Service and Maintenance Manual

Models

X17JP - X500AJ

X20JP - X600AJ

P/N - 3121623

October 21, 2013

TABLE OF CONTENTS

SECTION NO. TITLE PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B Hydraulic System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

SECTION 1 - SPECIFICATIONS

1.1 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 Power source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

HONDA ENGINE IGX440 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

HATZ ENGINE 1B40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

PERKINS ENGINE 402D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4 Specifications and Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.5 Function speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6 Pressure setting PSI (BAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.7 Major components weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.8 Lubrification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.9 Serial number location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

SECTION 2 - GENERAL

2.1 Machine Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Delivery Inspection and Frequent Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Annual Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Service and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety and Workmanship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Components Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Component Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Pressure-Fit Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bolt Usage and Torque Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic Lines and Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Lubrication and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Lubrication and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Changing Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Cylinder Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Cylinder Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Pins and Composite Bearing Repair Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.6 Welding on JLG Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Do the Following When Welding on JLG Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Do NOT Do the Following When Welding on JLG Equipment . . . . . . . . . . . . . . . . . . . . . . . 2-5

3121448 – JLG Lift – i

TABLE OF CONTENTS

SECTION NO. TITLE PAGE NO.

SECTION 3 - CHASSIS & TURNTABLE

3.1 RUBBER TRACK MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Checking track tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operations for loosening/tightening the track. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Checking The Rubber Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Replacing The Rubber Tracks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing the rubber track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Checking tightness of nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2 UNDERCARRIGE COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Replacement roller lower wheel and tracks adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Replacement sprocket and gear motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3 AXLE EXTENSION REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.4 TRACK DRIVE - BONFIGLIOLI (2T700C2K032002) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.5 SWING DRIVE (IMO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.6 HONDA ENGINE IGX440 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3.7 HATZ ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-69

3.8 PERKINS ENGINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-97

3.9 ENGINE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-127

3.11 CHANGING THE ELECTRIC MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-128

SECTION 4 - BOOM & PLATFORM

4.1 BOOM MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removal of the Boom Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Disassembly of the Main Boom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Assembly of the Main Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Installation of the Boom Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2 BOOM DISASSEMBLY X20JP - X600AJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Checking wear and deformation of ropes and pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Three month inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.4 ROPES TENSION ADJUSTMENT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.5 ROTARY ACTUATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.6 PLATFORM REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.7 LOAD CELL AND FOOTSWITCH REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

SECTION 5 - HYDRAULICS

5.1 CYLINDER REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 REPLACEMENT HYDRAULIC PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

5.3 FUNCTION PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

5.4 HYDRAULIC COMPONENT START-UP PROCEDURES AND RECOMMENDATIONS. . . . . . . . . .5-33

5.5 PRESSURE SETTING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

SECTION 6 - JLG CONTROL SYSTEM

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 PLATFORM/REMOTE CONTROL STATION LCD DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3 CANBUS COMMUNICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

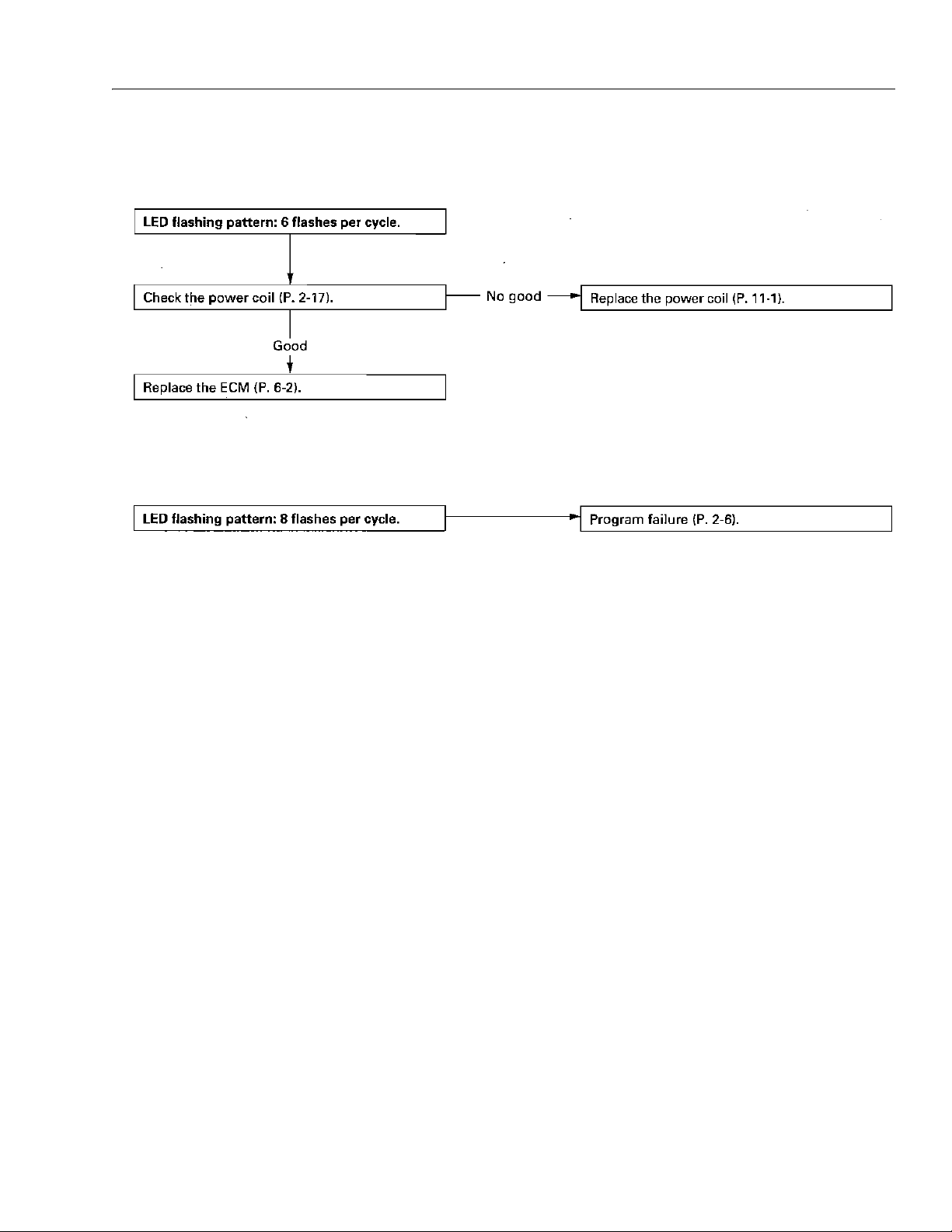

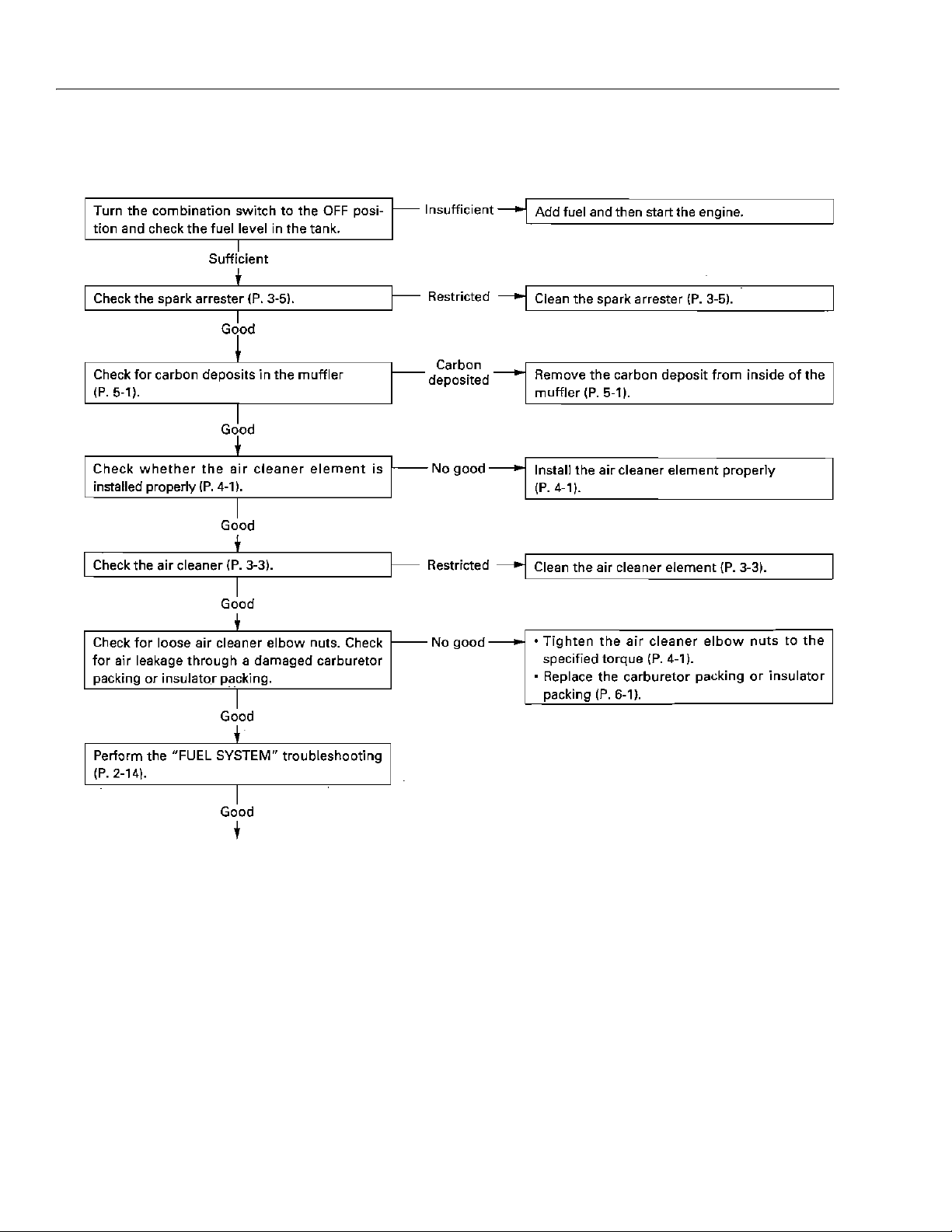

Can-Bus diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Module flashing code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.4 CALIBRATION REQUIREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

6.5 PLATFORM REMOTE CONTROL SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.6 MENU INPUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

6.7 LANGUAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

6.8 MENU ERRORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

6.9 RAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-44

ii – JLG Lift – 3121448

TABLE OF CONTENTS

SECTION NO. TITLE PAGE NO.

6.10 CURRENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-46

6.11 WORKING HOURS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

6.12 MACHINE SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-52

6.13 JOYSTICK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-69

6.14 CALIBRATING JOYSTICK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-70

6.15 LITHIUM SYSTEM FAULT CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-71

SECTION 7 - BASIC ELECTRICAL INFORMATION & SCHEMATICS

7.1 DESCRIPTION FOR MODELS X17JP/X500AJ - X600AJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 HOW TO READ THE WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.3 A - PHOTOCELLS - SAFETY EXCLUSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.4 B - SLEW PROXIMITY - 1° ARM SWITCH - STABILIZERS PRESSURE SENSOR . . . . . . . . . . . . .7-4

7.5 C - OUTRIGGERS SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.6 D - CAN NETWORK - CYLINDERS POSITION SENSORS - MODEM. . . . . . . . . . . . . . . . . . . . . . .7-6

7.7 E - ROPES SWITCH - JIB POSITION SWITCH - PEDAL - LOAD CELL . . . . . . . . . . . . . . . . . . . . . 7-7

7.8 F - GROUND POSITION CONTROL BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.9 G - AERIAL SAFETY LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

7.10 H - EMERGENCY DESCEND ELECTRO VALVES - WIDENING CYLINDER SENSOR

OPTIONAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

7.11 I - GROUND PART: TRACKS - UNDERCARRIAGE WIDENING - 2° SPEED - PROPORTIONAL

ELECTRO VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

7.12 J - GROUND PART: OUTRIGGERS - ELECTRIC DIVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

7.13 K - AERIAL PART: BASKET LEVELLING - BASKET ROTATION - JIB - PROPORTIONAL

ELECTRO VALVE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.14 L - AERIAL PART: 1° CYLINDER - 2° CYLINDER - EXTENSION - ROTATION. . . . . . . . . . . . . . . . .7-14

7.15 M - ENGINE DIESEL VERSIONS: RPM REGULATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

7.16 N - ENGINE DIESEL PERKINS 2 CYLINDERS: SENSOR AND ELECTRO STOP . . . . . . . . . . . . .7-16

7.17 O - ENGINE DIESEL PERKINS 2 CYLINDERS: START AND SPARKS. . . . . . . . . . . . . . . . . . . . . .7-17

7.18 P - ENGINE DIESEL HATZ 1 CYLINDER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

7.19 Q - ENGINE GASOLINE HONDA 1 CYLINDER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

7.20 R - 12 VOLT POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

7.21 S - 120/230 VOLT LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21

7.22 T - COMPONENTS LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

7.23 U - COMPONENTS ABBREVIATION MEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

7.26 V - CONNECTORS LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.35 Y - LITHIUM BATTERY SYSTEM 48 VOLT X17JP - X500AJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-35

7.45 Z - LITHIUM BATTERY SYSTEM 72 VOLT X20JP - X600AJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-45

3121448 – JLG Lift – iii

1.1 CAPACITIES

MACHINE TYPE DRIBE HUB DRIVE CAPACITIES

X17JP

X500AJ

X20JP

X600AJ

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

Table 1-1. DRIVE HUB CAPACITIES

BONFIGLIOLI

700C2K I:32 + MAG12 VP

BONFIGLIOLI

7C 00/2 2 K A A 36 G016VP30 LA

Table 1-2. HYDRAULIC & FUEL TANK CAPACITIES

AUTO

2 SPEED

2 SPEED 0,32 L (0,08 gal)

0,4 L (0.10 gal)

MACHINE

X17JP / X500AJ 10,56 gal (40 L) 1.55 gal (5.9 L) 1.3 gal (5 L)

X20JP / X600AJ 10,56 gal (40 L) 1.55 gal (5.9 L) 2.6 gal (10 L)

HYDRAULIC OIL TANK

CAPACITY

GASOLINE DIESEL

FUEL TANK

3121623 – JLG Lift – 1-1

SECTION 1 - SPECIFICATIONS

1.2 TRACKS

Machine

Model

Typ e Part Number

LOW PROFILE BLACK

COLOR

053715L0

Table 1-3. Track Specifications

Rubber Belt Track Undercar-

Dimen-

sions

riage

Drawing

Model

X17JP

X500AJ

X20JP

X600AJ

LOW PROFILE NO

MARKING

LOW PRO-

FILE BLACK

COLOR

053715LB

257215L0

Cm

180X37X

72

Cm

200X48X

66

PT9

PT10

LOW PROFILE NO

MARKING

257215LB

1-2 – JLG Lift – 3121623

MODEL

X17JP-X500AJ

X20JP-X600AJ

1.3 POWER SOURCE

SECTION 1 - SPECIFICATIONS

Table 1-4. Ground bearing pressure

PRESSURES AND REACTIONS TO THE GROUND

ON TRACKS

Maximum ground bearing

pressure

[daN/cm²] - [PSI]

0,67 daN/cm² 9,7 PSI 1731 daN 3892 lbf 2,45 daN/cm² 35.5 PSI

0,64 daN/cm² 9,2 PSI 2150 daN 4833 lbf 3,04 daN/cm² 45 PSI

Maximum ground

bearing pressure

on each pad

[daN] - [lbf]

ON OUTRIGGER

Maximum ground bearing

pressure

[daN/cm²] - [PSI]

Table 1-5. Power configuration

X17JP X20JP

Gasoline Engine Honda iGX440

15 hp (11.1 kW)

Diesel Engine Hatz 1B40

10 hp (7.46 kW)

Electric Motor 90Ah 48V Lithium-Ion 90Ah 70V Lithium-Ion

AC Electric Motor 110V 50 Hz (2,2 KW)

120V 60 Hz (1.2 kW)

230V 50 Hz (2.2 kW)

230V 60 Hz (2.2 kW)

NOTE: RPM Tolerances are ± 50.

Perkins 402.05

14 hp (10.44 Kw)

3121623 – JLG Lift – 1-3

SECTION 1 - SPECIFICATIONS

HONDA ENGINE iGX440

Table 1-6. SPECIFICATIONS HONDA ENGINE iGX440

Model iGX440U

Description code GCAWK

Type 4-stroke, overhead camshaft, single cylinder, inclined by 15°

Displacement

Bore x stroke 88.0 x 72.1 mm (3.46 x 2.84 in)

Maximum horsepower

Recommended maximum operation bhp

Maximum torque

11.2 kW (15.2 HP) / 3,600 min

8.0 kW (10.8 HP) / 3,600 min

29.8 N·m (3.0 kgf·m, 22 lbf·ft)/2,500 min

Compression ratio 8.1 : 1

Minimum fuel consumption 328 g/kW·h (241 g/HP·h, 0.53 lb/HP·h)

Ignition system CDI

Ignition timing (at no load)

10° B.T.D.C./1,400 min

13° B.T.D.C./3,600 min

Spark plug BKR7E-E (NGK), K22PR-UR (DENSO)

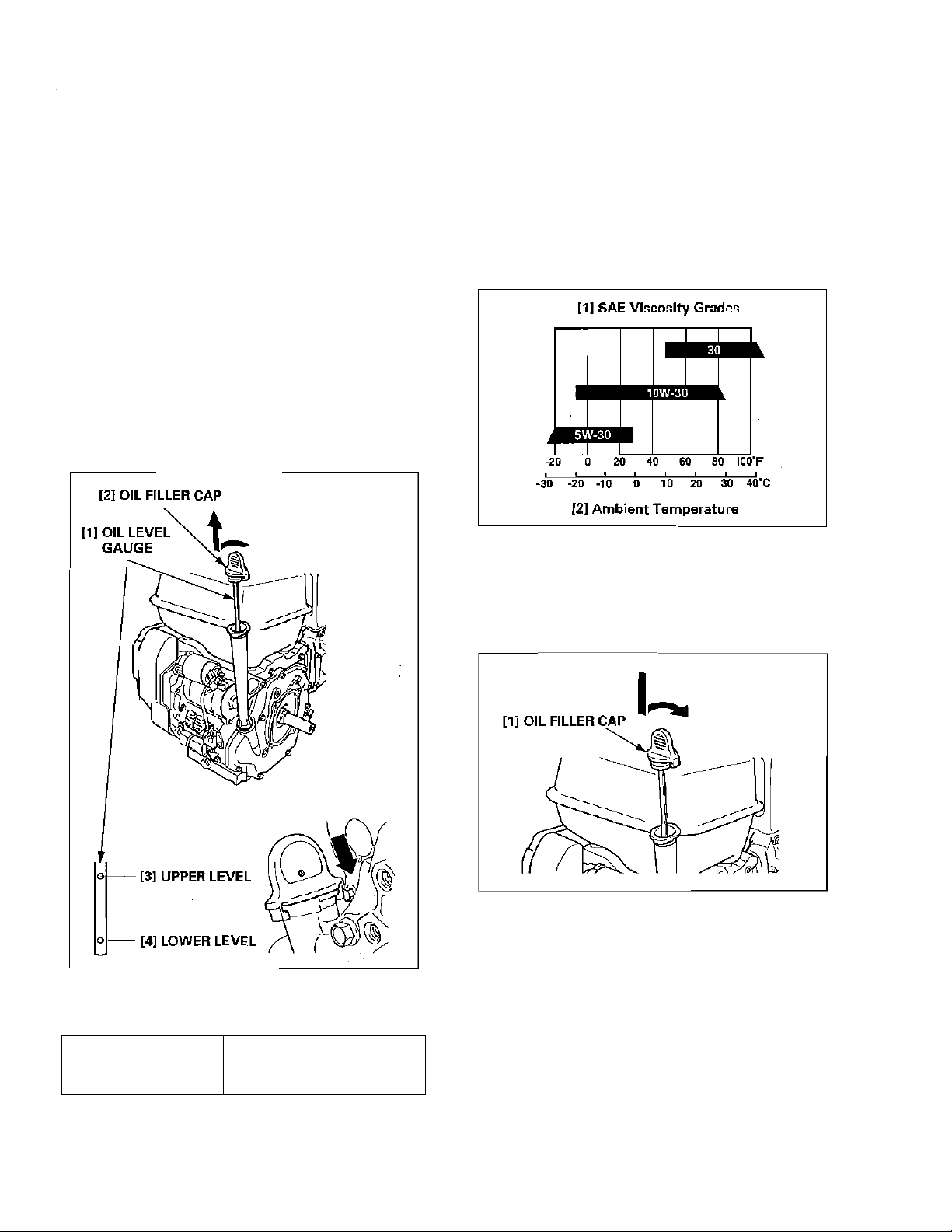

Lubrication system Forced splash type

Oil capacity 1.10 l (1.16 US qt, 0.97 lmp qt)

Cooling system Forced air

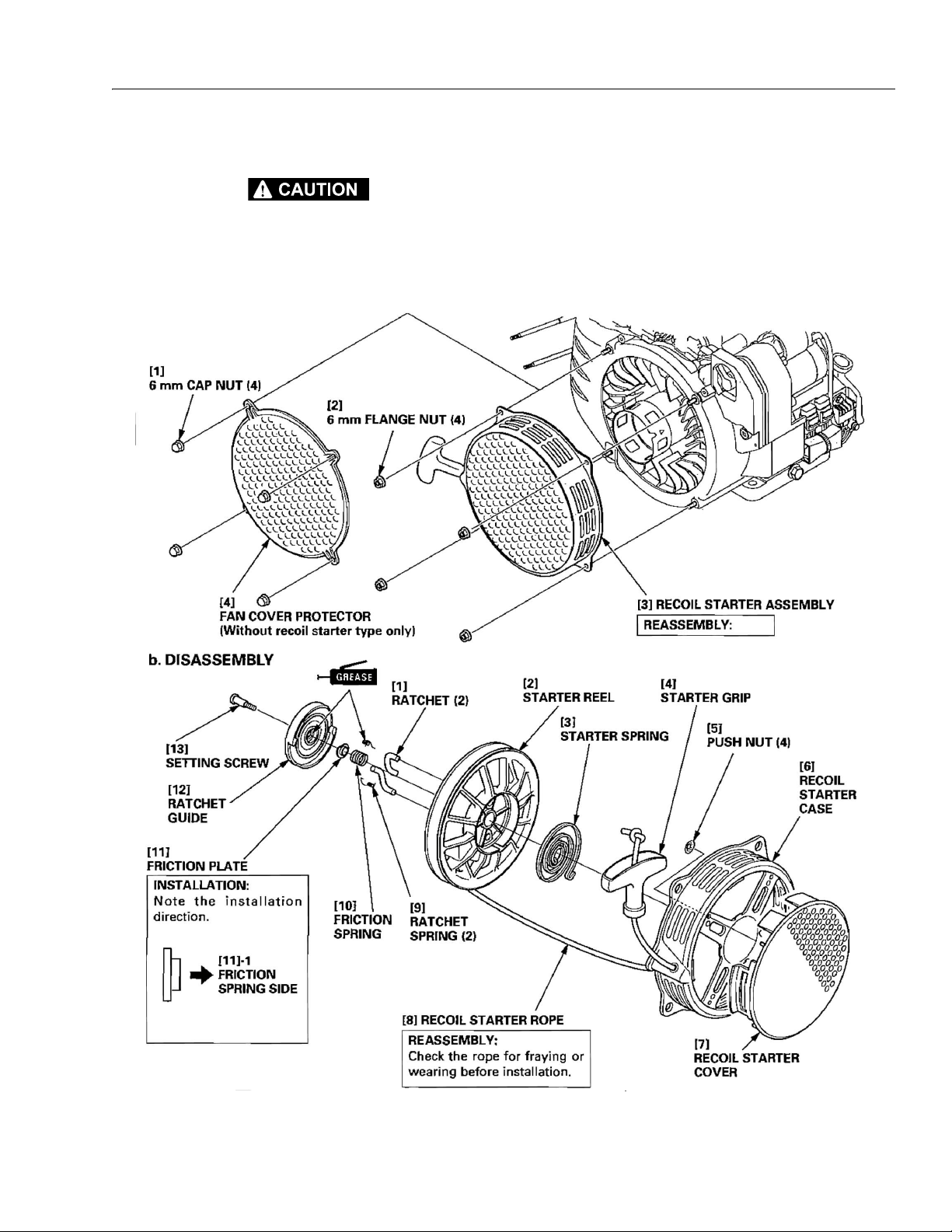

Starting system Recoil and starter motor

Stopping system Ignition primary circuit open

Carburetor Horizontal type batter fly valve

Air cleaner Dual element type

Governor STR (Self Tuning Regulator) governor

Fuel used Unleaded gasoline with a pump octane rating 86 or higher

438 cm

3

(26.7cu-in)

-1

-1

-1

(rpm)

-1

(rpm)

(rpm)

(rpm)

-1

(rpm)

1-4 – JLG Lift – 3121623

SECTION 1 - SPECIFICATIONS

HATZ ENGINE 1B40

Table 1-7. SPECIFICATIONS HATZ ENGINE 1B40

Typ e 1B40

Design Air-cooled four-stroke diesel engine

Combustion system Direct injection

Number of cylinders 1

Bore / stroke 88 / 76 mm

Displacement

Lubricating oil capacity without oil sump with oil

sump

Difference between “max” and “min” levels without

oil sump with oil sump

1.5

3.2

0.8

2.2

Lubricating oil consumption (after running in) 1% of fuel consumption at full load max.)

Lubricating oil pressure (oil temperature 100 °C) 2.5 bars at 3000 r.p.m. (approx.)

Direction of rotation, power take-off end anti-clockwise

Valve clearance 10 - 30 °C

Inlet and exhaust valve

Max. tilt angle in operation, in direction

Weight (incl. fuel tank, air-cleaner, exhaust silencer,

Flywheel 25° down

or automatically

55 kg approx.

recoil starter and electric starter)

Battery capacity max. 12 V / 60 Amp/h

3

462 cm

1)

l, approx.

1)

l, approx.

1)

l, approx.

1)

l, approx.

0.10 mm

2)

3)

all other directions 35°

3)

PERKINS ENGINE 402D

Table 1-8. SPECIFICATIONS PERKINS ENGINE 402D

Ty pe

Maximum Operating Speed (rpm)

Cylinders and Arrangement

Bore 67 mm (2.64 inch)

Stroke 72 mm (2.83 inch)

Displacement 0.507 L (30.939 in3)

Aspiration

Compression Ratio 23.5:1

Firing Order 1-2

Rotation that is viewed from the flywheel

Valve Lash Setting (Inlet) 0.20 mm (0.008 inch)

Valve Lash Setting (Exhaust)

Injection Indirect

402D-05 Engine

3600 rpm

In-Line two cylinder

(1)

NA

Counterclockwise

0.20 mm (0.008 inch)

3121623 – JLG Lift – 1-5

SECTION 1 - SPECIFICATIONS

1.4 SPECIFICATIONS AND PERFORMANCE DATA

Reach Specifications

Table 1-9. Reach Specifications

Max working Height

(inclusive operator)

Max Height (basket floor) 14,96 m 18,05 m 49' 06" 59' 19"

Horizontal Outreach 7 m 9.20 m 22' 95" 30' 17"

Up & Over Height 15'

Swing (non continuous) 360°

Jib - overall length 1,68 m 1,68 m 1,68 m 1,68 m

Gradeability 36,4%

Ground slope limit stabilization 12° 15° 12° 15°

Limit Approach / Depart angles

Dimensional Data

X17JP

CE

16.96 m 20.05 m NA NA

(7.80 m)

Table 1-10. SPECIFICATIONS PERKINS ENGINE 402D

X20JP

CE

18'.01"

(8.20 m)

X500AJ

ANSI

(7.80 m)

Front 20° /

Rear 20°

15'

X600AJ

ANSI

18'.01"

(8.20 m)

X17JP/

X500AJ

P la tf or m siz e (s ta nd ar d 2 p er so ns ) 0.69 m x 1.34 m

Pla t fo r m siz e (n a r ro w o ne p e rso n ) 0.62 m x 0.79 m

Stowed width (with std. 2P platform) 1,34 m

Stowed width (without platform) 0.80 m

Stowed height (on tracks) 2 m 1.99 m

Stowed length (on tracks) 4.53 m 5 m

O ut ri gg er f oo tp rin t 2.89 m x 2,88 m 2.92 m x 2.93 m

Gross machine weight:

Gasoline

Diesel

Lithium battery

1-6 – JLG Lift – 3121623

2230 Kg

2230 Kg

2300 Kg

X20JP/

X600AJ

2840 Kg

2880 Kg

2990 Kg

1.5 FUNCTION SPEEDS

SECTION 1 - SPECIFICATIONS

Table 1-11. Functions speed (in seconds)

FUNCTIONS SPEED RANGE

FUN CT IO N TIM E S ec

X 17 JP

X500AJ

TELESCOPE EXTEND 15" - 20" 21" - 28"

TELESCOPE RETRACT 16" - 22" 16" - 20"

TOWER BOOM UP 21" - 24" 30" - 35"

TOWER BOOM DOWN 19" - 22" 30" - 35"

UPPER BOOM UP 25" - 29" 35" - 40"

UPPER BOOM DOWN 24" - 30" 35" - 40"

BASKET ROTATE RIGTH 7" - 10" 7" - 10"

BASKET ROTATE LEFT 7" - 10" 7" - 10"

SWING LEFT 40" - 45" 45" - 50"

SWING RIGTH 40" - 45" 45" - 50"

JIB UP 7" - 10" 7" - 10"

JIB DOWN 7" - 10" 7" - 10"

BASKET LEVEL UP 40" - 58" 33" - 55"

BASKET LEVEL DOWN 35" - 52" 37" - 50"

DRIVE SPEED TO BE

COMPLETED

TIM E S ec

X20JP

X600AJ

TO BE

COMPLETED

Machine Orientation When Doing Speed Tests

Lift: Boom Retracted. Telescope Retracted. Lift Up,

Record Time, Lift Down, Record Time.

Swing: Machine stabilized, upper Boom at Full Elevation.

Telescope Retracted. Swing the Turntable to the end stop.

Swing the Opposite Direction, Record Time.

Te l es c o pe : Boom at Full Elevation; Telescope Retracted;

Telescope Out, Record Time. Telescope In, Record Time.

Drive: Test to be done on a smooth level surface. Drive

Select Switch should be set at 2WD High Engine. Start

approximately 25 ft. (7.62 m) from starting point so that

the unit is at maximum speed when starting the test.

Platform Rotate: Platform level and completely rotated

one direction. Rotate the opposite direction, Record Time.

Rotate the other direction, Record Time.

Articulating Jib: Platform level and centered with the

boom. Start with the Jib down. Jib Up, Record Time. Jib

Down, Record Time.

Lower Lift: Upper Boom horizontal. Telescoped In. Lower

Lift Up, Record Time. Lower Lift Down, Record Time.

TE S T N OT E S

1. Stop watch should be started with the function, not

with the controller or switch.

2. All speed tests are run from ground with remote control connected on the basket.

3. Function speeds may vary due to cold, thick hydraulic oil. Test should be run with the oil temperature

above 100° F (38° C).

3121623 – JLG Lift – 1-7

SECTION 1 - SPECIFICATIONS

1.6 PRESSURE SETTINGS - PSI (BAR)

Table 1-12. Pressure settings

UNDERCARRIAGE

Model

X14JP-X500 AJ

X20JP-X600AJ

Table 1-13. Pressure settings

Model Automatic reductions drive speed

X17JP - X500AJ

X20JP - X600AJ

Left and Right

Control Valve

Bar PSI Bar PSI

165 2393 185 2045

Bar PSI

26 380

NA NA

TOWER

Control Valve

1-8 – JLG Lift – 3121623

1.7 MAJOR COMPONENT WEIGHTS

SECTION 1 - SPECIFICATIONS

Table 1-14. Weight components

3121623 – JLG Lift – 1-9

SECTION 1 - SPECIFICATIONS

1.8 LUBRICATION

Figure 1-1.

1-10 – JLG Lift – 3121623

Table 1-15.

SECTION 1 - SPECIFICATIONS

* Readily biodegradable classification indicates one of the

following: CO2 Conversion > 60% per EPA 560/6-82-003 /

CO2 Conversion > 80% per CEC-L-33-A-93

** Virtually Non-toxic classification indicates an LC50 >

5000 per OECD 203

*** Fire Resistant classification indicates Factory Mutual

Research Corp. (FMRC) Approval

Flash point (C.O.C) for 68-46-32-22: 210°C

3121623 – JLG Lift – 1-11

SECTION 1 - SPECIFICATIONS

1.9 SERIAL NUMBER LOCATION

A serial number plate is affixed on to the frame a frame.

The following illustration showing the position.

Figure 1-2. Plate

SER IAL NU M BER

PLA T E L OC AT I ON

1-12 – JLG Lift – 3121623

NOTES:

SECTION 1 - SPECIFICATIONS

3121623 – JLG Lift – 1-13

SECTION 2. GENERAL

SECTION 2 - GENERAL

2.1 MACHINE PREPARATION, INSPECTION, AND MAINTENANCE

General

This section provides the necessary information needed

by those personnel that are responsible to place the

machine in operation readiness and maintain its safe

operating condition. For maximum service life and safe

operation, ensure that all the necessary inspections and

maintenance have been completed before placing the

machine into service.

Preparation, Inspection, and Maintenance

It is important to establish and conform to a comprehensive inspection and preventive maintenance program. The

following table outlines the periodic machine inspections

and maintenance recommended by JLG Industries, Inc.

Consult your national, regional, or local regulations for further requirements for aerial work platforms. The frequency

of inspections and maintenance must be increased as

environment, severity and frequency of usage requires.

Pre-Start Inspection

It is the User’s or Operator’s primary responsibility to perform a Pre-Start Inspection of the machine prior to use

daily or at each change of operator. Reference the Operator’s and Safety Manual for completion procedures for the

Pre-Start Inspection. The Operator and Safety Manual

must be read in its entirety and understood prior to performing the Pre-Start Inspection.

Pre-Delivery Inspection and Frequent Inspection

The Pre-Delivery Inspection and Frequent Inspection shall

be performed by a qualified JLG equipment mechanic.

JLG Industries, Inc. recognizes a qualified JLG equipment

mechanic as a person who, by possession of a recognized degree, certificate, extensive knowledge, training, or

experience, has successfully demonstrated the ability and

proficiency to service, repair, and maintain the subject

JLG product model.

The Pre-Delivery Inspection and Frequent Inspection procedures are performed in the same manner, but at different times. The Pre-Delivery Inspection shall be performed

prior to each sale, lease, or rental delivery. The Frequent

Inspection shall be accomplished for each machine in service for 3 months or 150 hours (whichever comes first);

out of service for a period of more than 3 months; or when

purchased used. The frequency of this inspection must be

increased as environment, severity and frequency of

usage requires.

Reference the JLG Pre-Delivery and Frequent Inspection

Form and the Inspection and Preventative Maintenance

Schedule for items requiring inspection during the performance of these inspections. Reference the appropriate

areas of this manual for servicing and maintenance procedures.

Annual Machine Inspection

The Annual Machine Inspection must be performed by a

Factory-Certified Service Technician on an annual basis,

no later than thirteen (13) months from the date of the

prior Annual Machine Inspection. JLG Industries, Inc. recognizes a Factory-Certified Service Technician as a person who has successfully completed the JLG Service

Training School for the subject JLG product model. Reference the machine Service and Maintenance Manual and

appropriate JLG inspection form for performance of this

inspection.

Reference the JLG Annual Machine Inspection Form and

the Inspection and Preventative Maintenance Schedule for

items requiring inspection during the performance of this

inspection. Reference the appropriate areas of this manual for servicing and maintenance procedures.

For the purpose of receiving safety-related bulletins, it is

important that JLG Industries, Inc. has updated ownership

information for each machine. When performing each

Annual Machine Inspection, notify JLG Industries, Inc. of

the current machine ownership.

Preventative Maintenance

In conjunction with the specified inspections, maintenance shall be performed by a qualified JLG equipment

mechanic. JLG Industries, Inc. recognizes a qualified JLG

equipment mechanic as a person who, by possession of a

recognized degree, certificate, extensive knowledge, training, or experience, has successfully demonstrated the

ability and proficiency to service, repair, and maintain the

subject JLG product model.

Reference the Preventative Maintenance Schedule and

the appropriate areas of this manual for servicing and

maintenance procedures. The frequency of service and

maintenance must be increased as environment, severity

and frequency of usage requires.

3121623 – JLG Lift – 2-1

SECTION 2 - GENERAL

Table 2-1. Inspection and Maintenance

Type Frequency

Pre-Start

Inspection

Pre-Delivery

Inspection

Frequent

Inspection

Annual Machine

Inspection

Preventative

Maintenance

Prior to use each day; or

At each Operator change.

Prior to each sale, lease, or

rental delivery.

In service for 3 months or 150 hours,

whichever comes first; or

Out of service for a period of more than

3 months; or

Purchased used.

Annually, no later than 13 months from

the date of the prior inspection.

At intervals as specified in the Service

and Maintenance Manual.

2.2 SERVICE AND GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this book.

Safety and Workmanship

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

Cleanliness

1. The most important single item in preserving the

long service life of a machine is to keep dirt and foreign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals, and filters are provided to

keep air, fuel, and oil supplies clean; however, these

items must be maintained on a scheduled basis in

order to function properly.

Primary

Responsibility

User or Operator User or Operator Operator and Safety Man-

Owner, Dealer, or

User

Owner, Dealer, or

User

Owner, Dealer, or

User

Owner, Dealer, or

User

2. At any time when air, fuel, or oil lines are disconnected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or component is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Service

Qualification

Qualified JLG

Mechanic

Qualified JLG

Mechanic

Factory-Certified

Service Techni-

cian

Qualified JLG

Mechanic

Reference

ual

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual and applicable JLG

inspection form.

Service and Maintenance

Manual

Components Removal and Installation

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90 degrees.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc., have been

removed and that no adjacent parts are interfering.

2-2 – JLG Lift – 3121623

SECTION 2 - GENERAL

Component Disassembly and Reassembly

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts

When assembling pressure-fit parts, use an anti-seize or

molybdenum disulfide base compound to lubricate the

mating surface.

Bearings

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored, or burned.

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to install.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be installed on a shaft, apply pressure to the

inner race.

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System

1. Keep the system clean. If evidence of metal or rubber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified intervals. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

Battery

Clean battery, using a non-metallic brush and a solution of

baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry battery and coat terminals with

an anti corrosion compound.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in the Lubrication Chart in Section 1.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat-treated bolts, studs, and steel nuts, in accordance with recommended shop practices. (See

Torque Chart Section 1.)

3121623 – JLG Lift – 2-3

2.3 LUBRICATION AND INFORMATION

Hydraulic System

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g., using inadequate hydraulic oil, allowing

moisture, grease, filings, sealing components, sand,

etc., to enter when performing maintenance, or by

permitting the pump to cavitate due to insufficient

system warm-up or leaks in the pump supply (suction) lines.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced as necessary, at the speci-

SECTION 2 - GENERAL

fied intervals required in the Lubrication Chart in

Section 1. Always examine filters for evidence of

metal particles.

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or corrosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

Hydraulic Oil

Refer to Section 1 for recommendations for viscosity

ranges.

Changing Hydraulic Oil

1. Filter elements must be changed after the first 50

hours of operation and every 300 hours (unless

specified otherwise) thereafter. If it is necessary to

change the oil, use only those oils meeting or

exceeding the specifications appearing in this manual. If unable to obtain the same type of oil supplied

with the machine, consult local supplier for assistance in selecting the proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG

Industries recommends changing the hydraulic oil

annually.

2. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contaminants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

Lubrication Specifications

Specified lubricants, as recommended by the component

manufacturers, are always the best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose grease requirements.

Should any question arise, regarding the use of greases in

maintenance stock, consult your local supplier for evaluation. Refer to Section 1 for an explanation of the lubricant

key designations appearing in the Lubrication Chart.

2.4 CYLINDER DRIFT TEST

Maximum acceptable cylinder drift is to be measured

using the following methods.

Cylinder Drift

Table 2-2. Cylinder Drift

CYLINDER BORE

DIAMETER

inches mm inches mm

2,17 55 0.020 0.53

2.36 60 0.021 0.54

2,56 65 0.029 0.74

2,95 75 0.013 0.35

3,15 80 0.011 0.29

3,94 100 0.007 0.20

4.52 115 0.005 0.15

Drift is to be measured at the cylinder rod with a calibrated

dial indicator. The cylinder oil must be at ambient temperature and temperature stabilized.

The cylinder must have the normal load, which is the normal platform load applied.

If the cylinder passes this test, it is acceptable.

MAX ACCEPTABLE DRIF

IN 1 MINUTES

3. While the unit is shut down, a good preventive main-

tenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

2-4 – JLG Lift – 3121623

SECTION 2 - GENERAL

2.5 PINS AND COMPOSITE BEARING REPAIR GUIDELINES

Filament wound bearings.

1. Pinned joints should be disassembled and

inspected if the following occurs:

a. Excessive sloppiness in joints.

b. Noise originating from the joint during operation.

2. Filament wound bearings should be replaced if any

of the following is observed:

a. Frayed or separated fibers on the liner surface.

b. Cracked or damaged liner backing.

c. Bearings that have moved or spun in their hous-

ing.

d. Debris embedded in liner surface.

3. Pins should be replaced if any of the following is

observed (pin should be properly cleaned prior to

inspection):

a. Detectable wear in the bearing area.

b. Flaking, pealing, scoring, or scratches on the pin

surface.

c. Rusting of the pin in the bearing area.

2.6 WELDING ON JLG EQUIPMENT

NOTE: This instruction applies to repairs, or modifications to the

machine and to welding performed from the machine on

an external structure, or component,

Do the Following When Welding on JLG Equipment

• Disconnect the battery.

• Disconnect the moment pin connection (where fitted)

• Ground only to structure being welded.

Do NOT Do the Following When Welding on JLG Equipment

• Ground on frame and weld on any other area than the

chassis.

• Ground on turntable and weld on any other area than

the turntable.

• Ground on the platform/support and weld on any other

area than the platform/support.

• Ground on a specific boom section and weld on any

other area than that specific boom section.

• Allow pins, wear pads, wire ropes, bearings, gearing,

seals, valves, electrical wiring, or hoses to be between

the grounding position and the welded area.

4. Re-assembly of pinned joints using filament wound

bearings.

a. Housing should be blown out to remove all dirt

and debris...bearings and bearing housings

must be free of all contamination.

b. Bearing / pins should be cleaned with a solvent

to remove all grease and oil...filament wound

bearing are a dry joint and should not be lubricated unless otherwise instructed (i.e. sheave

pins).

c. Pins should be inspected to ensure it is free of

burrs, nicks, and scratches which would damage the bearing during installation and operation.

FAILURE TO COMPLY WITH THE ABOVE REQUIREMENTS MAY

RESULT IN COMPONENT DAMAGE (I.E. ELECTRONIC MODULES,

SWING BEARING, COLLECTOR RING, BOOM WIRE ROPES ETC.)

3121623 – JLG Lift – 2-5

SECTION 2 - GENERAL

NOTES:

2-6 – JLG Lift – 3121623

SECTION 3 - CHASSIS & TURNTABLE

A

SECTION 3. CHASSIS & TURNTABLE

3.1 RUBBER TRACK MAINTENANCE

Checking track tension

Stop the machine on firm, level surface. Lift the machine into

safe conditions and place stable supports under the undercarriage frame for total support. Parallel with the central

roller of the under-carriage, measure distance (A) from the

bottom of the roller to the rigid inside of the rubber belt.

Track tension is normal if measurement (A) is between 10

and 15 mm.

If track tension is not within the measurements specified

above, loose or too taught, follow the procedures illustrated

in the paragraph below.

Figure 3-1.

4. When correct track tension has been obtained, turn

valve (1) in a clockwise direction and tighten it.

Clean all traces of grease.

Figure 3-2.

5. To tighten the track, connect a grease gun to

greaser (2) and add grease until belt tension is

within the specified values.

Operations for loosening/tightening the track

The grease contained in the hydraulic track is pressurised.

For this reason, do not loosen the greasing valve (1) by

more than 1 turn; if the valve is loosened too much, it risks

being expelled under the effect of the pressure of the

grease, putting the safety of the operator at risk. Never

loosen greaser (2).

When gravel or mud are blocked between the toothed wheel

and the track links, remove it before loosening.

1. Remove the screws and take of adjustment access

lid 3.

2. To loosen the track, slowly unscrew valve 1 in an

anti-clockwise direction for no more than one turn.

One turn of valve 1 is sufficient to loosen the track.

3. If the grease does not start to drain, turn the track

slowly.

IT IS NOT NORMAL IF THE TRACK REMAINS

TAUGHT AFTER HAVING TURNED VALVE (1) IN AN

ANTI-CLOCKWISE DIRECTION OR IF THE TRACK IS

STILL LOOSE AFTER HAVING PUT GREASE INTO

GREASER (2). NEVER TRY TO REMOVE THE TRACKS

OR DISASSEMBLE THE TRACK-TENSIONED CYLINDER BECAUSE THE GREASE PRESSURE INSIDE THE

TRACK IS VERY DANGEROUS.

3121623 – JLG Lift – 3-1

SECTION 3 - CHASSIS & TURNTABLE

PATTERN

WHEEL SIDE

SPROCKET

HOLE

METAL CORE

STEEL WIRE

g

WORN PARTS

CRACK

Checking The Rubber Tracks

Figure 3-3. Rubber Track Structure

The structure of the rubber track is illustrated in Figure 3-3.

The steel ropes and the metal core are imbedded into the

rubber. The carved profiles are used to give traction when

moving over loose land. They are situated in the lower part

resting on the ground, while the wheel guides situated inside

the track, prevent the track from escaping from the guide

rollers.

CAUSES OF DAMAGE

1. Breakage of the steel ropes

Excessive tension causes the steel ropes to break in

the following conditions:

a. when stones or foreign bodies accumulate

between the track and the under-carriage

frame;

b. when the track escapes from its guide;

c. in the case of strong friction such as rapid

direction changes.

2. Wear and breakage of the metal cores

As for breakage of the steel ropes, stated above,

excessive tension may cause the metal cores to

bend or break, as may the following causes:

a. incorrect contact between toothed wheel and

track;

b. breakage of internal rollers;

c. functioning on sandy land.

3. Separation of the metal cores

Figure 3-4.

a. The metal core acts as a type of adhesive of

the rubber between the core itself and the

steel ropes. Separation may be caused by

excessive tension as breakage of the ropes

for the following reasons:

b. The metal cores have been wound by the

worn toothed wheel as indicated in the figure.

When this wear and abrasion is detected, the

toothed wheel must be replaced as soon as

possible.

c. If it breaks, as stated in item 2, "Wear and

breakage of the metal cores", the track must

be replaced because this damage leads to a

complete loss of functions.

4. Abrasion and fatigue cracks

a. The cracks at the base of the carved profile

occur due to bending fatigue of the rubber

caused by the toothed wheel and the tracktensioning wheel.

b. The cracks and bends on the edge of the rub-

ber are due to manoeuvres with the track in

presence of cement kerbs and edges.

Figure 3-5.

c. The cracks and abrasions in the rubber on the

tracks of the roller guide originate from fatigue

from the compression of the rubber by the

weight of the wheel, together with functioning

on sandy land, or repeated and abrupt

changes of direction.

d. Abrasion of the carved profiles may occur

especially if slewing on concrete surfaces or

on gravel or hard surfaces are carried out.

e. The damage indicated in paragraphs a, b,

and c above, must not be considered fatal for

the track and, even if in presence of gradual

3-2 – JLG Lift – 3121623

SECTION 3 - CHASSIS & TURNTABLE

4

5

6

5

20

2

0

2

B

H

1

9

and progressive damage, they allow the track

to continue working. The development of the

damage indicated in point 3 leads to the

exposure of the metal cores and if they are

exposed for more than half of the track circumference, it means that it is time to replace

them. It can however still be used.

5. Cracks due to external factors

Cracks on external track surfaces (those in contact

with the ground) are often due to contact with

gravel, sharp stones, sharp materials, nails, glass,

which cause cuts. From the rubber properties point

of view, this is inevitable although it does depend on

service conditions. Cracks on the internal surface of

the circumference and on the edge of the rubber

originate from contact of the belt with the structure

of the undercarriage or with sharp concrete edges.

The increase in cracks is relatively small. Even if it

does not appear to be in good condition the track

can be used in heavy duty conditions.

Replacing The Rubber Tracks

THE GREASE CONTAINED IN THE HYDRAULIC

TRACK IS PRESSURISED. FOR THIS REASON, DO NOT

LOOSEN THE GREASING VALVE (1) BY MORE THAN 1

TURN; IF THE VALVE IS LOOSENED TOO MUCH, IT

RISKS BEING EXPELLED UNDER THE EFFECT OF

THE PRESSURE OF THE GREASE, PUTTING THE

SAFETY OF THE OPERATOR AT RISK. NEVER

LOOSEN GREASER (2).

4. If the grease does not start to drain, turn the track

slowly.

5. Insert three steel pipes (4) inside the track in the

space between the rollers. Turn the driving wheel

backwards (5) in a way that the steel pipes proceed

with the track and engage on the track-tensioning

wheel. Apply force (6) laterally to allow the track to

run and lift it from the track-tensioning wheel.

Figure 3-7.

Installing The Rubber Track

ENSURE SAFE CONDITIONS WITH THE MACHINE

LIFTED TO PROCEED WITH MOUNTING THE

TRACKS.

When gravel or mud are blocked between the toothed wheel

and the track links, remove it before loosening.

Removing The Rubber Track

1. Check that the grease contained in the hydraulic cyl-

inder has been removed.

2. Engage the track links with the toothed wheel and

1. Stop the machine on solid, level land, lift it and sup-

port it in safe conditions, using the outriggers.

position the other end of the track on the track-tensioning wheel.

3. Turn the driving wheel in reverse (7) pushing the

track plate inside the frame (8).

4. Position the track using a steel pipe and turn the

driving wheel again.

5. Ensure that the track links are correctly engaged in

the toothed wheel and in the track-tensioning wheel.

Figure 3-6.

2. Remove the screws and take of adjustment access

6. Adjust track tension (see paragraph -Operations for

loosening/tightening the track).

7. Rest the tracked under-carriage on the ground.

lid 3.

3. To loosen the track, slowly unscrew valve 1 in an

anti-clockwise direction for no more than one turn.

One turn of valve 1 is sufficient to loosen the track.

3121623 – JLG Lift – 3-3

SECTION 3 - CHASSIS & TURNTABLE

8

7

52

0

20

2

B

H1

9

Figure 3-8.

Checking tightness of nuts and bolts

Depending on the use of the platform, it is indispensable to

check the parts and the nuts and bolts in general, which are

subject to loosening.

Pay particular attention to the frame components, such as

track-tensioning wheels, traversing geared motors, driving

wheels and guide rollers. Check that they are tightened sufficiently as indicated in the following table.

The values indicated are to be applied unless otherwise

stated in this manual.

3-4 – JLG Lift – 3121623

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load

See Note 4

Clamp Load

See Note 4

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m] LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0,1120 0,00604

48 0,1120 0,00661

6 32 0,1380 0,00909

40 0,1380 0,01015

8 32 0,1640 0,01400

36 0,1640 0,01474

10 24 0,1900 0,01750

32 0,1900 0,02000

1/4 20 0,2500 0,0318 2860 122 14 114 13 2860 143 16 129 15

28 0,2500 0,0364 3280 139 16 131 15 3280 164 19 148 17

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m] LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0,3125 0,0524 4720 20 25 20 25 20 25 4720 25 35 20 25 20 25

24 0,3125 0,0580 5220 25 35 20 25 20 25 5220 25 35 25 35 20 25

3/8 16 0,3750 0,0775 7000 35 50 35 50 35 50 7000 45 60 40 55 35 50

24 0,3750 0,0878 7900 40 55 40 55 35 50 7900 50 70 45 60 35 50

7/16 14 0,4375 0,1063 9550 60 80 55 75 50 70 9550 70 95 65 90 50 70

20 0,4375 0,1187 10700 65 90 60 80 60 80 10700 80 110 70 95 60 80

1/2 13 0,5000 0,1419 12750 90 120 85 115 80 110 12750 105 145 95 130 80 110

20 0,5000 0,1599 14400 100 135 95 130 90 120 14400 120 165 110 150 90 120

9/16 12 0,5625 0,1820 16400 130 175 125 170 115 155 16400 155 210 140 190 115 155

18 0,5625 0,2030 18250 145 195 135 185 130 175 18250 170 230 155 210 130 175

5/8 11 0,6250 0,2260 20350 180 245 170 230 160 220 20350 210 285 190 260 160 220

18 0,6250 0,2560 23000 205 280 190 260 180 245 23000 240 325 215 290 180 245

3/4 10 0,7500 0,3340 30100 320 435 300 280 380 30100 375 510 340 460 280 380

16 0,7500 0,3730 33600 355 485 335 455 315 430 33600 420 570 380 515 315 430

7/8 9 0,8750 0,4620 41600 515 700 485 660 455 620 41600 605 825 545 740 455 620

14 0,8750 0,5090 45800 570 775 535 730 500 680 45800 670 910 600 815 500 680

1 8 1,0000 0,6060 51500 730 995 685 930 645 875 51500 860 1170 775 1055 645 875

12 1,0000 0,6630 59700 845 1150 795 1080 745 1015 59700 995 1355 895 1215 745 1015

1 1/8 7 1,1250 0,7630 68700 1095 1490 1030 1400 965 1310 68700 1290 1755 1160 1580 965 1310

12 1,1250 0,8560 77000 1225 1665 1155 1570 1085 1475 77000 1445 1965 1300 1770 1085 1475

1 1/4 7 1,2500 0,9690 87200 1545 2100 1455 1980 1365 1855 87200 1815 2470 1635 2225 1365 1855

12 1,2500 1,0730 96600 1710 2325 1610 2190 1510 2055 96600 2015 2740 1810 2460 1510 2055

1 3/8 6 1,3750 1,1550 104000 2025 2755 1905 2590 1785 2430 104000 2385 3245 2145 2915 1785 2430

12 1,3750 1,3150 118100 2300 3130 2165 2945 2030 2760 118100 2705 3680 2435 3310 2030 2760

1 1/2 6 1,5000 1,4050 126500 2690 3660 2530 3440 2370 3225 126500 3165 4305 2845 3870 2370 3225

12 1,5000 1,5800 142200 3020 4105 2845 3870 2665 3625 142200 3555 4835 3200 4350 2665 3625

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT REPRESENT FULL STRENGTH CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED, ADDITIONAL TESTING IS REQUIRED.

SOCKET HEAD CAP SCREWS

Torque

(Dry)

K = .20

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140 OR Precoat 85®

K=0.18

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131) K=0.15

Zinc Yellow Chromate Fasteners (Ref 4150707)*Magni Coating (Ref 4150701)*

Torque

(Dry) K = .17

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140 OR Precoat 85®

K=0.16

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131) K=0.15

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED STEEL OR RAW ALUMINUM

SECTION 3 - CHASSIS & TURNTABLE

Figure 3-9.

3121623 – JLG Lift – 3-5

SECTION 3 - CHASSIS & TURNTABLE

Size TPI Bolt Dia

Tensile

Stress Area

Clamp Load Clamp Load

In Sq In LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m] IN-LB [N.m] LB IN-LB [N.m] IN-LB [N.m] IN-LB [N.m]

4 40 0,1120 0,00604 380 8 0,9 6 0,7

48 0,1120 0,00661 420 9 1,0 7 0,8

6 32 0,1380 0,00909 580 16 1,8 12 1,4

40 0,1380 0,01015 610 18 2,0 13 1,5

8 32 0,1640 0,01400 900 30 3,4 22 2,5

36 0,1640 0,01474 940 31 3,5 23 2,6 1320 43 5

10 24 0,1900 0,01750 1120 43 4,8 32 3,5 1580 60 7

32 0,1900 0,02000 1285 49 5,5 36 4 1800 68 8

1/4 20 0,2500 0,0318 2020 96 10,8 75 9 105 12 2860 143 16 129 15

28 0,2500 0,0364 2320 120 13,5 86 10 135 15 3280 164 19 148 17

In Sq In LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m] FT-LB [N.m] LB FT-LB [N.m] FT-LB [N.m] FT-LB [N.m]

5/16 18 0,3125 0,0524 3340 17 23 13 18 19 26 16 22 4720 25 35 20 25 20 25

24 0,3125 0,0580 3700 19 26 14 19 21 29 17 23 5220 25 35 25 35 20 25

3/8 16 0,3750 0,0775 4940 30 41 23 31 35 48 28 38 7000 45 60 40 55 35 50

24 0,3750 0,0878 5600 35 47 25 34 40 54 32 43 7900 50 70 45 60 35 50

7/16 14 0,4375 0,1063 6800 50 68 35 47 55 75 45 61 9550 70 95 65 90 50 70

20 0,4375 0,1187 7550 55 75 40 54 60 82 50 68 10700 80 110 70 95 60 80

1/2 13 0,5000 0,1419 9050 75 102 55 75 85 116 68 92 12750 105 145 95 130 80 110

20 0,5000 0,1599 10700 90 122 65 88 100 136 80 108 14400 120 165 110 150 90 120

9/16 12 0,5625 0,1820 11600 110 149 80 108 120 163 98 133 16400 155 210 140 190 115 155

18 0,5625 0,2030 12950 120 163 90 122 135 184 109 148 18250 170 230 155 210 130 175

5/8 11 0,6250 0,2260 14400 150 203 110 149 165 224 135 183 20350 210 285 190 260 160 220

18 0,6250 0,2560 16300 170 230 130 176 190 258 153 207 23000 240 325 215 290 180 245

3/4 10 0,7500 0,3340 21300 260 353 200 285 388 240 325 30100 375 510 340 460 280 380

16 0,7500 0,3730 23800 300 407 220 298 330 449 268 363 33600 420 570 380 515 315 430

7/8 9 0,8750 0,4620 29400 430 583 320 434 475 646 386 523 41600 605 825 545 740 455 620

14 0,8750 0,5090 32400 470 637 350 475 520 707 425 576 45800 670 910 600 815 500 680

1 8 1,0000 0,6060 38600 640 868 480 651 675 918 579 785 51500 860 1170 770 1045 645 875

12 1,0000 0,6630 42200 700 949 530 719 735 1000 633 858 59700 995 1355 895 1215 745 1015

1 1/8 7 1,1250 0,7630 42300 800 1085 600 813 840 1142 714 968 68700 1290 1755 1160 1580 965 1310

12 1,1250 0,8560 47500 880 1193 660 895 925 1258 802 1087 77000 1445 1965 1300 1770 1085 1475

1 1/4 7 1,2500 0,9690 53800 1120 1518 840 1139 1175 1598 1009 1368 87200 1815 2470 1635 2225 1365 1855

12 1,2500 1,0730 59600 1240 1681 920 1247 1300 1768 1118 1516 96600 2015 2740 1810 2460 1510 2055

1 3/8 6 1,3750 1,1550 64100 1460 1979 1100 1491 1525 2074 1322 1792 104000 2385 3245 2145 2915 1785 2430

12 1,3750 1,3150 73000 1680 2278 1260 1708 1750 2380 1506 2042 118100 2705 3680 2435 3310 2030 2760

1 1/2 6 1,5000 1,4050 78000 1940 2630 1460 1979 2025 2754 1755 2379 126500 3165 4305 2845 3870 2370 3225

12 1,5000 1,5800 87700 2200 2983 1640 2224 2300 3128 1974 2676 142200 3555 4835 3200 4350 2665 3625

Values for Zinc Yellow Chromate Fasteners (Ref 4150707)

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140) K=.18

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

K=0.15

SAE GRADE 5 BOLTS & GRADE 2 NUTS

Torque

(Dry)

Torque

(Loctite® 262

TM

or Vibra-

TITE

TM

131)

Torque

Lubricated

Torque

(Loctite® 242

TM

or 271

TM

OR Vibra-TITE

TM

111 or

140)

SAE GRADE 8 (HEX HD) BOLTS & GRADE 8 NUTS*

3. * ASSEMBLY USES HARDENED WASHER

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

Torque

(Dry or Loctite® 263)

K= 0.20

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

3-6 – JLG Lift – 3121623

Figure 3-10.

il ize the machine on level ground.

Size PITCH

Tensile

Stress

Area

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

Torque

(Lub)

Torque

(Loctite® 262

TM

OR Vibra-

TITE

TM

131)

Torque

(Loctite®

242

TM

or 271

TM

OR Vibra-

TITE

TM

111 or

140)

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

K = 0.20

Torque

(Lub OR Loctite®

242

TM

or 271

TM

OR

Vibra-TITE

TM

111 or

140)

K= 0.18

Torque

(Loctite® 262

TM

OR

Vibra-TITE

TM

131)

K=0.15

Clamp Load

See Note 4

Torque

(Dry or Loctite®

263

TM

)

K = .17

Torque

(Lub OR Loctite®

242

TM

or 271

TM

OR Vibra-TITE

TM

111 or 140)

K = .16

Torque

(Loctite® 262

TM

OR Vibra-TITE

TM

131)

K = .15

Sq mm KN [N.m] [N.m] [N.m] [N.m] KN [N.m] [N.m] [N.m] kN [N.m] [N.m] [N.m]

3 0,5 5,03 2,19 1,3 1,0 1,2 1,4 3,13

3.5 0,6 6,78 2,95 2,1 1,6 1,9 2,3 4,22

4 0,7 8,78 3,82 3,1 2,3 2,8 3,4 5,47

5 0,8 14,20 6,18 6,2 4,6 5,6 6,8 8,85

6 1 20,10 8,74 11 7,9 9,4 12 12,5 12,5 13 12 11

7 1 28,90 12,6 18 13 16 19 18,0 25 23 19 18,0 21 20 19

8 1,25 36,60 15,9 26 19 23 28 22,8 37 33 27 22,8 31 29 27

10 1,5 58,00 25,2 50 38 45 55 36,1 70 65 55 36,1 61 58 54

12 1,75 84,30 36,7 88 66 79 97 52,5 125 115 95 52,5 105 100 95

14 2 115 50,0 140 105 126 154 71,6 200 180 150 71,6 170 160 150

16 2 157 68,3

219 164 197 241

97,8

315 280 235 97,8 265 250 235

18 2,5 192 83,5 301 226 271 331 119,5 430 385 325 119,5 365 345 325

20 2,5 245 106,5 426 320 383 469 152,5 610 550 460 152,5 520 490 460

22 2,5 303 132,0 581 436 523 639 189,0 830 750 625 189,0 705 665 625

24 3 353 153,5 737 553 663 811 222,0 1065 960 800 220,0 900 845 790

27 3 459 199,5 1080 810 970 1130 286,0 1545 1390 1160 286,0 1315 1235 1160

30 3,5 561 244,0 1460 1100 1320 1530 349,5 2095 1885 1575 349,5 1780 1680 1575

33 3,5 694 302,0 1990 1490 1790 2090 432,5 2855 2570 2140 432,5 2425 2285 2140

36 4 817 355,5 2560 1920 2300 2690 509,0 3665 3300 2750 509,0 3115 2930 2750

42 4,5 1120 487,0 4090 3070 3680 4290 698,0 5865 5275 4395 698,0 4985 4690 4395

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT REPRESENT FULL STRENGTH CAPABILITY OF SHCS. IF HIGHER LOAD IS REQUIRED, ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED STEEL OR RAW ALUMINUM

Spec #4150701Values for Zinc Yellow Chromate Fasteners (Ref 4150707)

CLASS 10.9 METRIC (HEX HEAD) BOLTS

CLASS 10 METRIC NUTS

CLASS 12.9 SOCKET HEAD CAP SCREWS M3 - M5*

CLASS 8.8 METRIC (HEX HEAD) BOLTS

CLASS 8 METRIC NUTS

CLASS 12.9 SOCKET HEAD CAP SCREWS

M6 AND ABOVE*

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE = ±10%

SECTION 3 - CHASSIS & TURNTABLE

Figure 3-11.

3121623 – JLG Lift – 3-7

SECTION 3 - CHASSIS & TURNTABLE

1

4

5

3

2

1

6

7

11

9

8

12

10

12

11

3.2 UNDERCARRIGE COMPONENTS

a. Fully extend the undercarriage.

b. Remove the tracks (see paragraph 3.1).

c. Remove the key ignition, and a tag with warning

do not start the machine.

Figure 3-12.

Replacement roller lower wheel and tracks adjuster

4. Apply loctite 243 and torque the nuts 2 on the lower

roller at 125Nm.

Replacement sprocket and Gear Motor

Figure 3-14.

Sprocket remove

1. Fully extend the undercarriage.

2. Remove the tracks (see paragraph 3.1).

3. Remove the key ignition, and a tag with warning do

not start the machine.

4. Remove screws 6.

5. Remove the sprocket 7.

Figure 3-13.

Disassembly

1. Remove the nuts 2 on the lower roller.

2. Remove the lower roller 3.

3. Remove the front idler 5.

4. Remove the tracks adjuster 4.

ASSEMBLY

1. Fit the tracks adjuster 4.

2. Instal the front idler 5.

Gear motor remove

1. Remove cover 9.

2. Disconnect and tag the hydraulic hoses from the

gearmotor.

3. Remove the valve 10 to access all the screws 11 (on

single speed versions only).

4. Remove the screws 11.

5. Remove the gearmotor 12.

3. Instal the lower roller 3.

3-8 – JLG Lift – 3121623

SECTION 3 - CHASSIS & TURNTABLE

1

6

7

11

9

8

12

10

12

11

Gear motor installation

1. Fix the screws 11.

2. Instal the valve 10.

3. Connect the Hydraulic hoses

4. Instal the cover 9.

Sprocket installation

1. Instal the sprocket

2. Instal the screws 6

Table 3-1. Final drive torque valves

Machine model Description Torque valve Loctite type+

X17J P - X500AJ Screw TECEI M 10X25

12,9

X20JP - X600AJ Screw TECEI M 10X25

12,9

84 Nm Loctite 243

84 Nm Loctite 243

3121623 – JLG Lift – 3-9

SECTION 3 - CHASSIS & TURNTABLE

1

2

3

5

6

4

7

8

9

9

3.3 AXLE EXTENSION REMOVAL

Figure 3-15.

1. Stabilize the machine on level surface.

2. Extend the undercarriage.

3. Engine and key off.

4. Remove the key ignition, and a tag with warning do not

start the machine.

5. Open the hydraulic cap, and operate the function

undercarriage extend/retract to discharge any residual

pressure in the system.

8. Using a suitable lifting device (minimum 200kg capacity) to remove the track frame.

Figure 3-18.

9. Remove screw and nut 3-6.

10. Remove the pin 4.

11. Disconnect, tag and plug the hydraulic hoses from the

cylinder extension.

12. Remove the cylinder.

Figure 3-16.

6. Remove the cotter pin 1 (figure 3-16)

7. Remove the pin 2.

Figure 3-17.

Figure 3-19.

NOTE: Before to install the undercarriage frame inspect the slide

guides 9.

a. Unscrew the screws 7.

b. Remove the stop slide guides 8.

c. Remove the slide guides 9.

d. Check the thickness of slide guides, if less than

3.5 mm, damage, with deep scratches or with

deformation, replace its. Otherwise clean them

and install by adding Grease GR MU EP1 before

to install the track guides.

e. Use medium strength Loctite (Loctite 243) on

screws 7 and tightening torque of 10 Nm.

3-10 – JLG Lift – 3121623

3.4 TRACK DRIVE - BONFIGLIOLI (2T700C2K032002)

Table 3-2.

MACHINE TYPE SPEED

X17JP - X500AJ

X20JP - X600AJ

700C2K

7002C2K

AUTO TWO

TWO SPEED

SECTION 3 - CHASSIS & TURNTABLE

INFORMATION

FOR ALL ENQUIRIES REGARDING GENERAL INFORMATION ON THE PRODUCT, SPARE PARTS, ASSISTANCE ETC, ALWAYS GIVE THE IDENTIFICATION

DATA STAMPED ON THE ID PLATE.

SPEED

The gearmotor has two plates, one gives data on the

gearbox and the other data on the hydraulic motor.

Product Identification

The data to identify the product are shown on the identification plate attached to it.

The plates must not be removed or damaged during the

life of the product. The following illustration shows how

the data is set out.

Figure 3-20.

3121623 – JLG Lift – 3-11

SECTION 3 - CHASSIS & TURNTABLE

Lifting and handling

If the handling occurs when the product is still

packaged, simply follow the instructions given on the

packaging and/or use normal hoisting means.

NOTE: For the weight of the gearmotor refer to Table 1-14

Figure 3-21.

3-12 – JLG Lift – 3121623

SECTION 3 - CHASSIS & TURNTABLE

TECHNICAL INFORMATIONS

PRODUCT DESCRIPTION

The Bonfiglioli Trasmital gearmotors of the series

decribed in this manual are designed and built for

application as track drive for crawled machines

equipped with open or closed loop hydraulic circuit

depending on the application.

The unit includes:

Planetary gearbox

- 2/3 reduction stages planetary gearbox, with

rotating housing

- Connecting flange to the machine frame

- Connecting flange to the sprocket.

Hydraulic motor

Orbit fixed displacement motor including:

- Brake valve, this valve is installed for drive applications

on tracked vehicles such as mini excavators and similar

with open loop circuits; -Internal brake port directly controlled by the motor supply ports.

Figure 3-22. Hydraulic scheme X17JP - X500AJ

3121623 – JLG Lift – 3-13

SECTION 3 - CHASSIS & TURNTABLE

Figure 3-23. Hydraulic scheme X20JP - X600AJ

3-14 – JLG Lift – 3121623

The illustrations show the parts and the main functions of

the gearmotor.

SECTION 3 - CHASSIS & TURNTABLE

Figure 3-24.

3121623 – JLG Lift – 3-15

SECTION 3 - CHASSIS & TURNTABLE

Legend:

Figure 3-25.

1 M10x1 Filling and draining oil plug

2 M10x1 Level oil plug

P1 - P2 3/8“ G 19 TPI (depth 14 mm) Motor port

Table 3-3.

3-16 – JLG Lift – 3121623

DIRECTION OF ROTATION

When assembling the track drive on the machine and

connecting the hoses, follow instructions shown in

below sketch for proper direction of rotation.

SECTION 3 - CHASSIS & TURNTABLE

Figure 3-26.

Ta b l e 3 - 4 .

3121623 – JLG Lift – 3-17

SECTION 3 - CHASSIS & TURNTABLE

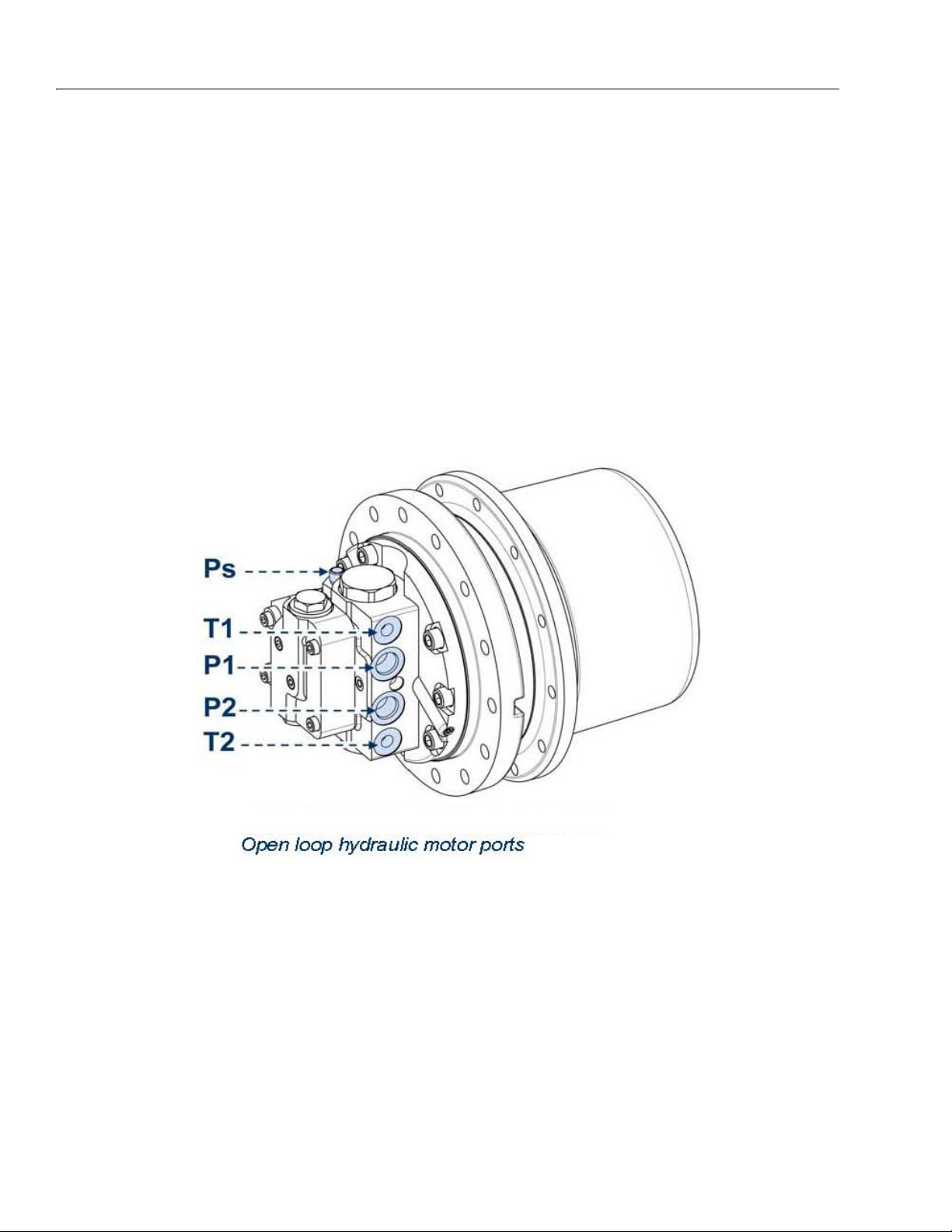

CONNECTION OF THE HYDRAULIC SYSTEM

1. Clean the surface to be connected on the hydraulic

motor.

2. Connect the hoses to the hydraulic motor ports (for

hoses sizes and dimensions refer to the installation

drawing).

Motor open loop hydraulic circuit

a. Service ports: P1-P2

b. Drain port: T1 or T2

c. 2 speed control port: Ps

3-18 – JLG Lift – 3121623

GEARBOX LUBRICATION

The motor and the gearbox have separate lubrication. The

gearbox is lubricated by oil splashing. The recommended oil

type has to be EP characteristics according to

MIL-L-2105 C & API GL5.

For standard working conditions, the recommended oil is:

For heavy duty working conditions (high loads, high duty

cycles or high ambient temperatures), the recommended oil

is:

SECTION 3 - CHASSIS & TURNTABLE

In the following table the most common brands of lubricant

and the types recommended are shown.

DURING THE OPERATION THE OIL TEMPERATURE MUST NOT

EXCEED 85-90° C INTERMITTENT.

IN CASE OF LUBRICATION WITH SYNTHETIC OILS, IS RECOMMENDED TO USE ONLY OILS WITH PAO BASE IF NOT OTHERWISE SPECIFIED WHEN ORDERING. DO NOT MIX TOGETHER

OILS OF DIFFERENT BRANDS OR CHARACTERISTICS. USE OILS

LISTED IN THE TABLE OR SIMILAR PRODUCTS WITH EQUIVALENT CHARACTERISTICS IN ORDER TO NOT MODIFY THE BRAKE

PERFORMANCES (IF PRESENT).

For information about characteristics of lubricating oils and