JLG 45e Service Manual

CORPORATE OFFICE

JLG INDUSTRIES, INC.

1 JLG Drive

McConnellsburg, PA.

17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

Models

30e

35e

n35e

40e

n40e

45e

3120861

October 1, 2001

SERVICE & MAINTENANCE

WWW.JLG.COM

JLG Industries (Australia)

P.O. Box 5119

11 Bolwarra Road

Port Macquarie

N.S.W. 2444

Australia

Phone: (61) 2 65 811111

Fax: (61) 2 65 810122

JLG Industries (UK)

Unit 12, Southside

Bredbury Park Industrial Estate

Bredbury

Stockport

SK6 2sP

England

Phone: (44) 870 200 7700

Fax: (44) 870 200 7711

JLG Deutschland GmbH

Max Planck Strasse 21

D-27721 Ritterhude/lhlpohl

Bei Bremen

Germany

Phone: (49) 421 693 500

Fax: (49) 421 693 5035

JLG Industries (Italia)

Via Po. 22

20010 Pregnana Milanese - MI

Italy

Phone: (39) 02 9359 5210

Fax: (39) 02 9359 5845

JLG Latino Americana Ltda.

Rua Eng. Carlos Stevenson,

80-Suite 71

13092-310 Campinas-SP

Brazil

Phone: (55) 19 3295 0407

Fax: (55) 19 3295 1025

JLG Europe B.V.

Jupiterstraat 234

2132 HJ Foofddorp

The Netherlands

Phone: (31) 23 565 5665

Fax: (31) 23 557 2493

JLG Industries (Norge AS)

Sofeimyrveien 12

N-1412 Sofienyr

Norway

Phone: (47) 6682 2000

Fax: (47) 6682 2001

JLG Polska

UI. Krolewska

00-060 Warsawa

Poland

Phone: (48) 91 4320 245

Fax: (48) 91 4358 200

JLG Industries (Europe)

Kilmartin Place,

Tan n o ch s id e Pa r k

Uddingston G71 5PH

Scotland

Phone: (44) 1 698 811005

Fax: (44) 1 698 811055

JLG Industries (Pty) Ltd.

Unit 1, 24 Industrial Complex

Herman Street

Meadowdale

Germiston

South Africa

Phone: (27) 11 453 1334

Fax: (27) 11 453 1342

Plataformas Elevadoras

JLG Iberica, S.L .

Trapadella, 2

P. I . C a s t e l l b i s b a l S u r

08755Castellbisbal

Spain

Phone: (34) 93 77 24700

Fax: (34) 93 77 11762

JLG Industries (Sweden)

Enkopingsvagen 150

Box 704

SE - 175 27 Jarfalla

Sweden

Phone: (46) 8 506 59500

Fax: (46) 8 506 59534

INTRODUCTION

3120861 – JLG Lift – A-1

SECTION A. INTRODUCTION - MAINTENANCE SAFETY

PRECAUTIONS

A GENERAL

This section contains the general safety precautions which

must be observed during maintenance of the aerial plat-

form. It is of utmost importance that maintenance person-

nel pay strict attention to these warnings and precautions

to avoid possible injury to themselves or others, or dam-

age to the equipment. A maintenance program must be

followed to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED, IS A SAFETY VIOLA-

TION.

The specific precautions to be observed during mainte-

nance are inserted at the appropriate point in the manual.

These precautions are, for the most part, those that apply

when servicing hydraulic and larger machine component

parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support is

provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CON-

TROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPER-

ATOR.

B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems

operate at extremely high potentially dangerous pressures.

Every effort should be made to relieve any system pres-

sure prior to disconnecting or removing any portion of the

system.

Relieve system pressure by cycling the applicable control

several times with the engine stopped and ignition on, to

direct any line pressure back into the reservoir. Pressure

feed lines to system components can then be disconnected

with minimal fluid loss.

C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION MAY RESULT IN MACHINE DAMAGE, PERSONNEL

INJURY OR DEATH AND IS A SAFETY VIOLATION.

• NO SMOKING IS MANDATORY. NEVER REFUEL DUR-

ING ELECTRICAL STORMS. ENSURE THAT FUEL

CAP IS CLOSED AND SECURE AT ALL OTHER

TIMES.

• REMOVE ALL RINGS, WATCHES AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAU-

TIONS ON MACHINE AND IN SERVICEMANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

• USE CAUTION WHEN CHECKING A HOT, PRESSUR-

IZED COOLANT SYSTEM.

• NEVER WORK UNDER AN ELEVATED BOOM UNTIL

BOOM HAS BEEN SAFELY RESTRAINED FROM ANY

MOVEMENT BY BLOCKING OR OVERHEAD SLING,

OR BOOM SAFETY PROP HAS BEEN ENGAGED.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

• BATTERY SHOULD ALWAYS BE DISCONNECTED-

DURING REPLACEMENT OF ELECTRICAL COMPO-

NENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACH-

MENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

INTRODUCTION

A-2 – JLG Lift – 3120861

REVISON LOG

March, 1989 - Original Issue

October, 1994 - Revised

August, 1997 - Revised

January, 1999 - Revised

June, 1999 -Revised

October 1, 2001 -Revised

3120743 – JLG Lift – i

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

IINTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

EFFECTIVITY CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

SECTION 1 - SPECIFICATIONS

1.1 CAPACITIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 COMPONENT DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 PERFORMANCE DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 TORQUE SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.5 LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.6 PRESSURE SETTINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.7 CYLINDER SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.8 MAJOR COMPONENT WEIGHTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.9 CRITICAL STABILITY WEIGHTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

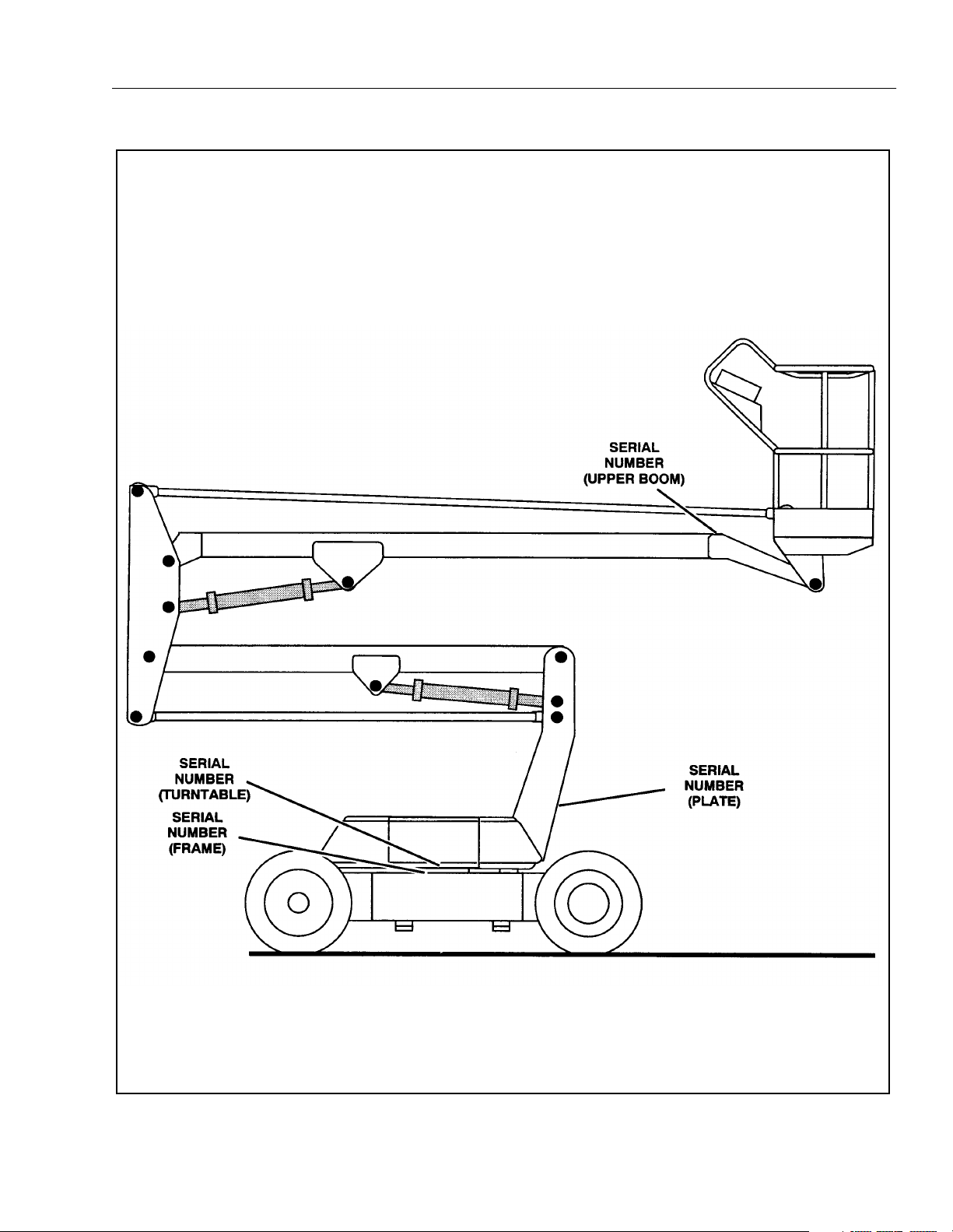

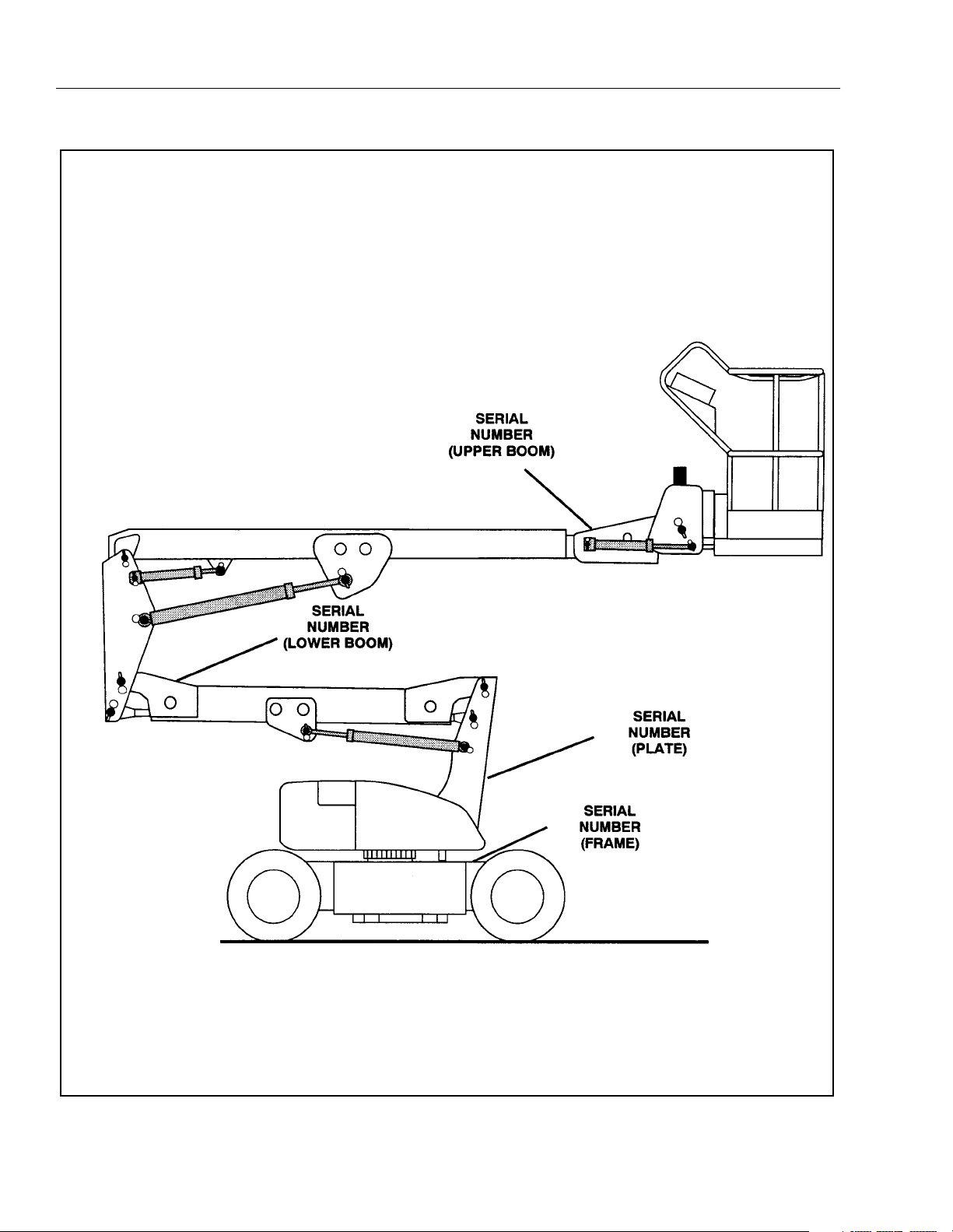

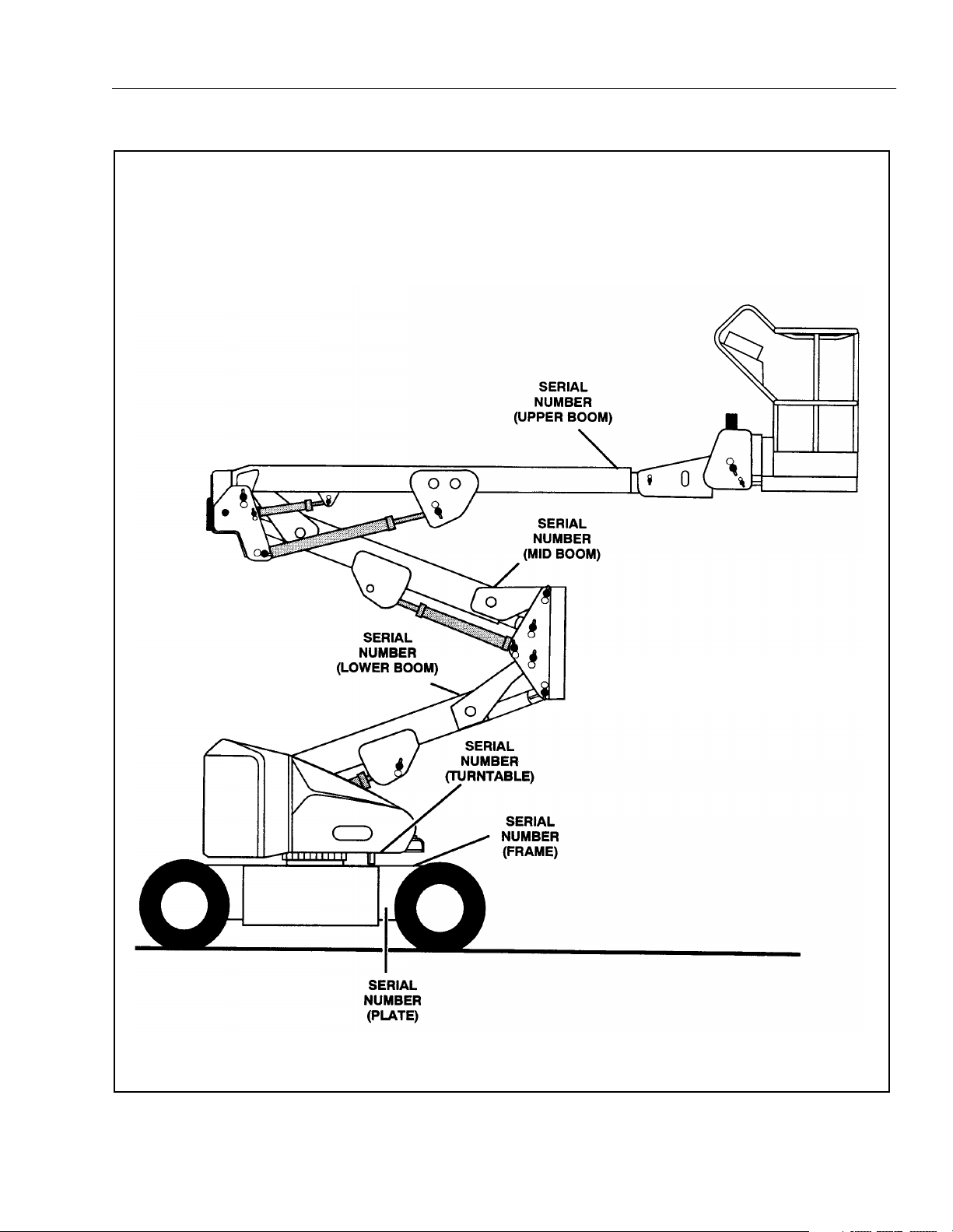

1.10 SERIAL NUMBER LOCATIONS. (See Figure 1-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

SECTION 2 - PROCEDURES

2.1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 SERVICING AND MAINTENANCE GUIDELINES.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 LUBRICATION INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 CYLINDERS - THEORY OF OPERATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 VALVES - THEORY OF OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.6 MOTOR CONTROLLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.7 WEAR PADS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.8 BOOM MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.9 CYLINDER CHECKING PROCEDURES.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.10 CYLINDER REPAIR.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2.11 CYLINDER REMOVAL AND INSTALLATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2.12 TILT INDICATOR SWITCH LEVELING PROCEDURE. (If Equipped.) . . . . . . . . . . . . . . . . . . . . . .2-29

2.13 BOOM LIMIT SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

2.14 POWER TRACK REMOVAL PROCEDURE (35/n35/40/n40/45 electric). . . . . . . . . . . . . . . . . . . . . 2-29

2.15 PRESSURE SETTING PROCEDURES. (In Sequence) (See Figure 2-29) . . . . . . . . . . . . . . . . . .2-29

2.16 SWING BEARING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

2.17 DRIVE TORQUE HUB. (See Figure 2-34) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

2.18 DRIVE BRAKE ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

2.19 MID AND LOWER LIFT CYLINDER BLEEDING PROCEDURE. (40/n40/45 electric) . . . . . . . . . .2-46

2.20 BOOM SYNCHRONIZING PROCEDURE. (40/n40/45 electric) . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

2.21 FREE WHEELING PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

2.22 FOOTSWITCH ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

2.23 AXLE DRAIN PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

2.24 PREVENTIVE MAINTENANCE AND INSPECTION SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

SECTION 3 - TROUBLESHOOTING

3.1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 TROUBLESHOOTING INFORMATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 HYDRAULIC CIRCUIT CHECKS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

ii – JLG Lift – 3120743

TABLE OF CONTENTS (Continued)

FIGURE NO. TITLE PAGE NO.

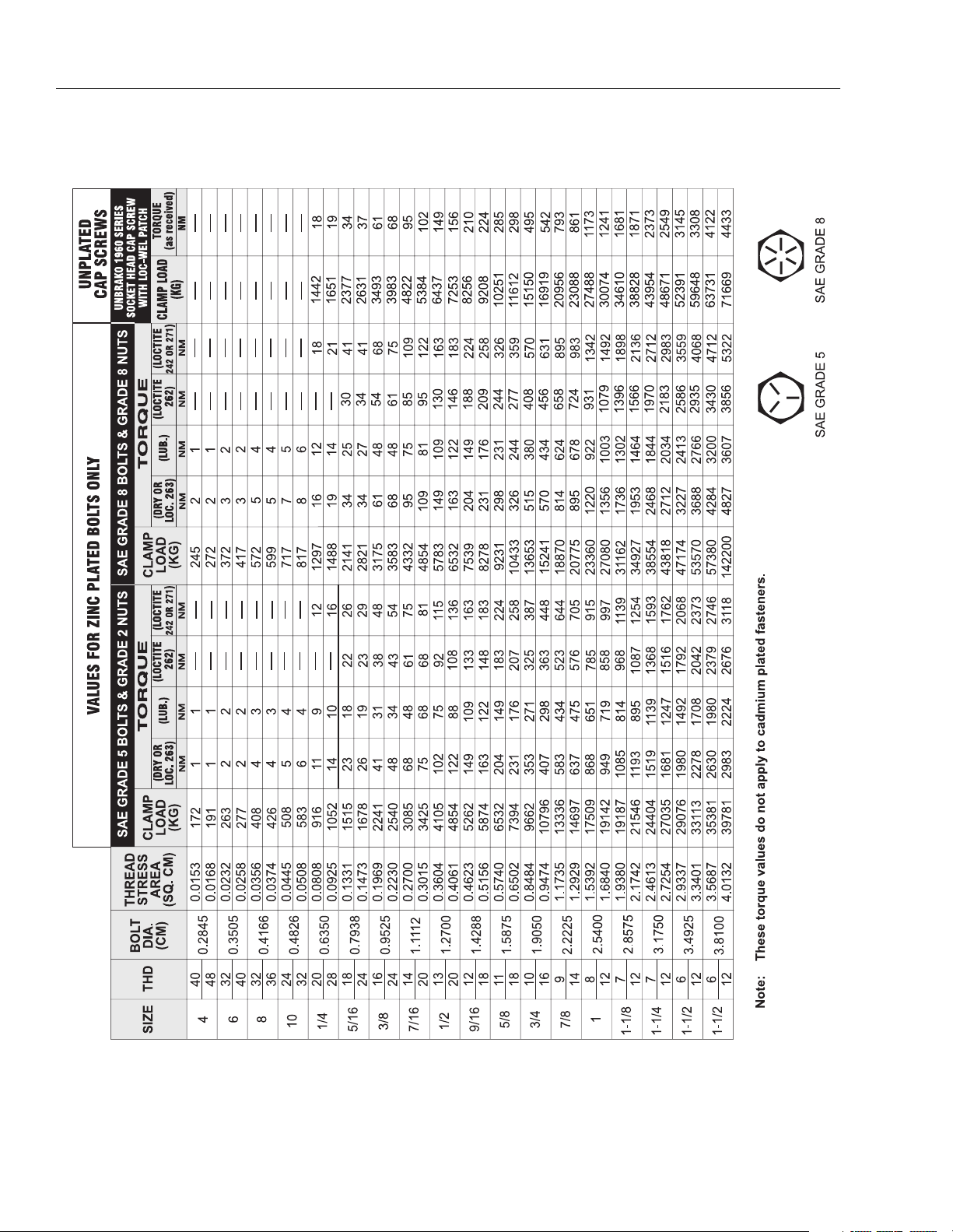

1-1. Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

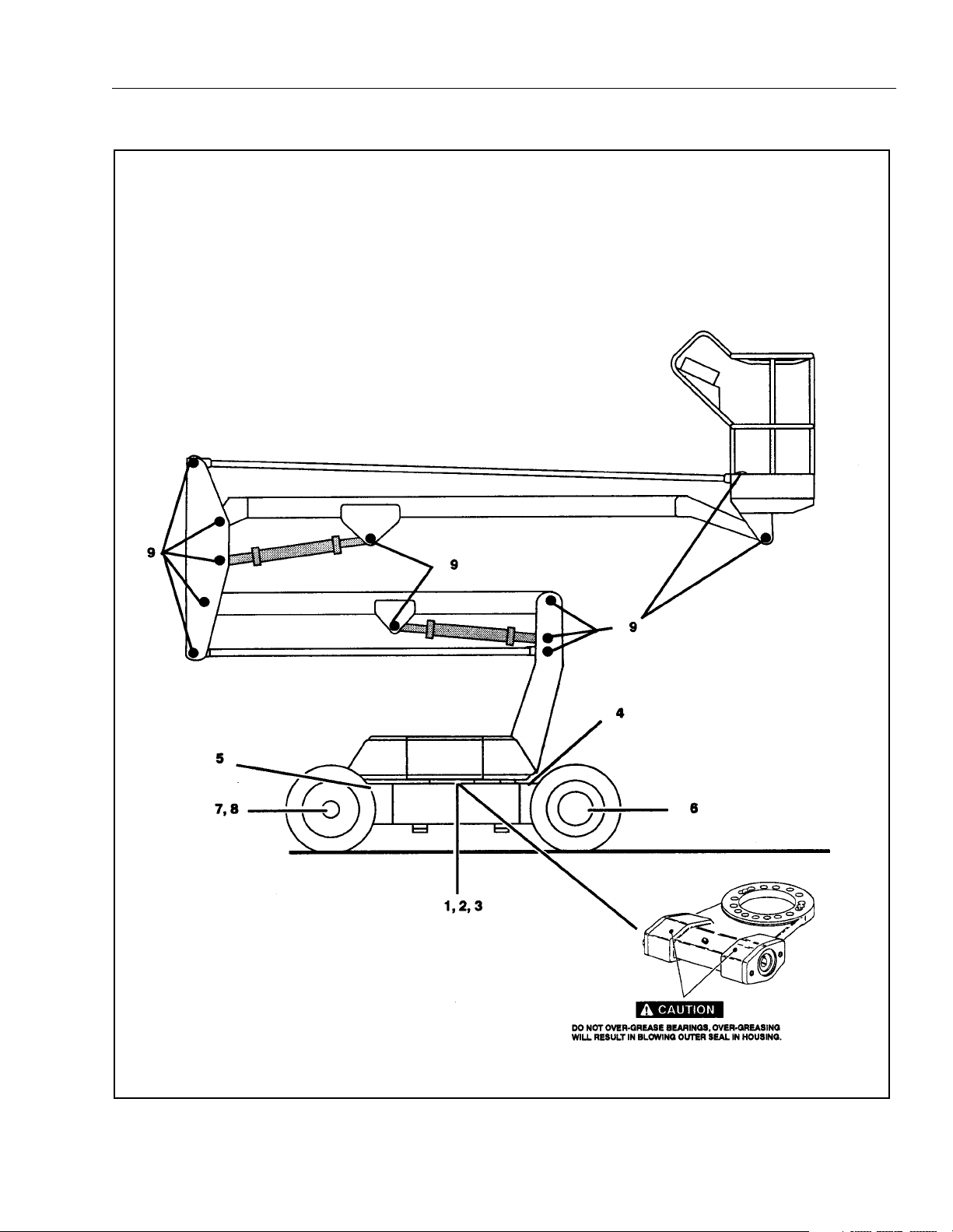

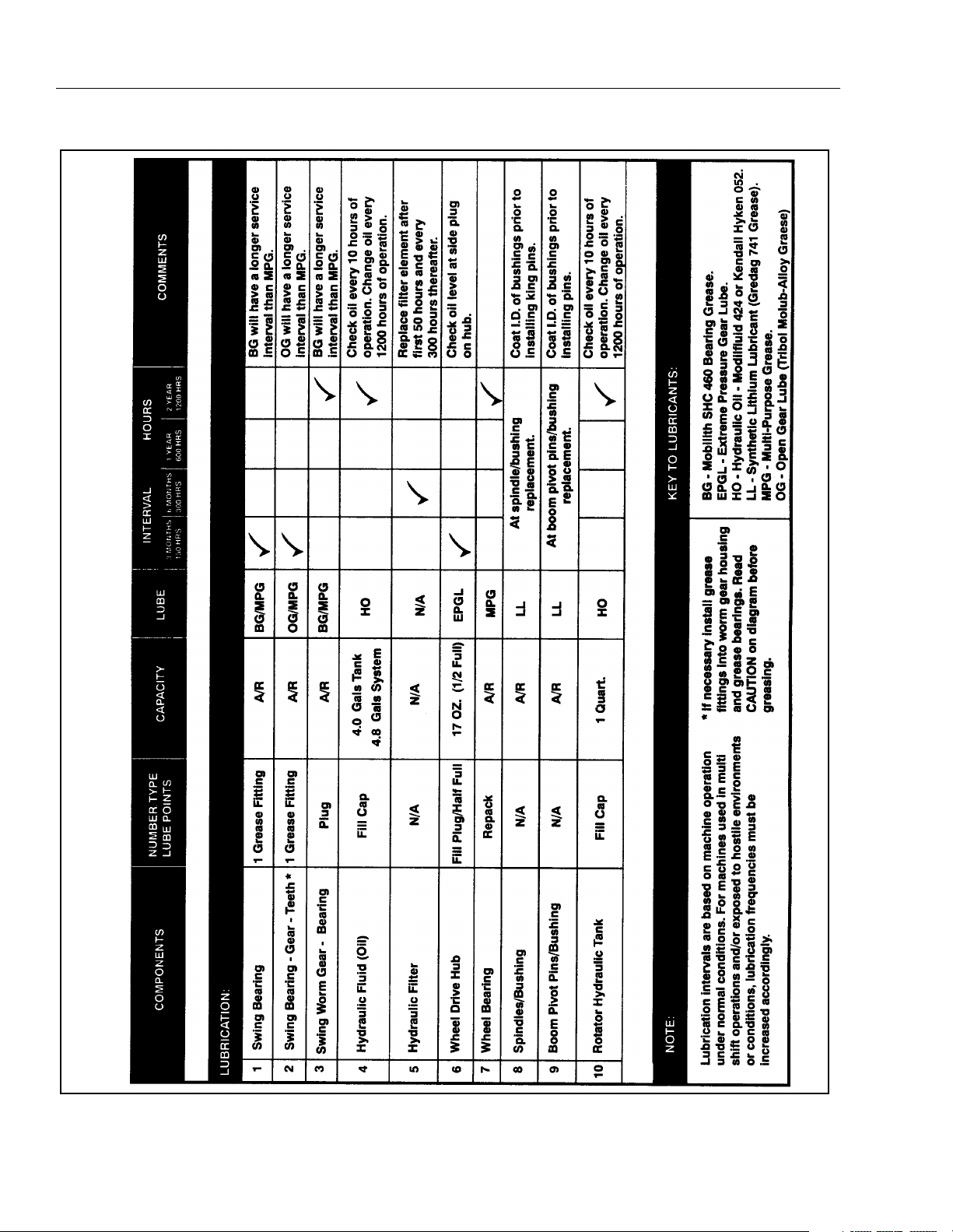

1-2. Lubrication Chart - 30 electric. (Sheet 1 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1-2. Lubrication Chart - 30 electric. (Sheet 2 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

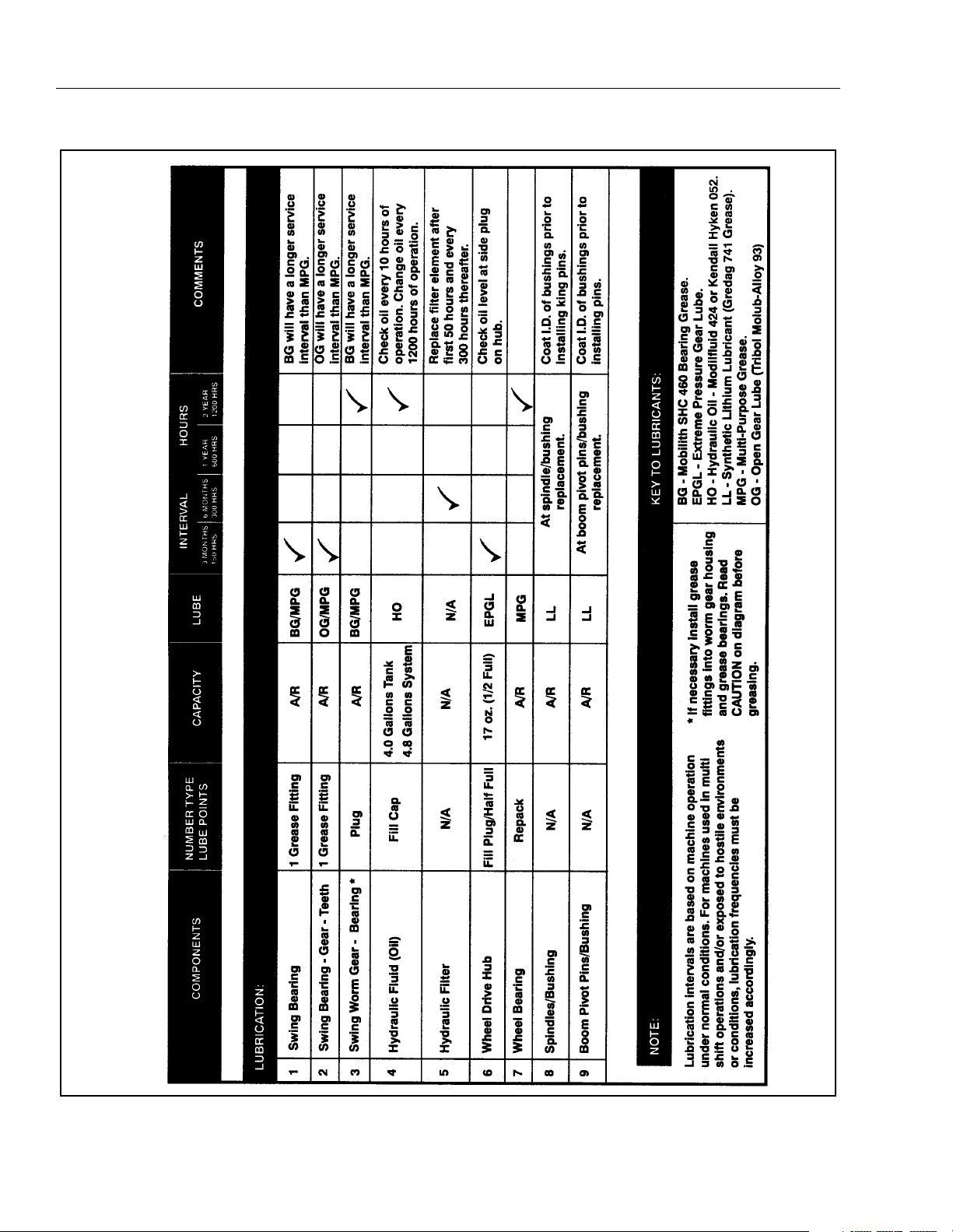

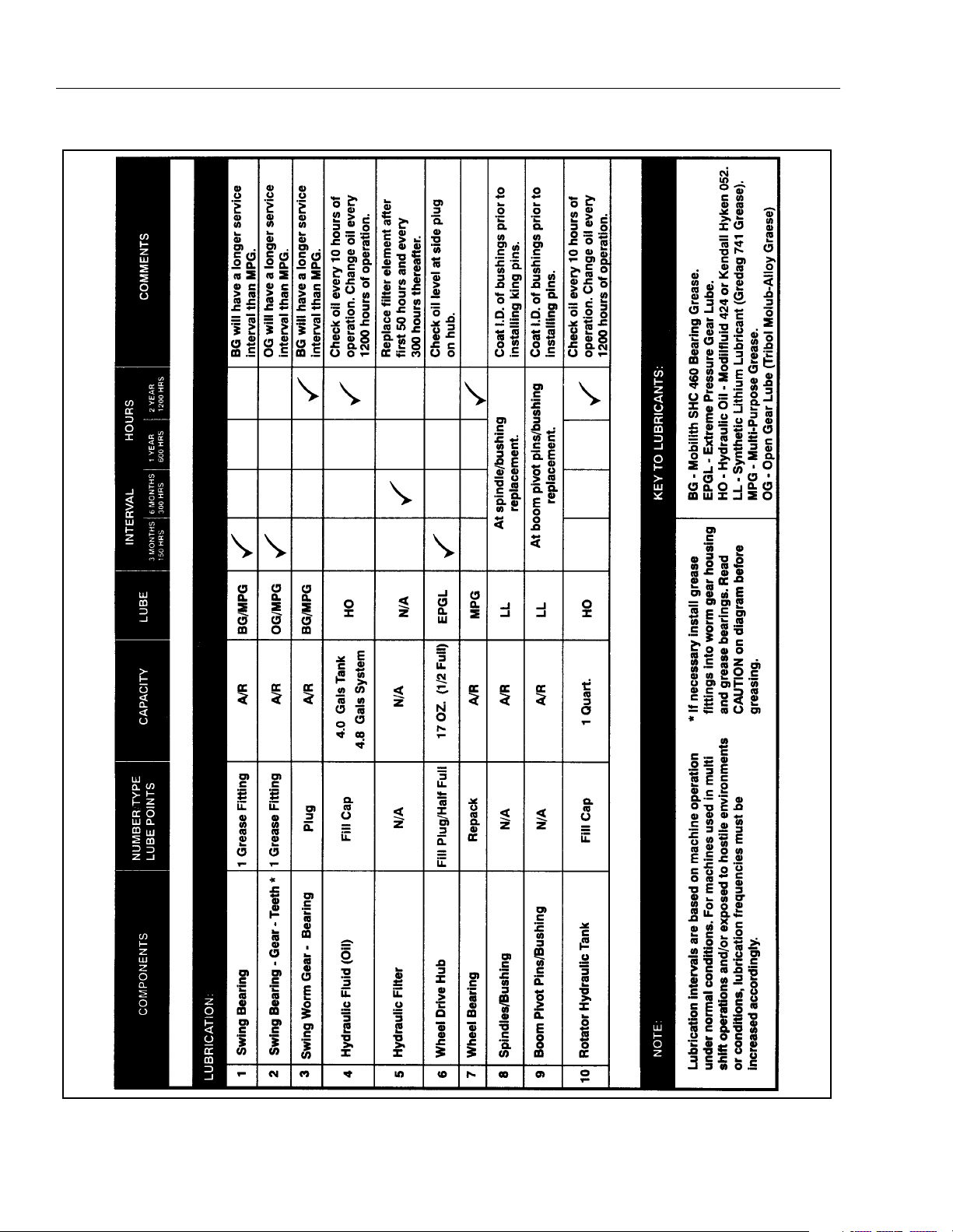

1-2. Lubrication Chart - 35/n35 electric. (Sheet 3 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1-2. Lubrication Chart - 35/n35 electric. (Sheet 4 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

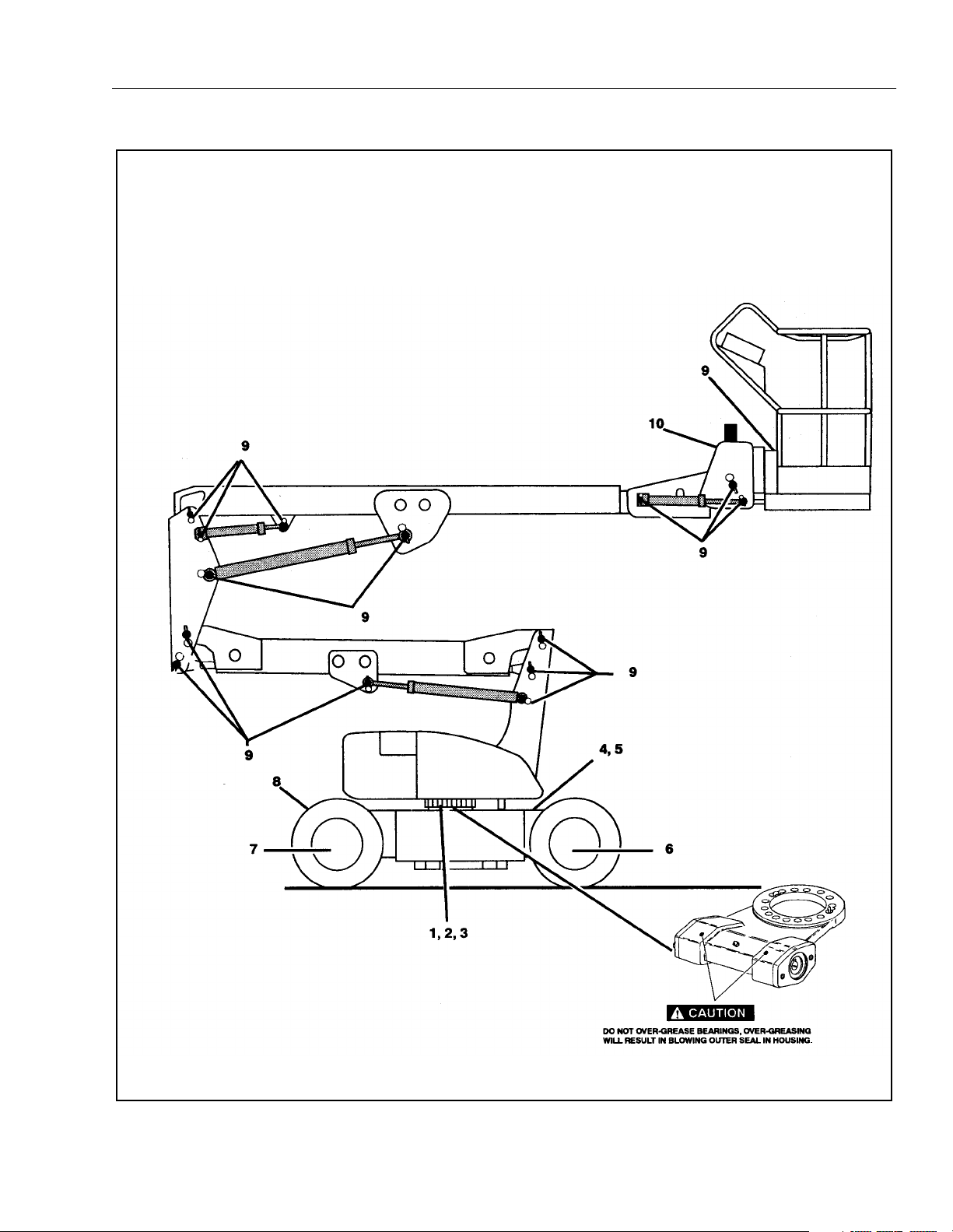

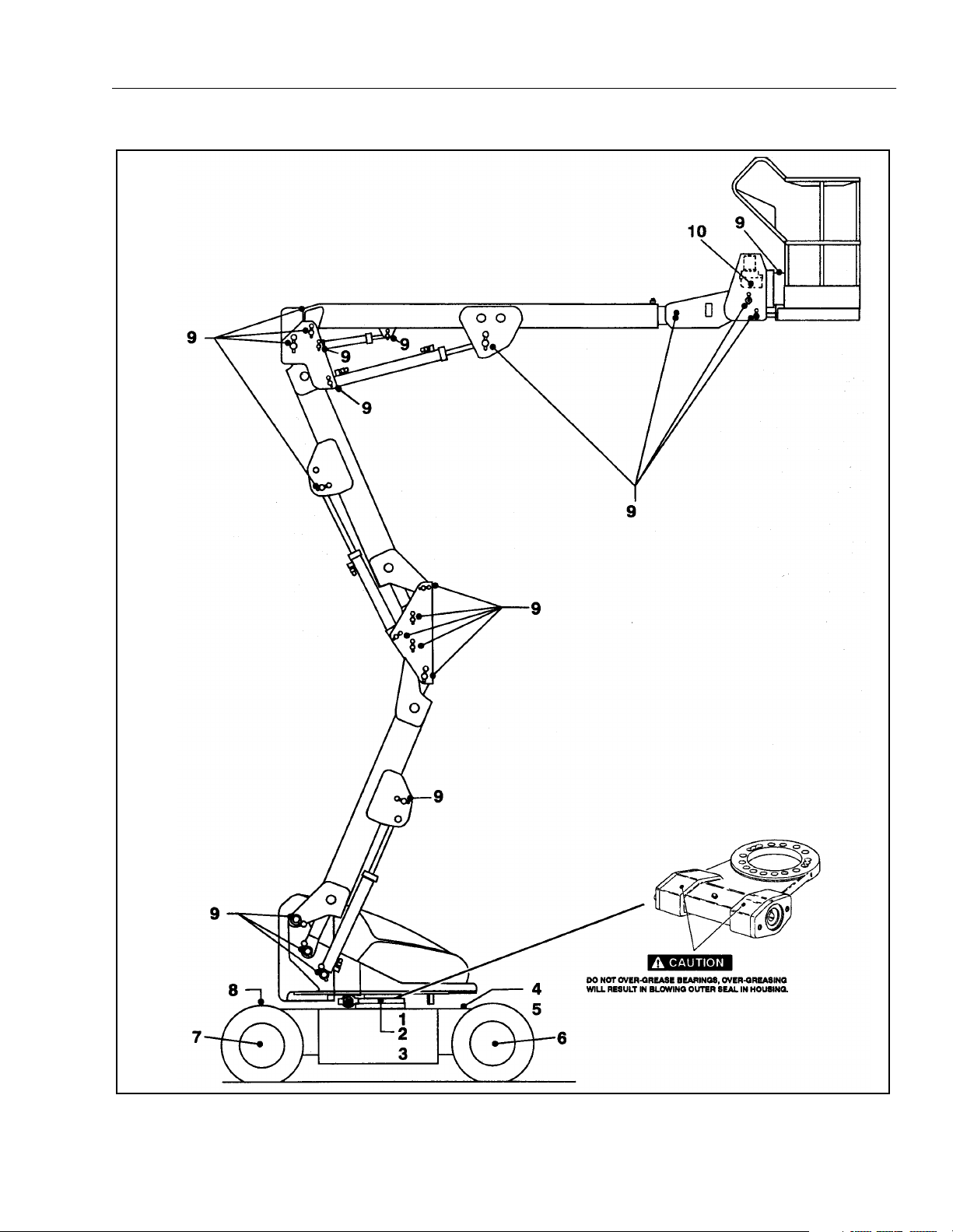

1-2. Lubrication Chart - 40/n40/45 electric. (Sheet 5 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1-2. Lubrication Chart - 40/n40/45 electric. (Sheet 6 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1-3. Serial Number Locations - 30 electric. (Sheet 1 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1-3. Serial Number Locations - 35/n35 electric. (Sheet 2 of 3).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

1-3. Serial Number Locations - 40/n40/45 electric. (Sheet 3 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

2-1. Sevcon Controller Troubleshooting Flow Charts. (Sheet 1 of 4).. . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-1. Sevcon Controller Troubleshooting Flow Charts. (Sheet 2 of 4).. . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-1. Sevcon Controller Troubleshooting Flow Charts. (Sheet 3 of 4).. . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-1. Sevcon Controller Troubleshooting Flow Charts. (Sheet 4 of 4).. . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-2. Location and Thickness of Wear Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-3. Locations of Components - Platform Support (Model 30). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-4. Location of Components - Removal of Base Boom. (Model 30) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-5. Location of Components - Platform Support. (Models 35/n35/40/n40/45) . . . . . . . . . . . . . . . . . .2-12

2-6. Location of Components - Slave Leveling Cylinder.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2-7. Location of Components - Removal of Base Boom. (Models 35/n35/40/n40/45) . . . . . . . . . . . . .2-12

2-8. Location of Components - Aft End of Fly Boom Wear Pad Adjustments. . . . . . . . . . . . . . . . . . . . 2-13

2-9. Location of Components - Removal of Telescope Cyllinder.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-10. Location of Components - Front Base Boom Wear Pad Adjustments. . . . . . . . . . . . . . . . . . . . . . 2-13

2-11. Boom Prop Configurations - 30 electric. (Sheet 1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

2-11. Boom Prop Configurations - 35/n35 electric. (Sheet 2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2-11. Boom Prop Configurations - 35/n35 electric. (Sheet 3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2-12. Removal of Cylinder Retainer.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2-13. Removal of Set Screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2-14. Removal of Seals and O-Rings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

2-15. Removal of Piston Seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

2-16. Rod Seal Installation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2-17. Wiper Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2-18. Poly-Pak Piston Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2-19. "O"-Ring Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2-20. Piston Seal Kit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2-21. Steer Cylinder Piston Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2-22. Installing Retainer Ring on Telescope Cylinder Barrel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2-23. Lift Cylinder Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2-24. Upper Boom Lift Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2-25. Mid Boom Lift Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2-26. Lower Boom Lift Cyllinder Removal.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2-27. Upper Telescope Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2-28. Tilt Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

2-29. Pressure Setting Procedures - 30 electric. (Sheet 1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2-29. Pressure Setting Procedures - 35/n35 electric. (Sheet 2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

2-29. Pressure Setting Procedures - 40/n40/45 electric. (Sheet 3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . .2-34

2-30. Swing Bearing Feeler Gauge Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2-31. Swing Bearing Tolerance Boom Placement - 30/35/n35 electric. . . . . . . . . . . . . . . . . . . . . . . . . .2-36

2-31. Swing Bearing Tolerance Boom Placement - 40/n40/45 electric. . . . . . . . . . . . . . . . . . . . . . . . . .2-38

2-32. Swing Bearing Tolerance Measuring Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

2-33. Swing Bearing Torquing Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

2-34. Drive Hub Assembly - 30/35/n35/40/n40/45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

2-35. Drive Brake Assembly - 30/35/n35/40/n40/45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

2-36. Port "P" Location.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

2-37. Synchronizing Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

2-38. Upright Leveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

3120743 – JLG Lift – iii

TABLE OF CONTENTS

2-39. Drive Brake Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

2-40. Drive Axle Drain Plate.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

3-1. Electrical Schematic 30 electric. (Sheet 1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3-1. Electrical Schematic 30 electric. (Sheet 2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3-1. Electrical Schematic 30 electric. (Sheet 3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3-1. Electrical Schematic 30 electric. (Sheet 4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3-2. Electrical Schematic 35/40/45 electric. (Sheet 1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3-2. Electrical Schematic. 35/40/45 electric. (Sheet 2 of 4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-2. Electrical Schematic. 35/40/45 electric. (Sheet 3 of 4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3-2. Electrical Schematic. 35/40/45 electric. (Sheet 4 of 4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3-3. Hydraulic Diagram - 30 electric. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3-4. Hydraulic Diagram - 35 electric. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3-5. Hydraulic Diagram - 40/45 electric.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

TABLE NO. TITLE PAGE NO.

1-1 Hydraulic Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-2 Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-3 Cylinder Specifications.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-4 Cylinder Specifications.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-5 Cylinder Specifications.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-6 Cylinder Specifications.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2-1 Cylinder Piston Nut Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

2-2 Holding Valve Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

2-3 PREVENTIVE MAINTENANCE AND INSPECTION SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

3-1 PLATFORM ASSEMBLY - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2 BOOM ASSEMBLY - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-2 BOOM ASSEMBLY - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-2 BOOM ASSEMBLY - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-2 BOOM ASSEMBLY - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3-3 TURNTABLE ASSEMBLY - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-4 CHASSIS ASSEMBLY - TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3-4 CHASSIS ASSEMBLY - TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3-5 HYDRAULIC SYSTEM - TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-6 ELECTRICAL SYSTEM - TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

iv – JLG Lift – 3120743

TABLE OF CONTENTS (Continued)

This page left intentionally blank.

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-1

SECTION 1. SPECIFICATIONS

1.1 CAPACITIES.

Hydraulic Oil Tank.

4.0 gallons (15.14 liters).

Hydraulic System.

Approximately 4.8 gallons (18.2 liters).

Torque Hubs (2).

17 ounces (0.5 liters).

1.2 COMPONENT DATA.

Battery Charger.

Input, 110 VAC,60 HZ.

Output, 48 VDC (23 Amps.).

Batteries (8).

6 Volt, 370 AmpHour (20 hour rate).

Drive System.

Drive Motor - 36 VDC, 4.1 H.P. @ 1880 rpm. continuous,

rotation - reversible.

Drive Brake- 24 VDC, spring-applied, electrically released.

Tires - 30 electric.

Tires - ST205 75R15, Load Range C, 6 Ply Rating, 70 psi

(4.9 kg/cm

2

).

Foam Filled - 205 75R15, 6 Ply Rating, 70 psi (4.9 kg/cm

2

).

Solid Tires - 26 x 7 x 20 Lug Tread Non marking Com-

pound. (Optional)

Tires - n35/n40 electric.

Solid Tires - 22 x 6 x 16 Lug Tread Dual Service Com-

pound.

Solid Tires - 22 x 6 x 16 Lug Tread Non marking Com-

pound. (Optional)

Tires - 35/40 electric. (Prior to March of 1996)

Tires - ST225 75R15, Load Range D, 8 Ply Rating, 80 psi

(5.5 kg/cm

2

).

Tires - ST225 75R15, Load Range D, 8 Ply Rating, Foam

Filled. (Optional)

Tires - 35/40 electric. (March of 1996 to Present)

Tires - G 78 - 15, Load Range E, 10 Ply Rating, 80 psi (5.5

kg/cm

2

).

Tires - G 78 - 15, Load Range E, 10 Ply Rating, Foam

Filled. (Optional)

Solid Tires - 22 x 6.5 x 16 Lug Tread Non marking Com-

pound. (Optional)

Tires 10 - 16.5 NHS, 8 Ply, 70 psi (4.9 kg/cm

2

).

Tires 10 - 16.5 NHS, 8 Ply, 70 psi (4.9 kg/cm

2

), Foam Filled

Tires - 45 electric.

Tires - LT215 85R16, Load Range E, 10 Ply Rating, 90 psi

(6.2 kg/cm

2

).

Tires - LT215 85R16, Load Range E, 10 Ply Rating, Foam

Filled. (Optional)

Tires 10 - 16.5 NHS, 8 Ply, 70 psi (4.9 kg/cm

2

).

Tires 10 - 16.5 NHS, 8 Ply, 70 psi (4.9 kg/cm

2

), Foam

Filled.

Hydraulic Filter.

Return, 10 Micron.

Hydraulic Pump/Electric Motor Assembly.

Motor - 48 VDC, 2.14 H.P. @ 2700 rpm.

Pump -1.6 cm

3

/rev.

Pump Output - 4.13 lpm @ 137.9 Bar.

1.3 PERFORMANCE DATA.

EE Rated, Certified By U/L.

Travel Speed.

30 electric - 6.4 kph.

35 electric - 4.8 kph.

n35 electric - 4.1 kph.

40 electric - 4.8 kph.

n40 electric - 4.1 kph.

45 electric - 4.2 kph.

Gradeability.

25%.

Maximum Slope

3%

SECTION 1 - SPECIFICATIONS

1-2 – JLG Lift – 3120861

Turning Radius (Inside).

30 electric - 1.33 m.

35 electric - 1.31 m.

n35 electric - 1.60 m.

40 electric - 1.31 m.

n40 electric - 1.60 m.

45 electric - 1.31 m.

Turning Radius (Outside).

30 electric - 3.63 m.

35 electric - 3.63 m.

n35 electric - 3.63 m.

40 electric - 3.63 m.

n40 electric - 3.63 m.

45 electric - 3.63 m.

Upper Boom Speed.

30 electric - Lift Up - 15 - 25 seconds.

30 electric - Lift Down - 17 - 27 seconds.

35/n35 electric - Lift Up - 40 - 50 seconds.

35/n35 electric - Lift Down - 32 - 42 seconds.

40/n40 electric - Lift Up - 40 - 50 seconds.

40/n40 electric - Lift Down - 59 - 69 seconds.

45 electric - Lift Up - 40 - 50 seconds.

45 electric - Lift Down - 39 - 49 seconds.

Lower Boom Speed.

30 electric - Lift Up - 16 - 26 seconds.

30 electric - Lift Down - 19 - 29 seconds.

35/n35 electric - Lift Up - 49 - 59 seconds.

35/n35 electric - Lift Down - 30 - 40 seconds.

40/n40 electric - Lift Up - 50 - 60 seconds.

40/n40 electric - Lift Down - 23 - 29 seconds.

45 electric - Lift Up - 58 - 68 seconds.

45 electric - Lift Down - 28 - 38 seconds.

Swing Speed - 360 Degrees.

30 electric - 55 - 65 seconds.

35/n35 electric - 65 - 75 seconds.

40/n40 electric - 85 - 95 seconds.

45 electric - 85 - 95 seconds.

Machine Weight.

30 electric - 2,164 kg.

35 electric - 4,309 kg.

n35 electric - 10,200 lb. (4,627 kg).

40 electric - 4,853 kg.

n40 electric - 5,366 kg.

45 electric - 5,352 kg.

Max. Tire Load.

30 electric - 1,161 kg.

35 electric - 1,624 kg.

n35 electric - 1,928 kg.

40 electric - 2,132 kg.

n40 electric - 2,343 kg.

45 electric - 2,656 kg.

Machine Height (stowed).

30 electric - 6 ft. 7.0 in. (2.0 m.).

35/n35 electric - 6 ft. 7.0 in. (2.0 m.).

40/n40 electric - 6 ft. 7.0 in. (2.0 m.).

45 electric - 6 ft. 7.0 in. (2.0 m.).

Machine Length (stowed).

30 electric - 4.75 m.

35/n35 electric - 5.18 m.

40 electric - 5.36 m.

n40 electric - 5.28 m.

45 electric - 5.69 m.

Up and Over Platform Height.

30 electric - 5.05 m.

35/n35 electric - 5.46 m.

40/n40 electric - 6.10 m.

45 electric - 7.49 m.

Horizontal Reach Up and Over.

30 electric - 4.09 m.

35/n35 electric - 6.25 m.

40/n40 electric - 6.25 m.

45 electric - 6.91 m.

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-3

Machine Width.

30 electric - 1.75 m.

35 electric - 1.75 m.

n35 electric - 1.50 m.

40 electric - 1.75 m.

n40 electric - 1.50 m.

45 electric - 1.75 m.

Wheel Base.

30 electric - 1.93 m.

35/n35 electric - 2.01 m.

40/n40 electric - 2.01 m.

45 electric - 2.01 m.

Working Height.

30 electric - 9.14 m.

35/n35 electric - 10.67 m.

40/n40 electric - 12.19 m.

45 electric - 13.72 m.

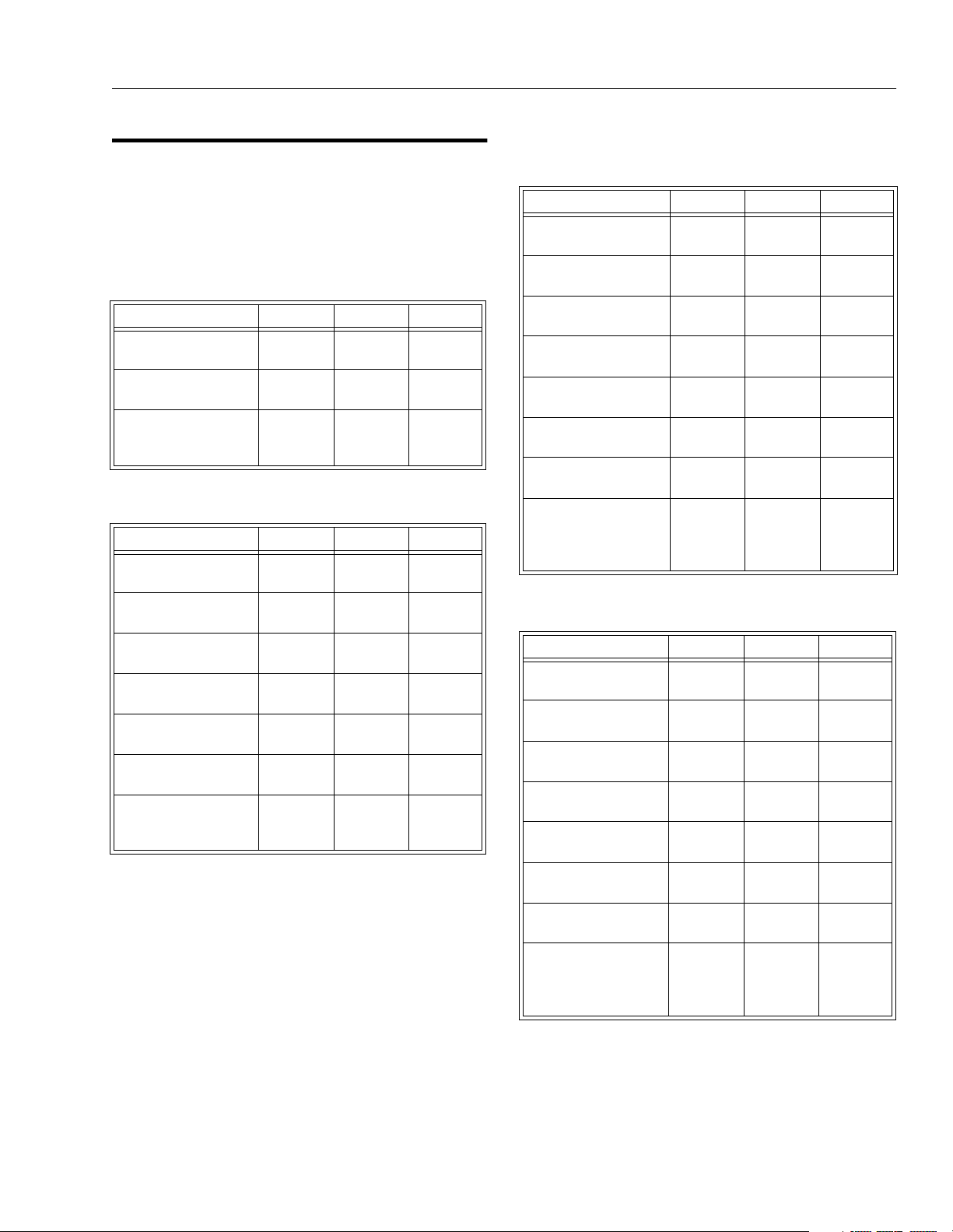

1.4 TORQUE SPECIFICATIONS.

NOTE: *Check swing bearing bolts for security after first 50

hours of operation and every 600 hours thereafter.

(See paragraph 2-16, - Swing Bearing.)

NOTE: When maintenance becomes necessary or a fas-

tener has loosened, refer to the Torque Chart, Figure

1-1, to determine proper torque value.

1.5 LUBRICATION.

Hydraulic Oil.

Table 1-1. Hydraulic Oil.

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system ser-

vice. JLG Industries recommends Mobilfluid 424

hydraulic oil, which has an SAE viscosity index of

152.

NOTE: When temperatures remain consistently below 20

degrees (-7 degrees C), an amount of no. 2 diesel

fuel, not to exceed 20% of system capacity, may be

added to the hydraulic oil reservoir. This diesel fuel

will “thin” the hydraulic oil for easier cold weather

operation, and will almost completely dissipate from

the hydraulic system over a several month period of

time. When cold weather is past, it may be neces-

sary to drain and refill the hydraulic system to rid the

system of any remaining diesel fuel.

NOTE: Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscosities. If use of hydraulic oil other

than Mobilfluid 424 is desired, contact JLG Indus-

tries for proper recommendations.

Description

Torque Value

(Dry)

Interval Hours

A. Bearing To

Chassis

See Note 50/600*

B. Bearing To

Tu r nt a b le

See Note 50/600*

C. Wheel Bolts 122 Nm 150

HYDRAULIC SYSTEM

OPERATING

TEMPERATURE RANGE

SAE VISCOSITY GRADE

0 F to 23 F (-18 C to -5 C) 10W

0 F to 210 F (-18 C to +99 C) 10W-20,10W-30

50 F to 210 F (+10 C to +9 9 C) 20W-20

SECTION 1 - SPECIFICATIONS

1-4 – JLG Lift – 3120861

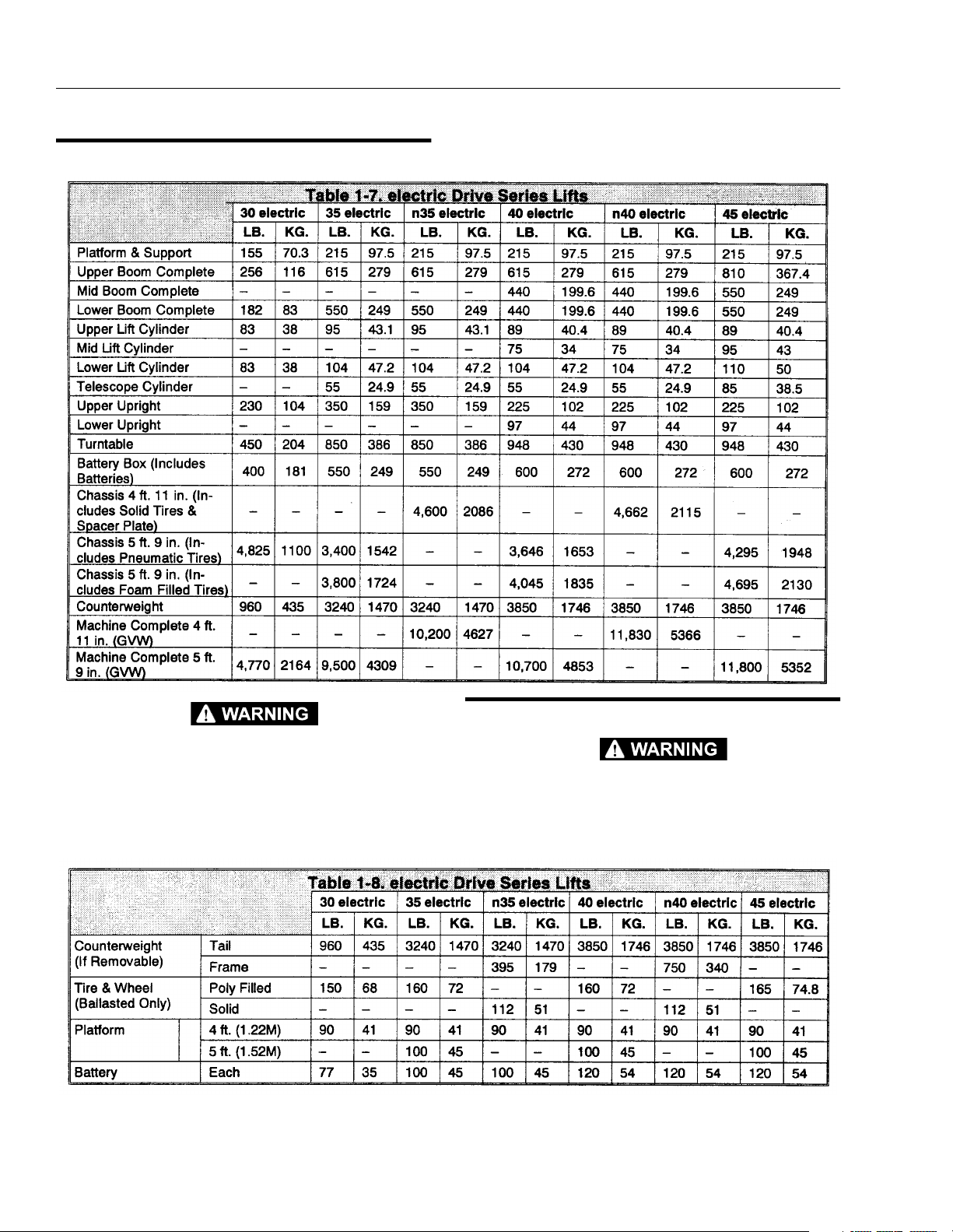

Lubrication Specifications

Table 1-2. Lubrication Specifications.

*MPG may be substituted for these lubricants, if neces-

sary, but service intervals will be reduced.

NOTE: Refer to Lubrication Chart, Figure1-2, for specific

lubrication procedures.

1.6 PRESSURE SETTINGS.

NOTE: Model 30 electric.

Hydro-Air Valve 4640725.

Lift Down Relief - 900 psi (62 bar).

Articulate and Lift Down Relief - 725 psi (49.99 bar).

Swing Relief - 1000 psi (68.95 bar).

Hydro-Air Valve 4640726.

Steer Relief - 1100 psi (75.84 bar).

Main Relief at Pump - 2600 psi (179.27 bar).

NOTE: Model 35/n35 electric.

Hydro-Air Valve 4640843.

Upper Lift Down Relief - 600 psi (41.37 bar).

Lower Lift Down Relief - 600 psi (41.37 bar).

Swing Relief - 1000 psi (68.95 bar).

Telescope In Relief - 2150 psi (148.25 bar).

Platform Level Up Relief - 2500 psi (172.37 bar).

Platform Level Down Relief - 1200 psi (82.74 bar).

Hydro-Air Valve 4640726.

Steer Relief - 1500 psi (103.42 bar).

Main Relief at Pump - 2600 psi (179.27 bar).

NOTE: Model 40/n40/45 electric.

Hydro-Air Valve 4640797.

Upper Lift Down Relief - 650 psi (44.82 bar).

Mid/Lower Lift Down Relief - 1700 psi (117.21 bar).

Swing Relief - 1000 psi (68.95 bar).

Telescope In Relief - 2150 psi (148.25 bar).

Platform Level Up Relief - 2500 psi (172.37 bar).

Platform Level Down Relief - 1200 psi (82.74 bar).

Hydro-Air Valve 4640726.

Steer Relief - 2300 psi (158.59 bar).

Main Relief at Pump - 3200 psi (220.64 bar).

KEY SPECIFICATIONS

MPG Mul tipurpose Grease having a minimum drippin g point

of 350 F (178 C). Exc ellent water resistance and

adhesive qualities, and being of extreme pressure

type. (Timken OK 40 pound s minimum.)

EPGL Extreme Pressure Gear Lube (oi l) meeting API service

classification GL- 5 or MIL-Spec MIL-L-2105.

HO Hydraulic Oil. API service classification GL-3, e.g.

Mobilfluid 424.

OG* Open Gear Lube - Mobil tac 375NC - Aerosol spray

(JLG Part No. 3020036)

BG* Bearing Grease (JLG Part No. 3020029) Mobili th SHA

460.

LL Synthetic Lithium L ubricant, Gredag 741 Grease . (JLG

Part No. 3020022)

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-5

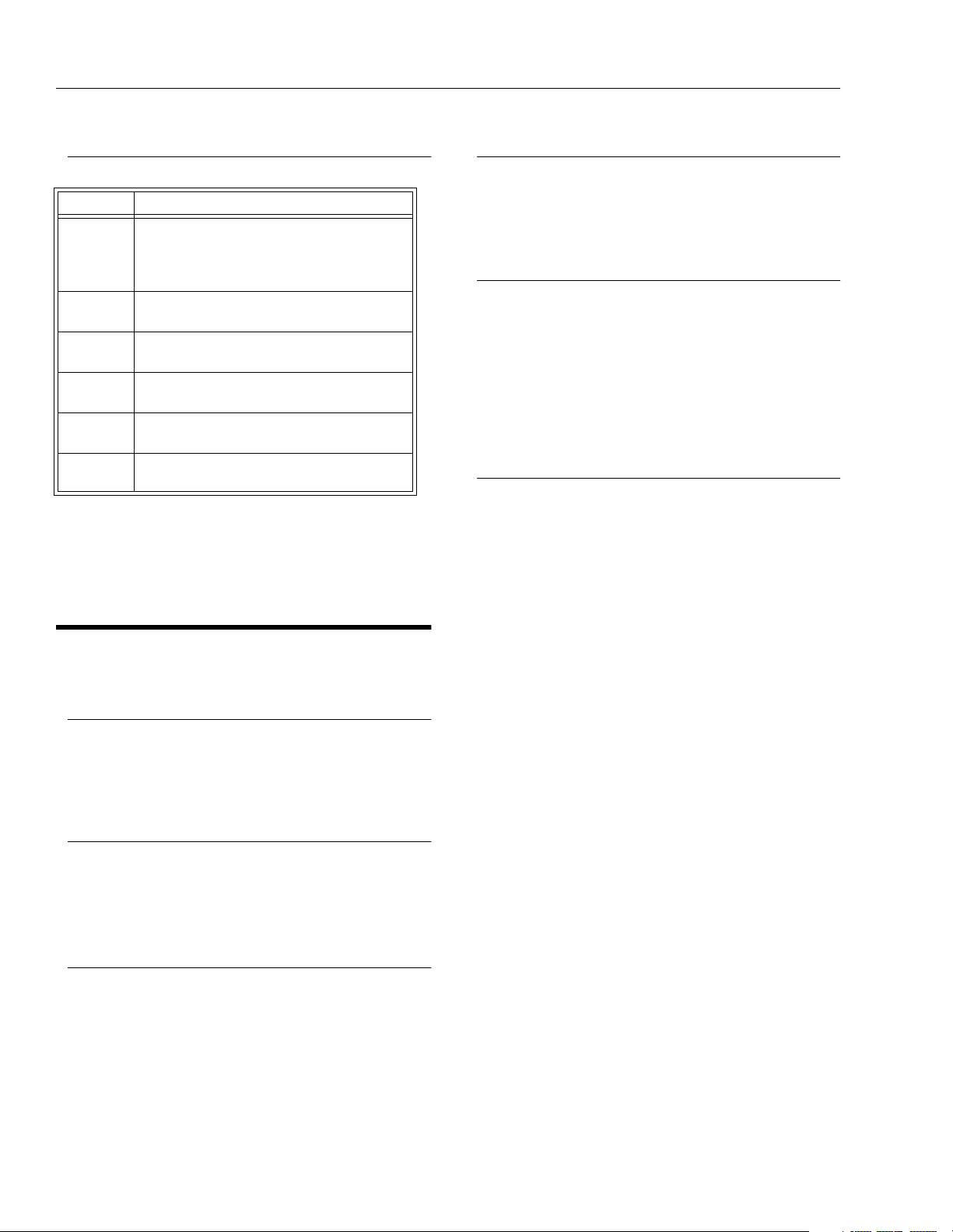

1.7 CYLINDER SPECIFICATIONS.

NOTE: All dimensions are given in inches (in.), with the met-

ric equivalent, millimeters (mm), given in parenthe-

ses.

Table 1-3. Cylinder Specifications.

30 electric

Table 1-4. Cylinder Specifications.

35/n35 electric

Table 1-5. Cylinder Specifications.

40/n40 electric

Table 1-6. Cylinder Specifications.

45 electric

DESCRIPTION BORE STROKE ROD DIA.

Upper Lift Cylinder 3.00

(76.2)

14.62

(371.5)

1.50

(38.1)

Lower Lift Cylinder 3.00

(76.2)

14.62

(371.5)

1.50

(38.1)

Steer Cylinder

(Double Rod)

2.00

(50.8)

3.00

(76.2)

each direction

1.25

(31.8)

each rod

DESCRIPTION BORE STROKE ROD DIA.

Upper Lift Cylinder 3.00

(76.2)

24.4375

(620.7)

1.50

(38.1)

Lower Lift Cylinder 3.50

(88.9)

25.375

(644.5)

2.00

(50.8)

Telescope Cylinder 2.00

(50.8)

79

(2006.6)

1.25

(31.8)

Master Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Slave Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Rotator Cylinder 1.875

(47.6)

15.250

(387.3)

1.00

(25.4)

Steer Cylinder

(Double Rod)

2.00

(50.8)

3.00

(76.2)

each direction

1.25

(31.8)

each rod

DESCRIPTION BORE STROKE ROD DIA.

Upper Lift Cylinder 3.00

(76.2)

28.3125

(719.1)

1.50

(38.1)

Mid Lift Cylinder 3.00

(76.2)

21.25

(539.7)

1.50

(38.1)

Lower Lift Cylinder 3.50

(88.9)

23.1875

(589.0)

2.00

(50.8)

Telescope Cylinder 2.00

(50.8)

79

(2006.6)

1.25

(31.8)

Master Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Slave Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Rotator Cylinder 1.875

(47.6)

15.250

(387.3)

1.00

(25.4)

Steer Cylinder

(Double Rod)

2.00

(50.8)

3.00

(76.2)

each direc-

tion

1.25

(31.8)

each rod

DESCRIPTION BORE STROKE ROD DIA.

Upper Lift Cylinder 3.00

(76.2)

28.3125

(719.1)

1.50

(38.1)

Mid Lift Cylinder 3.00

(76.2)

21.25

(539.7)

1.50

(38.1)

Lower Lift Cylinder 4.00

(101.6)

23.25

(590.5)

2.25

(57.1)

Telescope Cylinder 2.00

(50.8)

92

(2337)

1.25

(31.8)

Master Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Slave Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Rotator Cylinder 1.875

(47.6)

15.250

(387.3)

1.00

(25.4)

Steer Cylinder

(Double Rod)

2.00

(50.8)

3.00

(76.2)

each direc-

tion

1.25

(31.8)

each rod

SECTION 1 - SPECIFICATIONS

1-6 – JLG Lift – 3120861

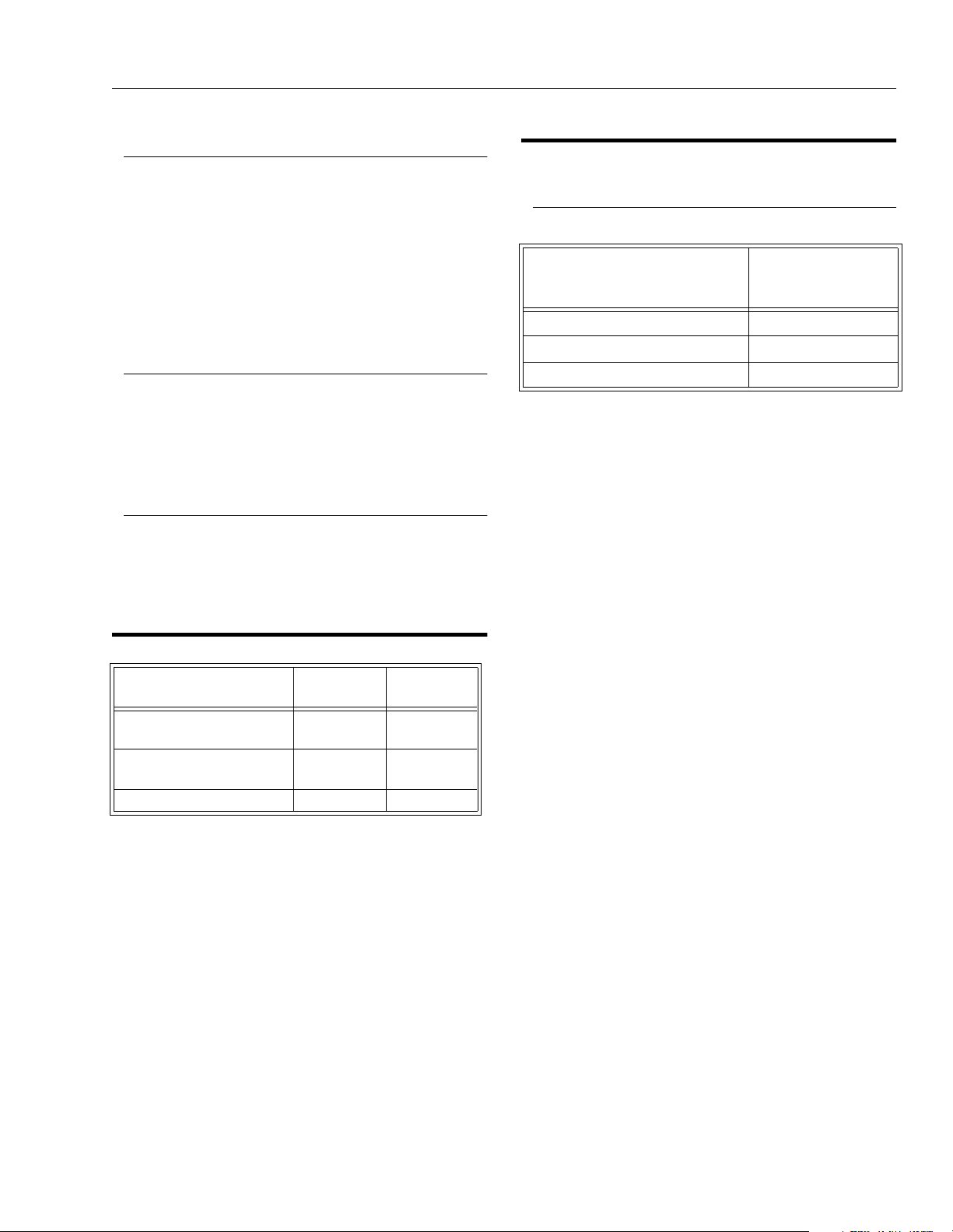

1.8 MAJOR COMPONENT WEIGHTS.

SELECT LIFTING EQUIPMENT WITH CAPACITY CAPABLE OF

SAFELY SUPPORTING WEIGHT.

1.9 CRITICAL STABILITY WEIGHTS.

DO NOT REPLACE ITEMS CRITICAL TO STABILITY WITH ITEMS

OF DIFFERENT WEIGHT OR SPECIFICATION (FOR EXAMPLE:

BATTERIES, FILLED TIRES, PLATFORM) DO NOT MODIFY UNIT IN

ANY WAY TO AFFECT STABILITY.

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-7

1.10 SERIAL NUMBER LOCATIONS.

(SEE FIGURE 1-3)

Model 30/35/n35 electric.

For machine identification, a serial number plate is affixed

to the turntable, facing the platform basket. If the serial

number plate is damaged or missing, the machine serial

number is stamped on the top left side of the frame and

the top left side of the turntable. In addition, the serial

number is stamped on top of the end of the upper boom

at the platform, and lower boom at the upright.

Model 40/n40/45 electric.

For machine identification, a serial number plate is affixed

to the left rear of frame, in front of left rear wheel. If the

serial number plate is damaged or missing, the machine

serial number is stamped on the top left side of the frame

and the top left side of the turntable. In addition, the serial

number is stamped on top of the end of the upper boom,

mid boom, and lower boom at the left rear of the booms.

SECTION 1 - SPECIFICATIONS

1-8 – JLG Lift – 3120861

Figure 1-1. Torque Chart.

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-9

Figure 1-2. Lubrication Chart - 30 electric. (Sheet 1 of 6)

SECTION 1 - SPECIFICATIONS

1-10 – JLG Lift – 3120861

Figure 1-2. Lubrication Chart - 30 electric. (Sheet 2 of 6)

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-11

Figure 1-2. Lubrication Chart - 35/n35 electric. (Sheet 3 of 6)

SECTION 1 - SPECIFICATIONS

1-12 – JLG Lift – 3120861

Figure 1-2. Lubrication Chart - 35/n35 electric. (Sheet 4 of 6)

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-13

Figure 1-2. Lubrication Chart - 40/n40/45 electric. (Sheet 5 of 6)

SECTION 1 - SPECIFICATIONS

1-14 – JLG Lift – 3120861

Figure 1-2. Lubrication Chart - 40/n40/45 electric. (Sheet 6 of 6)

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-15

Figure 1-3. Serial Number Locations - 30 electric. (Sheet 1 of 3)

SECTION 1 - SPECIFICATIONS

1-16 – JLG Lift – 3120861

Figure 1-3. Serial Number Locations - 35/n35 electric. (Sheet 2 of 3)

SECTION 1 - SPECIFICATIONS

3120861 – JLG Lift – 1-17

Figure 1-3. Serial Number Locations - 40/n40/45 electric. (Sheet 3 of 3)

SECTION 1 - SPECIFICATIONS

1-18 – JLG Lift – 3120861

SECTION -

3120861 – JLG Lift – -1

SECTION 2. PROCEDURES

2.1 GENERAL.

This section provides information necessary to perform

maintenance on the aerial platform. Descriptions, tech-

niques and specific procedures are designed to provide

the safest and most efficient maintenance for use by per-

sonnel responsible for ensuring the correct installation

and operation of machine components and systems.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

The maintenance procedures included consist of servic-

ing and component removal and installation, disassembly,

and assembly, inspection, lubrication and cleaning. Infor-

mation on any special tools or test equipment is also pro-

vided where applicable.

2.2 SERVICING AND MAINTENANCE

GUIDELINES.

General.

The following information is provided to assist you in the

use and application of servicing and maintenance proce-

dures contained in this chapter.

Safety and Workmanship.

Your safety and that of others is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

Cleanliness.

1. The most important single item in preserving the

long service life of a machine is to keep dirt and for-

eign materials out of the vital components. Precau-

tions have been taken to safeguard against this.

Shields, covers, seals and filters are provided to

keep oil supplies clean; however, these items must

be maintained on a scheduled basis in order to func-

tion properly.

2. At any time when hydraulic oil lines are discon-

nected, clear adjacent areas as well as the openings

and fittings themselves. As soon as a line or compo-

nent is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or main-

tenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their contain-

ers until they are ready to be used.

Component Removal and Installation.

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpendicular as possible to top of part being

lifted.

2. Should it be necessary to remove a component on

an angle, keep in mind that the capacity of an eye-

bolt or similar bracket lessens, as the angle between

the supporting structure and the component

becomes less than 90 degrees.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc. have been

removed and that no adjacent parts are interfering.

Component Disassembly and Reassembly.

When disassembling or reassembling a component, com-

plete the procedural steps in sequence. Do not partially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, other than

those recommended, without obtaining proper approval.

Pressure Fit Parts.

When assembling pressure fit parts, use an “anti-seize” or

molybdenum disulfide base compound to lubricate the

mating surface.

Bearings.

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bearing.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored or burned.

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to be installed.

SECTION -

-2 – JLG Lift – 3120861

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bear-

ing is to be installed on a shaft, apply pressure to the

inner race.

Gaskets.

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application.

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat treated bolts, studs and steel nuts, in accor-

dance with recommended shop practices (See Fig-

ure 1-1).

Hydraulic Lines and Electrical Wiring.

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when disconnecting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System.

1. Keep the system clean. If evidence of metal or rub-

ber particles are found in the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication.

Service applicable components with the amount, type,

and grade of lubricant recommended in this manual, at

the specified interval. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

Batteries.

Clean batteries using a non-metallic brush and a solution

of baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry batteries and coat terminals with

an anti-corrosion compound.

Lubrication and Servicing.

Components and assemblies requiring lubrication and

servicing are shown in Lubrication Chart.

2.3 LUBRICATION INFORMATION.

Hydraulic System.

1. The primary enemy of a hydraulic system is contam-

ination. Contaminants enter the system by various

means, e.g.; inadequate hydraulic oil, allowing mois-

ture, grease, filings, sealing components, sand, etc.

to enter when performing maintenance, or by per-

mitting the pump to cavitate due to insufficient sys-

tem warm-up.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty opera-

tion. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced at the specified intervals

required in Figure 1-2. Always examine filters for evi-

dence of metal particles.

3. Cloudy oils indicate a high moisture content which

permits organic growth, resulting in oxidation or cor-

rosion. If this condition occurs, the system must be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is oper-

ating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing compo-

nents.

Hydraulic Oil.

1. Refer to Table 1-1 for recommendations for viscosity

ranges.

SECTION -

3120861 – JLG Lift – -3

2. JLG recommends Mobilfluid 424 Hydraulic Oil,

which has an SAE viscosity of 10W-30 and a viscos-

ity index of 152.

NOTE: Start-up of hydraulic system with oil temperatures

below -15 degrees F. is not recommended. If it is

necessary to start the system in a sub-zero environ-

ment, it will be necessary to heat the oil with a low

density 100VAC heater to a minimum temperature of

-15 degrees F.

3. The only exception to the above is to drain and fill

the system with Mobil DTE11 oil or its equivalent.

This will allow start up at temperatures down to -20

degrees F. However, use of this oil will give poor per-

formance at temperatures above 120 degrees F.

Systems using DTE11 oil should not be operated at

temperatures above 200 degrees F. under any con-

dition.

Changing Hydraulic Oil.

1. Use of any of the recommended hydraulic oils elimi-

nates the need for changing the oil on a regular

basis. However, filter elements must be changed

after the first 50 hours of operation and every 300

hours thereafter. If it is necessary to change the oil,

use only those oils meeting or exceeding the specifi-

cations appearing in this manual. If unable to obtain

the same type of oil supplied with the machine, con-

sult local supplier for assistance in selecting the

proper equivalent. Avoid mixing petroleum and syn-

thetic base oils. JLG Industries recommends chang-

ing the hydraulic oil every two years.

2. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contami-

nants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

3. While the unit is shut down, a good preventive main-

tenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

Lubrication Specifications

Specified lubricants, as recommended by the component

manufacturers, are always the best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose requirements. Should

any question arise regarding the use of greases in mainte-

nance stock, consult your local supplier for evaluation.

Refer to Table 1-2 for an explanation of the lubricant key

designations appearing in the Lubrication Chart.

2.4 CYLINDERS - THEORY OF OPERATION.

Systems Incorporating Double Acting

Cylinders.

30 electric - Upper Boom Lift, Lower Boom Lift, and

Steer.

35/n35 electric - Upper Boom Lift, Lower Boom Lift,

Telescope, Slave, Master, Rotator, and Steer.

40/n40/45 electric - Upper Boom Lift, Mid Boom Lift,

Lower Boom Lift, Telescope, Slave, Master, Rotator,

and Steer.

A double acting cylinder is one that requires oil flow to

operate the cylinder rod in both directions. Directing oil

(by actuating the corresponding control valve to the pis-

ton side of the cylinder) forces the piston to travel toward

the rod end of the barrel, extending the cylinder rod (pis-

ton attached to rod). When the oil flow is stopped, move-

ment of the rod will stop. By directing oil to the rod side of

the cylinder, the piston will be forced in the opposite direc-

tion and the cylinder rod will retract.

Holding valves are used in the Lift circuits to prevent

retraction of the cylinder rod should a hydraulic line rup-

ture or leak develop between the cylinder and its related

control valve.

2.5 VALVES - THEORY OF OPERATION.

Control Valves.

30 electric - Control Valve 4640725 this valve controls

Swing, Lower Lift, and Upper Lift.

35/n35 electric - Control Valve 4640843 this valve con-

trols Platform, Telescope, Swing, Lower Lift, and Upper

Lift.

40/n40/45 electric - Control Valve 4640797 this valve

controls Platform, Telescope, Swing, Lower Lift, and

Upper Lift.

It consists of cartridge type valves in an anodized alumi-

num manifold. The cartridge valves provide for control of

flow, volume of flow and pressure in the hydraulic system.

The directional control valves are solenoid operated, three

position, 4-way sliding spool type valves. One valve is pro-

vided for each of the three functions. Energizing one of

the electrical coils on a valve will divert the supply of

hydraulic oil to provide motion of that function in one

direction. Energizing the other coil will divert the oil for

motion in the other direction. When neither coil is ener-

gized, the supply of hydraulic oil is blocked.

Flow control valves in the lift circuits provide for control of

the rate of flow when the oil is flowing out of the cap ends

of the cylinders (the load is being lowered). An adjusting

screw on each cartridge flow control valve allows the rate

of flow (speed) to be adjusted. When oil is flowing into the

cap end of the lift cylinders, an internal check valve feature

allows unrestricted flow.

SECTION -

-4 – JLG Lift – 3120861

Pressure relief valves limit the pressure in the swing circuit

and the rod end of each lift cylinder. When the pressure in

one of those circuits reaches the set point of the valve, the

valve opens, allowing enough flow to return to the reser-

voir so that the set pressure is not exceeded. An adjusting

screw on each cartridge relief valve allows the set pres-

sure to be adjusted.

The aluminum manifold provides the passages through

which the hydraulic oil is diverted to provide the desired

movement of the actuators. No moving parts of the valves

slide against the manifold and so it is not subject to wear.

Steer Valve 4640726.

(30/35/n35/40/n40/45 electric)

This valve controls the STEER function. It consists of

screw-in cartridge type valves in an anodized aluminum

manifold. The cartridge valves provide for control of direc-

tion of flow and pressure in the STEER hydraulic circuit.

The directional control valve is a solenoid operated, three

position, 4-way sliding spool type valve. Energizing one of

the electrical coils on the valve will divert the supply of

hydraulic oil to provide steering in one direction. Energiz-

ing the other coil will divert the oil for steering in the other

direction. When neither coil is energized, the supply of

hydraulic oil is blocked.

A pressure relief valve limits the pressure in the steer cir-

cuit. When the pressure reaches the set point of the valve,

the valve opens, allowing enough flow to return to the res-

ervoir so that pressure is not exceeded. An adjusting

screw on the cartridge relief valve allows the set pressure

to be adjusted.

The aluminum manifold provides the passages through

which hydraulic oil is diverted to provide the desired

movement of the steer cylinder. No moving parts of the

valves slide against the manifold and so it is not subject to

any wear.

2.6 MOTOR CONTROLLER.

Modes of Operation.

1. Traction Motor Drive.

a. Drive in either forward or reverse will start only if

the following conditions are satisfied:

1. Function switches off.

2. No procedure or diagnostic faults present.

3. FWD or REV selected as appropriate.

b. Once in “drive” mode, activating a function

switch shall not cause drive mode to be exited,

the pump/traction contactor drive shall not be

energized (shall be left at the traction position). If

a function switch is selected during traction, a

procedure fault will occur when neutral is

selected, remaining until a function switch and

both directions are no longer selected.

c. When neutral is selected, the controller will con-

trol smooth stopping of the machine, using plug

braking, before the electric brake is allowed to

operate.

d. If a function switch is activated in neutral, when

the vehicle has stopped and the brake is

applied, then pump mode will become opera-

tional.

1. Pump Motor Drive.

a. Pump motor drive will start only if the following

conditions are satisfied:

1. FWD and REV switch off.

2. Traction mode off (brake applied).

a. Pump drive shall only be enabled when the

direction selector inputs are in neutral and the

machine is stationary. Once pump drive mode

has been entered, then the status of the direc-

tion selector inputs shall no longer interlock

pump operation. If a direction switch is selected

during pump drive, a procedure fault will occur

when the function switch is no longer selected,

remaining until both directions and the function

switch are no longer selected.

Features.

1. Features in Traction Mode.

a. Maximum Speed Control.

The controller incorporates a function to limit the maxi-

mum speed of the machine to a percentage of maximum

possible speed. The function operates in such a manner

as to control vehicle speed by limiting the percentage on

of the switching device to keep the machine speed below

the maximum permitted value or, if required, to apply vari-

able plug braking to restrict machine speed when travel-

ing down a grade. The speed is controlled based on the

percentage of accelerator input.

1. Features in Pump Mode.

a. Proportional Control of Pump Motor Speed.

The pump motor speed shall be controlled by

varying the percentage on of the switching ele-

ment in relation to a separate pump accelerator

input.

b. Soft Start.

The pump motor speed control incorporates a

“soft start” facility by applying acceleration delay

to changes in the applied percentage on of the

switching element.

Loading...

Loading...