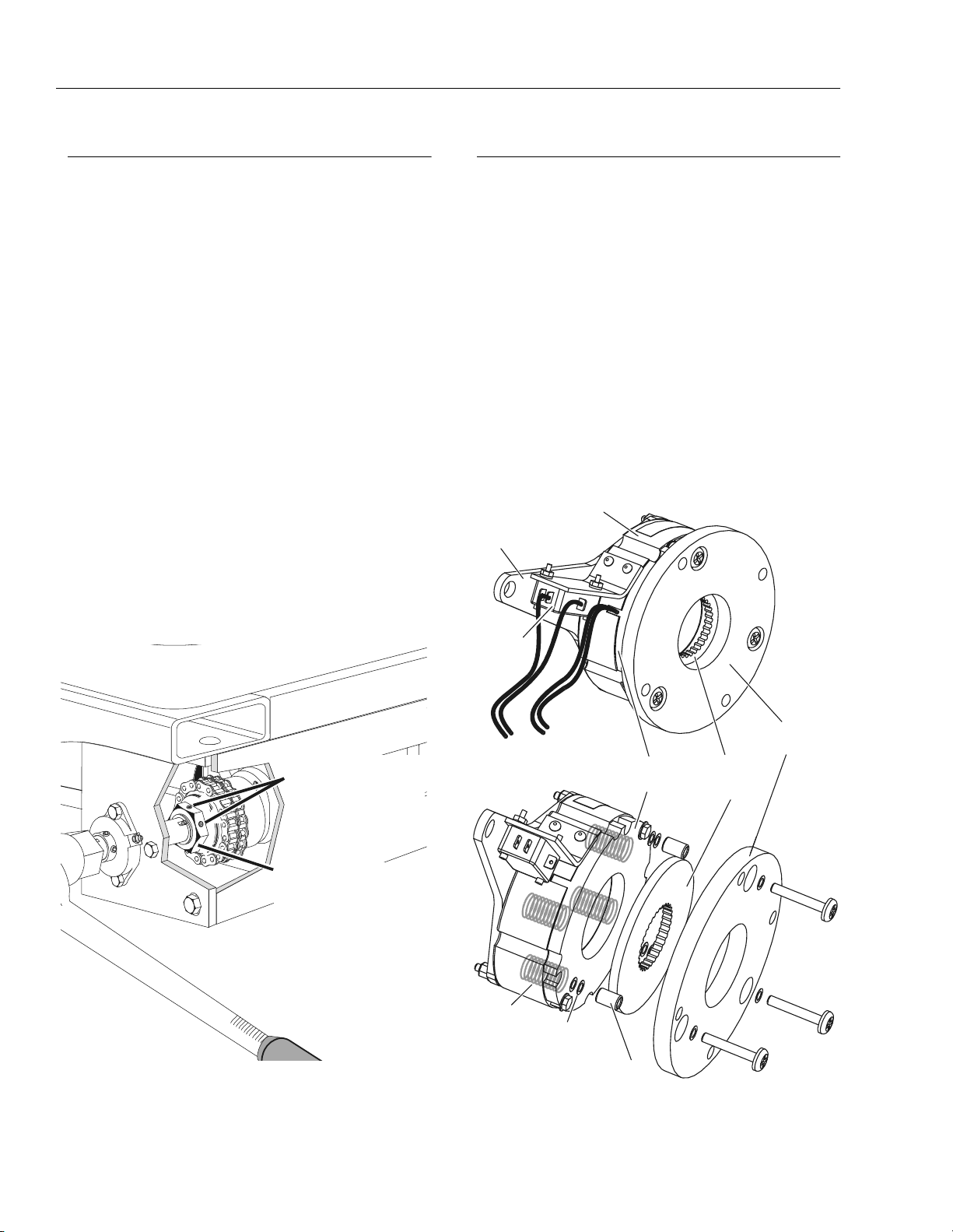

Torque Limiting Clutch Maintenance

VP Series machines are equipped with a torque limiting

clutch coupling on each drive axle. The clutch is mounted

inline on the drive axle between the drive wheel and the

drive motor gear box. The clutch is designed to slip at a

pre-set torque if the machines rear wheels are over-driven

while the machine is being towed, pushed or forklifted,

thus preventing damage to the drive gear box. Although

factory pre-set, the clutch assembly and torque should be

checked at the following interval:

• Every 3 months.

Visual Inspection and Limiting Torque

Checking Procedure

1. Locate the machine on a firm level surface.

KEEP MACHINE LEVEL OR SLIGHTLY TILTED TOWARD FORKLIFT

TRUCK WHEN LIFTING TO PREVENT MACHINE FROM SLIDING

OFF LIFTING TINES.

2. Carefully raise the lift to gain access to the underside of the base frame. Refer to Section 2.4, "Positioning Lift For Access to Components Located

Under the Base Frame".

3. Locate the clutch assembly on each rear drive axle

and check for the following;

a. Check the coupling chains for any loose or miss-

ing parts, i.e. pins, links, etc., replace if necessary.

b. Check that the allen-head set screws on the

(large) clutch adjusting nut are in place and

secure. Tighten or replace if necessary.

c. Check for any debris wedged in or wrapped

around the clutch coupling chains and axle

shafts. Remove debris and clean area if necessary.

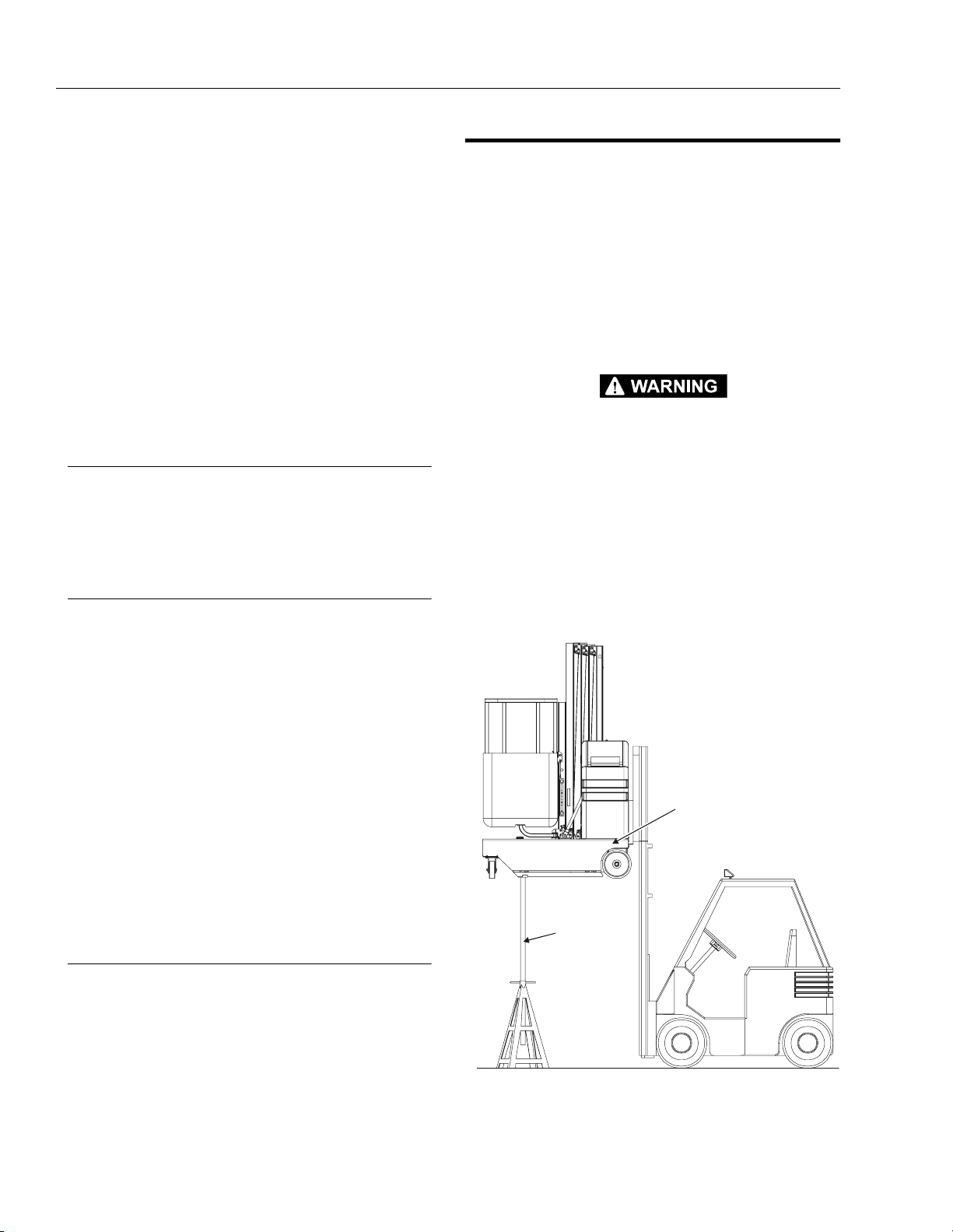

Checking Clutch - Torque Setting (ft. lb.)

NOTE: Check that the machines brakes are engaged before

applying torque to the rear drive wheels.

1. Remove the drive wheels from the drive axles.

2. Select a torque wrench capable of setting a torque

of at least 185 ft. lb. Insert special tool (P/N-

0080229) into a 3/4" socket on the torque wrench.

3. Slide the tool onto the end of the drive axle aligning

the key on the axle shaft (install key on axle, if necessary), with key slot in the tool. (See Figure 2-2.)

4. Turn the torque wrench and note the torque setting

when the torque limiting clutch releases. The torque

(slip) setting should be set at 185 ft. lb. Check both

rear drive axles.

NOTE: The allowable breaking torque for the torque limiting

clutch can be set as much as 35 ft. lb. less than the

factory setting of 185 ft. lb., but never more than the

185 ft. lb. factory setting.

5. If torque setting is OK, re-install the wheels and

lower machine, IF NOT, see the following note.

NOTE: If torque setting is outside the allowable range of

specifications, the torque limiting clutch will need

adjustment. See Torque Limiting Clutch Adjustment

following.

SERVICE TOOL

P/N-0080229

(REQUIRES A 1-3/4” SOCKET)

TORQUE

LIMITING

CLUTCH

LOCATION

Figure 2-2. Check Torque Limit Clutch -

Torque Setting.

3120728 – JLG Lift – 2-5

SECTION 2 - SERVICE PROCEDURES

TORQUE LIMIT

CLUTCH

ADJUSTING NUT

ADJUSTING NUT

SET SCREWS

Torque Limiting Clutch Adjustment

NOTE: The large adjusting nut on the side of the clutch

assembly is a standard type thread.

If the torque (slip) setting of the clutch assembly is

under spec (by more than 35 ft. lb.), the large adjusting nut must be (tightened) turned clockwise to

increase the torque setting.

If the torque (slip) setting is over spec (over 185 ft.

lb.) the large adjusting nut must be (loosened),

turned counter-clockwise to decrease the torque setting.

1. Loosen the two (2) adjusting nut setscrews located

on the large adjusting nut on the clutch assembly.

(See Figure 2-3.)

2. Hold the drive axle steady using service tool (P/N-

0080229) and the torque wrench used to check the

torque setting.

3. Depending on how far off the original torque setting

was (see note at beginning of this procedure),

tighten or loosen the adjusting nut accordingly, then

recheck the (slip) torque setting.

4. When proper torque setting is achieved, re-tighten

the two (2) adjusting nut, setscrews.

5. Re-install the drive wheels, remove the jack stand

and lower the machine to ground.

Drive Motor Brake Adjustment/Removal

(See Figure 2-4. & Figure 2-5.)

Mounted onto the front of each drive motor housing is a

brake assembly. The brakes are normally ENGAGED

(brakes on) when the machine is parked and are

RELEASED electrically (brakes off) under normal driving

conditions, when the joystick is enabled and pushed in

any direction. The brakes can also be RELEASED manually using the manual brake release lever mounted on the

side of the mast.

NOTE: The brakes are intended only as parking brakes to

keep the machine from moving while at rest. The

brakes are not used to stop the machine during driving operations, this braking is controlled by the drive

motors themselves. Under normal driving conditions,

once released the brakes are not engaged again

until the machine comes to a complete stop.

MANUAL

BRAKE

RELEASE

ARM

LIMIT

(MICRO)

SWITCH

MAGNETIC

COIL

HOUSING

MOUNTING

PLATE

ARMATURE

PLATE

FRICTION

BRAKE

DISK

SPRINGS

SHIM WASHERS

Figure 2-3. Torque Limit Clutch -

Adjustment Components.

(AS REQUIRED)

SPACER

Figure 2-4. Brake Assembly Components

2-6 – JLG Lift – 3120728

SECTION 2 - SERVICE PROCEDURES

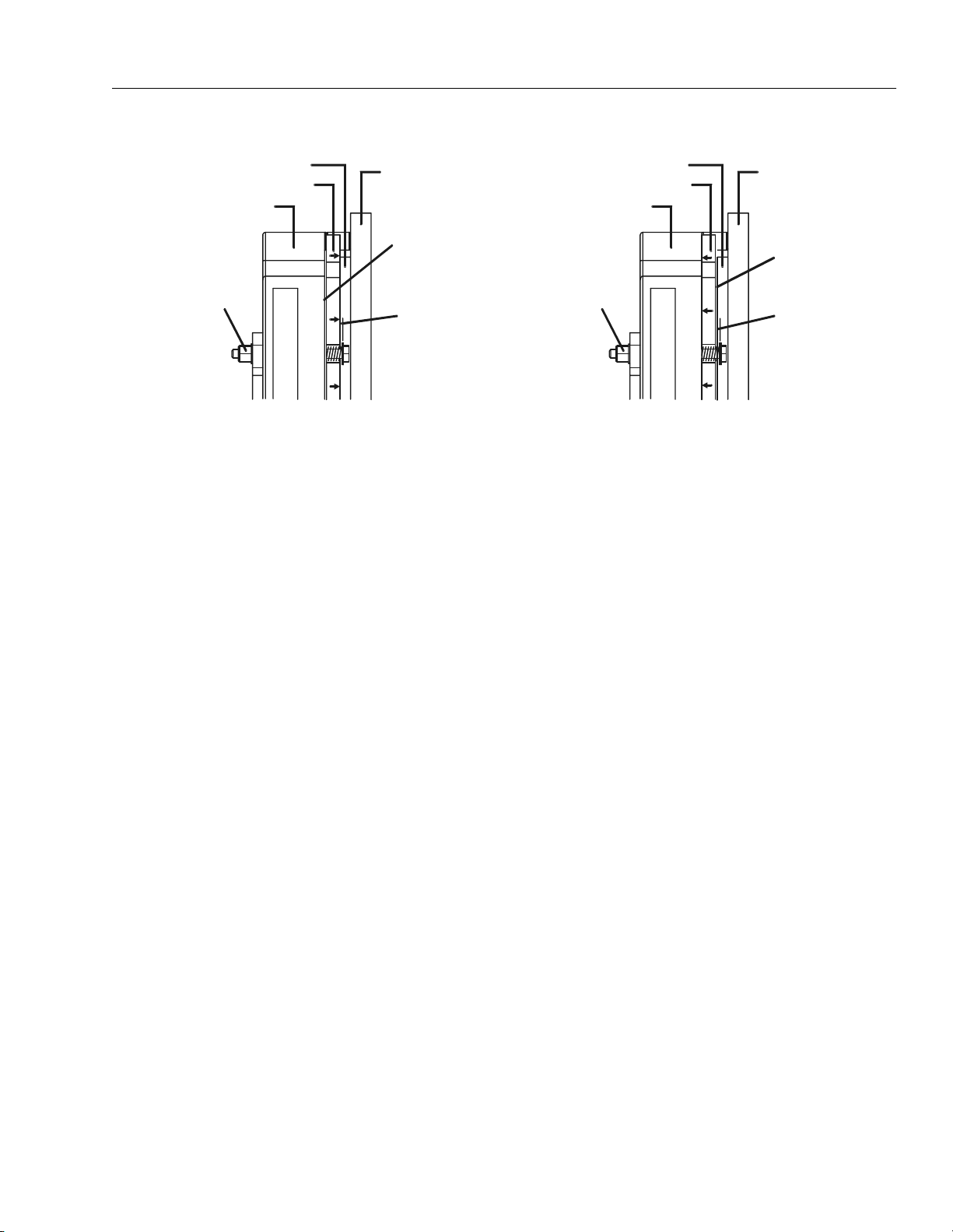

E

FRICTION BRAKE DISK FRICTION BRAKE DISK

ARMATURE PLATE ARMATURE PLATE

MAGNETIC COIL

(Not Energized)

MANUAL

RELEASE ARM/

ADJUSTMENT

SCREW

GAP SETTINGS - BRAKE ON

(Magnet Not Energized)

MOUNTING PLATE MOUNTING PLAT

0.006” GAP

BETWEEN

ARMATURE

PLATE AND

MAGNETIC COIL

0.020” GAP

UNDER

SCREW HEAD

BETWEEN

ARMATURE

PLATE

MAGNETIC COIL

(Energized)

MANUAL

RELEASE ARM/

ADJUSTMENT

SCREW

GAP SETTINGS - BRAKE RELEASED

Figure 2-5. Brake Armature Plate & Brake Disk Adjustment.

Operation (See Figure 2-4. & Figure 2-5.)

When the magnetic coil is not energized (brake on), the

armature plate is pushed away from the magnetic coil surface by heavy springs internally mounted in the magnetic

coil housing. This pressure forces the armature plate

against the friction brake disk holding it tight between the

armature plate and the mounting plate. The brake is not

released until either the magnetic coil is energized pulling

the armature plate away from the friction brake disk or the

brake is manually released using the manual brake

release handle.

A correctly adjusted brake will ideally have a measurment

of approximately .006" (but will operate normally at .004" to

.010") between the armature plate and magnetic coil

housing surface when the brakes are ENGAGED (brakes

3. With the brakes ENGAGED measure the air gap

between the armature plate and the magnetic coil

housing. The correct setting should be .006", however the brakes will operate properly if the measurement is a minimum of .004" and a maximum of .010".

(See Figure 2-5.)

4. If the air gap falls outside the maximum allowable

setting of .010" the friction disk has worn. To correct

this replace the disk with a new one.

5. It the air gap is below the minimum allowable setting

of .004", recheck the areas between the magnetic

coil housing, armature plate, friction disk and

mounting plate for debris. Clean as neccessary. Also

check that the manual release arm screws are not

tightened to tight.

on).

Never allow any type of lubricant (oil, grease, hydraulic

fluid, etc.) to come in contact with the brake friction disk or

it’s contacting surfaces. Also if the brake becomes

clogged with debris or dirt the brake may not release

properly.

Manual Release Arm - Screw Adjustment

NOTE: Always check the armature plate gap setting is within

spec before attempting to adjust the manual release

arm screw adjustment.

1. With the brakes ENGAGED (brakes on) the air gap

Checking/Adjusting Armature Plate Gap Setting

1. First inspect that all parts of the brake assembly are

tight and secure. Tighten as necessary.

2. Inspect the brake for any debris which may be

lodged in the air gap between the armature plate

and magnetic coil when the brakes are ENGAGED

(brakes on); on either side of the friction disk when

the brake is RELEASED (brakes off); or any dirt or

debris lodged between the manual release arm and

the magnetic coil housing. Clean and remove debris

as necessary.

under the head of the manual release arm screw to

the surface of the armature plate should be set at

.020". Adjust using the locknut on the release arm

end of the screw.

2. With the brakes electrically RELEASED (brakes off)

the air gap under the screw head increases to

approximately .026" due to the armature plate movement towards the magnetic coil, releasing the friction brake disk. When the brakes are RELEASED

(brakes off) manually the screw head pulls in against

the armature plate releasing the friction brake disk.

0.006” GAP

BETWEEN

FRICTION

DISK AND

ARMATURE

PLATE

0.026” GAP

UNDER

SCREW HEAD

BETWEEN

ARMATURE

PLATE

(Magnet Energized)

3120728 – JLG Lift – 2-7

SECTION 2 - SERVICE PROCEDURES

S

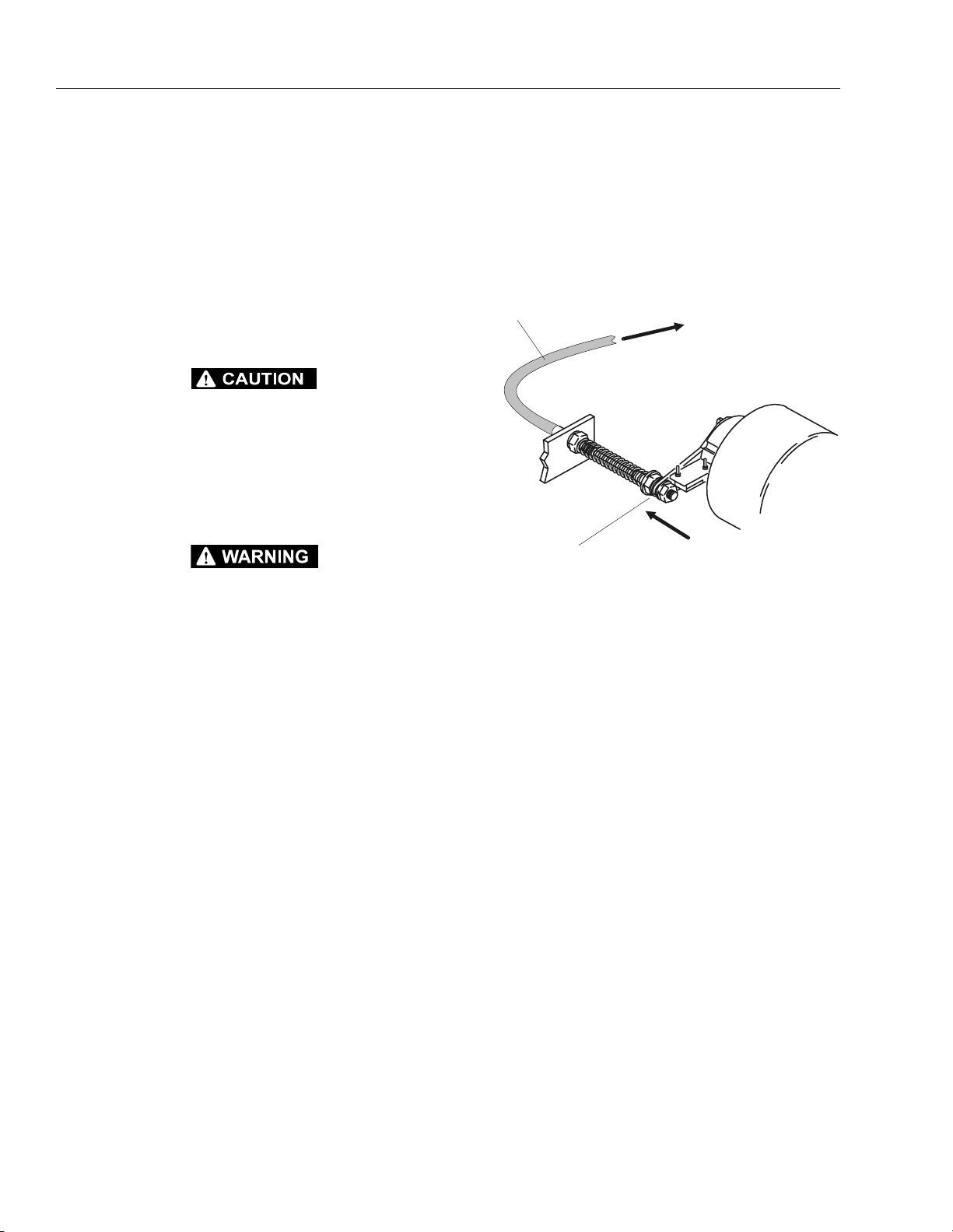

Brake Assembly Removal

1. Lift the machine to gain access to the underside

(See Section 2-4., "Positioning Lift For Access To

Components Located Under The Base Frame").

2. Disconnect the brake magnetic coil wiring connector

and the brake limit (micro) switch wiring connector

from their wiring harness connectors.

3. Disconnect the manual brake release cable from the

manual brake release arm attached to the brake

assembly.

4. Lower machine back down to ground level.

PLACE MACHINE ON A LEVEL SURFACE BEFORE BEFORE

REMOVING THE BRAKE ASSEMBLIES. MACHINE MAY ROLL

AWAY IF NOT SETTING ON A LEVEL SURFACE.

5. Using the Ground Control Switch, raise the platform

to gain access to the brake assemblies mounted on

the end of the drive motors located at the base of the

mast.

NEVER WORK UNDER AN ELEVATED PLATFORM UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED FROM ANY MOVEMENT

BY BLOCKING OR OVERHEAD SLING.

6. Remove the four (4) hex cap screws securing the

brake assembly to the end of the drive motor and

remove the brake assembly from the end of the

drive motor.

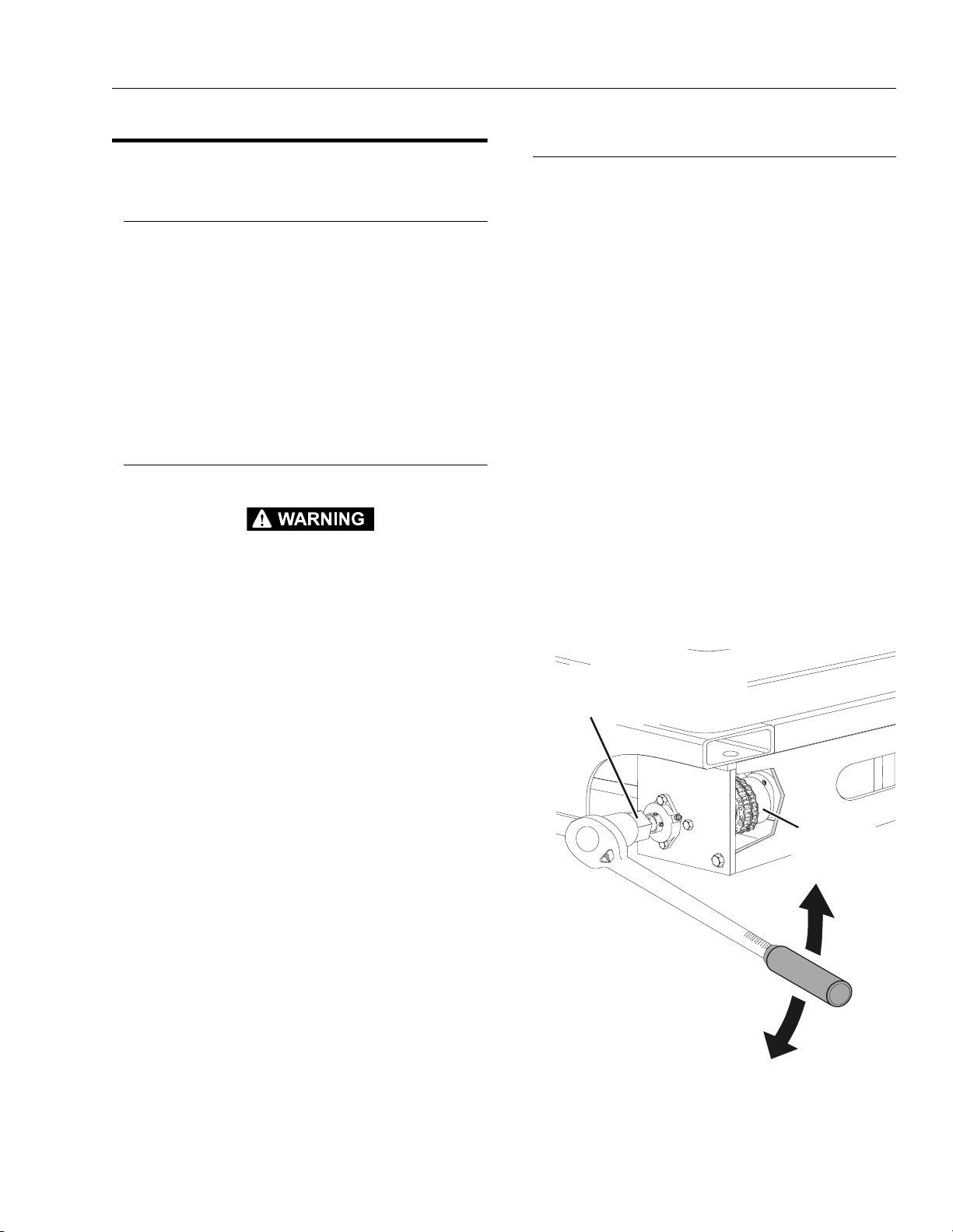

6. Reconnect the manual release brake cable to the

manual release lever (Y shaped lever) and adjust

cable so brakes are released when manual release

lever is in the down position. (See Figure 2-6.)

MANUAL

RELEASE

BRAKE

CABLE

SET MANUAL

BRAKE RELEASE

HANDLE TO

FREE WHEELING

AND ADJUST HERE

UNTIL BRAKE DISK

IS COMPLETELY

RELEA

ED

TO MANUAL

RELEASE

BRAKE

HANDLE

MOUNTED

ON SIDE OF

MAST

BRAKES

ARE RELEASED

WHEN CABLE

PULLS LEVER

IN THIS DIRECTION

Figure 2-6. Manual Release Brake Cable Adjustment.

Brake Assembly Installation

1. Guide the manual release lever, brake coil and brake

limit switch wiring connectors through the opening

in the drive motor cover and base frame while sliding the brake assembly onto the front of the drive

motor. Engage the teeth of the disk brake with the

teeth on the drive motor brake gear.

2. If necessary, manually release the brake disk using

the manual release lever to allow the brake assembly to turn and align the four holes in the brake

mounting plate with the mating holes in the drive

motor end plate.

3. Secure the brake assembly to the drive motor using

four (4) hex cap screws with washers. Torque evenly

to 44 in. lbs.

4. Lift the machine to gain access to the underside

(See Section 2-4., "Positioning Lift For Access To

Components Located Under The Base Frame").

5. Reconnect the brake coil and brake limit switch wiring connectors to their respective wiring harness

connectors.

2-8 – JLG Lift – 3120728

SECTION 2 - SERVICE PROCEDURES

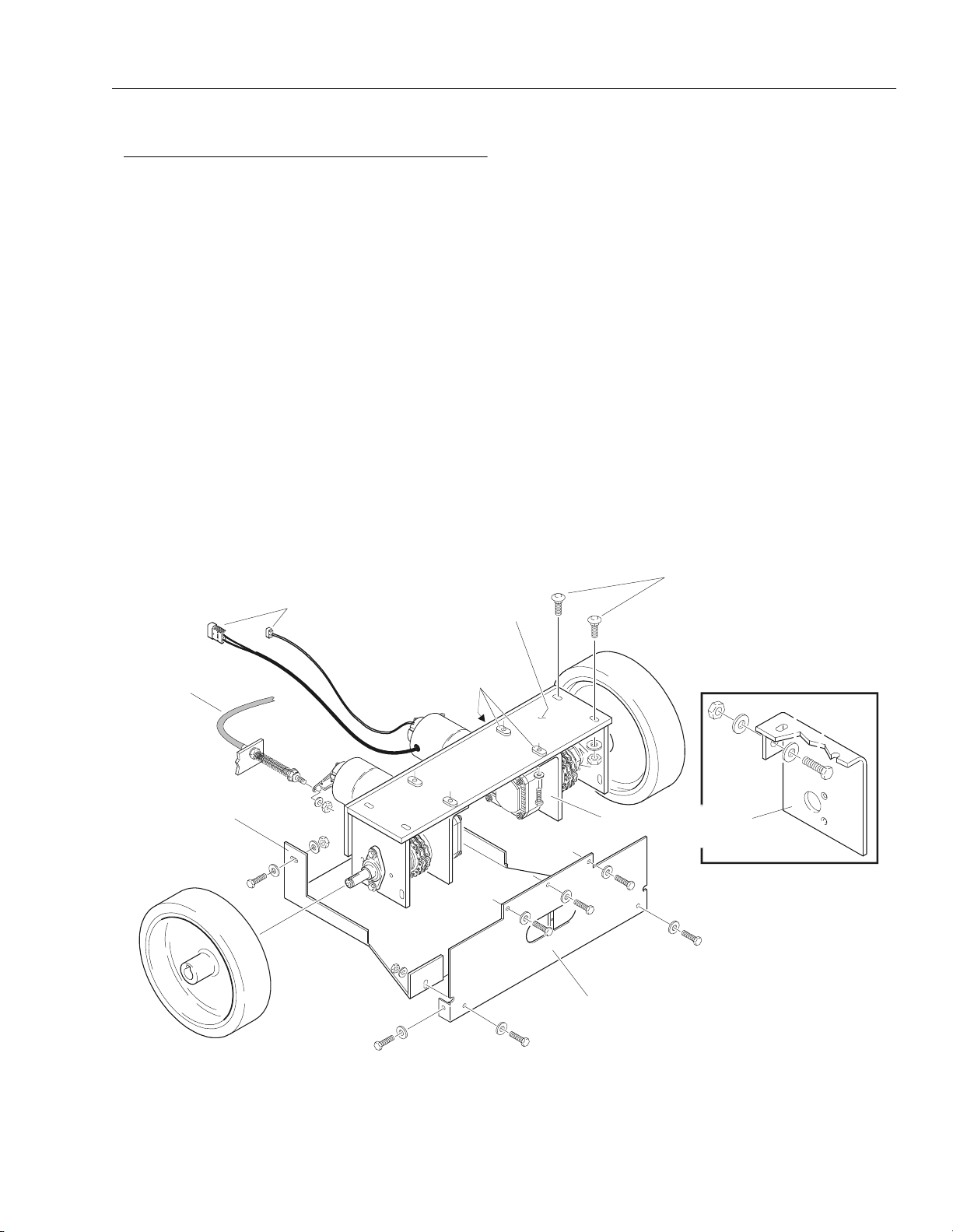

OTO

(2 EACH INSIDE FORK LIFT POCKET)

DRIVE MOTOR MOUNT

DRIVE MOTOR MOUNT

Drive Motor Removal

(See Figure 2-7.)

The VP drive motors consist of three sections, the gear

box atttached to the rear of the drive motor, the electric

drive motor itself, and the brake assembly mounded at the

front of the drive motor. Each drive motor is mounted independently of the other on a completely removable drive

assembly weldment at the back of the machine.

1. Disconnect the positive battery terminal from the left

side battery.

2. Remove the rear plate weldment from the machine,

(plate with the tie down lug) and set aside. Three (3)

bolts hold the top of the rear plate weldment to the

base frame, four (4) bolts attach it to the motor cover

weldment (located under machine) at the back and

on the sides.

3. Carefully raise the lift to gain access to the underside of the base frame. Refer to Section 2.4, "Positioning Lift For Access to Components Located

Under the Base Frame".

4. Remove the remaining two (2) bolts attaching the

motor cover to the base frame and set it aside.

DRIVE MOTOR/

BRAKE WIRING

CONNECTORS

DRIVE MOTOR

ASSEMBLY WELDMENT

5. Disconnect the wiring connectors to the drive motor

and the brake assembly on either or both sides,

depending on which drive assembly(ies) is being

removed.

6. Disconnect the manual release brake cable from the

brake assembly arm on either or both drive motors if

removing the complete drive assembly.

NOTE: If removing each drive motor seperately continue to

Step 7. If removing the complete drive assembly

with both motors attached go to Step 11.

7. Remove the one (1) bolt, nut, and two (2) washers

from the front of the drive motor mounting plate.

8. While holding the drive motor in place, remove the

remaining two (2) bolts with washers holding the

drive motor mounting plate to the drive motor

assembly weldment.

9. Slide the drive motor and torque limiting clutch

assembly towards the center of the machine, sliding

the torque limiting clutch off the outer drive shaft.

10. Move drive motor assembly and torque limiting

clutch to a suitable work bench for disassembly.

DRIVE M

ASSEMBLY

WELDMENT

ATTACH BOLTS

R

MANUAL

RELEASE

BRAKE

CABLE

DRIVE MOTOR

PLATE FASTENERS

(THREE ON EACH MOUNT

ALSO SEE INSET)

COVER

PLATE

REAR PLATE

WELDMENT

Figure 2-7. Drive Motor Assembly Removal.

3120728 – JLG Lift – 2-9

SECTION 2 - SERVICE PROCEDURES

Gear Box Disassembly/Assembly

IF REMOVING THE COMPLETE DRIVE ASSEMBLY, IT WEIGHS

APPROXIMATELY XX LB. AND WILL REQUIRE ASSISTANCE TO

LOWER. PREFERABLY USE A MOVABLE TRANSMISSSION OR

OTHER HYDRAULIC JACK TO CAREFULLY LOWER ASSEMBLY

FROM UNDER MACHINE.

11. Carefully remove the four (4) nuts and washers

(outer most holes on the drive assembly weldment)

from the carriage bolts attaching the drive motor

assembly to the base frame. Be aware of the weight

of the assembly before completely removing the fasteners, see the CAUTION above.

12. Lower the drive assembly and place on a suitable

work surface.

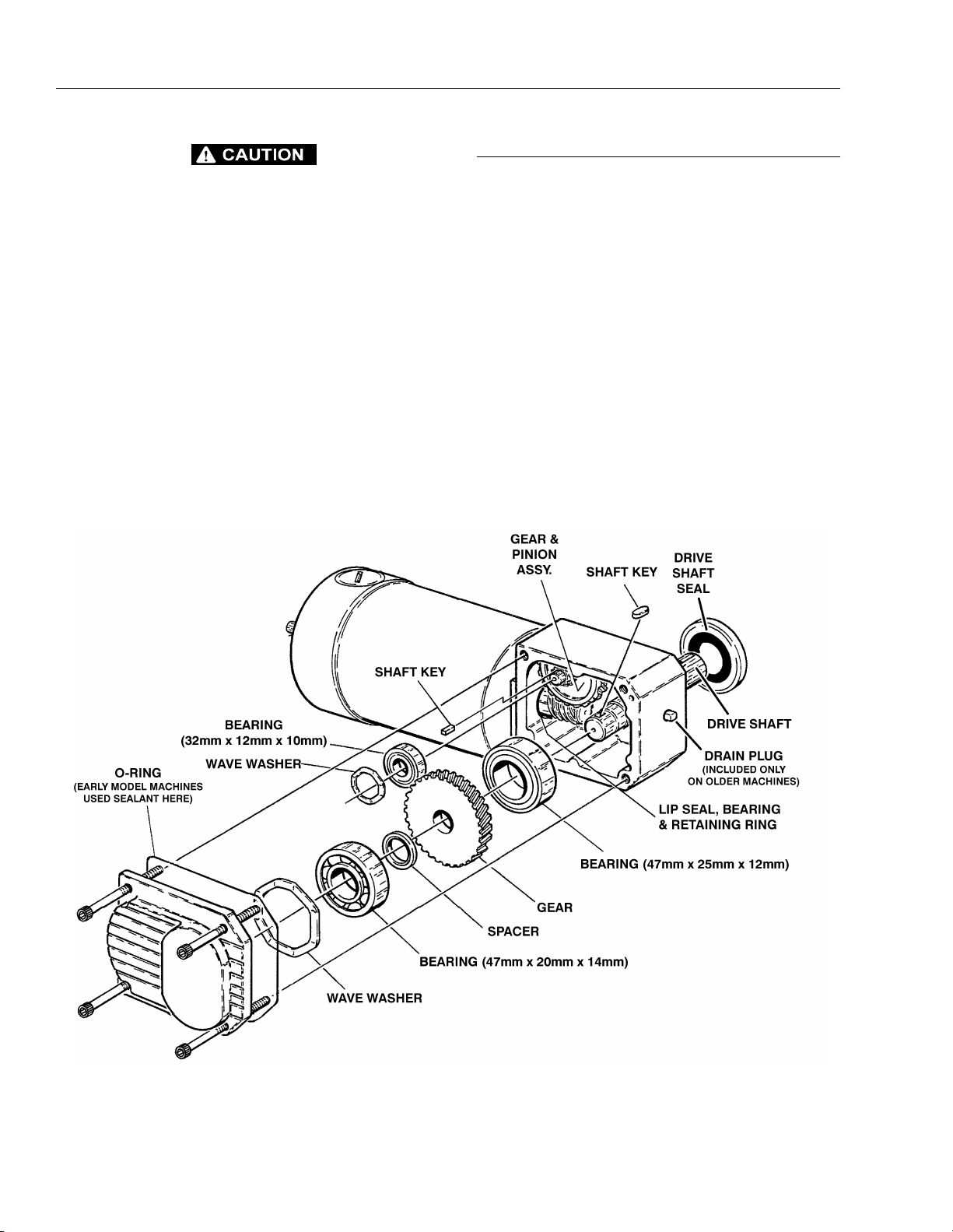

(See Figure 2-8.)

The drive motor gear box is mounted on the rear of each

drive motor transferring power from the electric drive

motor to the rear drive wheels. It is a right angle worm

gear type box with a 50:1 reduction drive ratio. The internal gears and bearings of the gear box are lubricated by

175cc’s of gear oil in an unvented aluminum alloy housing. Early VP machines included a oil drain plug on the

rear surface of the gear box housing, later model

machines do not. The following procedures disassemble

and assemble the gear box housing internal components.

Gear Box Disassembly (See Figure 2-8.)

1. Remove the drive motor/gear box/brake assembly

from the machine using the procedure outlined previously in this section of the manual.

Figure 2-8. Drive Motor Gear Box Assembly.

2-10 – JLG Lift – 3120728

SECTION 2 - SERVICE PROCEDURES

S

G

NOTE: The gear oil can be drained out when the side cover

is removed in the next step. Remove the side cover

from the gear box with the drive shaft side pointing

down, then tilt drive motor/gear box assembly to

drain the oil into a suitable container.

2. Remove the four (4) hex cap screws securing the

side cover to the gear box housing, and remove the

side cover and rubber seal ring. (Note: Early model

machines did not have the rubber seal ring and were

sealed with sealant only.) Be careful not to scratch or

gouge the mating surfaces between the cover and

the gear box housing. This area is sealed by the rubber ring/sealant and may leak oil if damaged.

3. Remove the wave washers from atop the large and

small bearings and lay inside their respective holes

in the side cover.

4. Using a suitable catch container, drain the gear oil

from the gear box housing.

5. Remove the drive shaft assembly from the housing.

Place the drive motor/gear box assembly on a

hydraulic press with the open side of the gear box

housing facing down. Support the gear box housing

surface but do not block the free travel of the drive

gear and bearings, on the drive shaft or the pinion

gear assembly.

6. With the open surface of the housing properly supported, carefully press the drive shaft down through

until it is free of the housing. When the drive shaft

assembly is free, slide it completely out of the housing.

7. To remove the large (47mm) (cover side) bearing

and (housing side) bearing from the drive shaft, use

a suitable hydraulic press and press the bearing(s)

off the shaft. Keep the spacer from between the

cover side bearing and the drive shaft gear for reuse

during assembly.

8. To remove the small (32mm) bearing(s) from the

gear (brass) and pinion assembly, use a suitable

hydrauic press and press the bearing(s) off the gear

and pinion shaft.

9. To remove the (brass) worm gear from the pinion

assembly, use a suitable hydraulic press and press

the gear off the pinion shaft. Keep the (brass) gear

key for reuse during assembly.

10. Inspect the drive shaft seal for cuts, cracks and

wear, or if showing signs of leakage. Replace if necessary.

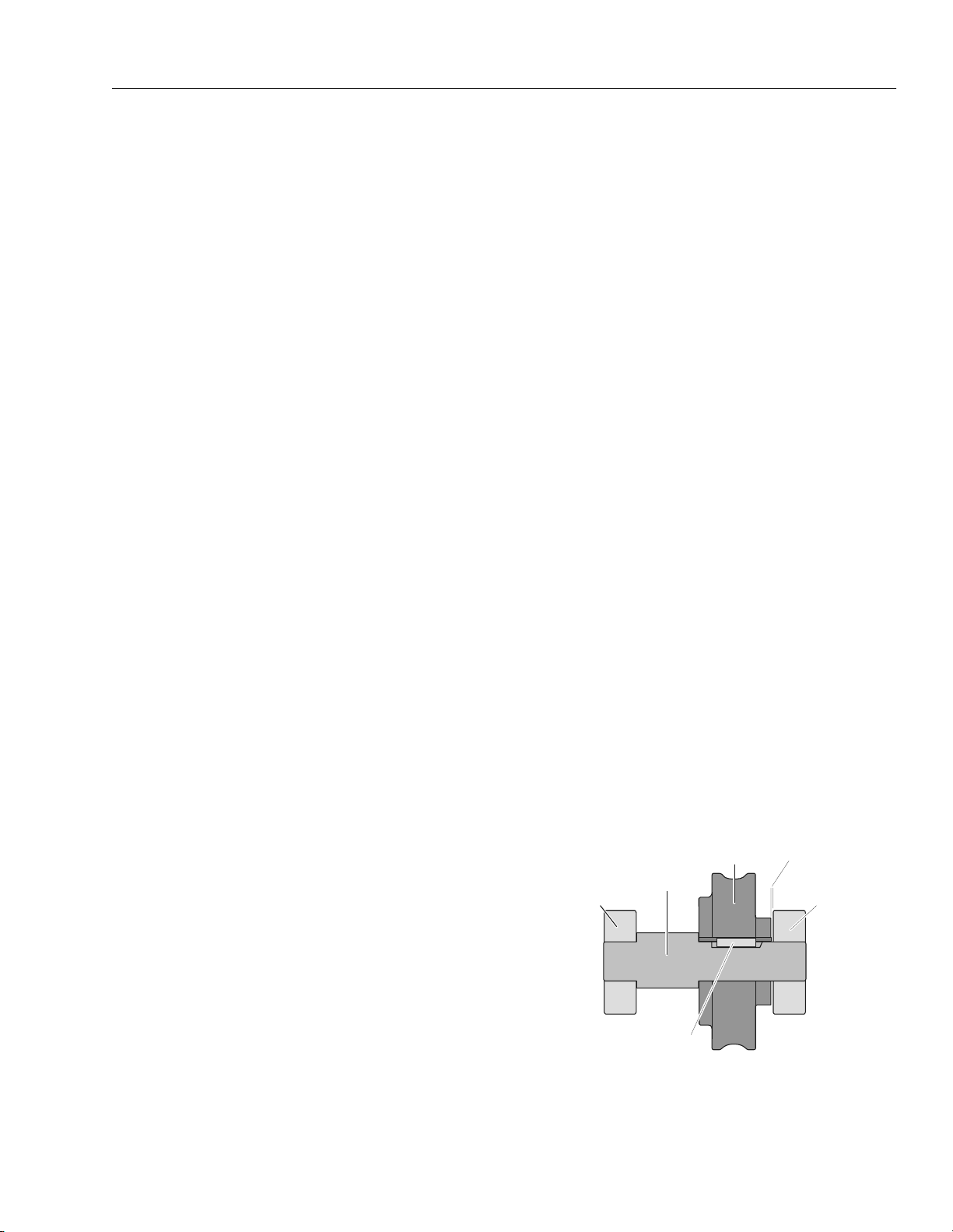

Gear/Pinion Shaft Assembly (See Figure 2-9.)

1. Locate the pinion gear/shaft, place the key for the

(brass) worm gear into the slot on the gear shaft.

2. Press the (brass) worm gear onto the pinion shaft

and align the keyway in the (brass) worm gear with

the key on the pinion shaft. Press the (brass) worm

gear onto the shaft until it bottoms out against the

pinion gear teeth.

NOTE: Press bearings onto the shaft pressing only against

the bearing inner race. Do not press against the

outer race or damage could occur to the bearing.

3. Press the small (32mm) bearings onto the ends of

the pinion shaft. The inner race of the bearing on the

pinion gear side can be bottomed out against the

pinion gear. Do not press the bearing on the (brass)

worm gear side of the shaft in tight against the

(brass) worm gear. This bearing must be flush with

the end of the shaft on the outside, yet have clearance from the (brass) worm gear on the inside, so it

can rotate freely.

Drive Shaft Assembly (See Figure 2-10.)

1. Slide the (housing side), 42mm x 25mm x 12mm

(thinner) bearing onto the long end of the drive shaft.

Press the bearing inner race until it bottoms against

the shaft shoulder between the drive gear and the

bearing.

2. Slide the narrow spacer onto the drive gear end of

the shaft and press the (cover side) 42mm x 20mm x

14mm (wider) bearing onto the drive shaft until it

bottoms against the spacer. This bearing should be

flush with the end of the drive shaft.

IDE PROFILE

32mm

BEARING

WORM

GEAR

(BRASS)

PINION GEAR/

SHAFT

LEAVE

GAP HERE

32mm

BEARIN

WORM GEAR

KEY

Figure 2-9. Gear/Pinion Shaft Assembly.

3120728 – JLG Lift – 2-11

SECTION 2 - SERVICE PROCEDURES

O

G

Final Gear Box Assembly

1. If necessary, install a new drive shaft lip seal into the

drive shaft hole in the gear box housing before

assembling the drive shaft gear set into the gear

box. Install the seal so it is even with the bottom of

the chamfer in the drive shaft hole on the outside of

the housing and flush with the bearing seat on the

inside of the housing.

2. Lube the drive shaft seal with a thin film of oil before

sliding the drive shaft over the seal.

3. Position the gear box with open cover side up, allow

space under the gear box for the drive shaft to

extend through without obstruction.

4. Hold the gear and pinion, and drive shaft assembies

together with the pinion gear and the ring gear on

the drive shaft meshing. Now carefully slide these

assemblies into the gear box housing sliding the

drive shaft through the drive shaft lip seal.

NOTE: While assembling the gear assemblies into the gear

box housing, be careful with the drive shaft seal and

the softer brass worm gear and brass drive worm

gear from the drive motor.

5. Continue to drop the gear assemblies into the gear

box, align the bearings with the bearing seats in the

housing on both assemblies. Drop the gear and pinion (smaller) bearing into it’s seat first, while wiggling

that gear set align the drive shaft bearing and wiggle

it into it’s seat. When both are seated continue to

next step.

6. With the gear box still positoned with the open cover

side up, fill the gear box with six (6) ounces (U.S.)

(175cc’s) of good quality worm gear oil (Specifica-

tion - SAE 90 weight - AGMA#5 - EP Compounded).

When pouring the gear oil, wet the gears and bearings with the oil.

7. Wet with gear oil and place the large wave washer

on the end of the drive shaft bearing and the small

wave washer on the end of the gear and pinion bearing.

8. Clean the mating surfaces of the side cover and the

gear box and check that the cover dow guide pins

are properly installed in the cover.

9. On older model gear boxes apply sealant to the

cover mating surface on the gear box. On newer

model gear boxes insert the rubber seal into the

groove in the cover.

10. Using the cover dow guide pins, place the cover

onto the gear box housing.

11. Secure using the four (4) hex cap screws, torque

screws evenly to 90 in. lbs.

12. Install the drive motor back onto the machine.

N

PINI

GEAR

SPACER

PINION GEAR KEY

42mm x 25mm x 12mm

BEARING

DRIVE SHAFT

SIDE PROFILE

42mm x 20mm x 14mm

BEARIN

Figure 2-10. Drive Shaft Assembly.

2-12 – JLG Lift – 3120728

Loading...

Loading...