Operation and Safety Manual

®

Original Instructions - Keep this manual with the machine at all times.

Model(s)

AM Series

20AM

25AM

30AM

ANSI

36AM

41AM

P/N - 3121211

November 12, 2014

NOTES:

FOREWORD

FOREWARD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and

operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

3121211 – JLG Lift – a

FOREWORD

DANGER

CAUTION

NOTICE

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL

RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY

RESULT IN MINOR OR MODERATE INJURY. IT MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE A

YELLOW BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

WILL HAVE AN ORANGE BACKGROUND.

INDICATES INFORMATION OR A COMPANY POLICY THAT RELATES

DIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

b – JLG Lift – 3121211

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLE-

NOTICE

NOTICE

TINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED

JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETY

RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THIS

PRODUCT.

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE

OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES,

INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE UPDATED

AND ACCURATE.

For :

• Accident Reporting

•Product Safety Publications

•Current Owner

Updates

• Questions Regarding

Product Safety

• Standards and Regulations Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding

Product Modifications

Contact :

Product Safety and Reliability Department

JLG Industries, Inc.

1 JLG Drive

McConnellsburg, PA 17233

FOREWORD

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL

INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR

WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRODUCT.

or Your Local JLG Office

(See addresses on manual rear cover)

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

3121211 – JLG Lift – c

Phone: 717-485-5161

E-mail: ProductSafety@JLG.com

FOREWORD

REVISION LOG

Original Issue of Manual . . . . . . . . . . . . . . . . . . . . . . . . July 6, 2005

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . June 30, 2006

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . June 4, 2007

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . May 5, 2008

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . January 5, 2010

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . June 14, 2010

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . November 12, 2014

d – JLG Lift – 3121211

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 TRANSPORTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tipping Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tilt Back Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3 PRE-OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrocution Hazard . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.5 MAINTENANCE SAFETY PRECAUTIONS . . . . . . . . .1-10

SECTION - 2 - USER RESPONSIBILITIES, MACHINE

PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING. . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Training . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Responsibility . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 PREPARATION, INSPECTION, AND

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 PRE-START INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . 2-4

3121211 – JLG Lift – i

2.4 FUNCTION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5 DAILY WALK-AROUND INSPECTION. . . . . . . . . . . . . 2-5

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

SECTION - 3 - MACHINE CONTROLS AND INDICATORS

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 CONTROLS AND INDICATORS . . . . . . . . . . . . . . . . . . 3-1

Ground Control Station . . . . . . . . . . . . . . . . . . . . . . 3-1

Manual Descent Valve . . . . . . . . . . . . . . . . . . . . . . . 3-3

Platform Control Station . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 DECAL INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . 3-5

SECTION - 4 - MACHINE OPERATION

4.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 OPERATING CHARACTERISTICS AND

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 BATTERY CHARGING & MAINTENANCE -

(DC MODELS ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

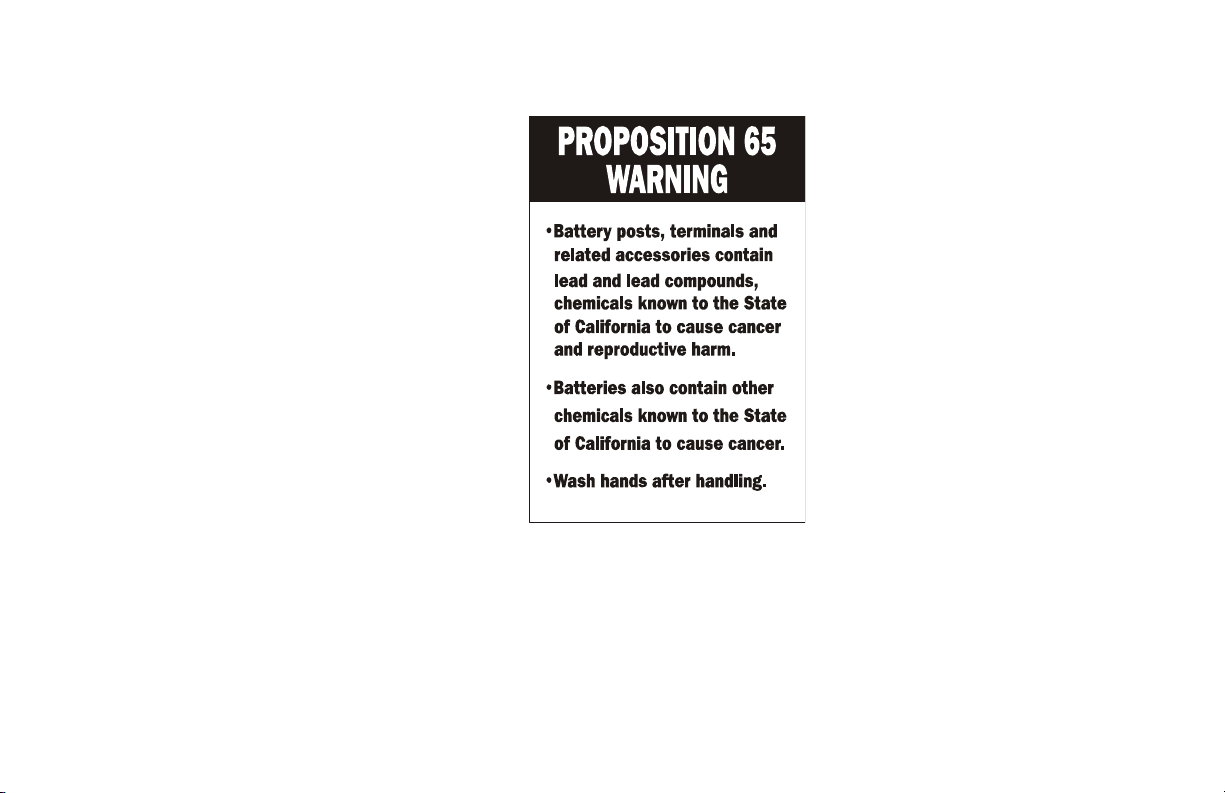

Battery Maintenance and Safety . . . . . . . . . . . . . . 4-2

Battery Charger Operation . . . . . . . . . . . . . . . . . . . 4-3

Abnormal Cycle Indicator LED. . . . . . . . . . . . . . . . 4-4

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

4.4 MACHINE SET-UP AND OPERATION. . . . . . . . . . . . . .4-5

Caster Brake Operation . . . . . . . . . . . . . . . . . . . . . . 4-5

Outrigger Installation. . . . . . . . . . . . . . . . . . . . . . . . 4-6

Platform Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Platform Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5 QUICK-CHANGE PLATFORM MOUNTS. . . . . . . . . . .4-9

Platform Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Platform Installation . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.6 MACHINE SHUT DOWN AND PARK . . . . . . . . . . . . 4-10

4.7 TRANSPORT, LIFTING AND TIE DOWN. . . . . . . . . . 4-11

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Transporting by Pushing. . . . . . . . . . . . . . . . . . . . 4-11

Tilt-Back Assembly Set-up (AM36/AM41) -

Machines Prior to S/N - 0900031618 . . . . . . . . 4-11

Tilt-Back Assembly Set-up (AM36/AM41) -

Machines S/N - 0900031618 to Present . . . . . 4-15

Pickup Truck Loading Device (Option). . . . . . . 4-19

Lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Machine Tie Down. . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

ii – JLG Lift – 3121211

SECTION - 5 - OPTIONAL EQUIPMENT

5.1 OPTIONAL EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . 5-1

22" x 25" Quick-Change Platform . . . . . . . . . . . . . 5-1

26" x 26" Quick-Change Platform . . . . . . . . . . . . . 5-1

28" x 26" Quick-Change Platform . . . . . . . . . . . . . 5-1

25" x 26" Step-in Molded Platform

w/Swing-up Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Tool Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Fluorescent Tube Caddy . . . . . . . . . . . . . . . . . . . . . 5-1

Crane Hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Straddle Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Ladder for Straddle Extension . . . . . . . . . . . . . . . . 5-1

Extra Power Pack (Battery, Charger & Case) . . . 5-2

Platform Auxiliary Power Lowering Device . . . . 5-2

Laser Positioning Device . . . . . . . . . . . . . . . . . . . . . 5-2

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Machine Cycle Counter Meter . . . . . . . . . . . . . . . . 5-2

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

5.2 AM-SE - STRADDLE EXTENSION –

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Straddle Adaptor Wiring Components . . . . . . . 5-3

Straddle Adaptor Wiring Installation . . . . . . . . . 5-3

AM-SE - Straddle Extension –

Set-up And Operation . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Straddle Extension - Components. . . . . . . . . . . . 5-7

Mounting - Straddle Extension to AM . . . . . . . . 5-7

Positioning Straddle Unit and

Lifting AM Machine. . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Lowering AM Machine on Straddle Unit . . . . . 5-10

Straddle and AM Machine Disassembly . . . . . 5-11

SECTION - 6 - EMERGENCY PROCEDURES

6.1 GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . . . . 6-1

Operator Unable to Control Machine. . . . . . . . . 6-1

Platform Caught Overhead . . . . . . . . . . . . . . . . . . 6-1

Righting of Tipped Machine . . . . . . . . . . . . . . . . . 6-1

6.3 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . . . . . 6-2

3121211 – JLG Lift – iii

SECTION - 7 - GENERAL SPECIFICATIONS AND OPERATOR

MAINTENANCE

7.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . 7-2

Machine Specifications . . . . . . . . . . . . . . . . . . . . 7-2

Electrical Specifications . . . . . . . . . . . . . . . . . . . . 7-3

Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . 7-3

Platform Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Machine Component Weights . . . . . . . . . . . . . 7-5

Serial Number Locations . . . . . . . . . . . . . . . . . . . . . 7-5

7.3 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . 7-6

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Battery Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.4 SUPPLEMENTAL INFORMATION . . . . . . . . . . . . . . . 7-10

SECTION - 8 - INSPECTION AND REPAIR LOG

LIST OF FIGURES

2-1. Daily Walk-Around inspection. . . . . . . . . . . . . . . . . . 2-7

3-1. Ground Control Station.. . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2. Manual Descent Valve Location.. . . . . . . . . . . . . . . . 3-3

3-3. Manual Descent Valve Location.. . . . . . . . . . . . . . . . 3-4

3-4. Platform Control Station.. . . . . . . . . . . . . . . . . . . . . . . 3-4

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

3-5. Decal Installation. (ANSI/CSA)

(Machines prior to S/N-0900031618) . . . . . . . . . . . .3-5

3-6. Decal Installation (CE)

(Machines prior to S/N-0900031618) . . . . . . . . . . . .3-8

3-7. Decal Installation. (ANSI/CSA)

(Machines S/N-0900031618 to Present). . . . . . . . 3-11

3-8. Decal Installation (CE)

(Machines S/N-0900031618 to Present). . . . . . . . 3-14

4-1. Battery Fluid Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4-2. Battery Box and Charger Assembly.

(D.C. Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-3. Dual Voltage Charger - Front Panel. . . . . . . . . . . . . .4-4

4-4. Setting & Releasing Caster Brake . . . . . . . . . . . . . . . .4-5

4-5. Outrigger Installation. . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4-6. Quick Change Platform Mount. . . . . . . . . . . . . . . . . .4-9

4-7. Tilt-Back Assembly Set-Up. . . . . . . . . . . . . . . . . . . . . 4-12

4-8. Tilt-Back Assembly Set-Up -

Machines S/N - 0900031618 to Present. . . . . . . . 4-16

4-9. Tilt-Back Assembly Set-Up -

Machines S/N - 0900031618 to Present. . . . . . . . . . . . . . . 4-17

4-10. Tilt-Back Assembly Set-Up -

Machines S/N - 0900031618 to Present. . . . . . . . . . . . . . . 4-18

4-11. Loading Machine onto Bed of Pick-Up Truck. . . 4-20

5-1. Hour Meter Location. (Option) . . . . . . . . . . . . . . . . . .5-2

5-2. SE-Adapter - Wiring - Grommet & Spring Clip

Mounting Hole Locations.

(Same For Both Sides) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-3. Straddle Adapter Wiring Harness to AM Wiring

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-4. Straddle Extension Component Assembly. . . . . . . 5-8

5-5. Side Lifting Rail - Quick Release Pins.. . . . . . . . . . . 5-11

LIST OF TABLES

1-1 Minimum Approach Distance (M.A.D.) . . . . . . . . . . 1-6

2-1 Inspection and Maintenance Table . . . . . . . . . . . . . 2-3

3-1 Decal Installation Chart (ANSI and CSA). . . . . . . . . 3-6

3-2 Decal Installation Chart (CE Specification) . . . . . . 3-9

3-3 Decal Installation Chart (ANSI and CSA). . . . . . . . 3-12

3-4 Decal Installation Chart (CE Specification) . . . . . 3-15

4-1 Maximum Platform Capacity. . . . . . . . . . . . . . . . . . . . 4-8

4-2 AM Machine Gross Weights. . . . . . . . . . . . . . . . . . . 4-23

7-1 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . 7-6

7-2 Lubrication Intervals for Various Components. . . 7-9

8-1 Inspection and Repair Log. . . . . . . . . . . . . . . . . . . . . . 8-1

iv – JLG Lift – 3121211

SECTION 1. SAFETY PRECAUTIONS

SECTION 1 - SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper and

safe machine operation and maintenance. For proper machine

use, it is mandatory that a daily routine is established based on

the content of this manual. A maintenance program using the

information provided in this manual and the Service and Maintenance Manual must also be established by a qualified person

and followed to ensure that the machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine should

not operate the machine until this manual has been read, training is accomplished, and operation of the machine has been

completed under the supervision of an experienced and qualified operator. If there is a question with regard to safety training,

inspection, maintenance and operation, please contact JLG

Industries, Inc. ("JLG").

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE

MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER.

3121211 – JLG Lift – 1-1

1.2 TRANSPORTING

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN THIS SECTION

AND ON MACHINE MAY RESULT IN MACHINE DAMAGE, PERSONNEL INJURY

OR DEATH AND IS A SAFETY VIOLATION.

Transport

• The platform must be completely empty of tools and

debris.

• Ensure platform is fully lowered. Remove and stow outriggers.

• Never allow personnel in platform while moving machine.

• To move machine use handles provided on the mast cross-

bar.

SECTION 1 - SAFETY PRECAUTIONS

Tipping Hazards

FAILURE TO COMPLY WITH THE FOLLOWING TIPPING HAZARD INSTRUCTIONS

COULD CAUSE THE UNIT TO TIP OVER OR BE HARD TO CONTROL WHEN BEING

MOVED, WHICH COULD RESULT IN SERIOUS INJURY OR DEATH.

• On a level surface, always travel with the platform end leading the way.

• Watch for obstructions around machine and overhead.

• Check travel path for persons, holes, bumps, drop-offs,

obstructions, debris, and coverings which may conceal

other hazards.

• Before placing machine on floors, trucks and other surfaces,

check allowable capacity of surfaces.

1-2 – JLG Lift – 3121211

SECTION 1 - SAFETY PRECAUTIONS

• Two persons are required on slopes up to 5°. A forklift must

be used when moving units on slopes greater than 5°.

• Always travel up or down a slope with the platform end of

the machine positioned towards the low side of the slope.

the operator and assistant must walk beside to guide the

machine.

• Never position the unit sideways on a slope.

• Do not elevate the platform or move the machine on a soft

surface.

• Use caution and check clearances when moving machine in

restricted or close quarters.

• Always use an assistant when moving machine in areas

where vision is obstructed.

• Keep non-operating personnel at least 6 feet (1.8 m) away

from machine during moving operations.

3121211 – JLG Lift – 1-3

SECTION 1 - SAFETY PRECAUTIONS

Tilt Back Procedure

(AM36 & AM41 Machines Only)

• The platform must be completely empty of tools and

debris.

• Ensure platform is fully lowered. Remove and stow outriggers.

• Tilt machine back only on a flat, firm and level surface.

1-4 – JLG Lift – 3121211

SECTION 1 - SAFETY PRECAUTIONS

1.3 PRE-OPERATION

General

• Read and understand this manual before operating the

machine.

• Only authorized and qualified personnel can operate the

machine.

• Do not operate this machine until complete training is performed by authorized personnel.

• Before operation check work area for machine traffic such

as forklifts, cranes, and other construction equipment.

• Set-up machine for operation only on a smooth, firm surface on which the machine is capable of being leveled.

• Be sure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence.

Disconnect power to overhead cranes.

• The operator is to take safety measures to avoid all hazards

in the work area prior to machine operation.

• Do not operate this machine until it has been serviced and

maintained according to requirements specified in the Service and Maintenance manual.

• Before machine operation perform inspections and functional checks. Refer to in Section 2 of this manual for

detailed instructions.

3121211 – JLG Lift – 1-5

SECTION 1 - SAFETY PRECAUTIONS

• Warn personnel not to work, stand, or walk under a raised

platform. Position barricades on floor, if necessary.

• Be sure all safety devices are operating properly. Modification of these devices is a safety violation.

• Never operate machine in high wind, rain or snow.

• Do not operate or raise the platform while on trucks, trail-

ers, railway cars, floating vessels, scaffolds or other equipment unless approved by JLG.

• Approved head gear must be worn by all operating and

ground personnel.

• Read, understand, and obey all dangers, warnings, cautions

and operating instructions on the machine and in this manual.

• All operating personnel must be familiar with emergency

controls and emergency operation of the machine as specified in this manual.

Electrocution Hazard

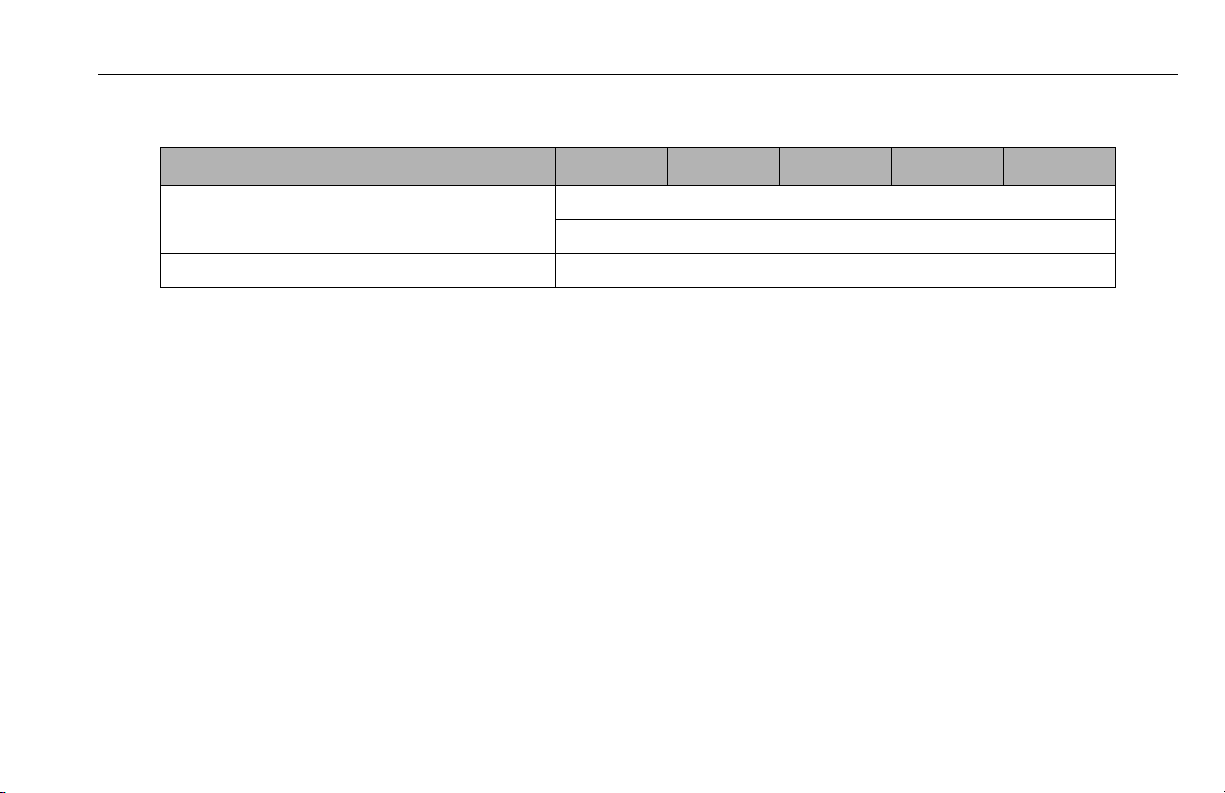

Table 1-1. Minimum Approach Distance (M.A.D.)

VOLTAGE RANGE

(PHASE TO PHASE)

MINIMUM APPROACH

DISTANCE - Feet (m)

0-50KV 10 (3)

O ve r 50 K V to 2 00 K V 15 (5)

Over 200KV to 350K V 20 (6)

Over 350KV to 500K V 25 (8)

Over 500KV to 750K V 35 (11)

Over 750KV to 1000KV 45 (14)

NOTE: This Minimum Approach Distance shall apply except where

employer, local, or governmental regulations are more stringent.

1-6 – JLG Lift – 3121211

SECTION 1 - SAFETY PRECAUTIONS

Maintain a clearance of at least 10 ft (3m) between any part of

the machine and its occupants, their tools, and their equipment from any electrical line or apparatus carrying up to

50,000 volts. One foot (0.3m) additional clearance is required

for every additional 30,000 volts or less.

The minimum approach distance may be reduced if insulating barriers are installed to prevent contact, and if the barriers

are rated for the voltage of the line being guarded. These barriers shall not be part of (or attached to) the machine. The minimum approach distance shall be reduced to a distance within

the designed working dimensions of the insulating barrier.

This determination shall be made by a qualified person in

accordance with employer, local, or governmental requirements for work practices near energized equipment.

1.4 OPERATION

• Do not operate any machine on which instruction placards

or decals are missing or illegible.

• Never exceed the maximum platform capacity.

• Operate AC units with an extension cord rated at a mini-

mum of 15 amps.

• Prior to entering the platform ensure all leveling jacks have

been properly installed and the unit’s base frame is level

according to the bubble leveling indicator on base frame,

and all wheels are completely off the ground.

• While operating the machine, always look in the direction

of machine movement.

• Never operate a machine that is not operating properly. If a

malfunction occurs, shut down the machine.

• When applicable by reason of local regulations or job-site/

employer safety rules, personnel in the platform shall at all

times wear approved fall protection devices. The authorized lanyard attachment is on the side of the machine’s

mast.

3121211 – JLG Lift – 1-7

SECTION 1 - SAFETY PRECAUTIONS

• Check work area for clearance overhead, on sides, and bottom of platform when lifting and lowering platform.

• Never use the mast assembly to enter or leave the platform.

• Do not increase the platform size with unauthorized deck

extensions or attachments.

• Never attempt to use the machine as a crane.

• Do not tie off machine to any adjacent structure.

1-8 – JLG Lift – 3121211

SECTION 1 - SAFETY PRECAUTIONS

• Platform to structure transfers at elevated positions are discouraged. Where transfer is necessary, enter and exit

through the gate only with the platform within 1 foot (0.3

m) of the adjacent safe and secure structure. 100% tie-off is

also required in this situation using (2) lanyards. One lanyard must be attached to the platform, the second lanyard

attached to the structure. The lanyard connected to the

platform must not be disconnected until the transfer to the

structure is complete.

• Do not allow personnel to tamper with, or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• During operation, keep all body parts inside platform railing.

• Never position ladders, steps, or similar items on unit to

provide additional reach for any purpose.

• When working from platform both feet must be firmly positioned on deck.

• Do not perform work that will subject unit to a horizontal

force or create a swaying motion of the platform.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Avoid any build up of debris on the platform floor. keep

mud, oil, grease and other slippery substances from footwear and platform floor.

• Do not operate machine from platform without the gate in

place and properly closed.

3121211 – JLG Lift – 1-9

SECTION 1 - SAFETY PRECAUTIONS

1.5 MAINTENANCE SAFETY PRECAUTIONS

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN THIS SECTION

COULD RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS

A SAFETY VIOLATION.

• Remove all rings, watches, and jewelry when performing

any maintenance.

• Do not wear long hair unrestrained, or loose fitting clothing

and neckties which are apt to become caught on or entangled in equipment.

• Observe and obey all danger, warning, caution and other

instructions on machine.

• Keep standing surfaces and hand holds free of oil, grease,

water, etc.

• Never work under an elevated platform until platform has

been safely restrained from any movement by blocking or

overhead sling.

• Before making adjustments, lubricating or performing any

other maintenance, shut off all power controls.

• Battery should always be disconnected during replacement

of electrical components.

• Keep all support equipment and attachments stowed in

their proper place.

• Use only approved, nonflammable cleaning solvents.

1-10 – JLG Lift – 3121211

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is necessary that it be operated and maintained only by trained personnel.

Persons under the influence of drugs or alcohol or who are subject to seizures, dizziness or loss of physical control must not

operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and

at the ground, emergency controls and safety systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of

the machine to recognize a malfunction or potential

malfunction.

6. The safest means to operate the machine where overhead obstructions, other moving equipment, and

obstacles, depressions, holes, dropoffs.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified person in an open area free of obstructions until the trainee has

developed the ability to safely control and operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility and authority to shut down the machine in case of a malfunction or other unsafe condition of either the machine or the

job site.

3121211 – JLG Lift – 2-1

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

NOTICE

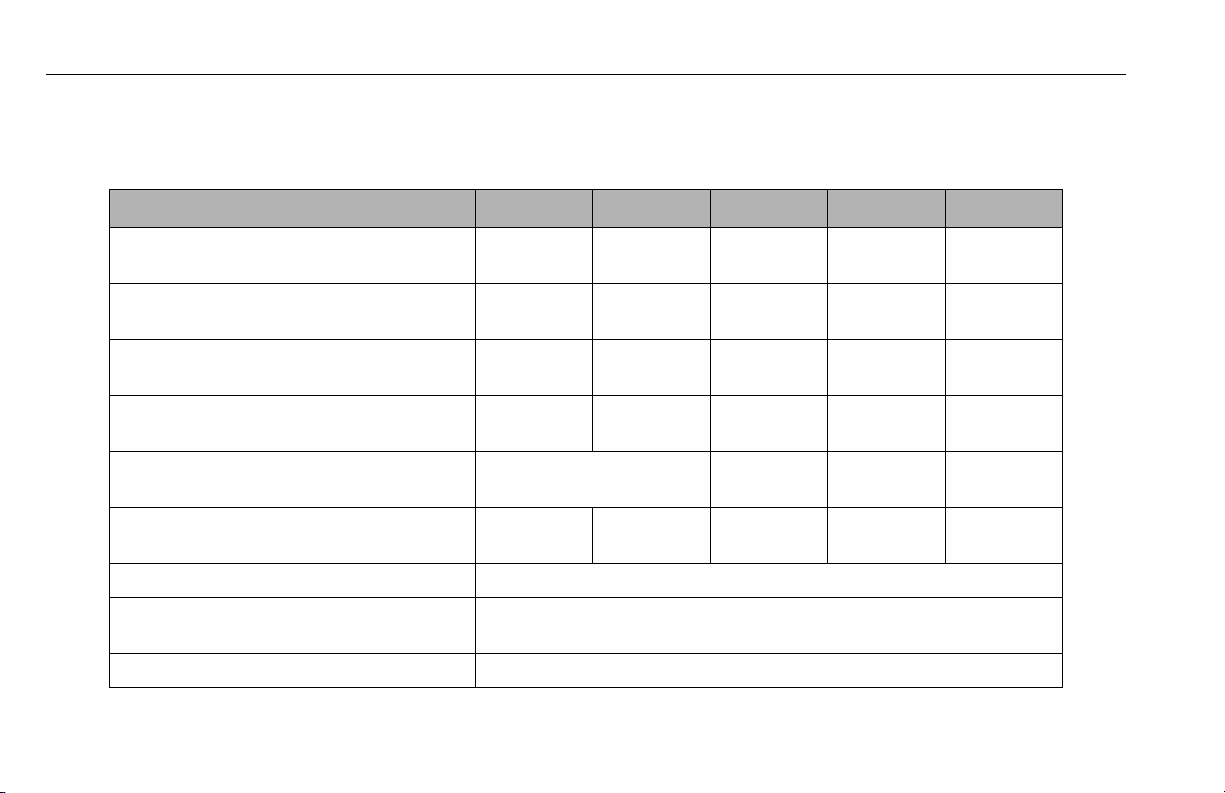

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

The following table covers the periodic machine inspections

and maintenance recommended by JLG Industries, Inc. Consult

local regulations for further requirements for aerial work platforms. The frequency of inspections and maintenance must be

increased as necessary when the machine is used in a harsh or

hostile environment, if the machine is used with increased frequency, or if the machine is used in a severe manner.

JLG INDUSTRIES, INC. RECOGNIZES A FACTORY-TRAINED SERVICE TECHNICIAN AS A PERSON WHO HAS SUCCESSFULLY COMPLETED THE JLG SERVICE

TRAINING SCHOOL FOR THE SPECIFIC JLG PRODUCT MODEL.

2-2 – JLG Lift – 3121211

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

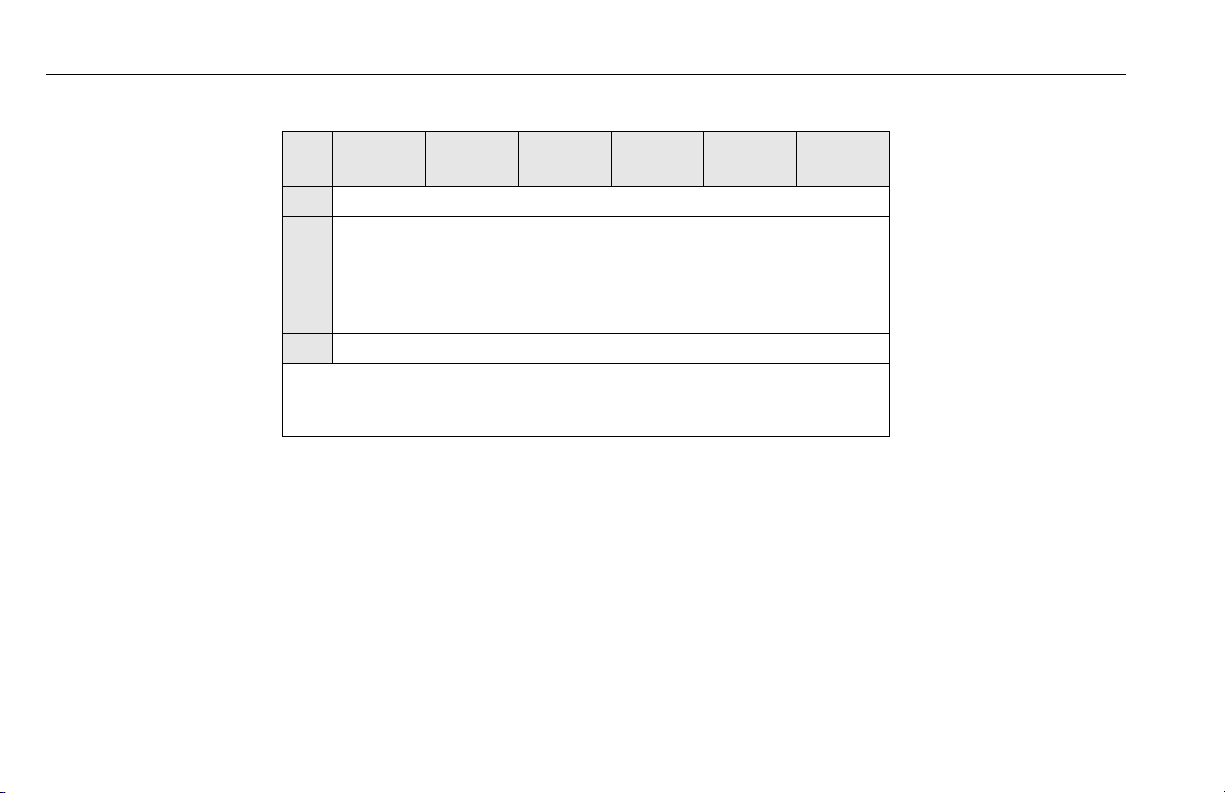

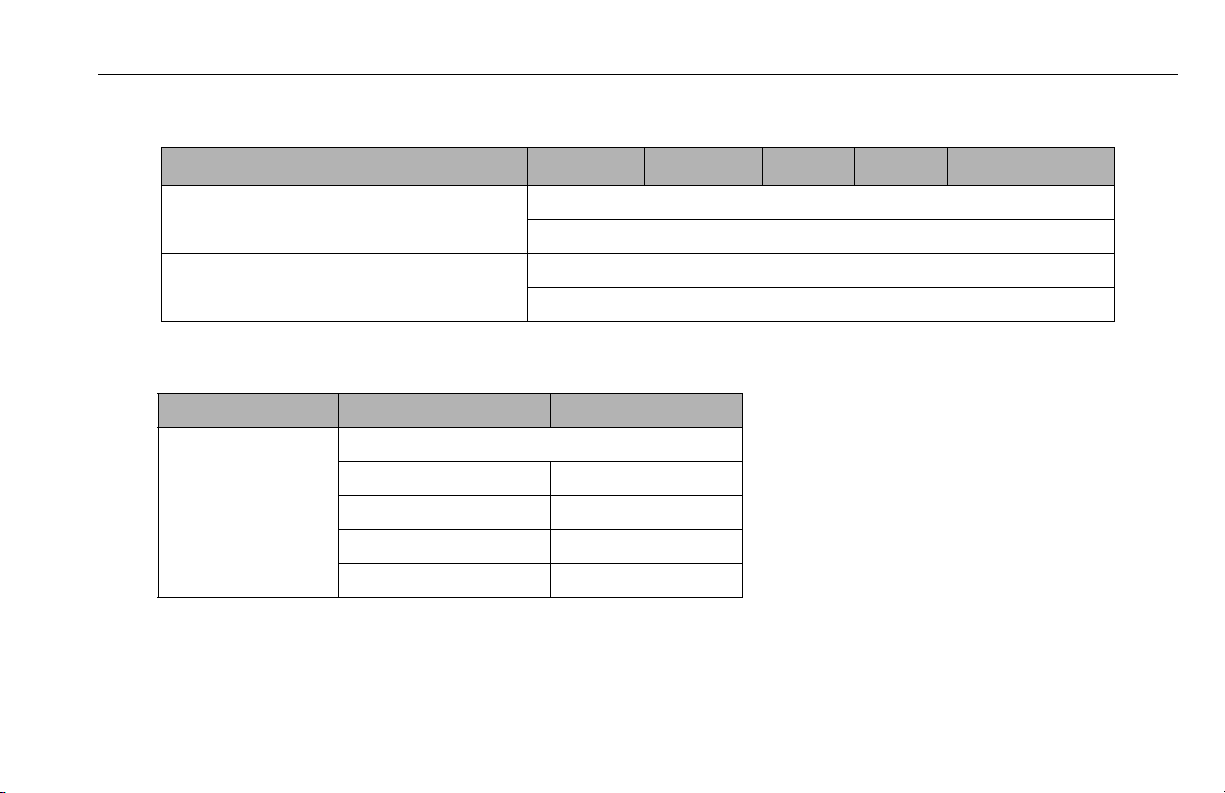

Table 2-1. Inspection and Maintenance Table

TYPE FREQUENCY

Pre-Start

Inspection

Pre-Delivery Inspection

(See Note Below)

Frequent

Inspection

Annual Machine

Inspection

Preventative

Maintenance

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

Before using each day; or whenever there’s an Operator

change.

Before each sale, lease, or rental delivery. Owner, Dealer, or User Qualified JLG Mechanic Service and Maintenance Manual

In service for 3 months or 150 hours, whichever comes

first; or Out of service for a period of more than 3

months; or Purchased used.

Annually, no later than 13 months from the date of prior

inspection.

At intervals as specified in the Service and Maintenance

Manual.

PRIMARY

RESPONSIBILITY

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer, or User Qualified JLG Mechanic Service and Maintenance Manual

Owner, Dealer, or User Factory-Trained

Owner, Dealer, or User Qualified JLG Mechanic Service and Maintenance Manual

SERVICE

QUALIFICATION

Service Technician

(Recommended)

and applicable JLG inspection

form

and applicable JLG inspection

form

Service and Maintenance Manual

and applicable JLG inspection

form

REFERENCE

3121211 – JLG Lift – 2-3

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.3 PRE-START INSPECTION

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil, fuel,

or battery fluid) or foreign objects. Report any leakage

to the proper maintenance personnel.

2. Decals and Placards – Check all for cleanliness and

legibility. Make sure none of the decals and placards

are missing. Make sure all illegible decals and placards

are cleaned or replaced.

3. Operators and Safety Manuals – Make sure a copy of

the Operator and Safety Manual, AEM Safety Manual

(ANSI Markets Only), and ANSI Manual of Responsibilities (ANSI Markets Only) is enclosed in the weather

resistant storage container.

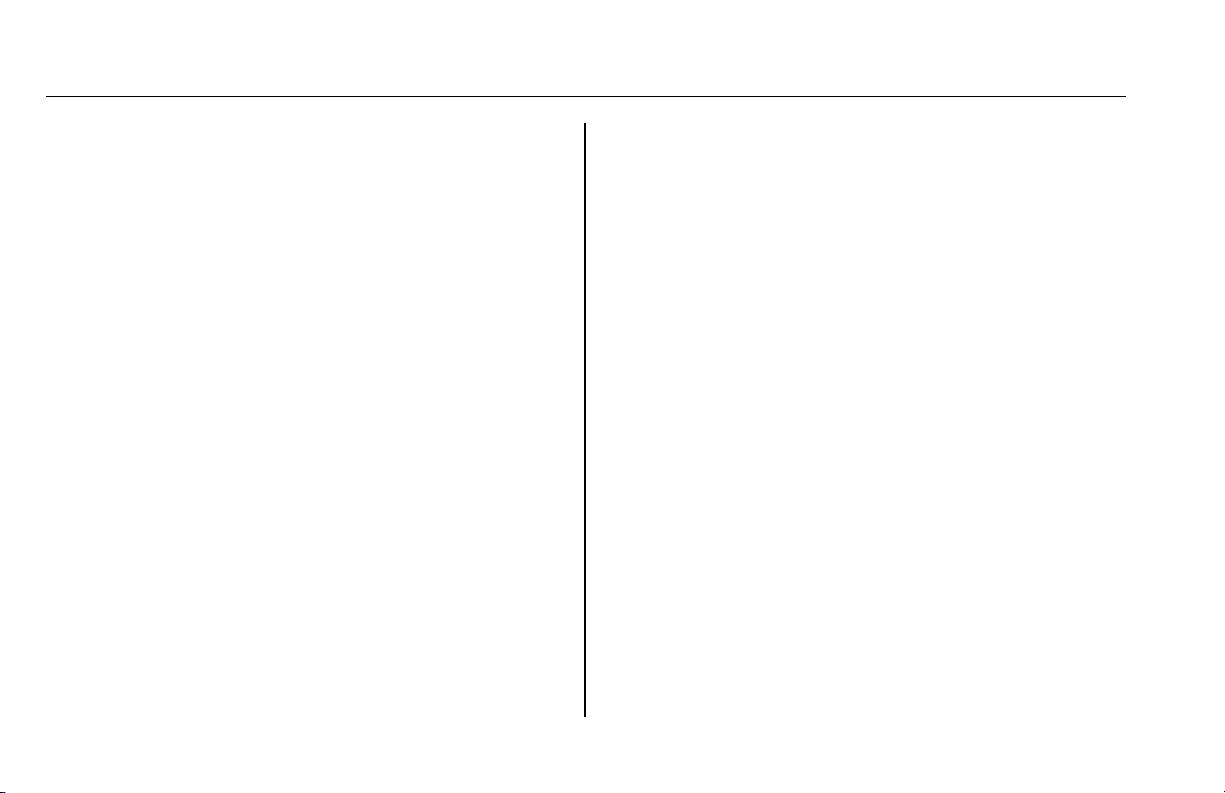

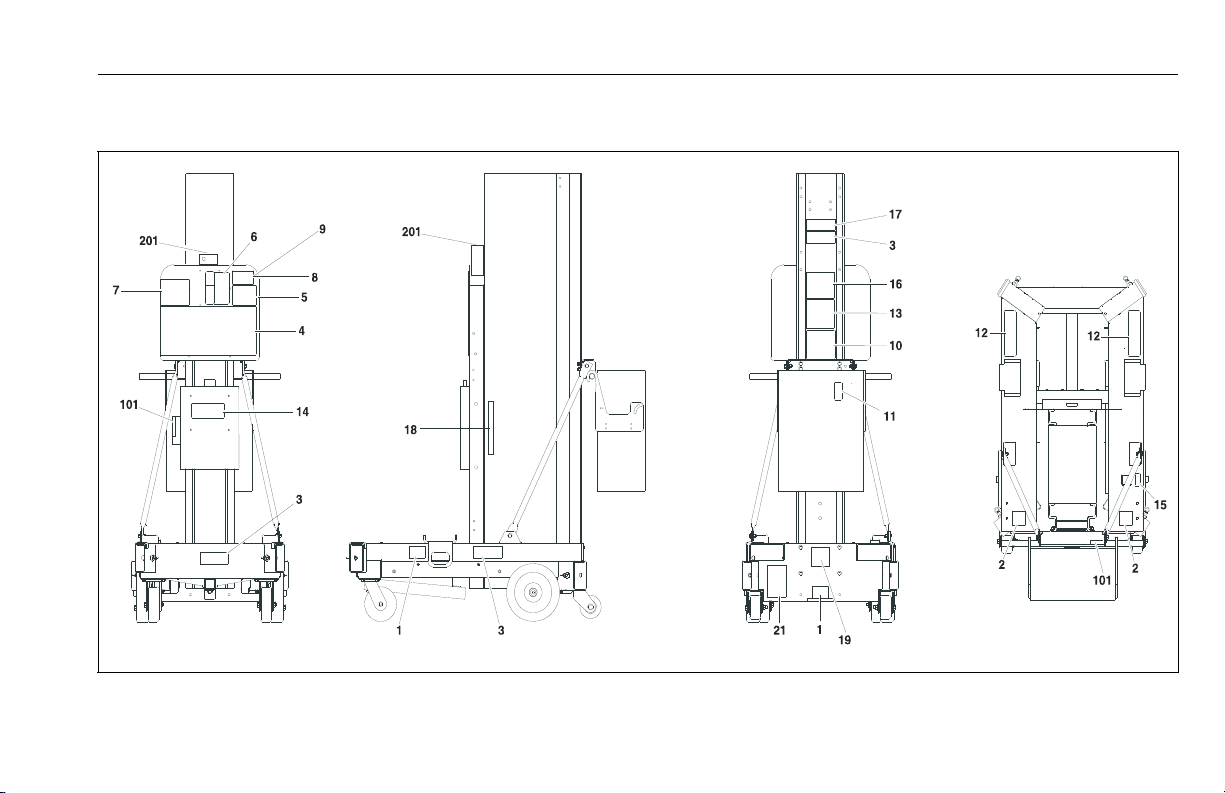

4. Walk-Around Inspection – Refer to Figure 2-1. on

page 2-7.

5. Battery – Charge as required.

6. Fuel – (Combustion Engine Powered Machines Only) –

Add proper fuel as necessary.

7. Hydraulic Oil – Check hydraulic oil level. Add hydraulic oil as required.

8. Function Check – Once “Walk-Around” Inspection is

complete, perform a function check of all systems in

an area free of overhead and ground level obstructions. Refer to Section 3 for specific instructions.

IF MACHINE DOES NOT OPERATE PROPERLY, TURN OFF MACHINE IMMEDIATELY! REPORT PROBLEM TO PROPER MAINTENANCE PERSONNEL. DO NOT

OPERATE MACHINE UNTIL IT IS DECLARED SAFE FOR OPERATION.

2-4 – JLG Lift – 3121211

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

CAUTION

NOTICE

2.4 FUNCTION CHECK

The function check of all systems should be performed in an

area free of overhead and ground level obstructions. Perform a

function check as follows:

1. Set-up machine for operation according to instructions in Section 3. Install outriggers, level machine,

make sure all wheels are off the ground, etc.

2. Enter platform, raise and lower platform 2 ft to 3 ft

(.61m to .92 m) several times. Check for smooth elevation and lowering of platform.

3. With platform completely lowered, check hydraulic oil

level in reservoir at ground control station. Maintain

an oil level to "Fill to Line" indicator on side of reservoir. NEVER USE HYDRAULIC BRAKE FLUID.

2.5 DAILY WALK-AROUND INSPECTION

General

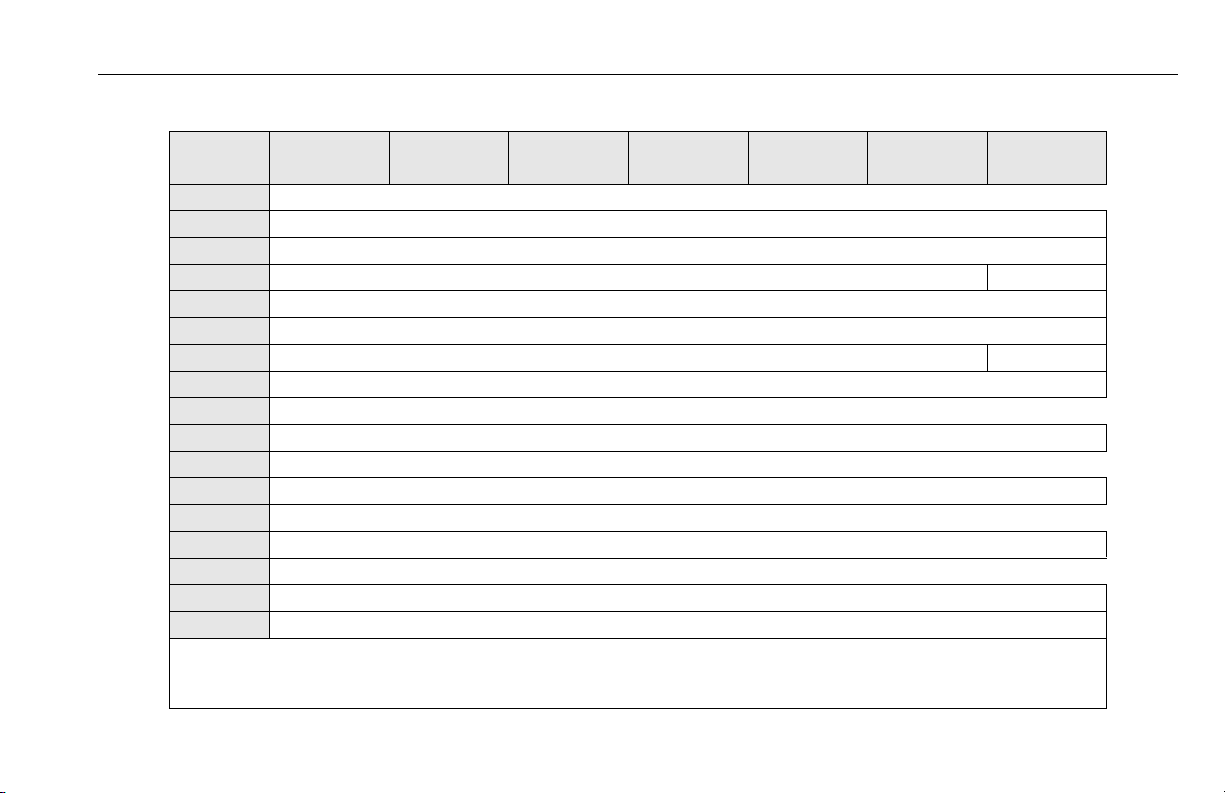

Begin Walk-Around Inspection at item 1 (See Figure 2-1. on

page 2-7). Continue around machine checking each item in this

check list.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS OFF DURING

WALK-AROUND INSPECTION.

DO NOT OVERLOOK VISUAL INSPECTION OF CHASSIS UNDERSIDE. CHECKING

THIS AREA MAY RESULT IN DISCOVERY OF CONDITIONS WHICH COULD CAUSE

EXTENSIVE MACHINE DAMAGE.

NOTE: On each item, make sure there are no loose or missing

parts. That they are securely fastened and that no visible

damage exists in addition to any other criteria mentioned.

1. Front Caster Wheels - Properly secured, wheels and

casters turn freely. Brakes lock and release - prevent

wheels from rolling when locked.

2. Rear Wheels - Properly secured. Wheels turn freely.

3. Tiltback Wheels - Properly secured. Wheels turn

freely.

3121211 – JLG Lift – 2-5

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

4. Base Frame - Components properly secured, no loose

wires dangling below base; bubble level in place and

functioning properly.

5. Tilt Back Assembly - (36AM/41AM Models Only) Prop-

erly secured; no parts missing i.e.. safety pins, gas

spring cylinder(s), caster wheels, etc.

6. Battery/Charger Box Assembly - (DC Voltage

Machines) Proper battery electrolyte level, no cable

corrosion. Battery box pivots freely when machine is

tilted for transporting (36AM/41AM Models Only).

7. Outrigger Interlock Indicator LED’s - See note

above.

8. Outrigger Sockets - Outrigger lock/release pins in

place and secure, no visible damage. Outrigger interlock contacts (inside outrigger sockets) secure and

clean.

9. Outrigger Beams - Outrigger interlock contacts properly installed and clean (on bottom of outrigger

assembly). Leveling jacks secure to the outrigger

assembly, lubricated and functioning properly.

10. Motor/Pump/Reservoir Power Unit - No evidence of

hydraulic leaks. Check that hydraulic reservoir fluid

level is filled to the "Fill to Line" mark on the side of the

reservoir.

11. Manual Release Control Valve - See note above.

12. Ground Controls - Key switch operable, placards

secure and legible; emergency stop switch, properly

set for operation.

13. Mast Assembly - Inspect mast chains or cables as per

note above.

14. Platform Rail Installation - Entry gate/bar in proper

working order.

15. Platform Assembly - Secure to mast; Control and

power cables properly tensioned and seated in control

cable sheaves; control cable sheaves rotate freely.

16. Platform Controls - Placards secure and legible,

emergency shut-off button set for operation. Operators manual enclosed in manual storage tube.

2-6 – JLG Lift – 3121211

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

1

2

3

5

8

4

6

7

9

11

10

12

13

16

15

14

1. Caster Wheels and Brakes

2. Rear Wheel

3. Tilt Back Wheel

4. Base Frame

5. Tilt-Back Assembly (Not Shown - 36/41AM only)

6. Battery/Charger Box Assembly

7. Outrigger Interlock Indicator LED’s

8. Outrigger Sockets

9. Outrigger Beams

10. Motor/Pump/Reservoir Power Unit

11. Manual Release Control Valve

12. Ground Controls

13. Mast Assembly

14. Platform Rail Installation

15. Platform Assembly

16. Platform Controls

3121211 – JLG Lift – 2-7

Figure 2-1. Daily Walk-Around inspection

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

NOTES:

2-8 – JLG Lift – 3121211

SECTION 3 - MACHINE CONTROLS AND INDICATORS

NOTICE

SECTION 3. MACHINE CONTROLS AND INDICATORS

3.1 GENERAL

3.2 CONTROLS AND INDICATORS

Ground Control Station

THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND OPERATION. THE USER AND OPERATOR ARE RESPONSIBLE FOR

CONFORMING WITH GOOD SAFETY PRACTICES.

This section provides the necessary information needed to

understand control functions.

3121211 – JLG Lift – 3-1

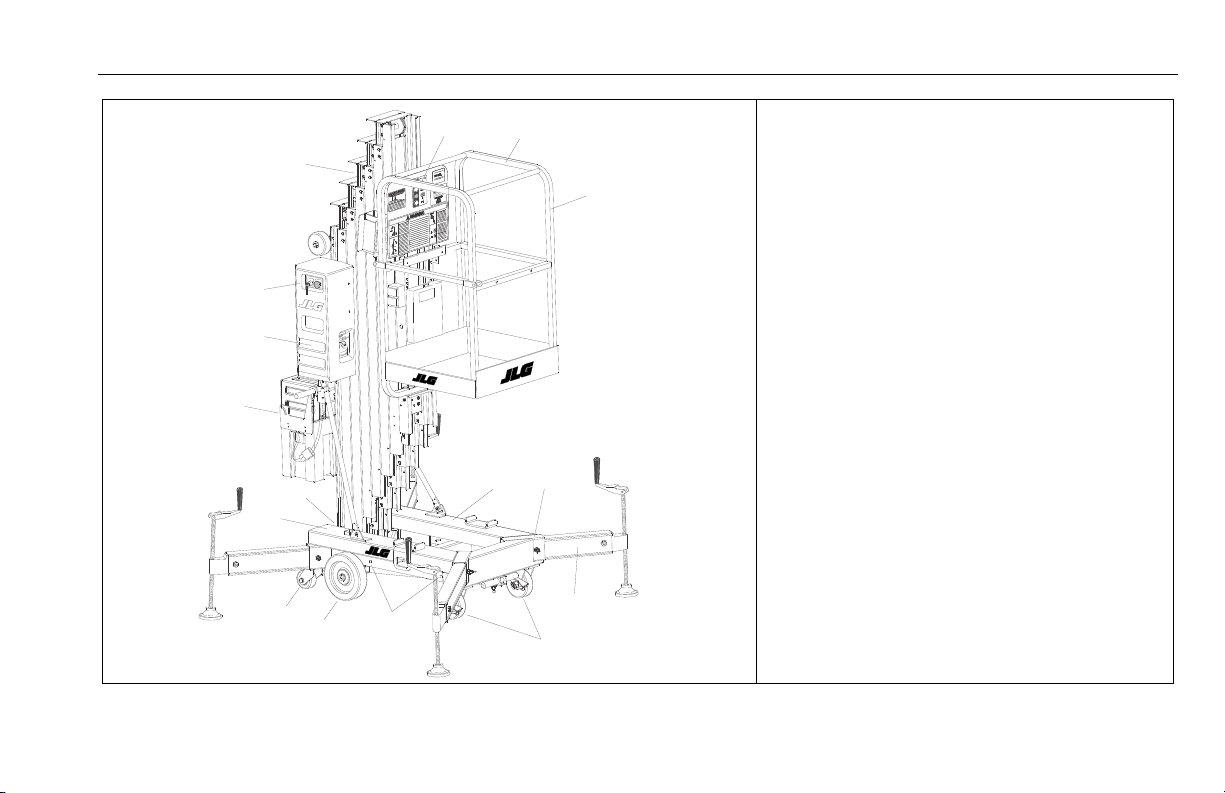

(See Figure 3-1.)

NOTE: For overnight parking or battery charging, be sure the

POWER ON/OFF KEY SWITCH is positioned to OFF to prevent battery drain.

1. POWER ON/OFF Key Switch

A key switch located on the ground control station controls

power to all functions on the machine.

2. POWER/EMERGENCY STOP

The two position switch allows power to the platform and

ground controls when RESET (ON). When pushed in (OFF),

power is shut off to the platform and ground controls.

3. HYDRAULIC RESERVOIR / CIRCUIT BREAKER / FUSE

(located inside the ground control station housing)

The hydraulic oil level can be checked through an access

hole in the side of the cover.

NOTE: Check hydraulic oil only when platform is completely low-

ered and after cycling platform up/down a few times.

SECTION 3 - MACHINE CONTROLS AND INDICATORS

2

1

3

A 20 amp reset type circuit breaker is located on the cover of

the electrical box on AM-AC Models.

On AM-DC Models, a 5 Amp fuse is located inside the ground

control station cover.

Figure 3-1. Ground Control Station.

1. Power ON/OFF Key

2. Power/Emergency Stop

3. Hydraulic Reservoir/Circuit Breaker/Fuse

3-2 – JLG Lift – 3121211

Manual Descent Valve

1

2

3

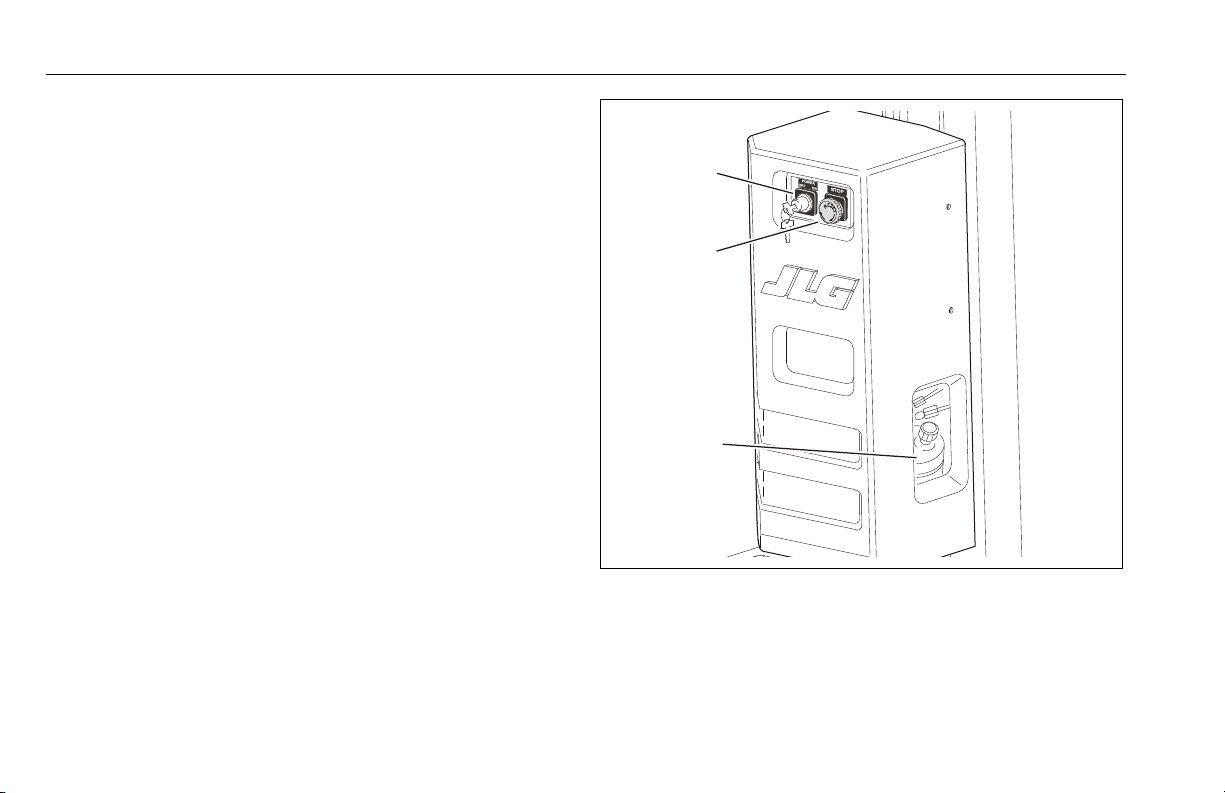

(See Figure 3-2. or Figure 3-3.)

Located at the rear and bottom of the base frame. This pull to

release - spring loaded return valve (RED Knob), allows for

lowering of th e platform in an emergenc y or powe r failure.

Platform Control Station

(See Figure 3-4.)

1. POWER/EMERGENCY STOP

A two position mushroomed shaped switch furnishes power

to the platform and ground controls when RESET (ON).

When pushed in (OFF), power is shut off to the platform and

ground controls.

2. PLATFORM UP Button.

When depressed simultaneously with ENABLE button raises

the platform.

3. FUNCTION ENABLE Button.

This (GREEN) button must be depressed for machine to

operate.

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Figure 3-2. Manual Descent Valve Location.

1. Manual Descent Valve

2. Tie-Down Lugs

3. Mast

4. PLATFORM DOWN Button.

When depressed simultaneously with ENABLE button lowers

the platform.

3121211 – JLG Lift – 3-3

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1

2

3

1

2

3

4

Figure 3-3. Manual Descent Valve Location.

1. Manual Descent Valve

2. Tie-Down Lugs

3. Mast

3-4 – JLG Lift – 3121211

Figure 3-4. Platform Control Station.

1. Emergency Stop (RED)

2. Platform UP (WHITE)

3. Function Enable (GREEN)

4. Platform DOWN (WHITE)

3.3 DECAL INSTALLATIONS

SECTION 3 - MACHINE CONTROLS AND INDICATORS

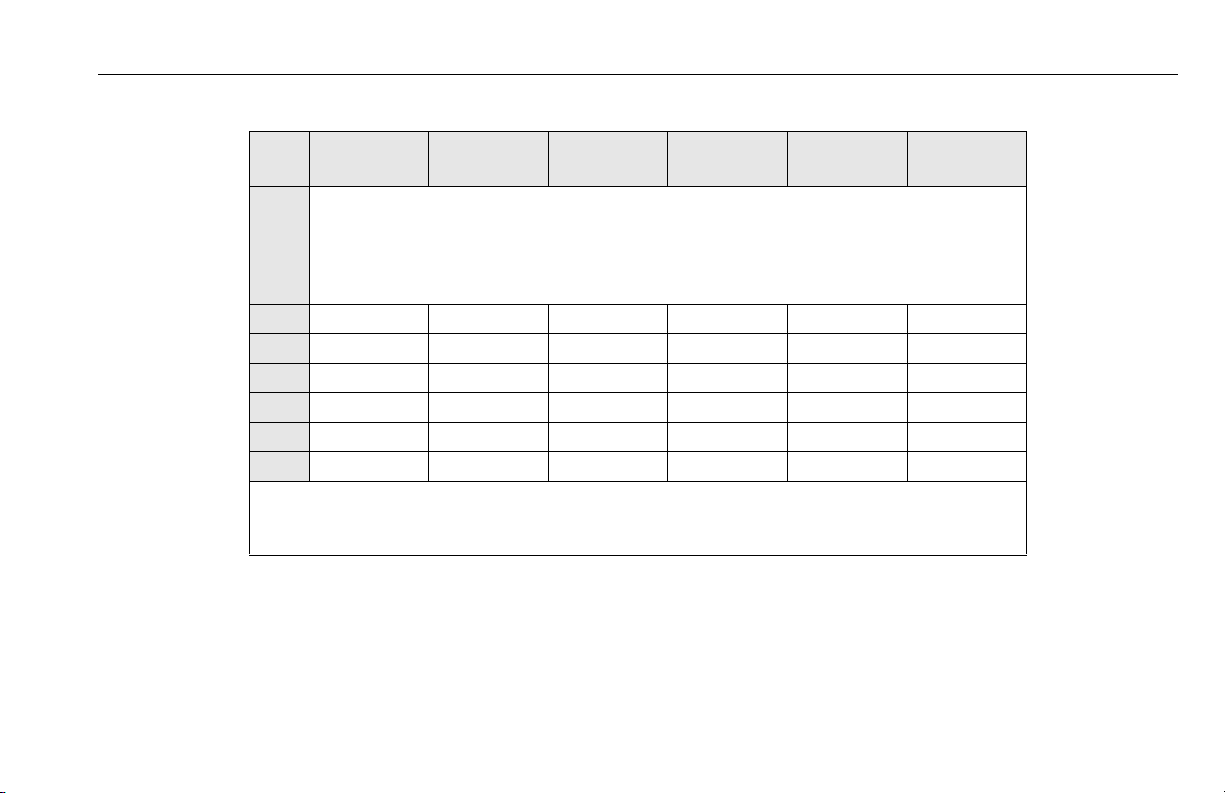

Figure 3-5. Decal Installation. (ANSI/CSA) (Machines prior to S/N-0900031618)

3121211 – JLG Lift – 3-5

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-1. Decal Installation Chart (ANSI and CSA) (See Figure 3-5.)

Item ANSI

ANSI

(LAT)

ANSI

(BRZ)

ANSI

(JPN)

ANSI

(CHI)

CSA

(FRE)

1 1702300 1702300 1702300 1702300 1702300 1703814

2 1703073 1703073 1703073 1703073 1703073 1703817

3 — 1703681 — 1703681 1703681 —

4 1703778 1704027 1704019 1704084 1704075 1703778

5 1703779 — — — — —

6 1703780 1704028 1704020 1704085 1704076 1703780

7 1703781 1704029 1704021 1704086 1704077 1703781

8

9

1706346

1706344

(1)

(2)

1707100

1707101

(1)

(2)

1707102

1707103

(1)

(2)

1707104

1707105

(1)

(2)

1707106

1707107

(1)

(2)

1706344

1706366

(1)

(2)

10 1703784 1704030 1704022 1704088 1704078 1703784

11 1703785 1704031 1704023 1704089 1704079 1703785

12 1703786 1704032 1704024 1704090 1704081 1703786

13

1703787

(3)

1704033

(3)

1704025

(3)

1704091

(3)

1704082

(3)

1703787

(3)

14 1703788 1703788 1703788 1703788 1703788 1703788

15 1703789 1704034 1704026 1704092 1704083 1703789

16 1707081 1707080 1707080 1707080 1707080 1707081

3-6 – JLG Lift – 3121211

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-1. Decal Installation Chart (ANSI and CSA) (See Figure 3-5.)

Item ANSI

17

18 1703815 — 1703828 1704151 — 1703815

19 ——————

20 ——————

21 1700584 1700584 1700584 1700584 1700584 1700584

101 3251243 3251243 3251243 3251243 3251243 3251243

201 1703994 1703994 1703994 1703994 1703994 1703994

NOTE: (1) - 30AM/36AM/41AM Only

(2) - 20AM/25AM Only

(3) - Installed on 36AM or 41AM machines with tiltback option only.

ANSI

(LAT)

ANSI

(BRZ)

1703902 - 20AM

1703903 - 25AM

1703904 - 30AM

1703905 - 36AM

1703906 - 41AM

ANSI

(JPN)

ANSI

(CHI )

CSA

(FRE)

3121211 – JLG Lift – 3-7

SECTION 3 - MACHINE CONTROLS AND INDICATORS

5

4

3

6

11

2

16

13

16

16

10

9

7

18

18

12

14

13

17

15

8

19

20

Figure 3-6. Decal Installation (CE) (Machines prior to S/N-0900031618)

3-8 – JLG Lift – 3121211

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-2. Decal Installation Chart (CE Specification) (See Figure 3-6.)

Item

CE

(ENG/(AUS)CE(DUT)

CE

(FRE)

CE

(GER)

CE

(ITA)

CE

(SPA)

1 1001098588 - Decal Kit *

2 1701509 *

3 1704094 * (1)

4 1704095 * (2)

5 1705801 *

6 1705802 *

7 1705803 *

8 1705805 *

9 1705831 *

10 1001098578 * (3)

11 1001098579 *

12 1700584

13 1702300

14 1702631

15 1702928

16 1703681

17 1703817

3121211 – JLG Lift – 3-9

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-2. Decal Installation Chart (CE Specification) (See Figure 3-6.)

Item

18 4420051

19

20 3252606

NOTE: (1) - 30/36/41AM

CE

(ENG/(AUS)CE(DUT)

(2) - 20/25AM

(3) - Installed on 36AM or 41AM machines with tiltback option only.

CE

(FRE)

1703902 - 20AM

1703903 - 25AM

1703904 - 30AM

1703905 - 36AM

1703906 - 41AM

CE

(GER)

CE

(ITA)

CE

(SPA)

3-10 – JLG Lift – 3121211

15

20

148

21

164

12

2

20

148

12

14

4

7

163

6

8

135

1

3

118

20

148

13

117

10

154

11

16

16

219

SECTION 3 - MACHINE CONTROLS AND INDICATORS

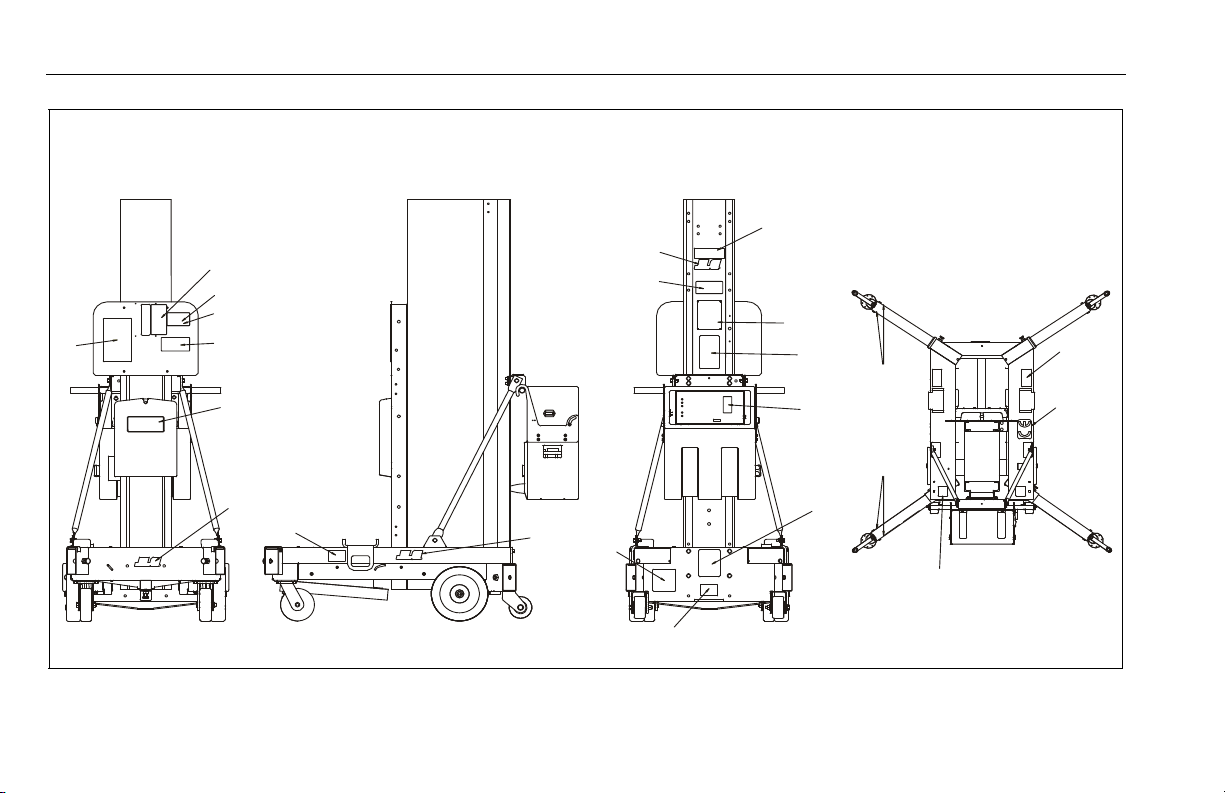

Figure 3-7. Decal Installation. (ANSI/CSA) (Machines S/N-0900031618 to Present)

3121211 – JLG Lift – 3-11

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-3. Decal Installation Chart (ANSI and CSA) (See Figure 3-7.)

Item ANSI

ANSI

(LAT)

ANSI

(BRZ)

ANSI

(JPN)

ANSI

(CHI - SIMP)

ANSI

(CHI - TRAD)

CSA

(FRE)

1 1700584

2 1702300

3 Bar Code - Not Available

4 1703778 1704027 1704019 1704084 1704075 1706692 1703778

5 1703779 — — — — — —

6 1703780 1704028 1704020 1704085 1704076 1706693 1703780

7 1703781 1704029 1704021 1704086 1704077 1706694 1703781

(1)

8

(2)

8

1706346 1707101 1707103 1707105

1706344 1707100 1707102 1707104

1707107

1707106

1706366

1706344

9 Not Used

10 1703784 1704030 1704022 1704088 1704078 1706696 1703784

11 1703785 1704031 1704023 1704089 1704079 1706697 1703785

12 1703786 1704032 1704024 1704090 1704081 1703786

13

(3)

1703787 1704033 1704025 1704091 1704082 1706695 1703787

14 1701509

15 1703789 1704034 1704026 1704092 1704083 1706699 1703789

16 1703817

17 Not Used

3-12 – JLG Lift – 3121211

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-3. Decal Installation Chart (ANSI and CSA) (See Figure 3-7.)

Item ANSI

18 Not Used

19 1001115864

20 1703681

21 Not Used 1703464

101 to 115 Not Used

116 Serial Number Plate - Not Available

117 Not Used 1706351

118 Model Designation - 20AM-1703902 / 25AM-1703903 / 30AM-1703904 / 36AM-1703905 / 41AM-1703906

119 to 134 Not Used

135 1703994

136 to 147 Not Used

148 1703681 - JLG Logo

149 to 153 Not Used

154 1001110242 - JLG Service

155 to 162 Not Used

163 Max. Outrigger Load Options: 20AM-1706445 / 25AM-1706446 / 30AM-1706447 / 36AM-1706448 / 41AM-1706449

164 Voltage Options: 3252761-120V AC / 3252760-220V-240V AC

NOTE: (1) - 20AM/25AM Only

(2) - 30AM/36AM/41AM Only

(3) - Installed on 36AM or 41AM machines with tiltback option only.

ANSI

(LAT)

ANSI

(BRZ)

ANSI

(JPN)

ANSI

(CHI - SIMP)

ANSI

(CHI - TRAD)

CSA

(FRE)

3121211 – JLG Lift – 3-13

SECTION 3 - MACHINE CONTROLS AND INDICATORS

118

15

10

9

4

3

8

6

116

161612

19

51

14

15

15

52

164

7

7

12

53

17

1

10

5

4

3

11

13

135

OR

CE SPEC.

AUSTRALIAN

SP EC.

5

3-14 – JLG Lift – 3121211

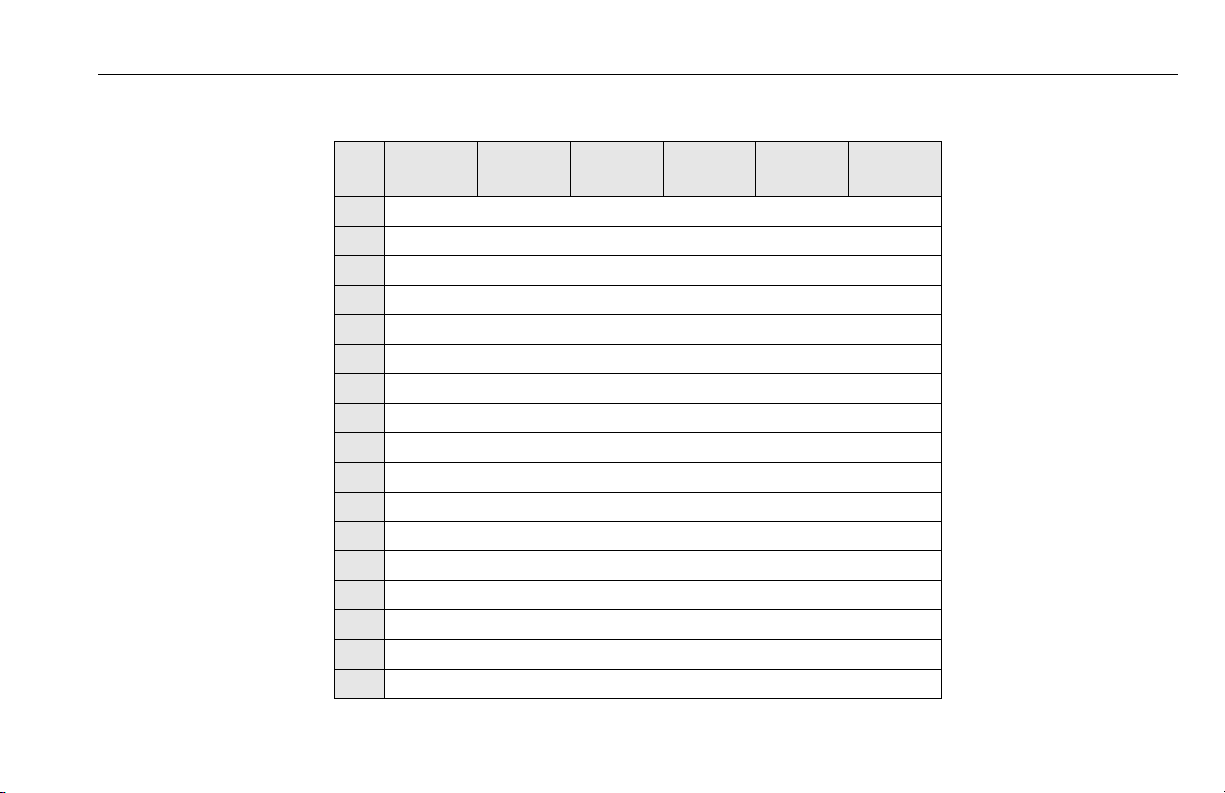

Figure 3-8. Decal Installation (CE) (Machines S/N-0900031618 to Present)

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-4. Decal Installation Chart (CE Specification) (See Figure 3-8.)

Item

CE

(ENG)

CE

(DUT)

CE

(FRE)

CE

(GER )

CE

(ITA)

CE

(SPA)

CE

(AUS)

1 1701509

2 Not Used

3

1704094

(1)

/ 1704095

(2)

4 1705801 1703780

5 1702802 1703781

6 1705803 1703785

7 1705805 1703786

8 1705831 1703784

9 1001098578 1703787

10 1001098579 1703778

11 1700584

12 1702300

13 Not Available - BarCode

14 1702928 —

15 1703681

16 1703817

17 4410051 —

3121211 – JLG Lift – 3-15

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-4. Decal Installation Chart (CE Specification) (See Figure 3-8.)

Item

18 Not Used

19 1001115864

20 to 50 Not Used

51 Not Used 1703789

52 Not Used 1703464

53 Not Used 1705796

101 to 115 Not Used

116 Serial Number Plate - Not Available

117 Not Used

118

119 to 134 Not Used

135 1703994 (Optional)

136 to 163 Not Used

164 120V - AC - 3255761 / 220V-240V AC - 3255760

NOTE: (1) - 30/36/41AM

CE

(ENG)

20AM-1703902 / 25AM-1703903 / 30AM-1703904 / 36AM-1703905 / 41AM-1703906

(2) - 20/25AM

(3) - Installed on 36AM or 41AM machines with tiltback option only.

CE

(DUT)

CE

(FRE)

Model Designation Options:

CE

(GER)

CE

(ITA)

CE

(SPA)

CE

(AUS)

3-16 – JLG Lift – 3121211

SECTION 4. MACHINE OPERATION

SECTION 4 - MACHINE OPERATION

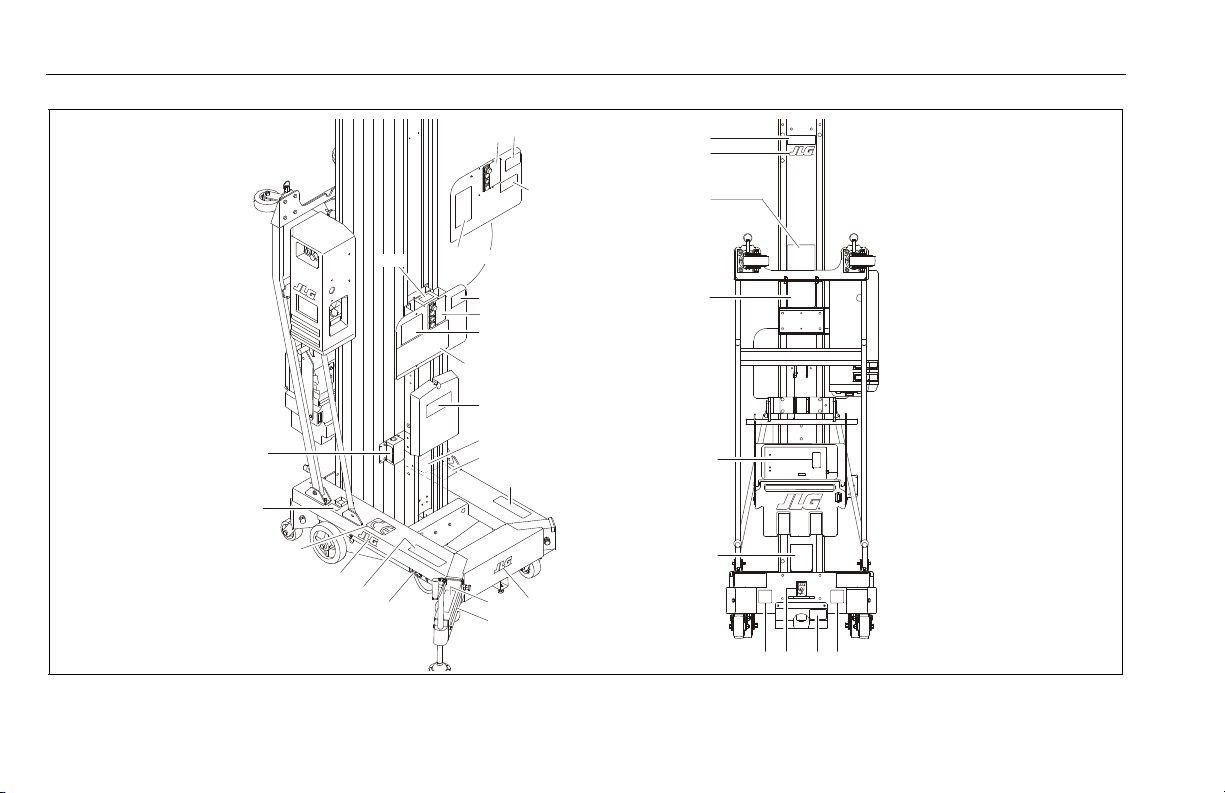

4.1 DESCRIPTION

This machine is a manually propelled machine, with a work platform mounted to an elevating aluminum mast mechanism. The

personnel lift’s intended purpose is to provide personnel (with

their tools and supplies) access to areas above ground level.

The primary operator control station is in the platform. From

this control station, the operator can raise and lower the platform. A ground control station is provided to lower the platform

to the ground in an emergency if the operator in the platform is

unable to do so, or if a power failure should occur.

Vibrations emitted by these machines are not hazardous to an

operator in the work platform. The equivalent continuous AWeighted sound pressure level at the work platform is less than

70dB(A).

3121211 – JLG Lift – 4-1

4.2 OPERATING CHARACTERISTICS AND LIMITATIONS

Capacities

The platform can be raised above the stowed position if:

• The machine is positioned on a smooth, firm surface on

which the machine is capable of being leveled.

• Load is within manufacturer’s rated capacity.

• All machine systems are functioning properly.

• The machine is leveled and outriggers are properly installed

as indicated by the outrigger interlock LED lights on the

base frame.

SECTION 4 - MACHINE OPERATION

NOTICE

1/8 "

(3 mm)

1

3

2

4

4.3 BATTERY CHARGING & MAINTENANCE - (DC MODELS ONLY)

AM-DC Models are equipped with a 12 volt, 10 amp output dual voltage (120/240V) input battery charger. The charger is

microprocessor controlled featuring an automatic charge sensing circuit which can determine cell voltage and regulate charger output and terminate charging as required.

MACHINES BUILT STARTING WITH S/N-0900031618 AND LATER WERE

EQUIPPED WITH A NEW COMPACT DESIGN HOUSING FOR THE CHARGER AND

BATTERY. THE CHARGER AND BATTERY OPERATION ARE UNCHANGED.

Battery Maintenance and Safety

BATTERY ACID IS HIGHLY CORROSIVE. AVOID CONTACT WITH SKIN AND CLOTHING AT

ALL TIMES.

BATTERY ACID RELEASES AN EXPLOSIVE GAS WHILE CHARGING, ALLOW NO OPEN

FLAMES, SPARKS OR LIGHTED TOBACCO PRODUCTS IN THE AREA WHILE CHARGING

BATTERIES. CHARGE BATTERIES ONLY IN A WELL VENTILATED AREA.

ADD ONLY DISTILLED WATER TO BATTERIES. WHEN ADDING DISTILLED WATER TO THE

BATTERIES, A NON-METALLIC CONTAINER AND/OR FUNNEL MUST BE USED.

The battery fluid level should be approximately 1/8" (3mm)

below vent tubes. (See Figure 4-1.)

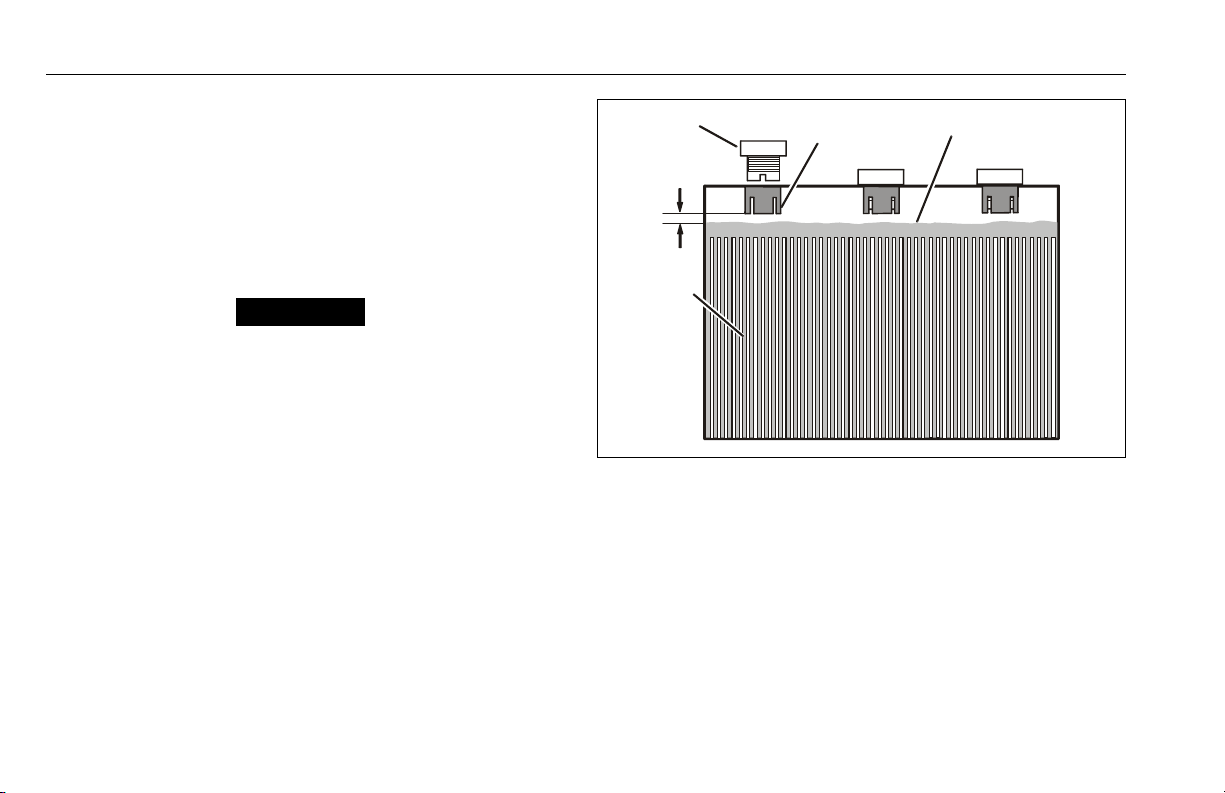

Figure 4-1. Battery Fluid Level.

1. Battery Filler Cap

2. Vent Tub e

3. Fluid Level

4. Cell Plates

4-2 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

NOTICE

2

1

4

3

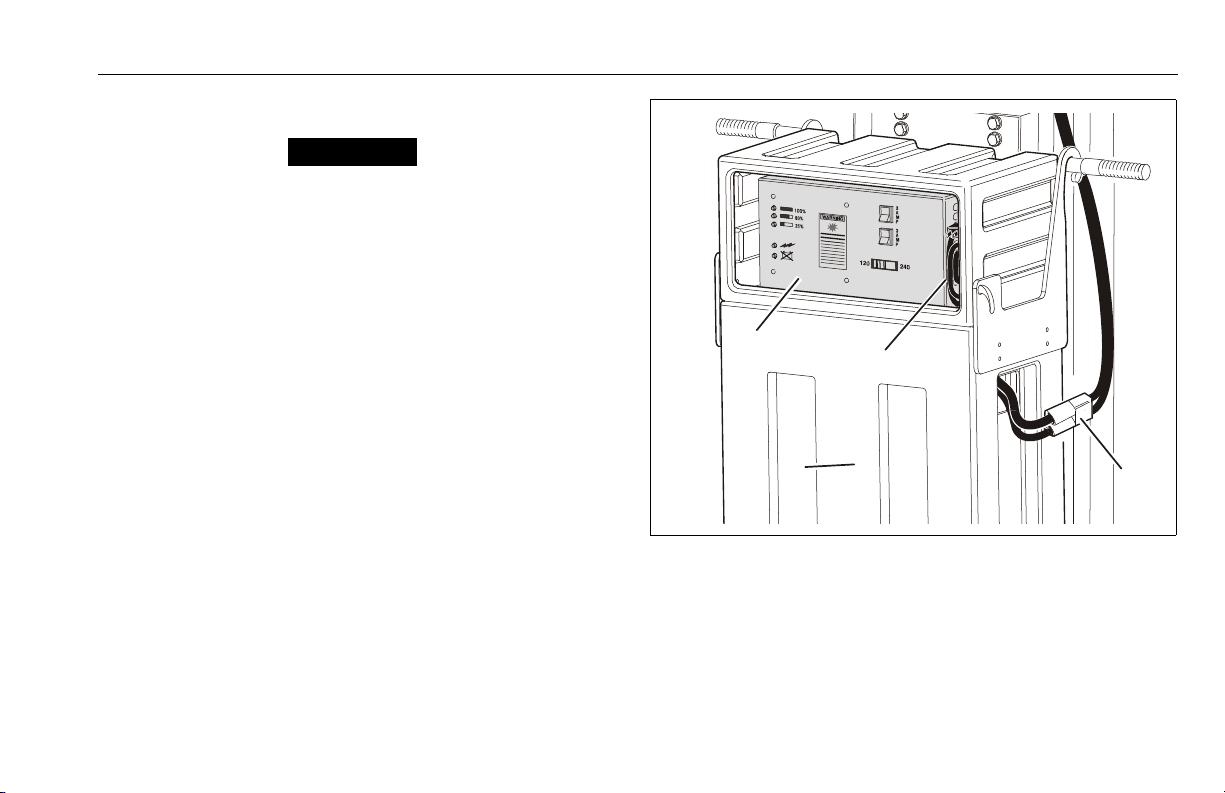

Battery Charger Operation

ALWAYS CHECK THE VOLTAGE SELECT SWITCH ON THE FACE OF THE BATTERY

CHARGER BEFORE OPERATION. IF NOT SET TO THE PROPER AC POWER INPUT

VOLTAGE, THE CHARGER MAY BE DAMAGED.

1. Turn the ground control key switch to the OFF position.

2. Set the AC voltage switch on the face of the charger

for the local AC line voltage.

3. Plug the battery charger AC power cable, stowed

inside the battery/charger carrier (beside charger) into

a properly grounded receptacle. Use a suitable extension cord, if necessary.

4. The charger runs through a self-diagnostic check. The

LED’s on the face of the charger flash in the following

sequence;

a. First all five (5) LED’s flash three (3) times.

b. Next each LED lights in sequence.

c. Finally all five (5) LED’s flash three (3) times again.

5. When ready to charge, the CHARGER ON LED and the

INCOMPLETE CHARGE (25%) LED on the front panel of

the charger will light up, the charger will then begin to

charge the batteries.

Figure 4-2. Battery Box and Charger Assembly.

(D.C. Model Only)

1. Battery Box/Charger Assembly

2. DC Battery Charger

3. Charger AC Power Cord

4. DC - Battery to Machine Main

Power Connec tor

3121211 – JLG Lift – 4-3

SECTION 4 - MACHINE OPERATION

1

2

3

4

5

6. When the battery cell voltage reaches 2.37 V/cell the

80% CHARGE LED will light up. The charger then continues to monitor the increase in charge until it sees

no increase, and then terminates the charging process.

7. The CHARGE COMPLETE (100%) LED will light when

the batteries are fully charged.

8. Unplug the charger AC power cord and stow the cord.

Abnormal Cycle Indicator LED

The ABNORMAL CYCLE indicator LED will light when;

• The AC input to the charger was interrupted.

• There is a dead cell or cells in the battery.

• One or more of the battery connectors are loose or cor-

roded.

Figure 4-3. Dual Voltage Charger - Front Panel.

1. % of Charge in Progress

LED’s (Green)

2. Charger On LED (Green)

3. Abnormal Cycle LED

(Yellow)

4. Circuit AC Circuit Breakers

5. AC Voltage Selection

Switch

4-4 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

4.4 MACHINE SET-UP AND OPERATION

To set-up machine for operation the operator must:

1. Position machine in work area.

NOTE: If AC powered machine, connect machine to a grounded

AC receptacle with a heavy duty extension cord equipped

with an equipment grounding conductor.

If DC powered machine, check battery box assembly is

installed, battery is charged and connected to machine’s

DC receptacle.

2. Set key switch to ON position at ground control station.

3. Check both emergency stop switches are in RESET

position for operation.

4. Check manual decent control valve (red knob) is

closed.

APPLY FRONT CASTER BRAKES SO MACHINE DOES NOT ROLL IN ANY DIRECTION. DO NOT INSTALL OUTRIGGERS OR ELEVATE PLATFORM UNTIL FRONT

CASTER BRAKES ARE LOCKED.

5. Apply caster brakes.

6. Install outriggers.

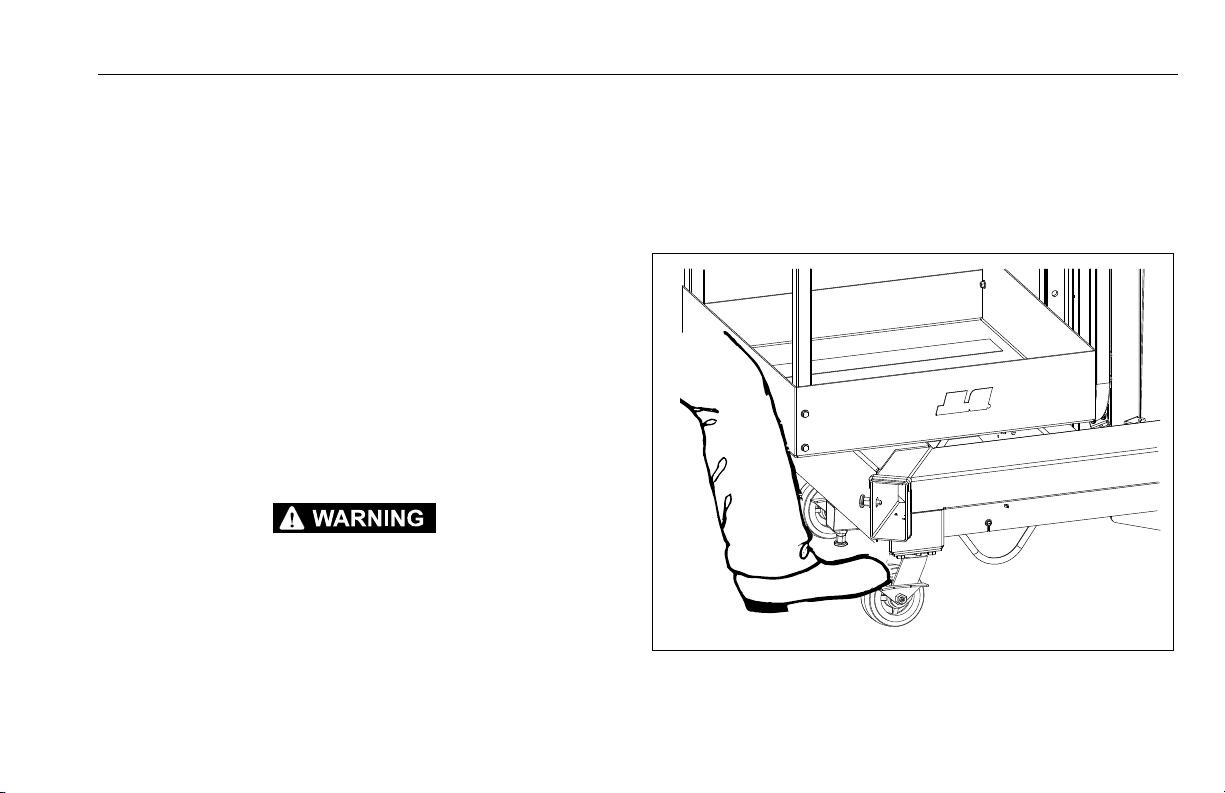

Caster Brake Operation

1. Press down on caster brake lever on both casters at

front of machine to apply caster brakes.

2. To disengage caster brake, apply pressure or lift up on

caster brake lever.

Figure 4-4. Setting & Releasing Caster Brake

3121211 – JLG Lift – 4-5

SECTION 4 - MACHINE OPERATION

NOTICE

NOTICE

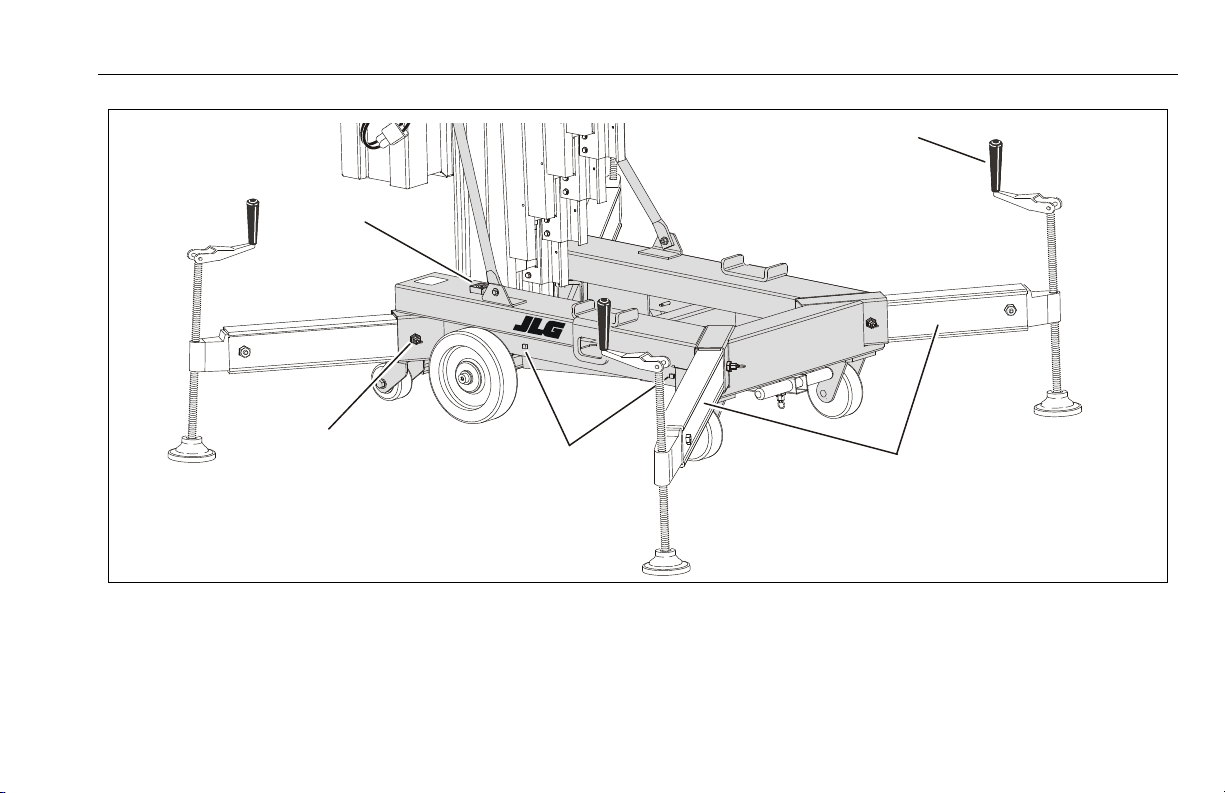

Outrigger Installation

(See Figure 4-5. on page 4-7)

AS A SAFETY PRECAUTION, DUE TO DIFFERENT LENGTHS, OUTRIGGER BEAMS

ARE DESIGNED TO FIT A SPECIFIC MODEL AND ARE NOT INTERCHANGEABLE.

1. Remove one outrigger beam from the stowage socket.

2. Insert outrigger beam into an outrigger socket on the

base frame with outrigger interlock contact on the

bottom. Push outrigger beam in socket until locking

pin on side of outrigger socket snaps into the outrigger beam detent. Repeat for remaining outriggers.

3. With all outriggers inserted, turn each outrigger jack

down, lifting entire machine until all wheels are off the

ground.

4. When all four (4) wheels are off the ground, use the

bubble level on the base frame to level machine.

MACHINE WILL OPERATE ONLY IF ALL FOUR (4) INTERLOCK LED LIGHTS ARE

ILLUMINATED.

4-6 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

3

2

4

1

5

Figure 4-5. Outrigger Installation.

1. Bubble Level Indicator

2. Outrigger Lock/Release Pin

3. Interlock LED’s

4. Outrigger Beam Assembly

5. Leveling Jack

3121211 – JLG Lift – 4-7

SECTION 4 - MACHINE OPERATION

Platform Loading

platform maximum rated load capacity is shown on a placard

located on the platform control panel. Applies to all available

AM model platforms.

Maximum capacity for each model is as follows:

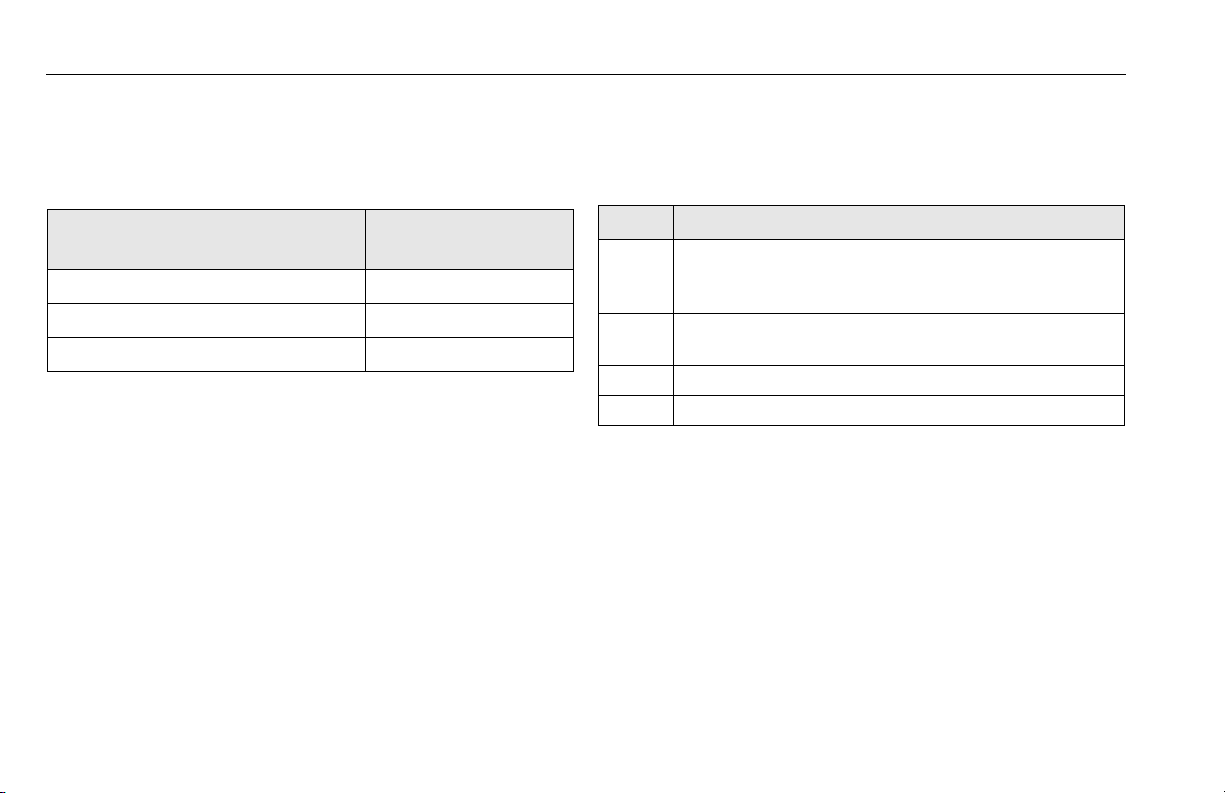

Table 4-1. Maximum Platform Capacity.

PLATFORM CAPACITY

MODEL

20AM -

DC/AC

25AM -

DC/AC

30AM -

DC/AC

36AM -

DC/AC

41AM -

DC/AC

FOR MACHINES BUILT TO SPECIFICATION

ANSI & C.S.A. -

B354.1-04

350 lb.

(160 kg)

350 lb.

(160 kg)

350 lb.

(160 kg)

300 lb.

(135 kg)

300 lb.

(135 kg)

CE

350 lb.

(160 kg)

350 lb.

(160 kg)

300 lb.

(135 kg)

300 lb.

(135 kg)

300 lb.

(135 kg)

C.S.A. -

B354.1-M82

300 lb.

(135 kg)

300 lb.

(135 kg)

300 lb.

(135 kg)

250 lb.

(113 kg)

250 lb.

(113 kg)

Platform Operation

1. Enter platform and close gate/slide bar.

2. To raise platform, press FUNCTION ENABLE button and

platform UP button simultaneously. Upon reaching

desired elevation level, release UP and FUNCTION

ENABLE buttons.

CHECK AREA BENEATH PLATFORM IS FREE OF PERSONNEL AND OBSTRUCTIONS PRIOR TO LOWERING PLATFORM.

3. To lower platform, press FUNCTION ENABLE button

and platform DOWN button on control panel simultaneously.

4-8 – JLG Lift – 3121211

4.5 QUICK-CHANGE PLATFORM MOUNTS

1

2

3

4

(See Figure 4-6.)

The AM model is equipped with platform mounting for quick

and simple exchange of platforms.

Platform Removal

1. Remove both pins holding lower platform support rail

to platform lower mount.

2. Remove both pins holding upper platform support rail

to platform upper mount.

3. Using suitable lifting equipment or another person,

swing lower platform support rail forward, away from

mast to clear platform lower mount, then lift upper

platform support rail up and out of platform upper

mount.

SECTION 4 - MACHINE OPERATION

Figure 4-6. Quick Change Platform Mount.

1. Platform Upper Mount

2. Upper Mount Attach Pins

3. Platform Lower Mount

4. Lower Mount Attach Pins

3121211 – JLG Lift – 4-9

SECTION 4 - MACHINE OPERATION

Platform Installation

1. Using two people or suitable lifting equipment, lift

platform and set platform upper support rail into the

upper platform mount on the mast.

2. Swing platform lower support rail into lower platform

mount on the mast.

3. Secure platform support rails with two (2) platform

upper mount pins, and two (2) lower platform mount

pins.

4.6 MACHINE SHUT DOWN AND PARK

1. Ensure platform is fully lowered, turn key switch to

OFF position.

2. Store outrigger beams in stowage sockets.

3. Move machine to a well-protected and well-ventilated

area. In a hostile environment, cover machine for protection.

4. Apply caster brakes and chock at least two wheels

when parking machine for extended time.

5. Remove key switch to disable machine from unauthorized use.

4-10 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

CAUTION

NOTICE

4.7 TRANSPORT, LIFTING AND TIE DOWN

General

To move machine from work area to work area the operator

may:

• Push machine on its base wheels.

• Push machine in Tilt-Back mode.

(36AM and 41AM only)

• Move machine using a forklift.

• Load machine on back of a pickup truck, using the built-in

load bar.

NOTE: 36AM and 41AM machines are equipped with a perma-

nently attached tilt-back assembly to allow machine to fit

through standard size doorways.

Transporting by Pushing

The standard machine’s base frame is equipped with load bearing wheels mounted on a straight axle at the mast end of the

machine; and a pair of heavy duty swivel caster wheels

mounted on the frame at the platform end of the machine.

REFER TO SECTION 1.2, TRANSPORTING SAFETY PRECAUTIONS BEFORE

TRANSPORTING MACHINE.

Tilt-Back Assembly Set-up (AM36/AM41) - Machines Prior to S/ N - 0900031618

(See Figure 4-7.)

PLATFORM MUST BE FULLY LOWERED, AND OUTRIGGER BEAMS MUST BE

STOWED. ON DC MODELS ENSURE BATTERY BOX/CHARGER ASSEMBLY IS NOT

OBSTRUCTED AND IS CLEAR TO SWING ONCE MACHINE IS TILTED.

1. Move machine to an area that is level, clear and free of

obstacles.

2. Hold the tilt-back assembly in place and remove the

release pins from the mast support crossbar.

3. Carefully lower the tilt-back assembly as far as it will

go.

4. Pull either of the gas spring cylinders up out of their

retaining clip. Guide the groove pins on the end of the

cylinder into the slot on the end of the mast crossbar.

Secure both cylinders to the mast support crossbar by

replacing the pins removed in step 2 to lower the tiltback assembly.

5. Extend and lock the T-handle bar located under the

front of the machine. A release/lock pin is located on

the bottom of the bar.

6. With both hands on the grips of the T-handle lifting

bar, carefully tilt the machine back onto the tilt-back

assembly.

3121211 – JLG Lift – 4-11

SECTION 4 - MACHINE OPERATION

1

2

Figure 4-7. Tilt-Back Assembly Set-Up.

4-12 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

3

4

Figure 4-7. Tilt-Back Assembly Set-Up.

3121211 – JLG Lift – 4-13

SECTION 4 - MACHINE OPERATION

5

6

Figure 4-7. Tilt-Back Assembly Set-Up.

4-14 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

NOTICE

CAUTION

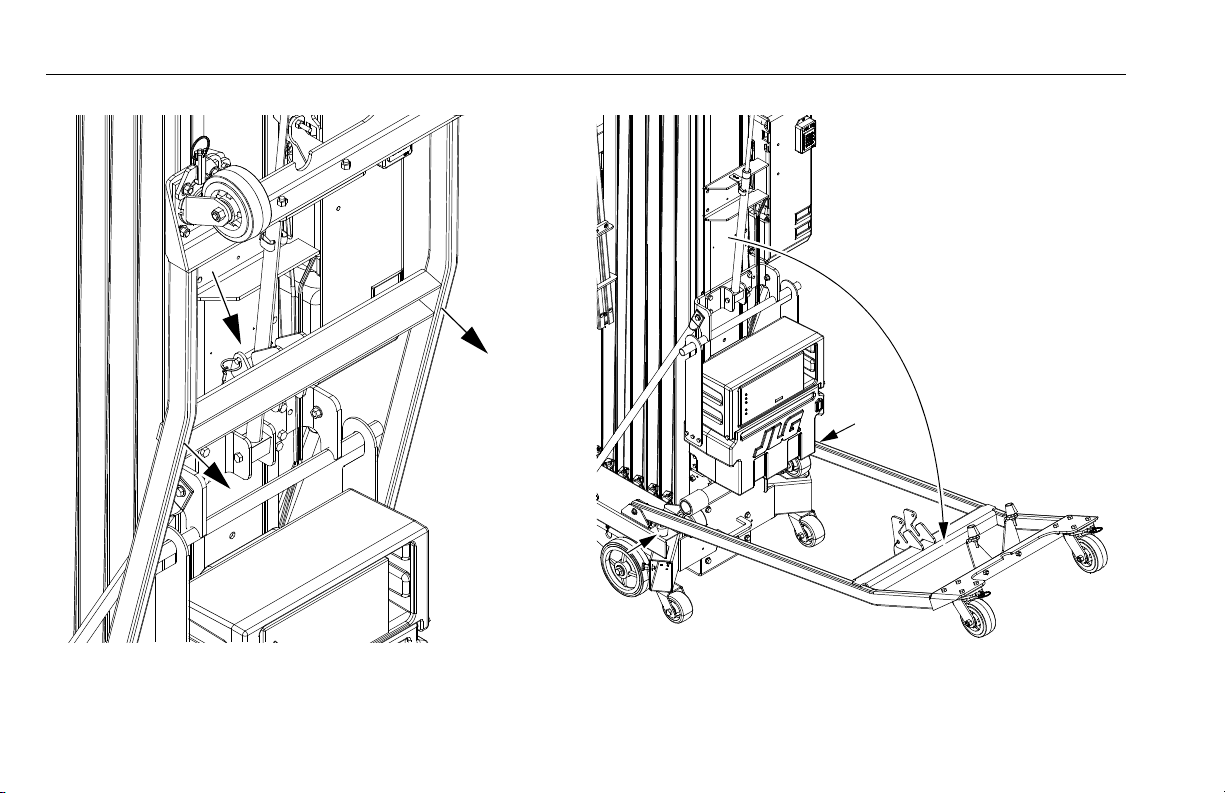

Tilt-Back Assembly Set-up (AM36/AM41) - Machines S/N 0900031618 to Present

(See Figure 4-8., Figure 4-9. and Figure 4-10.)

PLATFORM MUST BE FULLY LOWERED, AND OUTRIGGER BEAMS MUST BE

STOWED. ON DC MODELS ENSURE BATTERY BOX/CHARGER ASSEMBLY IS NOT

OBSTRUCTED AND IS CLEAR TO SWING ONCE MACHINE IS TILTED.

REFER TO SECTION 1.2, TRANSPORTING SAFETY PRECAUTIONS BEFORE

TRANSPORTING MACHINE.

1. Move machine to an area that is level, clear and free of

obstacles.

2. (Step 1) Hold the tilt-back assembly in place and

remove the release pin securing the tilt-back assembly

to the gas spring cylinder.

3. Lower the tilt-back assembly as far as it will go onto it’s

rubber bumpers.

4. (Step 2) Pull the gas spring cylinder out of it’s retaining

clip on the back of the mast assembly. Lower and

extend or retract the cylinder to guide the groove pins

on the end of the cylinder into the slots on the tiltback crossbar assembly bracket. Secure the cylinder to

the tilt-back crossbar bracket by replacing the pin

removed in step 1 to lower the tilt-back assembly.

NOTE: If moving machine in other than a straight line forward,

unlock tilt-back swivel wheels by pulling the swivel wheel

lock pins out then turning pins 90° to the unlock position.

This will allow the tilt-back swivel wheels to rotate freely

and steer machine while moving.

5. (Step 3) Fully extend the T-handle lifting bar located

under the front of the machine by pulling down on

the release/lock pin located under the bar. Fully

extend the lifting bar until the release/lock pin snaps

back in, locking the bar in place. Push or pull bar to be

certain it is secure before lifting machine.

6. (Step 4) With both hands on the grips of the T-handle

lifting bar, carefully lift the front of the machine and

tilt the machine back onto the tilt-back assembly and

the gas spring cylinder.

7. Push machine around using the loop grips just behind

the front swivel wheel assemblies under the base

frame.

3121211 – JLG Lift – 4-15

SECTION 4 - MACHINE OPERATION

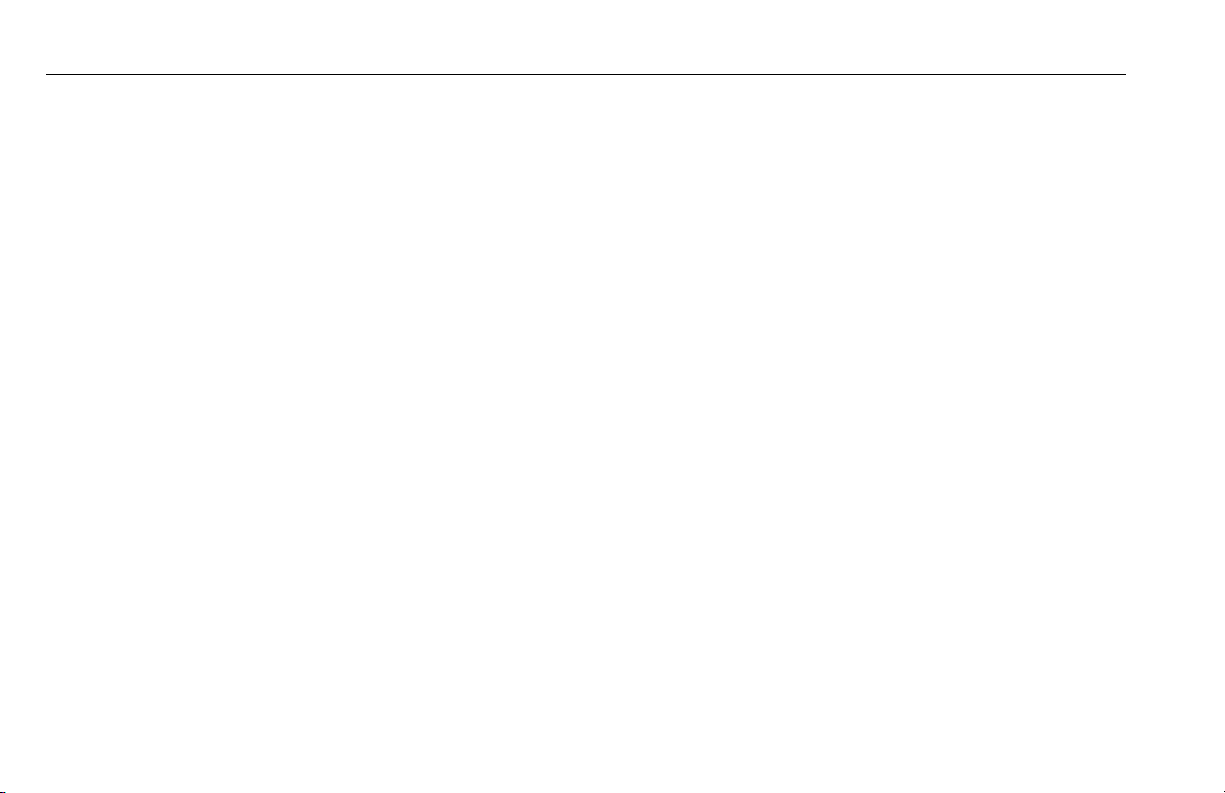

Step 1

Figure 4-8. Tilt-Back Assembly Set-Up - Machines S/N - 0900031618 to Present.

4-16 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

Step 2

Step 3

Figure 4-9. Tilt-Back Assembly Set-Up - Machines S/N - 0900031618 to Present.

3121211 – JLG Lift – 4-17

SECTION 4 - MACHINE OPERATION

Step 4

Figure 4-10. Tilt-Back Assembly Set-Up - Machines S/N - 0900031618 to Present.

4-18 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

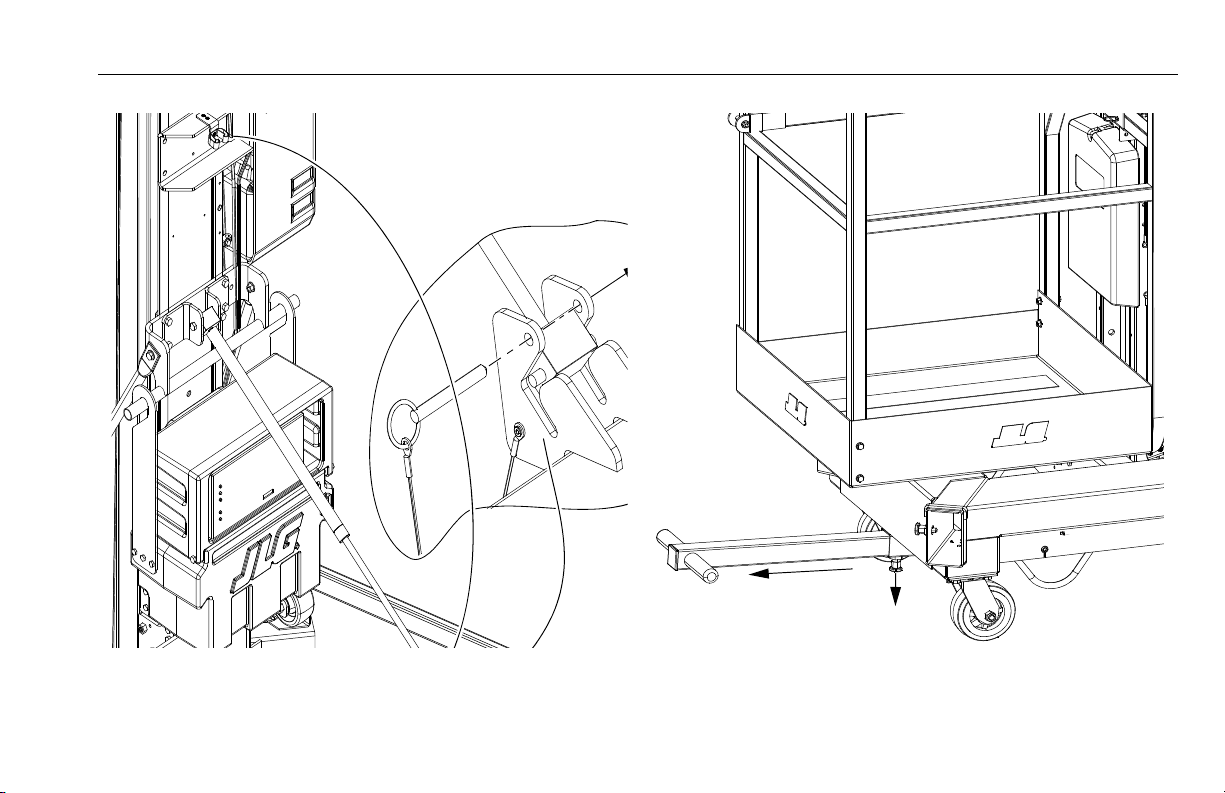

Pickup Truck Loading Device (Option)

(See Figure 4-11.)

NOTE: The stowed mast height of the 36AM and 41AM exceeds

the length of most pick-up truck beds. JLG does not recommend transporting those models by pick-up truck.

AM model machines can be transported in a standard full size

pickup truck. If the machine is equipped with the loading device

option, it can be loaded and unloaded by one person.

NOTE: For a smooth rolling surface and even weight distribution,

it is recommended that 3/4" to 1" (2 to 2.5cm) thick plywood be placed in the truck bed and out onto the tailgate.

This should avoid tailgate damage.

Park truck on a firm, smooth, level surface with the tailgate

open. Remove the battery/charger storage box from DC model

machines.

1. Set load pivot bar on back of mast so bar is set approximately 1 - 2 in (3 to 5 cm) above tailgate height. Use

the spring loaded locking pin to raise or lower the load

pivot bar. Once bar is locked in place, push machine

against the tailgate.

2. At front of the machine, extend the T-handle lifting bar

from the base frame.

3. Begin lifting the machine onto the tailgate of the truck

with the T-handle lifting bar. As machine begins to

pivot be certain the load pivot bar is engaging the

truck tailgate.

4. Continue lifting and pushing machine onto the truck

bed, firmly grasp the machine by the base frame

pushing it all the way into truck bed.

5. Secure machine to the truck bed with rope or tie down

hooks to limit any machine movement while transporting.

To unload machine from truck bed, reverse loading instructions

above.

3121211 – JLG Lift – 4-19

SECTION 4 - MACHINE OPERATION

1

2

Figure 4-11. Loading Machine onto Bed of Pick-Up Truck.

4-20 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

3

4

Figure 4-11. Loading Machine onto Bed of Pick-Up Truck.

3121211 – JLG Lift – 4-21

SECTION 4 - MACHINE OPERATION

5

Figure 4-11. Loading Machine onto Bed of Pick-Up Truck.

4-22 – JLG Lift – 3121211

SECTION 4 - MACHINE OPERATION

Lifting

To lift the machine, use suitable lifting equipment capable of

handling the weight of the machine.

NOTE: Fork lifts, cranes, chains, slings, etc. must be capable of

handling the following weights:

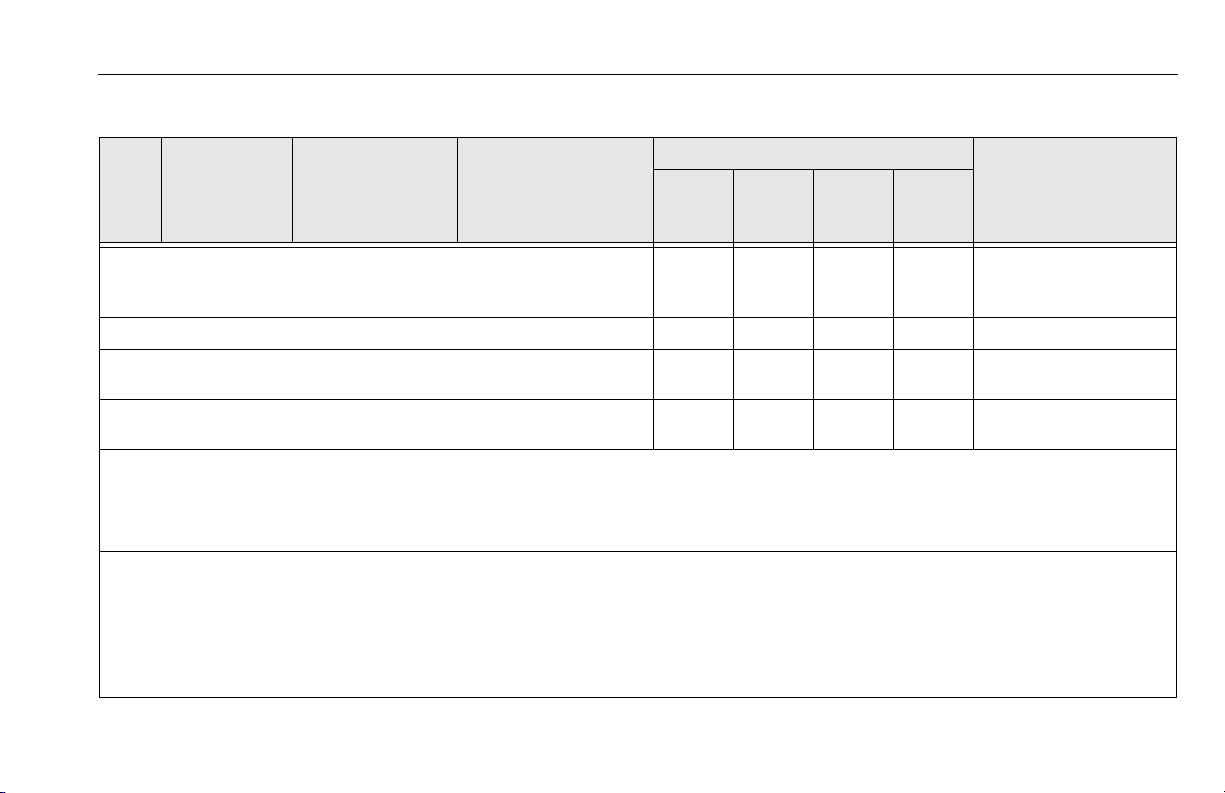

Table 4-2. AM Machine Gross Weights

AM Model Gross Weight

20AM-AC 717 lb. (325kg)

20AM-DC 785 lb. (356kg)

25AM-AC 800 lb. (363kg)

25AM-DC 871 lb. (395kg)

30AM-AC 871 lb. (395kg)

30AM-DC 941 lb. (427kg)

36AM-AC 973 lb. (441kg)

36AM-DC 1043 lb. (473kg)

41AM-AC 1072 lb. (486kg)

41AM-DC 1142 lb. (518kg)

NOTE: All AM models are equipped with forklift pockets at the

mast end of frame for transporting the unit. An optional

crane hook is available. Do not lift with a crane without

the optional crane hook.

Machine Tie Down

Secure the machine to the transport vehicle using the tie down

lug weldments provided on the rear and sides of the machine.

1. Transport only with platform in the stowed position.

2. Remove all loose items from machine.

3121211 – JLG Lift – 4-23

SECTION 4 - MACHINE OPERATION

NOTES:

4-24 – JLG Lift – 3121211

SECTION 5. OPTIONAL EQUIPMENT

SECTION 5 - OPTIONAL EQUIPMENT

5.1 OPTIONAL EQUIPMENT

The following optional equipment is available for AM model

machines:

22" x 25" Quick-Change Platform

The 22" (56cm) long by 25" (64cm) wide platform features a

gull wing gate opening.

26" x 26" Quick-Change Platform

The 26" (66cm) long by 26" (66cm) wide platform features a

side entry gate opening.

28" x 26" Quick-Change Platform

The 28" (71cm) long by 26" (66cm) wide platform features a

gull wing gate opening.

25" x 26" Step-in Molded Platform w/Swing-up Gate

The 25" (64cm) long by 26" (66cm) wide Step-in Molded Platform features a tough molded shell base and sides mounted

to a welded steel frame.

3121211 – JLG Lift – 5-1

Tool Tray

Platform attachment to hold hand tools or other small items

placed in the tray.

Fluorescent Tube Caddy

Platform attachment for handling fluorescent tubes.

Crane Hook

Attached at the top rear of the mast, the crane hook is used to

lift the machine up or down to another level.

Straddle Extension (Requires Straddle Adapter)

(See Section 5.2 for Installation and Use instructions)

The AM-SE Straddle Extension allows a user to lift the

machine and move it over obstacles up to 4 ft. (1.2m) in

height.

Ladder for Straddle Extension

This ladder allows the user entry to the AM machine once it is

raised using the Straddle Extension.

SECTION 5 - OPTIONAL EQUIPMENT

Extra Power Pack (Battery, Charger & Case)

Includes the battery, charger and molded case.

Platform Auxiliary Power Lowering Device

The Platform Auxiliary Power Lowering device is a switch activated battery backed electrical circuit designed to provide

power to the platform control box in the event of loss of the

machines power supply.

Laser Positioning Device

Attached to the platform, this device allows the operator to

more accurately position the machine under a work area

before raising the platform in position.

Hour Meter

(See Figure 5-1., Hour Meter Location. (Option)

The machine hour meter accumulates pump operation time

during the platform LIFT UP cycle only. The reading indicates

hours and tenths of an hour.

Machine Cycle Counter Meter

The Cycle Counter Meter is located on the front side of the

Ground Control Station. This meter tracks the number of

cycles the mast travels up and down during macheine operation. This information can be used to determine maintenance

intervals and other for other informational purposes when

Figure 5-1. Hour Meter Location. (Option)

1. Hour Meter

5-2 – JLG Lift – 3121211

SECTION 5 - OPTIONAL EQUIPMENT

NOTICE

5.2 AM-SE - STRADDLE EXTENSION – INSTALLATION

Description

The AM-SE straddle extension increases the versatility of the AM

Series by providing a bridge for access to areas where obstacles

such as rows of seats, machines, counters or stairwells are

encountered.

The straddle extension provides clearance of up to 48 inches

(1.2m) in height and is adjustable from 104 to 128 inches (2.6m

to 3.3 m) in length.

Straddle Adaptor Wiring Components

The straddle wiring for both the AM Series includes the following parts:

1. Two (2) short wiring harness’.

2. Two (2) Spring Clips.

3. Four (4) #10-24 x .625 long bolts, nuts and lock wash-

ers.

4. Two (2) 3/8" I.D.\ 1/2" O.D grommets.

Straddle Adaptor Wiring Installation

1. Set up machine installing outriggers, level machine

and raise the platform as high as necessary to allow

access base frame.

NEVER WORK UNDER AN ELEVATED PLATFORM UNTIL PLATFORM HAS BEEN

SAFELY RESTRAINED FROM ANY MOVEMENT BY JACK STAND OR OVERHEAD

SLING.

2. Place a floor jack or other suitable support between

the mast and floor before working underneath platform.

ON AC MACHINES UNPLUG THE POWER CORD, DC POWERED MACHINES DISCONNECT THE MAIN POWER SUPPLY CONNECTOR ON THE SIDE OF THE BATTERY STORAGE/CHARGER BOX.

NOTE: The holes in the base frame for mounting the spring clips

and routing the wires through the center crossmember to

the interlock relay may already exist. If not continue with

Step 3, if holes are there, jump to Step 5.

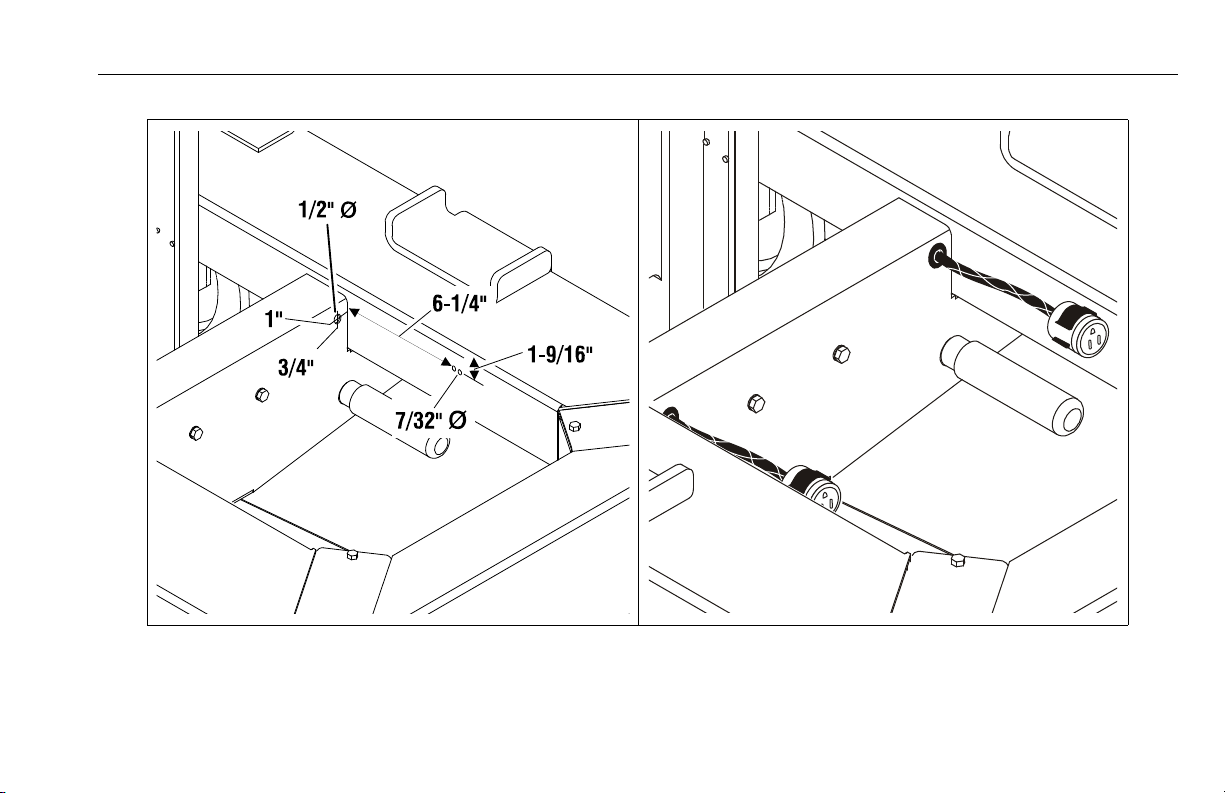

3. Drill two (2) .219 diameter (7/32") holes per side for

each spring clip see Figure 5-2.

3121211 – JLG Lift – 5-3

SECTION 5 - OPTIONAL EQUIPMENT

4. Drill one (1) .50 diameter (1/2") hole, one (1) per side

into the center frame crossmember for the wiring

grommet see Figure 5-2.

5. Install the spring clips to the base frame at location of

drilled holes, using two (2) #10-24 x .625 bolts and

two (2) nuts and two (2) lock washers per spring clip.

6. Install the grommets supplied into the .50 dia. holes.

7. Locate the two short adapter wiring harnesses and

route one through each grommeted hole on the center frame crossmember.

8. Wire the adapter wiring harness ends together and to

the interlock relay wires as shown in Figure 5-3.

9. Press the two (2) - three (3) prong connector ends into

the spring clips mounted on the base frame.

10. Reconnect power to the machine and lower the platform to the stowed position. Stow the outriggers.

11. To verify installation, set-up and assemble straddle

extension as described in the Section 5-3. If outrigger

interlock LED’s on the straddle extension light up

when completely assembled, and power is supplied to

the platform, then installation is complete.

5-4 – JLG Lift – 3121211

SECTION 5 - OPTIONAL EQUIPMENT

Figure 5-2. SE-Adapter - Wiring - Grommet & Spring Clip Mounting Hole Locations.

(Same For Both Sides)

3121211 – JLG Lift – 5-5

SECTION 5 - OPTIONAL EQUIPMENT

2

3

1

4

G

S

G

S

RED 16

YEL 1

YEL 1

WHI TE 16

GREEN

YELLOW

YELLOW

YELLOW

GREEN 16

GREEN

BLACK

BLU

BLU

BLU

BLU

GREENGREEN

GREEN

BLACK

OUTPUT

B+

GRND.

1

3

4

2

++

Figure 5-3. Straddle Adapter Wiring Harness to AM Wiring Connections.

1. Grommet 3. Potted Relay

2. Crossmember 4. Butt Splice

NOTE: Cut (1) Green, (1) Yellow, and (1) Yellow 1 wire and install the Adapter Harness with butt splice terminals.

5-6 – JLG Lift – 3121211

SECTION 5 - OPTIONAL EQUIPMENT

5.3 AM-SE - STRADDLE EXTENSION – SET-UP AND OPERATION

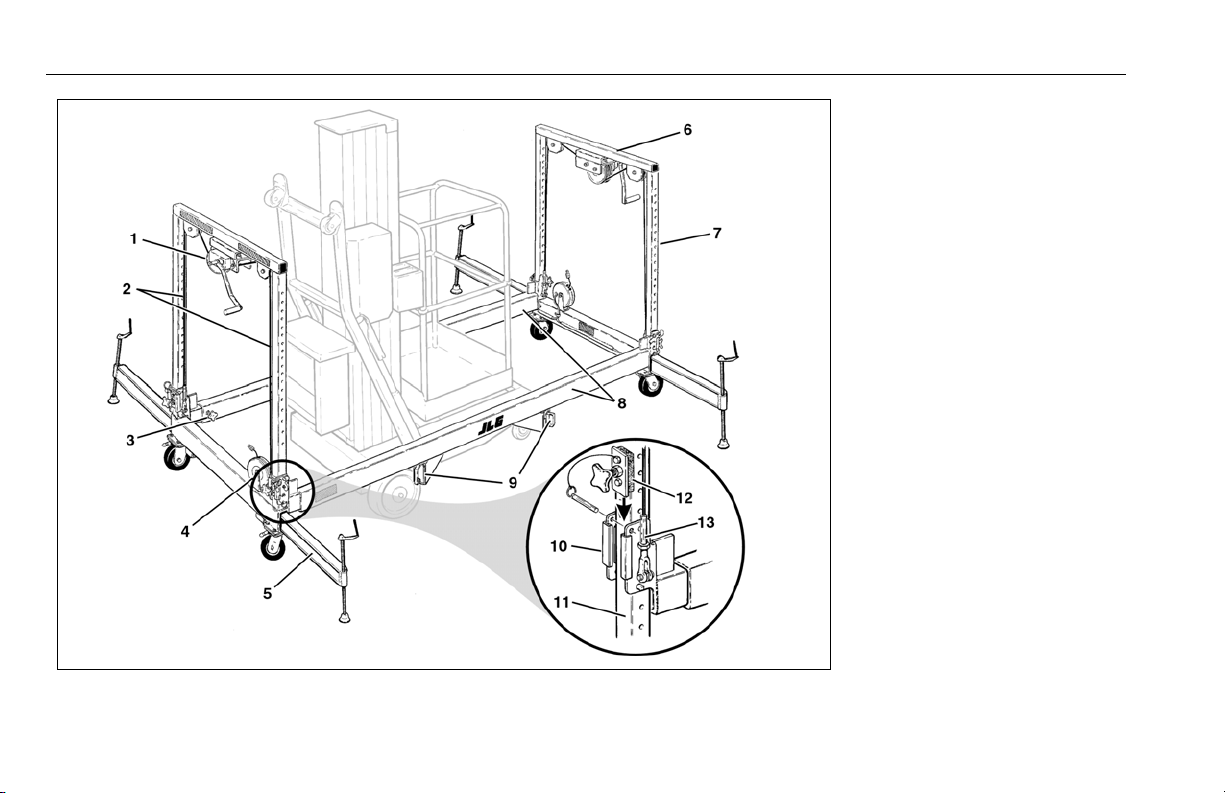

Straddle Extension - Components

The AM-SE Straddle Extension can be set up by one person

without tools. The AM-SE consists of eight (8) structural components.

1. Two (2) extendable side lifting rails.

2. Two (2) end straddle supports on locking swivel caster

wheels, each with lifting winch and winch cables, outrigger interlock - retractable cable reel and quickrelease safety pins.

3. Four (4) short outrigger beams which interconnect the

straddle extension side lifting rails with the AM base

outrigger sockets.

Mounting - Straddle Extension to AM

(See Figure 5-4.)

1. Near work area find a suitable area large enough to

assemble the AM machine to the Straddle Extension.

2. Insert one (1) of the short outrigger beams into an

outrigger socket in the AM base. Push it in until the

locking pin secures the beam in place.

3. Next, slide a side lifting rail onto the short outrigger

beam.

4. Align the side lifting rail with the other AM outrigger

socket on this side of the machine and install another

short outrigger beam. Push the short beam in until

the locking pin in the AM base secures the beam in

place.

5. Mount the remaining side lifting rail to the other side

of the AM machine repeating steps 2, 3 and 4.

6. Mount a straddle end support by aligning the two vertical rails of the end support with the adjust bracket

opening on ends of the side lifting rails.

NOTE: For added stability of the end support, lock the castor

wheels on the bottom of the support so they are parallel

with the outrigger sockets.

7. Insert end support vertical rails into the adjust brackets (in against the slide pads), and insert an adjust

bracket end cap (with slide pad against vertical rail)

into the slot on the adjust brackets on both side rails.

8. Secure end caps with the quick-release pin wired to

the end cap.

9. Repeat steps 6, 7 and 8 to mount the other straddle

end support.

10. Attach the winch lift cable clevis ends to the lifting

lugs, using the quick-release pins attached to winch

cables.

3121211 – JLG Lift – 5-7

SECTION 5 - OPTIONAL EQUIPMENT

1. Winch Assembly

2. Winch Lift Cables

3. Side Rail Locking Screw

4. Interlock Cable Reel

5. AM Unit Outriggers