Service and Maintenance Manual

Model

450A

450AJ

3120869

February 16, 2000

INTRODUCTION

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A GENERAL

This section contains the general safety precautions

which must be observed during maintenance of the aerial

platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves or others, or

damage to the equipment. A maintenance program must

be followed to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED, IS A SAFETY VIOLATION.

The specific precautions to be observed during maintenance are inserted at the appropriate point in the manual.

These precautions are, for the most part, those that apply

when servicing hydraulic and larger machine component

parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPERATOR.

B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems

operate at extremely high potentially dangerous pressures. Every effort should be made to relieve any system

pressure prior to disconnecting or removing any portion of

the system.

C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION MAY RESULT IN MACHINE DAMAGE, PERSONNEL

INJURY OR DEATH AND IS A SAFETY VIOLATION.

• NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL

CAP IS CLOSED AND SECU RE AT ALL OTHER

TIMES.

• REMOVE ALL RINGS, WATCHES AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICEMANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

• USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

• NEVER WORK UNDER AN ELEVATED BOOM UNTIL

BOOM HAS BEEN SA FELY RESTRAINED FROM ANY

MOVEMENT BY BLOCKING OR OVERHEAD SLING,

OR BOOM SAFETY PROP HAS BEEN ENGAGED.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

• BATTERY SHOULD ALWAYS BE DISCONNECTEDDURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

Relieve system pressure by cycling the applicable control

several times with the engine stopped and ignition on, to

direct any line pressure back into the reservoir. Pressure

feed lines to system components can then be disconnected with minimal fluid loss.

3120869 – JLG Lift – A-1

INTRODUCTION

REVISON LOG

May, 1998 - Original Issue

August 5, 1999 - Revised

2-54 thru 2-57 - Updated 10-12-99

2-59 - Updated 10-12-99

1-4 thru 1-6 - Updated 11-1-99

2-26 - Updated 11-1-99

1-2 and 1-3 - Updated 2-16-00

2-59 thru 2-62 - Updated 2-16-00

A-2 – JLG Lift – 3120869

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B Hydraulic System Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

SECTION 1 - SPECIFICATIONS

1.1 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Component Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 Specifications and Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.5 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.7 Pressure Settings - PSI (Bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.8 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.9 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.10 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.11 Function Speeds (in Seconds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.12 Serial Number Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

SECTION 2 - PROCEDURES

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Service and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Lubrication and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 Cylinders - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 Valves - Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.6 Boom Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.7 Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.8 Cylinder Checking Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.9 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.10 Mid and Lower Lift Cylinder Bleeding Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.11 Hydraulic Pump (gear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.12 Swing Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2.13 Worm gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2.14 Boom Synchronizing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2.15 Extend-A-Reach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2.16 Adjustment Procedure For Lockout Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2.17 Torque Hub (Prior to S/N 39594) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

2.18 Torque Hub (S/N 39594 to Present) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

2.19 Drive Brake (Ausco) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

2.20 Boom Limit Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

2.21 Lift Up and Platform Level Down Disable Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

2.22 Throttle Checks and Adjustments - Deutz Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

2.23 Drive and Steer Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

2.24 Lift and Swing Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

2.25 Function Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

2.26 Tilt Alarm Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

2.27 Pressure Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

2.28 Hydraulic Component Start-Up Procedures and Recommendations . . . . . . . . . . . . . . . . . . . . . .2-59

2.29 Semi-Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

2.30 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-63

3120869 – JLG Lift – i

TABLE OF CONTENTS

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION 3 - TROUBLESHOOTING

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Hydraulic Circuit Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-2. Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-3. Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

2-1. Location of Components - Boom Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2-2. Location of Components - Removal of Telescope Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-3. Location of Components - Front Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-4. Boom Prop Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-5. Cylinder Barrel Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-6. Capscrew Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-7. Cylinder Rod Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-8. Tapered Bushing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-9. Gar-Max Bearing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-10. Rod Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-11. Wiper Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-12. Installation of Head Seal Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-13. Piston Seal Kit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2-14. Tapered Bushing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2-15. Seating the Tapered Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2-16. Poly-Pak Piston Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2-17. Rod Assembly Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2-19. Swing Bearing Feeler Gauge Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2-18. Swing Bearing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2-20. Swing Bearing Tolerance Measuring Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

2-21. Swing Bearing Torquing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2-22. Synchronizing Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2-23. Extend-A-Reach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2-24. Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

2-25. Ring Gear/Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

2-26. Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2-27. Torque Hub (Prior to S/N 39594) - Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

2-28. Torque Hub (Prior to S/N 39594) - Cutaway View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2-29. Torque Hub (S/N 39594 to Present) - Cutaway View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

2-30. Cluster Gear Punch Marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

2-31. Drive Brake (Ausco) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

2-32. Switch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

2-33. Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

2-34. Addco Adjustments - Deutz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

2-35. Drive and Steer Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

2-36. Lift and Swing Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

2-37. Function Control Card Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-54

2-38. Tilt Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

2-39. Main Valve (Proportional Controls) - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

2-40. Main Valve (Proportional Controls) - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-57

2-41. Valve Location - Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

ii – JLG Lift – 3120869

TABLE OF CONTENTS

LIST OF FIGURES (continued)

FIGURE NO. TITLE PAGE NO.

3-1. Electrical Components Installation - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3-2. Electrical Components Installation - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3-3. Electrical Schematic - Boom, Turntable, Chassis - Deutz - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . .3-22

3-4. Electrical Schematic - Boom, Turntable, Chassis - Deutz - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . .3-23

3-5. Electrical Schematic - Platform -Deutz - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3-6. Electrical Schematic - Platform -Deutz - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3-7. Hydraulic Schematic - Proportional Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-2 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-3 Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-4 Mobil EAL Envirosyn H 46 Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1-5 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-6 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-7 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-8 Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2-1 Cylinder Head and Tapered Bushing Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-2 Holding Valve Torque Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-3 Hydraulic Pump Bolt Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2-4 Position Controller Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

2-5 Adjustment Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-62

2-6 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-64

3-1 Platform Assembly - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Boom Assembly - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-3 Turntable Assembly - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-4 Chassis Assembly - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3-5 Hydraulic System - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3-6 Electrical System - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3120869 – JLG Lift – iii

TABLE OF CONTENTS

This Page Left Blank Intentionally.

iv – JLG Lift – 3120869

SECTION 1 - SPECIFICATIONS

SECTION 1. SPECIFICATIONS

1.1 CAPACITIES

Fuel Tank - 62.5 liters

Hydraulic Oil Tank - 106 liters

Torque Hub - 0.5 liters

NOTE: Torque hubs should be one half full of lubricant.

Engine Crankcase (Ford LRG425) - 4.5 L

Engine Crankcase (Deutz F3M1011F) - 6 L

1.2 COMPONENT DATA

Engine - Deutz F3M1011F

Fuel - Diesel

No. of Cylinders - 3

BHP at Max. RPM - 48

RPM Setting (No Load) - Mid - 1500

1.3 TIRES

12x16.5

1.4 SPECIFICATIONS AND PERFORMANCE

DATA

Max. Platform Height - 13.8 M

Max. Horizontal Reach - 7.3 M

Unrestricted Rated Capacity - 230kg

Maximum Capacity - 230 kg

Maximum Tire Load (450A) - 3230 kg

Maximum Tire Load (450AJ) - 3357 kg

Overall Width - 1.98 m

Tai lsw in g - Z ero

Stowed Height - 2.24 m

Stowed Length - 6.15 m

Wheelbase - 1.98 m

Ground Clearance - 28 cm

Platforms - 0.76m x 1.22M

0.76m x 1.52M

0.76m x 1.83M

Rated Gradeability - 2WD -30%

4WD - 40%

• Pneumatic - 6 Bar

•Weight: 58 kg

12x16.5

• Fo am-Filled

• Weight: 149 kg

33/1550x16.5

• Pneumatic - 6 Bar

•Weight: 61 kg

33/1550x16.5

• Fo am-Filled

• Weight: 179 kg

33/16LL x 16.1

• Pneumatic - 3 bar

• Weight: 41.5 kg

33/16LL x 16.1

• Foam-Filled

• Weight: 193 kg

System Voltage - 12 Volts

Max. Hydraulic System Operating Pressure - 207 bar

Travel Speed (2WD) - 7.2 kph

Travel Speed (4WD) - 3.6 mph

Ground Bearing Pressure (450A)

12x16.5 pneu. - 3.23 kg/cm

12x16.5 FF - 3.93 kg/cm

33/1550x16.5 pneu. - 2.46 kg/cm

33/1550x16.5 FF - 3.51 kg/cm

Ground Bearing Pressure (450AJ)

12x16.5 pneu. - 3.37 kg/cm

12x16.5 FF - 4.07 kg/cm

33/1550x16.5 pneu. - 2.53 kg/cm

33/1550x16.5 FF - 3.65 kg/cm

2

2

2

2

2

2

2

2

3120869 – JLG Lift – 1-1

SECTION 1 - SPECIFICATIONS

1.5 TORQUE REQUIREMENTS

wear and rust protection characteristics as mineral oils,

but will not adversely affect ground water or the environment when spilled or leaked in small amounts. Mobil

Table 1-1.Torque Requirements

Description Torque Value Interval Hours

Wheel Lugs 170 ft. lbs.

Semi-Track

Wheel Lugs

Swing Bearing

(Dry)

Swing Bearing

((Loctite)

(231 Nm)

90 ft. lbs.

(122 Nm)

220 ft. lbs.

(298 Nm)

240 ft. lbs.

(326 Nm)

150

150

50/600*

50/600*

EAL224H has a viscosity of 34 cST at 40° C and a viscosity

index of 213. The operating range of this oil is -18° C to

+83° C.

IT IS RECOMMENDED THAT MOBIL EAL224H HYDRAULIC OIL BE

STORED ABOVE FREEZING (0° C) AS THE OIL MAY APPEAR

CLOUDY AFTER EXPOSURE TO LOW TEMPERATURES FOR

EXTENDED PERIODS OF TIME. THE CLOUDINESS WILL DISAPPEAR

WHEN THE OIL IS WARMED TO AT LEAST 10° C AND AGITATED. DO

NOT ATTEMPT TO "THIN" THE OIL WITH NO.2 DIESEL FUEL. FOR

BEST RESULTS, STORE THE OIL ABOVE FREEZING.

* Check swing bearing bolts for security after first 50

hours of operation and every 600 hours thereafter.

NOTE: Accidentally mixing Mobil EAL224 H hydraulic oi l with

other mineral oils will cause no loss of performance

characteristics. However, biodegradability may be

1.6 LUBRICATION

Hydraulic Oil

Table 1-2.Hydraulic Oil

Hydraulic System

Operating

Temperature Range

+0° to + 18 0° F

(-18° to +83 ° C)

+0° to + 21 0° F

(-18° to +99 ° C)

+50° to + 2 10° F

(+10° to + 99° C

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

S.A.E. Viscosity

Grade

10W

10W-20, 10W30

20W-20

reduced and toxicity may be increased, depending

on the oil and level of contamination.

Lubrication Specifications

Table 1-3.Lubrication Specifications.

KEY SPECIFICATIONS

MPG Multipurpos e Grease having a minimum d ripping point of 350

degrees F. Excellent water resistance and adhesive qualities; and

being of extreme p ressure type (Timken OK 40 po unds minimum).

EPGL Extreme Pressu re Gear Lube (oil) meeting API Se r-

vice Classification GL-5 or Mil-Spec Mil-L-2105.

HO Hydraulic Oil. API Service Classification GL-3, SAE

10W-20, Viscosity Index 152, e.g. Kendall Hyken 052.

EO Engine (crankcase) Oil. Gas - API SF/SG class, MIL-L-

2104. Diesel - API CC/CD class, MIL-L-2104B/MIL-L2104C.

chemical stability for mobile hydraulic system service. JLG Industries recommends Mobilfluid 424

hydraulic oil, which has an SAE viscosity index of

152.

NOTE: When temperatures remain consistently below 20

degrees F. (-7 degrees C.), JLG Industries recommends the use of Mobil DTE11.

Aside from JLG recommendations, it is not advisable to

mix oils of different brands or types, as they may not contain the same required additives or be of comparable viscosities. If use of hydraulic oil other than Mobilfluid 424 is

desired, contact JLG Industries for proper recommendations.

Some machines may be specially equipped with Mobil

EAL224H biodegradable and non-toxic hydraulic oil. This

oil is vegetable oil based and possesses the same anti-

Updated 2-16-00

NOTE: Refer to Lubrication Chart for spe cific lubricatio n pr o-

cedures..

Table 1-4. Mobil EAL Envirosyn H 46 Specs

Type Synthetic Biodegradable

ISO Viscosity Grade 46

Specific Gravity .910

Pour Point, Max -44° F (-44° C)

Flash Point, Min. 500° F (260° C)

Weight

Viscosity

at 40° C 45 cSt

at 100° C 8.0 cSt

Viscosity In dex 153

7.64 lb. per gal.

(0.9 kg per liter)

1-2 – JLG Lift – 3120869

SECTION 1 - SPECIFICATIONS

1.7 PRESSURE SETTINGS - PSI (BAR)

Main Relief

Main Relief - 3000 (207)

Lift Up - 3000 (207) - Governed by Main Relief

Lift Down - 2500 (172) - Governed by Level Down Relief

Level Down - 2500 (172)

Level Up - 2500 (172)

Swing (Right & Left) - 1750 (121)

Drive

Drive - Pre-Set 4500 (310)

1.8 MAJOR COMPONENT WEIGHTS

Table 1-5.Major Component Weights

Component LB. KG.

6 ft Platform 160 73

5 ft. Platform 145 66

4 ft. Platform 130 59

Extend-A-Reach 230 104

Upper Boom (450A) 985 447

Upper Boom (450A J) 1250 567

Upper Upright 212 96

Tower Boom 515 234

Lower Upright 100 45

Tower Link 150 68

Turntable 3560 1615

Engine Tray 890 404

Hydraulic Tray 225 102

Tail Counterweight 3410 1547

Bolt-on T/T Cwt. ( AJ) 487 221

Chassis (12x16.5 pneu. t ires) 4200 1905

12x16.5 pneu. Tire & Wheel 130 59

12x16.5 F/F Tire & Wheel 305 138

33/15.5x16.5 pneu. Tire & Wheel 150 68

33/15.5x16.5 F/F Tire & Whee l 374 170

33/16LL x 16.1 pneu Tire & Wheel 91.5 41.5

33/16LL x 16.1 F/F Tire & Wheel 426 193.4

1.9 CRITICAL STABILITY WEIGHTS

Table 1-6.Critical Stability Weights

Component LB. KG.

Ford Engine 339 154

Deutz Engine 441 200

Isuzu Engine 389 176

6 ft Platform 160 73

5 ft. Platform 145 66

4 ft. Platform 130 59

Bolt-on T/T Cwt. (AJ) 487 221

12x16.5 pneu. Tire & Wheel 130 59

12x16.5 F/F Tire & Wheel 305 138

33/15.5x16.5 pneu. Tire & Wh eel 150 68

33/15.5x16.5 F/F Tire & Whee l 374 170

33/16LL x 16.1 pneu Tire & Wheel 91.5 41.5

33/16LL x 16.1 F/F Tire & Wheel 426 193.4

1.10 CYLINDER SPECIFICATIONS

Table 1-7.Cylinder Specifications

Cylinder Bore Stroke Rod Dia.

Oscillation 2.5 in.

(63.5 mm)

Lower Lift 4.5 in.

(114.3 mm)

Mid Lift 4. 0 in.

(101.6 mm)

Upper Lift 3.5 in.

(88.9 mm)

Telescope 2 in.

(50.8 mm)

Level 4.0 in.

(101.6 mm)

Jib 3.0 in.

(76.2 mm)

Rotate 1. 5 in.

(38.1 mm)

4.125 in.

(104.8 mm)

21.5 in.

(546.1 mm)

18.8 in.

(479.5 mm)

24.4 in.

(619.4 mm)

83.75 in.

(2127.25 mm)

10.9 in.

(277.5 mm)

18.4 in.

(467.4 mm)

9.3 in.

(236.2 mm)

(44.45 mm)

(63.5 mm)

(50.8 mm)

(63.5 mm)

(31.75 mm)

(31.75 mm)

(38.1 mm)

1.75 in.

2.5 in.

2.0 in.

2.5 in.

1.25 in.

1.25 in.

1.5 in.

0.75 in.

(19 mm)

Updated 2-16-00

3120869 – JLG Lift – 1-3

SECTION 1 - SPECIFICATIONS

Figure 1-1. Lubrication Diagram

Updated 11-1-99

1-4 – JLG Lift – 3120869

Components

Lubrication

Swing Bearing - Internal

1

Ball Bearing

Swing Bearing - Teeth

2a

End Bearings - Worm

2b

Gear*

Wheel Bearings (2WD

3

Only)

Wheel Drive Hub

4

Hydraulic Return Filter

5

Hydraulic Charge Filter

6

Hydraulic Oil

7

Suction Strainer s (In Tank)

8

Steer Cylinder

9

Oscillation Cylinders

10

SECTION 1 - SPECIFICATIONS

Table 1-8. Lubrication Chart

Interval Hours

Number/Type

Lube Points

2 Grease Fitt ing A/R MPG X

Spray On A/R OGL X More frequent lubrication intervals may be

2 A/R MPG X Remove grease fittings and install plugs after

Repack A/R MPG X

Level/Fill Plug 0.5 liters (1/2 full) EPGL X Change after first 150 hours then every 1200

N/A N/A N/A X Change after first 50 hours and every 300

N/A N/A N/A X Change after first 50 hours and every 300

F il l C a p 116 li t er s Tan k

2 N/A N/A X Remove and clean at time of hydraulic oil

4A/RMPGX

2A/RMPGX

Capacity Lube

124 liters System

3

Months

150 hrs

6

Months

300 hrs

1 Year

600 hrs

2 Years

1200 hrs

required.

greasing.

hours of operation.

hours thereafter or as indicated by condition

indicator.

hours thereafter or as indicated by condition

indicator.

HO X Check level daily.

Change every 1200 hours.

change.

Comments

Engines

Oil Change w/Filter - Ford

11

Oil Change w/Filter - Deutz

12

Oil Change w/Filter - Isuzu

13

Fuel Filter - Ford

14

Fill Cap/Spin-on

Element

Fill Cap/Spin-on

Element

Fill Cap/Spin-on

Element

Replaceable

5 Quarts (4 .7 L) EO X Check leve l daily; change every 150 hour s.

Adjust fina l oil level by m ark on dipstick .

6 liters crankcase

**4. 5 liters cooler

5.6 liters crankcase

6.1 liters w/ cooler

EO X Check level da ily; change eve ry 600 hours.

Adjust fina l oil level by m ark on dipstick .

EO X Check level da ily; change eve ry 150 hours.

Adjust fina l oil level by m ark on dipstick .

N/A N/A X

Element

15

16

Fuel Filter - Deutz

Fuel Filter - Isuzu

Replaceable

Element

Replaceable

N/A N/A X

N/A N/A X

Element

17

Air Filter - Ford

Replaceable

N/A N/A X Or as indicated by condition indicator

Element

Updated 11-1-99

3120869 – JLG Lift – 1-5

SECTION 1 - SPECIFICATIONS

Table 1-8. Lubrication Chart

Interval Hours

Components

Air Filter - Deut z

18

Air Filter - Isuzu

19

NOTES: KEY TO LUBRICANTS

Lubrication intervals are based on machine operation under normal conditions. For machines used in multi shift operations and/or exposed to hostile environments or conditions, lubrication frequencies must be increased accordingly.

* If necessary install grease fittings into worm gear housing and grease bearings.

DO NOT OVERGREASE BEARINGS. OVERGREASING BEARINGS WILL RESULT IN

BLOWING OUTER SEAL IN HOUSING.

**When changing oil in the Deutz oil cooled engine, drain both the crankcase and the cooler. When refilling it is acceptable to overfill crankcase (10.5 L),

capacity of both crankcase and cooler combined). Start engine, allow the engine to run until the thermostat opens (approximately 105 degrees C) cooler will

fill up within minutes; shut down and wait for approximately two minutes. Check oil level, fill oil to max marking on dipstick.

Number/Type

Lube Points

Replaceable

Element

Replaceable

Element

Capacity Lube

N/A N/A X Or as indicated by condition indicator

N/A N/A X Or as indicated by condition indicator

3

Months

150 hrs

6

Months

300 hrs

1 Year

600 hrs

2 Years

1200 hrs

EO

EPGL

HO

MPG

OGL

Engine Oil

Extreme Pressure Gear Lube

Hydraulic Fluid (Mobil DTE-11M)

Multi-Purpose Grease

Open Gear Lubricant - Mobiltac 375 or

equivalent

Comments

Updated 11-1-99

1-6 – JLG Lift – 3120869

SECTION 1 - SPECIFICATIONS

1.11 FUNCTION SPEEDS (IN SECONDS)

450A

Main Boom Lift Up - 22-38

Main Boom Lift Down - 12-24

Tele In - 12-24

Tele Out - 20-32

Swing - 85-110

Rotate (Left & Right) - 16-25

450AJ

Main Boom Lift Up - 22-38

Main Boom Lift Down - 12-24

Tele In - 9-20

Tele Out - 14-30

Swing - 85-110

Rotate (Left & Right) - 16-25

E-A-R Up - 9-24

E-A-R Down - 12-24

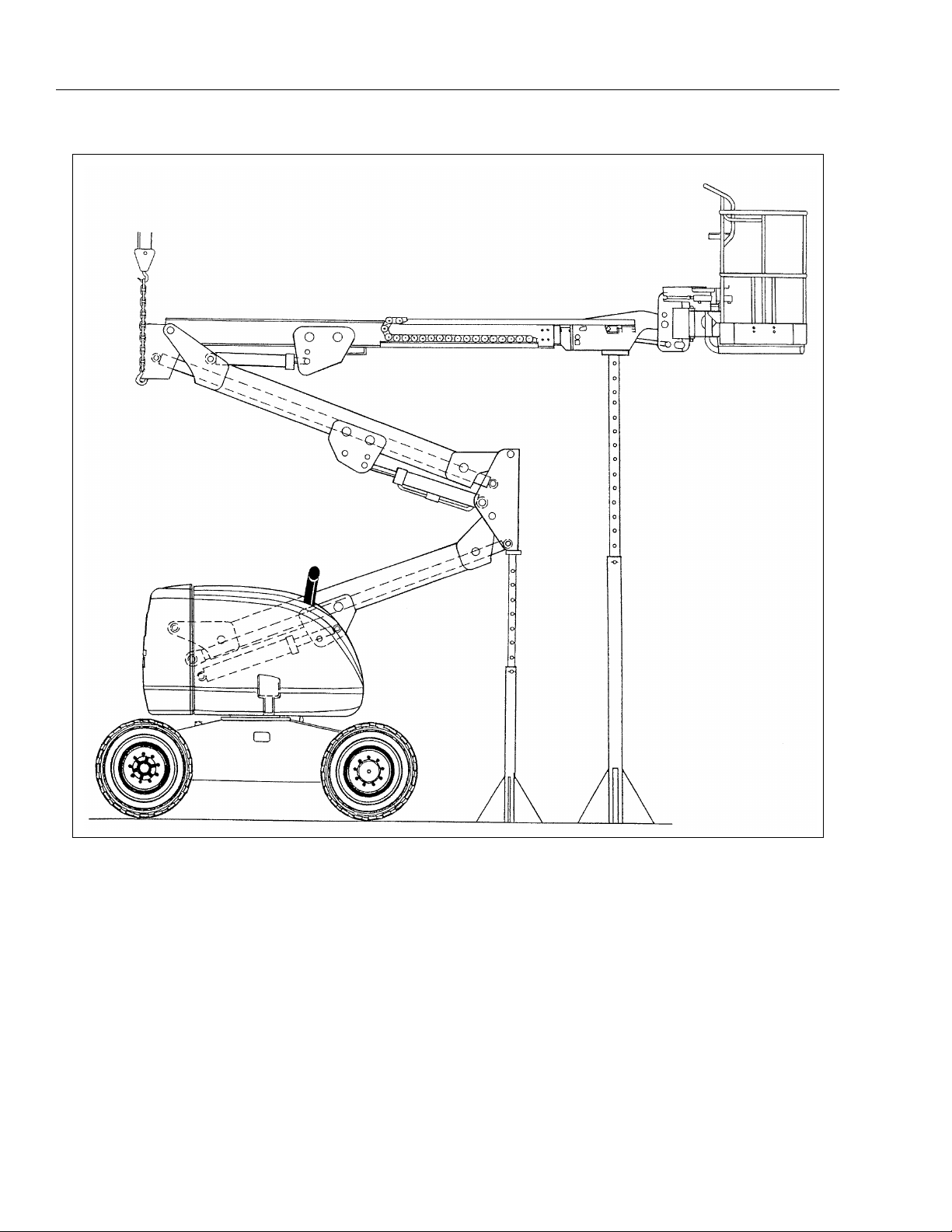

1.12 SERIAL NUMBER LOCATION

A serial number plate is affixed to the left rear side of the

frame. If the serial number plate is damaged or missing,

the machine serial number is stamped on the left side of

the frame.

xxxxxxx

SERIAL NUMBER

PLATE

SERIAL NUMBER

STAMPEDON FRAME

Figure 1-2. Serial Number Locations

3120869 – JLG Lift – 1-7

SECTION 1 - SPECIFICATIONS

NM

TORQUE

(as received)

UNPLATED

CAP SCREWS

UNBRAKO 1960 SERIES

WITH LOC-WEL PATCH

SOCKET HEAD CAP SCREW

CLAMP LOAD

)

(LOCTITE

242 OR 271

262)

(LOCTITE

(LUB.)

TORQUE

(KG)

NM

NM

NM

2

4

4

5

1

1

2

6

18

19

1442

1651

18

12

14

21

34

37

2377

2631

41

41

30

34

25

27

61

68

3493

3983

68

75

54

61

48

48

95

102

4822

5384

122

109

85

95

81

75

149

156

6437

7253

183

163

130

146

122

109

210

224

8256

9208

224

258

188

209

149

176

285

298

10251

11612

326

359

244

277

231

244

495

542

15150

16919

570

631

408

456

380

434

793

861

20956

23088

895

983

658

724

624

678

1173

1241

27488

30074

1492

1342

931

1079

922

1003

1681

1871

34610

38828

1898

2136

1396

1566

1464

1302

2373

2549

43954

48671

2712

2983

1970

2183

1844

2034

3145

3308

52391

59648

3559

4068

2586

2935

2413

2766

4122

4433

63731

71669

4712

5322

3430

3856

3200

3607

SAE GRADE 8

SAE GRADE 5

VALUES FOR ZINC PLATED BOLTS ONLY

(DRY OR

SAE GRADE 8 BOLTS & GRADE 8 NUTS

CLAMP

(LOCTITE

(LOCTITE

TORQUE

(DRY OR

SAE GRADE 5 BOLTS & GRADE 2 NUTS

CLAMP

AREA

STRESS

THREAD

DIA.

BOLT

NM

LOC. 263)

(KG)

LOAD

)

NM

242 OR 271

262)

NM

NM

(LUB.)

NM

LOC. 263)

(KG)

LOAD

(SQ. CM)

(CM)

2

2

245

272

1

1

1

1

172

191

0.0153

0.0168

0.2845

3

3

372

417

2

2

2

2

263

277

0.0232

0.0258

0.3505

5

5

572

599

3

3

4

4

408

426

0.0356

0.0374

0.4166

7

8

717

817

4

4

6

5

508

583

0.0445

0.0508

0.4826

16

19

1297

1488

16

12

9

10

11

14

916

1052

0.0808

0.0925

0.6350

34

34

2141

2821

29

26

22

23

19

18

26

23

1515

1678

0.1473

0.1331

0.7938

61

68

3175

3583

54

48

38

43

34

31

48

41

2241

2540

0.2230

0.1969

0.9525

95

109

4332

4854

81

75

68

61

68

48

68

75

3085

3425

0.3015

0.2700

1.1112

149

163

5783

6532

115

136

92

108

75

88

102

122

4105

4854

0.4061

0.3604

1.2700

204

231

7539

8278

163

183

133

148

109

122

149

163

5874

5262

0.5156

0.4623

1.4288

298

326

9231

10433

224

258

183

207

149

176

204

231

7394

6532

0.6502

0.5740

1.5875

515

570

15241

13653

387

448

325

363

271

298

353

407

9662

10796

0.9474

0.8484

1.9050

814

895

18870

20775

644

705

523

576

434

475

583

637

14697

13336

1.2929

1.1735

2.2225

1220

1356

23360

27080

915

997

785

858

651

719

868

949

19142

17509

1.6840

1.5392

2.5400

1736

1953

31162

34927

968

1087

814 1139

895 1254

1085

1193

21546

19187

2.1742

1.9380

2.8575

2468

2712

38554

43818

1593

1762

1368

1516

1139

1247

1519

1681

27035

24404

2.7254

2.4613

3.1750

3227

3688

47174

53570

2068

2373

1792

2042

1492

1708

1980

2278

29076

33113

2.9337

3.3401

3.4925

4284

4827

57380

142200

2746

3118

2379

2676

1980

2630

35381

3.5687

4.0132 39781 2983 2224

3.8100

Figure 1-3. Torque Chart

9

8

7

7

6

THD

SIZE

40

48

40

36

32

28

18

16

14

13

12

11

32

32

24

20

24

24

20

20

8

6

4

10

1/4

5/16

3/8

7/16

1/2

9/16

18

5/8

18

10

3/4

16

7/8

14

12

12

1

1-1/8

1-1/4

12

12

1-1/2

6

1-1/2

12

Note: These torque values do not apply to cadium plated fasteners.

1-8 – JLG Lift – 3120869

SECTION 2. PROCEDURES

SECTION 2 - PROCEDURES

2.1 GENERAL

This section provides information necessary to perform

maintenance on the aerial platform. Descriptions, techniques and specific procedures are designed to provide

the safest and most efficient maintenance for use by personnel responsible for ensuring the correct installation

and operation of machine components and systems.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

The maintenance procedures included consist of servicing and component removal and installation, disassembly

and assembly, inspection, lubrication and cleaning. Information on any special tools or test equipment is also provided where applicable.

2.2 SERVICE AND GUIDELINES

General

The following information is provided to assist you in the

use and application of servicing and maintenance procedures contained in this chapter.

Safety and Workmanship

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

nent is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Components Removal and Installation

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90 degrees.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc., have been

removed and that no adjacent parts are interfering.

Component Disassembly and Reassembly

When disassembling or reassembling a component, complete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure-Fit Parts

When assembling pressure-fit parts, use an anti-seize or

molybdenum disulfide base compound to lubricate the

mating surface.

Cleanliness

1. The most important single item in preserving the

long service life of a machine is to keep dirt and foreign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals, and filters are provided to

keep air, fuel, and oil supplies clean; however, these

items must be maintained on a scheduled basis in

order to function properly.

2. At any time when air, fuel, or oil lines are disconnected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or compo-

3120869 – JLG Lift – 2-1

SECTION 2 - PROCEDURES

Bearings

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored, or burned.

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to install.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be installed on a shaft, apply pressure to the

inner race.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand-fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location, as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

Hydraulic System

1. Keep the system clean. If evidence of metal or rubber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified intervals. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

Battery

Clean battery, using a non-metallic brush and a solution of

baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry battery and coat terminals with

an anti corrosion compound.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in the Lubrication Chart in Section 1.

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat-treated bolts, studs, and steel nuts, in accordance with recommended shop practices. (See

Torque Chart Section 1.)

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

2.3 LUBRICATION AND INFORMATION

Hydraulic System

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g., using inadequate hydraulic oil, allowing

moisture, grease, filings, sealing components, sand,

etc., to enter when performing maintenance, or by

permitting the pump to cavitate due to insufficient

system warm-up or leaks in the pump supply (suction) lines.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced as necessary, at the specified intervals required in the Lubrication Chart in

Section 1. Always examine filters for evidence of

metal particles.

2-2 – JLG Lift – 3120869

SECTION 2 - PROCEDURES

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or corrosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

Hydraulic Oil

1. Refer to Section 1 for recommendations for viscosity

ranges.

2. JLG recommends Mobilfluid 424 hydraulic oil, which

has an SAE viscosity of 10W-30 and a viscosity

index of 152.

NOTE: Start-up of hydraulic system with oil temperatures

below -26 de grees C (- 15 degrees F ) is not recommended. If it is necessary to start the system in a

sub-zero environment, it will be necessary to heat

the oil with a low density, 100VAC heater to a minimum temperature of -26 degrees C (-15 degrees F).

3. The only exception to the above is to drain and fill

the system with Mobil DTE 11 oil or its equivalent.

This will allow start up at temperatures down to -29

degrees C (-20 degrees F). However, use of this oil

will give poor performance at temperatures above49

degrees C (120 degrees F). Systems using DTE 11

oil should not be operated at temperatures above 94

degrees C (200 degrees F) under any condition.

Changing Hydraulic Oil

1. Use of any of the recommended crankcase or

hydraulic oils eliminates the need for changing the

oil on a regular basis. However, filter elements must

be changed after the first 50 hours of operation and

every 300 hours thereafter. If it is necessary to

change the oil, use only those oils meeting or

exceeding the specifications appearing in this manual. If unable to obtain the same type of oil supplied

with the machine, consult local supplier for assistance in selecting the proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG

Industries recommends changing the hydraulic oil

annually.

nants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

3. While the unit is shut down, a good preventive maintenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

Lubrication Specifications

Specified lubricants, as recommended by the component

manufacturers, are always the best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose grease requirements.

Should any question arise, regarding the use of greases in

maintenance stock, consult your local supplier for evaluation. Refer to Section 1 for an explanation of the lubricant

key designations appearing in the Lubrication Chart.

2.4 CYLINDERS - THEORY OF OPERATION

Systems Incorporating Double Acting

Cylinders

Cylinders are of the double acting type. Systems incorporating double acting cylinders are as follows: Slave Level,

Master Level, Lift, Telescope, Axle Lockout and Steer. A

double acting cylinder is one that requires oil flow to operate the cylinder rod in both directions. Directing oil (by

actuating the corresponding control valve to the piston

side of the cylinder) forces the piston to travel toward the

rod end of the barrel, extending the cylinder rod (piston

attached to rod). When the oil flow is stopped, movement

of rod will stop. By directing oil to the rod side of the cylinder, the piston will be forced in the opposite direction and

the cylinder rod will retract.

Systems Incorporating Holding Valves

Holding valves are used in the - Lift, Telescope, Lockout,

and Slave Level circuits to prevent retraction of the cylinder rod should a hydraulic line rupture or a leak develop

between the cylinder and its related control valve.

2. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contami-

3120869 – JLG Lift – 2-3

SECTION 2 - PROCEDURES

2.5 VALVES - THEORY OF OPERATION

Solenoid Control Valve

Control valves used are four-way three-position solenoid

valves of the sliding spool design. When a circuit is activated and the control valve solenoid energizes, the spool

is shifted and the corresponding work port opens to permit oil flow to the component in the selected circuit with

the opposite work port opening to reservoir. Once the circuit is deactivated (control returned to neutral) the valve

spool returns to neutral (center) and oil flow is then

directed through the valve body and returns to reservoir. A

typical control valve consist of the valve body, sliding

spool, and two solenoid assemblies. The spool is

machine fitted in the bore of the valve body. Lands on the

spool divide the bore into various chambers, which, when

the spool is shifted, align with corresponding ports in the

valve body open to common flow. At the same time other

ports would be blocked to flow. The spool is spring loaded

to center position, therefore when the control is released,

the spool automatically returns to neutral, prohibiting any

flow through the circuit.

Relief Valves

Relief valves are installed at various points within the

hydraulic system to protect associated systems and components against excessive pressure. Excessive pressure

can be developed when a cylinder reaches its limit of

travel and the flow of pressurized fluid continues from the

system control. The relief valve provides an alternate path

for the continuing flow from the pump, thus preventing

rupture of the cylinder, hydraulic line or fitting. Complete

failure of the system pump is also avoided by relieving circuit pressure. The relief valve is installed in the circuit

between the pump outlet (pressure line) and the cylinder

of the circuit, generally as an integral part of the system

valve bank. Relief pressures are set slightly higher than

the load requirement, with the valve diverting excess

pump delivery back to the reservoir when operating pressure of the component is reached.

2.6 BOOM MAINTENANCE

IF PERFORMING MAINTENANCE ON THE BOOM, DO NOT USE A

LIFTING DEVICE TO LIFT THE BOOMS UNLESS THE HOLDING

VALVES HAVE BEEN REMOVED FIRST. FAILURE TO DO SO WILL

RESULT IN SEVERE DAMAGE TO THE BOOM.

Removal of the Boom Assembly

1. Remove the platform and platform support as follows:

a. Disconnect electrical cable from control con-

sole.

b. Tag and disconnect the hydraulic lines running

to the rotate cylinders. Cap the hydraulic lines

and ports.

c. Using an overhead crane or suitable lifting

device, use nylon support straps to support the

platform/support.

NOTE: When removing the retaining pin from the rod end of

the level cylinder, make sure the cylinder is properly

supported.

d. Remove bolts and keeper pins that secures the

retaining pins. Using a suitable brass drift and

hammer, remove the retaining pins from the platform support.

LIFT CYLINDER

PIVOT PIN

BOOM

PIVOT

LEVEL

LINK

PIVOT

Figure 2-1. Location of Components - Boom Removal

2-4 – JLG Lift – 3120869

SECTION 2 - PROCEDURES

2. Remove the boom from the turntable as follows:

a. Disconnect wiring harness from ground control

harness connector.

HYDRAULIC LINES AND PORTS SHOULD BE CAPPED IMMEDIATELY AFTER DISCONNECTING LINES TO AVOID ENTRY OF

CONTAMINANTS INTO SYSTEM.

b. Tag and disconnect hydraulic lines from boom

to control valve. Use a suitable container to

retain any residual hydraulic fluid. Cap all

hydraulic lines and ports.

c. Using a suitable lifting equipment, adequately

support boom weight along entire length.

d. Remove the bolts and keeper pins securing the

lift cylinder pivot pin. Using a suitable brass drift

and hammer, remove the pivot pin from the

lower boom.

NOTE: To gain access for removal of the pivot pins, it may

be necessary to remove the ground control box,

hydraulic and fuel tanks, and the counterweight.

e. Remove hardware securing the level link pivot

pin. Using a suitable brass drift and hammer,

remove the pin from the level link and turntable.

f. Remove hardware securing the lower boom

pivot pin. Using a suitable brass drift and hammer, remove pin from the turntable.

g. Using all applicable safety precautions, carefully

lift boom assembly clear of turntable and lower

to ground or suitable supported work surface.

Disassembly of the Main Boom

1. Loosen jam nuts on aft end of fly boom wear pad

adjustment and loosen adjustments.

2. Using a portable power source, attach hose to telescope cylinder port block. Using all applicable

safety precautions, activate hydraulic system and

extend cylinder to gain access to cylinder rod retaining pin. Shut down hydraulic system.

3. Carefully disconnect hydraulic hose from retract port

of cylinder. There will be initial weeping of hydraulic

fluid which can be caught in a suitable container.

After initial discharge, there should be no further

leakage from the retract port.

4. Remove hardware securing telescope cylinder to

the fly boom section, then remove pin from fly.

5. Remove hardware securing telescope cylinder to

the base boom section.

WHEN REMOVING TELESCOPE CYLINDER FROM BOOM SECTIONS. CARE SHOULD BE TAKEN NOT TO LEAVE CYLINDER

REST ON POWERTRACK WHICH COULD CAUSE DAMAGE TO

POWERTRACK.

FLY BOOM

RETAINING RING

RETAINING RING

BASE BOOM

TELESCOPE CYLINDER

Figure 2-2. Location of Components - Removal of Telescope Cylinder

3120869 – JLG Lift – 2-5

SECTION 2 - PROCEDURES

Figure 2-3. Location of Components - Front Wear Pads

6. Using a suitable lifting device, remove telescope cylinder from boom sections.

7. Using a piece of tape, mark the length of hoses and

wires from front of fly boom and bottom of base

boom for reassembly.

8. Remove hardware securing the front wear pads on

base boom section, remove wear pads.

9. Remove hardware securing the powertrack to the aft

end of the fly boom section.

10. Using a suitable lifting device, remove fly boom from

boom section.

11. Remove hydraulic lines and electrical cables from

powertrack.

12. Remove hardware securing powertrack to the base

boom section. Remove powertrack.

Inspection

1. Inspect all boom pivot pins for wear, scoring or other

damage, and for tapering or ovality. Replace pins as

necessary.

2. Inspect lift cylinder pins for wear, scoring or other

damage, and for tapering or ovality. Ensure pin surfaces are protected prior to installation. Replace pins

as necessary.

3. Inspect telescope cylinder rod attach pin for wear,

scoring or other damage. Replace pin as necessary.

4. Inspect inner diameter of boom pivot bushings for

scoring, distortion, wear or other damage. Replace

bushings as necessary.

5. Inspect wear pads for wear.

6. Inspect all threaded components for damage such

as stretching, thread deformation, or twisting.

Replace as necessary.

7. Inspect structural units of boom assembly for bending, cracking, separation of welds, or other damage.

Replace boom sections as necessary.

Assembly of the Main Boom

1. Install power track to the attach point on the base

boom section. Secure power track with the attaching

hardware.

2. Install hydraulic lines and electrical cables into the

power track.

3. Install wear pads to the aft end of the fly section.

4. Using suitable lifting equipment, slide fly section into

the base section until power track attach point aligns

with holes in side of base section.

5. Attach the power track to the aft end of fly boom

section. Secure power track with the attaching hardware.

6. Using suitable lifting equipment, slide fly boom section out to gain access to telescope cylinder attach

pin hole.

7. Measure the distance between the telescope cylinder port block attach point on base boom section

and the attach point on fly boom section.

8. Connect a suitable auxiliary hydraulic power source

to the telescope cylinder port block.

9. Extend the telescope cylinder the distance of the

two attach points.

10. Secure the sling and lifting device at the telescope

cylinder’s approximate center of gravity, and lift the

cylinder to the aft end of the boom assembly.

WHEN INSERTING THE TELESCOPE CYLINDER INTO THE BOOM,

CARE MUST BE TAKEN NOT TO DAMAGE THE POWER TRACK

ASSEMBLY.

11. Slowly slide the telescope cylinder into boom

assembly, align rod end with attach point in fly section. Insert pin and secure with retaining ring.

12. Align bolt holes at aft end of base boom section with

telescope cylinder port block. Secure telescope cylinder with hardware.

2-6 – JLG Lift – 3120869

SECTION 2 - PROCEDURES

13. Install wear pads at end of base boom section.

Using shims, adjust the adjustable wear pads to

zero clearance. Adjust pads alternately side to side,

so that fly boom section is centered in base boom

section.

14. Retract boom section fully. Using shims, adjust wear

pads at aft end of boom section to zero clearance.

Adjust pads alternately side to side, so that fly boom

section is centered in base boom section.

15. Disconnect auxiliary power source from telescope

cylinder.

Installation of the Boom Assembly

1. Using suitable lifting equipment, position boom

assembly on turntable so that boom pivot holes in

both boom and turntable are aligned.

2. Install boom pivot pin, ensuring that location of the

hole in pivot pin aligns with attach point on upright.

3. Using all applicable safety precautions, operate lifting equipment in order to position boom lift cylinder

and level link so that holes in cylinder rod end and

level link are aligned with the one in the turntable.

Insert cylinder pins.

4. If necessary, gently tap pins into position with a soft

headed mallet, ensuring that attach holes in pins are

aligned with attach holes in boom structure. Secure

with hardware.

5. Connect all hosing and wiring.

6. Install the platform to the boom assembly.

7. Connect all hosing and wiring at platform control

station.

8. Using all safety precautions, operate machine systems and extend and retract boom for four or five

cycles.

9. Shut down machine systems and check for leakage.

2.7 DRIFT TEST

NOTE: It is recommended that the machine be shut down in

the test mode for at least one hour prior to beginning

the drift test. This will allow the oil temperature in the

cylinder to stabilize with the ambient temperature.

Thermal expansion or retraction of the hydraulic oil

can greatly affect cylinder movement.

Telescope Cylinder

NOTE: Switches referenced in this pro ce dur e are loc ated on

the Ground Control Panel.

1. Activate hydraulic system, properly set extendable

axles and position boom in stowed position; adhere

to all safety precautions.

BEFORE RAISING AND EXTENDING BOOM, ENSURE THAT

AREAS ABOVE AND BELOW BOOM AND PLATFORM AND AHEAD

OF PLATFORM ARE CLEAR OF ALL OBSTRUCTIONS AND PERSONNEL.

2. Position LIFT control switch to UP and hold until

boom reaches horizontal.

3. Position TELESCOPE control switch to OUT and

hold until boom extends approximately 1.2 meters

(4 feet); measure from end of base section to end of

mid section.

4. Position LIFT control switch to UP and hold until

boom reaches maximum elevation. Shut down

engine.

5. Tag and carefully disconnect the hydraulic lines to

the telescope cylinder at control valve.

6. Observe oil flow from cylinder lines. Oil leaking from

extend port hose indicates a leaking counterbalance

valve. Oil leaking from retract port hose indicates

leakage by cylinder piston.

7. Leave boom elevated in test position for approximately one hour.

BEFORE LOWERING BOOM, ENSURE THAT AREAS BELOW

BOOM AND PLATFORM ARE CLEAR OF ALL PERSONNEL AND

OBSTRUCTIONS.

3120869 – JLG Lift – 2-7

SECTION 2 - PROCEDURES

8. Position LIFT control switch to DOWN and hold until

boom reaches horizontal; check boom length

against measurement. If boom has retracted more

than 2.5 cm (1 inch) and oil is leaking around rodend of telescope cylinder (check with light and

inspection mirror), seals are defective and require

replacement, or cylinder rod is scored and cylinder

requires overhaul or replacement. If boom has

retracted and oil is leaking from counterbalance

valve, the valve is either improperly adjusted, or

defective and requires replacement.

9. Connect hydraulic lines to control valve.

Lift Cylinder

NOTE: Switches referenced in thi s p r oc edu re are lo ca ted on

the Ground Control Panel.

1. Activate hydraulic system, properly set extendable

axles and position boom in stowed position; adhere

to all safety precautions.

NOTE: Tape measure or cord should be at least 2 meters (6

feet) long for use in this test.

2. Attach tape measure or cord to bottom of platform.

BEFORE RAISING BOOM, ENSURE THAT AREAS ABOVE AND

BELOW BOOM AND PLATFORM ARE CLEAR OF ALL OBSTRUCTIONS AND PERSONNEL.

3. With boom fully retracted, place LIFT control switch

to UP and hold until platform is approximately 2

meters (6 feet) above ground level. Shut down

engine.

4. Tag and carefully disconnect hydraulic lines to lift

cylinder at control valve. Use a suitable container to

retain any residual hydraulic fluid.

5. Observe oil flow from cylinder lines. Oil leaking from

extend port hose indicates a leaking counterbalance

valve. Oil leaking from retract port hose indicates

leakage by cylinder piston.

6. Leave boom elevated in test position for approximately one (1) hour.

7. With tape measure or cord used for reference,

check to see whether boom has lowered (crept)

more than 7.5 cm (3 inches).

8. If boom has lowered and oil is leaking around rodend cap of cylinder, seals in cylinder are defective

and require replacement. If boom has lowered and

oil is leaking from the counterbalance valve, the

valve is either improperly adjusted or defective and

requires replacement.

ENSURE THAT HYDRAULIC LINES ARE CONNECTED AS

MARKED PRIOR TO BEING DISCONNECTED.

9. Connect hydraulic lines to control valve.

2.8 CYLINDER CHECKING PROCEDURE

IF PERFORMING MAINTENANCE ON THE BOOM CYLINDERS, DO

NOT USE A LIFTING DEVICE TO LIFT THE BOOMS UNLESS THE

HOLDING VALVES HAVE BEEN REMOVED FIRST. FAILURE TO DO

SO WILL RESULT IN SEVERE DAMAGE TO THE BOOM.

NOTE: Cylinder check must be performed anytime a system

component is replaced or when improper system

operation is suspected.

Cylinders Without Counterbalance Valves Master Cylinder and Steer Cylinder

1. Using all applicable safety precautions, activate

engine and fully extend cylinder to be checked. Shut

down engine.

2. Carefully disconnect hydraulic hoses from retract

port of cylinder. There will be some initial weeping of

hydraulic fluid which can be caught in a suitable

container. After the initial discharge, there should be

no further drainage from the retract port.

3. Activate engine and extend cylinder.

4. If cylinder retract port leakage is less than 6-8 drops

per minute, carefully reconnect hose to port and

retract cylinder. If leakage continues at a rate of 6-8

drops per minute or more, cylinder repair must be

made.

5. With cylinder fully retracted, shut down engine and

carefully disconnect hydraulic hose from cylinder

extend port.

6. Activate engine and retract cylinder. Check extend

port for leakage.

7. If extend port leakage is less than 6-8 drops per

minute, carefully reconnect hose to extend port,

than activate cylinder through one complete cycle

and check for leaks. If leakage continues at a rate of

6-8 drops per minute or more, cylinder repairs must

be made.

2-8 – JLG Lift – 3120869

SECTION 2 - PROCEDURES

Cylinders With Dual Counterbalance Valves Slave Level, Lift, and Telescope

OPERATE ALL FUNCTIONS FROM GROUND CONTROL STATION

ONLY.

1. Using all applicable safety precautions, activate

hydraulic system.

IF WORKING ON THE PLATFORM LEVEL CYLINDER, STROKE

PLATFORM LEVEL CYLINDER FORWARD UNTIL PLATFORM SITS

AT A 45 DEGREES ANGLE.

2. Shut down hydraulic system and allow machine to

sit for 10-15 minutes. If machine is equipped with

bang-bang or proportional control valves, turn IGNITION SWITCH to ON, move control switch or lever

for applicable cylinder in each direction, then turn

IGNITION SWITCH to OFF. If machine is equipped

with hydraulic control valves, move control lever for

applicable cylinder in each direction. This is done to

relieve pressure in the hydraulic lines. Carefully

remove hydraulic hoses from appropriate cylinder

port block.

3. There will be initial weeping of hydraulic fluid, which

can be caught in a suitable container. After the initial

discharge, there should be no further leakage from

the ports. If leakage continues at a rate of 6-8 drops

per minute or more, the counterbalance valve is

defective and must be replaced.

2.9 CYLINDER REPAIR

NOTE: The following are general procedures that apply to

all of the cylinders on this machine. Procedures that

apply to a specific cylinder will be so noted.

Disassembly

DISASSEMBLY OF THE CYLINDER SHOULD BE PERFORMED ON

A CLEAN WORK SURFACE IN A DIRT FREE WORK AREA.

1. Connect a suitable auxiliary hydraulic power source

to the cylinder port block fitting.

DO NOT FULLY EXTEND CYLINDER TO THE END OF STROKE.

RETRACT CYLINDER SLIGHTLY TO AVOID TRAPPING PRESSURE.

2. Operate the hydraulic power source and extend the

cylinder. Shut down and disconnect the power

source. Adequately support the cylinder rod, if applicable.

3. If applicable, remove the cartridge-type holding

valve and fittings from the cylinder port block. Discard o-rings.

4. To check piston seals, carefully remove the counterbalance valve from the retract port. After initial discharge, there should be no further leakage from the

ports. If leakage occurs at a rate of 6-8 drops per

minute or more, the piston seals are defective and

must be replaced.

5. If no repairs are necessary or when repairs have

been made, replace counterbalance valve and carefully connect hydraulic hoses to cylinder port block.

6. If used, remove lifting device from upright or remove

prop from below main boom, activate hydraulic system and run cylinder through one complete cycle to

check for leaks.

3120869 – JLG Lift – 2-9

SECTION 2 - PROCEDURES

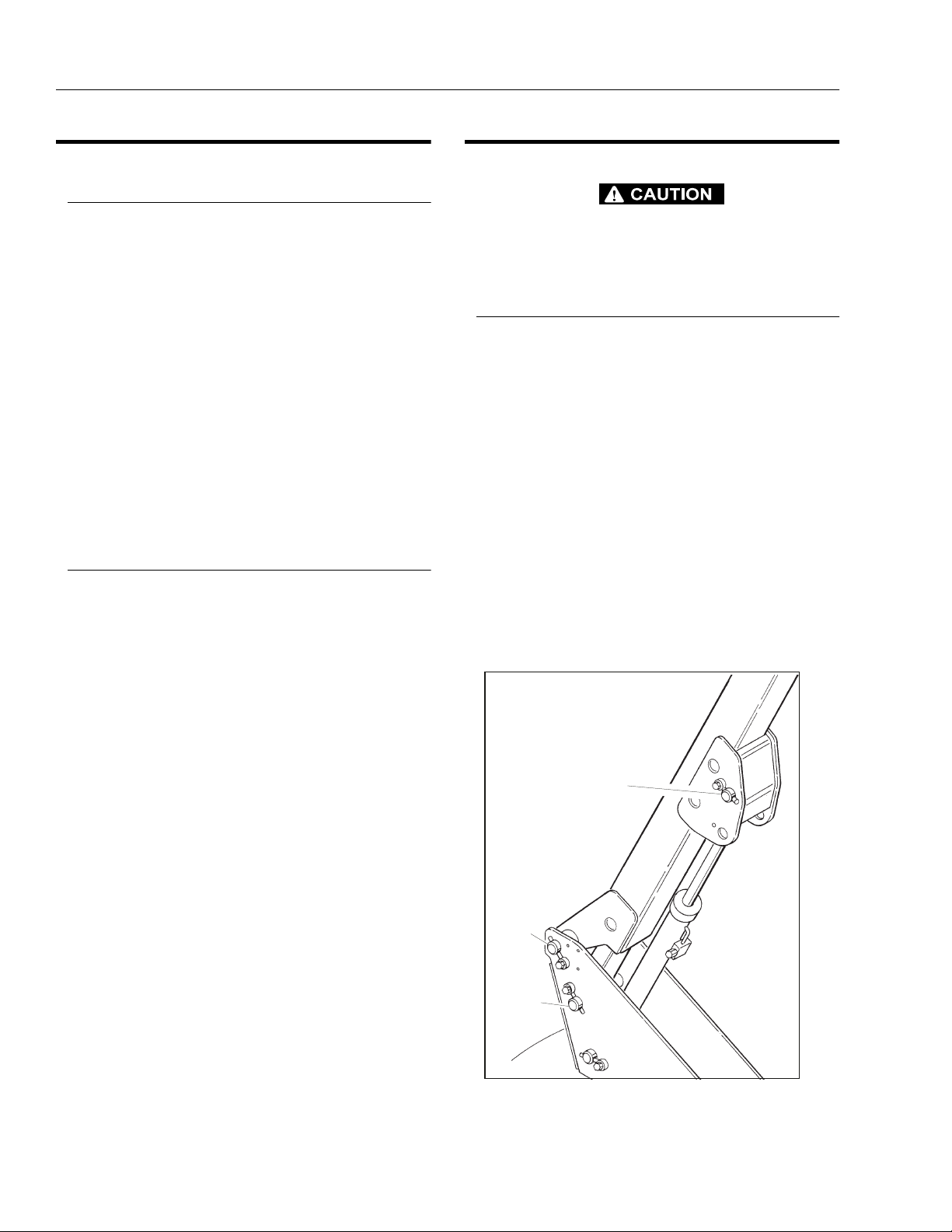

Figure 2-4. Boom Prop Configuration

2-10 – JLG Lift – 3120869

SECTION 2 - PROCEDURES

4. Place the cylinder barrel into a suitable holding fixture.

Figure 2-5. Cylinder Barrel Support

5. Mark cylinder head and barrel with a center punch

for easy realignment. Using an allen wrench, loosen

the cylinder head retainer cap screws, and remove

cap screws from cylinder barrel.

7. Attach a suitable pulling device to the cylinder rod

port block end or cylinder rod end, as applicable.

EXTREME CARE SHOULD BE TAKEN WHEN REMOVING THE CYLINDER ROD, HEAD, AND PISTON. AVOID PULLING THE ROD OFFCENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON AND

CYLINDER BARREL SURFACES.

8. With the barrel clamped securely, apply pressure to

the rod pulling device and carefully withdraw the

complete rod assembly from the cylinder barrel.

Figure 2-6. Capscrew Removal

NOTE: St eps 6 applies only t o the lower lift and tele scope

cylinders.

6. Using a spanner wrench, loosen the end cap or

head retainer, and remove from cylinder barrel.

Figure 2-7. Cylinder Rod Support

9. Using suitable protection, clamp the cylinder rod in

a vise or similar holding fixture as close to the piston

as possible.

10. Loosen and remove the cap screw(s), if applicable,

which attach the tapered bushing to the piston.

11. Insert the cap screw(s) in the threaded holes in the

outer piece of the tapered bushing. Progressively

tighten the cap screw(s) until the bushing is loose

on the piston.

3120869 – JLG Lift – 2-11

SECTION 2 - PROCEDURES

Figure 2-8. Tapered Bushing Removal

12. Remove the bushing from the piston.

13. Screw the piston CCW, by hand, and remove the

piston from cylinder rod.

14. Remove and discard the piston o-rings, seal rings,

and backup rings.

15. Remove piston spacer, if applicable, from the rod.

16. Remove the rod from the holding fixture. Remove

the cylinder head gland and retainer plate, if applicable. Discard the o-rings, back-up rings, rod seals,

and wiper seals.

Cleaning and Inspection

1. Clean all parts thoroughly in an approved cleaning

solvent.

2. Inspect the cylinder rod for scoring, tapering, ovality,

or other damage. If necessary, dress rod with

Scotch Brite or equivalent. Replace rod if necessary.

3. Inspect threaded portion of rod for excessive damage. Dress threads as necessary.

7. Inspect threaded portion of piston for damage.

Dress threads as necessary.

8. Inspect seal and o-ring grooves in piston for burrs

and sharp edges. Dress applicable surfaces as necessary.

9. Inspect cylinder head inside diameter for scoring or

other damage and for ovality and tapering. Replace

as necessary.

10. Inspect threaded portion of head for damage. Dress

threads as necessary.

11. Inspect seal and o-ring grooves in head for burrs

and sharp edges. Dress applicable surfaces as necessary.

12. Inspect cylinder head outside diameter for scoring

or other damage and ovality and tapering. Replace

as necessary.