BECKHOFF KL6904 User Manual

Operating instructions for

KL6904

TwinSAFE logic terminal with 4 fail-safe outputs

Version: 2.1.1

Date: 2015-11-03

Table of contents

Table of contents

1 |

Foreword |

3 |

||

|

1.1 |

Notes on the manual |

3 |

|

|

|

1.1.1 |

Disclaimer |

3 |

|

|

1.1.2 |

Brands |

3 |

|

|

1.1.3 |

Patents |

3 |

|

|

1.1.4 |

Copyright |

3 |

|

|

1.1.5 |

Delivery conditions |

3 |

|

1.2 |

Safety instructions |

4 |

|

|

|

1.2.1 |

Delivery state |

4 |

|

|

1.2.2 Operator's obligation to exercise diligence |

4 |

|

|

|

1.2.3 Description of safety symbols |

5 |

|

|

|

1.2.4 Origin of the document |

5 |

|

|

|

1.2.5 |

Documentation issue status |

6 |

2 |

System description |

7 |

||

|

2.1 |

The Beckhoff Bus Terminal system |

7 |

|

|

|

2.1.1 |

Bus Coupler |

8 |

|

|

2.1.2 |

Bus Terminals |

9 |

|

|

2.1.3 |

K-bus |

9 |

|

|

2.1.4 |

Power contacts |

9 |

|

2.2 |

TwinSAFE |

10 |

|

|

|

2.2.1 The I/O construction kit is extended safely |

10 |

|

|

|

2.2.2 |

Safety concept |

10 |

|

|

2.2.3 KL1904, KL2904 – Bus Terminals with 4 fail-safe inp uts or outputs |

11 |

|

|

|

2.2.4 KL6904 TwinSAFE logic terminal with 4 fail-safe outputs |

11 |

|

|

|

2.2.5 The fail-safe principle (Fail Stop) |

11 |

|

3 |

Product description |

12 |

||

|

3.1 |

General description |

12 |

|

|

3.2 |

Intended use |

13 |

|

|

3.3 |

Technical data |

14 |

|

|

3.4 |

Safety parameters |

15 |

|

|

3.5 |

Dimensions |

15 |

|

KL6904 |

1 |

Table of contents

4 |

Operation |

16 |

||

|

4.1 |

Installation |

16 |

|

|

|

4.1.1 |

Safety instructions |

16 |

|

|

4.1.2 |

Transport / storage |

16 |

|

|

4.1.3 |

Mechanical installation |

17 |

|

|

4.1.4 |

Electrical installation |

18 |

|

|

4.1.5 |

Tested devices |

22 |

|

4.2 |

Configuration of the KL6904 in the TwinCAT System Manager |

23 |

|

|

|

4.2.1 |

Configuration requirements |

23 |

|

|

4.2.2 |

Inserting a Beckhoff Bus Coupler |

23 |

|

|

4.2.3 |

Inserting a Beckhoff Bus Terminal |

23 |

|

|

4.2.4 |

Inserting a KL6904 |

23 |

|

|

4.2.5 |

Address settings on the TwinSAFE terminals |

25 |

|

|

4.2.6 |

Entering the TwinSAFE addresses in the System Manager |

26 |

|

|

4.2.7 |

Creating a TwinSAFE group |

27 |

|

|

4.2.8 |

Append a function block |

30 |

|

|

4.2.9 |

KL6904 user and version administration |

36 |

|

|

4.2.10 |

Loading the project into the KL6904 |

37 |

|

|

4.2.11 |

Communication between TwinCAT controllers |

39 |

|

4.3 |

Diagnostics |

43 |

|

|

|

4.3.1 |

Diagnostic LEDs |

43 |

|

4.4 |

Maintenance |

46 |

|

|

|

4.4.1 |

Cleaning |

46 |

|

4.5 |

Service life |

46 |

|

|

4.6 |

Decommissioning |

47 |

|

|

|

4.6.1 |

Disposal |

47 |

5 |

Appendix |

|

48 |

|

|

5.1 |

Beckhoff Support and Service |

48 |

|

|

|

5.1.1 |

Beckhoff branches and partner companies Beckhoff Support |

48 |

|

|

5.1.2 |

Beckhoff company headquarters |

48 |

|

5.2 |

Certificates |

49 |

|

2 |

KL6904 |

Foreword

1 Foreword

1.1 Notes on the manual

This description is only intended for the use of trained specialists in control and automation technology familiar with the applicable national standards. It is essential that the following notes and explanations are followed when installing and commissioning these components.

The responsible staff must ensure that the application or use of the products described satisfy all the safety requirements, including all the relevant laws, regulations, guidelines and standards.

1.1.1 Disclaimer

This documentation has been prepared with care. The products described are, however, constantly under development. For this reason, the documentation may not always have been fully checked for consistency with the performance data, standards or other characteristics described.

If it should contain technical or editorial errors, we reserve the right to make changes at any time and without notice.

No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this documentation.

1.1.2 Brands

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered trademarks of and licensed by Beckhoff Automation GmbH.

The use by third parties of other brand names or trademarks contained in this documentation may lead to an infringement of the rights of the respective trademark owner.

1.1.3 Patents

The EtherCAT technology is patent protected, in particular by the following applications and patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with the corresponding applications and registrations in various other countries.

The TwinCAT technology is patent protected, in particular by the following applications and patents: EP0851348, US6167425 with the corresponding applications and registrations in various other countries.

1.1.4 Copyright

© Beckhoff Automation GmbH & Co. KG.

The copying, distribution and utilization of this document as well as the communication of its contents to others without express authorization is prohibited. Offenders shall be held liable for damages. All rights conferred by patent grant or registration of a utility model or registered design are reserved.

1.1.5 Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

KL6904 |

3 |

Foreword

1.2 Safety instructions

1.2.1 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

1.2.2 Operator's obligation to exercise diligence

The operator must ensure that

∙the TwinSAFE products are only used as intended (see section Product description);

∙the TwinSAFE products are only operated in sound condition and in working order (see chapter

Cleaning).

∙the TwinSAFE products are operated only by suitably qualified and authorized personnel.

∙the personnel is instructed regularly about relevant occupational safety and environmental protection aspects, and is familiar with the operating instructions and in particular the safety instructions contained herein.

∙the operating instructions are in good condition and complete, and always available for reference at the location where the TwinSAFE products are used.

∙none of the safety and warning notes attached to the TwinSAFE products are removed, and all notes remain legible.

4 |

KL6904 |

Foreword

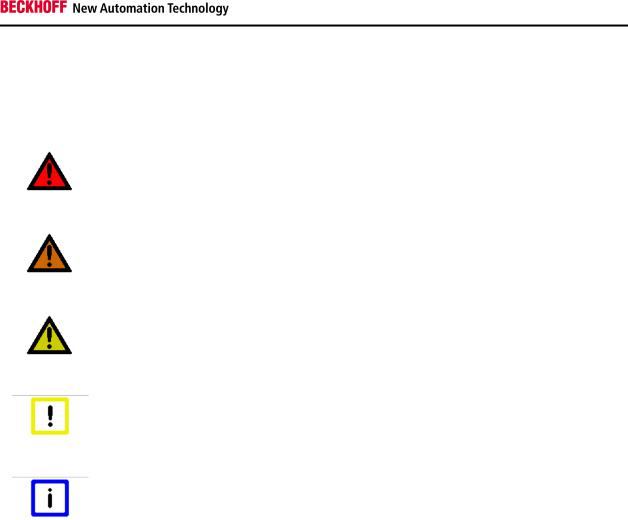

1.2.3 Description of safety symbols

The following safety symbols are used in these operating instructions. They are intended to alert the reader to the associated safety instructions.

|

Serious risk of injury! |

|

DANGER |

Failure to follow the safety instructions associated with this symbol directly endangers |

|

the life and health of persons. |

||

|

|

|

|

Caution - Risk of injury! |

|

WARNING |

Failure to follow the safety instructions associated with this symbol endangers the life |

|

and health of persons. |

||

|

|

|

|

|

|

|

Personal injuries! |

|

CAUTION |

Failure to follow the safety instructions associated with this symbol can lead to injuries |

|

to persons. |

||

|

|

|

|

Damage to the environment or devices |

|

Attention |

Failure to follow the instructions associated with this symbol can lead to damage to the |

|

environment or equipment. |

||

|

||

|

|

|

|

|

|

|

Tip or pointer |

|

Note |

This symbol indicates information that contributes to better understanding. |

|

|

||

|

|

1.2.4 Origin of the document

These operating instructions were originally written in German. All other languages are derived from the German original.

KL6904 |

5 |

Foreword

1.2.5 Documentation issue status

Version |

Comment |

|

2.1.1 |

∙ |

Certificate updated |

|

|

|

2.1.0 |

∙ |

Company address amended |

|

∙ |

Document origin added |

|

∙ |

Version history added |

|

∙ |

EN954 example removed |

|

∙ |

Safety parameters extended |

|

|

|

2.0.1 |

∙ |

Reference to EN 60068-2-29 removed |

|

|

|

2.0.0 |

∙ |

Description of the configuration in the TwinCAT System Manager added |

|

∙ |

Certificates added |

|

∙ Note on test pulses of the outputs added |

|

|

∙ |

Tested devices extended |

|

|

|

1.1.4 |

∙ |

Diagrams corrected |

|

∙ |

Flash codes corrected |

|

|

|

1.1.3 |

∙ |

Pin assignment corrected |

|

|

|

1.1.2 |

∙ |

Technical data updated |

|

|

|

1.1.1 |

∙ |

LED and graphics updated |

|

|

|

1.1.0 |

∙ |

Technical data extended |

|

∙ |

Editorial amendments |

|

|

|

1.0.3 |

∙ |

Description of LEDs and blink codes updated |

|

∙ |

TwinSAFE description updated |

|

|

|

1.0.2 |

∙ |

Note relating to qualified software tool amended |

|

|

|

1.0.1 |

∙ |

LoP list incorporated |

|

|

|

1.0.0 |

∙ |

First publication |

|

|

|

6 |

KL6904 |

System description

2 System description

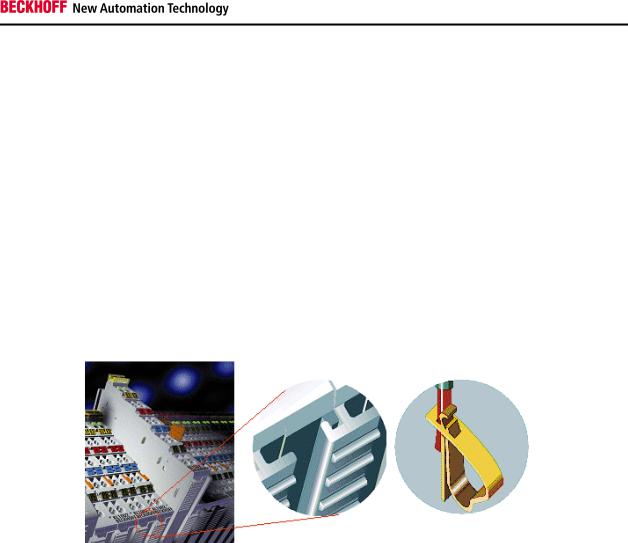

2.1 The Beckhoff Bus Terminal system

The Beckhoff Bus Terminal system is used for decentralized connection of sensors and actuators to a control system. The Beckhoff Bus Terminal system components are mainly used in industrial automation and building management applications. In its minimum configuration, a bus station consists of a Bus Coupler or a Bus Terminal Controller and Bus Terminals connected to it. The Bus Coupler forms the communication interface to the higher-level controller, and the terminals are the interface to sensors and actuators. The whole bus station is clipped onto a 35 mm DIN mounting rail (EN 60715). The mechanical cross connection of the bus station is established via a slot and key system at the Bus Coupler and the Bus Terminals.

The sensors and actuators are connected with terminals via the screwless Cage Clamp© connection system.

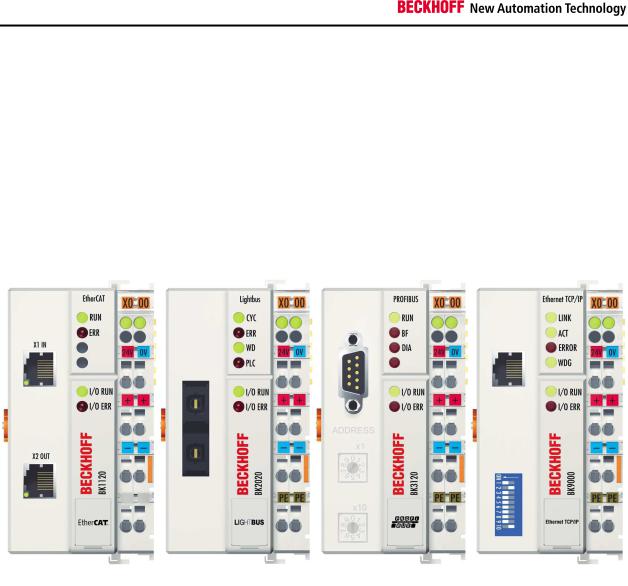

Since a wide range of different communication standards are established in industrial automation, Beckhoff offers Bus Couplers for all common bus systems (e.g. BK3120 for PROFIBUS, BK9000 for Ethernet, etc.).

KL6904 |

7 |

System description

2.1.1 Bus Coupler

Mechanical data

Mechanical data |

Bus Coupler |

Material |

polycarbonate, polyamide (PA6.6). |

|

|

Dimensions (W x H x D) |

47 mm x 100 mm x 68 mm |

|

|

Installation |

on 35 mm mounting rail (EN50022) with locking |

|

|

Attachable by |

double slot and key connection |

|

|

Connection technology

Connection technology |

Bus Coupler |

|

Wiring |

cage Clamp® spring-loaded system |

|

Connection cross-section |

0.08 mm2 ... 2.5 mm2, stranded wire, solid wire |

|

Fieldbus connection |

depending on fieldbus |

|

|

|

|

Power contacts |

3 spring contacts |

|

|

|

|

Current load |

10 |

A |

|

|

|

Rated voltage |

24 |

VDC |

|

|

|

8 |

KL6904 |

System description

2.1.2 Bus Terminals

Mechanical data

Mechanical data |

Bus Terminal |

Material |

polycarbonate, polyamide (PA6.6). |

|

|

Dimensions (W x H x D) |

12 mm x 100 mm x 68 mm or 24 mm x 100 mm x 68 mm |

|

|

Installation |

on 35 mm mounting rail (EN50022) with locking |

|

|

Attachable by |

double slot and key connection |

|

|

Connection technology

Connection technology |

Bus Terminal |

Wiring |

cage Clamp® spring-loaded system |

Connection cross-section |

0.08 mm2 ... 2.5 mm2, stranded wire, solid wire |

Fieldbus connection |

depending on fieldbus |

|

|

Power contacts |

up to 3 blade/spring contacts |

|

|

Current load |

10 A |

|

|

Rated voltage |

depends on Bus Terminal type |

|

|

2.1.3 K-bus

The K-Bus is the data path within a terminal strip. The K-Bus is led through from the Bus Coupler through all the terminals via six contacts on the terminals' side walls. The end terminal terminates the K-Bus.

2.1.4 Power contacts

The operating voltage is passed on to following terminals via three power contacts. Terminal strip can be split into galvanically isolated groups by means of potential feed terminals as required. The power feed terminals play no part in the control of the terminals, and can be inserted at any locations within the terminal strip.

KL6904 |

9 |

System description

2.2 TwinSAFE

2.2.1 The I/O construction kit is extended safely

With the TwinSAFE Terminals, Beckhoff offers the option of simply expanding the proven Bus Terminal system, and to transfer the complete cabling for the safety circuit into the already existing fieldbus cable. Safe signals can be mixed with standard signals without restriction. This saves design effort, installation and material. Maintenance is simplified significantly through faster diagnosis and simple replacement of only a few components.

The new KLx9xx series Bus Terminals only include three basic functionalities: digital KL19xx inputs, digital KL29xx outputs and a KL6904 link unit. For a large number of applications, all sensors and actuators can be wired on these Bus Terminals. The required logical link of the inputs and the outputs is handled by the KL6904. For small to medium-sized configurations, the tasks of a fail-safe PLC can thus be handled within the Bus Terminal system.

2.2.2 Safety concept

TwinSAFE: Safety and I/O technology in one system

∙Extension of the familiar Beckhoff I/O system with TwinSAFE terminals

∙Freely selectable mix of safe and standard signals

∙Logic link of the I/Os in the KL6904 TwinSAFE logic terminal

∙Safety-relevant networking of machines via bus systems

TwinSAFE protocol (FSoE)

∙Transfer of safety-relevant data via any media (“genuine black channel”)

∙TwinSAFE communication via fieldbus systems such as EtherCAT, Lightbus, PROFIBUS or Ethernet

∙IEC 61508:2010 SIL 3 compliant

Configuring instead of wiring: the TwinSAFE configurator

∙Configuration of the TwinSAFE system via the TwinCAT System Manager

∙System Manager for editing and displaying all bus parameters

∙Certified function blocks such as emergency stop, operation mode, etc.

∙Simple handling

∙Typical function blocks for machine safety

∙Freely selectable fieldbus connection with the KL6904 TwinSAFE logic terminal

KL6904 TwinSAFE logic Bus Terminal

∙Link unit between TwinSAFE input and output terminals

∙Configuration of a simple, flexible, cost-effective, decentralized safety controller

∙No safety requirements for higher-level control system

∙TwinSAFE enables networks with up to 1023 TwinSAFE devices

∙TwinSAFE logic terminal can establish up to 15 connections (TwinSAFE connections).

∙Several TwinSAFE logic terminals are cascadable in a network

∙Safety functions such as emergency stop, protective door, etc. are already included

∙Safe outputs integrated

∙Suitable for applications up to SIL 3 according to IEC 61508:2010

10 |

KL6904 |

System description

TwinSAFE digital input (KL1904) and output terminal (KL2904)

∙All current safety sensors can be connected

∙Operation with a TwinSAFE logic terminal

∙KL1904 with 4 fail-safe inputs for sensors (24 VDC) with floating contacts

∙KL2904 with four safe channels for actuators (24 VDC, 0.5 A per channel)

∙conforming to IEC 61508:2010 SIL 3

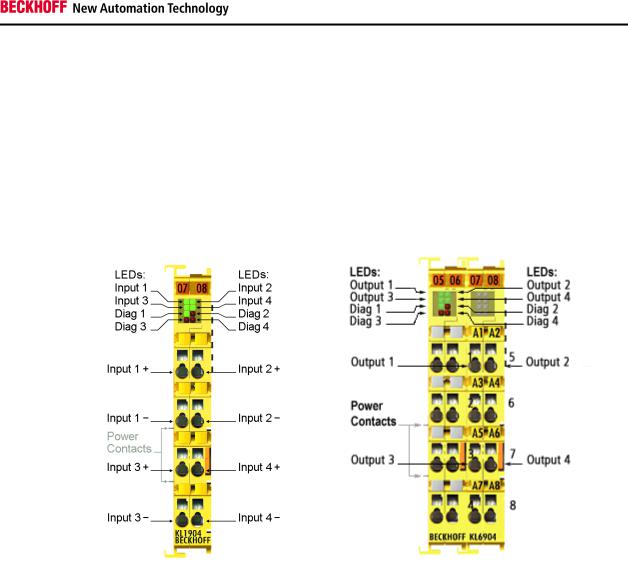

2.2.3 KL1904, KL2904 – Bus Terminals with 4 fail-sa fe inputs or outputs

The KL1904 and KL2904 Bus Terminals enable connection of common safety sensors and actuators. They are operated with the KL6904 TwinSAFE logic terminal. The TwinSAFE logic terminal is the link unit between the TwinSAFE input and output terminals. It enables the configuration of a simple, flexible and cost-effective decentralized safety control system.

Therefore, there are no safety requirements for the higher-level controller! The typical safety functions required for the automation of machines, such as emergency stop, protective door, two-hand etc., are already permanently programmed in the KL6904. The user configures the KL6904 terminal according to the safety requirements of his application.

2.2.4 KL6904 TwinSAFE logic terminal with 4 fail-safe outputs

The KL6904 TwinSAFE logic terminal is a digital output terminal with four fail-safe outputs with 0.5 A, 24 VDC. The KL6904 meets the requirements of IEC 61508:2010 SIL 3 and

DIN EN ISO 13849-1:2006 (Cat 4, PL e).

2.2.5 The fail-safe principle (Fail Stop)

The basic rule for a safety system such as TwinSAFE is that failure of a part, a system component or the overall system must never lead to a dangerous condition. The safe state is always the switched off and wattless state.

KL6904 |

11 |

Product description

3 Product description

3.1 General description

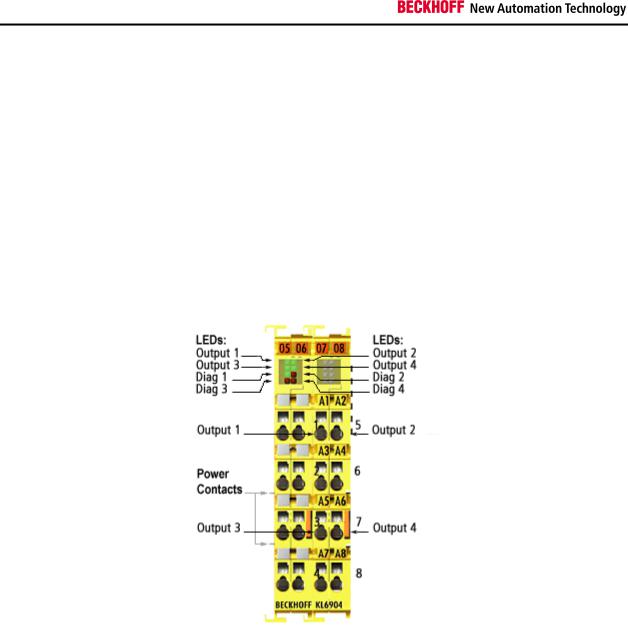

KL6904 TwinSAFE logic terminal with four fail-safe outputs

The KL6904 is a safe small controller with digital outputs for connecting actuators (contactors, relays, etc.) with a maximum current 0.5 A (24 VDC). The Bus Terminal has 4 fail-safe outputs.

The EL6930 meets the requirements of IEC 61508:2010 SIL 3, DIN EN ISO 13849-1:2006 (Cat 4, PL e), NRTL, UL508, UL1998 and UL991.

The Bus Terminal has the standard design of a Beckhoff Bus Terminal.

12 |

KL6904 |

Product description

3.2 Intended use

Caution - Risk of injury!

TwinSAFE terminals may only be used for the purposes described below!

WARNING

The TwinSAFE terminals expand the application range of Beckhoff Bus Terminal system with functions that enable them to be used for machine safety applications. The TwinSAFE terminals are designed for machine safety functions and directly associated industrial automation tasks. They are therefore only approved for applications with a defined fail-safe state. This safe state is the wattless state. Fail-safety according to the relevant standards is required.

The TwinSAFE terminals enable connection of:

∙24 VDC sensors (KL1904) such as

emergency stop push buttons, pull cord switches, position switches, two-hand switches, safety mats, light curtains, light barriers, laser scanners etc.

∙24 VDC actuators (KL2904, KL6904) such as

contactors, protective door switches with tumbler, signal lamps, servo drives etc.

Test pulses

When selecting actuators please ensure that the KL6904 test pulses do not Note lead to actuator switching or diagnostic message from the KL6904.

The test pulses of the KL6904 terminal outputs are not configurable and cannot be switched off.

The following modules were developed for these tasks:

∙The KL1904 terminal is an input module with digital inputs.

∙The KL2904 terminal is an output module with digital outputs.

∙The KL6904 terminal is a logic module with digital outputs.

These modules are suitable for operation with

∙Beckhoff BKxxxx series Bus Couplers

∙Beckhoff BXxxxx series Bus Terminal Controllers (with firmware version ≥ 1.20) (Beckhoff BCxxxx series Bus Terminal Controllers are not supported!)

∙Beckhoff CXxxxx series Embedded PCs with K-Bus connection

Follow the machinery directive

The TwinSAFE terminals may only be used in machines according to the Machinery CAUTION Directive.

Ensure traceability

The buyer has to ensure the traceability of the device via the serial number.

CAUTION

KL6904 |

13 |

Product description

3.3 Technical data

Product designation |

|

KL6904 |

Number of inputs |

|

0 |

|

|

|

Number of outputs |

|

4 |

|

|

|

Status display |

|

4 (one green LED per output) |

|

|

|

Error reaction time |

|

≤ watchdog times |

|

|

|

Output current per channel |

max. 500 mA, min. 20 mA |

|

|

|

|

Actuators |

|

When selecting actuators please ensure that the |

|

|

output test pulses do not lead to actuator switching. |

|

|

|

Cable length between |

(unshielded) |

max. 100 m |

actuator and terminal |

|

|

(shielded) |

max. 100 m |

|

|

|

|

Wire cross section |

|

min. 0.75 mm2 |

Input process image |

|

192 byte max. |

|

|

|

Output process image |

|

192 byte max. |

|

|

|

KL6904 supply voltage |

|

24 VDC (-15%/+20%) |

|

|

|

Current consumption from K-bus |

max. 250 mA |

|

|

|

|

Power dissipation of the terminal |

typically 2 W |

|

|

|

|

Electrical isolation (between the channels) |

no |

|

|

|

|

Electrical isolation (between the channels and the |

yes |

|

K-Bus) |

|

|

|

|

|

Insulation voltage (between the channels and the |

insulation tested with 500 VDC |

|

K-Bus, under common operating conditions) |

|

|

|

|

|

Dimensions (W x H x D) |

|

24 mm x 100 mm x 68 mm |

|

|

|

Weight |

|

approx. 100 g |

|

|

|

Permissible ambient temperature (operation) |

0 to +55 |

|

|

|

|

Permissible ambient temperature |

-25 to +70 |

|

(transport/storage) |

|

|

|

|

|

Permissible air humidity |

|

5 % to 95 %, non-condensing |

|

|

|

Permissible air pressure |

|

750 hPa to 1100 hPa |

(operation/storage/transport) |

|

|

|

|

|

Climate category according to EN 60721-3-3 |

3K3 |

|

|

|

|

Permissible level of contamination |

level of contamination 2 |

|

|

|

(comply with the chapter Cleaning) |

|

|

|

Impermissible operating conditions |

TwinSAFE terminals must not be used under the |

|

|

|

following operating conditions: |

|

|

∙ under the influence of ionizing radiation |

|

|

∙ in corrosive environments |

|

|

∙ in an environment that leads to |

|

|

unacceptable soiling of the Bus Terminal |

|

|

|

Vibration / shock resistance |

according to EN 60068-2-6 / EN 60068-2-27 |

|

|

|

|

EMC immunity/emission |

|

according to EN 61000-6-2 / EN 61000-6-4 |

|

|

|

Shocks |

|

15 g with pulse duration 11 ms in all three axes |

|

|

|

Protection class |

|

IP20 |

|

|

|

Permitted operating environment |

control cabinet or terminal box with minimum |

|

|

|

protection class IP54 according to IEC 60529 |

|

|

|

Permissible installation position |

horizontal |

|

|

|

|

Approvals |

|

CE, TÜV SÜD |

|

|

|

14 |

KL6904 |

Loading...

Loading...