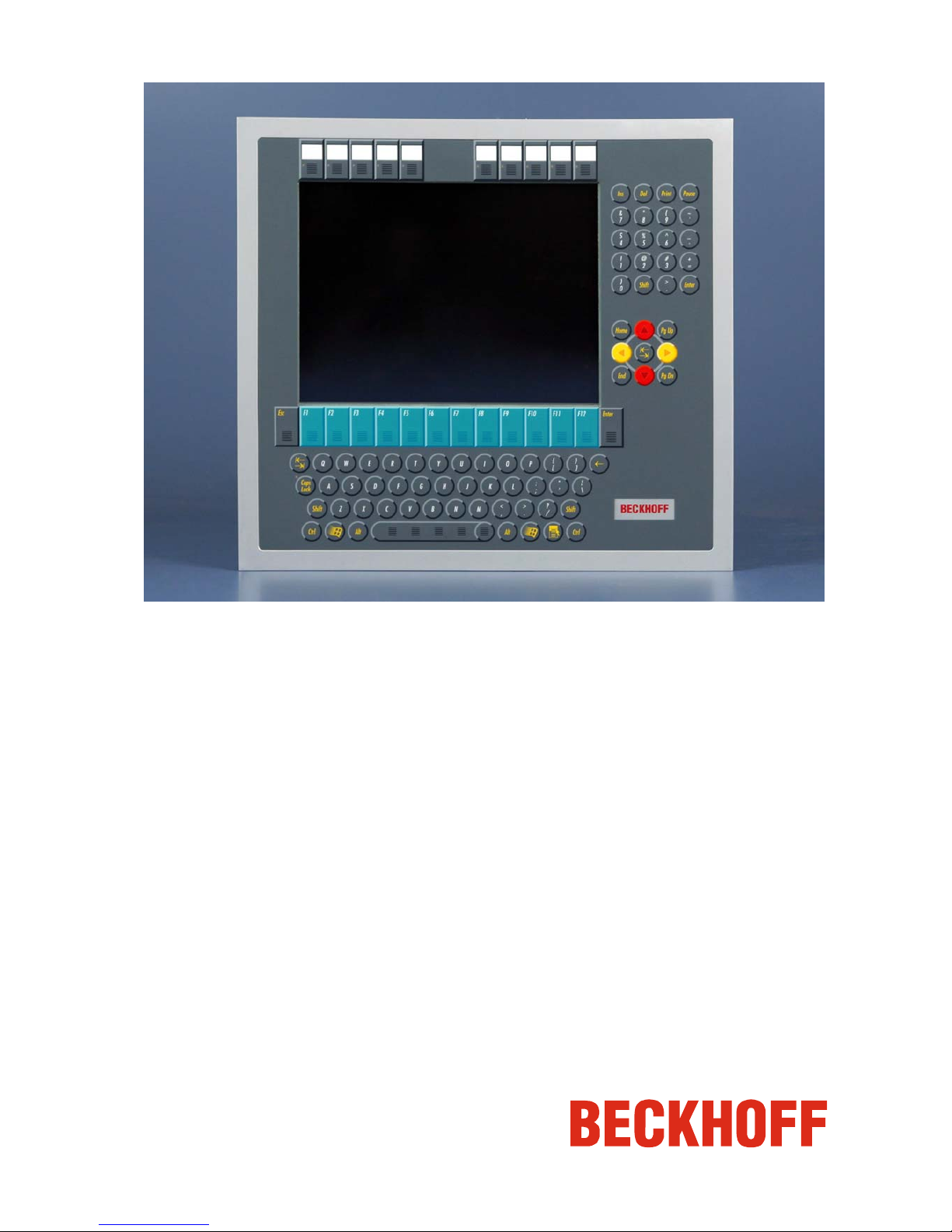

Beckhoff CP6201, CP6212, CP6202, CP6213, CP6221 Installation And Operating Instructions Manual

...

Installation and Operating instructions for

Built-in Panel PC CP62xx

Version: 1.7

Date: 2007-10-19

General Notes

Table of contents

1.

2.

3.

4.

General Notes 3

Notes on the documentation 3

Liability conditions 3

Description of safety symbols 3

Basic safety measures 4

Operator's obligation to exercise diligence 5

Operator requirements 5

Product Description 6

Appropriate Use 6

Interfaces 6

Fieldbus 6

Serial interface 6

DVI (Digital Visual Interface) 6

USB-Interfaces 6

Network connection 6

Power supply 6

Additional plug-in cards (optional) 6

Ground connection 6

Access to the drives 6

Installation Instructions 7

Transport and Unpacking 7

Transport 7

Unpacking 7

Installation of the PC in the control cabinet 8

Earthing measures 8

Assembly dimensions 9

Mounting of the Panel-PC 10

Power Supply Connection 11

Pin assignment of the connector 11

Fitting the cable 12

Material for assembling the connectors 12

Assembling the connectors 12

Connecting Power Supply 13

Cable Cross Sections 13

PC_ON, Power-Status, UPS output 13

Wiring diagram 14

Connecting devices 14

Connecting cables 14

Check voltage rating and connect 15

Operating Instructions 16

Switching the Industrial PC on and off 16

First switching on and driver installation 16

Operation 16

Keyboard codes 17

Servicing and maintenance 19

Cleaning the Industrial PC 19

Replacing the battery on the motherboard 19

Servicing 19

Replacing the fluorescent lamps in the display 19

Lamp sets 20

Emergency procedures 20

Shutting down 20

Disposal 20

CP62xx 1

General Notes

5.

6.

7.

UPS Software Components (optional) 21

Installation on the PC 21

Help files 21

Troubleshooting 22

Fault correction 22

Service and Support 23

Beckhoff's branch offices and representatives 23

Beckhoff headquarters 23

Beckhoff Support 23

Beckhoff Service 23

Appendix 24

Technical data 24

Approvals 24

FCC: Federal Communications Commission Radio Frequency Interference

Statement 24

FCC: Canadian Notice 24

2 CP62xx

General Notes

General Notes

Notes on the documentation

This description is only intended for the use of trained specialists in control

and automation engineering who are familiar with the applicable national

standards. It is essential that the following notes and explanations are

followed when installing and commissioning these components.

Liability conditions

The responsible staff must ensure that the application or use of the

products described satisfy all the requirements for safety, including all the

relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described

are, however, constantly under development. For this reason, the

documentation may not always be have been fully checked for consistency

with the performance data, standards or other characteristics described.

None of the statements in this manual represent a guarantee for as set out

in § 443 of the German Civil Code or a statement about the assumed use

according to the contract as set out in § 434 para. 1 clause 1 no. 1 of the

German Civil Code. In the event that it contains technical or editorial errors,

we retain the right to make alterations at any time and without warning. No

claims for the modification of products that have already been supplied

may be made on the basis of the data, diagrams and descriptions in this

documentation.

© This documentation is protected by copyright. Any reproduction or third

party use of this publication, whether in whole or in part, without the written

permission of Beckhoff Automation GmbH, is forbidden.

Description of safety symbols

The following safety symbols are used in this operating manual. They are

intended to alert the reader to the associated safety instructions.

Danger

This symbol is intended to highlight risks for the life or health of personnel.

Warning

This symbol is intended to highlight risks for equipment, materials or the

environment.

i

Note

This symbol indicates information that contributes to better understanding.

CP62xx 3

General Notes

Basic safety measures

Only switch the PC off after

closing the software

Before the Industrial PC is switched off, software that is running must

be properly closed.

Otherwise it is possible that data on the hard disk is lost. Please read the

section Switching the Industrial PC on and off.

Warning

Switch off all parts of the equipment, then uncouple the fieldbus!

Before opening the housing of the PC, and whenever the PC is being used

for purposes other than plant control, such as during functional tests

following repair, all parts of the equipment must first be switched off, after

which the Industrial PC can be uncoupled from the plant.

Pulling out the fieldbus connection plug uncouples the PC (optional).

Items of equipment that have been switched off must be secured against

being switched on again.

The Industrial PC’s power supply unit must be supplied with

24VDC.

Danger

Do not open the power supply unit while voltage is applied!

The supply voltage must be switched off before the power supply unit

housing is opened.

Do not exchange any parts when under power!

When components are being fitted or removed, the supply voltage must be

switched off.

Fitting work on the Industrial PC can result in damage:

• If metal objects such as screws or tools fall onto operating circuit

boards.

• If connecting cables internal to the PC are removed or inserted

during operation.

• If plug-in cards are removed or inserted when the PC is switched

on.

Danger

Displays used for the control panel’s LC-display are operated with a

voltage of up to 1000 V, depending on type. For that reason:

The supply voltage must be disconnected before the housing of the

Control Panel is opened.

4 CP62xx

General Notes

Operator's obligation to exercise diligence

The operator must ensure that

• the Industrial PC is only used for its intended purpose (see Product

Description section);

• the Industrial PC is only operated in a sound condition and in

working order;

• the instruction manual is in good condition and complete, and

always available for reference at the place of installation of the

Industrial PC;

• the Industrial PC is operated, maintained and repaired only by

suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational

safety and environmental protection aspects, and is familiar with

the operating manual and in particular the safety notes contained

herein.

• none of the safety and warning notes attached to the Industrial PC

are removed, and all notes remain legible.

National regulations

depending on the machine

type

Depending on the type of machine and plant in which the Industrial PC is

used, national regulations governing the controllers of such machines will

apply, and must be observed by the operator. These regulations cover,

amongst other things, the intervals between inspections of the controller.

The operator must initiate such inspections in good time.

Warning

Only trained persons may open the Industrial PC housing!

The operator is responsible for ensuring that only trained electrical staff

opens the housing of the Industrial PC.

Procedure in the event of a

fault

In the event of faults at the Industrial PC, the list in the section

Troubleshooting can be used to determine the measures to be taken.

Operator requirements

Read the operating

instructions

Anyone who uses the Industrial PC must have read these operating

instructions.

Software knowledge

Every user must be familiar with all the functions of the software installed

on the Industrial PC to which he has access.

CP62xx 5

Product Description

Product Description

Appropriate Use

The CP62xx Build-in Panel PC is designed for industrial application in

machine and plant engineering. A steel plate housing with aluminum front

contains a TFT display, touch screen/ pad (optional) and a PC keyboard

(optional). The Industrial PC is installed in the front of control cabinets.

Do not use the Build-in

Panel PC in areas of

explosive hazard

The Build-in Panel PC must not be used where there is a risk of

explosion.

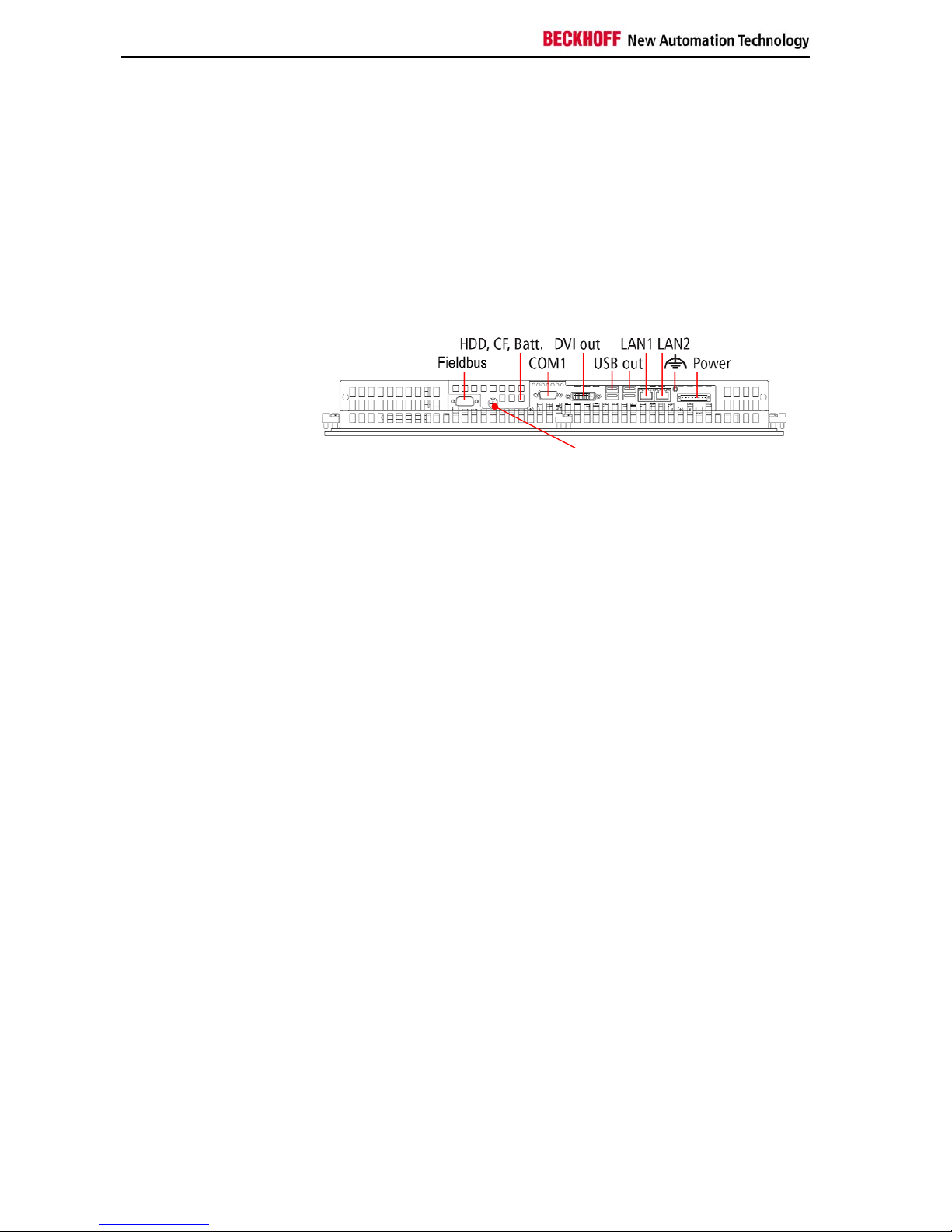

Interfaces

Interfaces to the Build-in

Panel PC

Fieldbus

Fieldbus

The Industrial PC has one fieldbus-interface, which is brought to a 9 pin

SUB-D plug connector.

Serial interface

RS 232

COM1

The Industrial PC has one serial interfaces, COM1, using the type RS232,

which are each brought to a 9 pin SUB-D plug connector.

DVI (Digital Visual Interface)

DVI out

The DVI connection is used for transferring the video signal. DVI-I standard

is supported.

USB-Interfaces

USB out

The four USB interfaces are used for connecting peripheral devices with

USB connection. USB2.0 standard is supported.

Network connection

LAN1

The RJ-45 connector allows the PC to be connected to a 10/100BASE-T

Local Area Network (LAN).

LAN2

The RJ-45 connector allows the PC to be connected to a 100/1000BASE-T

Local Area Network (LAN).

Power supply

Power

The power supply for the Industrial PC is established via the

socket.

Additional plug-in cards (optional)

Type plate

There is a type plate on the top of the Industrial PC which provides

information about the hardware configuration of the Industrial PC at the

time it was supplied.

Ground connection

Ground connection

The Control Panel is grounded via the stud bolt.

Access to the drives

Access to hard-disk, CFCard and battery

After solving the knurled screw, the cap can be removed and allows access

to hard disk, battery and CF-Card.

Knurled screw

6 CP62xx

Loading...

Loading...