fanuc 30iB, 31i B, 32i- B Parameter Manual

FANUC Series 30+-MODEL B

FANUC Series 31+-MODEL B

FANUC Series 32+-MODEL B

PARAMETER MANUAL

B-64490EN/03

•No part of this manual may be reproduced in any form.

•All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and Foreign Trade Law”. The export of Series 30i-B, Series 31i-B5 from Japan is subject to an export license by the government of Japan. Other models in this manual may also be subject to export controls.

Further, re-export to another country may be subject to the license of the government of the country from where the product is re-exported. Furthermore, the product may also be controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters. However, we cannot describe all the matters which must not be done, or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be regarded as ”impossible”.

B-64490EN/03 |

DEFINITION OF WARNING, CAUTION, AND NOTE |

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine. Precautions are classified into Warning and Caution according to their bearing on safety. Also, supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

•Read this manual carefully, and store it in a safe place.

s-1

B-64490EN/03 |

PREFACE |

PREFACE

Applicable models

The models covered by this manual, and their abbreviations are :

Model name |

|

Abbreviation |

|

FANUC Series 30i–B |

30i –B |

|

Series 30i |

FANUC Series 31i–B |

31i –B |

|

Series 31i |

FANUC Series 31i–B5 |

31i –B5 |

|

|

|

|

||

FANUC Series 32i–B |

32i –B |

|

Series 32i |

NOTE

1For an explanatory purpose, the following descriptions may be used according to the types of path control used:

-T series: For the lathe system

-M series: For the machining center system

2Unless otherwise noted, the model names 31i-B, 31i-B5, and 32i-B are collectively referred to as 30i. However, this convention is not necessarily observed when item 3 below is applicable.

3Some functions described in this manual may not be applied to some products. For details, refer to the DESCRIPTIONS (B-64482EN).

Related manuals of Series 30i- MODEL B Series 31i- MODEL B Series 32i- MODEL B

The following table lists the manuals related to Series 30i-B, Series 31i-B, Series 32i-B. This manual is indicated by an asterisk(*).

Table 1 Related manuals

Manual name |

Specification number |

|

DESCRIPTIONS |

B-64482EN |

|

CONNECTION MANUAL (HARDWARE) |

B-64483EN |

|

CONNECTION MANUAL (FUNCTION) |

B-64483EN-1 |

|

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) |

B-64484EN |

|

OPERATOR’S MANUAL (For Lathe System) |

B-64484EN-1 |

|

OPERATOR’S MANUAL (For Machining Center System) |

B-64484EN-2 |

|

MAINTENANCE MANUAL |

B-64485EN |

|

PARAMETER MANUAL |

B-64490EN |

* |

Programming

Macro Executor PROGRAMMING MANUAL

Macro Compiler PROGRAMMING MANUAL

C Language Executor PROGRAMMING MANUAL

B-63943EN-2 B-66263EN B-63943EN-3

PMC

|

PMC PROGRAMMING MANUAL |

B-64513EN |

|

|

|

Network |

|

|

|

|

PROFIBUS-DP Board CONNECTION MANUAL |

B-63993EN |

|

|

|

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL |

B-64014EN |

|

|

|

DeviceNet Board CONNECTION MANUAL |

B-64043EN |

|

|

|

FL-net Board CONNECTION MANUAL |

B-64163EN |

|

|

|

CC-Link Board CONNECTION MANUAL |

B-64463EN |

|

|

p-1

PREFACE |

B-64490EN/03 |

||

|

|

|

|

|

Manual name |

Specification number |

|

|

Operation guidance function |

|

|

|

MANUAL GUIDE i |

B-63874EN |

|

|

(Common to Lathe System/Machining Center System) OPERATOR’S MANUAL |

|

|

|

MANUAL GUIDE i (For Machining Center System) OPERATOR’S MANUAL |

B-63874EN-2 |

|

|

MANUAL GUIDE i (Set-up Guidance Functions) OPERATOR’S MANUAL |

B-63874EN-1 |

|

|

Dual Check Safety |

|

|

|

Dual Check Safety CONNECTION MANUAL |

B-644483EN-2 |

|

Related manuals of SERVO MOTOR αi/βi series |

|

|

|

The following table lists the manuals related to SERVO MOTOR αi/βi series |

|

|

|

|

Table 2 Related manuals |

|

|

|

Manual name |

Specification number |

|

|

FANUC AC SERVO MOTOR αi series DESCRIPTIONS |

B-65262EN |

|

|

FANUC AC SERVO MOTOR αi series / FANUC AC SERVO MOTOR βi series / |

|

|

|

FANUC LINEAR MOTOR LiS series / |

B-65270EN |

|

|

FANUC SYNCHRONOUS BUILT-IN SERVO MOTOR DiS series |

||

|

|

|

|

|

PARAMETER MANUAL |

|

|

|

FANUC AC SPINDLE MOTOR αi series DESCRIPTIONS |

B-65272EN |

|

|

FANUC AC SPINDLE MOTOR αi/βi series, BUILT-IN SPINDLE MOTOR Bi series |

B-65280EN |

|

|

PARAMETER MANUAL |

||

|

|

|

|

|

FANUC SERVO AMPLIFIER αi series DESCRIPTIONS |

B-65282EN |

|

|

FANUC AC SERVO MOTOR αi series / FANUC AC SPINDLE MOTOR αi series / |

B-65285EN |

|

|

FANUC SERVO AMPLIFIER αi series MAINTENANCE MANUAL |

||

|

|

|

|

CNCs that are described in this manual can be connected to following servo motors and spindle motors. This manual mainly assumes that the FANUC SERVO MOTOR αi series of servo motor is used. For servo motor and spindle information, refer to the manuals for the servo motor and spindle that are actually connected.

p-2

|

B-64490EN/03 |

|

TABLE OF CONTENTS |

|||

|

TABLE OF CONTENTS |

|

|

|||

|

DEFINITION OF WARNING, CAUTION, AND NOTE ................................. |

s-1 |

||||

|

PREFACE |

.................................................................................................... |

|

p-1 |

||

|

1 |

DISPLAYING PARAMETERS................................................................. |

1 |

|

||

|

2 SETTING PARAMETERS FROM MDI .................................................... |

2 |

|

|||

|

3 INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE |

|

|

|||

|

|

RS232C INTERFACE.............................................................................. |

4 |

|

||

|

|

3.1 |

OUTPUTTING PARAMETERS THROUGH THE RS232C INTERFACE....... |

4 |

|

|

|

|

3.2 |

INPUTTING PARAMETERS THROUGH THE RS232C INTERFACE........... |

5 |

|

|

|

|

3.3 |

I/O FORMATS ............................................................................................... |

6 |

|

|

|

|

|

3.3.1 |

Keywords ................................................................................................................. |

6 |

|

|

|

|

3.3.2 |

Inch/Metric Switching.............................................................................................. |

7 |

|

|

|

|

3.3.3 |

Bit Format................................................................................................................. |

7 |

|

|

|

|

3.3.4 |

Bit Machine Group Format ...................................................................................... |

7 |

|

|

|

|

3.3.5 |

Bit Path Format ........................................................................................................ |

8 |

|

|

|

|

3.3.6 |

Bit Axis Format ........................................................................................................ |

8 |

|

|

|

|

3.3.7 |

Bit Spindle Format ................................................................................................... |

9 |

|

|

|

|

3.3.8 |

Byte/Word/Two-Word Format................................................................................. |

9 |

|

|

|

|

3.3.9 |

Byte/Word/Two-Word Machine Group Format....................................................... |

9 |

|

|

|

|

3.3.10 |

Byte/Word/Two-Word Path Format....................................................................... |

10 |

|

|

|

|

3.3.11 |

Byte/Word/Two-Word Axis Format ...................................................................... |

10 |

|

|

|

|

3.3.12 |

Byte/Word/Two-Word Spindle Format.................................................................. |

11 |

|

|

|

|

3.3.13 |

Real Number Format .............................................................................................. |

11 |

|

|

|

|

3.3.14 |

Real Number Machine Group Format.................................................................... |

12 |

|

|

|

|

3.3.15 |

Real Number Path Format ...................................................................................... |

12 |

|

|

|

|

3.3.16 |

Real Number Axis Format...................................................................................... |

13 |

|

|

|

|

3.3.17 |

Real Number Spindle Format................................................................................. |

13 |

|

|

|

|

3.3.18 |

Start and End of a Record....................................................................................... |

14 |

|

|

4 |

DESCRIPTION OF PARAMETERS ...................................................... |

15 |

|

||

|

|

4.1 |

INPUT TYPE................................................................................................ |

15 |

|

|

|

|

4.2 |

DATA TYPE................................................................................................. |

15 |

|

|

|

|

4.3 |

REPRESENTATION OF PARAMETERS .................................................... |

16 |

|

|

|

|

4.4 |

STANDARD PARAMETER SETTING TABLES........................................... |

17 |

|

|

|

|

4.5 |

PARAMETERS OF SETTING...................................................................... |

20 |

|

|

|

|

4.6 |

PARAMETERS OF RS232C INTERFACE .................................................. |

22 |

|

|

|

|

|

4.6.1 |

Parameters Common to All Channels .................................................................... |

23 |

|

|

|

|

4.6.2 |

Parameters of Channel 1 (I/O CHANNEL=0) ....................................................... |

27 |

|

|

|

|

4.6.3 |

Parameters of Channel 1 (I/O CHANNEL=1) ....................................................... |

28 |

|

|

|

|

4.6.4 |

Parameters of Channel 2 (I/O CHANNEL=2) ....................................................... |

29 |

|

|

|

4.7 |

PARAMETERS OF CNC SCREEN DISPLAY FUNCTIONS........................ |

29 |

|

|

|

|

4.8 |

PARAMETERS OF ETHERNET/DATA SERVER FUNCTIONS.................. |

30 |

|

|

|

|

4.9 |

PARAMETERS OF POWER MATE CNC.................................................... |

33 |

|

|

|

|

4.10 PARAMETERS OF ETHERNET/FL-net FUNCTIONS................................. |

34 |

|

||

|

|

4.11 PARAMETERS OF SYSTEM CONFIGURATION ....................................... |

35 |

|

||

c-1

TABLE OF CONTENTS |

B-64490EN/03 |

||

4.12 |

PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM (1 OF 3) |

...... 37 |

|

4.13 |

PARAMETERS OF COORDINATE SYSTEM (1 OF 2) ............................... |

|

48 |

4.14 |

PARAMETERS OF STORED STROKE CHECK ......................................... |

|

55 |

4.15 |

PARAMETERS OF THE CHUCK AND TAIL STOCK BARRIER ................. |

|

60 |

4.16 |

PARAMETERS OF FEEDRATE .................................................................. |

|

65 |

4.17 |

PARAMETERS OF ACCELERATION/DECELERATION CONTROL |

.......... |

79 |

4.18 |

PARAMETERS OF SERVO (1 OF 2) .......................................................... |

|

94 |

4.19 |

PARAMETERS OF DI/DO (1 OF 2)........................................................... |

|

128 |

4.20 |

PARAMETERS OF DISPLAY AND EDIT (1 OF 5) .................................... |

|

138 |

4.21 |

PARAMETERS OF PROGRAMS (1 OF 4)................................................ |

|

169 |

4.22 |

PARAMETERS OF PITCH ERROR COMPENSATION ............................ |

|

184 |

4.23 |

PARAMETERS OF SPINDLE CONTROL ................................................. |

|

192 |

4.24 |

PARAMETERS OF TOOL COMPENSATION (1 OF 3) ............................. |

|

232 |

4.25 |

PARAMETERS OF CANNED CYCLES..................................................... |

|

254 |

|

4.25.1 Parameters of Canned Cycle for Drilling (1 of 2) ................................................ |

|

254 |

|

4.25.2 Parameters of Thread Cutting Cycle .................................................................... |

|

261 |

|

4.25.3 Parameters of Multiple Repetitive Canned Cycle ................................................ |

|

261 |

|

4.25.4 Parameters of Canned Cycle for Drilling (2 of 2) ................................................ |

|

266 |

|

4.25.5 Parameters of Canned Cycle for Grinding (for Grinding Machine)..................... |

|

270 |

4.26 |

PARAMETERS OF RIGID TAPPING ........................................................ |

|

274 |

4.27 |

PARAMETERS OF SCALING/COORDINATE ROTATION ....................... |

|

287 |

4.28 |

PARAMETERS OF SINGLE DIRECTION POSITIONING......................... |

|

289 |

4.29 |

PARAMETERS OF POLAR COORDINATE INTERPOLATION ................ |

|

289 |

4.30 |

PARAMETERS OF NORMAL DIRECTION CONTROL............................. |

|

290 |

4.31 |

PARAMETERS OF INDEX TABLE INDEXING.......................................... |

|

293 |

4.32 |

PARAMETERS OF INVOLUTE INTERPOLATION ................................... |

|

295 |

4.33 |

PARAMETERS OF EXPONENTIAL INTERPOLATION ............................ |

|

296 |

4.34 |

PARAMETERS OF FLEXIBLE SYNCHRONOUS CONTROL (1 OF 2) .... |

297 |

|

4.35 |

PARAMETERS OF STRAIGHTNESS COMPENSATION (1 OF 2) ........... |

|

300 |

4.36 |

PARAMETERS OF INCLINATION COMPENSATION .............................. |

|

303 |

4.37 |

PARAMETERS OF CUSTOM MACROS................................................... |

|

304 |

4.38 |

PARAMETERS OF PATTERN DATA INPUT ............................................ |

|

325 |

4.39 |

PARAMETERS OF POSITIONING BY OPTIMUM ACCELERATION ....... |

326 |

|

4.40 |

PARAMETERS OF SKIP FUNCTION ....................................................... |

|

328 |

4.41 |

PARAMETERS OF EXTERNAL DATA INPUT/OUTPUT .......................... |

|

339 |

4.42 |

PARAMETERS OF FINE TORQUE SENSING.......................................... |

|

340 |

4.43 |

PARAMETERS OF MANUAL HANDLE RETRACE (1 OF 2) .................... |

|

341 |

4.44 |

PARAMETERS OF GRAPHIC DISPLAY (1 OF 5) .................................... |

|

346 |

4.45 |

PARAMETERS OF SCREEN DISPLAY COLORS (1 OF 2)...................... |

|

348 |

4.46 |

PARAMETERS OF RUN HOUR AND PARTS COUNT DISPLAY............. |

|

349 |

4.47 |

PARAMETERS OF TOOL MANAGEMENT FUNCTIONS (1 OF 2)........... |

|

352 |

4.48 |

PARAMETERS OF TOOL LIFE MANAGEMENT (1 OF 2)........................ |

|

352 |

4.49 |

PARAMETERS OF POSITION SWITCH FUNCTIONS ............................. |

|

361 |

4.50PARAMETERS OF MANUAL OPERATION AND AUTOMATIC

OPERATION.............................................................................................. |

363 |

4.51 PARAMETERS OF MANUAL HANDLE (1 OF 2) ...................................... |

365 |

c-2

B-64490EN/03 |

TABLE OF CONTENTS |

4.52PARAMETERS OF REFERENCE POSITION WITH MECHANICAL

|

STOPPER ................................................................................................. |

370 |

4.53 |

PARAMETERS OF SOFTWARE OPERATOR'S PANEL .......................... |

372 |

4.54 |

PARAMETERS OF PROGRAM RESTART (1 OF 2)................................. |

375 |

4.55 |

PARAMETERS OF HIGH-SPEED CYCLE CUTTING ............................... |

376 |

4.56 |

PARAMETERS OF ROTARY TABLE DYNAMIC FIXTURE OFFSET ....... |

384 |

4.57 |

PARAMETERS OF POLYGON TURNING ................................................ |

385 |

4.58 |

PARAMETERS OF THE ELECTRONIC GEAR BOX (EGB) ..................... |

392 |

4.59 |

PARAMETERS OF AXIS CONTROL BY PMC (1 OF 3) ........................... |

403 |

4.60 |

PARAMETERS OF MULTI-PATH CONTROL ........................................... |

412 |

4.61 |

PARAMETERS OF INTERFERENCE CHECK BETWEEN PATHS .......... |

414 |

4.62PARAMETERS OF SYNCHRONOUS/COMPOSITE CONTROL AND

|

SUPERIMPOSED CONTROL (1 OF 3) ..................................................... |

418 |

4.63 |

PARAMETERS OF ANGULAR AXIS CONTROL ...................................... |

431 |

4.64 |

PARAMETERS OF AXIS SYNCHRONOUS CONTROL ........................... |

433 |

4.65PARAMETERS OF SEQUENCE NUMBER COMPARISON AND STOP.. 442

4.66PARAMETERS OF CHOPPING/HIGH PRECISION OSCILLATION

|

FUNCTION ................................................................................................ |

442 |

4.67 |

PARAMETERS OF AI CONTOUR CONTROL (1 OF 2)............................ |

444 |

4.68 |

PARAMETERS OF HIGH-SPEED POSITION SWITCH (1 OF 2) ............. |

448 |

4.69 |

OTHER PARAMETERS ............................................................................ |

451 |

4.70 |

PARAMETERS OF MAINTENANCE ......................................................... |

457 |

4.71PARAMETERS OF THE INCORRECT OPERATION PREVENTION

|

FUNCTION ................................................................................................ |

459 |

4.72 |

PARAMETERS OF AUTOMATIC DATA BACKUP.................................... |

466 |

4.73 |

PARAMETERS OF AXIS CONTROL ........................................................ |

467 |

4.74 |

PARAMETERS OF PARALLEL AXIS CONTROL ..................................... |

469 |

4.75 |

PARAMETERS OF AXIS SWITCHING ..................................................... |

469 |

4.76 |

PARAMETERS OF TOOL RETRACT AND RECOVER ............................ |

470 |

4.77 |

PARAMETERS OF SCREEN DISPLAY COLORS (2 OF 2)...................... |

470 |

4.78 |

PARAMETERS OF HIGH-SPEED SMOOTH TCP (1 OF 2)...................... |

471 |

4.79 |

PARAMETERS OF DUAL CHECK SAFETY (1 OF 2)............................... |

472 |

4.80 |

PARAMETERS OF WAVEFORM DIAGNOSIS ......................................... |

472 |

4.81PARAMETERS OF THREE-DIMENSIONAL ROTARY ERROR

|

COMPENSATION...................................................................................... |

473 |

4.82 |

PARAMETERS OF 3-DIMENSIONAL ERROR COMPENSATION ........... |

475 |

4.83 |

PARAMETERS OF 3-DIMENSIONAL MACHINE POSITION |

|

|

COMPENSATION...................................................................................... |

477 |

4.84PARAMETERS OF ROTATION AREA INTERFERENCE CHECK

|

(1 OF 2) ..................................................................................................... |

479 |

4.85 |

PARAMETERS OF BUILT-IN 3D INTERFERENCE CHECK .................... |

483 |

4.86 |

PARAMETERS OF SPINDLE CONTROL WITH SERVO MOTOR ........... |

517 |

4.87 |

PARAMETERS OF PATH TABLE OPERATION ....................................... |

523 |

4.88PARAMETERS OF WORKPIECE SETTING ERROR COMPENSATION

(1 OF 2) ..................................................................................................... |

526 |

c-3

TABLE OF CONTENTS |

B-64490EN/03 |

4.89PARAMETERS OF LINEAR INCLINATION COMPENSATION

|

FUNCTION ................................................................................................ |

527 |

4.90 |

PARAMETERS OF TILTED WORKING PLANE COMMAND.................... |

528 |

4.91 |

PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM (2 OF 3) .... |

529 |

4.92 |

PARAMETERS OF DI/DO (2 OF 2)........................................................... |

530 |

4.93PARAMETERS OF FEEDRATE CONTROL AND

|

ACCELERATION/DECELERATION CONTROL........................................ |

530 |

4.94 |

PARAMETERS OF PROGRAM RESTART (2 OF 2)................................. |

531 |

4.95 |

PARAMETERS OF TOOL CENTER POINT CONTROL ........................... |

532 |

4.96PARAMETERS OF MACHINE CONFIGURATION SELECTING

FUNCTION ................................................................................................ |

535 |

4.97 PARAMETERS OF COORDINATE SYSTEM (2 OF 2) ............................. |

536 |

4.98PARAMETERS OF SYNCHRONOUS/COMPOSITE CONTROL AND

|

SUPERIMPOSED CONTROL (2 OF 3) ..................................................... |

538 |

4.99 |

PARAMETERS OF PROGRAMS (2 OF 4)................................................ |

538 |

4.100 |

PARAMETERS OF DISPLAY AND EDIT (2 OF 5) .................................... |

539 |

4.101 |

PARAMETERS OF EMBEDDED MACRO (1 OF 2) .................................. |

545 |

4.102 |

PARAMETERS OF DISPLAY AND EDIT (3 OF 5) .................................... |

546 |

4.103 |

PARAMETERS OF GRAPHIC DISPLAY (2 OF 5) .................................... |

549 |

4.104 |

PARAMETERS OF DISPLAY AND EDIT (4 OF 5) .................................... |

553 |

4.105 |

PARAMETERS OF TOOL COMPENSATION (2 OF 3) ............................. |

563 |

4.106 |

PARAMETERS OF OPTIMUM TORQUE |

|

|

ACCELERATION/DECELERATION FOR RIGID TAPPING...................... |

566 |

4.107 |

PARAMETERS OF ARBITRARY SPEED THREADING............................ |

569 |

4.108 |

PARAMETERS OF PROGRAMS (3 OF 4)................................................ |

572 |

4.109 |

PARAMETERS OF MACHINING QUALITY LEVEL ADJUSTMENT ......... |

584 |

4.110 |

PARAMETERS OF WORKPIECE SETTING ERROR COMPENSATION |

|

|

(2 OF 2) ..................................................................................................... |

585 |

4.111 |

PARAMETERS OF HIGH-SPEED SMOOTH TCP (2 OF 2)...................... |

586 |

4.112 |

PARAMETERS OF SERVO (2 OF 2) ........................................................ |

588 |

4.113 |

PARAMETERS OF AXIS CONTROL BY PMC (2 OF 3) ........................... |

589 |

4.114 |

PARAMETERS OF PMC ........................................................................... |

590 |

4.115 |

PARAMETERS OF EMBEDDED MACRO (2 OF 2) .................................. |

601 |

4.116 |

PARAMETERS OF HIGH-SPEED POSITION SWITCH (2 OF 2) ............. |

603 |

4.117 |

PARAMETERS OF MALFUNCTION PROTECTION................................. |

604 |

4.118 |

PARAMETERS OF MANUAL HANDLE (2 OF 2) ...................................... |

604 |

4.119 |

PARAMETERS OF SYNCHRONOUS/COMPOSITE CONTROL AND |

|

|

SUPERIMPOSED CONTROL (3 OF 3) ..................................................... |

611 |

4.120 |

PARAMETERS OF AXIS CONTROL BY PMC (3 OF 3) ........................... |

612 |

4.121 |

PARAMETERS OF EXTERNAL DECELERATION POSITIONS |

|

|

EXPANSION.............................................................................................. |

614 |

4.122 |

PARAMETERS OF DISPLAY AND EDIT (5 OF 5) .................................... |

616 |

4.123 |

PARAMETERS OF TOOL MANAGEMENT FUNCTIONS (2 OF 2)........... |

624 |

4.124 |

PARAMETERS OF TOOL LIFE MANAGEMENT (2 OF 2)........................ |

636 |

4.125 |

PARAMETERS OF STRAIGHTNESS COMPENSATION (2 OF 2) ........... |

636 |

4.126 |

PARAMETERS OF FLEXIBLE SYNCHRONOUS CONTROL (2 OF 2) .... |

638 |

c-4

B-64490EN/03 |

TABLE OF CONTENTS |

|

4.127 |

PARAMETERS OF PROGRAMS (4 OF 4)................................................ |

641 |

4.128 |

PARAMETERS OF MANUAL LINER/CIRCULAR INTERPOLATION........ |

642 |

4.129 |

PARAMETERS OF CANNED CYCLES FOR DRILLING M CODE |

|

|

OUTPUT IMPROVEMENT ........................................................................ |

643 |

4.130 |

PARAMETERS OF THE MACHINING CONDITION SELECTION |

|

|

FUNCTION ................................................................................................ |

644 |

4.131 |

PARAMETERS OF PARAMETER CHECK SUM FUNCTION ................... |

649 |

4.132 |

PARAMETERS OF DUAL CHECK SAFETY (2 OF 2)............................... |

651 |

4.133 |

PARAMETERS OF SAFETY FUNCTION BY FL-net................................. |

651 |

4.134 |

PARAMETERS OF PARAMETERS OF AXIS CONTROL/INCREMENT |

|

|

SYSTEM (3 OF 3)...................................................................................... |

652 |

4.135 |

PARAMETERS OF LINEAR SCALE WITH ABSOLUTE ADDRESS |

|

|

REFERENCE POSITION .......................................................................... |

652 |

4.136 |

PARAMETERS OF PIVOT AXIS CONTROL............................................. |

653 |

4.137 |

PARAMETERS OF FSSB (1 OF 2) ........................................................... |

656 |

4.138 |

PARAMETERS OF SERVO GUIDE Mate ................................................. |

656 |

4.139 |

PARAMETERS OF GRAPHIC DISPLAY (3 OF 5) .................................... |

657 |

4.140 |

PARAMETERS OF EMBEDDED ETHERNET........................................... |

658 |

4.141 |

PARAMETERS OF ROTATION AREA INTERFERENCE CHECK |

|

|

(2 OF 2) ..................................................................................................... |

660 |

4.142 |

PARAMETERS OF PERIODICAL SECONDARY PITCH |

|

|

COMPENSATION...................................................................................... |

678 |

4.143 |

PARAMETERS OF MANUAL HANDLE RETRACE (2 OF 2) .................... |

679 |

4.144 |

PARAMETERS OF AI CONTOUR CONTROL (2 OF 2)............................ |

681 |

4.145 |

PARAMETERS OF CYLINDRICAL INTERPOLATION.............................. |

683 |

4.146 |

PARAMETERS OF OPTIMAL TORQUE |

|

|

ACCELERATION/DECELERATION .......................................................... |

684 |

4.147 |

PARAMETERS OF NANO SMOOTHING.................................................. |

687 |

4.148 |

PARAMETERS OF TOOL COMPENSATION (3 OF 3) ............................. |

689 |

4.149 |

PARAMETERS OF 5-AXIS MACHINING FUNCTION............................... |

696 |

4.150 |

PARAMETERS OF FSSB (2 OF 2) ........................................................... |

716 |

4.151 |

PARAMETERS OF GRAPHIC DISPLAY (4 OF 5) .................................... |

724 |

4.152 |

PARAMETERS OF HIGH PRECISION OSCILLATION FUNCTION ......... |

725 |

4.153 |

PARAMETERS OF SPINDLE UNIT COMPENSATION AND NUTATING |

|

|

ROTARY HEAD TOOL LENGTH COMPENSATION................................. |

727 |

4.154 |

PARAMETERS OF GRAPHIC DISPLAY (5 OF 5) .................................... |

729 |

APPENDIX |

|

|

A CHARACTER CODE LIST.................................................................. |

747 |

|

c-5

B-64490EN/03 |

1.DISPLAYING PARAMETERS |

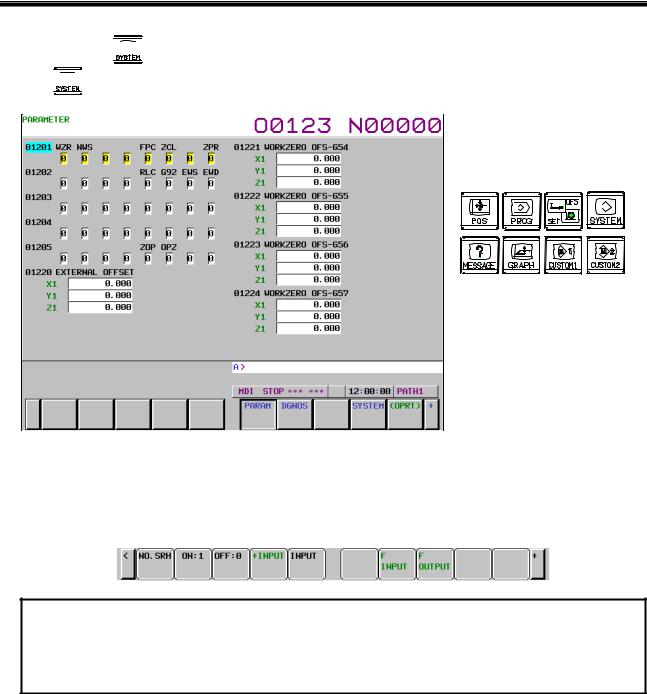

1 DISPLAYING PARAMETERS

Follow the procedure below to display parameters.

1 Press the

function key on the MDI unit as many times as required, or alternatively, press the

function key on the MDI unit as many times as required, or alternatively, press the

function key once, then the [PARAM] section display soft key. The parameter screen is then selected.

function key once, then the [PARAM] section display soft key. The parameter screen is then selected.

Function keys

2The parameter screen consists of multiple pages. Use step (a) or (b) to display the page that contains the parameter you want to display.

(a)Use the page select key or the cursor move keys to display the desired page.

(b)Enter the data number of the parameter you want to display from the keyboard, then press the [NO.SRH] soft key. The parameter page containing the specified data number appears with the cursor positioned at the data number. (The data is displayed in reverse video.)

NOTE

If key entry is started with the section select soft keys displayed, they are replaced automatically by operation select soft keys including [NO.SRH]. Pressing the [(OPRT)] soft key can also cause the operation select keys to be displayed.

- 1 -

2.SETTING PARAMETERS FROM MDI |

B-64490EN/03 |

2 SETTING PARAMETERS FROM MDI

Follow the procedure below to set parameters.

1Place the NC in the MDI mode or the emergency stop state.

2Follow the substeps below to enable writing of parameters.

2-1 To display the setting screen, press the

function key as many times as required, or

function key as many times as required, or

alternatively press the

function key once, then the [SETTING] section select soft key.

function key once, then the [SETTING] section select soft key.

(The first page of the setting screen appears.)

2-2 Position the cursor on "PARAMETER WRITE" using the cursor move keys. 2-3 Press the [(OPRT)] soft key to display operation select soft keys.

2-4 To set "PARAMETER WRITE=" to 1, press the [ON:1] soft key, or alternatively enter 1 and press the [INPUT] soft key. From now on, the parameters can be set. At the same time an alarm condition (SW0100 PARAMETER WRITE ENABLE) occurs in the CNC.

3To display the parameter screen, press the

function key as many times as required, or alternatively press the

function key as many times as required, or alternatively press the

function key once, then the [PARAM] section select soft key. (See Chapter 1, "DISPLAYING PARAMETERS.")

function key once, then the [PARAM] section select soft key. (See Chapter 1, "DISPLAYING PARAMETERS.")

4Display the page containing the parameter you want to set, and position the cursor on the parameter. (See Chapter 1, "DISPLAYING PARAMETERS.")

5Enter data, then press the [INPUT] soft key. The parameter indicated by the cursor is set to the entered data.

[Example] |

12000 [INPUT] |

- 2 -

B-64490EN/03 |

2.SETTING PARAMETERS FROM MDI |

Data can be entered continuously for parameters, starting at the selected parameter, by separating each data item with a semicolon (;).

[Example]

Entering 10;20;30;40 and pressing the [INPUT] soft key assigns values 10, 20, 30, and 40 to parameters in order starting at the parameter indicated by the cursor.

6Repeat steps 4 and 5 as required.

7If parameter setting is complete, set "PARAMETER WRITE=" to 0 on the setting screen to disable further parameter setting.

8Reset the NC to release the alarm condition (SW0100).

If an alarm condition (PW0000 PLEASE TURN OFF POWER) occurs in the NC, turn it off before continuing operation.

- 3 -

3. INPUTTING AND OUTPUTTING PARAMETERS |

|

THROUGH THE READER/PUNCHER INTERFACE |

B-64490EN/03 |

3 INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE RS232C INTERFACE

This section explains the parameter input/output procedures for input/output devices connected to the RS232C interface.

The following description assumes the input/output devices are ready for input/output. It also assumes parameters peculiar to the input/output devices, such as the baud rate and the number of stop bits, have been set in advance. (See Section 4.5, “PARAMETERS OF RS232C INTERFACE.”)

3.1 OUTPUTTING PARAMETERS THROUGH THE RS232C INTERFACE

1Select the EDIT mode or set to Emergency stop.

2To select the parameter screen, press the

function key as many times as required, or alternatively press the

function key as many times as required, or alternatively press the

function key once, then the [PARAM] section select soft key.

function key once, then the [PARAM] section select soft key.

3Press the [(OPRT)] soft key to display operation select soft keys, then press the forward menu key located at the right-hand side of the soft keys to display another set of operation select keys including [F OUTPUT].

4Pressing the [F OUTPUT] soft key changes the soft key display as shown below:

5Press the [EXEC] soft key to start parameter output. When parameters are being output, "OUTPUT" blinks in the state display field on the lower part of the screen.

6When parameter output terminates, "OUTPUT" stops blinking. Press the

key to interrupt parameter output.

key to interrupt parameter output.

-4 -

|

3. INPUTTING AND OUTPUTTING PARAMETERS |

B-64490EN/03 |

THROUGH THE RS232C INTERFACE |

3.2 INPUTTING PARAMETERS THROUGH THE RS232C INTERFACE

1Place the NC in the emergency stop state.

2Enable parameter writing.

2-1 To display the setting screen, press the

function key as many times as required, or

function key as many times as required, or

alternatively press the

function key once, then the [SETTING] section select soft key.

function key once, then the [SETTING] section select soft key.

The first page of the setting screen appears.

2-2 Position the cursor on "PARAMETER WRITE" using the cursor move keys.

2-3 Press the [(OPRT)] soft key to display operation select soft keys.

2-4 To set "PARAMETER WRITE=" to 1, press the [ON:1] soft key, or alternatively enter 1, then press the [INPUT] soft key. From now on, parameters can be set.

At the same time an alarm condition (SW0100 PARAMETER WRITE ENABLE) occurs in the NC.

3To select the parameter screen, press the

function key as many times as required, or alternatively press the

function key as many times as required, or alternatively press the

key once, then [PARAM] soft key.

key once, then [PARAM] soft key.

4Press the [(OPRT)] soft key to display operation select keys, then press the forward menu key located at the right-hand side of the soft keys to display another set of operation select soft keys including [F INPUT].

5Pressing the [F INPUT] soft key changes the soft key display as shown below:

6Press the [EXEC] soft key to start inputting parameters from the input/output device. When parameters are being input, "INPUT" blinks in the state display field on the lower part of the screen.

Press the |

key to interrupt parameter input. |

7When parameter read terminates, "INPUT" stops blinking, and an alarm condition (PW0100) occurs in the NC. Turn it off before continuing operation.

- 5 -

3. INPUTTING AND OUTPUTTING PARAMETERS |

|

||||

|

THROUGH THE READER/PUNCHER INTERFACE |

B-64490EN/03 |

|||

3.3 |

I/O FORMATS |

|

|

||

|

|

This section describes the I/O formats of parameters. |

|

|

|

|

|

Parameters are classified by data format as follows: |

|

|

|

|

|

|

|

|

|

|

|

|

Data format |

|

Remarks |

|

|

Bit |

|

|

|

|

|

Bit machine group |

Data of these formats is represented by an 8-digit |

||

|

|

Bit path |

|

||

|

|

|

binary number, with each digit corresponding to a bit. |

||

|

|

Bit axis |

|

||

|

|

|

|

|

|

|

|

Bit spindle |

|

|

|

|

|

Byte |

|

|

|

|

|

Byte machine group |

|

|

|

|

|

Byte path |

|

|

|

|

|

Byte axis |

|

|

|

|

|

Byte spindle |

|

|

|

|

|

Word |

|

|

|

|

|

Word machine group |

|

|

|

|

|

Word path |

|

|

|

|

|

Word axis |

|

The setting range of data varies from one parameter |

|

|

|

Word spindle |

|||

|

|

to another. |

|

||

|

|

2-word |

|

|

|

|

|

|

For details, refer to the description of each parameter. |

||

|

|

2-word machine group |

|||

|

|

|

|

||

|

|

2-word path |

|

|

|

|

|

2-word axis |

|

|

|

|

|

2-word spindle |

|

|

|

|

|

Real |

|

|

|

|

|

Real machine group |

|

|

|

|

|

Real path |

|

|

|

|

|

Real axis |

|

|

|

|

|

Real spindle |

|

|

|

3.3.1 |

Keywords |

|

|

||

The alphabetic characters listed below are used as keywords.

A numeric value after each keyword has the following meaning:

Keyword |

Meaning of a numeric value that follows |

N |

Parameter number |

Q |

Data identifier (1: Parameter data, 0: Pitch error compensation data) |

|

Machine group number (1 and up) of a machine group type parameter |

|

Path number (1 and up) of a path type parameter |

A |

Controlled axis number (1 and up) of an axis type parameter |

S |

Spindle number (1 and up) of a spindle type parameter |

P |

Value of a parameter independent of inch/metric switching |

M |

Metric input value of a parameter dependent on inch/metric switching |

I |

Inch input value of a parameter dependent on inch/metric switching |

- 6 -

|

|

3. INPUTTING AND OUTPUTTING PARAMETERS |

|

|

B-64490EN/03 |

THROUGH THE RS232C INTERFACE |

|

|

3.3.2 |

Inch/Metric Switching |

|

For parameters dependent on inch/metric switching such as those for length and feedrate, whether data is inch data or metric data is specified by the input mode in the case of input from the MDI panel, or by the keyword I or M prefixed to the data in the case of input from an external I/O device. The keyword I or M is added also when data is output to an external I/O device.

If the input mode or keyword differs from the actually used mode as in a case where data input in the inch mode is used in the metric mode, the CNC performs automatic data conversion. So, data need not be converted according to a mode change. Moreover, when parameter data is displayed, the data is converted according to the display mode. However, when data is output to an external I/O device, the original data is output according to the original keyword.

3.3.3 |

Bit Format |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

P |

******** |

; |

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

An 8-digit binary number after P represents the bit values (0/1) of a parameter, with the first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example |

|

N00010Q1P00000001; |

|

Parameter No. |

10 |

Parameter value |

Bit 0 is set to 1, and the other bits are set to 0. |

3.3.4 |

Bit Machine Group Format |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

|

Q1 |

T |

** |

P |

******** |

T |

** |

P |

******** |

|

|

|

; |

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after T represents a machine group number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each machine group, with the first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01005Q1T1P10000001T2P10000001 ;

Parameter No. 1005 Parameter value

1st machine group: Bits 0 and 7 are set to 1, and the other bits are set to 0.

2nd machine group: Bits 0 and 7 are set to 1, and the other bits are set to 0.

- 7 -

3. INPUTTING AND OUTPUTTING PARAMETERS |

|

|

|

|

|

|||||||||||||

|

THROUGH THE READER/PUNCHER INTERFACE |

|

B-64490EN/03 |

|

||||||||||||||

3.3.5 |

Bit Path Format |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

|

Q1 |

L |

** |

P |

******** |

L |

** |

P |

******** |

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after L represents a path number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each path, with the first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01005Q1L1P10000001L2P10000001.......;

Parameter No. 1005 Parameter value

Path 1: Bits 0 and 7 are set to 1, and the other bits are set to 0. Path 2: Bits 0 and 7 are set to 1, and the other bits are set to 0.

3.3.6 Bit Axis Format

N |

***** |

Q1 |

A |

** |

P |

******** |

A |

** |

P |

******** |

|

|

|

; |

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after A represents a controlled axis number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each controlled axis, with the first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01005Q1A1P10000001A2P10000001A3P10000001.......;

Parameter No. |

1005 |

|

Parameter value |

|

|

1st axis: |

Bits 0 and 7 are set to 1, and the other bits are set to 0. |

|

2nd axis: |

Bits 0 and 7 are set to 1, and the other bits are set to 0. |

|

3rd axis: |

Bits 0 and 7 are set to 1, and the other bits are set to 0. |

|

|

▪ |

|

- 8 -

|

|

|

|

|

|

|

|

|

3. INPUTTING AND OUTPUTTING PARAMETERS |

|||||||||

|

B-64490EN/03 |

|

|

|

|

|

|

THROUGH THE RS232C INTERFACE |

||||||||||

|

3.3.7 |

Bit Spindle Format |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

|

Q1 |

S |

** |

P |

******** |

S |

** |

P |

******** |

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after S represents a spindle number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each spindle, with the first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N05603Q1S1P00001000S2P00001000S3P00000000;

Parameter No. 5603 Parameter value

1st spindle: Bit 3 is set to 1, and the other bits are set to 0. 2nd spindle: Bit 3 is set to 1, and the other bits are set to 0.

3rd spindle: All bits are set to 0.

3.3.8 Byte/Word/Two-Word Format

N |

***** |

Q1 |

P |

******** |

; |

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after P represents a parameter value (integer).

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example |

|

N00100Q1P31515; |

|

Parameter No. |

100 |

Parameter value |

31515 |

3.3.9 |

Byte/Word/Two-Word Machine Group Format |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

|

Q1 |

T |

** |

P |

****** |

T |

** |

P |

****** |

|

|

|

; |

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after T represents a machine group number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each machine group.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example |

|

|

N01020Q1T1P88T2P89......; |

|

|

Parameter No. |

1020 |

|

Parameter value |

1st machine group: |

88 |

|

2nd machine group: |

89 |

|

▪ |

|

- 9 -

3. INPUTTING AND OUTPUTTING PARAMETERS |

|

|

|

|

|

|

|

|

|

|||||||||

|

THROUGH THE READER/PUNCHER INTERFACE |

|

|

|

B-64490EN/03 |

|

||||||||||||

|

3.3.10 Byte/Word/Two-Word Path Format |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

L |

** |

P |

****** |

|

L |

** |

P |

****** |

|

|

|

; |

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after L represents a path number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each path.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01020Q1L1P88L2P89L3P90......;

Parameter No. |

1020 |

Parameter value |

Path 1: 88 |

|

Path 2: 89 |

|

Path 3: 90 |

|

▪ |

3.3.11 Byte/Word/Two-Word Axis Format

N |

***** |

Q1 |

A |

** |

P |

****** |

A |

** |

P |

****** |

|

|

|

; |

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after A represents a controlled axis number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each controlled axis.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01020Q1A1P88A2P89A3P90A4P66......;

Parameter No. |

1020 |

Parameter value |

1st axis: 88 |

|

2nd axis: 89 |

|

3rd axis: 90 |

|

4th axis: 66 |

|

▪ |

- 10 -

|

|

|

|

|

|

|

|

3. INPUTTING AND OUTPUTTING PARAMETERS |

|||||||||

|

B-64490EN/03 |

|

|

|

|

|

THROUGH THE RS232C INTERFACE |

||||||||||

|

3.3.12 Byte/Word/Two-Word Spindle Format |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

S |

** |

P |

****** |

S |

** |

P |

****** |

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after S represents a spindle number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each spindle.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example |

|

N05680Q1S1P19S2P19S3P0S4P0; |

|

Parameter No. |

5680 |

Parameter value |

1st spindle: 19 |

|

2nd spindle: 19 |

|

3rd spindle: 0 |

|

4th spindle: 0 |

3.3.13 |

Real Number Format |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

P |

****** |

; |

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

M |

****** |

; |

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

I |

****** |

; |

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after each of P, M, and I represents the value (real number) of a parameter.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01451Q1P5000.0;

Parameter No. |

1451 |

Parameter value |

5000.0 |

- 11 -

3. INPUTTING AND OUTPUTTING PARAMETERS |

|

|

|

|

|

|

|

|

|

|||||||||

|

THROUGH THE READER/PUNCHER INTERFACE |

|

|

|

|

B-64490EN/03 |

|

|||||||||||

|

3.3.14 Real Number Machine Group Format |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

T |

** |

P |

****** |

|

T |

** |

P |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

T |

** |

M |

****** |

|

T |

** |

M |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

T |

** |

I |

****** |

|

T |

** |

I |

****** |

|

|

|

; |

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after T represents a machine group number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each machine group.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01220Q1T1M50.0T2M60.0........;

Parameter No. |

1220 |

Parameter value |

1st machine group: 50.0 |

|

2nd machine group: 60.0 |

|

▪ |

3.3.15 Real Number Path Format

N |

***** |

Q1 |

L |

** |

P |

****** |

L |

** |

P |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

L |

** |

M |

****** |

L |

** |

M |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

L |

** |

I |

****** |

L |

** |

I |

****** |

|

|

|

; |

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after L represents a path number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each path. A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01220Q1L1M50.0L2M60.0L3M70.0 ;

Parameter No. 1220

Parameter value Path 1: 50.0

Path 2: 60.0

Path 3: 70.0

- 12 -

|

|

|

|

|

|

|

|

3. INPUTTING AND OUTPUTTING PARAMETERS |

|||||||||

|

B-64490EN/03 |

|

|

|

|

|

THROUGH THE RS232C INTERFACE |

||||||||||

|

3.3.16 Real Number Axis Format |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

A |

** |

P |

****** |

A |

** |

P |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

A |

** |

M |

****** |

A |

** |

M |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

A |

** |

I |

****** |

A |

** |

I |

****** |

|

|

|

; |

|

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after A represents a controlled axis number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each controlled axis.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01220Q1A1M50.0A2M60.0A3M70.0A4M0.0A5M0.0 ........;

Parameter No. |

1220 |

Parameter value |

1st axis: 50.0 |

|

2nd axis: 60.0 |

|

3rd axis: 70.0 |

|

4th axis: 0.0 |

|

5th axis: 0.0 |

|

▪ |

3.3.17 Real Number Spindle Format

N |

***** |

Q1 |

S |

** |

P |

****** |

S |

** |

P |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

S |

** |

M |

****** |

S |

** |

M |

****** |

|

|

|

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

***** |

Q1 |

S |

** |

I |

****** |

S |

** |

I |

****** |

|

|

|

; |

A numeric value after N represents a parameter number. Q1 indicates that the data is parameter data.

A numeric value after S represents a spindle number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each spindle.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N05898Q1S1P30.0S2P30.0S3P0.0S4P0.0;

Parameter No. |

5898 |

Parameter value |

1st spindle: 30.0 |

|

2nd spindle: 30.0 |

|

3rd spindle: 0.0 |

|

4th spindle: 0.0 |

- 13 -

3. INPUTTING AND OUTPUTTING PARAMETERS |

|

THROUGH THE READER/PUNCHER INTERFACE |

B-64490EN/03 |

3.3.18 Start and End of a Record

A parameter record starts with "%" and ends with "%".

Example |

|

%; ......................................... |

Start of record |

N00000Q1P00001100; |

|

N00002Q1P00000000; |

|

▪ |

|

▪ |

|

N09162Q1P00000000; |

|

N09163Q1P00000000; |

|

% .......................................... |

End of record |

When parameters and pitch error compensation data are included in a single file, the file starts with "%" and ends with "%".

- 14 -

B-64490EN/03 |

4.DESCRIPTION OF PARAMETERS |

4 DESCRIPTION OF PARAMETERS

4.1 INPUT TYPE

There are two input types for parameters depending on their usage.

Setting input

These parameters are set depending on NC programs or machining usage.

When the memory protection signal KEY is “1”, they can be input on SETTING screen. They can also be input on PARAMETER screen.

Parameter input

These parameters are adjusted and set depending on each machine.

They can be input on PARAMETER screen.

NOTE

To make input on PARAMETER screen enable, it is needed that PARAMETER

WRITE on SETTING screen is “1” or that parameter PWE (No.8900#0) is “1”.

4.2 DATA TYPE

Parameters are classified by data type as follows:

Data type |

Valid data range |

Remarks |

|

Bit |

|

|

|

Bit machine group |

0 or 1 |

|

|

Bit path |

|

||

Bit axis |

|

|

|

Bit spindle |

|

|

|

Byte |

|

|

|

Byte machine group |

-128 to 127 |

Some parameters handle these types of |

|

Byte path |

|||

0 to 255 |

data as unsigned data. |

||

Byte axis |

|||

|

|

||

Byte spindle |

|

|

|

Word |

|

|

|

Word machine group |

-32768 to 32767 |

Some parameters handle these types of |

|

Word path |

|||

0 to 65535 |

data as unsigned data. |

||

Word axis |

|||

|

|

||

Word spindle |

|

|

|

2-word |

|

|

|

2-word machine group |

0 to ±999999999 |

Some parameters handle these types of |

|

2-word path |

|||

data as unsigned data. |

|||

2-word axis |

|

||

|

|

||

2-word spindle |

|

|

|

Real |

|

|

|

Real machine group |

See the Standard Parameter |

|

|

Real path |

|

||

Setting Tables. |

|

||

Real axis |

|

||

|

|

||

Real spindle |

|

|

- 15 -

4.DESCRIPTION OF PARAMETERS |

B-64490EN/03 |

NOTE

1Each of the parameters of the bit, bit machine group, bit path, bit axis, and bit spindle types consists of 8 bits for one data number (parameters with eight different meanings).

2For machine group types, parameters corresponding to the maximum number of machine groups are present, so that independent data can be set for each machine group.

3For path types, parameters corresponding to the maximum number of paths are present, so that independent data can be set for each path.

4For axis types, parameters corresponding to the maximum number of control axes are present, so that independent data can be set for each control axis.

5For spindle types, parameters corresponding to the maximum number of spindles are present, so that independent data can be set for each spindle axis.

6The valid data range for each data type indicates a general range. The range varies according to the parameters. For the valid data range of a specific parameter, see the explanation of the parameter.

4.3REPRESENTATION OF PARAMETERS

Parameters of the bit type, bit machine group type, bit path type, bit axis type,

and bit spindle type #7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

0000 |

|

|

EIA |

NCR |

ISP |

CTV |

TVC |

Data No. |

|

Data (Data #0 to #7 are bit positions.) |

|

|

|||

Parameters other than the bit-type parameters above |

|

|

|||||

1023 |

|

Number of the servo axis for each axis |

|

|

|||

Data No. |

|

|

|

Data |

|

|

|

- 16 -

B-64490EN/03 |

4.DESCRIPTION OF PARAMETERS |

NOTE

1The bits left blank in Chapter 4, “DESCRIPTION OF PARAMETERS” and parameter numbers that appear on the display but are not found in the parameter list are reserved for future expansion. They must always be 0.

2A parameter usable with only one path control type, namely, the lathe system (T series) or the machining center system (M series), is indicated using two rows as shown below. When a row is blank, the parameter is not usable with the corresponding series.

[Example 1]

Parameter HTG is a parameter common to the M and T series, but

Parameters RTV and ROC are parameters valid only for the T series.

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

|

||

1403 |

|

RTV |

|

HTG |

ROC |

|

|

|

|

T series |

|

|

|

HTG |

|

|

|

|

|

M series |

|

|

|

|

|

|

|

|

|

|

||

[Example 2]

The following parameter is provided only for the M series.

1411 |

|

|

T series |

|

Cutting feedrate |

M series |

|

|

|

3When "to" is inserted between two parameter numbers, there are parameters with successive numbers between the two starting and ending parameter numbers, but those intermediate parameter numbers are omitted for convenience.

4The lower-case letter "x" or "s" following the name of a bit-type parameter indicates the following:

-”

x” : Bit axis type parameters

x” : Bit axis type parameters

-”

s” : Bit spindle type parameters

s” : Bit spindle type parameters

4.4STANDARD PARAMETER SETTING TABLES

Overview

This section defines the standard minimum data units and valid data ranges of the CNC parameters of the real type, real machine group type, real path type, real axis type, and real spindle type. The data type and unit of data of each parameter conform to the specifications of each function.

Explanation

(A) Length and angle parameters (type 1)

Unit of data |

Increment system |

Minimum data unit |

Valid data range |

|||

|

IS-A |

0.01 |

-999999.99 |

to +999999.99 |

||

mm |

IS-B |

0.001 |

-999999.999 |

to +999999.999 |

||

IS-C |

0.0001 |

-99999.9999 |

to |

+99999.9999 |

||

deg. |

||||||

IS-D |

0.00001 |

-9999.99999 |

to |

+9999.99999 |

||

|

||||||

|

IS-E |

0.000001 |

-999.999999 |

to |

+999.999999 |

|

|

IS-A |

0.001 |

-99999.999 |

to |

+99999.999 |

|

|

IS-B |

0.0001 |

-99999.9999 |

to |

+99999.9999 |

|

inch |

IS-C |

0.00001 |

-9999.99999 |

to |

+9999.99999 |

|

|

IS-D |

0.000001 |

-999.999999 |

to |

+999.999999 |

|

|

IS-E |

0.0000001 |

-99.9999999 to |

+99.9999999 |

||

- 17 -

4.DESCRIPTION OF PARAMETERS |

|

|

|

|

B-64490EN/03 |

|||

(B) Length and angle parameters (type 2) |

|

|

|

|

||||

|

Unit of data |

Increment system |

|

Minimum data unit |

|

Valid data range |

||

|

|

IS-A |

|

0.01 |

0.00 |

|

to +999999.99 |

|

|

mm |

IS-B |

|

0.001 |

0.000 |

to +999999.999 |

||

|

IS-C |

|

0.0001 |

0.0000 |

to |

+99999.9999 |

||

|

deg. |

|

||||||

|

IS-D |

|

0.00001 |

0.00000 |

to |

+9999.99999 |

||

|

|

|

||||||

|

|

IS-E |

|

0.000001 |

0.000000 |

to |

+999.999999 |

|

|

|

IS-A |

|

0.001 |

0.000 |

to |

+99999.999 |

|

|

|

IS-B |

|

0.0001 |

0.0000 |

to |

+99999.9999 |

|

|

inch |

IS-C |

|

0.00001 |

0.00000 |

to |

+9999.99999 |

|

|

|

IS-D |

|

0.000001 |

0.000000 |

to |

+999.999999 |

|

|

|

IS-E |

|

0.0000001 |

0.0000000 to |

+99.9999999 |

||

(C) Velocity and angular velocity parameters |

|

|

|

|

||||

|

Unit of data |

Increment system |

|

Minimum data unit |

|

Valid data range |

||

|

|

IS-A |

|

0.01 |

0.0 |

to |

+999000.00 |

|

|

mm/min |

IS-B |

|

0.001 |

0.0 |

to |

+999000.000 |

|

|

IS-C |

|

0.0001 |

0.0 |

to |

+99999.9999 |

||

|

degree/min |

|

||||||

|

IS-D |

|

0.00001 |

0.0 |

to |

+9999.99999 |

||

|

|

|

||||||

|

|

IS-E |

|

0.000001 |

0.0 |

to |

+999.999999 |

|

|

|

IS-A |

|

0.001 |

0.0 |

to |

+96000.000 |

|

|

|

IS-B |

|

0.0001 |

0.0 |

to |

+9600.0000 |

|

|

inch/min |

IS-C |

|

0.00001 |

0.0 |

to |

+4000.00000 |

|

|

|

IS-D |

|

0.000001 |

0.0 |

to |

+400.000000 |

|

|

|

IS-E |

|

0.0000001 |

0.0 |

to |

+40.0000000 |

|

If bit 7 (IESP) of parameter No. 1013 is set to 1, the valid data ranges for IS-C, IS-D, and IS-E are extended as follows:

Unit of data |

Increment system |

Minimum data unit |

Valid data range |

||

mm/min |

IS-C |

0.001 |

0.000 to +999000.000 |

||

IS-D |

0.0001 |

0.0000 |

to +99999.9999 |

||

degree/min |

|||||

IS-E |

0.00001 |

0.0000 |

to +99999.9999 |

||

|

|||||

|

IS-C |

0.0001 |

0.0000 |

to +9600.0000 |

|

inch/min |

IS-D |

0.00001 |

0.00000 |

to +4000.00000 |

|

|

IS-E |

0.00001 |

0.00000 |

to +4000.00000 |

|

(D)Acceleration and angular acceleration parameters

Unit of data |

Increment system |

Minimum data unit |

Valid data range |

|||

|

IS-A |

0.01 |

0.00 |

to +999999.99 |

||

mm/sec2 |

IS-B |

0.001 |

0.000 |

to +999999.999 |

||

IS-C |

0.0001 |

0.0000 |

|

|||

deg./sec2 |

to |

+99999.9999 |

||||

IS-D |

0.00001 |

0.00000 |

to |

+9999.99999 |

||

|

||||||

|

IS-E |

0.000001 |

0.000000 |

to |

+999.999999 |

|

|

IS-A |

0.001 |

0.000 |

to |

+99999.999 |

|

inch/sec2 |

IS-B |

0.0001 |

0.0000 |

to |

+99999.9999 |

|

IS-C |

0.00001 |

0.00000 |

to |

+9999.99999 |

||

|

IS-D |

0.000001 |

0.000000 |

to |

+999.999999 |

|

|

IS-E |

0.0000001 |

0.0000000 to |

+99.9999999 |

||

If bit 7 (IESP) of parameter No. 1013 is set to 1, the valid data ranges for IS-C, IS-D, and IS-E are extended as follows:

- 18 -

Loading...

Loading...