BECKHOFF ET9300 User Manual

Application Note ET9300

(EtherCAT Slave Stack Code)

Version 1.7

Date: 2015-01-13

LEGAL NOTICE

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered trademarks of and licensed by Beckhoff Automation GmbH. Other designations used in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following German patent applications and patents: DE10304637, DE102004044764, DE102005009224, DE102007017835 with corresponding applications or registrations in various other countries.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under development. For that reason the documentation is not in every case checked for consistency with performance data, standards or other characteristics. In the event that it contains technical or editorial errors, we retain the right to make alterations at any time and without warning. No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this documentation.

Copyright

© Beckhoff Automation GmbH

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without express authorization are prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

II |

Application Note ET9300 |

|

|

|

|

|

|

|

DOCUMENT HISTORY |

|

|

|

|

|

|

|

|

|

|

|

Version |

|

|

|

|

Comment |

|

|

|

|

|

|

|

|

|||

|

1.0 |

|

|

|

|

Start document |

|

|

|

|

|

|

|

|

|||

|

1.1 |

|

|

|

|

Chapter 4 “Hardware access”. |

|

|

|

|

|

|

|

|

Define descriptions; prototypes changed |

|

|

|

|

|

|

|

|

|||

|

1.2 |

|

|

|

|

Add chapter 5 Application |

|

|

|

|

|

|

|

|

Add chapter 9 Tool |

|

|

|

|

|

|

|

|

Add chapter 9 TestApplication |

|

|

|

|

|

|

|

|

Enhance Hardware access (chapter 4) |

|

|

|

|

|

|

|

|

update name references |

|

|

|

|

|

|

|

|

Enhance EoE chapter |

|

|

|

|

|

|

|

|

|||

|

1.3 |

|

|

|

|

TestApplication; chapter9 :Update object/entry description (0x2020.1, 0x3003, 0x3004 and |

|

|

|

|

|

|

|

|

0x3007) |

|

|

|

|

|

|

|

|

Update “HW_GetTimer()” description |

|

|

|

|

|

|

|

|

SSC Tool: Edit file information |

|

|

|

|

|

|

|

|

Update SSC Structure |

|

|

|

|

|

|

|

|

Add “Find Setting” dialog description |

|

|

|

|

|

|

|

|

Update naming in Object chapter |

|

|

|

|

|

|

|

|

|||

|

1.4 |

|

|

|

|

SSCTool: |

|

|

|

|

|

|

|

- |

Remove Wizard |

|

|

|

|

|

|

|

|

- |

Add Configuration handling |

|

|

|

|

|

|

|

|||

|

1.5 |

|

|

|

|

Editorial changes |

|

|

|

|

|

|

|

|

Add “Getting Started” chapter |

|

|

|

|

|

|

|

|

Add description for hardware adaption |

|

|

|

|

|

|

|

|

Test Application: |

|

|

|

|

|

|

|

|

- Add new test description |

|

|

|

|

|

|

|

|

- |

Enhance/update application description |

|

|

|

|

|

|

|

- Describe mechanism to control the behaviors |

|

|

|

|

|

|

|

|

Enhance Application chapter |

|

|

|

|

|

|

|

|

- |

Add setting description |

|

|

|

|

|

|

|

- |

Interface variables |

|

|

|

|

|

|

|

- Guide to create an application |

|

|

|

|

|

|

|

|

Add “Synchronization” chapter |

|

|

|

|

|

|

|

|

Hardware chapter: Sync1_Isr() description added |

|

|

|

|

|

|

|

|

Update SSC configuration references |

|

|

|

|

|

|

|

|

Add “EEPROM Handling” chapter |

|

|

|

|

|

|

|

|

- |

EEPORM Emulation |

|

|

|

|

|

|

|

- |

EEPROM Programming |

|

|

|

|

|

|

|

|||

|

1.6 |

|

|

|

|

Editorial changes |

|

|

|

|

|

|

|

|

Update object list of test application |

|

|

|

|

|

|

|

|

Update SSC Tool description (chapter 12) according version 1.3.1 |

|

|

|

|

|

|

|

|

|||

|

1.7 |

|

|

|

|

Chapter 6.5.2 : Add offline object dictionary enhancement |

|

|

|

|

|

|

|

|

Add new mailbox test behaviors |

|

|

|

|

|

|

|

|

Indicate obsolete hardware functions |

|

|

|

|

|

|

|

|

Editorial changes |

|

|

|

|

|

|

|

|

Update SSC Tool screenshots and GUI description |

|

|

|

|

|

|

|

|

Add further test object in the test application |

|

|

|

|

|

|

|

|

Add object design rules |

|

|

|

|

|

|

|

|

Update references if TwinCAT 3 is used |

|

|

|

|

|

|

|

|

Add SSC OD Tool description |

|

|

|

|

|

|

|

|

Add optional EEPROM interface functions. |

|

|

|

|

|

|

|

|

Add Bootloader information |

|

|

NOTE: This document makes no claim to be complete regarding to the containing topics or the Slave Stack Code. For annotations or comments to this document please send an email to EthercatSSC@beckhoff.com.

Application Note ET9300 |

1 |

|

|

|

CONTENTS |

|

1 |

References |

|

|

7 |

2 |

Terms, Definition, Abbreviation |

8 |

||

|

2.1 |

Abbreviation |

8 |

|

3 |

Getting Started |

|

9 |

|

|

3.1 |

SSC Tool |

9 |

|

|

3.2 |

Default SSC files |

9 |

|

4 |

Code Structure |

|

11 |

|

5 |

Hardware Access |

|

12 |

|

|

5.1 |

Interrupt Handler |

16 |

|

|

5.2 |

Interface Functions/Macros |

16 |

|

|

|

5.2.1 |

Generic |

17 |

|

|

5.2.2 |

Read Access |

20 |

|

|

5.2.3 |

Write Access |

23 |

6 |

Application |

|

|

26 |

|

6.1 |

Application Settings |

26 |

|

|

6.2 |

SSC Functions |

26 |

|

|

6.3 |

Interface Functions |

27 |

|

|

|

6.3.1 |

Generic |

27 |

|

|

6.3.2 |

EtherCAT State Machine |

28 |

|

|

6.3.3 |

Process data handling |

30 |

|

6.4 |

Interface Variables |

30 |

|

|

6.5 |

Create an Application |

31 |

|

|

|

6.5.1 |

Adding a new Application |

31 |

|

|

6.5.2 |

Examples |

31 |

7 |

Objects |

|

|

41 |

|

7.1 |

Design/Structure Rules |

41 |

|

|

7.2 |

Define local memory |

41 |

|

|

7.3 |

Entry descriptions |

42 |

|

|

7.4 |

Object name |

42 |

|

|

7.5 |

Object description |

43 |

|

|

7.6 |

Index Ranges |

44 |

|

|

7.7 |

Implementation examples |

45 |

|

|

|

7.7.1 |

Usage of Object Deftype ENUM |

45 |

8 |

Mailbox |

|

|

47 |

|

8.1 |

FoE (File Transfer over EtherCAT) |

47 |

|

|

|

8.1.1 |

Testing FoE |

47 |

|

8.2 |

EoE (Ethernet over EtherCAT) |

47 |

|

|

|

8.2.1 |

Implementation |

47 |

|

|

8.2.2 |

EoE Examples |

49 |

9 |

Synchronization |

|

55 |

|

2 |

|

|

|

Application Note ET9300 |

|

9.1 |

Supported Sync Modes |

55 |

|

|

|

9.1.1 |

FreeRun |

57 |

|

|

9.1.2 |

SyncManager |

57 |

|

|

9.1.3 |

SyncManager/Sync0 |

58 |

|

|

9.1.4 |

SyncManager/Sync0/Sync1 |

58 |

|

|

9.1.5 |

Sync0 |

59 |

|

|

9.1.6 |

Sync0/Sync1 |

59 |

|

|

9.1.7 |

Subordinated Cycles |

59 |

10 |

CiA402 drive profile |

|

61 |

|

|

10.1 |

Objects |

|

61 |

|

10.2 |

State machine |

62 |

|

|

10.3 |

Operation modes |

64 |

|

|

10.4 |

TwinCAT setup |

65 |

|

|

|

10.4.1 |

Automatic network setup |

66 |

|

|

10.4.2 |

Manual network setup |

67 |

|

|

10.4.3 |

NC parameter setup |

69 |

11 |

TestApplication |

|

71 |

|

|

11.1 |

Slave Behavior Control |

71 |

|

|

|

11.1.1 |

Test Control Object |

71 |

|

|

11.1.2 |

User RAM 0xF80:0xF83 |

72 |

|

11.2 |

ESM Tests (0x2000 – 0x200F) |

72 |

|

|

11.3 |

Mailbox Tests (0x2010 – 0x201F) |

73 |

|

|

11.4 |

CoE Tests (0x2020 – 0x202F) |

73 |

|

|

11.5 |

FoE Tests (0x2030 – 0x203F) |

73 |

|

|

11.6 |

Generic Objects |

74 |

|

12 |

Tool |

|

|

77 |

|

12.1 |

Default Startup Dialogs |

77 |

|

|

12.2 |

Main User Interface Elements |

78 |

|

|

|

12.2.1 |

Tool Bar |

78 |

|

|

12.2.2 |

Windows |

82 |

|

12.3 |

Create Files |

83 |

|

|

12.4 |

Local SSC Update |

84 |

|

|

12.5 |

Project Update |

85 |

|

|

12.6 |

Import Configurations |

85 |

|

13 |

OD Tool |

|

|

87 |

|

13.1 |

Console application |

87 |

|

|

13.2 |

SSC Tool Integration |

87 |

|

|

13.3 |

PDO mapping and SM assign objects |

88 |

|

|

13.4 |

Syntax |

|

88 |

|

|

13.4.1 |

Comment |

88 |

|

|

13.4.2 |

Object Index |

88 |

|

|

|

||

|

Application Note ET9300 |

3 |

||

|

|

13.4.3 |

ObjectCode |

88 |

|

|

13.4.4 |

SI (Subindex) |

89 |

|

|

13.4.5 |

DataType |

89 |

|

|

13.4.6 |

Default/Min/Max |

90 |

|

|

13.4.7 M/O/C, B/S and rx/tx |

90 |

|

|

|

13.4.8 |

Access |

90 |

|

13.5 |

ENUM |

|

90 |

14 |

EEPROM Handling |

|

92 |

|

|

14.1 |

EEPROM Emulation |

92 |

|

|

14.2 |

EEPROM Programming |

92 |

|

|

|

14.2.1 EEPROM Programmer User Elements |

92 |

|

15 |

Bootloader |

|

|

94 |

Appendix |

|

|

95 |

|

|

Support and Service |

95 |

||

|

Beckhoff’s branch offices and representatives |

95 |

||

|

Beckhoff Headquarters |

95 |

||

|

Beckhoff Support |

95 |

||

|

Beckhoff Service |

95 |

||

|

EtherCAT Technology Group (ETG) Headquarters |

95 |

||

4 |

Application Note ET9300 |

FIGURES |

|

Figure 1: EtherCAT Slave Stack Code .................................................................................................. |

11 |

Figure 2: File-Stack Association ............................................................................................................ |

11 |

Figure 3: RxPdo data of an EtherCAT slave ......................................................................................... |

36 |

Figure 4: EL9800 Application object ranges.......................................................................................... |

45 |

Figure 5: Send EoE datagram ............................................................................................................... |

48 |

Figure 6: Receive EoE datagram .......................................................................................................... |

49 |

Figure 7: EoE Example 1 (Schema) ...................................................................................................... |

50 |

Figure 8: Network card settings............................................................................................................. |

51 |

Figure 9: Access EtherCAT Slave Settings........................................................................................... |

51 |

Figure 10: EoE EtherCAT Slave Settings.............................................................................................. |

52 |

Figure 11: Ping Command Window....................................................................................................... |

52 |

Figure 12: EoE Example 2 (Schema).................................................................................................... |

53 |

Figure 13: Enable IP Routing WinXP .................................................................................................... |

53 |

Figure 14: Enable IP Routing WinCE .................................................................................................... |

54 |

Figure 15: ESC Interrupt Signals........................................................................................................... |

55 |

Figure 16: Free Run .............................................................................................................................. |

57 |

Figure 17: SyncManager Synchronization ............................................................................................ |

57 |

Figure 18: SM/Sync0 Synchronization .................................................................................................. |

58 |

Figure 19: SM/Sync0/Sync1 Synchronization ....................................................................................... |

58 |

Figure 20: Sync0 Synchronization......................................................................................................... |

59 |

Figure 21: Sync0/Sync1 Synchronization.............................................................................................. |

59 |

Figure 22: Subordinated Cycles ............................................................................................................ |

60 |

Figure 23: CiA402 state transitions and option codes........................................................................... |

63 |

Figure 24: Axis configuration ................................................................................................................. |

65 |

Figure 25: Set device variable without PLC link .................................................................................... |

66 |

Figure 26: Scan for new EtherCAT devices with TwinCAT 2................................................................ |

66 |

Figure 27: Scan for new EtherCAT devices with TwinCAT 3................................................................ |

67 |

Figure 28: TwinCAT 2 CiA402 axis setup ............................................................................................. |

67 |

Figure 29: TwinCAT 3 CiA402 axis setup ............................................................................................. |

68 |

Figure 30: Add CiA402 device............................................................................................................... |

68 |

Figure 31: Link multiple variables .......................................................................................................... |

69 |

Figure 32: Encoder scaling.................................................................................................................... |

70 |

Figure 33: Velocity scaling..................................................................................................................... |

70 |

Figure 34: Configurator Main User Interface ......................................................................................... |

77 |

Figure 35: Configurator File Menu......................................................................................................... |

78 |

Figure 36: Create New Project .............................................................................................................. |

78 |

Figure 37: Configurator Project Menu ................................................................................................... |

78 |

Figure 38: Find Setting Dialog ............................................................................................................... |

79 |

Figure 39: Tool Menu ............................................................................................................................ |

79 |

Figure 40: Tool Options ......................................................................................................................... |

80 |

Figure 41: Configurator Locked Setting................................................................................................. |

80 |

Figure 42: Configurations List................................................................................................................ |

81 |

Figure 43: Configurator Help Menu ....................................................................................................... |

81 |

Figure 44: Configurator Project Information .......................................................................................... |

82 |

Figure 45: Configurator File Context Menu ........................................................................................... |

82 |

Figure 46: Configurator Slave Settings ................................................................................................. |

83 |

Figure 47: Configurator Create Files ..................................................................................................... |

84 |

Figure 48: Configurator Slave Stack Code Update ............................................................................... |

84 |

Figure 49: Configurator Project Update Dialog ..................................................................................... |

85 |

Figure 50: New Project | Import Configuration ...................................................................................... |

86 |

Figure 51: Options | Import Configuration ............................................................................................. |

86 |

Figure 52: SSC OD Tool workflow ........................................................................................................ |

87 |

Figure 53: Excel application definition example .................................................................................... |

87 |

Figure 54: Application file comment ...................................................................................................... |

88 |

Figure 55: EEPROM Programming Tool ............................................................................................... |

92 |

Figure 56: EEPROM Programmer | File ................................................................................................ |

93 |

Figure 57: EEPROM Programmer | Slaves........................................................................................... |

93 |

Figure 58: EEPROM Programmer | List Elements ................................................................................ |

93 |

Application Note ET9300 |

5 |

TABLES |

|

Table 1: Hardware Related Settings ..................................................................................................... |

12 |

Table 2: Recommended Hardware Configurations ............................................................................... |

14 |

Table 3: Application Related Settings ................................................................................................... |

26 |

Table 4: TSDOINFOENTRYDESC member variables .......................................................................... |

42 |

Table 5: "TOBJECT" member variables ................................................................................................ |

43 |

Table 6: Basic object index ranges ....................................................................................................... |

44 |

Table 7: Supported Sync Modes ........................................................................................................... |

56 |

Table 8: Object definitions in file cia402appl.h ................................................................................ |

61 |

Table 9: State machine.......................................................................................................................... |

64 |

Table 10: Linking of device and NC variables ....................................................................................... |

68 |

Table 11: Test Object ............................................................................................................................ |

71 |

Table 12: Test Object Entry................................................................................................................... |

71 |

Table 13: Test Control Object................................................................................................................ |

71 |

Table 14: Test Control Object Entries ................................................................................................... |

72 |

Table 15: Test Application | ESC Register 0xF80:0xF83 ...................................................................... |

72 |

Table 16: Test Object 0x2000 (ESM Group 1) ...................................................................................... |

72 |

Table 17: Test Object 0x2010 (Mailbox Group 1) ................................................................................. |

73 |

Table 18: Test Object 0x2020 (CoE Group 1)....................................................................................... |

73 |

Table 19: Test Object 0x2030 (FoE Group 1) ....................................................................................... |

73 |

Table 20: Generic Objects..................................................................................................................... |

74 |

Table 21: PDO mapping and SM assign object generation .................................................................. |

88 |

Table 22: Base Data Types ................................................................................................................... |

89 |

Table 23: Entry access rights ................................................................................................................ |

90 |

Table 24: Enum definition...................................................................................................................... |

91 |

Table 25: Enum usage .......................................................................................................................... |

91 |

Table 26: EEPROM Emulation Settings ................................................................................................ |

92 |

6 |

Application Note ET9300 |

1References

[1]ETG.6010 Implementation Guideline for the CiA402 Drive Profile (www.ethercat.org/ETG6010)

[2]ETG.1000 part 6 Application Layer protocol specification (www.ethercat.org/ETG1000)

[3]Application Note EL9800

[4]ETG.2000 Slave Information Specification (www.ethercat.org/ETG2000)

[5]ETG 5001 Modular Device Profile Specification (www.ethercat.org/ETG5001)

[6]ET1100 Datasheet

[7]ETG.1020 Protocol Enhancements (www.ethercat.org/ETG1020)

[8]EtherCAT Slave Quick Design Guide (http://download.beckhoff.com/download/Document/EtherCAT/Development_products/EtherC AT_Slave_Design_Quick_Guide.pdf)

Application Note ET9300 |

7 |

2 Terms, Definition, Abbreviation

Base Datatypes -- CoE Datatypes defined in ETG.1000.6

Entry – in conclusion with object single element,

in conclusion with object dictionary the objects

Subindex -- describes a single element (entry) of an object

Object dictionary – the object dictionary is a list of objects. Within this list each object is uniquely identified by an (object) index.

2.1Abbreviation

Abbreviation |

Description |

AL |

Application Layer |

CoE |

CANopen application profile over EtherCAT |

|

CANopen™ is a registered trademark of CAN in |

|

Automation e.V., Nuremberg, Germany |

|

CANopen™ Drive Profile specified in IEC 61800-7-201; |

CiA402 |

CANopen™ and CiA™ are registered trademarks of CAN |

|

in Automation e.V., Nuremberg, Germany |

csp |

cycle synchronous position |

csv |

cycle synchronous velocity |

DC |

Distributed Clocks |

EoE |

Ethernet over EtherCAT |

ESC |

EtherCAT Slave Controller |

FoE |

File Transfer over EtherCAT |

GPO |

General Purpose Output |

NC |

Numeric Control |

PDI |

Process data interface |

PDO |

Process Data Object |

PLC |

Programmable Logic Controller |

SI |

SubIndex |

SII |

Slave Information Interface |

SM |

Sync Manager |

SPI |

Serial Peripheral Interface |

SSC |

Slave Stack Code |

8 |

Application Note ET9300 |

3 Getting Started

This is a step by step instruction how to start the EtherCAT slave development with the Slave Stack Code (SSC).

There is also an EtherCAT Slave Design Quick Guide available in the downloaded SSC archive.

In general two possibilities are available either using the SSC Tool (3.1 SSC Tool) or the default SSC files (3.2 Default SSC files).

3.1SSC Tool

1.Download the Slave Stack Code here.

NOTE: To download the SSC the ETG member login and an EtherCAT Vendor ID is required. If you are not an ETG member click here or if you do not have an EtherCAT Vendor ID click here.

2.Unzip the downloaded archive.

3.Install "EtherCAT Slave Stack Code Tool.msi".

4.Start the SSC Tool (Start -> Program Files -> EtherCAT Slave Stack Code Tool -> SSC Tool).

5.Acknowledge the usage agreement.

6.Enter your Vendor ID and company name.

7.Create a new project (File -> New)

8.Select ...

a.the default SSC configuration.

b.a custom platform/application configuration. If a configuration file is available it can also be added via the "Import" button.

NOTE: If the SSC shall be executed on a third party platform, e.g. Texas Instruments AM335x or Renesas R-IN32M3, it is recommended to use the corresponding configuration.

9.If the default SSC configuration was selected the hardware settings should be adapted according to the target platform (Project Navigation -> "Hardware").

10.Select the slave application (Project Navigation -> "Application").

11.Save the project (File -> Save).

12.If Doxygen is installed a source code documentation can be created automatically (Tool -> Options -> Create Files -> Create Documentation).

13.Create the slave files (Project -> Create new Slave Files).

14.Click "Start".

15.Create a slave project with the target platform specific IDE, import the generated source files and run the slave binary. For further details see the IDE/SDK documentation of the platform vendor.

16.Make the ESI file available in the ESI cache of the EtherCAT configuration tool/master.

17.Connect the slave platform and the EtherCAT configuration tool and create a network.

18.Run the network configuration.

3.2Default SSC files

1.Download the Slave Stack Code here.

NOTE: To download the SSC the ETG member login and an EtherCAT Vendor ID is required. If you are not an ETG member click here or if you do not have an EtherCAT Vendor ID click here.

2.Unzip the downloaded archive.

3.Create a slave project with the target platform specific IDE, import the SSC files and run the slave binary. For further details see the IDE/SDK documentation of the platform vendor.

4.Adapt the settings in ecat_def.h to the target platform and application.

Application Note ET9300 |

9 |

5.Create an ESI file according to the settings in step 4.

6.Make the ESI file available in the ESI cache of the EtherCAT configuration tool/master.

7.Connect the slave platform and the EtherCAT configuration tool and create a network.

8.Run the network configuration.

10 |

Application Note ET9300 |

4 Code Structure

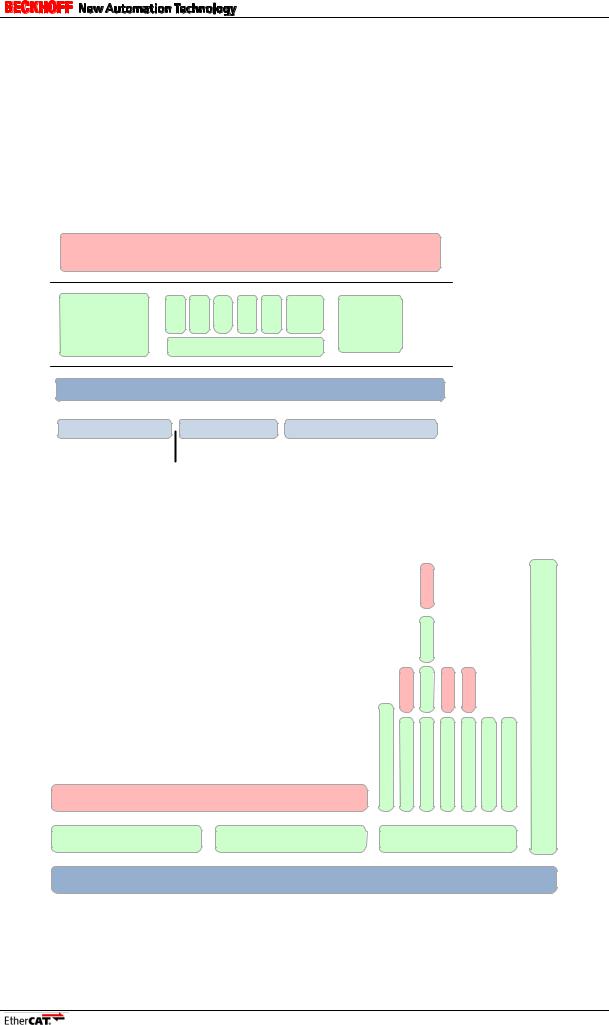

The EtherCAT slave stack as seen in Figure 1 consists of three parts:

-PDI/Hardware abstraction

-Generic EtherCAT stack

-User application

The functions and macros which shall be provided by the hardware access layer (Hardware function set) are defined in chapter 5 Hardware Access. The behavior of the generic EtherCAT stack is described in ETG.1000 Specification [2] . The functions which shall be provided by the application (Application function set) are defined in chapter 6 Application.

EtherCAT

State

Machine

0x0000 |

Register |

|

Application e.g. CiA402 Drive Profile

Application function set

AoE |

FoE |

EoE |

SoE |

VoE |

CoE |

Process |

|

|

|

|

|

|

|

|

|

|

|

|

|

data |

|

|

Mailbox |

|

|

||

|

Hardware function set |

|

||||

PDI and hardware abstraction |

||||||

|

|

Mailbox |

|

|

Process data |

|

|

0x1000 |

ESC address space (DPRAM) |

||||

|

|

|

||||

User

Application

Generic EtherCAT stack

Hardware

access

EtherCAT Slave

Controller (extract)

Figure 1: EtherCAT Slave Stack Code

Figure 2 shows the association between the Slave Stack Code layers and the source files.

User application files (el9800appl.*,cia402appl.*,... )

coeappl.*

|

aoeappl.* |

sdoserv.* objdef.* |

foeappl.* |

eoeappl.* |

|

|

header (ecat_def.h) |

Emergency (emcy.*) |

AoE (ecataoe.*) |

CoE (ecatcoe.*) |

FoE (ecatfoe.*) |

EoE (ecateoe.*) |

SoE (ecatsoe.*) |

VoE |

Slave configuration |

Sate machine (ecatslv.*) |

Process data handling (ecatappl.*) |

Mailbox handling (mailbox.*) |

PDI and hardware access functions (el9800hw.*; mcihw.*;fc1100hw.*)

Figure 2: File-Stack Association

The structure of the code can be adapted to the application specific requirements by using the Slave Stack Code Tool (chapter 12).

Application Note ET9300 |

11 |

5 Hardware Access

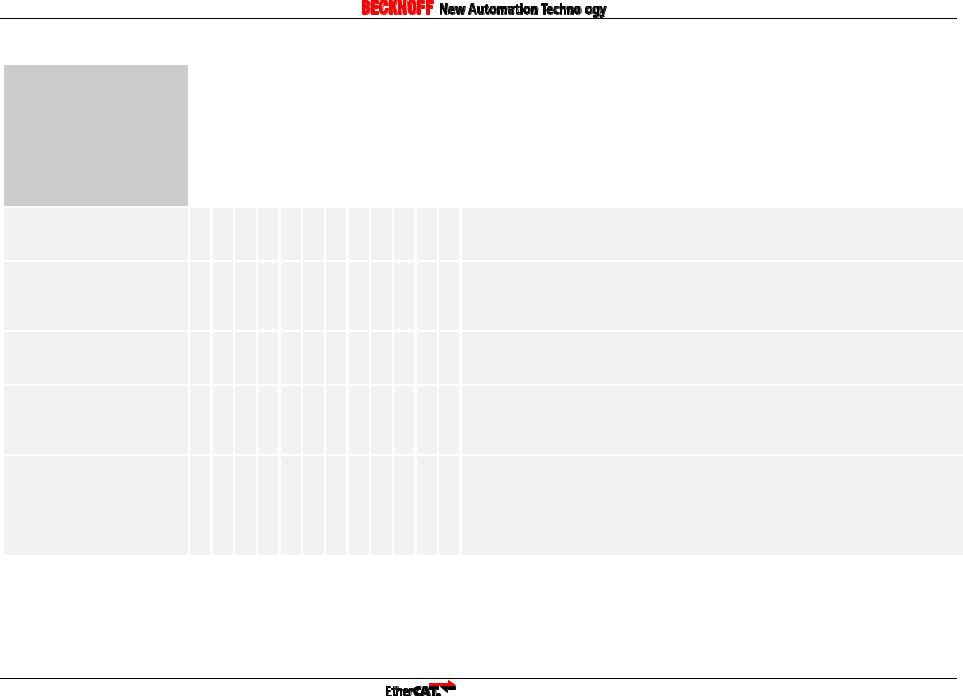

The Slave Stack Code is executable on multiple platforms and controller architectures. This chapter describes the available hardware implementations/settings and how to implement a new user specific hardware access.

To support multiple hardware architectures the SSC includes multiple settings to fulfill the specific hardware requirements. Table 1: Hardware Related Settings includes a list of the defined hardware settings (located in ecat_def.h or in the SSC Tool).

Define

EL9800_HW

Table 1: Hardware Related Settings

Description

Hardware access if the slave code is executed on the PIC mounted on EL9800 EtherCAT Evaluation Kit from Beckhoff Automation GmbH. It includes PIC initialization and ESC access via SPI. This configuration could also be used if the SSC needs to be adapted to any other 8 or 16Bit µC which accesses the ESC via SPI.

PIC24

PIC18

MCI_HW

FC1100_HW

CONTROLLER_16BIT

CONTROLLER_32BIT

ESC_16BIT_ACCESS

Activates the configuration for the Microchip PCI24HJ128GP306 µC which is mounted on the EL9800 EtherCAT Evaluation board since

Revision 4A. This setting shall only active if define “EL9800_HW” is also set.

Activates the configuration for the Microchip PIC18F452 µC which is mounted on the EL9800 EtherCAT Evaluation board, Revision 2. This setting shall only active if define “EL9800_HW” is also set.

Generic MCI implementation. Can be used if any kind of memory interface face is used to access the ESC.

Specific hardware implementation for the FC1100 PCI EtherCAT slave card from Beckhoff. Used on Win32 operating system.

This setting shall be used if the slave code is built for a 16Bit µC.

This setting shall be used if the slave code is built for a 32Bit µC.

If this setting is set, then only 16Bit aligned accesses will be performed on the ESC.

ESC_32BIT_ACCESS

MBX_16BIT_ACCESS

BIG_ENDIAN_16BIT

BIG_ENDIAN_FORMAT

If this setting is set, then only 32Bit aligned accesses will be performed on the ESC.

If this setting is set, then the slave code will only access mailbox data 16Bit aligned. If the mailbox data is copied to the local µC memory and the define “CONTROLLER_16BIT” is set, then this define should also be set.

These define needs to be set if the µC always accesses external memory 16Bit wise. It works in big endian format and the switching of Low Byte and High Byte is done in hardware.

This setting shall be set if the µC works in big endian format.

The settings “EL9800_HW”, “PIC24”, “PIC18”, MCI_HW”, “FC1100_HW” are used to activate a predefined hardware access implementation. An extract of platforms/ µC is listed in Table 2: Recommended Hardware Configurations including the recommended settings. Some of the configurations can also be selected if a new project is created with the SSC Tool (see comment). If none of these settings are used, then user specific hardware access files need to be added to the

12 |

Application Note ET9300 |

slave project.

In general the hardware access implementation needs to support the following features:

-ESC read/write access

-Timer supply (at least 1ms base tick)

-Calling of timer handler every 1ms (only required if timer interrupt handling is supported

,“ECAT_TIMER_INT” set to 1)

-Calling the interrupt specific functions (only required if synchronization is supported)

o PDI ISR (required if “AL_EVENT_SUPPORTED” set to 1) o SYNC0 ISR (required if “DC_SUPPORTED” set to 1)

Application Note ET9300 |

13 |

Platform

Microchip PIC18F452 Generic : 8Bit µC ; SPI ESC access

Microchip PIC24HJ128GP306 Generic: 16Bit µC; SPI ESC access

x86

(OS Windows)

Texas Instruments Sitara

AM335x

Altera® NIOS®II

(ESC connected via Avalon bus)

Table 2: Recommended Hardware Configurations

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BIG ENDIAN FORMAT |

|

|

Comment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

EL9800 HW |

|

PIC24 |

|

PIC18 |

|

MCI HW |

|

FC1100 HW |

|

CONTROLLER 16BIT |

|

CONTROLLER 32BIT |

|

ESC 16BIT ACCESS |

|

ESC 32BIT ACCESS |

|

MBX 16BIT ACCESS |

|

BIG ENDIAN 16BIT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

0 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

The stack is ready to use if the PIC 18 on the EL9800 EtherCAT Evaluation board |

|

|

|

|

|

|

|

|

|

|

|

|

is used. Otherwise there might be requirements to adapt the hardware access |

1 |

1 |

0 |

0 |

0 |

1 |

0 |

1 |

0 |

1 |

0 |

0 |

The stack is ready to use if the PIC 24 on the EL9800 EtherCAT Evaluation board |

|

|

|

|

|

|

|

|

|

|

|

|

is used. Otherwise there might be requirements to adapt the hardware access. |

0 |

0 |

0 |

0 |

1 |

0 |

1 |

0 |

1 |

0 |

0 |

0 |

The stack is ready to use if the stack shall run on a Win32 OS in user mode. |

|

|

|

|

|

|

|

|

|

|

|

|

Otherwise changes in hardware access might be required. |

|

|

|

|

|

|

|

|

|

|

|

|

The setting “FC1100_HW” is a adapted implementation based on “MCI_HW |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

To use the SSC on TI AM335x chips the hardware access files from the TI SDK |

|

|

|

|

|

|

|

|

|

|

|

|

need to be added to the project. The files can be added to the slave project via the |

|

|

|

|

|

|

|

|

|

|

|

|

patch file (delivered with the SDK), by selecting the TI configuration in the SSC |

|

|

|

|

|

|

|

|

|

|

|

|

Tool or by adding the files manually. |

0 |

0 |

0 |

1 |

0 |

x |

x |

x |

x |

x |

0 |

0 |

x: depends on the NIOS® configuration in the SOPC builder. |

|

|

|

|

|

|

|

|

|

|

|

|

In general the following points need to be adapted: |

-define “MAKE_PTR_TO_ESC”

-ISRs for Timer/PDI interrupt and Sync0 (depends on the supported features)

-Implement timer access functions and macros

Depending on the platform configuration further changes may be required.

14 |

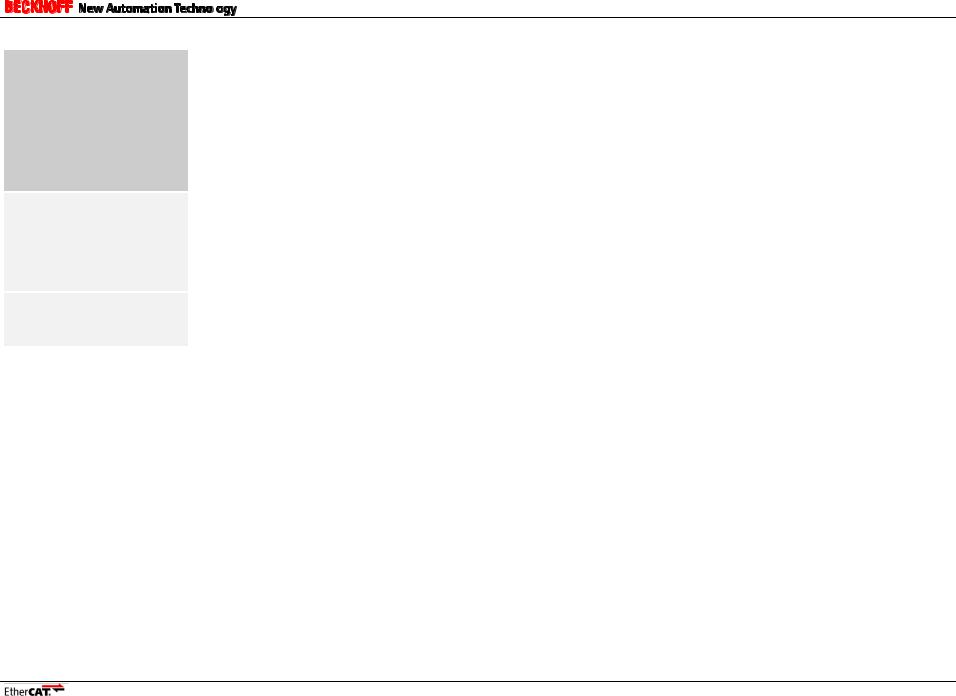

Application Note ET9300 |

Platform

Xilinx Microblaze™

(ESC connected via PLB)

Renesas - RIN32M3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTROLLER 16BIT |

|

|

CONTROLLER 32BIT |

|

|

|

|

|

|

|

|

|

|

|

|

MBX 16BIT ACCESS |

|

|

|

|

|

|

|

BIG ENDIAN FORMAT |

|

|

Comment |

|

||||

|

EL9800_HW |

|

|

|

PIC24 |

|

|

|

PIC18 |

|

|

MCI_HW |

|

|

|

FC1100_HW |

|

|

|

|

|

|

|

|

ESC_16BIT_ACCESS |

|

|

|

ESC_32BIT_ACCESS |

|

|

|

|

|

BIG_ENDIAN_16BIT |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

0 |

|

|

|

0 |

|

|

|

0 |

|

|

|

1 |

|

|

|

0 |

|

|

|

|

x |

|

|

|

x |

|

|

|

|

x |

|

|

|

|

x |

|

|

|

x |

|

|

|

|

x |

|

|

|

0 |

|

|

|

x: depends on the Microblaze™ configuration. |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In general the following points need to be adapted: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- define “MAKE_PTR_TO_ESC” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- ISRs for Timer/PDI interrupt and Sync0 (depends on the supported features) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Implement timer access functions and macros |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Depending on the platform configuration further changes may be required. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

|

0 |

|

|

|

|

0 |

|

|

|

|

0 |

|

|

|

0 |

|

|

|

|

0 |

|

|

|

|

0 |

|

|

|

0 |

|

|

|

|

0 |

|

|

|

|

0 |

|

|

|

0 |

|

|

|

|

0 |

|

|

|

0 |

|

|

|

To use the SSC on Renesas RIN32M3 chip the chip specific hardware access files |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

need to be added to the project. The files are added automatically if the Renesas |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PIN32M3 configuration is selected in the SSC Tool. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Application Note ET9300 |

15 |

5.1Interrupt Handler

The following functions are provided by the generic Slave Stack Code (defined in ecatappl.h) and need to be called from the hardware access layer.

Prototype: |

void ECAT_CheckTimer (void) |

Parameter |

void |

Return |

void |

Description |

This function needs to be called every 1ms from a timer ISR |

|

(ECAT_TIMER_INT = 1). If no timer interrupt is supported this function is called |

|

automatically when 1ms is elapsed (based on the provided timer). |

Prototype: |

void PDI_Isr (void) |

Parameter |

void |

Return |

void |

Description |

This function need to be called from the PDI ISR. For the PDI specific pin |

|

naming and the interrupt generation logic please refer to [6] . To support PDI |

|

interrupt handling it is also required to set “AL_EVENT_ENABLED” to 1. |

Prototype: |

void Sync0_Isr (void) |

Parameter |

void |

Return |

void |

Description |

This function needs to be called from the Sync0 ISR. The Sync0 interrupt is |

|

generated by the DC Unit of the ESC. It is currently not supported by default to |

|

map the Sync0 signal to the PDI interrupt. To support Dc synchronization |

|

“DC_SUPPORTED” need to be set. |

Prototype: |

void Sync1_Isr (void) |

Parameter |

void |

Return |

void |

Description |

This function needs to be called from the Sync1 ISR. The Sync1 interrupt is |

|

generated by the DC Unit of the ESC. It is currently not supported by default to |

|

map the Sync1 signal to the PDI interrupt. To support Dc synchronization |

|

“DC_SUPPORTED” need to be set. |

5.2Interface Functions/Macros

The functions and macros listed in this chapter need to be implemented by the hardware access layer.

16 |

Application Note ET9300 |

5.2.1Generic

Prototype: |

UINT16 HW_Init(void) |

Parameter |

void |

Return |

0 if initialization was successful |

|

> 0 if error has occurred while initialization |

Description |

Initializes the host controller, process data interface (PDI) and allocates |

|

resources which are required for hardware access. |

Prototype: |

void HW_Release(void) |

Parameter |

void |

Return |

void |

Description |

Release allocated resources. |

Prototype: |

UINT16 HW_GetALEventRegister(void) |

Parameter |

void |

Return |

Content of register 0x220-0x221 |

Description |

Get the first two bytes of the AL Event register (0x220-0x221). |

Prototype: |

UINT16 HW_GetALEventRegister_Isr(void) |

Parameter |

void |

Return |

Content of register 0x220-0x221 |

Description |

This function should be implemented if a special function for ESC access from |

|

interrupt service routines is required; otherwise this function is defined as |

|

HW_GetALEventRegister. |

|

Get the first two bytes of the AL Event register (0x220-0x221). |

Prototype: |

void HW_ResetALEventMask(UINT16 intMask) |

|

Parameter |

“intMask” |

Interrupt mask (disabled interrupt shall be zero) |

Return |

void |

|

Description |

Performs a logical AND with the AL Event Mask register (0x0204 : 0x0205). |

|

|

This function is only required if “AL_EVENT_ENABLED” is set. |

|

|

NOTE: This function is only required for SSC 5.10 or older. |

|

Application Note ET9300 |

17 |

Prototype: |

void HW_SetALEventMask(UINT16 intMask) |

|

Parameter |

“intMask” |

Interrupt mask (enabled interrupt shall be one) |

Return |

void |

|

Description |

Performs a logical OR with the AL Event Mask register (0x0204 : 0x0205). |

|

|

This function is only required if “AL_EVENT_ENABLED” is set. |

|

|

NOTE: This function is only required for SSC 5.10 or older. |

|

Prototype: |

void HW_SetLed(UINT8 RunLed,UINT8 ErrLed) |

|

Parameter |

“RunLed” |

EtherCAT Run LED state |

|

“ErrLed” |

EtherCAT Error LED state |

Return |

void |

|

Description |

Updates the EtherCAT Run and Error LEDs (or EtherCAT Status LED). |

|

Prototype: |

void HW_RestartTarget(void) |

|

Parameter |

void |

|

Return |

void |

|

Description |

Resets the hardware. This function is only required if |

|

|

“BOOTSTRAPMODE_SUPPORTED” is set. |

|

Prototype: |

void HW_DisableSyncManChannel(UINT8 channel) |

|

Parameter |

“channel” |

SyncManager channel |

Return |

void |

|

Description |

Disables selected SyncManager channel. Sets bit 0 of the corresponding 0x807 |

|

|

register. |

|

|

NOTE: This function is only required for SSC 5.10 or older. |

|

Prototype: |

void HW_EnableSyncManChannel (UINT8 channel) |

|

Parameter |

“channel” |

SyncManager channel |

Return |

void |

|

Description |

Enables selected SyncManager channel. Resets bit 0 of the corresponding |

|

|

0x807 register. |

|

|

NOTE: This function is only required for SSC 5.10 or older. |

|

18 |

Application Note ET9300 |

Prototype: |

TSYNCMAN * HW_GetSyncMan(UINT8 channel) |

|

Parameter |

“channel” |

SyncManager channel |

Return |

Pointer to the SyncManager channel description. The SyncManager description |

|

|

structure size is always 8 Byte, the content of “TSYNCMAN” differs depending |

|

|

on the supported ESC access. |

|

Description |

Gets the content of the SyncManager register from the stated channel. Reads 8 |

|

|

Bytes starting at 0x800 + 8*channel. |

|

|

NOTE: This function is only required for SSC 5.10 or older. |

|

Prototype: |

UINT32 HW_GetTimer(void) |

|

Parameter |

void |

|

Return |

Current timer value |

|

Description |

Reads the current register value of the hardware timer. If no hardware timer is |

|

|

available the function shall return the counter value of a multimedia timer. The |

|

|

timer ticks value (increments / ms) is defined in “ECAT_TIMER_INC_P_MS”. |

|

|

This function is required if no timer interrupt is supported (“ECAT_TIMER_INT” |

|

|

= 0) and to calculate the bus cycle time. |

|

Prototype: |

void HW_ClearTimer(void) |

|

Parameter |

void |

|

Return |

void |

|

Description |

Clears the hardware timer value. |

|

Prototype: |

UINT16 HW_EepromReload (void) |

|

Parameter |

void |

|

Return |

0 <> Error during EEPORM reload |

|

|

0 = EEPROM load correct |

|

Description |

This function is called if an EEPROM reload request is triggered by the master. |

|

|

Only required if EEPROM Emulation is supported and the function pointer |

|

|

“pAPPL_EEPROM_Reload” is not set. |

|

Application Note ET9300 |

19 |

5.2.2Read Access

Prototype: |

void HW_EscRead(MEM_ADDR *pData, UINT16 Address, UINT16 Len ) |

|

Parameter |

“pData” |

Pointer to local destination buffer. Type of the pointer depends |

|

|

on the host controller architecture (specified in ecat_def.h or |

|

|

the SSC Tool). |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid addresses are |

|

|

used depending on 8Bit/16Bit or 32 Bit ESC access (specified |

|

|

in ecat_def.h or the SSC Tool). |

|

“Len” |

Access size in Bytes |

Return |

void |

|

Description |

Reads from the EtherCAT Slave Controller. This function is used to access |

|

|

ESC registers and the DPRAM area. |

|

Prototype: |

void HW_EscReadIsr(MEM_ADDR *pData, UINT16 Address, UINT16 Len ) |

|

Parameter |

“pData” |

Pointer to local destination buffer. Type of the pointer depends |

|

|

on the host controller architecture (specified in ecat_def.h or |

|

|

the SSC Tool). |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid addresses are |

|

|

used depending on 8Bit/16Bit or 32 Bit ESC access (specified |

|

|

in ecat_def.h or the SSC Tool). |

|

“Len” |

Access size in Bytes |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

|

“HW_EscRead”. |

|

|

Reads from the EtherCAT Slave Controller. This function is used to access |

|

|

ESC registers and the DPRAM area. |

|

Prototype: |

void HW_EscReadDWord(UINT32 DWordValue, UINT16 Address) |

|

Parameter |

“DWordValue” |

Local 32Bit variable where the register value shall be stored. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid 32Bit addresses |

|

|

are used.. |

Return |

void |

|

Description |

Reads two words from the specified address of the EtherCAT Slave Controller. |

|

20 |

Application Note ET9300 |

Prototype: |

void HW_EscReadDWordIsr(UINT32 DWordValue, UINT16 Address) |

|

Parameter |

“DWordValue” |

Local 32Bit variable where the register value shall be stored. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid 32Bit addresses |

|

|

are used. |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

|

“HW_EscReadWord”. |

|

|

Reads two words from the specified address of the EtherCAT Slave Controller. |

|

Prototype: |

void HW_EscReadWord(UINT16 WordValue, UINT16 Address) |

|

Parameter |

“WordValue” |

Local 16Bit variable where the register value shall be stored. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid 16Bit addresses |

|

|

are used. |

Return |

void |

|

Description |

Reads one word from the specified address of the EtherCAT Slave Controller. |

|

|

Only required if “ESC_32BIT_ACCESS” is not set. |

|

Prototype: |

void HW_EscReadWordIsr(UINT16 WordValue, UINT16 Address) |

|

Parameter |

“WordValue” |

Local 16Bit variable where the register value shall be stored. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid 16Bit addresses |

|

|

are used. |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

“HW_EscReadWord”.

Reads one word from the specified address of the EtherCAT Slave Controller.

Only required if “ESC_32_BIT_ACCESS” is not set.

Application Note ET9300 |

21 |

Prototype: |

void HW_EscReadByte(UINT8 ByteValue, UINT16 Address) |

|

Parameter |

“ByteValue” |

Local 8Bit variable where the register value shall be stored. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. |

Return |

void |

|

Description |

Reads one byte from the EtherCAT Slave Controller. |

|

|

Only required if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are not |

|

|

set. |

|

Prototype: |

void HW_EscReadByteIsr(UINT8 ByteValue, UINT16 Address) |

|

Parameter |

“ByteValue” |

Local 8Bit variable where the register value shall be stored. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

|

“HW_EscReadByte”. |

|

|

Reads one byte from the EtherCAT Slave Controller. |

|

|

Only required if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are not |

|

|

set. |

|

Prototype: |

void HW_EscReadMbxMem(MEM_ADDR *pData, UINT16 Address, |

|

|

UINT16 Len ) |

|

Parameter |

“pData” |

Pointer to local destination mailbox buffer. Type of the pointer |

|

|

depends on the host controller architecture (specified in |

|

|

ecat_def.h or the SSC Tool). |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid addresses are |

|

|

used depending on 8Bit/16Bit or 32 Bit ESC access (specified |

|

|

in ecat_def.h or the SSC Tool). |

|

“Len” |

Access size in Bytes |

Return |

void |

|

Description |

Reads data from the ESC and copies to slave mailbox memory. If the local |

|

|

mailbox memory is also located in the application memory this function is equal |

|

|

to “HW_EscRead”. |

|

22 |

Application Note ET9300 |

5.2.3Write Access

Prototype: |

void HW_EscWrite(MEM_ADDR *pData, UINT16 Address, UINT16 Len ) |

|

Parameter |

“pData” |

Pointer to local source buffer. Type of the pointer depends on |

|

|

the host controller architecture (specified in ecat_def.h or the |

|

|

SSC Tool). |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid addresses are |

|

|

used depending on 8Bit/16Bit or 32 Bit ESC access (specified |

|

|

in ecat_def.h or the SSC Tool). |

|

“Len” |

Access size in Bytes |

Return |

void |

|

Description |

Writes from the EtherCAT Slave Controller. This function is used to access |

|

|

ESC registers and the DPRAM area. |

|

Prototype: |

void HW_EscWriteIsr(MEM_ADDR *pData, UINT16 Address, |

|

|

UINT16 Len ) |

|

Parameter |

“pData” |

Pointer to local source buffer. Type of the pointer depends on |

|

|

the host controller architecture (specified in ecat_def.h or the |

|

|

SSC Tool). |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid addresses are |

|

|

used depending on 8Bit/16Bit or 32 Bit ESC access (specified |

|

|

in ecat_def.h or the SSC Tool). |

|

“Len” |

Access size in Bytes |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

|

“HW_EscWrite”. |

|

|

Writes from the EtherCAT Slave Controller. This function is used to access ESC |

|

|

registers and the DPRAM area. |

|

Prototype: |

void HW_EscWriteDWord(UINT32 DWordValue, UINT16 Address) |

|

Parameter |

“DWordValue” |

Local 32Bit variable which contains the data to be written to |

|

|

the ESC memory area. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid 32Bit addresses |

|

|

are used. |

Return |

void |

|

Description |

Writes one word to the EtherCAT Slave Controller. |

|

Application Note ET9300 |

23 |

Prototype: |

void HW_EscWriteDWordIsr(UINT32 DWordValue, UINT16 Address) |

|

Parameter |

“DWordValue” Local 32Bit variable which contains the data to be written to |

|

|

|

the ESC memory area. |

|

“Address” |

EtherCAT Slave Controller address . Specifies the offset |

|

|

within the ESC memory area in Bytes. Only valid 32Bit |

|

|

addresses are used. |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

|

“HW_EscWriteWord”. |

|

|

Writes two words to the EtherCAT Slave Controller. |

|

Prototype: |

void HW_EscWriteWord(UINT16 WordValue, UINT16 Address) |

|

Parameter |

“WordValue” |

Local 16Bit variable which contains the data to be written to |

|

|

the ESC memory area. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid 16Bit addresses |

|

|

are used. |

Return |

void |

|

Description |

Writes one word to the EtherCAT Slave Controller. Only required if |

|

|

“ESC_32BIT_ACCESS” is not set. |

|

Prototype: |

void HW_EscWriteWordIsr(UINT16 WordValue, UINT16 Address) |

|

Parameter |

“WordValue” |

Local 16Bit variable which contains the data to be written to |

|

|

the ESC memory area. |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset within |

|

|

the ESC memory area in Bytes. Only valid 16Bit addresses |

|

|

are used. |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

|

“HW_EscWriteWord”. |

|

|

Writes one word to the EtherCAT Slave Controller. Only required if |

|

|

“ESC_32BIT_ACCESS” is not set. |

|

Prototype: |

void HW_EscWriteByte (UINT8 ByteValue, UINT16 Address) |

|

Parameter |

“ByteValue” |

Local 8Bit variable which contains the data to be written to |

|

|

the ESC memory area. |

24 |

|

Application Note ET9300 |

|

“Address” |

EtherCAT Slave Controller address.Specifies the offset within |

|

|

the ESC memory area in Bytes. |

Return |

void |

|

Description |

Writes one byte to the EtherCAT Slave Controller. |

|

|

Only defined if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are |

|

|

disabled. |

|

Prototype: |

void HW_EscWriteByteIsr(UINT8 ByteValue, UINT16 Address) |

|

Parameter |

“ByteValue” |

Local 8Bit variable which contains the data to be written to |

|

|

the ESC memory area |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset |

|

|

within the ESC memory area in Bytes. |

Return |

void |

|

Description |

This function should be implemented if a special function for ESC access from |

|

|

interrupt service routines is required; otherwise this function is defined as |

|

|

“HW_EscWriteByte”. |

|

|

Writes one byte to the EtherCAT Slave Controller. |

|

|

Only defined if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are |

|

|

disabled. |

|

Prototype: |

void HW_EscWriteMbxMem(MEM_ADDR *pData, UINT16 Address, |

|

|

UINT16 Len ) |

|

Parameter |

“pData” |

Pointer to local source mailbox buffer. Type of the pointer |

|

|

depends on the host controller architecture (specified in |

|

|

ecat_def.h or the SSC Tool). |

|

“Address” |

EtherCAT Slave Controller address. Specifies the offset |

|

|

within the ESC memory area in Bytes. Only valid addresses |

|

|

are used depending on 8Bit/16Bit or 32 Bit ESC access |

|

|

(specified in ecat_def.h or the SSC Tool). |

|

“Len” |

Access size in Bytes. |

Return |

void |

|

Description |

Writes data from the slave mailbox memory to ESC memory. If the local |

|

|

mailbox memory is also located in the application memory this function is equal |

|

|

to “HW_EscWrite”. |

|

Application Note ET9300 |

25 |

6 Application

This chapter includes an overview over the default (sample) applications, the application interface and a guideline how to start the own application development.

6.1Application Settings

The SSC contains a list of (sample) applications which can be used for master/slave testing or as basis for the application development. The corresponding settings are listed in Table 3: Application Related Settings (located in ecat_def.h or in the SSC Tool).

Table 3: Application Related Settings |

||

|

|

|

Define |

|

Description |

TEST_APPLICATION |

|

This application supports almost all SSC features. |

|

|

Furthermore it is possible to force specific application |

|

|

behavior (see chapter 9). |

|

|

NOTE: this application shall not be used as basis for the |

|

|

application development. |

EL9800_APPLICATION |

|

Application based on the EL9800 EtherCAT Evaluation |

|

|

Board. 8(4) LEDs: 8(4) switches; 16Bit analog input |

CiA402_DEVICE |

|

Sample Implementation for the CiA402 Drive Profile. This |

|

|

application supports 2 modular Axis. See chapter 8 for |

|

|

further information. |

SAMPLE_APPLICATION |

|

Hardware independent application. Recommend |

|

|

application is if no SSC Tool configuration is available for |

|

|

the target platform. |

SAMPLE_APPLICATION_INTERFACE |

|

Sample application for Win32 to create a dynamic link |

|

|

library. |

6.2SSC Functions

These functions are provided by the generic stack and shall be called from the application layer. The functions are declared in the header “applInterface.h”.

Prototype: |

UINT16 MainInit(void) |

Parameter |

Void |

Return |

0 if initialization was successful |

|

> 0 if error has occurred while initialization |

Description |

Initialize the generic slave stack. |

|

This function should be called after the platform including operating system and |

|

ESC is ready to use. |

Prototype: |

void MainLoop(void) |

Parameter |

Void |

Return |

Void |

Description |

This function handles the low priority function like EtherCAT state machine |

|

handling, mailbox protocols and if no synchronization is enabled also the |

|

application. |

|

This function shall be called cyclically from the application. |

26 |

Application Note ET9300 |

Prototype: |

void ECAT_StateChange(UINT8 alStatus, UINT16 alStatusCode) |

|

Parameter |

alStatus |

Requested Al Status |

|

alStatusCode |

AL Status Code. (if != 0 the error flag indication will be set) |

Return |

Void |

|

Description |

This function shall be called by the application to trigger state transition in case |

|

|

of an application error or to complete a pending transition. |

|

|

If the function was called due to an error it shall be again if the error is gone. |

|

|

NOTE: state requests to a higher state than the current state are not allowed. |

|

6.3Interface Functions

6.3.1Generic

Prototype: |

void APPL_Application(void) |

Parameter |

Void |

Return |

void |

Description |