BECKHOFF EL9800 User Manual

EL9800 Base Board

Version: 3.07

Date: 2013-10-16

Content

Content

1 |

Legal Notice |

5 |

|

|

1.1 |

Trademarks |

5 |

|

1.2 |

Patent Pending |

5 |

|

1.3 |

Disclaimer |

5 |

|

1.4 |

Copyright |

5 |

|

1.5 |

Safety Instructions |

6 |

|

|

1.5.1 Delivery Status |

6 |

|

|

1.5.2 Description of safety symbols |

6 |

|

1.6 |

Documentation issue status |

7 |

2 |

Product overview |

8 |

|

|

2.1 |

Power Supply |

9 |

|

2.2 |

Process Data Interface for EtherCAT postage stamps |

10 |

|

|

2.2.1 Process data interface dependent pinout of the headers J202 and TP202 |

11 |

|

2.3 |

PDI-Selection |

12 |

|

2.4 |

8/16 Bit µC-PDI-Interface |

14 |

|

2.5 |

32 Bit Digital-PDI-Interface |

17 |

|

2.6 |

PIC PDI-Interface |

19 |

|

2.7 |

SPI-PDI-Interface |

22 |

|

2.8 |

Distributed Clocks |

22 |

|

2.9 |

FPGA-Programmer |

23 |

|

2.10 |

PIC-Programmer |

24 |

3 Altera Quartus II Programmer™ |

26 |

|

3.1 |

Selecting the programming hardware |

27 |

3.2 |

Conversion of a SOF-File in the JIC-file format |

28 |

3.3 |

Choosing the programming file |

30 |

3.4 |

Programming of the FPGA/EEPROM |

30 |

4 Appendix |

31 |

|

4.1 |

Support and Service |

31 |

|

4.1.1 Beckhoff's branch offices and representatives |

31 |

4.2 |

Beckhoff Headquarters |

31 |

EL9800 |

1 |

Content

|

|

TABLES |

|

Table 1 Pinout of the headers J202 and TP202 ......................................................................................... |

11 |

||

Table 2 Positions of the PDI-Selector......................................................................................................... |

12 |

||

Table 3 Pinout of the connectors TP208 and J208 .................................................................................... |

16 |

||

Table 4 Pinout of the connector TP206 ...................................................................................................... |

16 |

||

Table 5 Port configuration of the digital PDI ............................................................................................... |

17 |

||

Table 6 |

Definition of the OE_CONF and OE_EXT signals......................................................................... |

17 |

|

Table 7 |

Pinout of the connectors TP207 and J207 .................................................................................... |

18 |

|

Table 8 |

Pinout of the connector J900......................................................................................................... |

19 |

|

Table 9 |

Location of the inputs and output ports on the PIC- ...................................................................... |

20 |

|

Table 10 Connection of SPI-interface, EEPROM and programming interface with the PIC24H ............... |

20 |

||

Table 11 |

Pinout of the connectors TP209 and J209 .................................................................................. |

20 |

|

Table 12 |

Pinout of the connector J510 ....................................................................................................... |

21 |

|

Table 13 |

Pinout of the connector J1005 ..................................................................................................... |

21 |

|

Table 14 |

Pinout of the connectors TP204 and J204 .................................................................................. |

22 |

|

2 |

EL9800 |

Content

FIGURES |

|

Figure 1 Overview about the EL9800 ............................................................................................................ |

8 |

Figure 2 Power Supply .................................................................................................................................. |

9 |

Figure 3 Pinout of the header J1203 ............................................................................................................. |

9 |

Figure 4 Header J1200 – Selection of the PDI header voltage..................................................................... |

9 |

Figure 5 Connection area fort he EtherCAT postage stamp ...................................................................... |

10 |

Figure 6 Pinout of the connectors J202 and TP202 ................................................................................... |

10 |

Figure 7 PDI-Selection Area....................................................................................................................... |

12 |

Figure 8 Pinout of the connector J1201 ..................................................................................................... |

13 |

Figure 9 µ-Controller PDI-Interface ............................................................................................................ |

14 |

Figure 10 Power pins on the connectors TP208 and J208 ........................................................................ |

14 |

Figure 11 Digital IO PDI-Interface .............................................................................................................. |

17 |

Figure 12 Voltages on the headers TP207 und J207................................................................................. |

19 |

Figure 13 PIC PDI-Interface ....................................................................................................................... |

19 |

Figure 14 Configuration and Status-Area of the Distributed Clocks .......................................................... |

22 |

Figure 15 FPGA Programming Interface .................................................................................................... |

23 |

Figure 16 PIC Programming Interface........................................................................................................ |

24 |

Figure 17 Quartus II Programmer™ ........................................................................................................... |

26 |

Figure 18 Hardware Setup Dialog .............................................................................................................. |

27 |

Figure 19 Setup Dialog – USB Blaster selected......................................................................................... |

27 |

Figure 20 Quartus II Programmer Dialog after „Auto-Detect“ processing .................................................. |

28 |

Figure 21 Convert Programming Files ....................................................................................................... |

29 |

Figure 22 Selection of the programming file............................................................................................... |

30 |

EL9800 |

3 |

Content

|

ABBREVIATIONS |

DC |

Direct Current |

EEPROM |

Electrically Erasable Programmable Read Only Memory. Non-volatile memory used |

|

to store ESC configuration and description. |

ESC |

EtherCAT Slave Controller |

EtherCAT |

Real-time Standard for Industrial Ethernet Control Automation Technology |

GND-Earth |

Ground-Earth |

LED |

Light Emitting Diode, used as an indicator |

PCB |

Printed Circuit Board |

PDI |

Process Data interface |

SPI |

Serial Peripheral Interface |

RJ45 |

FCC Registered Jack, standard Ethernet connector (8P8C) |

4 |

EL9800 |

Legal Notice

1 Legal Notice

1.1 Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered trademarks of and licensed by Beckhoff Automation GmbH. Other designations used in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owners.

1.2 Patent Pending

The EtherCAT Technology is covered, including but not limited to the following German patent applications and patents: DE10304637, DE102004044764, DE102005009224, DE102007017835 with corresponding applications or registrations in various other countries.

1.3 Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under development. For that reason the documentation is not in every case checked for consistency with performance data, standards or other characteristics. In the event that it contains technical or editorial errors, we retain the right to make alterations at any time and without warning. No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this documentation.

1.4 Copyright

© Beckhoff Automation GmbH 05/2009.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without express authorization are prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

EL9800 |

5 |

Legal Notice

1.5 Safety Instructions

Consider the following safety instructions and descriptions!

Product specific safety instructions are to be found on the following pages or in the areas mounting, wiring, commissioning etc.

1.5.1 Delivery Status

All the components are supplied in particular hardware and software configurations appropriate for the application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH. Product specific safety instructions are to be found on the following pages or in the areas mounting, wiring, commissioning etc.

1.5.2 Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the associated safety instructions.

|

Acute risk of injury! |

|

DANGER |

If you do not adhere the safety advise adjoining this symbol, there is immediate danger |

|

to life and health of individuals! |

||

|

||

|

|

|

|

|

|

|

Risk of injury! |

|

WARNING |

If you do not adhere the safety advise adjoining this symbol, there is danger to life and |

|

health of individuals! |

||

|

||

|

|

|

|

|

|

|

Hazard to individuals, environment and devices! |

|

CAUTION |

If you do not adhere the safety advise adjoining this symbol, there is obvious hazard to |

|

individuals, environment and materials! |

||

|

||

|

|

|

|

|

|

|

Note or pointer |

|

Note |

This symbol indicates information that contributes to better understanding. |

|

|

||

|

|

6 |

EL9800 |

Legal Notice

1.6 Documentation issue status

Version |

Comment |

3.0.0 |

First version |

|

|

3.0.1 |

Pinout of headers J202 and TP202 added |

|

|

3.0.2 |

CPU_CLK_IN added in Table 1 |

|

|

3.0.3 |

Signal level information added |

|

|

3.0.4 |

Changed J1202 to J1201 in Figure 8 |

|

|

3.0.5 |

A13, nTA and nTS added in Table 3 |

|

|

3.0.6 |

Changes in chapter 2.10 related to hex file import |

|

|

3.0.7 |

RB7 in Table 11 changed to “Not Connected” |

|

|

EL9800 |

7 |

Product overview

2 Product overview

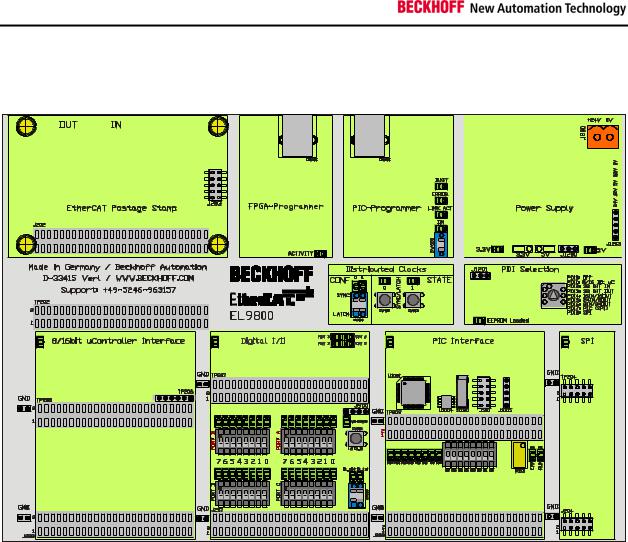

Figure 1 Overview about the EL9800

On this EtherCAT Evaluation Kit base board all supported Process Data Interfaces (PDI) of the EtherCAT Slave-Controllers (ESCs) can be evaluated and used for prototypic implementations. All EtherCAT postage stamps with the base name FB1XXX are compatible with this base board and can be used directly without adaptation. Separate documentations for each EtherCAT piggy back controller board are available for download and can also be found on the EtherCAT Evaluation Kit CD.

Figure 1 gives an overview of the EL9800 base board that supports four physical, configurable Process Data Interfaces. The following PDI variants area available

SPI-Interface

SPI-Interface with PIC

32 Bit digital interface

µ-Controller interface

As a user interface for changing the PDI to be used, a manual switch with eight different PDI configurations can be used.

For programming and debugging purposes different interfaces for FPGA-based EtherCAT piggy back controller boards and the integrated PIC24, manufactured by Microchip, are integrated on the board. Furthermore an area for Sync/Latch configuration, monitoring and manipulation allows the user to interact with the board. The integrated power supply is capable of powering extensive external hardware.

8 |

EL9800 |

Loading...

Loading...