Operation & Safety and

®

Service Manual

Triple-L™ Trailers

3121224

October 11, 2012

ANSI

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions

and operating procedures essential for the safe and proper trailer operation for its intended purpose. It is important to stress proper trailer usage at all times. All information in this manual must be read and understood

before any attempt is made to operate the trailer.

Because the manufacturer has no direct control over trailer operation and application, proper safety practices

are the responsibility of the owners, users, operators, lessors, and lessees.

All instructions in this manual are based upon the use of the trailer under proper operating conditions, with no

deviations from the original design. Any alteration or modification of the trailer is strictly forbidden without written approval from JLG Industries, Inc.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

FOREWORD

3121224 – Triple-L-Trailer – a

FOREWORD

This is the Safety Alert Symbol. It is used to alert you to the

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death

The Safety Alert Symbol will be used with the appropriate Safety Signal Word of “DANGER” “WARNING” or “CAUTION” to

a potential hazard and designate a level of seriousness. The Safety Signal Words are inserted throughout this manual in

Black/White. On the machine, the Safety Signal Words will have either a Red, Orange, or Yellow background as part of a

safety sign or decal. The “DANGER”, “WARNING”, and “CAUTION” Safety Signal Words, definitions, and associated colors

are as follows:

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF

NOT AVOIDED, WILL

SIGNAL WORD IS USED IN THE MOST EXTREME CASES. WHEN

INSTALLED ON THE, TRAILER. THIS SIGNAL WORD WILL HAVE A

RED BACKGROUND AS PART OF A DECAL.

RESULT IN SERIOUS INJURY OR DEATH. THIS

INDICATES A POTENTIALITY HAZARDOUS SITUATION WHICH, IF

NOT AVOIDED, COULD RESULT IN SERIOUS INJURY OR DEATH.

WHEN INSTALLED ON THE TRAILER, THIS SIGNAL WORD WILL

HAVE AN ORANGE BACKGROUND AS PART OF A DECAL.

INDICATES A POTENTIALITY HAZARDOUS SITUATION WHICH IF

NOT AVOIDED, MAY

MAY ALSO BE USED TO ALERT AGAINST UNSAFE PRACTICES.

WHEN INSTALLED ON THE TRAILER, THIS SIGNAL WORD WILL

HAVE A YELLOW BACKGROUND AS PART OF A DECAL.

The “IMPORTANT” Safety Signal Word may also appear in this manual or on the machine. This Safety Signal Word typically

will not appear with the Safety Alert Symbol, but contains important information that must be followed for safe and proper

operation, The “IMPORTANT” Safety Signal Word definition and associated color is as follows.

INDICATES INFORMATION OR A COMPANY POLICY THAT

RELATES DIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

RESULT IN MINOR OR MODERATE INJURY. IT

b – Triple-L-Trailer – 3121224

FOREWORD

ALL SAFETY-RELATED BULLETINS MUST BE ACCOMPLISHED ON THIS PRODUCT. JLG INDUSTRIES, INC. MAY HAVE ISSUED SAFETYRELATED BULLETINS FOR THIS JLG PRODUCT. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG DEALER FOR

INFORMATION REGARDING SAFETY-RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THIS PRODUCT.

FOR THE PURPOSE OF RECEIVING SAFETY-RELATED BULLETINS, IT IS IMPORTANT THAT THE CURRENT OWNER OF THIS UNIT

ENSURES JLG INDUSTRIES, INC. HAS UPDATED OWNERSHIP INFORMATION. CONTACT JLG INDUSTRIES, INC. TO ENSURE THAT THE

CURRENT OWNER RECORDS ARE UPDATED AND ACCURATE.

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN

ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL

PROPERTY OR THE JLG PRODUCT.

FOR :

•Accident Reporting

•Product Safety Publications

•Current Owner Updates

•Questions Regarding Product Safety

•Standards and Regulations Compliance Information

•Questions Regarding Special Product Applications

•Questions Regarding Product Modifications

CONTACT :

Product Safety and Reliability Department

JLG Industries, Inc.

1 JLG Drive

McConnellsburg, PA 17233

Toll Free: 877-JLG-SAFE

877-554-7233

E-mail: ProductSafety@JLG.com

3121224 – Triple-L-Trailer – c

FOREWORD

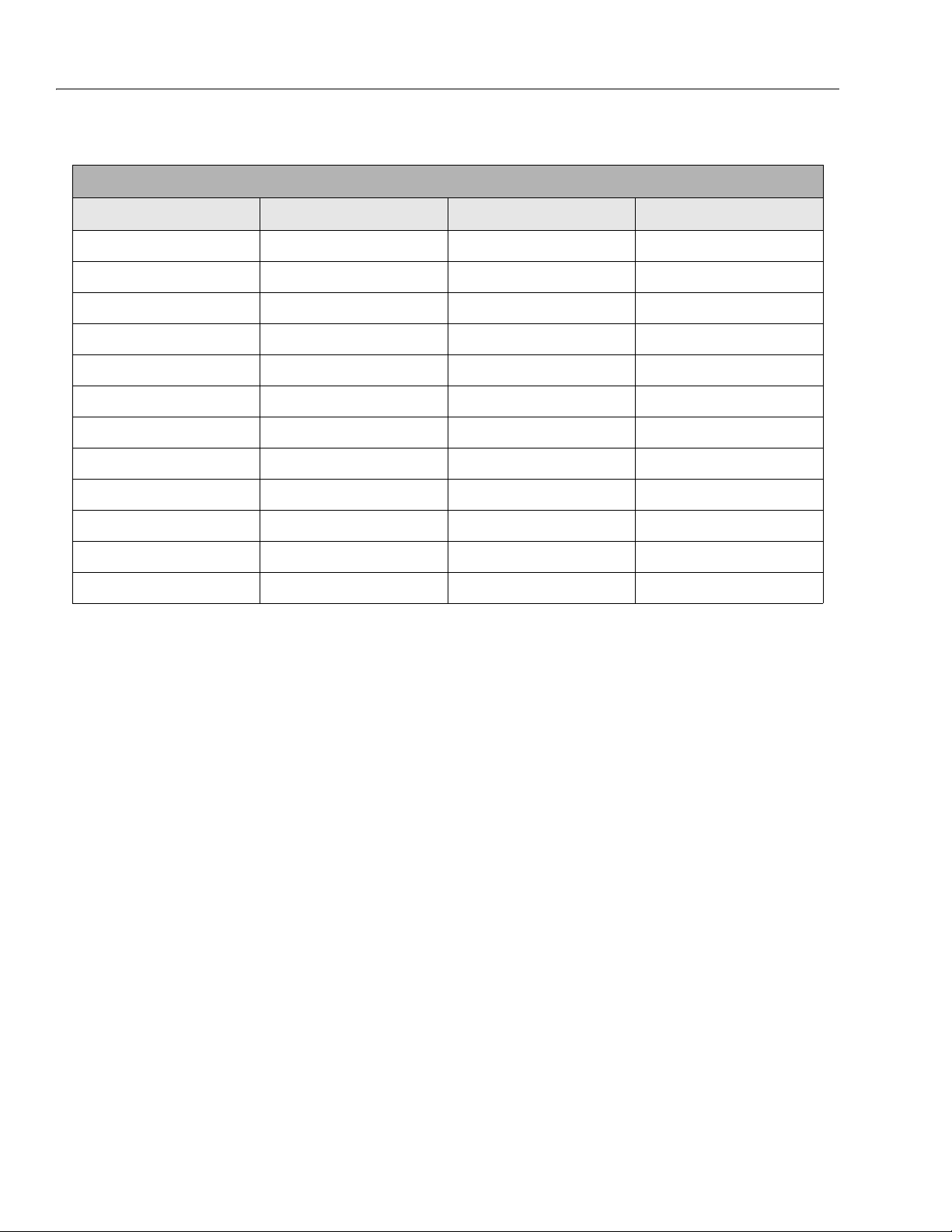

TRAILER NUMBER MODEL NUMBER SERIAL NUMBER VIN NUMBER

10

TRAILER IDENTIFICATION

1

2

3

4

5

6

7

8

9

11

12

d – Triple-L-Trailer – 3121224

NEW PRODUCT WARRANTY

NEW PRODUCT WARRANTY

1. WARRANTY. JLG Industries, Inc. (“Manufacturer”)

warrants each new product made by it to be free

from defects in material or workmanship for twelve

months from the date of initial sale, lease, rental, or

other disposition of such product. Manufacturer further warrants the structural elements of each new

product made by it, as defined in its then current

warranty policies and procedures, to be free from

defects in material or workmanship for one year

from the date of initial sale, lease, rental or other disposition of such product. Manufacturer agrees only

to repair or replace at its own expense, F.O.B. the

place or places of manufacturer, any part or parts of

the product found to be defective in material or

workmanship, provided Manufacturer is notified of

such defect or defects within the applicable warranty

period and given a reasonable time to correct the

defect. In no case shall any warranty extend to

defects in materials, components, or services furnished by third parties or to the erection or installation of the product performed by third parties.

Defects caused by chemical action or the presence

of abrasive materials and defects arising following

the operation beyond rated capacity or the improper

use or application of any products shall not be considered defects within the scope of the above mentioned warranty. If any repairs or alterations are

made or any parts are replaced during the periods

covered by any warranty above mentioned by other

than an authorized Manufacturer’s Distributor in

accordance with authorized Manufacturer’s service

manuals or with other than parts, accessories, or

attachments authorized by Manufacturer for use in

its products, customer shall pay for such repairs or

parts without recourse against Manufacturer, and

Manufacturer shall be relieved of responsibility for

fulfillment of the above mentioned warranty with

respect to parts or components for all repairs, alterations, or replacements so made. Manufacturer’s

obligations under this warranty shall at all times be

subject to its then current warranty policies and procedures. The above mentioned warranty shall not

apply to replacement or service parts made by and

sold by Manufacturer, with any obligation of the

Manufacturer to such parts governed solely by Manufacturer’s then current warranty policies and procedures.

2. DISCLAIMER AS TO CONSEQUENTIAL OR SPE-

CIAL DAMAGES. Under no circumstances shall

Manufacturer be liable for any consequential or special damages which any person firm, corporation, or

other entity may suffer or claim to suffer or incur or

claim to incur as a result of any defect in the product

or in any correction or alteration thereof made or furnished by Manufacturer or others. “Consequential”

or “special damages” as used herein includes but is

not limited to costs of transportation, lost sales, lost

orders, lost profits, lost income, increased overhead,

labor and material costs, and costs of manufacturing

variances and operational inefficiencies.

3. MAXIMUM LIABILITY. The maximum liability of

Manufacturer under the exclusive warranty set forth

herein shall be the amount paid to Manufacturer with

respect to the product to which such warranty

applies.

4. EXCLUSIVE AND ENTIRE WARRANTY. This war-

ranty constitutes Manufacturer’s entire warranty as

to the product and it is expressly agreed that the

remedies of customer and those claiming under

customer as stated in this warranty are exclusive.

Manufacturer does not assume (and has not authorized any other person to assume on its behalf) any

other warranty or liability in connection with any

product covered by this warranty.

NOTE: Manufacturer expressly disclaims any and all other

warranties of any kind whatsoever as to the product

furnished hereunder, including but not limited to

express or implied warranties as to merchantibility,

fitness for particular purposes sold, description or

quality of the product furnished hereunder.

5. NOTICE OF OCCURRENCE. This warranty shall

be void if, upon the occurrence of any incident

involving any product made by Manufacturer and

resulting in any personal injury or property damage,

customer shall fail to notify Manufacturer within 48

hours of such occurrence or permit Manufacturer

and its representatives to have immediate access to

such product and all records of or within the control

of customer relating to the product and occurrence.

6. LIMITATION OF LIABILITY

provisions herein shall apply to any and all claims or

suits brought against Manufacturer including any

claim based upon negligence, breach of contract,

breach of warranty, strict liability, or any other legal

theories upon which liability may be asserted

against Manufacturer.

NOTE: Manufacturer may at any time amend the foregoing

form of warranty without prior notice.

. The limitation of liability

3121224 – Triple-L-Trailer – e

NEW PRODUCT WARRANTY

REVISION LOG

Original Issue - May 23, 2003

Revised - August 7, 2003

Revised - March 3, 2004

Revised September 30, 2004 (Edited to 0010598 Rev 7, 0010599 Rev 9, 0010600 Rev 6, 0010601Rev 9,

0010602 Rev 10)

Revised - October 4, 2004

Revised - February 25, 2005

Revised - June 27, 2005

Revised - August 22, 2005

Revised - May 24, 2006

Revised - August 28, 2006

Revised - December 5, 2007

Revised - January 17, 2008

Revised - December 21, 2010

Revised - October 11, 2012

f – Triple-L-Trailer – 3121224

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .a

NEW PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .e

REVISION LOG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . f

SECTION 1 - SAFETY PRECAUTIONS

1.1 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Local and National Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Major Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 Reporting Safety Defects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.5 Safety Warning Labels on Your Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

SECTION 2 - TRAILER OPERATION

2.1 Trailer Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Trailer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.4 Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.5 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.6 Battery (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7 Deck Alarm System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.8 Tow Vehicle And Hitch Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.9 Coupling and Uncoupling the Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.10 Loading the Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2.11 Lift Tie Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.12 Towing Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.13 Pre-Tow Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.14 Breaking-in a New Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 3 - ACCESSORIES

3.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Scissor Lift chocks (If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

SECTION 4 - SERVICE AND MAINTENANCE

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Inspections, Service & Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.3 Inspection and Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.4 Bleeding Surge Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4.5 Trailer Connection to Tow Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.6 Tongue Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.7 Lights and Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.8 Trailer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.9 Wheel Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.10 Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.11 Unsealed Bearings (Hubs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.12 Deck Bearing Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

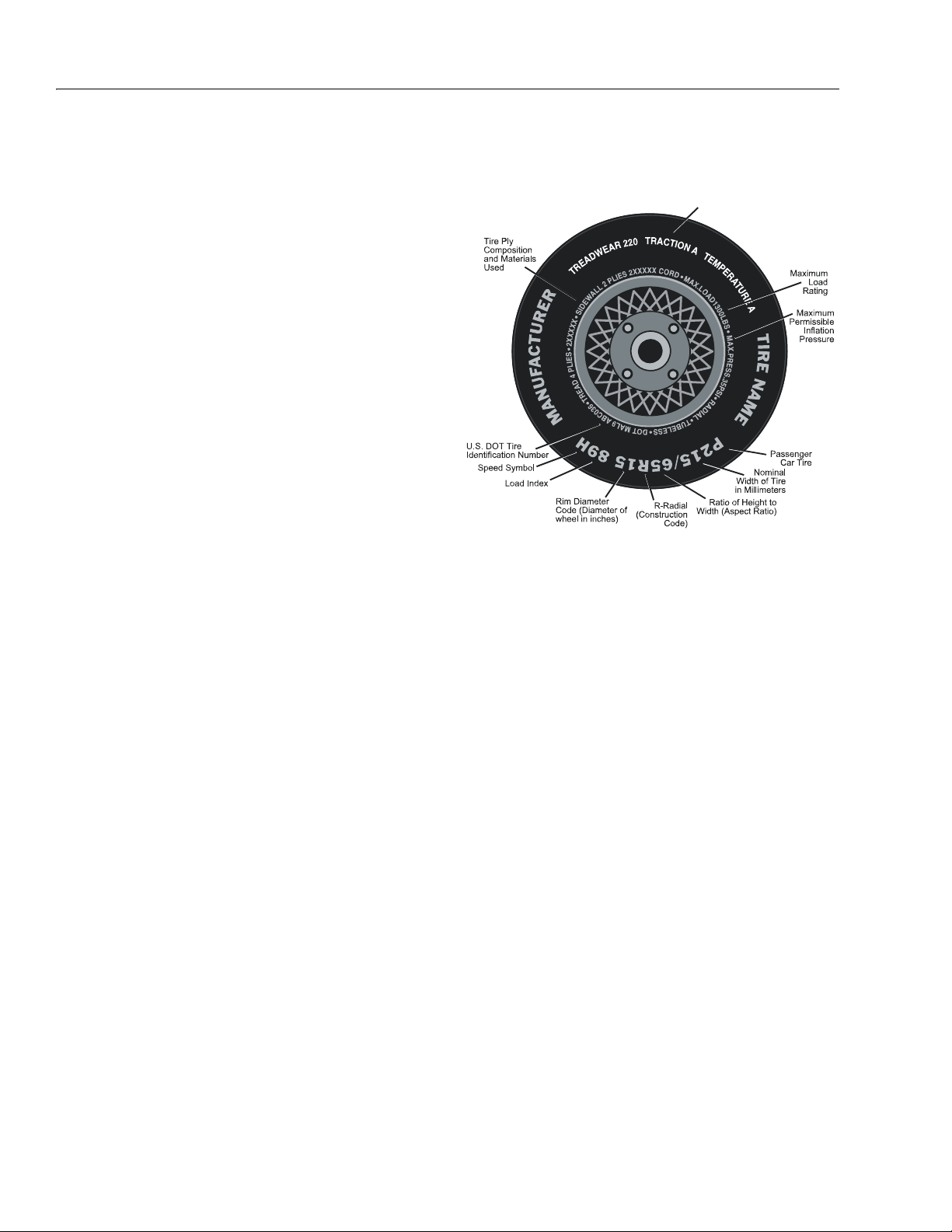

4.13 Tire and Wheel Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.14 Tire Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

3121224 – JLG Lift – i

TABLE OF CONTENTS (Continued)

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. VIN Label & Tire Information Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-2. Decal Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

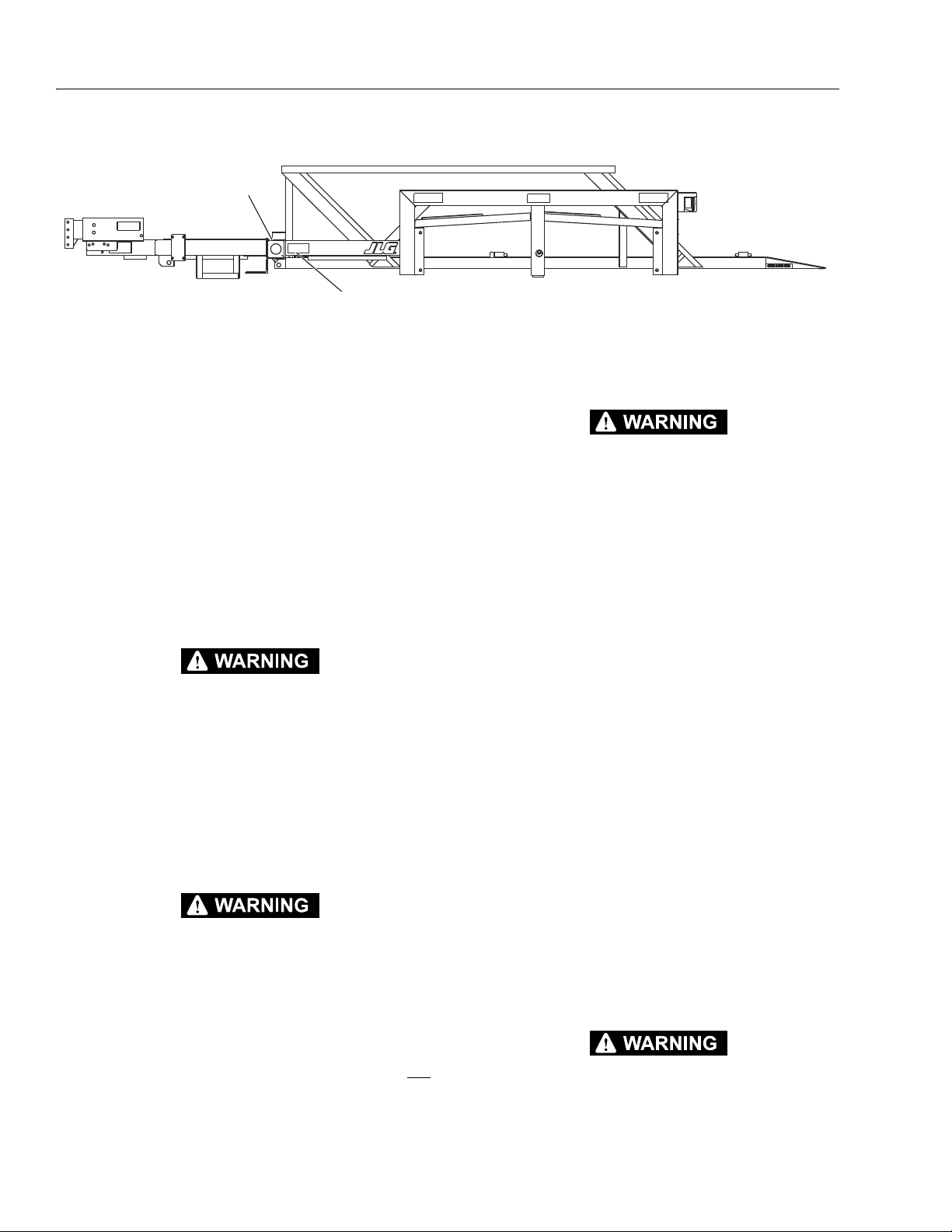

2-1. Trailer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2. Vehicle Identification Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-3. Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

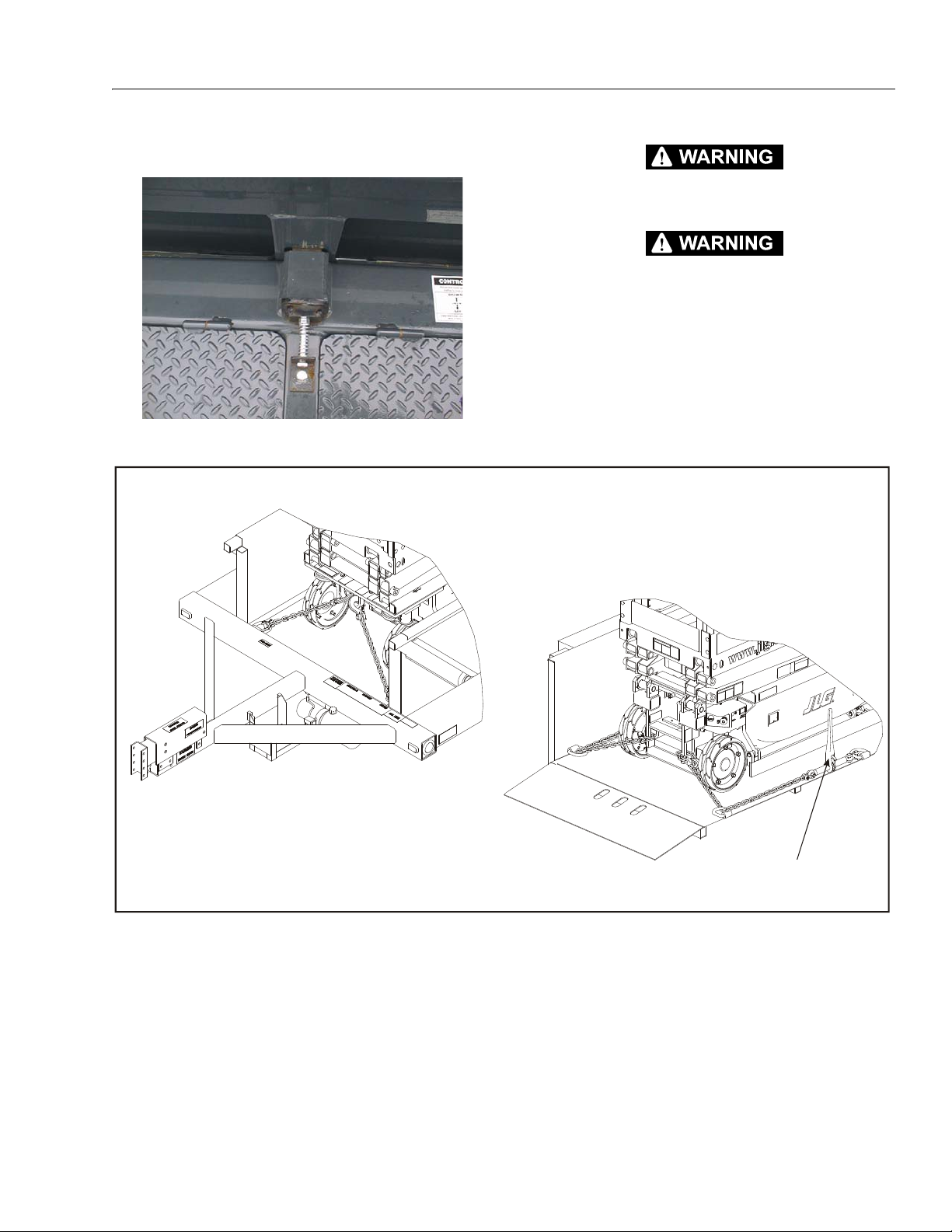

2-4. Lift Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

3-1. Battery Charger Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

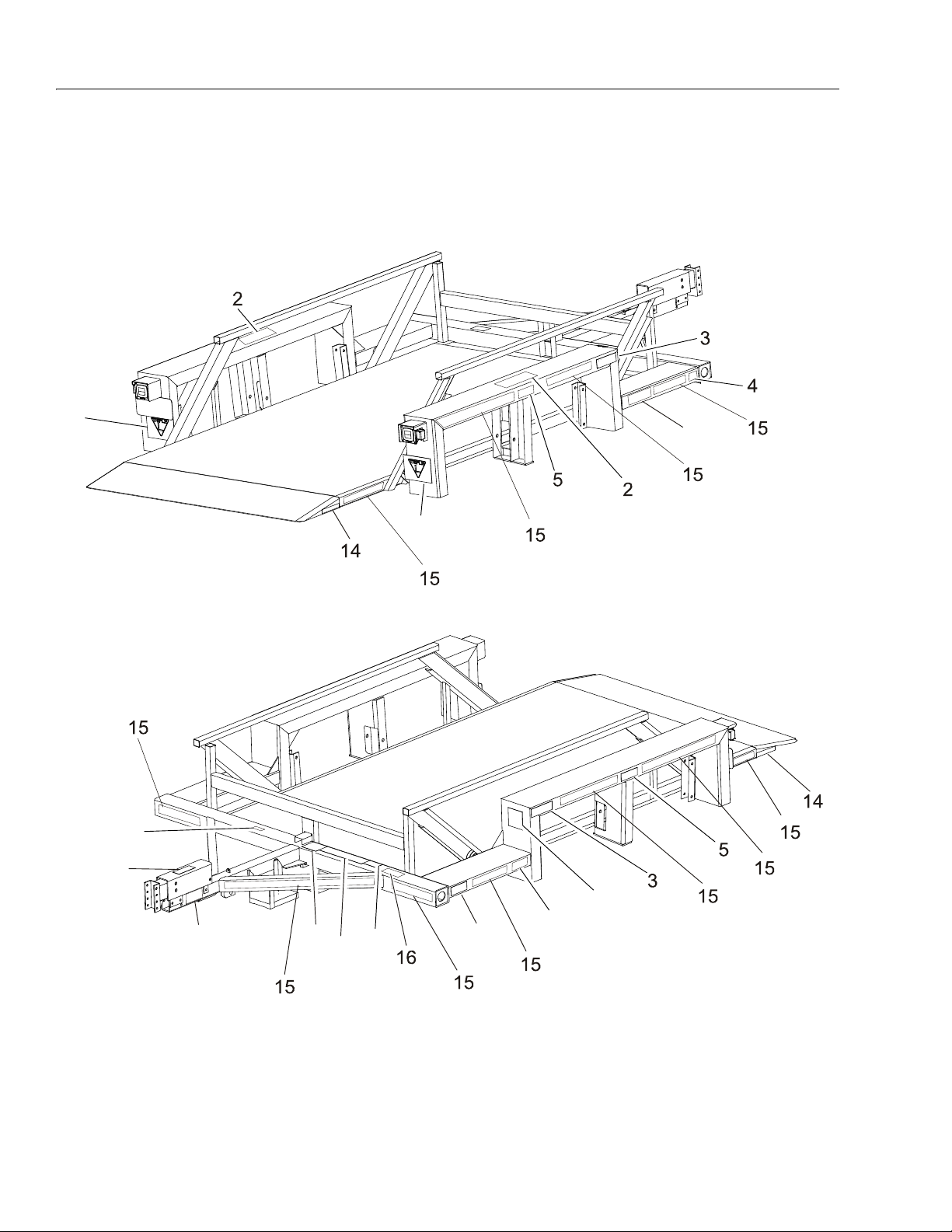

3-2. Tie Down Attach Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-3. Chock Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

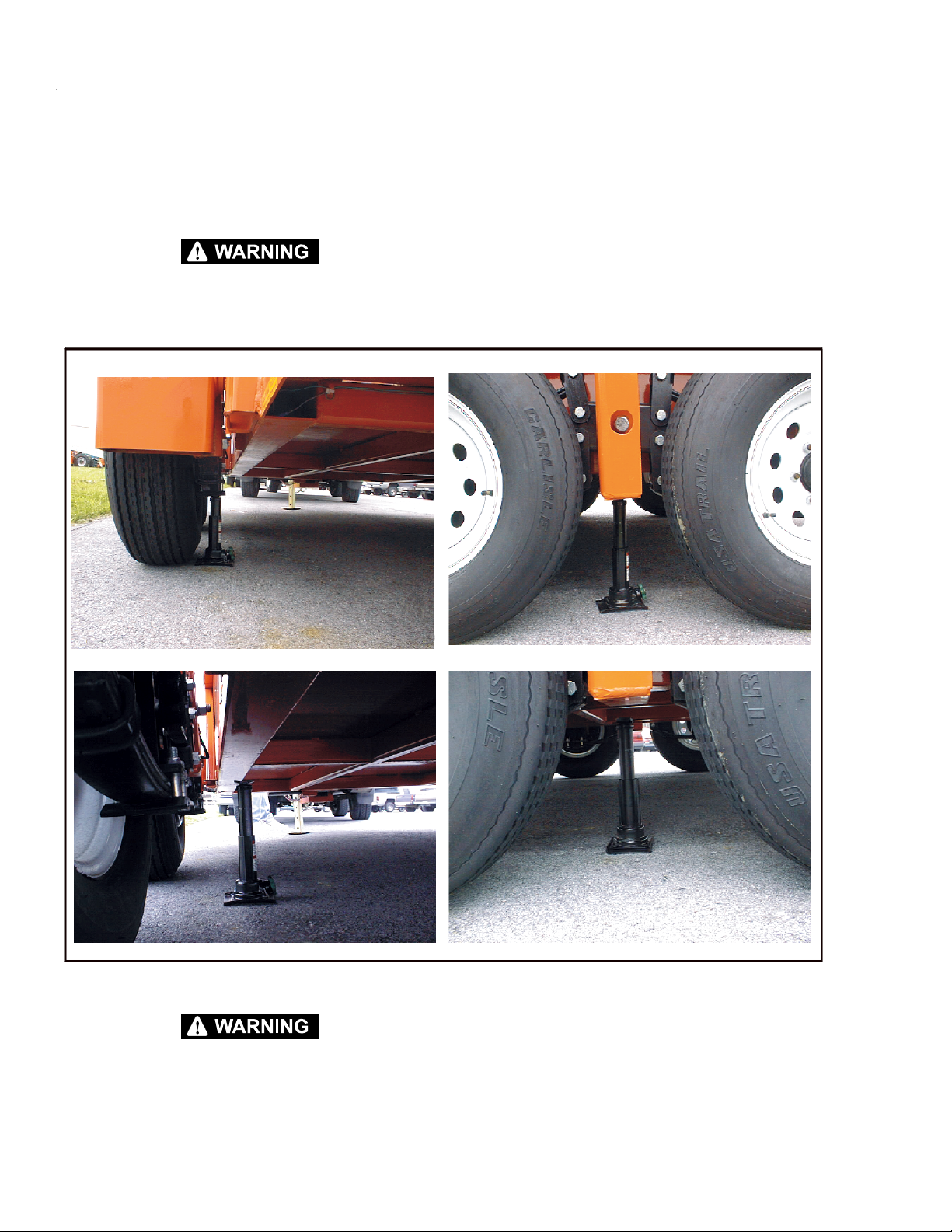

4-1. Jacking Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

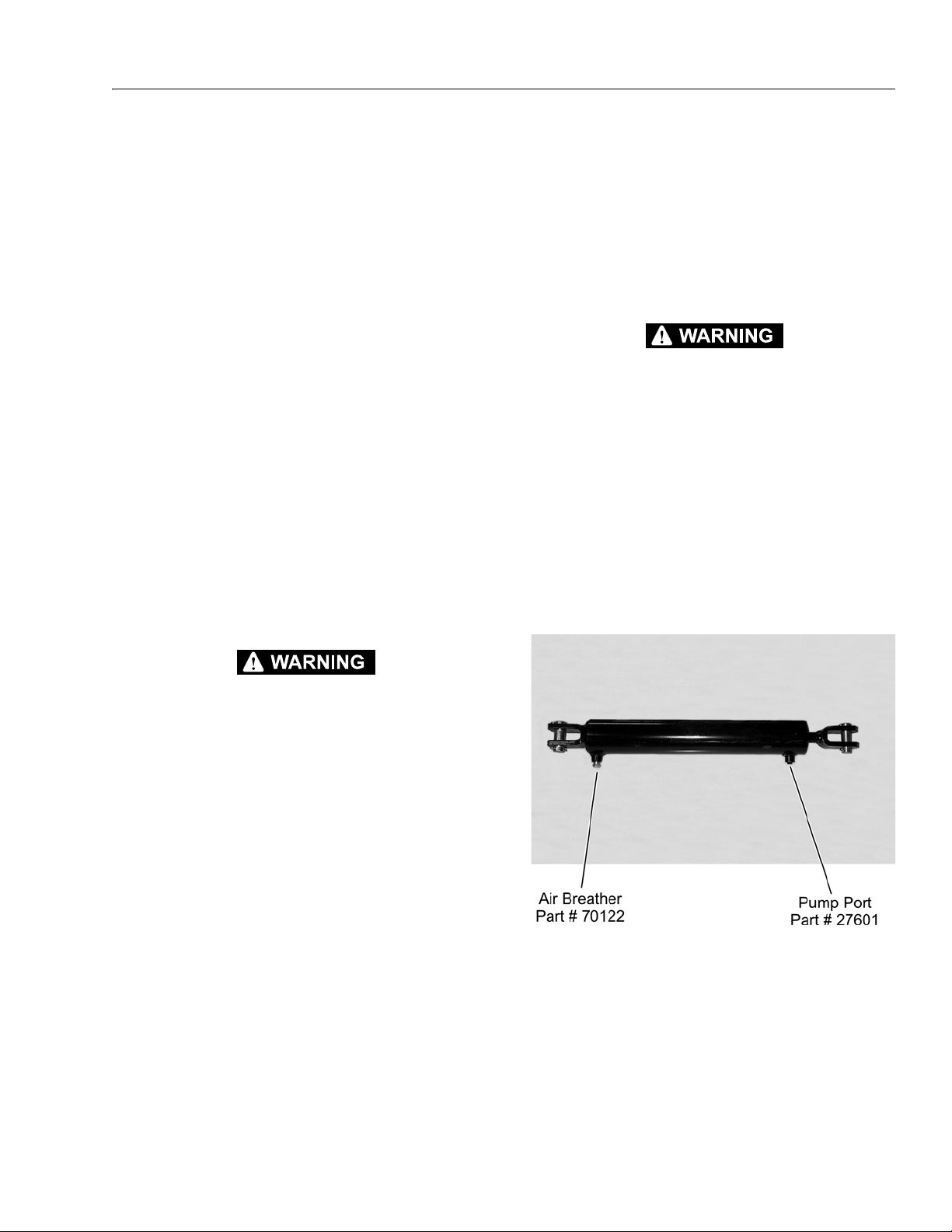

4-2. Hydraulic Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4-3. Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4-4. 12 Volt Motor/Pump Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

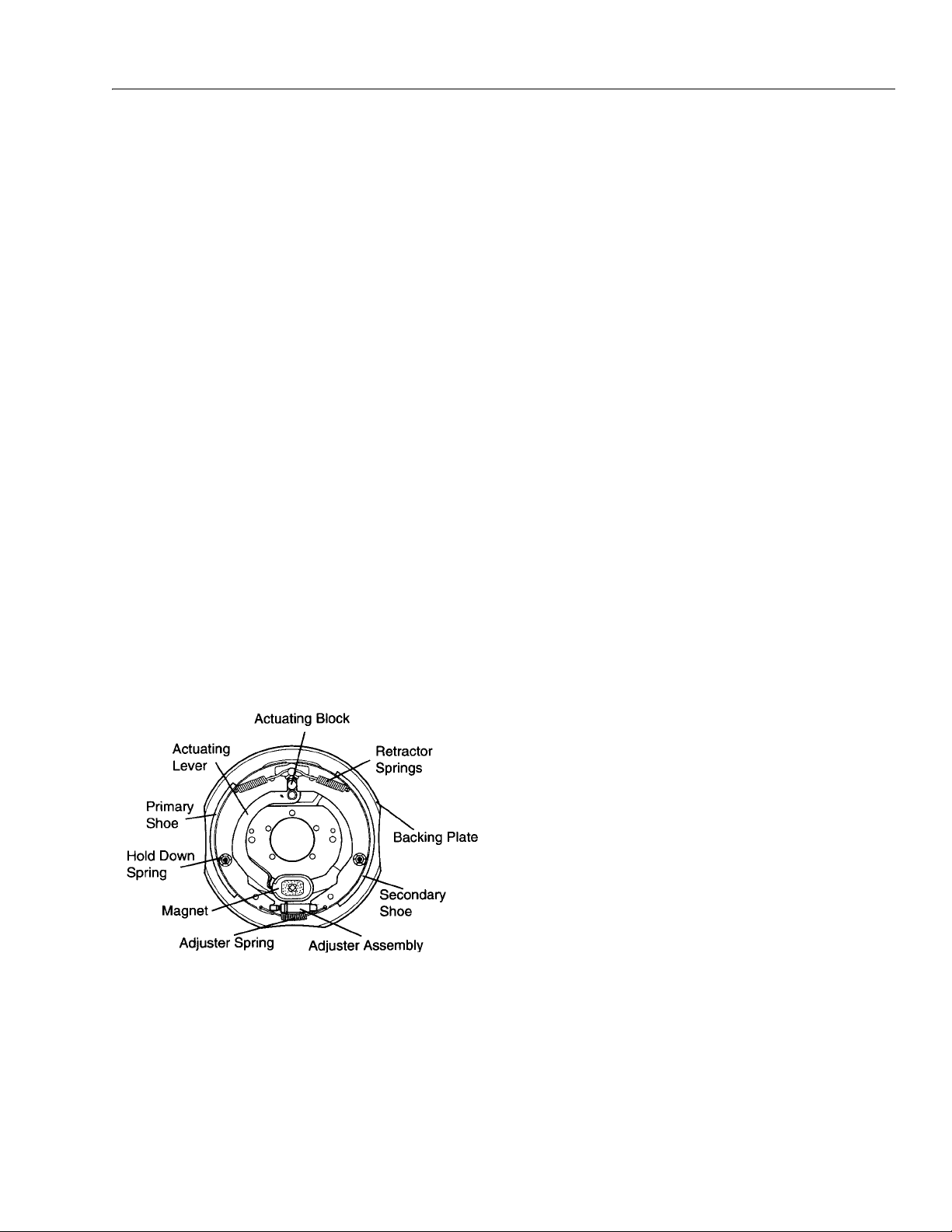

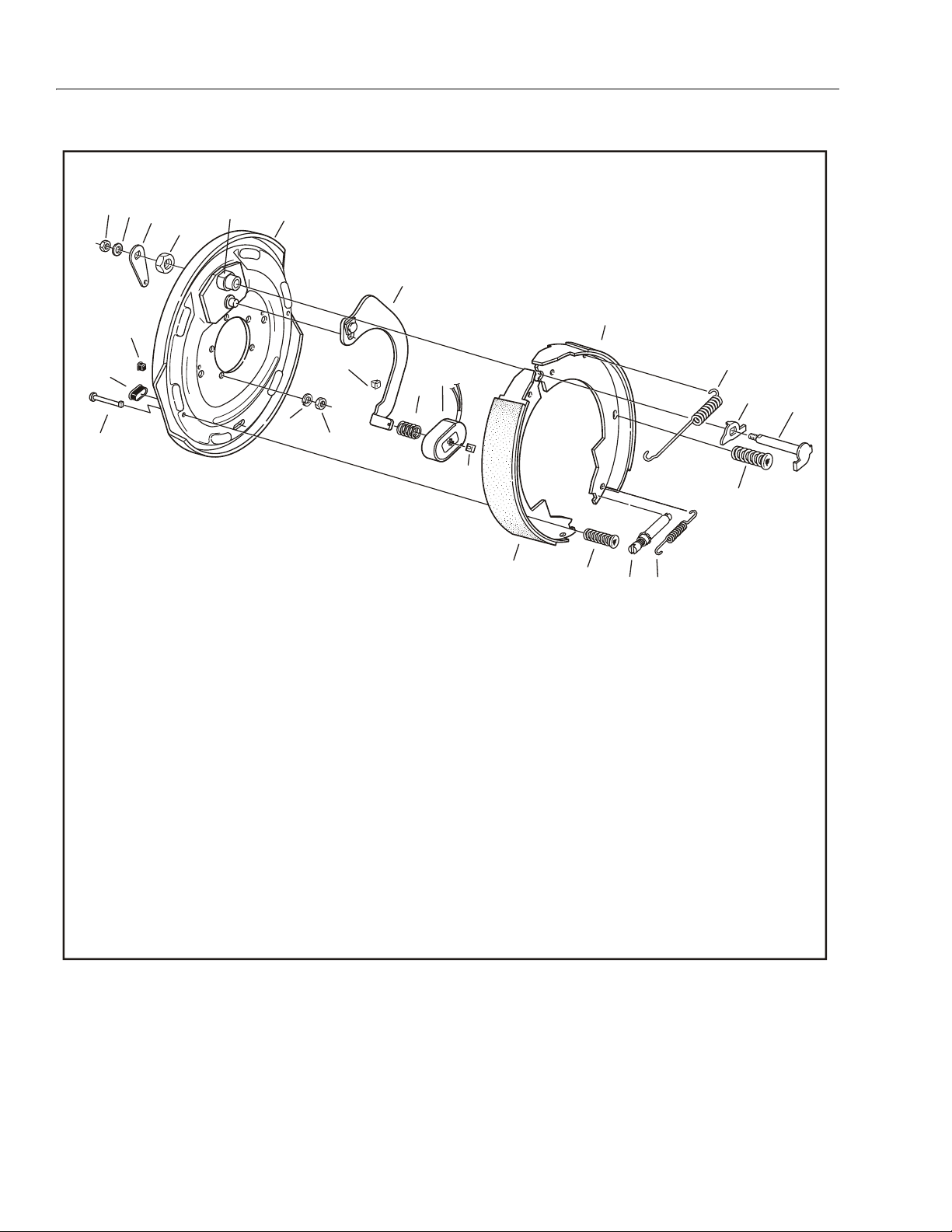

4-5. Electric Brakes with Parking Brake Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4-6. Hydraulic Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4-7. Trailer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4-8. Trailer Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-9. Dual, Quadra Spring Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-10. Flex Ride Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-11. Suspension Camber Setting (Fixed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

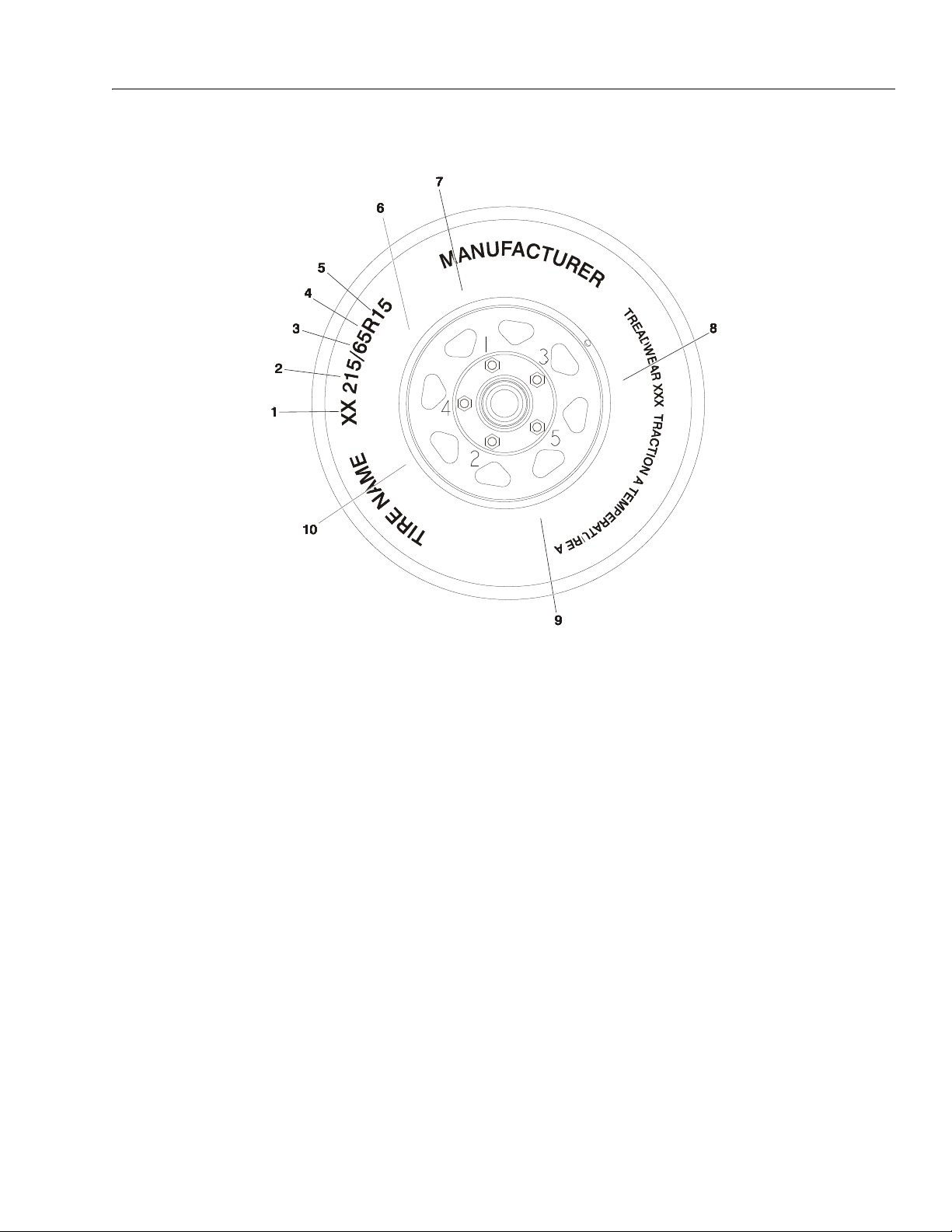

4-12. Tire Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Decal Location Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2-1 Trailer Model Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-2 Production Option and Accessory Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3-1 Chock Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

4-1 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-2 Motor/Pump Amperage Draw (No Load in Trailer). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3 Tire Inflation Pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

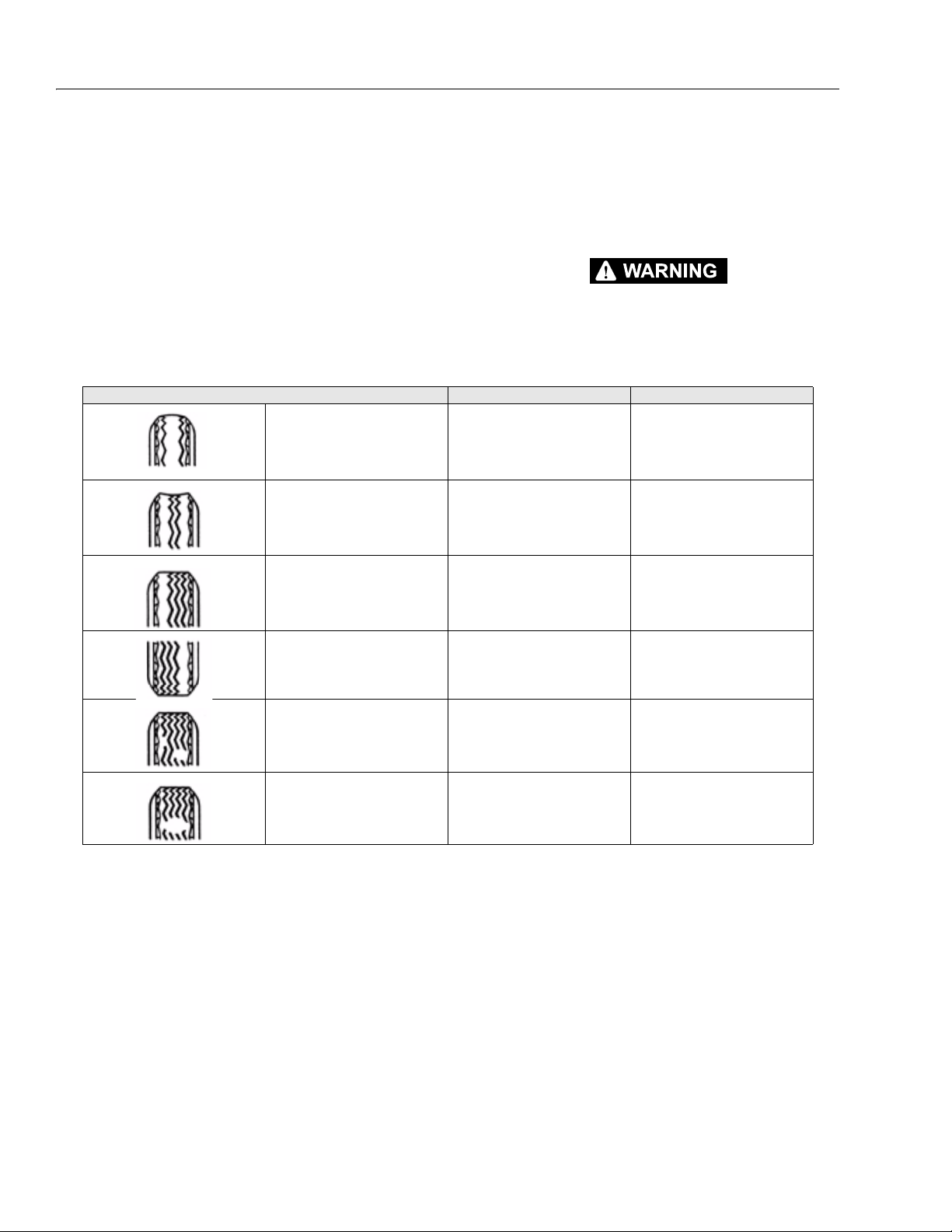

4-4 Tire Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

4-5 Wheel Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

ii – JLG Lift – 3121224

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 SAFETY INFORMATION

Safety Information, Alert Symbols, and Signal Words

An owner’s manual that provides general trailer information cannot cover all of the specific details necessary for

the proper combination of every trailer, tow vehicle and

hitch. Therefore, you must read, understand and follow

the instructions given by the tow vehicle and trailer hitch

manufacturers, as well as the instructions in this manual.

Triple-L™ Trailers are built with components produced by

various manufacturers. Some of these items have separate instruction manuals that were originally shipped with

the product. Where this manual indicates that you should

read another manual, and you do not have that manual,

call JLG to obtain a copy.

The safety information in this manual is denoted by the

safety alert symbols and signal words listed below:

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL RESULT IN SERIOUS INJURY OR DEATH. THIS

DECAL WILL HAVE A RED BACKGROUND.

1.3 MAJOR HAZARDS

Safe and proper usage of the trailer is essential to avoid

accidents. Unsafe use; separation of trailer from tow vehicle; and loss of control of the trailer or trailer/tow vehicle

combination can result in death or serious injury. Common causes for trailer accidents include:

a. Driving too fast for conditions

b. Failure to adjust handling while towing a trailer

c. Trailer improperly coupled to the hitch

d. Incorrect use of safety chains

e. Incorrect use of breakaway brake

f. Mismatch of trailer and hitch

g. Unsafe tires, lug nuts or wheels

h. Overload

i. Unsafe load distribution

j. Shifting cargo

k. Inappropriate cargo

l. Inoperable brakes, lights or mirrors

m. Modifying the trailer

n. Inadequate tow vehicle or towing hitch

o. Not properly maintaining the trailer structure.

INDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD RESULT IN SERIOUS INJURY OR DEATH. THIS

DECAL WILL HAVE AN ORANGE BACKGROUND.

INDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL

HAVE A YELLOW BACKGROUND.

INDICATES PROCEDURES ESSENTIAL FOR SAFE OPERATION.

THIS DECAL WILL HAVE A GREEN BACKGROUND.

1.2 LOCAL AND NATIONAL REGULATIONS

In many regions, a trailer is considered a motor vehicle. As

such, there are regulations (height, width, brakes etc.) that

must be followed by the owner and operator. It is the

responsibility of the trailer owner and operator to determine which regulations apply and to comply with these

requirements.

Driving too Fast for Conditions

With ideal road conditions, the maximum speed when

safely towing a trailer is 55 mph. If you drive too fast, the

trailer tires will overheat and possibly blowout. As your

speed increases, you are more likely to suddenly lose

control. Never exceed 55 mph while towing the trailer.

DECREASE YOUR SPEED AS ROAD, WEATHER AND LIGHTING

CONDITIONS DETERIORATE.

Failure to Adjust Handling While Towing a Trailer

When towing a trailer, your tow vehicle will have

decreased acceleration, increased stopping distance, and

increased turning radius (which means you must make

wider turns to keep from hitting curbs, vehicles, and anything else that is on the inside corner). In addition, you will

need a longer distance to pass, due to slower acceleration

and increased length.

Be alert for slippery conditions. You are more likely to be

affected by slippery road surfaces when driving a tow

vehicle with a trailer, than driving a tow vehicle without a

trailer.

3121224 – Triple-L-Trailer – 1-1

SECTION 1 - SAFETY PRECAUTIONS

Anticipate the trailer “swaying.” Swaying is the trailer reaction to the air pressure wave caused by passing trucks

and busses. Continued pulling of the trailer provides a stabilizing force to correct swaying. Do not apply the brakes

to correct trailer swaying.

Check rear view mirrors frequently to observe the trailer

and traffic.

Use lower gear when driving down steep or long grades.

Use the engine and transmission as a brake. Do not ride

the brakes, as they can overheat and become ineffective.

Be aware of your trailer height, especially when approaching roofed areas and when around trees.

Hitting a bump or depression in the road surface or running off the shoulder of the road, and then returning to the

road surface, can adversely affect the stability of the trailer

or towing vehicle.

Rounding a corner or curve at excessive speed can

adversely affect the stability of the trailer or towing vehicle.

Trailer Improperly Coupled to the Hitch

It is critical that the trailer be securely coupled to the hitch,

and that the safety chains are correctly attached. Uncoupling could result in death or serious injury.

Incorrect Use of Breakaway Brake

When equipped with brakes, a breakaway brake system

applies the brakes on your trailer if your trailer comes

loose from the hitch for any reason. The safety chains and

breakaway brake system must be in good condition and

properly rigged to be effective.

THE BREAKAWAY CABLE MUST BE CONNECTED TO THE TOW

VEHICLE; AND NOT TO ANY PART OF THE HITCH. BEFORE TOWING THE TRAILER, TEST THE FUNCTION OF THE BREAKAWAY

BRAKE SYSTEM. IF THE BREAKAWAY BRAKE SYSTEM IS NOT

WORKING, DO NOT TOW THE TRAILER; HAVE IT SERVICED OR

REPAIRED.

Mismatch of Trailer and Hitch

The use of a Weight Carrying Hitch instead of a Weight

Distributing Hitch can place too much tongue load on the

rear end of the towing vehicle. This combined loading can

cause the rear end of the towing vehicle to sag downward

and the forward end to be raised upward, causing steering problems and towing vehicle sway at other than slow

speeds.

DO NOT MOVE THE TRAILER UNTIL THE COUPLER IS SECURED

AND LOCKED TO HITCH, THE SAFETY CHAINS ARE SECURED

TO THE TOW VEHICLE AND THE TRAILER JACK(S) ARE FULLY

RETRACTED.

DO NOT TOW THE TRAILER ON THE ROAD UNTIL THE TIRES

AND WHEELS ARE CHECKED, THE TRAILER BRAKES ARE

CHECKED, THE BREAKAWAY CABLE IS CONNECTED TO THE

TOW VEHICLE, THE LOAD IS SECURED TO THE TRAILER AND

THE TRAILER LIGHTS ARE CONNECTED AND CHECKED.

Incorrect Use of Safety Chains

If your trailer comes loose from the hitch for any reason,

safety chains are provided so that control of the trailer can

still be maintained. The chains originally supplied with the

trailer are of proper size. Be sure the chains are not

allowed to drag while towing. If links become worn,

replace with proper size chain. Always check that the

chains are attached to the tow vehicle before towing.

FASTEN CHAINS ONLY TO FRAME OF TOW VEHICLE. DO NOT

FASTEN CHAINS TO ANY PART OF THE HITCH UNLESS THE

HITCH HAS HOLES OR LOOPS SPECIFICALLY FOR THAT PURPOSE. CROSS CHAINS UNDERNEATH HITCH AND COUPLER

WITH ENOUGH SLACK TO PERMIT TURNING AND TO HOLD

TONGUE UP, IF THE TRAILER COMES LOOSE.

BE SURE YOUR HITCH AND TOW VEHICLE ARE RATED FOR THE

GROSS VEHICLE WEIGHT RATING OF YOUR TRAILER.

Unsafe Tires, Lug Nuts or Wheels

NOTE: Reference Section 4 - Service and Maintenance,

Section 4.12, Tire and Wheel Maintenance, and

Section 4.13, TIRE SAFETY INFORMATION for

complete tire maintenance and safety information.

It is essential to visually inspect the trailer tires and wheels

before each tow.

If a tire has a bald spot, bulge, cuts, is showing any cords,

or is cracked, replace the tire before towing. If a tire has

uneven tread wear, take the trailer to a dealer or service

center for diagnosis. Uneven tread wear can be caused by

tire imbalance, axle misalignment or incorrect inflation.

Tires with too little tread will not provide adequate tracking

on wet roadways and could result in loss of control, leading to death or serious injury.

Improper tire pressure may cause an unstable trailer and

could result in a tire blowout and loss of control. Tires

must be inspected and inflated in accordance with section

4 of this manual.

1-2 – Triple-L-Trailer – 3121224

SECTION 1 - SAFETY PRECAUTIONS

MODEL

RIMS

THIS VEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY

STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE.

TIRES

PNBV/GVWR (kg/ lb)

DATE

INFL C

(KPa/psi)

PNBE/GAWR (ea.axle)(kg/lb)

Mfd. By:

JLG Industries, Inc

- McConnellsburg, PA--USA Phone 877-JLG-LIFT

SERIAL NO.

V.I. N. No.

VEHICLE

TYPE: TRAILER/REMORQUE

18617D

VIN Label

FD-322

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

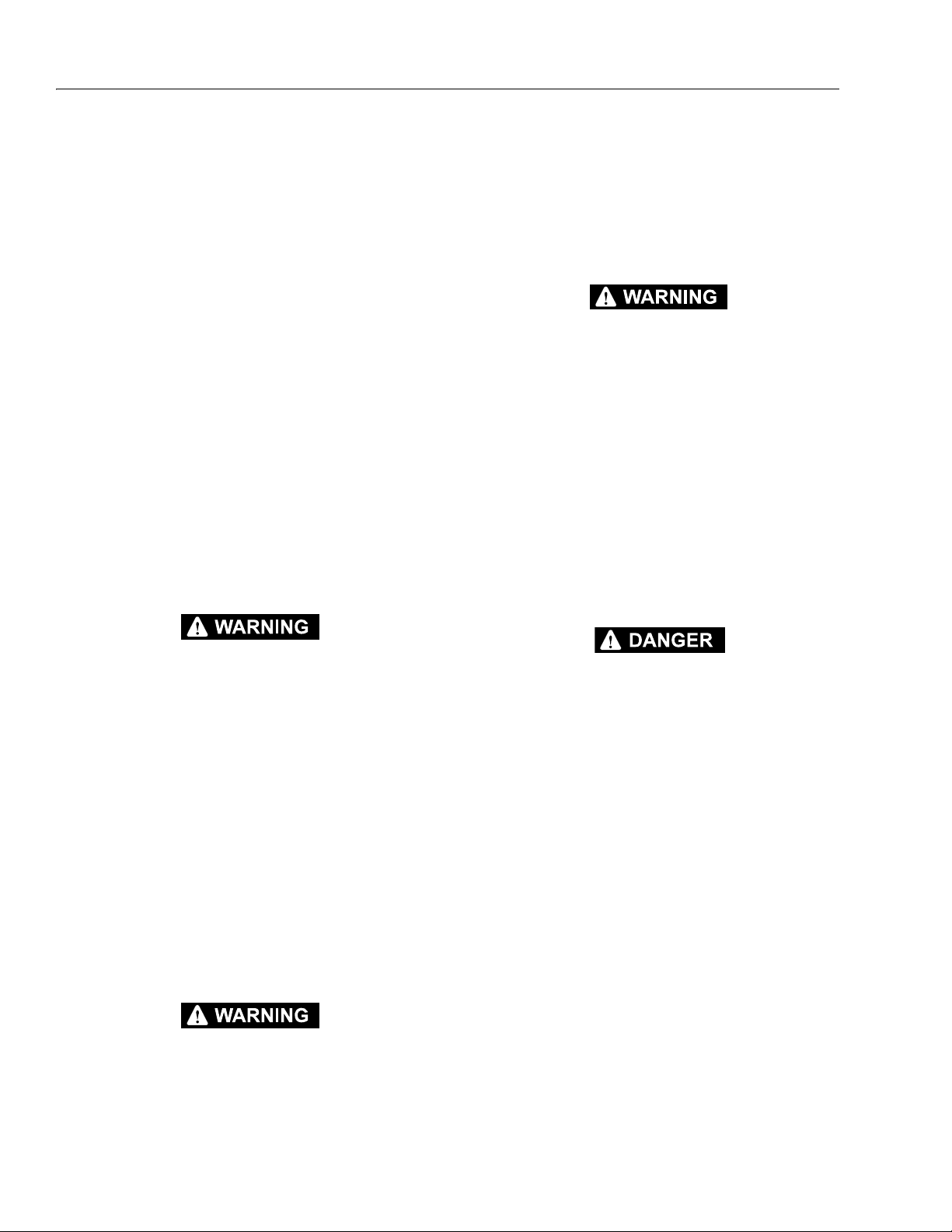

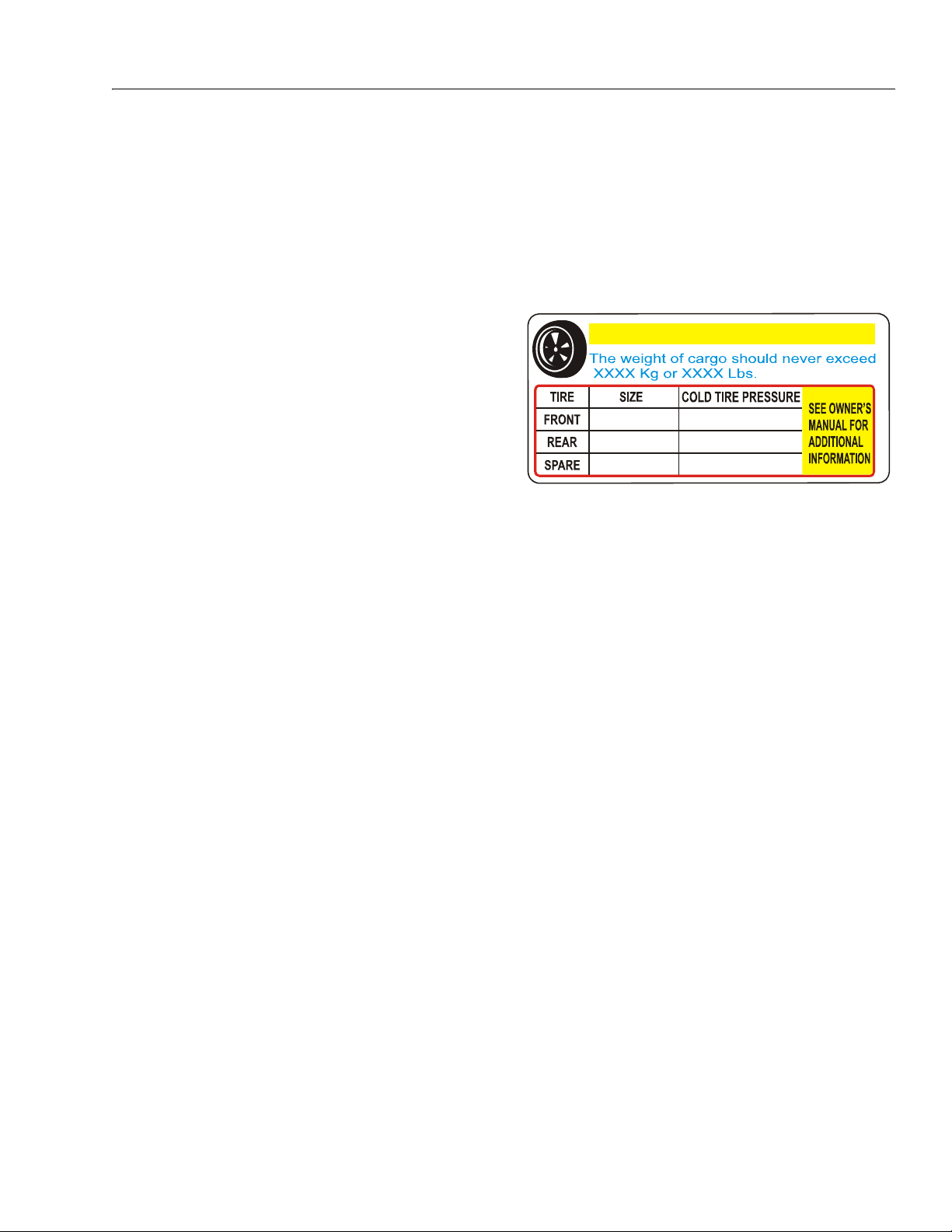

TIRE AND LOADING INFORMATION

Tire Information Label

TRAILER TIRES WILL BE INFLATED TO HIGHER PRESSURES

THAN PASSENGER VEHICLE TIRES. UNDER-INFLATED FRONT

TIRES ON THE TOWING VEHICLE COULD CAUSE STEERING

PROBLEMS. LOW PRESSURE IN THE REAR TIRES OF THE TOWING VEHICLE COULD CAUSE THE VEHICLE TO SWAY.

Trailer wheels and lug nuts are subjected to significant

side loads during tow. Before each tow, visually inspect

the lug nuts for loosening. Lug nuts must be tightened to

the proper torque in accordance with section 4 of this

manual.

Overload

The total weight of the load you put in or on the trailer, plus

the empty weight of the trailer itself, must not exceed the

trailer's Gross Vehicle Weight Rating (GVWR). If you do

not know the empty weight of the trailer, you must measure it at a scale.

Determining the load limits of a trailer includes more than

understanding the load limits of the tires alone. On all trailers there is a VIN (Vehicle Identification No.) label and Tire

Information Label that is located on the forward half of the

left (road) side of the unit. VIN Label indicates the trailer’s

Gross Vehicle Weight Rating (GVWR). This is the most

weight the fully loaded trailer can weigh. It will also provide the Gross Axle Weight Rating (GAWR). This is the

most a particular axle can support. If there are multiple

axles, the GAWR of each axle will be provided.

Steps for Determining Correct Load Limit

• Locate the statement, “The weight of cargo should

never exceed XXX kg or XXX lbs.,” on your vehicle’s

placard.

DO NOT LOAD A TRAILER SO THAT THE WEIGHT EXCEEDS THE

TRAILER GROSS VEHICLE WEIGHT RATING (GVWR) OR GROSS

AXLE WEIGHT RATING (GAWR).

The Tire Information Label provides tire and loading information and a statement regarding maximum cargo capacity. Inspect this label.

NOTE: Refer to Figure 1-1. for Tire Information Label and

VIN Label location.

Excessive loads and/or under-inflation cause tire overloading and, as a result, abnormal tire flexing occurs. This

situation can generate an excessive amount of heat and

lead to tire failure. It is the air pressure that enables a tire

to support the load, so proper inflation is critical. The

proper air pressure may be found on the VIN label and/or

on the Tire Information Label. This value should never

exceed the maximum cold inflation pressure stamped on

the tire.

• This figure equals the available amount of cargo and

luggage load capacity.

• Determine the combined weight of luggage and cargo

being loaded on the vehicle. That weight may not

safely exceed the available cargo and luggage load

capacity.

NOTE: Refer to production options and accessory weight

Table 2-2 for weights of various trailer options.

3121224 – Triple-L-Trailer – 1-3

SECTION 1 - SAFETY PRECAUTIONS

1

2

Figure 1-1. VIN Label & Tire Information Label

1. VIN Label 2. Tire Information Label

Unsafe Load Distribution

Uneven load distribution can cause tire, wheel, axle or

structural failure. Be sure your trailer is properly loaded. A

proper weight distribution is equal, right to left; and creates a tongue weight that is in the proper range for stable

trailer handling (between 10-15% of the total weight of the

cargo and the trailer). Towing stability also depends on

keeping the center of gravity as low as possible. Load

heavy items on the floor and over the axles, but do not

exceed the axle load rating (GAWR). When loading additional items, be sure to maintain even side-to-side weight

distribution and proper tongue weight.

MAKE CERTAIN THAT THE TONGUE WEIGHT IS WITHIN THE

ALLOWABLE RANGE. BE SURE TO DISTRIBUTE THE LOAD

FRONT-TO-REAR TO PROVIDE PROPER TONGUE WEIGHT, DISTRIBUTE THE LOAD EVENLY, RIGHT AND LEFT, TO AVOID TIRE

OVERLOAD AND KEEP THE CENTER OF GRAVITY LOW.

Shifting Cargo

Since the trailer “ride” can be bumpy and rough, you must

secure your cargo so that it does not shift while the trailer

is being towed.

TIE DOWN ALL LOADS WITH PROPER SIZED FASTENERS,

ROPES, STRAPS, ETC. IF YOUR TRAILER IS ENCLOSED OR

EQUIPPED WITH AN OPTIONAL TAILGATE, THE DOORS OR TAILGATE MUST BE SECURELY LATCHED BEFORE TOWING THE

TRAILER.

DO NOT TRANSPORT PEOPLE ON OR INSIDE THE TRAILER. THE

TRANSPORT OF PEOPLE PUTS THEIR LIVES AT RISK AND MAY

BE ILLEGAL.

DO NOT TRANSPORT FLAMMABLE, EXPLOSIVE, POISONOUS OR

OTHER DANGEROUS MATERIALS IN YOUR TRAILER.

EXCEPTIONS: FUEL IN THE TANKS OF EQUIPMENT BEING

HAULED; FUEL STORED IN THE TANK OF AN ON-BOARD GENERATOR

Inoperable Brakes, Lights or Mirrors

Be sure that all of the lights on your trailer are functioning

properly before towing your trailer. Lights on a trailer are

controlled via a connection to the tow vehicle, generally a

multi-pin electrical connector. Check the trailer taillights by

turning on your tow vehicle headlights. Check the trailer

brake lights by having someone step on the tow vehicle

brake pedal while you look at the trailer lights. Have someone activate the tow vehicle’s turn signals to check the

trailer’s turn signal lights.

If your trailer has electric brakes, your tow vehicle must

have an electric brake controller that sends power to the

trailer brakes. Before towing the trailer on the road, you

must operate the brake controller while trying to pull the

trailer in order to confirm that the electric brakes operate.

While towing the trailer at less than 5 mph, manually operate the electric brake controller in the tow vehicle cab. You

should feel the operation of the trailer brakes.

Inappropriate Cargo

If your trailer is designed for specific cargo, only carry that

cargo in the trailer. A utility trailer must not be used to

carry certain items, such as people, containers of hazardous substances or containers of flammable substances.

1-4 – Triple-L-Trailer – 3121224

BEFORE EACH TOW CHECK THAT THE TAILLIGHTS, BRAKE

LIGHTS AND TURN SIGNALS WORK AND CHECK THAT THE

ELECTRIC BRAKES WORK BY OPERATING THE BRAKE CONTROLLER INSIDE THE TOW VEHICLE.

SECTION 1 - SAFETY PRECAUTIONS

Standard mirrors usually do not provide adequate visibility

for viewing traffic to the sides and rear of towed trailer. You

must provide mirrors that allow you to safely observe

approaching traffic.

Modifying the Trailer

Essential safety items can be damaged by altering your

trailer. Even simply driving a nail or screw to hang something can damage an electrical circuit, hydraulic line or

other feature of the trailer.

Before making any alteration to your trailer, contact your

dealer or JLG at 1-877-JLG-SAFE (554-7233) between the

hours of 8:00 AM and 4:45 PM Eastern Standard time and

describe the alteration you are contemplating. Alteration

of the trailer structure or modification of mechanical, electrical, hydraulic or other systems on your trailer must be

approved by JLG and performed only by qualified technicians who are familiar with the system as installed on your

trailer.

Inadequate Tow Vehicle or Towing Hitch

It is essential for the tow vehicle and towing hitch to have a

rated towing capacity equal or greater than the trailer

Gross Vehicle Weight Rating (GVWR). Vehicle manufacturers will provide you with the maximum capacities of their

various models. The hitch ball size must be the same as

the coupler size. The height of the hitch ball must equal

that of the trailer coupler. If the hitch ball is too small, too

large, is underrated, is loose or is worn, the trailer could

come loose from the tow vehicle, and could cause death

or serious injury.

1.4 REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect that could

cause a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying JLG Industries, Inc.

If NHTSA receives similar complaints, it may open an

investigation, and if it finds that a safety defect exists in a

group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your dealer, or JLG

Industries, Inc.

To contact NHTSA, you may either call the Auto Safety

Hotline toll-free at 1-888-327-4236 (TTY: 1-800-424-9153);

go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

Further information about motor vehicle safety can also be

obtained from http://www.safercar.gov or from the JLG

PS&R Hotline at 1-877-JLG-SAFE (554-7233) between the

hours of 8:00 AM and 4:45 PM Eastern Standard time.

1.5 SAFETY WARNING LABELS ON YOUR TRAILER

All decals and safety warning labels are placed on the

trailer for a reason. Read, understand, and follow the

directions of all the decals. Should the decals become

worn or defaced, replace them immediately. Use the

appropriate part number and order from your local dealer

or direct from the trailer manufacturer.

BE SURE THE HITCH LOAD RATING IS EQUAL TO OR GREATER

THAN THE LOAD RATING OF THE COUPLER. BE SURE THE

HITCH SIZE MATCHES THE COUPLER SIZE. OBSERVE THE

HITCH FOR WEAR, CORROSION AND CRACKS BEFORE COUPLING. REPLACE WORN, CORRODED OR CRACKED HITCH COMPONENTS BEFORE COUPLING THE TRAILER TO THE TOW

VEHICLE. BE SURE THE HITCH COMPONENTS ARE TIGHT

BEFORE COUPLING THE TRAILER TO THE TOW VEHICLE.

ALL OF THE LABELS MUST BE ON THE TRAILER AND MUST BE

LEGIBLE. REPLACE ANY MISSING OR ILLEGIBLE LABELS. (SEE

FIGURE 1-2., DECAL LOCATION).

Not Properly Maintaining the Trailer Structure

Proper maintenance is essential for all trailer structural

components to operate properly. Structural components

can consist of the trailer deck assembly, deck latching

mechanism, suspension, and axle components. To ensure

safe and proper operation of the trailer, make sure that the

proper maintenance and inspections are performed.

3121224 – Triple-L-Trailer – 1-5

SECTION 1 - SAFETY PRECAUTIONS

1

1

6

7

10

98

11

13

4

12

12

Figure 1-2. Decal Location

1-6 – Triple-L-Trailer – 3121224

SECTION 1 - SAFETY PRECAUTIONS

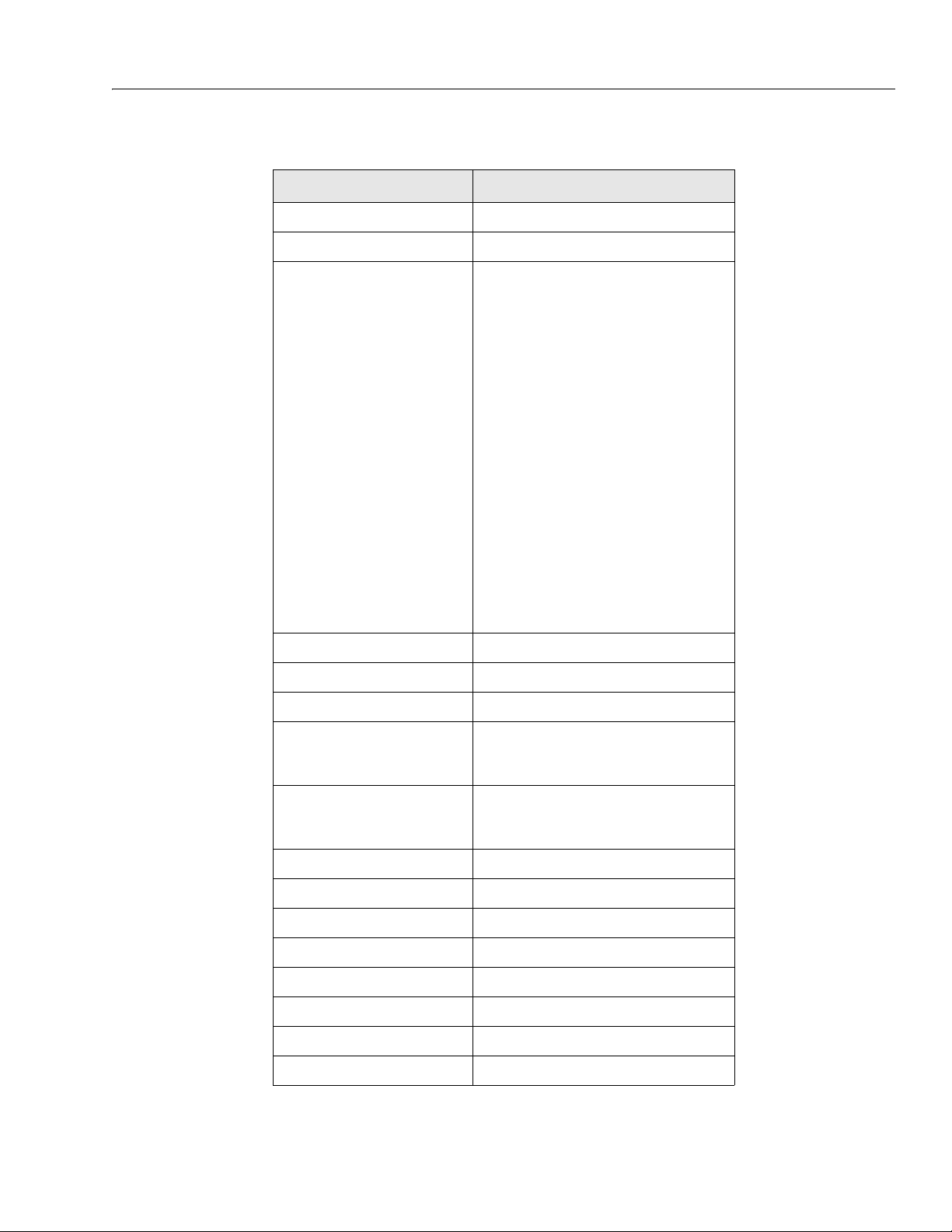

Table 1-1. Decal Location Legend

Item Number/Model Decal Number

1 1705809

2 1705782

3

Model UT610

Model UT612

Model UT614

Model EC-10

Model EC-12

Model EC-14

Model 248

Model UT28

Model 449

Model UT49

Model 4610

Model UT4610

Model 1012

Model 1014

Model UT912

Model UT914

Model 7910

Model 7612

Model 7614

Model 7616

1705761

1705762

1705763

1705764

1705765

1705766

1705767

1705768

1705769

1705770

1705771

1705772

1705773

1705774

1705775

1705776

1705777

1705778

1705779

1705780

4 1705810

5 70319

6 70327

7

all except Model 449 & UT49 1707075

1707076

8

70322

Model 449 & UT49 only

9 70325

10 70323

11 27611

12 1705783

13 70230

14 70317

15* 1705817

16 1706687

1001105881

*Note: These decals are only available on the following models; 1012/1014/UT912/UT914/EC10/EC12/EC14.

3121224 – Triple-L-Trailer – 1-7

SECTION 1 - SAFETY PRECAUTIONS

NOTES:

1-8 – Triple-L-Trailer – 3121224

SECTION 2 - TRAILER OPERATION

SECTION 2. TRAILER OPERATION

2.1 TRAILER MODELS

Triple-L™ Trailers employ a unique trailer deck design to make loading and unloading easier. The trailer deck can be lowered

to the ground while remaining level, allowing equipment to be rolled or driven directly onto the trailer deck.

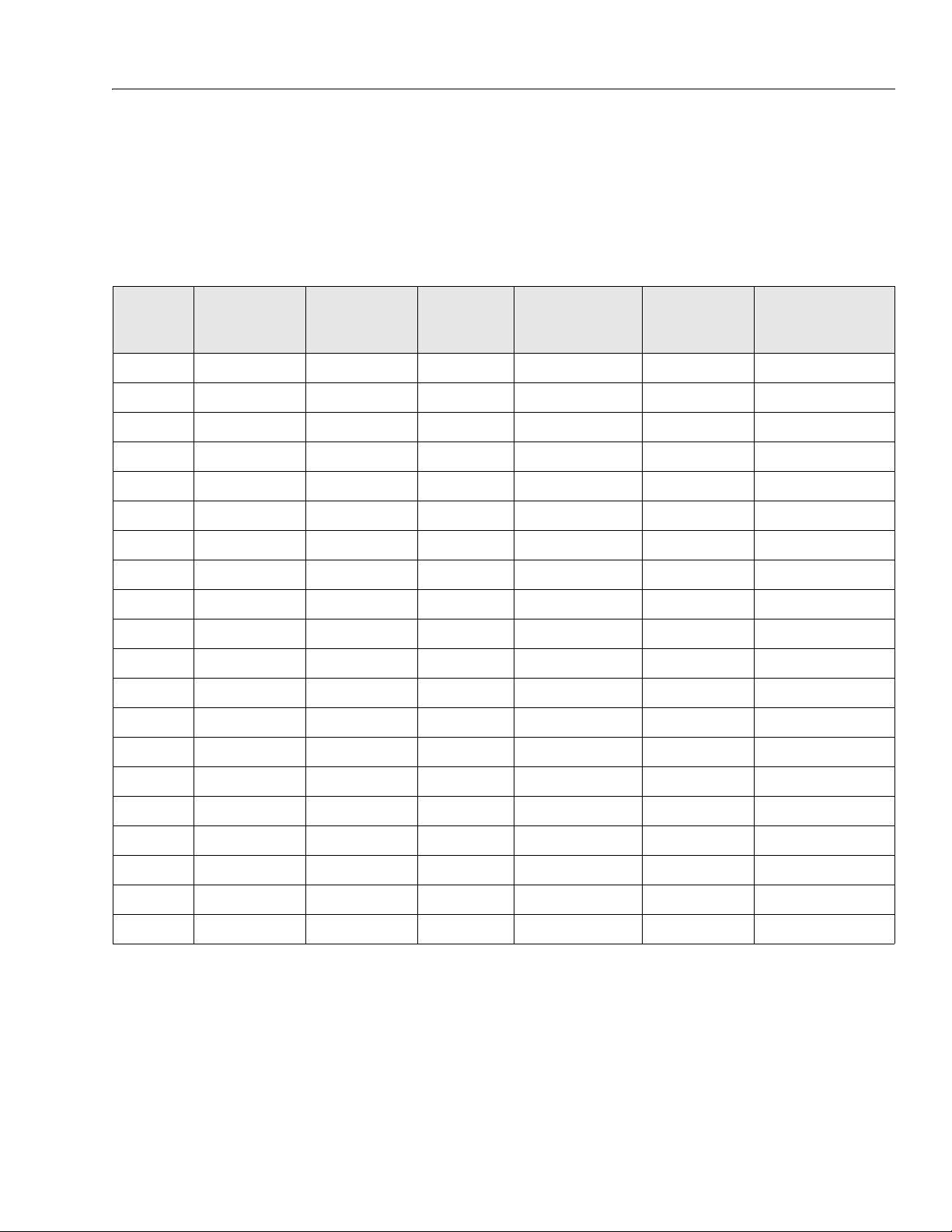

Table 2-1. Trailer Model Specifications

VEHICLE

MODEL DECK SIZE (in)

248 52 x 96 2200 Single Optional Hand Winch 3600 lbs (1633 kg)

449 52 x 108 5000 Single Electric Hydraulic 6810 lbs (3089 kg)

4610 72 x 120 4500 Single Electric Hydraulic 6537 lbs (2965 kg)

7610 70 x 120 7000 Tandem Electric - 1 Axle Hydraulic 9574 lbs (4343 kg)

7612 70 x 144 7000 Tandem Electric - 1 Axle Hydraulic 9750 lbs (4423 kg)

7614 70 x 168 7000 Tandem Electric - 1 Axle Hydraulic 9950 lbs (4513 kg)

7616 70 x 192 6500 Tandem Electric - 1 Axle Hydraulic 9700 lbs (4400 kg)

1012 70 x 144 10,000 Tandem Electric - 2 Axles Hydraulic 13,102 lbs (5943 kg)

1014 70 x 168 10,000 Tandem Electric - 2 Axles Hydraulic 13,342 lbs (6052 kg)

UT28 52 x 96 2000 Single Optional Hand Winch 3790 lbs (1719 kg)

UT49 52 x 108 4500 Single Electric Hydraulic 6460 lbs (2930 kg)

UT410 70 x 120 4000 Single Electric Hydraulic 6800 lbs (3085 kg)

UT610 70 x 120 6000 Tandem Electric - 1 Axle Hydraulic 9740 lbs (4418 kg)

UT612 70 x 144 6000 Tandem Electric - 1 Axle Hydraulic 9903 lbs (4492 kg)

CAPACITY

WEIGHT (lbs)

AXLE

STANDARD BRAKE

CONFIGURATION

LIFT GVWR

UT614 70 x 168 6000 Tandem Electric - 1 Axle Hydraulic 9720 lbs (4409 kg)

UT912 70 x 144 9000 Tandem Electric - 2 Axles Hydraulic 13,268 l bs (6018 kg)

UT914 70 x 168 9000 Tandem Electric - 2 Axles Hydraulic 13,570 l bs (6155 kg)

EC10 68 x 120 6000 Tandem Electric - 2 Axles Hydraulic 9600 lbs (4345 kg)

EC12 68 x 126 6000 Tandem Electric - 2 Axles Hydraulic 9800 lbs (4445 kg)

EC14 68 x 150 6000 Tandem Electric - 2 Axles Hydraulic 10,320 lbs (4681 kg)

3121224 – Triple-L-Trailer – 2-1

SECTION 2 - TRAILER OPERATION

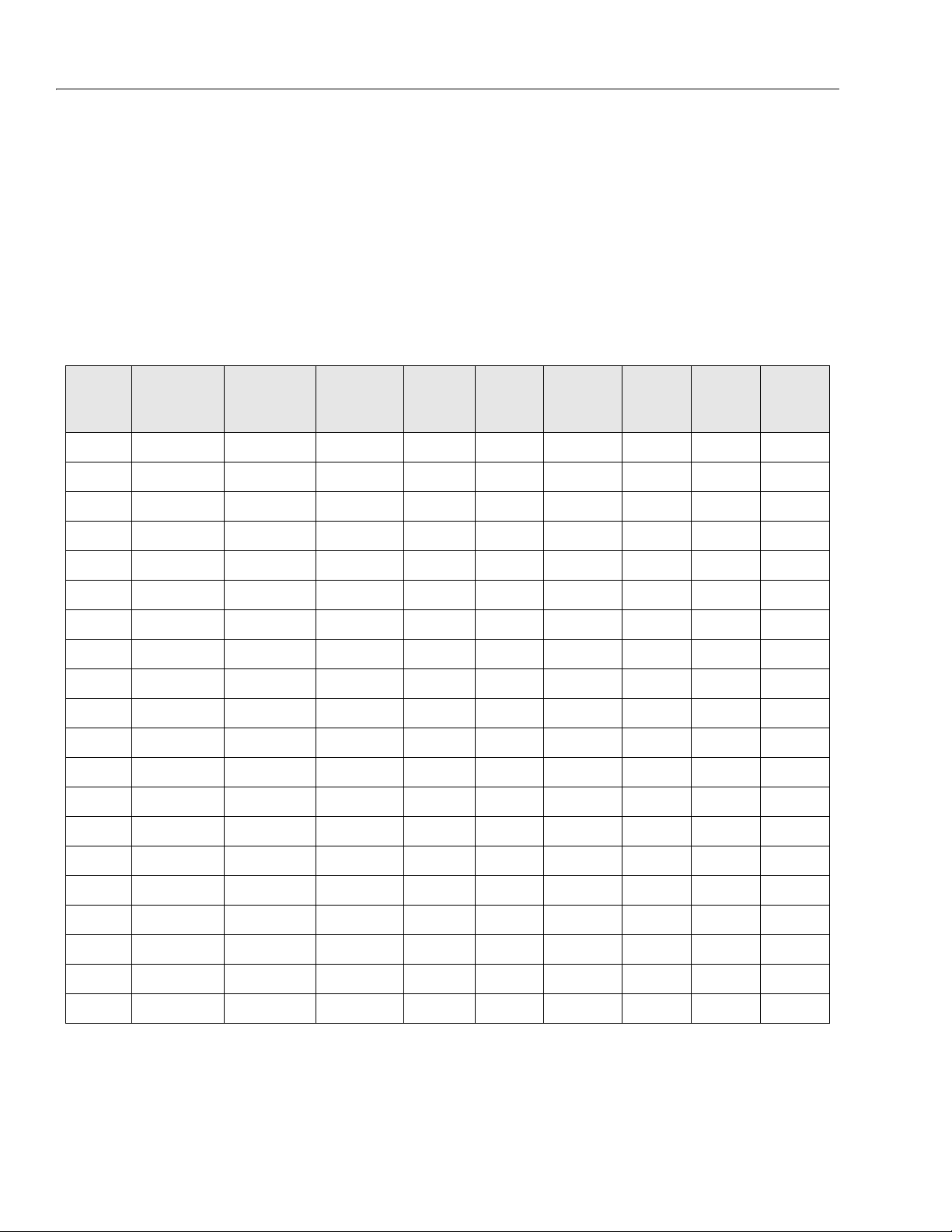

Production Option and Accessory Weights

Any time a trailer is equipped with a production option or accessory or one of these components is added to a trailer, the

weights listed in the following table must be subtracted from the rated vehicle capacity weight.

NOTE: The specified options and accessories must be considered part of cargo weight.

The single axle electric brake and battery are part of the base weight of the single axle trailer and double axle trailer

models 248 and UT28.

The dual electric brake and battery are part of the base weight of the 1012 and 1014 models.

Table 2-2. Production Option and Accessory Weights

HYDRAULIC

MODEL

248 19 lbs -- -- 50 lbs 20 lbs 45 lbs -- -- --

449 19 lbs -- -- 60 lbs 20 lbs 45 lbs -- -- --

4610 19 lbs -- -- 60 lbs 20 lbs 45 lbs -- -- --

7610 34 lbs 14 5 lbs 102 lbs 60 lbs 20 lbs 45 lbs -- -- --

7612 34 lbs 14 5 lbs 102 lbs 60 lbs 20 lbs 45 lbs -- -- --

7614 34 lbs 14 5 lbs 102 lbs 60 lbs 20 lbs 45 lbs -- -- --

7616 34 lbs 14 5 lbs 102 lbs 60 lbs 20 lbs 45 lbs -- -- --

1012 -- 48 lbs -- 60 lbs 20 lbs 45 lbs -- -- --

1014 -- 48 lbs -- 60 lbs 20 lbs 45 lbs -- -- --

UT28 19 lbs -- -- 50 lbs 20 lbs 45 lbs 90 lbs 108 lbs 38 lbs

UT49 19 lbs -- -- 60 lbs 20 lbs 45 lbs 90 lbs 108 lbs 38 lbs

UT410 19 lbs -- -- 60 lbs 20 lbs 45 lbs 100 lbs 117 lbs 49 lbs

UT610 34 lbs -- -- 60 lbs 20 lbs 45 lbs 100 lbs 117 lbs 49 lbs

UT612 34 lbs -- -- 60 lbs 20 lbs 45 lbs 111 lbs 129 lbs 49 lbs

BRAKE

(single axle)

HYDRAULIC

BRAKE

(dual axle)

ELECTRIC

BRAKE

(dual axle)

SPARE

TIRE

TIRE

MOUNT

WINCH

RAILS

(12 IN)

RAILS

(24 IN)

GATE

UT614 34 lbs -- -- 60 lbs 20 lbs 45 lbs 123 lbs 141 lbs 49 lbs

UT912 -- 48 lbs -- 60 lbs 20 lbs 45 lbs 111 lbs 129 lbs 49 lbs

UT914 -- 48 lbs -- 60 lbs 20 lbs 45 lbs 123 lbs 141 lbs 49 lbs

EC10 34 lbs -- -- 60 lbs 20 lbs 45 lbs -- -- --

EC12 34 lbs -- -- 60 lbs 20 lbs 45 lbs -- -- --

EC14 34 lbs -- -- 60 lbs 20 lbs 45 lbs -- -- --

2-2 – Triple-L-Trailer – 3121224

SECTION 2 - TRAILER OPERATION

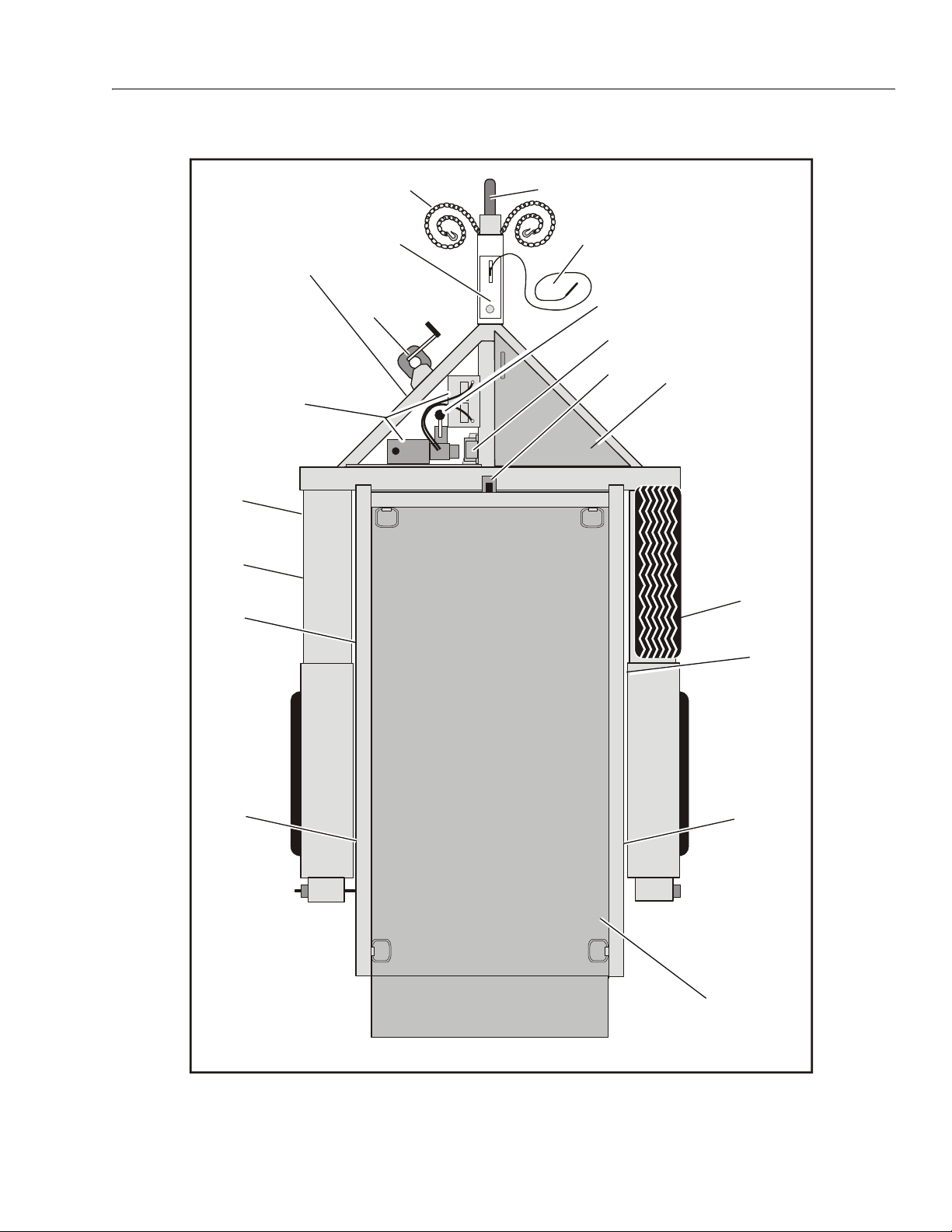

4518

3

13

9

20

16

16

7

Shown with

cover open

on this side

6

2

8

10

15

14

211212

Figure 2-1. Trailer Features

3121224 – Triple-L-Trailer – 2-3

SECTION 2 - TRAILER OPERATION

2.2 TRAILER FEATURES

1. Rails (Not Shown) - These surround the front and

sides of the deck and provide a means to aid in the

proper placement of cargo.

2. Storage - This compartment is used to secure the

owners manual, tools and other items.

3. Actuator - A device on the tongue of the trailer that

activates the optional hydraulic (surge) brake system.

4. Coupler - A device on the tongue of the trailer that

connects to the hitch on the tow vehicle.

5. Safety Chains - If the coupler connection comes

loose, the safety chains can keep the trailer attached

to the tow vehicle. With properly rigged safety

chains, it is possible to keep the tongue of the trailer

from digging into the road pavement, even if the

coupler-to-hitch connection comes apart.

6. Tongue Jack - A device on the trailer that is used to

raise and lower the coupler to aid in coupling and

uncoupling the trailer. The jack is sometimes called

the “landing gear.”

7. Motor/Pump Battery - This compartment holds the

motor/pump and battery. The battery provides the

electrical power for raising and lowering the trailer

deck and the power for the electrically operated

breakaway brake system. The pump/motor provides

hydraulic fluid to the cylinder that raises the deck

into place for transport.

8. Up/down Control - The control lever used to activate

the hydraulic system to lower or elevate the deck.

15. Serial Number - This is a 17 digit number, also

referred to as the Vehicle Identification Number

(VIN), that can be found on the identification plate

and stamped on the frame of the trailer.

16. Suspension - The system that allows the trailer

wheels to absorb bumps in the travel surface.

17. Trailer Lighting (and braking) connector (not shown)

- A device that connects electrical power from the

tow vehicle to the trailer. Electricity is used to turn on

brake lights, running lights, and turn signals as

required. In addition, if you trailer has a separate

braking system, the electrical connector will also

supply power to the brakes from the tow vehicle.

18. Breakaway Cable - If the coupler connection comes

loose, the breakaway cable can actuate emergency

electrical brakes on the trailer. The breakaway cable

must be rigged to the tow vehicle with appropriate

slack that will activate the brakes if the coupler connection comes loose.

19. Hitch (Not Shown) - A device on the tow vehicle that

supports the weight of the trailer tongue and pulls

the trailer. The coupler attaches to the hitch.

20. Descent Alarm - An alarm on the trailer that sounds

anytime the trailer is lowered.

21. Spare Tire (accessory) - A spare tire is mounted on

the side of the trailer.

DO NOT MOVE THE TRAILER UNTIL THE COUPLER IS SECURED

AND LOCKED TO HITCH, THE SAFETY CHAINS ARE SECURED

TO THE TOW VEHICLE AND THE TRAILER JACK(S) ARE FULLY

RETRACTED.

9. Travel Latch - A mechanism that prevents the deck

from lowering to the ground unintentionally.

10. Identification Plate - This placard contains the Vehicle Identification Number (VIN) and weight ratings

for the trailer.

11. Deck Bearing (Not Shown) - This component is

attached to the chassis and guides the bearing

channel when the trailer deck is being raised or lowered.

12. Bearing Channel - This component is part of the

trailer deck and rides on the deck bearing when the

deck is being raised or lowered.

13. Chassis - This is the structural frame work of the

trailer.

14. Deck - This is the surface where cargo is placed for

transport. It can be lowered for loading and raised

for transport.

DO NOT TOW THE TRAILER ON THE ROAD UNTIL THE TIRES

AND WHEELS ARE CHECKED, THE TRAILER BRAKES ARE

CHECKED, THE BREAKAWAY CABLE IS CONNECTED TO THE

TOW VEHICLE, THE LOAD IS SECURED TO THE TRAILER AND

THE TRAILER LIGHTS ARE CONNECTED AND CHECKED.

2-4 – Triple-L-Trailer – 3121224

SECTION 2 - TRAILER OPERATION

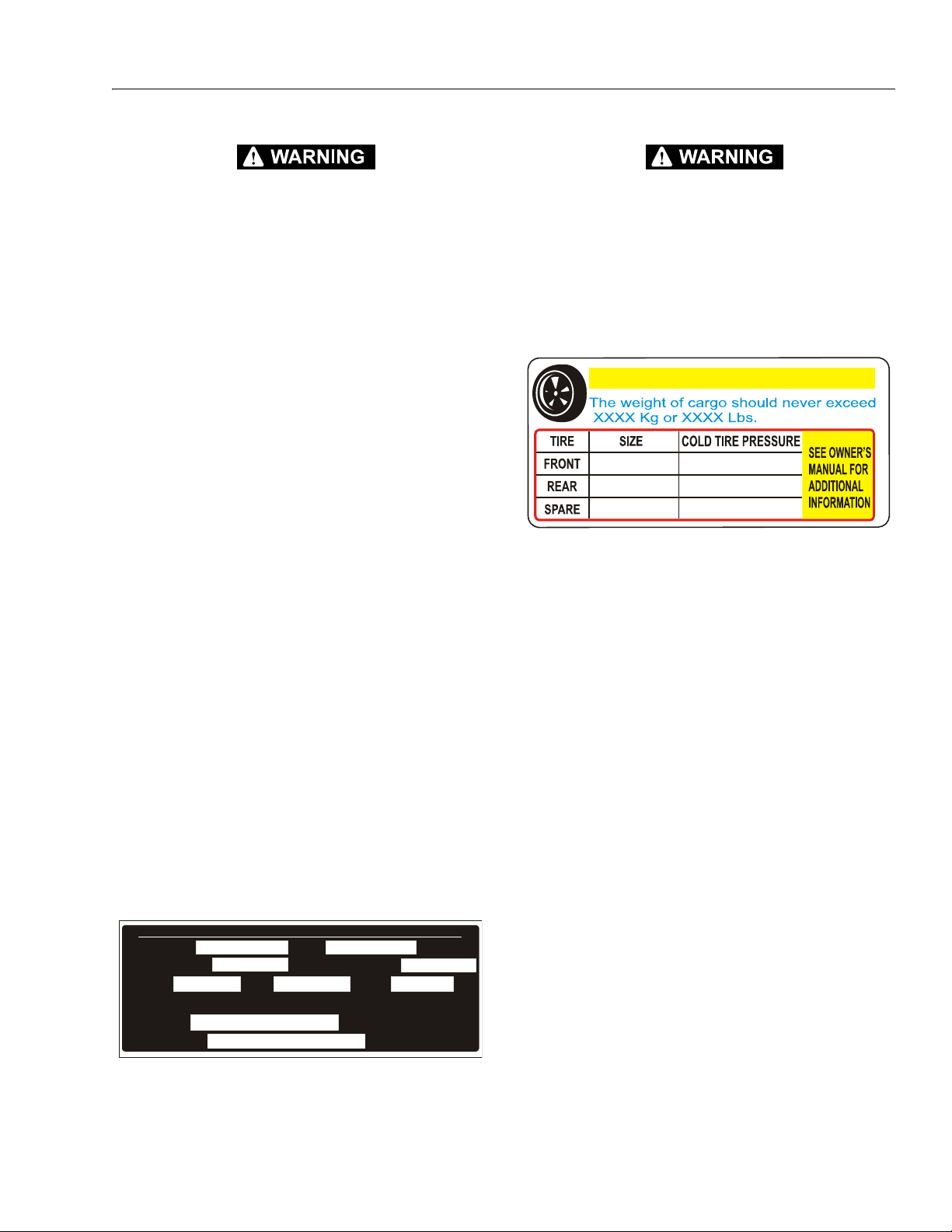

MODEL

RIMS

THIS VEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY

STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE.

TIRES

PNBV/GVWR (kg/ lb)

DATE

INFL C

(KPa/psi)

PNBE/GAWR (ea.axle)(kg/lb)

Mfd. By:

JLG Industries, Inc

- McConnellsburg, PA--USA Phone 877-JLG-LIFT

SERIAL NO.

V.I.N. No.

VEHICLE

TYPE: TRAILER/ REMORQUE

18617D

Figure 2-2. Vehicle Identification Plate

2.3 GENERAL

Trailer VIN Information

The Trailer Features figure shows the location of the Trailer

Identification Plate on your trailer.

The Trailer Identification Plate contains the following critical safety information for the use of your trailer.

a. GVWR: The maximum allowable gross weight of

the trailer and its contents. The gross weight of

the trailer includes the weight of the trailer and

all of the items within it (such as cargo, water,

food and other supplies). GVWR is sometimes

referred to as GTWR (Gross Trailer Weight Rating), or MGTW (Maximum Gross Trailer Weight).

GVWR, GTWR and MGTW are all the same rating.

b. GAWR: The maximum gross weight that an axle

can support. The sum total of the GAWR for all

trailer axles may be less than the GVWR for the

trailer, because some of the trailer load is to be

carried by the tow vehicle, rather than by the

trailer axle(s). The total weight of the cargo and

trailer must not exceed the GVWR, and the load

on an axle must not exceed its GAWR.

2.4 COUPLER

A coupler connects to a ball that is located on or under the

rear bumper of tow vehicle. This system of coupling a

trailer to a tow vehicle is sometimes referred to as “bumper pull.”

The trailer is equipped with a ball hitch coupler that is suitable for the size and weight of the trailer. Your trailer may

be equipped with a 2" or a 2-5/16" coupler. The load rating

of the coupler and the necessary ball size are listed on the

trailer tongue. Do not change the coupler to a smaller

size. You must provide a hitch and ball for your tow vehicle, where the load rating of the hitch and ball is equal to

or greater than that of your trailer. The ball size must be

the same as the coupler size. If the hitch ball is too small,

too large, is underrated, is loose or is worn, the trailer can

come loose from the tow vehicle, and may cause death or

serious injury.

THE TOW VEHICLE, HITCH AND BALL MUST HAVE A RATED

TOWING CAPACITY EQUAL TO OR GREATER THAN THE

TRAILER GVWR (GROSS VEHICLE WEIGHT RATING).

IT IS ESSENTIAL THAT THE HITCH BALL BE OF THE SAME SIZE

AS THE COUPLER.

2.5 BRAKES

Governmental regulations may contain various brake

requirements. Some of these regulations may require the

use of electric brakes only or require brakes on all wheels

of a tandem axle trailer.

NOTE: It is the responsibility of the owner to meet the

requirements of all governmental regulations in his

area.

Electric Brakes (Option)

c. RIMS - Specification of rims equipped on the

trailer.

d. TIRES - Size and load rating of tires equipped

on the trailer.

e. INFLC: The tire pressure (Pounds per Square

Inch) measured when Cold.

f. VIN: The Vehicle Identification Number is a 17

digit serial number located on the trailer identification plate.

3121224 – Triple-L-Trailer – 2-5

g. SERIAL NO - JLG manufacturing number. Use

this number when conducting business with

JLG.

The electric brakes on this trailer are similar to the drum

brakes on an automobile. The basic difference is that the

automotive brakes are actuated by hydraulic pressure

while electric trailer brakes are actuated by an electromagnet. The brakes are applied by a brake controller

installed on the tow vehicle.

Hydraulic Brakes - Surge Brakes (Option)

The hydraulic brakes (surge brakes) on the trailer are

actuated by a master cylinder. The hydraulic fluid from the

master cylinder is used to actuate the hydraulic wheel cylinder which, in turn applies force against the brake shoes

and drum. A surge tongue actuator is required for a trailer

with hydraulic brakes.

SECTION 2 - TRAILER OPERATION

2.6 BATTERY (OPTION)

Battery

The battery is carried on the trailer and is used for powering the motor running the hydraulic pump. If the trailer has

electric brakes, this same battery is used for power to the

break-away switch.

Batteries are considered an optional item which can be

purchased with the trailer or obtained locally. The battery

should be a 12 volt deep cycle.

12V

Deep Cycle

.

Switch is mounted directly to the starter solenoid located

under the deck control lever. The switch is activated when

the deck control lever is moved to the "down" position.

The switch has mounting adjustment to allow precise timing of the alarm.

NOTE: The Alarm has a fixed decibel rating.

2.7 DECK ALARM SYSTEM

The deck alarm is designed to give intermittent beeps as

the deck is lowered. The operator is responsible to see

that all personnel are clear of the deck when lowering. The

deck alarm is only intended to assist in giving additional

warning.

Testing System

Alarm should sound immediately when moving deck control lever to "down" position. If the alarm does not sound;

check the following:

1. When the spring trigger on the switch is depressed,

the alarm is off and when it is fully released, the

alarm is on.

2. The switch has an adjustable mounting bracket.

With the deck control lever in the neutral position,

set the switch just close enough to press on the

spring trigger, shutting off the alarm. It should then

release the trigger and operate correctly when you

move the deck control lever to the "down" position.

3. If alarm does not sound when spring trigger on

switch is released- check wiring to ensure that current is flowing to the alarm.

The alarm should sound automatically when the deck

control lever is moved to the "down" position

2-6 – Triple-L-Trailer – 3121224

SECTION 2 - TRAILER OPERATION

2.8 TOW VEHICLE AND HITCH INFORMATION

Follow all of the safety precautions and instructions in this

manual and the manuals of the tow vehicle and the hitch

to ensure safety of persons, cargo, and satisfactory life of

the trailer.

If the vehicle or hitch is not properly selected and matched

to the Gross Vehicle Weight Rating (GVWR) of your trailer,

you can cause an accident that could lead to death or

serious injury. If you already have (or plan to buy) a tow

vehicle, make certain your trailer rating (GVWR) is equal to

or less than the towing capacity and hitch rating of the tow

vehicle.

BE SURE YOUR HITCH AND TOW VEHICLE ARE RATED FOR THE

GROSS VEHICLE WEIGHT RATING OF YOUR TRAILER.

Tow Vehicle and Hitch

When equipping a vehicle to tow your trailer, ask the vehicle dealer for advice on how to properly outfit the towing

vehicle. Discuss the following information and equipment

with the vehicle dealer.

Coupler Height Adjustment

Remove the bolts securing the coupler to the mounting

bracket. Move the coupler up of down to desired height.

Secure with the bolts. For the Pintle Hitch Coupler, torque

the two bolts to 225 ft lb (305 Nm). For the Ball Couplers,

torque the four bolts to 150 ft lb (203 Nm).

Hitch Ball

The coupler on the trailer connects to the ball attached to

the hitch on the tow vehicle. The coupler, ball and hitch

transfer the towing forces between the tow vehicle and the

trailer.

Suspension System

Sway bars, shock absorbers, heavy duty springs, heavyduty tires and other suspension components must be able

to sufficiently serve the size and weight of the trailer that is

going to be towed.

Brake Controller

The brake controller is part of the tow vehicle and is

essential in the operation of trailers equipped with electric

brakes. The brake controller is not the same as the safety

breakaway brake system that may be equipped on the

trailer.

Side View Mirrors

Overall Carrying and Towing Capacity of Vehicle

Vehicle manufacturers will provide you with the maximum

capacities of their various models. No amount of reinforcement will give a 100 horsepower, 2,500 pound truck

the towing capacity that a 300 horsepower, 5,000 pound

truck has.

Towing Hitch

The towing hitch attached to your tow vehicle must have a

capacity equal to or greater than the load rating of the

trailer you intend to tow. The height of the hitch ball must

equal that of the trailer coupler. The hitch capacity must

also be matched to the tow vehicle capacity. Only your

vehicle dealer can provide and install the proper hitch on

your tow vehicle.

THE UNDERSIDE OF THE TRAILER TONGUE MUST BE BETWEEN

17” AND 19” ABOVE LEVEL GROUND BEFORE TOWING. ADJUST

THE COUPLER OR TOW VEHICLE HITCH TO ACHIEVE THIS

HEIGHT.

The size of the trailer that is being towed and your state

law regulations determine the size of the mirrors. However, some states prohibit extended mirrors on a tow vehicle, except while a trailer is actually being towed. In this

situation, detachable extended mirrors are necessary.

Check with your dealer or the appropriate state agency for

mirror requirements.

Heavy Duty Flasher

A Heavy Duty Flasher is an electrical component that may

be required when your trailer turn signal lights are

attached to the tow vehicle flasher circuit.

Electrical Connector

An Electrical Connector connects the light and brake systems on the trailer to the light and brake controls on the

towing vehicle.

Heavy Duty Engine Oil Cooling System

The tow vehicle engine works harder when a trailer is

being towed. Depending on the size of the trailer, you may

need to install a separate engine oil cooler. Inadequate

cooling may result in sudden engine failure. Ask the tow

vehicle dealer if it is necessary to install a heavy duty cooling system.

3121224 – Triple-L-Trailer – 2-7

SECTION 2 - TRAILER OPERATION

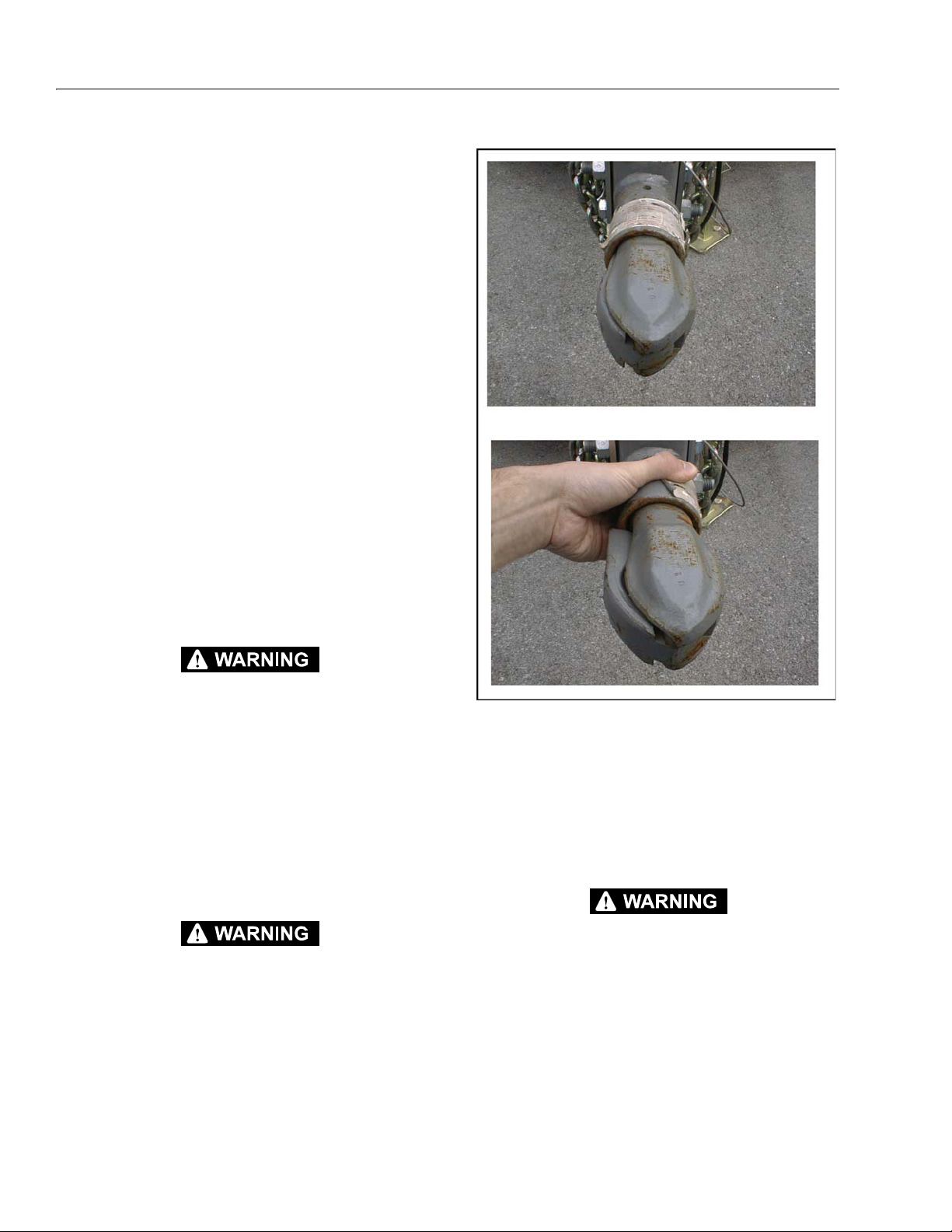

Figure 2-3. Coupler

Automatic Transmission Oil Cooler

The automatic transmission of a towing vehicle handles

more power when a trailer is being towed. Inadequate

cooling will shorten transmission life, and may result in

sudden transmission failure. Ask the tow vehicle dealer if it

is necessary to install a separate oil cooler for the automatic transmission.

Fire Extinguisher

A fire extinguisher should be carried in the tow vehicle.

Emergency Flares and Emergency Triangle Reflectors

Carry these warning devices when towing a trailer

because the hazard flashers of your towing vehicle will not

operate for as long a period of time when the battery is

running both the trailer lights and tow vehicle lights.

2.9 COUPLING AND UNCOUPLING THE TRAILER

The trailer must be properly and securely coupled to the

hitch of the tow vehicle.

UNCOUPLING OF THE TRAILER DURING TRANSPORT MAY

RESULT IN DEATH OR SERIOUS INJURY.

Before Coupling the Trailer to the Tow Vehicle

Be sure the size and rating of hitch ball match the size and

rating of the coupler. Hitch balls and couplers are marked

with their size and rating.

Wipe the hitch ball clean and inspect it visually and by feel

for flat spots, cracks and pits.

BEFORE EACH TOW, INSPECT THE HITCH BALL FOR WEAR,

CORROSION AND CRACKS BEFORE COUPLING TRAILER.

REPLACE WORN OR DAMAGED HITCH BALL.

NOTE: Rock the hitch ball in all directions to make sure it is

tight to the hitch, and visually check that the hitch

ball nut is solid against the lock washer and hitch

frame.

Prepare the Coupler and Hitch

Lubricate the hitch ball and the inside of the coupler with a

thin layer of automotive bearing grease to reduce wear

and ensure proper operation. If your trailer is equipped

with a tongue jack, raise the coupler above the ball height.

BEFORE EACH TOW, BE SURE THE HITCH BALL IS TIGHT TO

THE HITCH BEFORE COUPLING THE TRAILER.

1. Wipe the inside and outside of the coupler clean and

inspect it visually for cracks and deformations; feel

the inside of the coupler for worn spots and pits.

Be sure the coupler is tight to the tongue of the

trailer. All coupler fasteners must be visibly solid

against the trailer frame.

2-8 – Triple-L-Trailer – 3121224

2. Raise the bottom surface of the coupler to be above

the top of the hitch ball. Use the tongue jack if one is

provided; otherwise, use wood or concrete blocks to

support the trailer tongue.

3. As seen in Figure 2-3., Coupler, slide the collar on

the hitch toward the trailer until it opens up to accept

the ball from the tow vehicle.

4. Once the hitch on the trailer is open, align the tow

vehicle up with the trailer hitch.

5. Using the tongue jack, lower the entire weight of the

trailer on to the ball hitch of the tow vehicle.

6. Slide the collar on the hitch toward the tow vehicle to

lock into place.

7. Insert the pin into the hole behind the collar to lock

the collar into place.

8. Be sure the coupler is all the way on the hitch ball

and the collar/locking mechanism is engaged. A

properly engaged locking mechanism will allow the

coupler to raise the rear of the tow vehicle. Using the

tongue jack, test to see that you can raise the rear of

the tow vehicle by 1 inch, after the coupler is locked

to the hitch.

SECTION 2 - TRAILER OPERATION

FASTEN CHAINS TO FRAME OF TOW VEHICLE. DO NOT FASTEN

CHAINS TO ANY PART OF THE HITCH UNLESS THE HITCH HAS

HOLES OR LOOPS SPECIFICALLY FOR THAT PURPOSE.

CROSS CHAINS UNDERNEATH HITCH AND COUPLER WITH

ENOUGH SLACK TO PERMIT TURNING AND TO HOLD TONGUE

UP, IF THE TRAILER COMES LOOSE.

Attach and Test Electric Breakaway Brake System

BEFORE TOWING, CONNECT THE BREAKAWAY CABLE TO THE

TOW VEHICLE; AND NOT TO THE HITCH, BALL OR SUPPORT.

TEST THE FUNCTION OF THE BREAKAWAY BRAKE SYSTEM. IF

THE BREAKAWAY BRAKE SYSTEM IS NOT WORKING, DO NOT

TOW THE TRAILER. HAVE IT SERVICED OR REPAIRED.

If the coupler or hitch fails, a properly connected and

working breakaway brake system will apply electric

brakes on the trailer. The safety chains will keep the tow

vehicle attached and as the brakes are applied at the

trailer’s axles, the trailer/tow vehicle combination will

come to a controlled stop.

OVERLOADING CAN DAMAGE THE TONGUE JACK. DO NOT USE

THE TONGUE JACK TO RAISE THE TOW VEHICLE MORE THAN 1

INCH.

NOTE: If the coupler cannot be secured to the hitch ball, do

not tow the trailer.

9. Retract the tongue jack until it is fully retracted.

Rig the Safety Chains

Visually inspect the safety chains and hooks for wear or

damage. Replace worn or damaged safety chains and

hooks before towing.

Rig the safety chains so that they:

a. Cross each other underneath the coupler.

b. Loop around a frame member of the tow vehicle

or to holes provided in the hitch system (DO

NOT attach them to an interchangeable part of

the hitch assembly).

c. Have enough slack to permit tight turns, but not

be close to the road surface, so if the trailer

uncouples, the safety chains can hold the

tongue up above the road.

The breakaway brake system includes a battery, a switch

with a pullpin, and a breakaway brake controller. Read

and follow the instructions here as well as the instructions

that have been prepared by the breakaway brake controller manufacturer. If you do not have these instructions, call

JLG to obtain a copy.

The breakaway brake system may be fitted with a charging facility that draws power from the tow vehicle. If the

electrical system on your tow vehicle does not provide

power to the breakaway brake battery, you must periodically charge the battery to keep the breakaway brake system in working order.

1. Connect the pull pin cable to the tow vehicle so that

the pullpin will be pulled out before all of the slack in

the safety chains is taken up. Do not connect the

pullpin cable to a safety chain or to the hitch ball or

hitch ball assembly. This would keep the breakaway

brake system from operating when it is needed.

2. Remove the pullpin from the switch and test tow the

trailer, at less than 5 m.p.h. You should feel the trailer

resisting being towed, but the wheels will not necessarily be locked. If the brakes do not function, do not

tow the trailer until the brakes are repaired.

3. Immediately replace the pullpin. The breakaway

brake system battery discharges rapidly when the

pullpin is removed.

3121224 – Triple-L-Trailer – 2-9

SECTION 2 - TRAILER OPERATION

Connect the Electrical Cables

TO AVOID POSSIBLE INJURY DO NOT TOW THE TRAILER WITH

THE PULLPIN REMOVED AND THE BREAKAWAY BRAKE SYSTEM

ON BECAUSE THE BRAKES WILL OVERHEAT WHICH CAN

RESULT IN PERMANENT BRAKE FAILURE.

If you do not use your trailer for three or more months, or

during winter months:

a. Store the battery indoors

b. Charge the battery every three months.

Replace the breakaway brake battery according to the

intervals specified by the battery manufacturer.

Attach and Test Hydraulic Breakaway Brake System

If the coupler or hitch fails, a properly connected and

working breakaway brake system will apply the hydraulic

(surge) brakes on the trailer. The safety chains will keep

the tow vehicle attached and as the brakes are applied at

the trailer’s axles, the trailer/tow vehicle combination will

come to a controlled stop.

The breakaway brake system includes a cable attached to

an activation lever. Read and follow the instructions here

as well as the instructions that have been prepared by the

breakaway brake controller manufacturer.

Connect the breakaway cable to the tow vehicle so that

the activation lever will be pulled before all of the slack in

the safety chains is taken up. Do not connect the breakaway cable to a safety chain or to the hitch ball or hitch

ball assembly. This would keep the breakaway brake system from operating when it is needed.

Manually pull the activation lever and test tow the trailer, at

less than 5 m.p.h. You should feel the trailer resisting

being towed, but the wheels will not necessarily be

locked. If the brakes do not function, do not tow the trailer

until the brakes are repaired.

Reset the activation lever prior to towing.

Connect the trailer lights to the tow vehicle's electrical system using the electrical connectors.

Check all lights for proper operation:

a. Clearance and Running Lights (Turn on tow

vehicle headlights).

b. Brake Lights (Step on tow vehicle brake pedal).

c. Turn Signals (Operate tow vehicle directional

signal lever).

d. Backup Lights (Put tow vehicle gear shift into

reverse).

Check electric brakes for proper operation.

If your trailer has electric brakes, your tow vehicle must

have an electric brake controller that sends power to the

trailer brakes. Before towing the trailer on the road, you

must operate the brake controller while trying to pull the

trailer in order to confirm that the electric brakes operate.

While towing the trailer at less than 5 mph, manually operate the electric brake controller in the tow vehicle cab. You

should feel the operation of the trailer brakes.

BEFORE EACH TOW CHECK THAT THE TAILLIGHTS, BRAKE

LIGHTS AND TURN SIGNALS WORK. CHECK THAT THE ELECTRIC BRAKES WORK BY OPERATING THE BRAKE CONTROLLER

INSIDE THE TOW VEHICLE.

Uncoupling the Ball Hitch Trailer with Tongue Jack

Follow these steps to uncouple your ball hitch trailer from

the tow vehicle:

1. Block or chock trailer tires to prevent the trailer from

rolling, before jacking the trailer up.

2. Disconnect the electrical connector.

3. Disconnect the breakaway brake switch cable. For

an electric breakaway break system, promptly

replace the pullpin in the switchbox.

CONNECT THE BREAKAWAY CABLE TO THE TOW VEHICLE;

AND NOT TO THE HITCH, BALL OR SUPPORT. BEFORE TOWING

THE TRAILER, TEST THE FUNCTION OF THE BREAKAWAY

BRAKE SYSTEM. IF THE BREAKAWAY BRAKE SYSTEM IS NOT

WORKING, DO NOT TOW THE TRAILER. HAVE IT SERVICED OR

REPAIRED.

NOTE: Do not tow the trailer with the breakaway brake sys-

tem ON because the brakes will overheat which can

result in permanent brake failure.

4. Disconnect the safety chains from the tow vehicle.

5. Unlock the coupler and open it.

6. Before extending the tongue jack, make certain the

ground surface below the jack pad will support the

tongue load.

7. Rotate the jack handle (or crank) clockwise. This will

slowly extend the tongue jack and transfer the

weight of the trailer tongue to the jack.

2-10 – Triple-L-Trailer – 3121224

SECTION 2 - TRAILER OPERATION

2.10 LOADING THE TRAILER

Improper trailer loading causes many accidents and

deaths. To safely load a trailer, you must consider:

a. Overall load weight

b. Load weight distribution

c. Proper tongue weight

d. Securing the load properly

To determine that you have loaded the trailer within its rating, you must consider the distribution of weight, as well

as the total weight of the trailer and its contents. The trailer

axles carry most of the total weight of the trailer and its

contents (Gross Vehicle Weight, or “GVW”). The remainder of the total weight is carried by the tow vehicle hitch. It

is essential for safe towing that the trailer tongue and tow

vehicle hitch carry the proper amount of the loaded trailer

weight, otherwise the trailer can suddenly sway at towing

speed. Read the “Tongue Weight” section below.

Towing stability also depends on keeping the center of

gravity as low as possible. Load heavy items on the floor

and over the axles. When loading additional items, be

sure to maintain even side-to-side weight distribution and

proper tongue weight. The total weight of the trailer and its

contents must never exceed the total weight rating of the

trailer (Gross Vehicle Weight Rating, or “GVWR”).

For a ball hitch trailer the tongue weight should be

between 10% and 15% of the total trailer weight, including

the cargo. For example, a trailer, with a loaded weight of

4,000 pounds, should have 10-15% of 4,000 pounds on

the tongue. That is, the trailer would have 400 to 600

pounds on its tongue.

MAKE CERTAIN THAT TONGUE WEIGHT IS WITHIN THE ALLOWABLE RANGE. BE SURE TO DISTRIBUTE THE LOAD FRONT-TOREAR TO PROVIDE PROPER TONGUE WEIGHT, DISTRIBUTE THE

LOAD EVENLY, RIGHT AND LEFT, TO AVOID TIRE OVERLOAD;

AND KEEP THE CENTER OF GRAVITY LOW.

Checking Tongue Weight

To check the tongue weight, the tow vehicle and trailer

must be on level ground, as they will be when the trailer is

being towed.

If you know the weight on your tow vehicle axles when you

are not towing a trailer, trailer tongue weight can be determined with the use of a truck axle scale.

The recommended method of checking tongue weight is

to use an accessory called a “tongue weight scale.” Contact your dealer to check on the availability of a tongue

weight scale.

DO NOT LOAD A TRAILER SO THAT THE WEIGHT ON ANY TIRE

EXCEEDS ITS RATING. DO NOT EXCEED THE TRAILER GROSS

VEHICLE WEIGHT RATING (GVWR) OR AN AXLE GROSS AXLE

WEIGHT RATING (GAWR).

Tongue Weight

It is critical to have a portion of the trailer load carried by

the tow vehicle. The trailer tongue must exert an appropriate downward force on the hitch. This is necessary for two

reasons. The proper amount of tongue weight is necessary for the tow vehicle to be able to maintain control of

the tow vehicle/trailer system. If there is not enough

weight on the tongue, the tongue exerts an upward pull on

the hitch, the rear wheel of the tow vehicle can lose traction or grip and cause loss of control or the trailer can suddenly become unstable at high speeds.

If there is too much tongue weight, the front wheels of the

tow vehicle can be too lightly loaded and cause loss of

steering control and traction, as well, if the front wheels

are driving.

Tongue weight is necessary to insure that the trailer

axle(s) do not exceed their Gross Axle Weight Rating

(GAWR).

If necessary, the tongue weight may also be determined

through the use of a personal scale. When using a personal scale, the loaded trailer must be on a smooth and

level surface and the front and rear of the trailer wheels

must be blocked. If the tongue weight exceeds the personal scale capacity, a lever arrangement will be required

to determine the tongue weight.

BEFORE CHECKING TONGUE WEIGHT, BLOCK TRAILER

WHEELS, FRONT AND REAR.

The tongue weight can also be checked at an axle weighing scale.

Tongue Height

Proper tongue height is critical to maintaining stability during towing. After the trailer is loaded, check the tongue

height and ensure that the underside of the tongue is 17”19” above the ground.

THE UNDERSIDE OF THE TRAILER TONGUE MUST BE BETWEEN