JLG E45A-AJ Operator Manual

CORPORATE OFFICE

BS E N ISO 9001 C ertificate N o.6917

JLG INDUSTRIES, INC.

1 JLG Drive

McConnellsburg, PA 17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

EUROPEAN OFFICE

JLG INDUSTRIES (EUROPE)

Kilmartin Place,

Tannochside Park,

Uddingston, Scotland, G71 5PH

Telephone: 01698 811005

Fax: 01698 811055

AUSTRALIAN OFFICE

JLG INDUSTRIES (AUSTRALIA)

P.0. Bo x 9 7 2

11 Bolwarra Road

Port MacQuarie

N.S.W. 44

Australia

Telephone: 1 (065) 811111

Fax: 1 (065) 81 012 2

Models

M45A

M45AJ

E45A

E45AJ

Issued: April 1, 1999 PRINTED IN U.S.A. 3120883

Updated: March 15, 2000

OPERATORS & SAFETY

FOREWORD

FOREWORD

The purpose of this manual is to provide users with the operating procedures essential for the promotion of

proper machine operation for its intended purpose. It is important to over-stress proper machine usage. All

information in this manual should be READ and UNDERSTOOD before any attempt is made to operate the

machine. YOUR OPERATING MANUAL IS YOUR MOST IMPORTANT TOOL - Keep it with the machine.

REMEMBER ANY EQUIPMENT IS ON LY AS SAFE AS THE OPERATOR.

BECAUSE THE MANUFACTURER HAS NO DI RECT CONTROL OVER MACHINE APPLICATION AND

OPERATION, PROPER SAFETY PRACTICES ARE THE RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

ALL INSTRUCTIONS IN THIS MANUAL ARE BASED ON THE USE OF THE MACHINE UNDER PROPER

OPERATING CONDITI ONS, WITH NO DEVIATIONS FROM THE ORIGINAL DESIGN. ALTERATION AND/OR

MODIFICATION OF THE MACHINE IS STRICTLY FORBIDDEN, WITHOUT WRITTEN APPROVAL FROM

JLG INDUSTRIES, PER OSHA REGUL ATIONS AND APPLICABLE ANSI STANDARDS.

THIS SAFETY ALERT SYMBOL IS USED TO CALL ATTENTION TO POTENTIAL HAZARDS WHICH

MAY LEAD TO SERIOUS INJURY OR DEATH IF IGNORED.

Safety of personnel and proper u se of the mac hine are of pr imary conc ern, DANGER, WARNIN G, CAUTION, IMPORTANT, INST RUCTIONS an d NOTE are inserted thr oughout this manual to e mphasize these

areas. They are defined as follows :

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED WILL RESULT IN SERIOUS INJURY OR

DEATH.]

CAUTION INDICATES A POTENTIALLY HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR MODERATE

INJURY. IT MAY ALSO BE USED TO ALERT AGAINST UNSAFE

PRACTICES

JLG INDUSTRIES MAY HAVE ISSUED SAFETY RELATED BULLETINS FOR YOUR JLG PRODUCT. CONTACT JLG INDUSTRIES INC.

OR THE LOCAL AUTHOR IZED JLG DISTRIBUTO R FOR INFORMATION CONCERNING SAFETY RELATED BULLETINS WHICH MAY

HAVE BEEN ISSUED FOR YOUR JLG PRODUCT. ALL ITEMS REQUIRED BY THE SAFETY RELATED BULLETINS MUST BE COMPLETED ON THE AFFECTED JLG PRODUCT

WARNING INDICATES A POTENTIALLY HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED COULD RESULT IN SERIOUS INJURY

OR DEATH.

IMPORTANT OR INSTRUCTIONS INDICATES A PROCEDURES

ESSENTIAL FOR SAFE OPERATION AND WHICH, IF NOT FOLLOWED, MAY RESULT IN A MALFUNCTION OR DAMAG E TO THE

MACHINE.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes without prior notification. Contact JLG Industries, Inc. for updated information.

3120883 – JLG Lift – a

FOREWORD

This page left blank intentionally.

b – JLG Lift – 3120883

FOREWORD

All procedures herein are based on the use of the

machine under proper operating conditions, with no

deviation s fr om or igin al desi gn i nte nt. .. as p er OSHA

regulations.

READ & HEED!

The ownership, use, service, and/or maintenance of

this machine is subject to various governmental and

local laws and regu la tio ns. It is th e re sp ons ibil it y of

the owner/user to be knowledgeable of these laws

and regulations and to comply with them. The most

prevalent regulations of this type in the United States

are the Federal OSHA Safety Regulation s*. Listed

below, in abbreviated form are some of the requirements of Federal OSHA regulations in effect as of the

date of publication of this handbook.

The listing of these requirements shall not relieve

the owner/user of the responsibility and obligation

to determine all applicable laws and regulations and

their exact wording and re quirements, and t o comply with the requirements. Nor shall the listing of

these requirements constitute an assumption of

responsibility of liability on the part of JLG Industries, Inc.

1. Only trained and authoriz ed operat ors shall be

permitted to operate the aerial lift.

2. A malfunctioning lift shall be shut down until

repaired.

3. The controls shall be plainly marked as to their

function.

4. The controls shall be tested each day prior to

use to determ in e that they are in safe operat in g

condition.

5. All personnel in the platform shall, at all times,

wear approved fall protection devices and

other safety gear as required.

6. Load limits specified by the manufacturer shall

not be exceeded.

7. Instruction and warning placards must be legible.

8. Aerial lifts may be field modified for uses other

than those in te nd ed by the manufa cturer only if

certified in writ ing by the m anufac turer to be i n

conformity to JLG requirements and to be at

least as safe as it was prior to modification.

9. Aerial lifts shall not be used near electric power

lines unless the lines have been de energized

or adequate clearance is maintained.

10. Employees using aeri al lifts shall be instructed

on how to rec ognize and avoid un safe conditions and hazards.

11. Ground controls shall not be operated unless

permission has be en obtained fro m personnel

in the platform, except in case of an emergency.

12. Regular inspection of the job site and aerial lift

shall be performed by competen t persons.

13. Person n el sha ll always stand on the floor of the

platform, not on b oxes, planks, railing or oth er

devices, for a work position.

*Applicable Federal OSHA regulations for the

United States, as of the date of publicat ion of this

manual, include, but are not limited to, 29 CFR

1910.67, 29 CFR 1926.20, 29 CFR 1926.21, 29 CFR

1926.28, and 29 CFR 1926.453.

3120883 – JLG Lift – c

FOREWORD

REVISON LOG

April 1, 1999 - Original Issue

3-9 - Updated 5-7-99

3-9 - Updated 5-12-99

2-5 - Updated 5-21-99

4-3 - Updated 5-21-99

2-10 & 2-11 - Updated 6-1-99

3-10 thru 3-12 - Updated 6-1-99

6-1 - Updated 6-1-99

3-7 - Updated 7-13-99

3-13 - Updated 7-13-99

2-11 - Updated 8-4-99

4-1 - Updated 8-4-99

4-5 thru 4-7 - Updated 8-4-99

3-5 thru 3-8 - Updated 8-18-99

4-7 - Updated 9-21-99

2-9 - Updated 11-3-99

2-11 - Updated 11-3-99

5-1 - Updated 11-3-99

6-1 - Updated 12-1-99

4-1 - Updated 3-15-00

4-8 - Updated 3-15-00

d – JLG Lift – 3120883

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION - FOREWORD

SECTION 1 - SAFE TY PRECAUTIONS

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Driving/Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Electrocution Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.4 Pre-Operational. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.5 Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.6 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.7 Towing and Hauling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

SECTION 2 - PREPAR ATI ON AND INSPECTION

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Preparation For Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Delivery and Frequent Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.4 Daily Walk-around Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5 Daily Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.6 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.7 Battery Maintenance and Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Personnel Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Operating Characteristics and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.4 Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

SECTION 4 - MACHINE OPERATION

4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.3 Motor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.4 Traveling (Driving). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.5 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.6 Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.7 Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.8 Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.9 Machine Function Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.10 Shut Down and Park. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.11 Machine Lifting and Tie Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.12 Boom Synchronizing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

SECTION 5 - OPTIONAL EQUIPMENT

5.1 Motion Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Foam Filled Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 Non-marking Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.4 Rotating Beacon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.5 Tilt Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.6 Wheel Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.7 Battery Packs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.8 Platform Light s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.9 Control Console Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.10 Cylinder Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.11 Work Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

3120883 – JLG Lift – i

TABLE OF CONTENTS

(Continued)

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION 6 - EMERGENCY PROCEDURES

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Emergency Towing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.3 Emergency Cont rols and Their Locat ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.4 Emergency Ope ra t ion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.5 Incident Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

SECTION 7 - INSPEC TION AND REPAIR LOG

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

2-1. Basic Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2-2. Daily Walk-Around Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-3. Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-4. Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

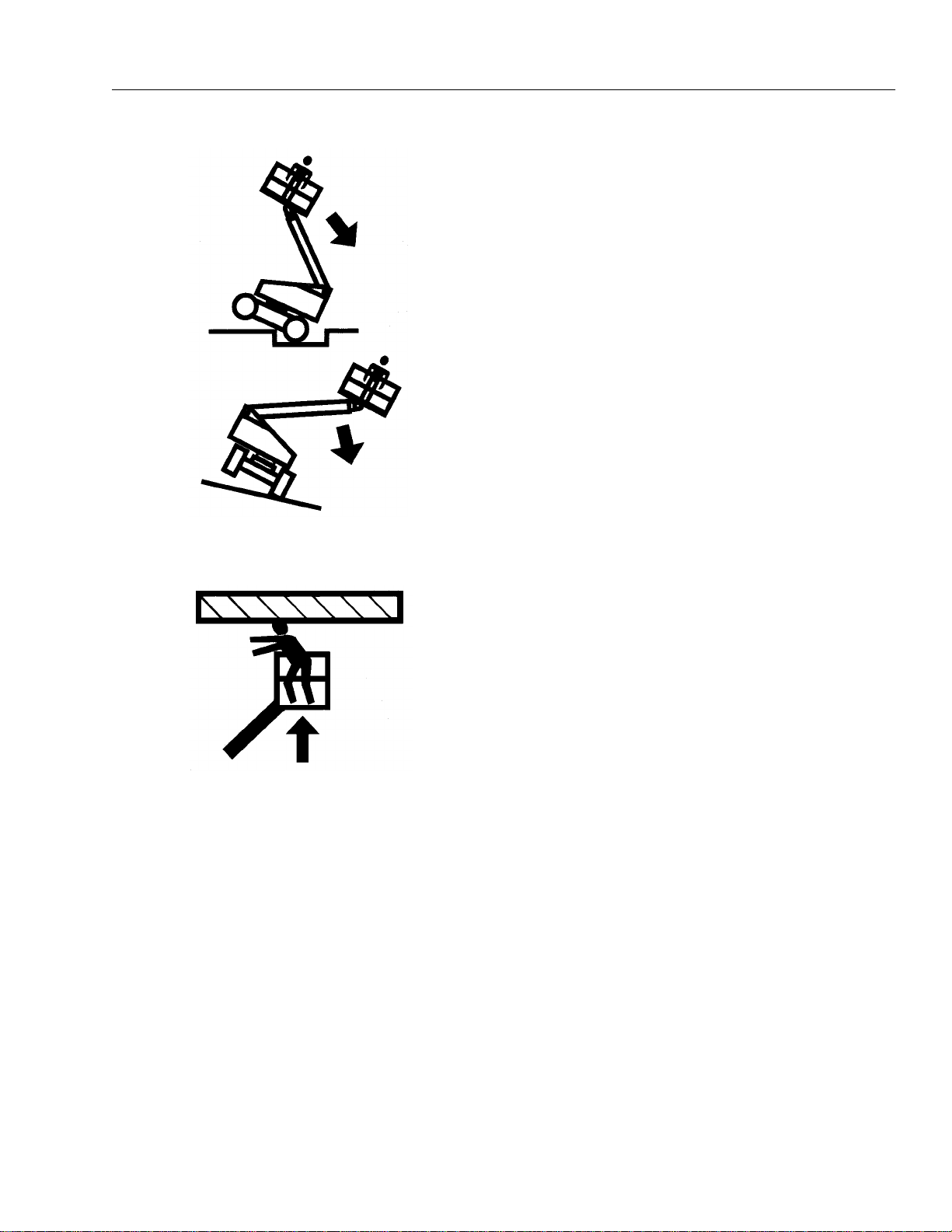

3-1. Position of Least Forward Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-2. Position of Least Backward Stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-3. Ground Control Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-4. Platform Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-5. Caution, Danger, Warning Decal Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-6. Control Panel Symbols (Sheet 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3-7. Control Panel Symbols (Sheet 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

4-1. Grade and Side Sl opes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-2. Upright Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-3. Lifting Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4-4. Chassis & Platform Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 M inimum Safe Approach Dis t anc e s (M .S.A.D.) to energi ze d (exposed or insulated)

power lines and parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2-1 Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

3-1 Simultaneous Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

7-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

ii – JLG Lift – 3120883

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section prescribes the prope r and safe practices for

major areas of machine usage. In order to promote proper

usage of the machine, it is mandatory that a daily routine

be establish ed based on instructions given in thi s s e ction.

A maintenance pr ogram must also be establishe d by a

qualified person and must be follow ed to ensure that the

machine is safe to operate.

The owner/user/operator of the machine should not

accept operating responsibility until this manual has been

read and understood, and operation of the machine,

under the supervisio n of an exper ienced and qualif ied person, has been completed. If there is a question on application and/or op eration, JLG Industri es Inc., sho uld be

consulted.

MODIFICATION OR ALTERATION OF AN AERIAL PLATFORM

SHALL BE MADE ONLY WITH PRIOR WRITTEN PERMISSION OF

THE MANUFACTURER.

1.2 DRIVING/TOWING

Before driving the machine, the user must be familiar with

the drive, steer and stopping characteristics. This is especially important when driving in close quarters.

The user should be familiar with the driving surface before

driving. The surface s hould be firm and level and grade s

should not exceed the allowable grade for the machine.

NOTE: Remember that the key to safe and proper usage is

common sense and its careful application.

The machine is not equipped with provisions for towing.

Refer to Section 6 for emergency towing procedures.

SPECIAL NOTE:

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION AND ON THE MACHINE COULD RESULT IN

MACHINE DAMAGE, PERSONNEL INJURY OR DEATH, AND IS A

SAFETY VIOLATION.

3120883 – JLG Lift – 1-1

SECTION 1 - SAFETY PRECAUTIONS

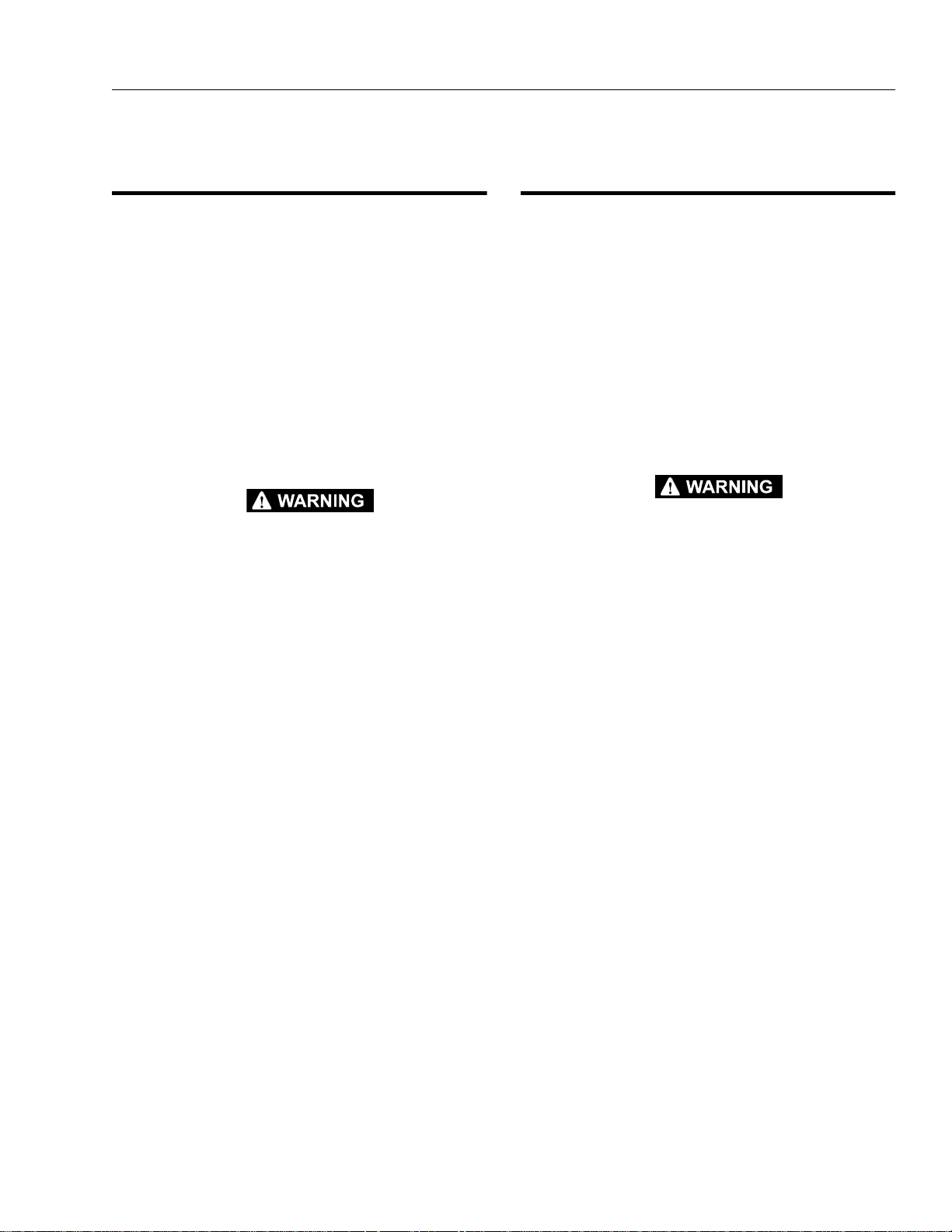

Table 1-1. Minimum Safe Approach Distances (M.S.A.D.) to energized (exposed or insulated) power lines and parts

Voltage Range

(Phase to Phase)

0 to 300V AVOID CONTACT

Over 300V to 50 KV 3

Over 50KV to 200 KV 5

Over 200 KV to 350 KV 6

Over 350 KV to 500 KV 8

Over 500 KV to 750 KV 11

Over 750 KV to 1000 KV 14

DANGER: DO NOT maneuver machine or personnel inside PROHIBITED ZONE. ASSUME all electrical parts and wiring

are ENERGIZED unless known otherwise.

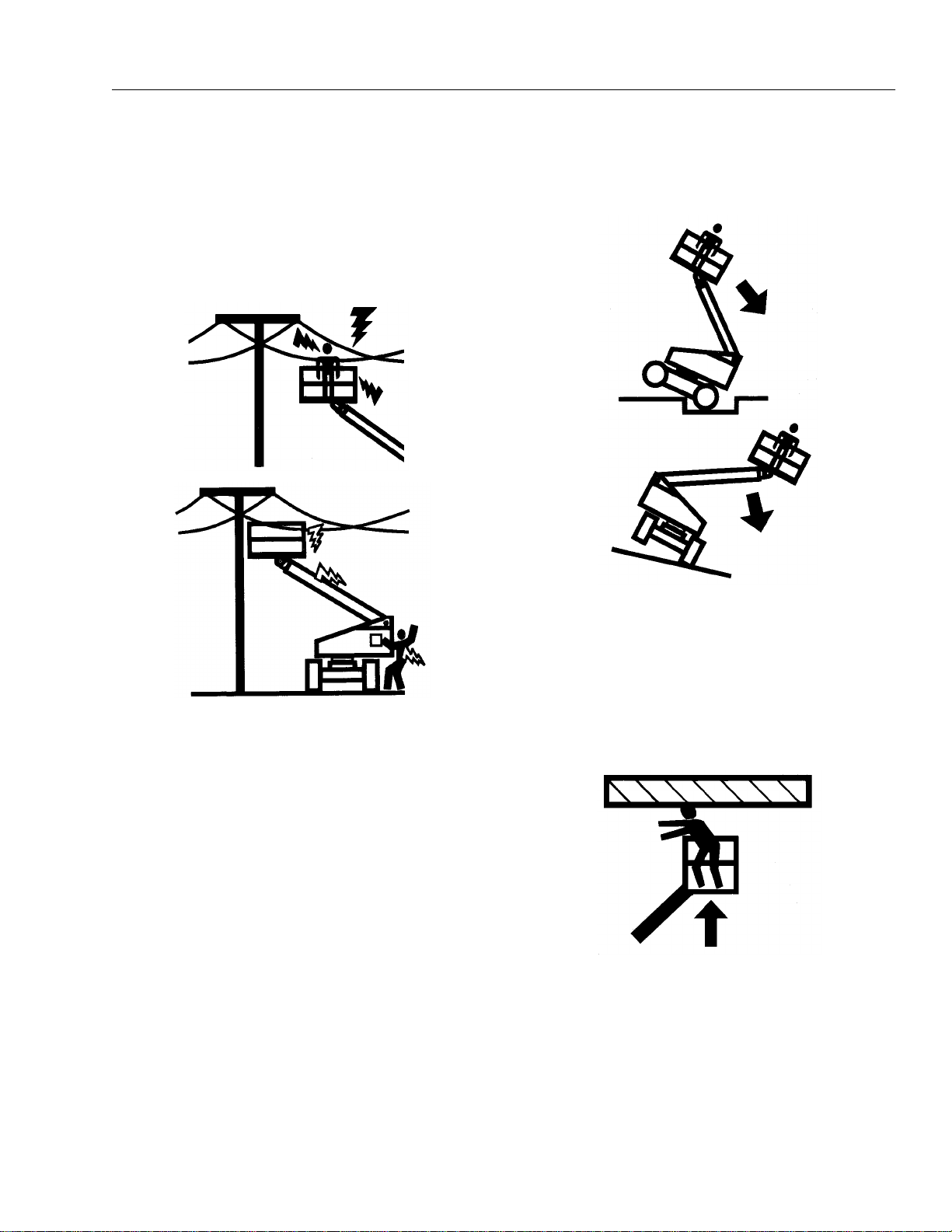

1.3 ELECTROCUTION HAZARD

MINIMUM SAFE APPROACH DISTANCE

in Meters

FROM CONTACT WITH OR PROXIMITY TO AN ELECTRICALLY CHARGED CONDUCTOR.

• MAINTAIN A CLEARANCE OF AT LEAST 3 M (10

FEET) BETWEEN ANY PART OF THE MACHINE OR

ITS LOAD AND ANY ELECTRICAL LINE OR APPARATUS CARRYING UP TO 50,000 VOLTS. 30.5 cm ADDITIONAL CLEARANCE IS REQUIRED FOR EVERY

ADDITIONAL 30,000 VOLT S OR LESS.

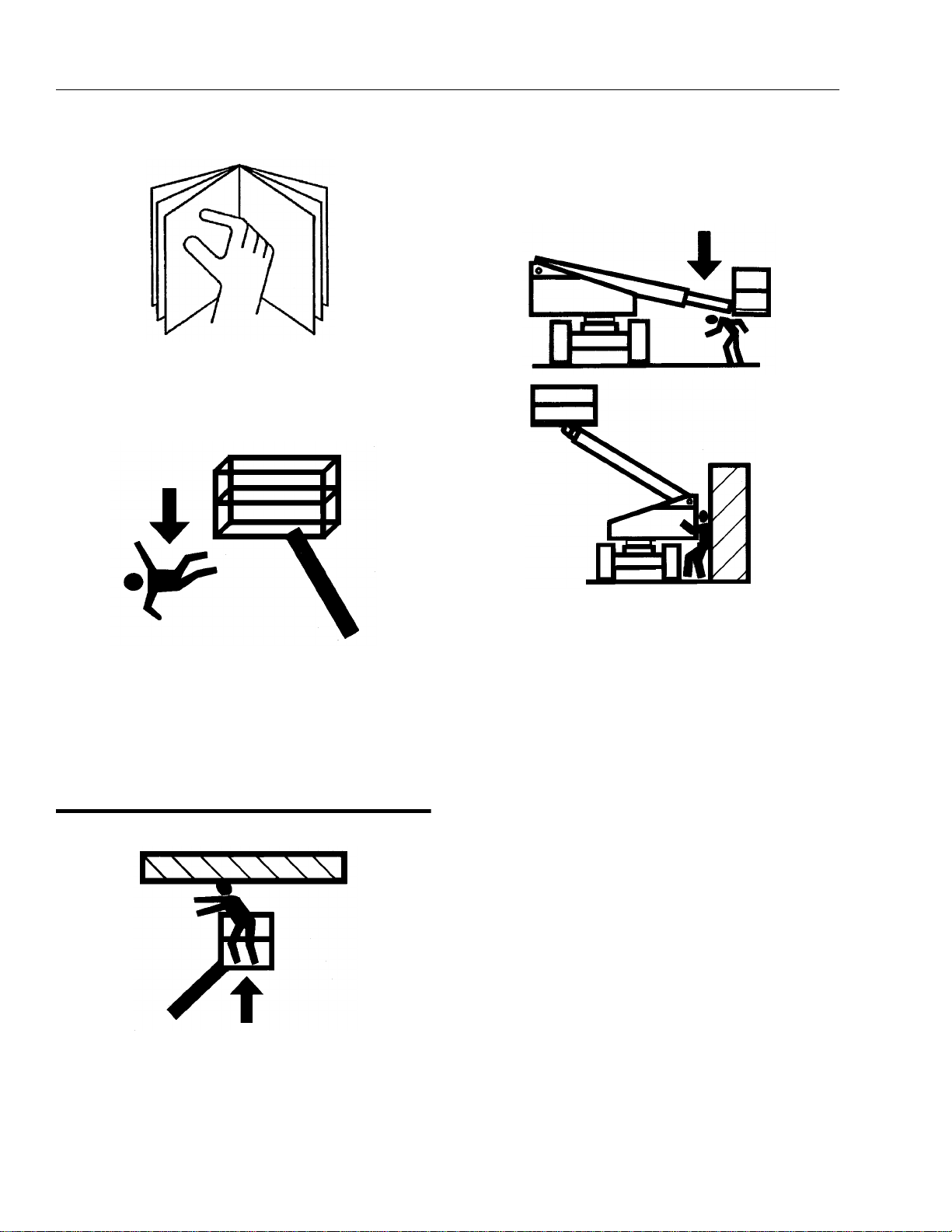

1.4 PRE-OPERATIONAL

• R EAD YOUR MANUAL. UNDERSTAND WHAT YOU’VE

READ - THEN BEGIN OPERATIONS.

• MAINTAIN SAFE CLEARANCE FROM ELECTRICAL

LINES AND APPARATUS. ALLOW FOR BOOM SWAY,

ROCK OR SAG AND ELECTRICAL LINE SWAYING.

THE MACHINE DOES NOT PROVIDE PROTECTION

• ALLOW ONLY AUTHORIZED AND QUALIFIED PERSONNEL TO OPERATE MACHINE W HO HAVE DEMONSTRATED THAT THEY UNDERSTAND SAFE AND

PROPER OPERATION AND MAINTENANCE OF THE

UNIT.

1-2 – JLG Lift – 3120883

SECTION 1 - SAFETY PRECAUTIONS

• AN OPERATOR MUST NOT ACCEPT OPERATING

RESPONSIBILITIES UNTIL ADEQUA TE TRAINING HAS

BEEN GIVEN BY COMPETENT AND AUTHORIZED

PERSONS.

• BEFORE OPERATION, CHECK WORK AREA FOR

OVERHEAD ELECTRIC LINES, MACHINE TRAFFIC

SUCH AS BRIDGE CRANES , HIGH W AY, RAILWAY AND

CONSTRUCTION EQUIPMENT.

• NEVER DISABLE OR MODIFY THE FOOTSWITCH OR

ANY OTHER SAFETY DEVICE. UNAUTHORIZED MODIFICATION OF THE MACHINE IS A SAFETY VIOLATION.

• PRECAUTIONS TO AVOID ALL KNOWN HAZARDS IN

THE WORK AREA MUST BE TAKEN BY THE OPERATOR AND HIS SUPERVISOR BEFORE STARTING THE

WORK.

• DO NOT OPERATE THIS MACHINE UNLESS IT HAS

BEEN SERVICED AND MAINTAINED ACCORDING TO

THE MANUFACTURERS SPECIFICATIONS AND

SCHEDULE.

• ENSURE DAILY INSPECTION AND FUNC TION CHEC K

IS PERFORMED PRIOR TO PLACING MACHINE INTO

OPERATION.

• DO NOT OPERATE MACHINE WHEN WIND CONDITIONS EXCEED 12.5 M/S (30MPH).

• NEVER OPERATE BOOM FUNCTIONS (TELE, SWING,

LIFT) WHEN MACHINE IS ON A TRUCK, OTHER VEHICLE, OR ABOVE GROUND STRUCTURE.

• THIS MACHINE CAN BE OPERATED IN NOMINAL

AMBIENT TEMPERATURES OF -20° C TO 40° C (0° F

TO 104°F). CONSULT FACTORY TO OPTIMIZE

OPERATION OUTSIDE THIS RANGE.

• APPROVED HEAD GEAR MUST BE WORN BY ALL

OPERATING AND GROUND PERSONNEL.

3120883 – JLG Lift – 1-3

SECTION 1 - SAFETY PRECAUTIONS

.

• R EAD AND OBEY ALL DANGERS, WARNINGS, CAUTIONS AND OPERATING INSTRUCTIONS ON

MACHINE AND IN THIS MANUAL.

• BE FAMILIAR WITH LOCATION AND OPERATION OF

GROUND STATION CONTROLS.

• ALWAYS POSITION BOOM OVER REAR (DRIVE) AXLE

IN LINE WITH DIRECTION OF TRAVEL. REMEMBER,

IF BOOM IS OVER FRONT (STEER) AXLE, DIRECTION

OF STEER AND DRIVE MOVEMENT WILL BE OPPOSITE FROM NORMAL OPERATION.

• ALWAYS USE THREE POINT CONTACT WHEN

ENTERING OR EXITING THE MAC HINE. FACE THE

MACHINE WHEN YOU ENTER OR LEAVE. THREE

POINT CONTACT MEANS THAT TWO HANDS AND

ONE FOOT OR O NE HAND AN D TWO F EET ARE IN

CONTACT WITH THE MACHINE AT ALL TIMES DURING MOUNT AND DISMOUNT.

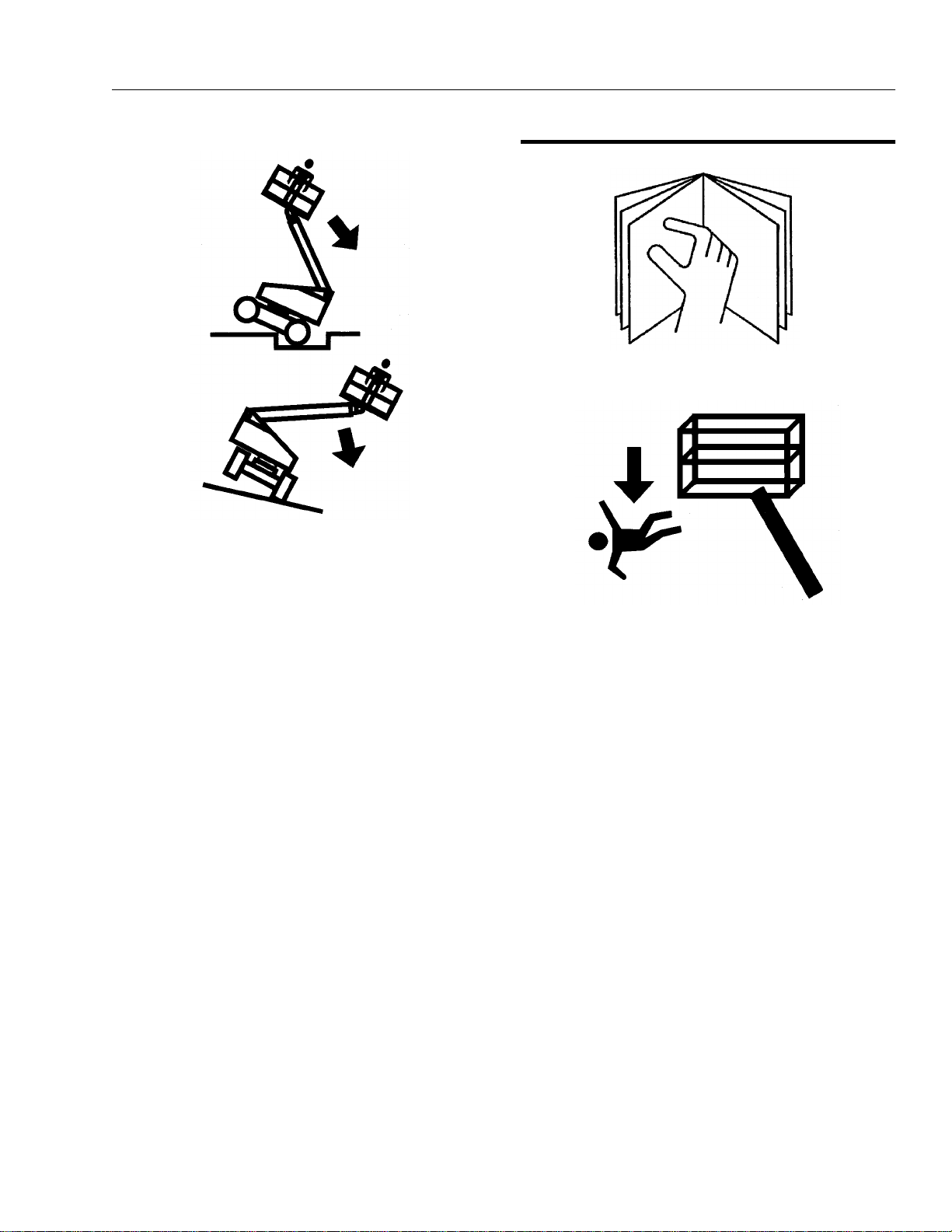

1.5 DRIVING

• WATCH FOR OBSTRUCTIONS AROUND MACHINE

AND OVERHEAD WHEN DRIVING.

• DO NOT USE DRIVE FUNCTION TO POSITION PLATFORM CLOSE TO OBSTACLES. USE BOOM FUNCTION INSTEAD.

• WHEN DRIVING IN HIGH SPEED, SWITCH TO LOW

SPEED BEFORE STOPPING. TRAVEL GRADES IN

LOW DRIVE, HIGH ENGINE ONLY.

• DO NOT USE HIGH SPEED DRIVE WHEN IN

RESTRICTED OR CLOSE QUARTERS, OR WHEN

DRIVING IN REVERSE.

• BE AWARE OF STOPPING DISTANCES WHEN TR AVELING IN HIGH AND LOW SPEEDS.

• ALWAYS POST A LOOKOUT AND SOUND HORN

WHEN DRIVING IN AREAS WHERE VISION IS

OBSTRUCTED.

• KEEP NON-OPERATING PERSONNEL AT LEAST 2 M

(6 FEET) AWAY FROM MACHINE DURING DRIVING

OPERATIONS.

1-4 – JLG Lift – 3120883

SECTION 1 - SAFETY PRECAUTIONS

1.6 OPERATION.

• R EAD YOUR MANUAL. UNDERSTAND WHAT YOU’VE

READ - THEN BEGIN OPERATIONS.

• CHECK TRAVEL PATH FOR PERSONS, HOLES,

BUMPS, DROP-OFFS, OBSTRUCTIONS, DEBRIS,

AND COVERINGS WHICH MAY CONCEAL HOLES

AND OTHER HAZARDS.

• TRAVEL IS PERMITTED ON GRADES NO GREATER

THAN THOSE INDICATED ON THE SERIAL NUMBER

PLATE.

• DO NOT DRIVE ON SIDESLOPES WHICH EXCEED 5°.

• DO NOT TRAVEL ON SOFT OR UNEVEN SURFACES,

AS TIPPING WILL OCCUR.

• DO NOT DRIVE MACHINE NEAR PITS, LOADING

DOCKS OR OTHER DROP-OFFS.

• PRIOR TO ENTERING AND EXITING PLATFORM AT

GROUND LEVEL, FULLY LOWER THE BOOM.

EXTEND BOOM UNTIL END OF FLY B OOM CONTACTS GROUND. WITH BOOM LIFT IN THIS CONFIGURATION, ENTER AND/OR EXIT PLATFORM

THROUGH GATE OPENING.

• JLG RECOMMENDS ALL PERSONS IN THE PLATFORM TO WEA R LANYARDS WITH AN APPR OVED

FALL PROTECTION DEVICE. SECURE LANYARD TO

DES IG NAT ED LA NYA RD AT TAC H P OI NT ON P LATFORM. KEEP GATE CLOSED AT ALL TIMES.

• TO AVOID FALLING - USE EXTREME CAUTION WHEN

ENTERING OR LEAVING PLATFORM ABOVE

GROUND. ENTER OR EXIT THRU GATE ONLY. PLATFORM FLOOR MUST BE WITHIN 30CM (1 FOOT) OF

ADJACENT - SA FE AND SECURE - S TRUCTURE.

ALLOW FOR PLATFORM VERTICAL MOVEMENT AS

WEIGHT IS TRANSFERRED TO OR FROM PLATFORM.

3120883 – JLG Lift – 1-5

SECTION 1 - SAFETY PRECAUTIONS

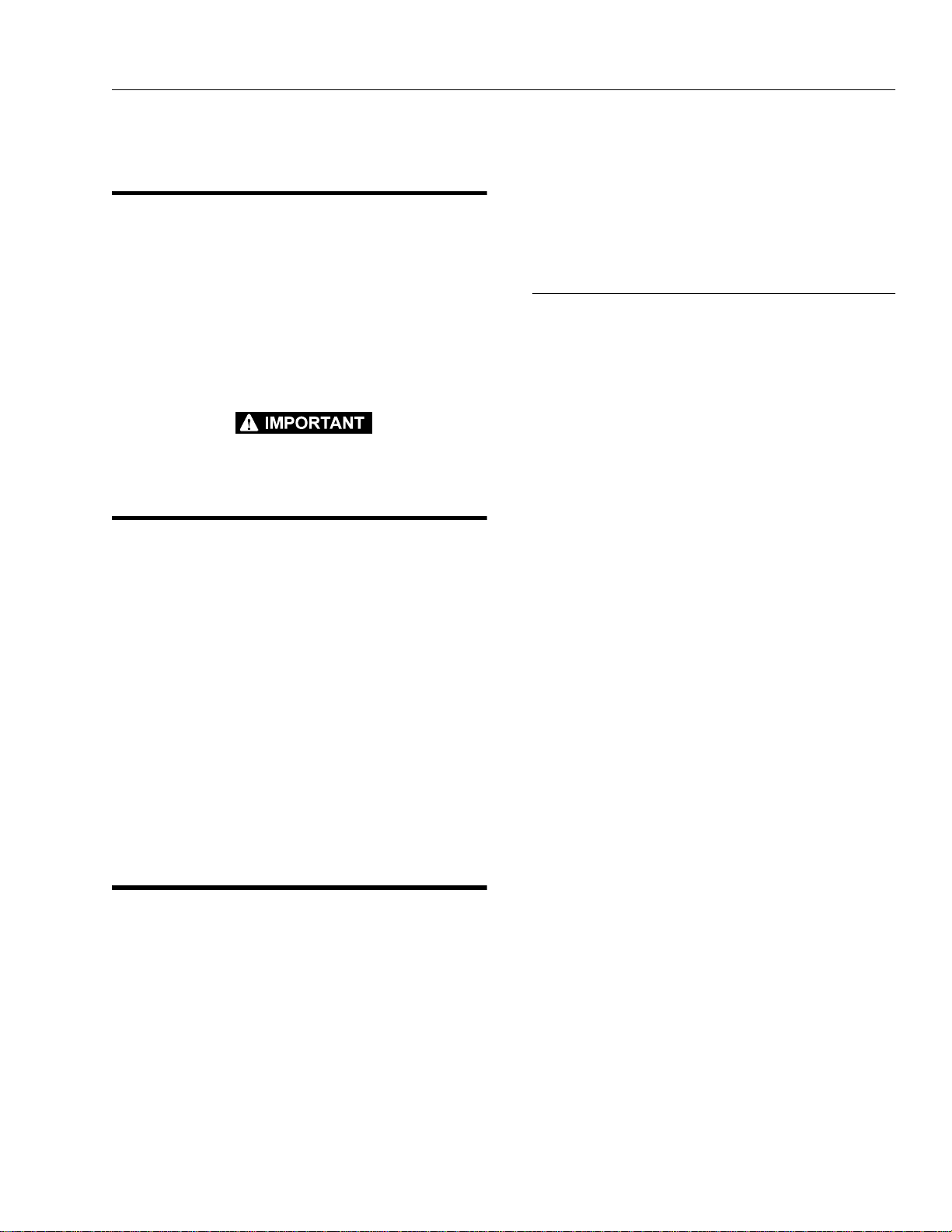

• TRANSFERS BETWEEN A STRUCTURE AND THE

AERIAL PLATFORM EXPOSE O PERATORS TO FALL

HAZARDS. THIS PRACTICE SHOULD BE D ISCOURAGED WHEREVER POS SIBLE. WHERE TRAN SFER

MUST BE ACCOMPLISHED TO PERFORM THE JOB

TWO LANYARDS WITH AN APPROVED FALL PROTECTION DEVICE WILL BE USED. ONE LANYARD

SHOULD BE ATTACHED TO THE AERIAL PLATFORM.

THE OTHER TO TH E STRUCTURE . THE LANYARD

THAT IS ATTACHED TO THE AERIAL PLATFORM

SHOULD NOT BE DISCONNECTED UNTIL S UCH

TIME AS THE TRANSFER TO THE STRUCTURE IS

COMPLETE. OTHERWIS E, D O NOT STEP OUTSID E

OF PLATFORM.

• DO NOT ADD NOTICE BOARDS OR SIMILAR ITEMS

TO THE PLATFORM. ADDITION OF SUCH ITEMS

INCREASES THE EXPOSED WIND AREA OF THE

MACHINE.

• NEVER POSITION LADDERS, STEPS, OR SIMILAR

ITEMS ON UNIT TO PROVIDE ADDITIONAL REACH

FOR ANY PURPOSE.

• WHEN RIDING IN OR WORKING FROM PLATFORM,

BOTH FEET MUST BE FIRMLY POSITIONED ON THE

FLOOR.

• KEEP OIL, MUD AND SLIPPERY SUBSTANCES

CLEANED FROM FOOT WEAR AND PLATFORM

FLOOR.

• NEVER "WALK" THE BOOM TO GAIN ACCESS TO OR

LEAVE PLATFORM.

• NEVER PLACE HANDS OR ARMS IN TOWER BOOM

OR UPRIGHT MECHANISM.

• KEEP ALL NON-OPERATING PERSONNEL AT LEAST

2 METERS AWAY FROM THE MACHI NE AT ALL

TIMES.

• IF PLATFORM OR BOOM IS CAUGHT SO THAT ONE

OR MORE WHEELS ARE OFF THE FLOOR, ALL PERSONNEL MUST BE REMOVED FROM PLATFORM

BEFORE ATTEMPTING TO FREE MACHINE. USE

CRANES, FORKLIFT TRUCKS OR OTHER EQUIPMENT TO REMOVE PERSONNEL AND STABILIZE

MACHINE MOTIO N , IF NECESSARY.

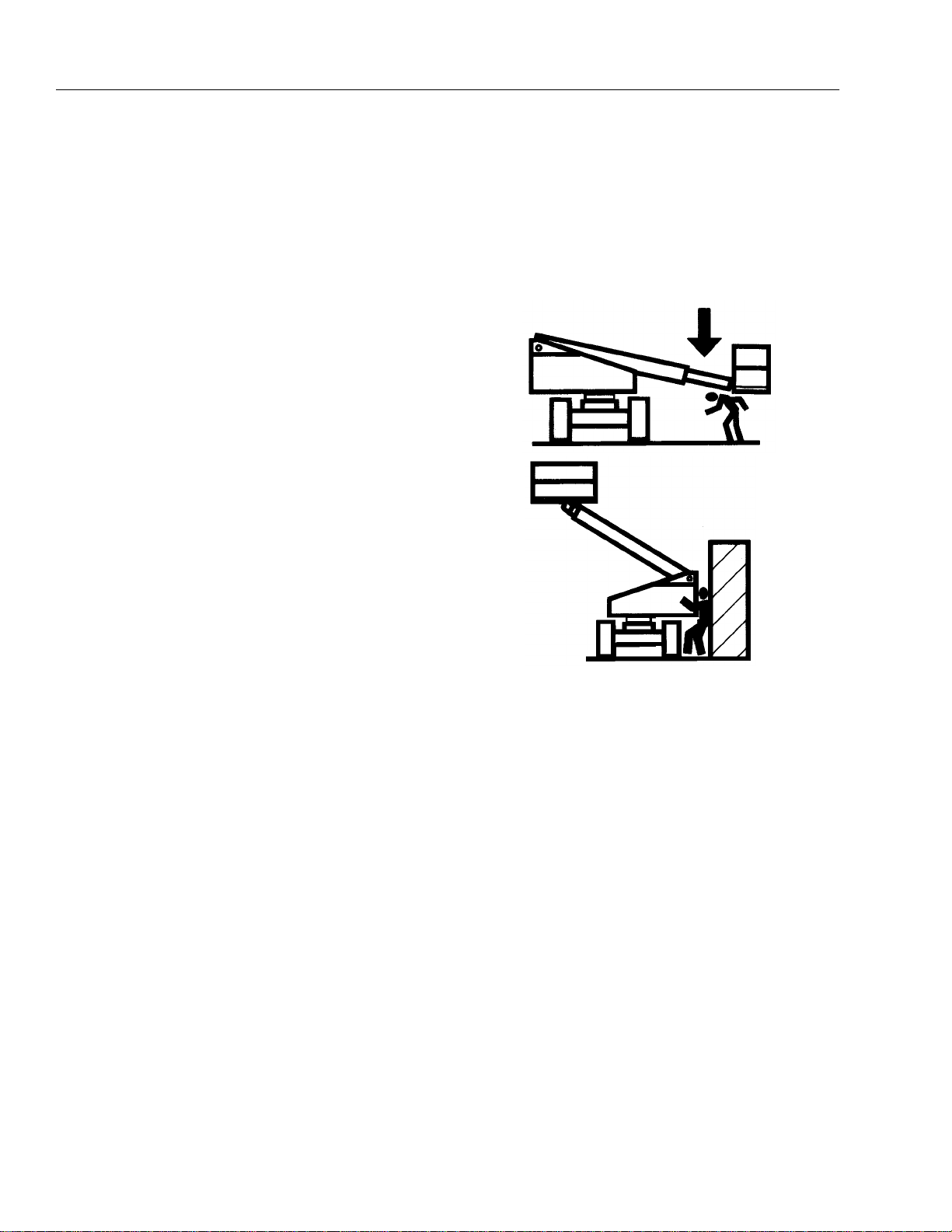

• THE OPERATOR IS RESPONSIBLE TO AVOID OPERATING MACHINE OVER GROUND PERSONNEL AND

TO WARN THEM NOT TO WORK, WALK OR STAND

UNDER A RAISED B OOM OR PL ATFORM. POSITI ON

BARRICADES ON FLOOR IF NECESSAR Y.

1-6 – JLG Lift – 3120883

SECTION 1 - SAFETY PRECAUTIONS

.

• ENSURE MACHINE IS POSITIONED ON A FIRM,

LEVEL AND UNIFORM SUPPORTING SURFACE

BEFORE RAISING OR EXTENDING BOOM.

• CHECK CLEARANCES AB OVE, ON SIDES AND BOTTOM OF PLATFORM WHEN RAISING, LOWERING,

SWINGING, AND TELESCOPING BOOM.

• EXERCISE EXTREME CAUTION AT ALL TIMES TO

PREVENT OBSTACLES FROM STRIKING OR INTER-

FERING WITH OPERATING CONTROLS AND PERSONS IN PLATFORM.

• ENSURE THAT OPERATORS OF OTHER OVERHEAD

AND FLOOR MACH INES ARE AWARE OF THE AERI AL

PLATFORMS PRESENCE. DISCONNECT POWER TO

OVERHEAD CRANES. POSITION BARRICADES ON

FLOOR IF NECESSARY.

• NEVER "SLAM" A CONTROL SWITCH OR LEVER

THROUGH NEUTRAL TO THE OPPOSITE DIRECTION.

ALWAYS RETU RN SWITCH TO NEUTRA L AND STOP;

THEN MOVE SWITCH TO THE DE SIRED POSI TION.

OPERATE LEVERS WITH SLOW, EVEN PRESSURE.

• DO NOT CARRY MATERIALS ON PLATFORM RAILING

UNLESS APPROVED BY JLG INDUSTRIES INC.

• NEVER PUSH OR PULL THE MACHINE OR OTHER

OBJECTS BY TELESCOPING THE BOOM.

• NEVER USE BOOM FOR ANY PURPOSE OTHER

THAN POSITIONING PERSON NEL, THEIR TO OLS

AND EQUIPMENT.

• NEVER EXCEED MANUFACTURERS RATED PLATFORM CAPACITY - REFER TO CAPACITY DECAL ON

MACHINE. DISTRIBUTE LOADS EVENLY ON PLATFORM FLOOR.

• NEVER OPERATE A MALFUNCTIONING MACHINE. IF

A MALFUNCTION OCCURS, SHUT DOWN THE

MACHINE, RED TAG IT, AND NOTIFY PROPER

AUTHORITIES.

• DO NOT REMOVE, MODIFY, OR DISABLE FOOTSWITCH BY BLOCKING OR ANY OTHER MEANS.

• DO NOT AS SIST A STUCK OR DISABLED MACHINE

BY PUSHING OR PULLIN G EXCEPT BY PULLING AT

CHASSIS TIE-DOWN LUGS.

• NEVER ATTEMPT USING BOOM AS A CRANE.

STRUCTURAL DAMAGE OR TIPPING MAY OCCUR.

• STOW B OOM AND SHUT OFF ALL POWER BEFORE

LEAVING MACHINE.

• NO STUNT DRIVING OR HORSEPLAY IS PERMITTED.

3120883 – JLG Lift – 1-7

SECTION 1 - SAFETY PRECAUTIONS

• NEVER ATTEMPT TO FREE A MACHINE STUCK IN

SOFT GROUND OR A S SI ST A MACH INE UP A STEE P

HILL OR RAMP BY USING BOOM "LIFT", "TELESCOPE", OR "SWING " FU N C TIONS.

• NEVER ATTACH WIRE, CABLE, OR ANY SIMILAR

ITEMS TO PLATFORM.

• DO NOT PLACE BOOM OR PLATFORM AGAINST ANY

STRUCTURE TO STEADY PLATFORM OR SUPPORT

STRUCTURES.

• DO NOT USE THE LIFT, SWING, OR TELESCOPE

FUNCTIONS FOR THE BOOM, TO MOVE EITHER THE

MACHINE OR OTHER OBJECTS.

• HYDRAULIC CYLINDERS SHOULD NEVER BE LEFT

FULLY EXTENDED OR RETRACTED FOR ANY

LENGTH OF TIME. ALWAYS "BUMP" CONTROL IN

OPPOSITE DIRECTION SLIGHTLY WHEN FUNCTION

BEING USED REACHES END OF TRAVEL. THIS

APPLIES TO MACHINES IN OPERATION OR IN

STOWED MODE.

• DO NOT OPERATE ANY MACHINE ON WHICH DANGER, WARNING, CAUTION OR INSTRUCTION PLACARDS OR DECALS ARE MISSING OR ILLEGIBLE.

• MACHINE MUST ALWAYS BE SHUT DOWN WHEN

REFUELING. NO SMOKING IS MA NDATORY. NEVER

REFUEL DURING AN ELECTRICAL STORM. ENSURE

THAT FUEL CAP IS CLOSED AND SECURE AT ALL

OTHER TIMES.

1.7 TOWING AND HAULING

• DO NOT TOW A MACHINE EXCEPT IN AN EMERGENCY. SEE SECTION 6 FOR EMERGENCY TOWING

PROCEDURES.

• LOCK TURNTABLE BEFORE TRAVELING LONG DISTANCES OR BEFORE HAULING MACHINE ON A

TRUCK OR TRAILER.

1-8 – JLG Lift – 3120883

SECTION 2 - PREPARATION AND IN SPECTION

SECTION 2. PREPARATION AND INSPECTION

2.1 GENERAL

This section provides the necessary information needed

by those personnel that are responsible to place the

machine in operation readiness, and lists checks that are

performed prior to use of the machine. It is important that

the information contained in this section be read and

understood before any attempt is made to operate the

machine. Ensure that all the necessary inspections have

been completed successfully before placing the machine

into service. These procedures will aid in obtainin g maximum service life and safe operation.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANC E,

SAFETY IS THE RESPONSIBILITY OF THE OWNER/OPERATOR.

2.2 PREPARATION FOR USE

Before a new machine is put into operation it must be

carefully inspecte d for any e vidence of damage resulting

from shipment and inspected pe riodically thereafter, as

outlined in Delivery and Frequent Inspection. (During initial start-up and run,) the unit should be thoroughly

checked for hydraulic leaks. A check of all components

should be made to assure their security.

All preparation n ecessar y to pl ace the machin e in oper ation readiness status is the responsibility of management

personnel. Preparation requires good common sense,

(i.e. lift works smoothly and brakes operate properly) coupled with a series of visual inspections. The mandatory

requirements are given in the Daily Walk Around Inspection.

It should be assured that the items appearing in the Delivery and Frequent Inspection and Functional Check are

complied with prior to putting the machine into service.

Frequent inspection shall be performed every 3 months or

150 hours whichever come first, or more often when

required by environment, severity, and frequency of

usage.

Chassis

1. Check front tires and wheel assemblies for loose or

worn spindles, components and hardware for security, tires for wear, damage and proper inflation.

2. Check front axle for loose, missing, and worn parts,

pivot pin for security.

3. Check steering assembly for loose or bent steer cylinder rods, steer cylinder and hydraulic lines for

leaks and security, and hardware for proper installation.

4. Check rear tires and wheel assemblies for security,

tires for wear, damage and prope r inflation.

5. Check drive hubs for da ma ge an d lea ks, a nd mo tors

for damage.

6. Check oil level in drive hubs by removing the fill

plugs and check plugs on top of each drive hub. Fill

each of the cavities until oil flows from each of the

check ports. Use Mobil DTE-11. Replace all plugs.

7. Check valves and hydraulic lines for damage, leakage and security.

8. Check pump/motor and accessories for damage,

loose or missing parts, leakage and security. Check

electrical connections for corrosion and tightness

and wiring for insulation damage. Check hydraulic

filter for condition of element. Replace as required.

NOTE: JLG recommends replacing the hydraulic filter ele-

ment after the first 50 hours of operation and then

every 600 hours thereafter, unless operating conditions requ ire earlier replacement.

2.3 DELIVERY AND FREQUENT INSPECTION

NOTE: This machine requires periodic safety and mainte-

nance inspections by an authorized JLG Dealer. A

decal located on the frame provides a place to

record (stamp) inspection dates. Check decal and

notify dealer if inspection is overdue.

The following checklist provides a systematic inspection

to assist in detecting defective, damaged, or improperly

installed parts. The checklist denotes the items to be

inspected and conditions to exam ine.

9. Check hydraulic reservoir and hydraulic lines for

damage, leakage and security.

10. Check batteries for damage, loose or missing vent

caps, electrical connections for tightness and evidence of corrosion, and electrolyte level. Add only

clean distilled water to battery after it has been

charged.

11. If equipped with on-board generator, check engine

and accessorie s for damage, loose or missing pa rt s ,

leakage and security. Check throttle solenoid and

linkage for damage, electrical connections for tightness, and evidence of corrosion and wiring for insu-

3120883 – JLG Lift – 2-1

SECTION 2 - PREPARAT ION AND INSPECTION

lation damage. Check exhaust for damage, wear

and leakage.

Turntable

1. Check turnt abl e for dama ge , loo se or mi ssi ng p arts,

and security. Check lift cylinders and hydraulic lines

for damage, leakage and security. Check swing

drive motor for damage, loose or missing parts,

hydraulic lines and component housings for evidence of leakage; worm gear for proper mesh with

swing gear.

2. Check swing bearing for damage, wear, lubrication

and loose or missing bearing bolts.

3. Check valves and hydraulic lines for damage, leakage, security and electrical connections for tightness

and evidence of corrosion.

4. Check ground controls for damage, loose or missing parts, security, electrical connections for tightness and evidence of corrosion and wiring for

insulation damage. Assure that all switches function

properly.

5. Check all cowl and access doors for damage,

proper operation and security.

6. Check Lower Boom pivot bushings for lubrication

and wear.

7. Check Lower Boom Lift Cylinder and hydraulic lines

for damage, leakage and security.

8. Check all pin and shaft retaining hardware for security and wear.

9. Check all electrical cables for damage, loose and

corroded connections.

Boom

1. Check Lower Boom and leveling link for damage,

missing parts and security.

2. Check all pin and shaft retaining hardware for security and wear.

8. Check Mid Boom pivot shaft and lift cylinder for

damage, missing parts and security.

9. Check all pin and shaft retaining hardware for security and wear.

10. Check Upper Upright, cross pins and hydraulic lines

for damage, wear, lubrication, leakage and security.

11. Check Upper Upright for damage, wear, lubrication

and security.

12. Check hydraulic lines mounted on upright for damage, leakage and security.

13. Check Upper Boom Lift Cylinder and cross pins and

hydraulic lines for damage, wear, lubrication, leakage and security.

14. Check Upper Boom pivot pin for damage, wear,

lubrication and security.

15. Check Upper Boom for damage, missing parts and

security.

16. Check Upper Boom wear pads for damage, missing

parts and security.

17. Check Upper Boom telescope cylinder, cross pins

and hydraulic lines for damage, wear, lubrication,

leakage and security.

18. Check Platform Leveling Cylinder, cross pins and

hydraulic lines for damage, wear, lubrication, leak-

age and security.

Platform

1. Check platform and control console for damage,

loose or missing part s , and security.

2. Check control switches and levers for damage,

loose or missing parts and security. Assure that lever

and lever lock functions properly.

3. Check control switches, levers and electrical connections for tightness and evidence of corrosion,

and wiring for defects and chafing damage. Assure

that switches function properly.

3. Check hydraulic lines and electrical cable for damage, missing parts and security.

4. Check limit sw itch connecti ons and plunger fo r corrosion and security.

5. Check Lower Upright cross pins and hydraulic lines

for damage, wear, lubrication, leakage and security.

6. Check Lower Upright for damage, wear, lubrication

and security.

7. Check hydraulic lines mounted on upright for damage, leakage and security.

2-2 – JLG Lift – 3120883

Loading...

Loading...