BECKHOFF AM8000 User Manual

Documentation

Synchronous Servomotor AM8000 and AM8500

Version: 2.4

Date : 2015-01-05

Documented motors – AM8000 and AM8500  Drive Technology

Drive Technology

Documented motors – AM8000 and AM8500

|

|

Stand |

Rated speed at rated supply |

Rotor moment of inertia |

Weight |

||||

|

Standstill |

|

voltage |

|

|||||

|

|

|

|

|

|

|

|||

AM8tuv-wxyz |

torque |

still |

|

|

|

without |

with |

without |

with |

|

current |

230 V AC |

400 V AC |

480 V AC |

|||||

|

|

brake |

brake |

brake |

brake |

||||

|

|

|

|

|

|

||||

AM8011-wByz |

0.20 Nm |

0.76 A |

8000 min-1 |

--- |

--- |

0.0294 kg cm² |

0.0521 kg cm² |

0.62 kg |

0.81 kg |

AM8012-wCyz |

0.38 Nm |

1.30 A |

8000 min-1 |

--- |

--- |

0.0482 kg cm² |

0.0709 kg cm² |

0.74 kg |

0.93 kg |

AM8013-wDyz |

0.52 Nm |

1.65 A |

8000 min-1 |

--- |

--- |

0.0670 kg cm² |

0.0897 kg cm² |

0.86 kg |

1.05 kg |

AM8021-wByz |

0.50 Nm |

0.85 A |

4000 min-1 |

8000 min-1 |

9000 min-1 |

0.134 kg cm² |

0.156 kg cm² |

1.00 kg |

1.10 kg |

AM8021-wDyz |

0.50 Nm |

1.60 A |

8000 min-1 |

9000 min-1 |

9000 min-1 |

0.134 kg cm² |

0.156 kg cm² |

1.00 kg |

1.10 kg |

AM8022-wDyz |

0.80 Nm |

1.50 A |

4500 min-1 |

8000 min-1 |

9000 min-1 |

0.253 kg cm² |

0.276 kg cm² |

1.30 kg |

1.60 kg |

AM8022-wEyz |

0.80 Nm |

2.44 A |

8000 min-1 |

9000 min-1 |

9000 min-1 |

0.253 kg cm² |

0.276 kg cm² |

1.30 kg |

1.60 kg |

AM8023-wEyz |

1.20 Nm |

2.20 A |

4500 min-1 |

8000 min-1 |

9000 min-1 |

0.373 kg cm² |

0.396 kg cm² |

1.70 kg |

1.90 kg |

AM8023-wFyz |

1.20 Nm |

3.40 A |

8000 min-1 |

9000 min-1 |

9000 min-1 |

0.373 kg cm² |

0.396 kg cm² |

1.70 kg |

1.90 kg |

AM8031-wCyz |

1.37 Nm |

1.00 A |

1400 min-1 |

3000 min-1 |

3400 min-1 |

0.462 kg cm² |

0.541 kg cm² |

1.80 kg |

2.20 kg |

AM8531-wCyz |

1.37 Nm |

1.00 A |

1400 min-1 |

3000 min-1 |

3400 min-1 |

1.670 kg cm² |

1.760 kg cm² |

2.40 kg |

2.60 kg |

|

|

|

|

|

|

|

|

|

|

AM8031-wDyz |

1.38 Nm |

1.95 A |

3300 min-1 |

6000 min-1 |

6800 min-1 |

0.462 kg cm² |

0.541 kg cm² |

1.80 kg |

2.20 kg |

AM8531-wDyz |

1.38 Nm |

1.95 A |

3300 min-1 |

6000 min-1 |

6800 min-1 |

1.670 kg cm² |

1.760 kg cm² |

2.40 kg |

2.60 kg |

|

|

|

|

|

|

|

|

|

|

AM8031-wFyz |

1.40 Nm |

3.20 A |

6000 min-1 |

9000 min-1 |

9000 min-1 |

0.462 kg cm² |

0.541 kg cm² |

1.80 kg |

2.20 kg |

AM8531-wFyz |

1.40 Nm |

3.20 A |

6000 min-1 |

9000 min-1 |

9000 min-1 |

1.670 kg cm² |

1.760 kg cm² |

2.40 kg |

2.60 kg |

|

|

|

|

|

|

|

|

|

|

AM8032-wDyz |

2.38 Nm |

1.70 A |

1500 min-1 |

3000 min-1 |

3400 min-1 |

0.842 kg cm² |

0.921 kg cm² |

2.40 kg |

2.80 kg |

AM8532-wDyz |

2.38 Nm |

1.70 A |

1500 min-1 |

3000 min-1 |

3400 min-1 |

2.050 kg cm² |

2.150 kg cm² |

3.00 kg |

3.30 kg |

|

|

|

|

|

|

|

|

|

|

AM8032-wEyz |

2.37 Nm |

2.95 A |

3200 min-1 |

6000 min-1 |

6800 min-1 |

0.842 kg cm² |

0.921 kg cm² |

2.40 kg |

2.80 kg |

AM8532-wEyz |

2.37 Nm |

2.95 A |

3200 min-1 |

6000 min-1 |

6800 min-1 |

2.050 kg cm² |

2.150 kg cm² |

3.00 kg |

3.30 kg |

|

|

|

|

|

|

|

|

|

|

AM8032-wHyz |

2.37 Nm |

5.10 A |

6000 min-1 |

9000 min-1 |

9000 min-1 |

0.842 kg cm² |

0.921 kg cm² |

2.40 kg |

2.80 kg |

AM8532-wHyz |

2.37 Nm |

5.10 A |

6000 min-1 |

9000 min-1 |

9000 min-1 |

2.050 kg cm² |

2.150 kg cm² |

3.00 kg |

3.30 kg |

|

|

|

|

|

|

|

|

|

|

AM8033-wEyz |

3.20 Nm |

2.10 A |

1500 min-1 |

3000 min-1 |

3400 min-1 |

1.220 kg cm² |

1.460 kg cm² |

3.00 kg |

3.60 kg |

AM8533-wEyz |

3.20 Nm |

2.10 A |

1500 min-1 |

3000 min-1 |

3400 min-1 |

2.440 kg cm² |

----. |

3.60 kg |

--- |

|

|

|

|

|

|

|

|

|

|

AM8033-wFyz |

3.22 Nm |

4.10 A |

3200 min-1 |

6000 min-1 |

6800 min-1 |

1.220 kg cm² |

1.460 kg cm² |

3.00 kg |

3.60 kg |

AM8533-wFyz |

3.22 Nm |

4.10 A |

3200 min-1 |

6000 min-1 |

6800 min-1 |

2.440 kg cm² |

--- |

3.60 kg |

--- |

|

|

|

|

|

|

|

|

|

|

AM8033-wJyz |

3.22 Nm |

6.80 A |

5900 min-1 |

9000 min-1 |

9000 min-1 |

1.220 kg cm² |

1.460 kg cm² |

3.00 kg |

3.60 kg |

AM8533-wJyz |

3.22 Nm |

6.80 A |

5900 min-1 |

9000 min-1 |

9000 min-1 |

2.440 kg cm² |

--- |

3.60 kg |

--- |

|

|

|

|

|

|

|

|

|

|

AM8041-wDyz |

2.37 Nm |

1.65 A |

1500 min-1 |

3000 min-1 |

3400 min-1 |

1.080 kg cm² |

1.730 kg cm² |

2.80 kg |

3.60 kg |

AM8541-wDyz |

2.37 Nm |

1.65 A |

1500 min-1 |

3000 min-1 |

3400 min-1 |

4.630 kg cm² |

5.270 kg cm² |

3.80 kg |

4.50 kg |

|

|

|

|

|

|

|

|

|

|

AM8041-wEyz |

2.45 Nm |

3.00 A |

3000 min-1 |

6000 min-1 |

6800 min-1 |

1.080 kg cm² |

1.730 kg cm² |

2.80 kg |

3.60 kg |

AM8541-wEyz |

2.45 Nm |

3.00 A |

3000 min-1 |

6000 min-1 |

6800 min-1 |

4.630 kg cm² |

5.270 kg cm² |

3.80 kg |

4.50 kg |

|

|

|

|

|

|

|

|

|

|

AM8041-wHyz |

2.40 Nm |

5.25 A |

6000 min-1 |

8000 min-1 |

8000 min-1 |

1.080 kg cm² |

1.730 kg cm² |

2.80 kg |

3.60 kg |

AM8541-wHyz |

2.40 Nm |

5.25 A |

6000 min-1 |

8000 min-1 |

8000 min-1 |

4.630 kg cm² |

5.270 kg cm² |

3.80 kg |

4.50 kg |

|

|

|

|

|

|

|

|

|

|

AM8042-wEyz |

4.10 Nm |

2.15 A |

1200 min-1 |

2500 min-1 |

2800 min-1 |

1.970 kg cm² |

2.620 kg cm² |

3.80 kg |

4.70 kg |

AM8542-wEyz |

4.10 Nm |

2.15 A |

1200 min-1 |

2500 min-1 |

2800 min-1 |

5.530 kg cm² |

6.160 kg cm² |

4.90 kg |

5.70 kg |

|

|

|

|

|

|

|

|

|

|

2 |

Version: 2.4 |

AM8000 and AM8500 |

|

Drive Technology |

|

|

Documented motors – AM8000 and AM8500 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stand |

Rated speed at rated supply |

Rotor moment of inertia |

Weight |

||||||

|

Standstill |

|

voltage |

|

|||||||

|

|

|

|

|

|

|

|

||||

AM8tuv-wxyz |

torque |

still |

|

|

|

without |

with |

without |

with |

||

|

current |

230 V AC |

400 V AC |

480 V AC |

|||||||

|

|

brake |

brake |

brake |

brake |

||||||

|

|

|

|

|

|

||||||

AM8042-wFyz |

4.10 Nm |

4.10 A |

2800 min-1 |

5000 min-1 |

5700 min-1 |

1.970 kg cm² |

2.620 kg cm² |

3.80 kg |

4.70 kg |

||

AM8542-wFyz |

4.10 Nm |

4.10 A |

2800 min-1 |

5000 min-1 |

5700 min-1 |

5.530 kg cm² |

6.160 kg cm² |

4.90 kg |

5.70 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8042-wJyz |

4.10 Nm |

6.90 A |

5000 min-1 |

8000 min-1 |

8000 min-1 |

1.970 kg cm² |

2.620 kg cm² |

3.80 kg |

4.70 kg |

||

AM8542-wJyz |

4.10 Nm |

6.90 A |

5000 min-1 |

8000 min-1 |

8000 min-1 |

5.530 kg cm² |

6.160 kg cm² |

4.90 kg |

5.70 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8043-wEyz |

5.65 Nm |

2.90 A |

1200 min-1 |

2500 min-1 |

2800 min-1 |

2.870 kg cm² |

3.520 kg cm² |

4.90 kg |

5.80 kg |

||

AM8543-wEyz |

5.65 Nm |

2.90 A |

1200 min-1 |

2500 min-1 |

2800 min-1 |

6.430 kg cm² |

--- |

6.00 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AM8043-wHyz |

5.65 Nm |

5.40 A |

2700 min-1 |

5000 min-1 |

5700 min-1 |

2.870 kg cm² |

3.520 kg cm² |

4.90 kg |

5.80 kg |

||

AM8543-wHyz |

5.65 Nm |

5.40 A |

2700 min-1 |

5000 min-1 |

5700 min-1 |

6.430 kg cm² |

--- |

6.00 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AM8043-wKyz |

5.60 Nm |

9.30 A |

5000 min-1 |

8000 min-1 |

8000 min-1 |

2.870 kg cm² |

3.520 kg cm² |

4.90 kg |

5.80 kg |

||

AM8543-wKyz |

5.60 Nm |

9.30 A |

5000 min-1 |

8000 min-1 |

8000 min-1 |

6.430 kg cm² |

--- |

6.00 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AM8051-wEyz |

4.80 Nm |

2.70 A |

1400 min-1 |

2500 min-1 |

3000 min-1 |

2.240 kg cm² |

2.900 kg cm² |

4.10 kg |

4.90 kg |

||

AM8551-wEyz |

4.80 Nm |

2.70 A |

1400 min-1 |

2500 min-1 |

3000 min-1 |

8.740 kg cm² |

9.400 kg cm² |

5.50 kg |

6.30 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8051-wGyz |

4.90 Nm |

4.75 A |

2700 min-1 |

5000 min-1 |

5700 min-1 |

2.240 kg cm² |

2.900 kg cm² |

4.10 kg |

4.90 kg |

||

AM8551-wGyz |

4.90 Nm |

4.75 A |

2700 min-1 |

5000 min-1 |

5700 min-1 |

8.740 kg cm² |

9.400 kg cm² |

5.50 kg |

6.30 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8051-wKyz |

4.90 Nm |

8.50 A |

5000 min-1 |

8000 min-1 |

8000 min-1 |

2.240 kg cm² |

2.900 kg cm² |

4.10 kg |

4.90 kg |

||

AM8551-wKyz |

4.90 Nm |

8.50 A |

5000 min-1 |

8000 min-1 |

8000 min-1 |

8.740 kg cm² |

9.400 kg cm² |

5.50 kg |

6.30 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8052-wFyz |

8.20 Nm |

3.30 A |

1100 min-1 |

2000 min-1 |

2400 min-1 |

4.080 kg cm² |

4.740 kg cm² |

5.70 kg |

6.60 kg |

||

AM8552-wFyz |

8.20 Nm |

3.30 A |

1100 min-1 |

2000 min-1 |

2400 min-1 |

10.600 kg cm² |

11.200 kg cm² |

7.00 kg |

7.90 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8052-wJyz |

8.20 Nm |

6.30 A |

2200 min-1 |

4000 min-1 |

4500 min-1 |

4.080 kg cm² |

4.740 kg cm² |

5.70 kg |

6.60 kg |

||

AM8552-wJyz |

8.20 Nm |

6.30 A |

2200 min-1 |

4000 min-1 |

4500 min-1 |

10.600 kg cm² |

11.200 kg cm² |

7.00 kg |

7.90 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8052-wLyz |

8.20 Nm |

11.30 A |

4000 min-1 |

7300 min-1 |

7500 min-1 |

4.080 kg cm² |

4.740 kg cm² |

5.70 kg |

6.60 kg |

||

AM8552-wLyz |

8.20 Nm |

11.30 A |

4000 min-1 |

7300 min-1 |

7500 min-1 |

10.600 kg cm² |

11.200 kg cm² |

7.00 kg |

7.90 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8053-wGyz |

11.40 Nm |

4.70 A |

1100 min-1 |

2000 min-1 |

2400 min-1 |

5.920 kg cm² |

7.040 kg cm² |

7.40 kg |

8.40 kg |

||

AM8553-wGyz |

11.40 Nm |

4.70 A |

1100 min-1 |

2000 min-1 |

2400 min-1 |

12.500 kg cm² |

--- |

8.80 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AM8053-wKyz |

11.40 Nm |

8.80 A |

2200 min-1 |

4000 min-1 |

4500 min-1 |

5.920 kg cm² |

7.040 kg cm² |

7.40 kg |

8.40 kg |

||

AM8553-wKyz |

11.40 Nm |

8.80 A |

2200 min-1 |

4000 min-1 |

4500 min-1 |

12.500 kg cm² |

--- |

8.80 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AM8053-wNyz |

11.40 Nm |

15.60 A |

4000 min-1 |

7000 min-1 |

7000 min-1 |

5.920 kg cm² |

7.040 kg cm² |

7.40 kg |

8.40 kg |

||

AM8553-wNyz |

11.40 Nm |

15.60 A |

4000 min-1 |

7000 min-1 |

7000 min-1 |

12.500 kg cm² |

--- |

8.80 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AM8061-wGyz |

12.80 Nm |

4.00 A |

800 min-1 |

1500 min-1 |

1700 min-1 |

11.100 kg cm² |

13.400 kg cm² |

9.80 kg |

11.60 kg |

||

AM8561-wGyz |

12.80 Nm |

4.00 A |

800 min-1 |

1500 min-1 |

1700 min-1 |

48.200 kg cm² |

50.600 kg cm² |

13.20 kg |

14.80 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8061-wJyz |

12.80 Nm |

7.80 A |

1600 min-1 |

3000 min-1 |

3400 min-1 |

11.100 kg cm² |

13.400 kg cm² |

9.80 kg |

11.60 kg |

||

AM8561-wJyz |

12.80 Nm |

7.80 A |

1600 min-1 |

3000 min-1 |

3400 min-1 |

48.200 kg cm² |

50.600 kg cm² |

13.20 kg |

14.80 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8061-wMyz |

12.80 Nm |

13.10 A |

2800 min-1 |

5000 min-1 |

5000 min-1 |

11.100 kg cm² |

13.400 kg cm² |

9.80 kg |

11.60 kg |

||

AM8561-wMyz |

12.80 Nm |

13.10 A |

2800 min-1 |

5000 min-1 |

5000 min-1 |

48.200 kg cm² |

50.600 kg cm² |

13.20 kg |

14.80 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8062-wJyz |

21.10 Nm |

6.20 A |

800 min-1 |

1500 min-1 |

1700 min-1 |

20.000 kg cm² |

22.300 kg cm² |

13.60 kg |

15.40 kg |

||

AM8562-wJyz |

21.10 Nm |

6.20 A |

800 min-1 |

1500 min-1 |

1700 min-1 |

57.100 kg cm² |

59.600 kg cm² |

17.00 kg |

18.70 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8062-wLyz |

21.10 Nm |

12.40 A |

1700 min-1 |

3000 min-1 |

3400 min-1 |

20.000 kg cm² |

22.300 kg cm² |

13.60 kg |

15.40 kg |

||

|

|

|

|

|

|

|

|

|

|

|

|

AM8000 and AM8500 |

Version: 2.4 |

3 |

Documented motors – AM8000 and AM8500 |

|

|

|

Drive Technology |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Stand |

Rated speed at rated supply |

Rotor moment of inertia |

Weight |

|

||||

|

Standstill |

|

voltage |

|

|

|||||

|

|

|

|

|

|

|

|

|||

AM8tuv-wxyz |

torque |

still |

|

|

|

without |

with |

without |

with |

|

|

current |

230 V AC |

400 V AC |

480 V AC |

|

|||||

|

|

brake |

brake |

brake |

brake |

|

||||

|

|

|

|

|

|

|

||||

AM8562-wLyz |

21.10 Nm |

12.40 A |

1700 min-1 |

3000 min-1 |

3400 min-1 |

57.100 kg cm² |

59.600 kg cm² |

17.00 kg |

18.70 kg |

|

|

|

|

|

|

|

|

|

|

|

|

AM8062-wPyz |

21.10 Nm |

20.30 A |

2800 min-1 |

5000 min-1 |

5000 min-1 |

20.000 kg cm² |

22.300 kg cm² |

13.60 kg |

15.40 kg |

|

AM8562-wPyz |

21.10 Nm |

20.30 A |

2800 min-1 |

5000 min-1 |

5000 min-1 |

57.100 kg cm² |

59.600 kg cm² |

17.00 kg |

18.70 kg |

|

|

|

|

|

|

|

|

|

|

|

|

AM8063-wKyz |

29.00 Nm |

8.70 A |

800 min-1 |

1500 min-1 |

1700 min-1 |

29.000 kg cm² |

34.900 kg cm² |

17.40 kg |

20.10 kg |

|

AM8563-wKyz |

29.00 Nm |

8.70 A |

800 min-1 |

1500 min-1 |

1700 min-1 |

66.100 kg cm² |

--- |

20.90 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

AM8063-wNyz |

29.00 Nm |

17.20 A |

1700 min-1 |

3000 min-1 |

3400 min-1 |

29.000 kg cm² |

34.900 kg cm² |

17.40 kg |

20.10 kg |

|

AM8563-wNyz |

29.00 Nm |

17.20 A |

1700 min-1 |

3000 min-1 |

3400 min-1 |

66.100 kg cm² |

--- |

20.90 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

AM8063-wRyz |

29.00 Nm |

29.50 A |

3000 min-1 |

4000 min-1 |

4000 min-1 |

29.000 kg cm² |

34.900 kg cm² |

17.40 kg |

20.10 kg |

|

AM8563-wRyz |

29.00 Nm |

29.50 A |

3000 min-1 |

4000 min-1 |

4000 min-1 |

66.100 kg cm² |

--- |

20.90 kg |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

AM8071-wKyz |

31.80 Nm |

9.60 A |

800 min-1 |

1500 min-1 |

1700 min-1 |

49.600 kg cm² |

68.300 kg cm² |

23.80 kg |

29.30 kg |

|

AM8071-wNyz |

31.80 Nm |

17.80 A |

1500 min-1 |

3000 min-1 |

3300 min-1 |

49.600 kg cm² |

68.300 kg cm² |

23.80 kg |

29.30 kg |

|

AM8071-wRyz |

29.00 Nm |

28.2 A |

3000 min-1 |

4000 min-1 |

4500 min-1 |

49.600 kg cm² |

68.300 kg cm² |

23.80 kg |

29.30 kg |

|

AM8072-wLyz |

54.60 Nm |

11.10 A |

500 min-1 |

1000 min-1 |

1100 min-1 |

92.300 kg cm² |

110.90 kg cm² |

33.20 kg |

38.70 kg |

|

AM8072-wPyz |

54.60 Nm |

20.60 A |

1000 min-1 |

2000 min-1 |

2200 min-1 |

92.300 kg cm² |

110.90 kg cm² |

33.20 kg |

38.70 kg |

|

AM8072-wTyz |

50.00 Nm |

37.50 A |

2000 min-1 |

3000 min-1 |

3300 min-1 |

92.300 kg cm² |

110.90 kg cm² |

33.20 kg |

38.70 kg |

|

AM8073-wNyz |

72.60 Nm |

14.70°A |

500 min-1 |

1000 min-1 |

1100 min-1 |

134.90 kg cm² |

153.60 kg cm² |

44.80 kg |

50.30 kg |

|

AM8073-wQyz |

72.60 Nm |

27.90 A |

1000 min-1 |

2000 min-1 |

2200 min-1 |

134.90 kg cm² |

153.60 kg cm² |

44.80 kg |

50.30 kg |

|

AM8073-wTyz |

70.00 Nm |

45.60 A |

2000 min-1 |

3000 min-1 |

3300 min-1 |

134.90 kg cm² |

153.60 kg cm² |

44.80 kg |

50.30 kg |

|

4 |

Version: 2.4 |

AM8000 and AM8500 |

|

Drive Technology |

Table of contents – AM8000 and AM8500 |

|

Chapter |

|

|

Page |

Table of contents – AM8000 and AM8500 |

|

||

Documented motors – AM8000 and AM8500..................................................................................................... |

|

2 |

|

Table of contents – AM8000 and AM8500 .......................................................................................................... |

|

5 |

|

1 |

Foreword ................................................................................................................................................ |

|

7 |

1.1 |

Notes on the documentation .......................................................................................................... |

|

7 |

1.2 |

Disclaimer ...................................................................................................................................... |

|

7 |

1.3 |

Brands............................................................................................................................................ |

|

7 |

1.4 |

Patents ........................................................................................................................................... |

|

7 |

1.5 |

Copyright........................................................................................................................................ |

|

7 |

1.6 |

Documentation issue status........................................................................................................... |

|

7 |

1.7 |

Appropriate use.............................................................................................................................. |

|

8 |

2 |

Guidelines and Standards ................................................................................................................... |

|

9 |

2.1 |

EC declaration of conformity.......................................................................................................... |

|

9 |

3 |

Safety.................................................................................................................................................... |

|

10 |

3.1 |

General safety instructions .......................................................................................................... |

|

10 |

3.1.1 |

Personnel qualification................................................................................................................. |

|

10 |

3.1.2 |

Description of safety symbols ...................................................................................................... |

|

10 |

3.2 |

Special safety instructions for AM8000 and AM8500 .................................................................. |

11 |

|

4 |

Handling ............................................................................................................................................... |

|

12 |

4.1 |

Transport...................................................................................................................................... |

|

12 |

4.2 |

Packaging .................................................................................................................................... |

|

12 |

4.3 |

Storage......................................................................................................................................... |

|

12 |

4.4 |

Maintenance / Cleaning ............................................................................................................... |

|

12 |

4.5 |

Disposal ....................................................................................................................................... |

|

13 |

5 |

Product identification ........................................................................................................................ |

|

14 |

5.1 |

AM8000 and AM8500, scope of supply ....................................................................................... |

14 |

|

5.2 |

AM8000 and AM8500 nameplate ................................................................................................ |

|

14 |

5.3 |

Type key AM8000 and AM8500................................................................................................... |

|

14 |

6 |

Technical description ........................................................................................................................ |

|

14 |

6.1 |

Design of the motors .................................................................................................................... |

|

15 |

6.2 |

General technical data ................................................................................................................. |

|

15 |

6.3 |

Standard features......................................................................................................................... |

|

16 |

6.3.1 |

Style ............................................................................................................................................. |

|

16 |

6.3.2 |

Shaft end, A-side.......................................................................................................................... |

|

16 |

6.3.3 |

Flange .......................................................................................................................................... |

|

16 |

6.3.4 |

Protection class............................................................................................................................ |

|

16 |

6.3.5 |

Overtemperature protection ......................................................................................................... |

|

16 |

6.3.6 |

Insulation material class............................................................................................................... |

|

16 |

6.3.7 |

Vibration class.............................................................................................................................. |

|

17 |

6.3.8 |

Vibrations and shocks.................................................................................................................. |

|

17 |

6.3.9 |

Connection technology ................................................................................................................ |

|

17 |

6.3.10 |

Feedback system......................................................................................................................... |

|

17 |

6.3.11 |

Holding brake ............................................................................................................................... |

|

17 |

6.3.12 |

Pole number................................................................................................................................. |

|

18 |

6.4 |

Options......................................................................................................................................... |

|

18 |

6.5 |

Selection criteria........................................................................................................................... |

|

18 |

6.6 |

Transport, assembly and disassembly......................................................................................... |

19 |

|

7 |

Mechanical installation ....................................................................................................................... |

|

20 |

7.1 |

Important notes ............................................................................................................................ |

|

20 |

7.2 |

Flange mounts ............................................................................................................................. |

|

21 |

8 |

Electrical installation........................................................................................................................... |

|

22 |

8.1 |

Important notes ............................................................................................................................ |

|

22 |

8.2 |

Connection of motors with pre-assembled cables ....................................................................... |

23 |

|

8.3 |

AX5000 connection diagram for motors with OCT and iTec-plug.................................................. |

24 |

|

8.4 |

AX5000 connection diagram for motors with OCT-Feedback ..................................................... |

25 |

|

8.5 |

AX5000 connection diagram for motors with OCT-Feedback ..................................................... |

26 |

|

AM8000 and AM8500 |

Version: 2.4 |

5 |

|

Table of contents – AM8000 and AM8500 |

Drive Technology |

||

8.6 |

AX5000 connection diagram for motors with OCT-Feedback ..................................................... |

|

27 |

8.7 |

AX5000 connection diagram for motors with resolver and yTec-plug............................................ |

|

28 |

8.8 |

AX5000 connection diagram for motors with resolver ................................................................. |

|

29 |

8.9 |

AX5000 connection diagram for motors with resolver ................................................................. |

|

30 |

8.10 |

AX5000 connection diagram for motors with resolver ................................................................. |

|

31 |

8.11 |

AX5000 connection diagram for motors with resolver ................................................................. |

|

32 |

8.12 |

AX5000 connection diagram for motors with Hiperface............................................................... |

|

33 |

9 |

Commissioning.................................................................................................................................... |

|

34 |

9.1 |

Important notes ............................................................................................................................ |

|

34 |

9.2 |

Guide for commissioning.............................................................................................................. |

|

34 |

9.3 |

Troubleshooting ........................................................................................................................... |

|

34 |

10 |

Technical data...................................................................................................................................... |

|

36 |

10.1 |

AM801x ........................................................................................................................................ |

|

37 |

10.1.1 |

Dimensional drawing AM801x ..................................................................................................... |

|

38 |

10.1.2 |

Radial / axial forces at the shaft end............................................................................................ |

|

38 |

10.1.3 |

Characteristic torque / speed curves ........................................................................................... |

|

38 |

10.2 |

AM802x ........................................................................................................................................ |

|

39 |

10.2.1 |

Dimensional drawing AM802x ..................................................................................................... |

|

40 |

10.2.2 |

Radial / axial forces at the shaft end............................................................................................ |

|

40 |

10.2.3 |

Characteristic torque / speed curves ........................................................................................... |

|

40 |

10.3 |

AM803x and AM853x................................................................................................................... |

|

41 |

10.3.1 |

Dimensional drawing AM803x and AM853x ................................................................................ |

|

42 |

10.3.2 |

Radial / axial forces at the shaft end............................................................................................ |

|

42 |

10.3.3 |

Characteristic torque / speed curves ........................................................................................... |

|

42 |

10.4 |

AM804x and AM854x................................................................................................................... |

|

43 |

10.4.1 |

Dimensional drawing AM804x and AM854x ................................................................................ |

|

44 |

10.4.2 |

Radial / axial forces at the shaft end............................................................................................ |

|

44 |

10.4.3 |

Characteristic torque / speed curves ........................................................................................... |

|

44 |

10.5 |

AM805x and AM855x................................................................................................................... |

|

45 |

10.5.1 |

Dimensional drawing AM805x and AM855x ................................................................................ |

|

46 |

10.5.2 |

Dimensional drawing AM805x-9000 and AM855x-9000 (Flange compatible to AM3x5x) ......... |

46 |

|

10.5.3 |

Radial / axial forces at the shaft end............................................................................................ |

|

47 |

10.5.4 |

Characteristic torque / speed curves ........................................................................................... |

|

47 |

10.6 |

AM806x and AM856x................................................................................................................... |

|

48 |

10.6.1 |

Dimensional drawing AM806x and AM856x ................................................................................ |

|

49 |

10.6.2 |

Dimensional drawing AM8063 and AM8563 with R-Winding ...................................................... |

|

49 |

10.6.3 |

Radial / axial forces at the shaft end............................................................................................ |

|

50 |

10.6.4 |

Characteristic torque / speed curves ........................................................................................... |

|

50 |

10.7 |

AM807x ........................................................................................................................................ |

|

51 |

10.7.1 |

Dimensional drawing AM807x ..................................................................................................... |

|

52 |

10.7.2 |

Radial / axial forces at the shaft end............................................................................................ |

|

53 |

10.7.3 |

Characteristic torque / speed curves ........................................................................................... |

|

53 |

11 |

Appendix ............................................................................................................................................. |

|

54 |

11.1 |

Support and Service..................................................................................................................... |

|

54 |

11.2 |

Beckhoff's branch offices and representatives ............................................................................ |

|

54 |

11.3 |

Beckhoff headquarters................................................................................................................. |

|

54 |

11.3.1 |

Beckhoff Support.......................................................................................................................... |

|

54 |

11.3.2 |

Beckhoff Service .......................................................................................................................... |

|

54 |

6 |

Version: 2.4 |

AM8000 and AM8500 |

Drive Technology |

1 Foreword |

1 Foreword

1.1Notes on the documentation

This description is only intended for trained specialists in control, automation and drive engineering who are familiar with the applicable national standards. It is essential that the following notes and explanations are followed when installing and commissioning these components. The "General safety instructions" and "Special safety instructions for AM8000 and AM8500" sections are also essential.

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Danger for persons, the environment or equipment

The motors are operated in the drive system in conjunction with Beckhoff servo drives. Please CAUTION observe the entire documentation which consists of:

−AM8000 and AM8500 documentation (this manual)

−Complete documentation (online and paper) for Beckhoff servo drives available at www.beckhoff.com.

−Complete machine documentation (provided by the machine manufacturer)

1.2Disclaimer

This documentation has been prepared with care. The products described are, however, constantly under development.

For this reason, the documentation may not always have been fully checked for consistency with the performance data, standards or other characteristics described.

If it should contain technical or editorial errors, we reserve the right to make changes at any time and without notice.

No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this documentation.

1.3Brands

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered and licensed brand names of Beckhoff Automation GmbH & Co. KG.

The use by third parties of other brand names or trademarks contained in this documentation may lead to an infringement of the rights of the respective trademark owner.

1.4Patents

The TwinCAT technology is patent protected, in particular by the following applications and patents: EP0851348, US6167425 with the corresponding applications and registrations in various other countries.

1.5Copyright

© Beckhoff Automation GmbH.

The copying, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited.

Offenders shall be held liable for damages. All rights conferred by patent grant or registration of a utility model or registered design are reserved.

1.6Documentation issue status

Ausgabe |

Bemerkung |

2.4 |

Graphic resolution adjusted |

2.3 |

Chapter update |

|

2.1; 3.2; 4.2; 4.4; 5.2; 5.3; 6.3.2; 6.3.3; 6.3.4; 6.3.5; 6.3.12; 10.2; 10.3; 10.4; 10.5; 10.6; 10.7 |

|

New chapter |

|

10.1; 10.1.1; 10.1.2 |

2.2 |

Chapter update |

|

6.3.5; 6.3.11; 10.5.1; 10.6; 10.7 |

|

New chapter |

|

6.6 |

2.1 |

General update (Series AM8500 added) |

AM8000 and AM8500 |

Version: 2.4 |

7 |

1 Foreword |

Drive Technology |

2.0Not published

1.2Chapter update

10.7.1

New chapter

6.3.8

1.1Chapter update

8.2.1.1; 8.3; 8.4; 8.5; 8.6

1.0First issue

1.7Appropriate use

Synchronous servomotors of the AM8000 and AM8500 series are designed as drives for handling equipment, textile machines, machine tools, packaging machines and similar machines with demanding requirements in terms of dynamics. The motors of the AM8000 and AM8500 series are exclusively intended for speedand/or torque-controlled operation via digital servo drives from Beckhoff.

The thermal protection contact incorporated in the motor windings must be analysed and monitored.

Caution – Risk of injury!

Electronic equipment is not fail-safe. The machine manufacturer is responsible for ensuring that

WARNING the connected motors and the machine are brought into a safe state in the event of a fault in the drive system.

The servomotors from the AM8000 and AM8500 series are exclusively designed for installation as components in electrical systems or machines and may only be operated as integrated components of the system or machine.

The motors may only be operated under the ambient conditions defined in this documentation.

8 |

Version: 2.4 |

AM8000 and AM8500 |

Drive Technology |

2 Guidelines and Standards |

2 Guidelines and Standards

Danger for persons

Servomotors of the AM8000 and AM8500 series are not classified as products within the CAUTION meaning of the EC Machinery Directive. Operation of the servomotors in machines or systems is

only permitted once the machine or system manufacturers has provided evidence of EC conformity of the complete machine or system.

2.1EC declaration of conformity

We,

Beckhoff Automation GmbH & Co. KG

Hülshorstweg 20

33415 Verl

Germany

hereby declare, under our sole responsibility, that the product range

motor series AM8000

(types AM801x, AM802x, AM803x, AM804x, AM805x, AM806x, AM807x)

motor series AM8500

(types AM853x, AM854x, AM855x, AM856x)

complies with following relevant regulations:

−EC Directive 2004/108/EC Electromagnetic compatibility

Applied harmonised standard EN 61800-3

−EC Directive 2006/95/EC

Electrical equipment designed for use within certain voltage limits Applied harmonised standard EN 61800-5-1

Attachment of the CE marking: |

2012 |

Issued by: |

Management |

|

H. Beckhoff |

|

Verl, 25.05.2012 |

AM8000 and AM8500 |

Version: 2.4 |

9 |

3 Safety |

Drive Technology |

3 Safety

3.1General safety instructions

3.1.1Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are familiar with the applicable national standards.

3.1.2Description of safety symbols

The following safety symbols and associated safety instructions are used in this document. These safety instructions must be read and followed.

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the life DANGER and health of persons.

Caution – Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and WARNING health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to CAUTION persons.

Damage to the environment or devices!

Failure to follow the safety instructions associated with this symbol can lead to damage to the Attention environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

Note

UL note

This symbol indicates important information regarding UL certification.

10 |

Version: 2.4 |

AM8000 and AM8500 |

Drive Technology |

3 Safety |

3.2Special safety instructions for AM8000 and AM8500

The safety instructions are designed to avert danger and must be followed during installation, commissioning, production, troubleshooting, maintenance and trial or test assemblies.

The servomotors of the AM8000 and AM8500 series are not designed for stand-alone operation and are always installed in a machine or system. After installation the additional documentation and safety instructions provided by the machine manufacturer must be read and followed.

Serious risk of injury through high electrical voltage!

•Never open the servomotor when it is live. The measured voltage between terminals U, V

WARNING and W must have dropped below 50 V. Opening the device would invalidate any warranty and liability claims against Beckhoff Automation GmbH.

•Negligent, improper handling of the servomotor and bypassing of the safety devices can lead to personal injury or death through electric shock.

•Ensure that the protective conductor is connected properly.

•The machine manufacturer must prepare a hazard analysis for the machine, and must take appropriate measures to ensure that unexpected movements cannot lead to injury to persons or to material damage.

•Power leads may be live, even if the motor is not running. Never undo the electrical connections to the motor when it is live. Under unfavourable conditions arcing may occur, resulting in injury and damage to contacts.

•Disconnect the servomotor from the servo drive and secure it against reconnection before working on electrical parts with a voltage > 50 V.

•The DC link voltage of the servo drive may exceed 890 VDC. Wait until the DC link capacitors are discharged before touching live terminals. The measured voltage between terminals DC+ and DC- (X02) must have dropped below 50 VDC.

Serious risk of injury through hot surfaces!

•The surface temperature may exceed 100 °C, resulting in a risk of burns.

WARNING • Avoid touching the housing during or shortly after operation.

•Leave the servomotor to cool down for at least 15 minutes after it is switched off.

•Use a thermometer to check whether the surface has cooled down sufficiently.

Danger for persons

•Carefully read this manual before using the servomotor thoroughly, paying particular

Attention attention to the safety instructions. In the event of any uncertainties please notify your sales office immediately and refrain from working on the servomotor.

•Only well trained, qualified electricians with sound knowledge of drive equipment may work on the device.

•During installation it is essential to ensure that the specified ventilation clearances and climatic conditions are adhered to. Further information can be found in the "Technical data" and "Mechanical installation" sections.

•If a servomotor is installed in a machine it must not be commissioned until proof of compliance of the machine with the latest version of the EC Machinery Directive has been provided. This includes all relevant harmonised standards and regulations required for implementation of this Directive in national legislation.

AM8000 and AM8500 |

Version: 2.4 |

11 |

4 Handling |

Drive Technology |

4 Handling

4.1Transport

• |

Climate category: |

2K3 according to EN 60721 |

• |

Transport temperature: |

-25 °C - +70 °C, max. fluctuation 20 K/hour |

• |

Transport humidity: |

relative humidity 5% - 95%, non-condensing |

•The servomotor may only be transported by qualified personnel and in the manufacturer's original recyclable packaging.

•Avoid hard impacts, particularly at the shaft end.

•If the packaging is damaged, check the motor for visible damage. Inform the transport company and, if necessary, the manufacturer.

4.2Packaging

•Cardboard packaging

Motor type |

Max. stacking height |

AM801x |

10 |

AM802x |

10 |

AM803x and AM853x |

6 |

AM804x and AM854x |

6 |

AM805x and AM855x |

5 |

AM806x and AM856x |

2 |

AM807x |

1 |

4.3Storage

• Climate category |

2K3 according to EN 60721 |

•Storage temperature: -25 °C - +70 °C, max. fluctuation 20 K/hour

• Air humidity: |

relative humidity 5% - 95%, non-condensing |

•Max. stacking height: see table Packaging

• Storage time: |

without limitation |

•Store only in the manufacturer’s original recyclable packaging

4.4Maintenance / Cleaning

•Maintenance and cleaning only by qualified personnel.

•The ball bearings have a grease filling with a service life of 30,000 hours under normal operating conditions. The bearings should be replaced after 30,000 hours of operation under rated conditions.

•Check the motor for bearing noise every 2,500 operating hours or once per year. If any noises are heard, stop the operation of the motor. The bearings must be replaced.

•In motors with optional shaft seal ring the ring must be lubricated every 5,000 hours. We recommend “MobilgreaseTM FM 222 lubricant” from Fa. Mobil.

•Opening the motor invalidates the warranty.

•Clean the housing with isopropanol or similar.

Destruction of the servomotor

Never immerse or spray the servomotor.

Attention

12 |

Version: 2.4 |

AM8000 and AM8500 |

Drive Technology |

4 Handling |

4.5Disposal

•In accordance with the WEEE 2002/96/EC Directives we take old devices and accessories back for professional disposal, provided the transport costs are taken over by the sender. Please send the devices to:

Beckhoff Automation GmbH & Co. KG Hülshorstweg 20

33415 Verl Germany

AM8000 and AM8500 |

Version: 2.4 |

13 |

5 Product identification |

Drive Technology |

5 Product identification

5.1AM8000 and AM8500, scope of supply

Please check that the delivery includes the following items:

•Motor from the AM8000 or AM8500 series

•Leaflet (short info)

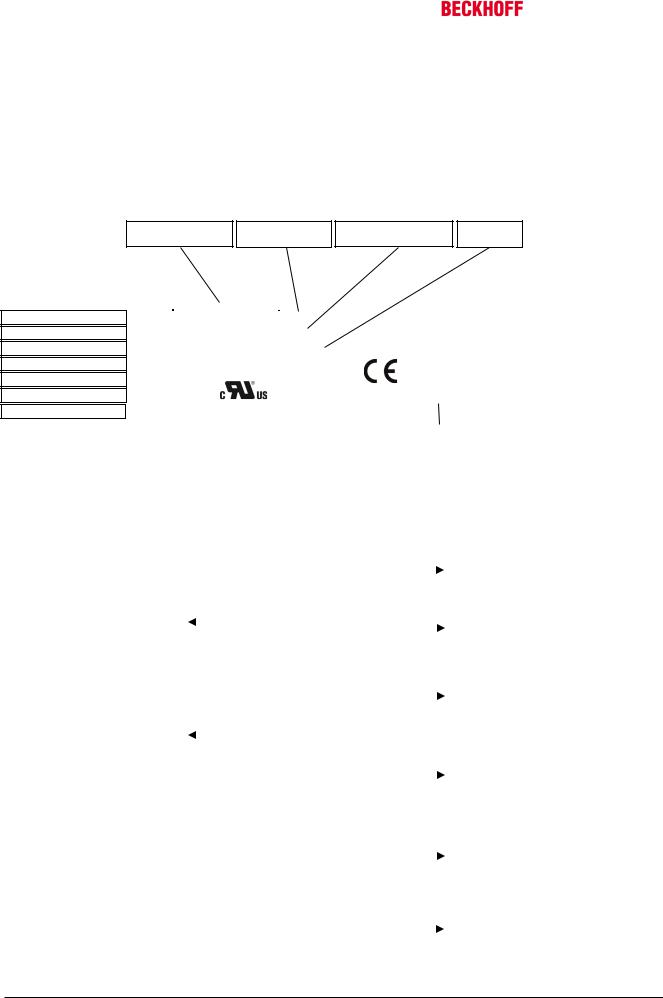

5.2AM8000 and AM8500 nameplate

Servomotor type |

Protection class |

Thermo contact type |

Brake type |

Standstill torque

Standstill current

Rated voltage

Nominal speed

Rated output

Insulation class

Certification USA / CAN

BECKHOFF |

|

|

|

|

|

AM8062-0P01-0000 |

|

|

|

|

|

M0 |

Nm |

IP54 |

Made in Germany |

||

I0 |

Arms |

Thermo |

|

|

|

UN |

Vrms |

Brake |

|

|

|

nN |

rpm |

|

|

|

|

PN |

kW |

|

|

|

|

ThCl |

F |

|

|

SN |

. |

File |

E355768 TOTALLY |

ENCLOSED |

|

|

|

|

|

|

|

|

|

|

|

|

|

Serial number |

|

|

|

|

|

|

|

5.3Type key AM8000 and AM8500

AM80 6 2 – 0 P 0 1 – 0000

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connection |

||

Flange size |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

0 |

rotatable angular connectors |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1 |

= 40 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Variants |

||||

2 |

= 58 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

3 |

= 72 mm |

|

|

|

|

|

|

|

|

|

|

0 |

standard |

|||||

|

|

|

|

|

|

|

|

|||||||||||

4 |

= 87 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

special |

||

5 |

= 104 mm |

|

|

|

|

|

|

|

|

|

|

9 |

flange compatible to AM3x5x |

|||||

6 |

= 142 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(only for AM805x and AM855x) |

|

7 |

= 194 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brake |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

none brake |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Construction |

|

|

|

|

|

|

|

|

|

|

|

1 |

24 V holding brake |

|||||

length |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Feedback unit |

|||

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

3 |

|

|

|

|

|

|

|

|

|

|

0 |

resolver, 2-pole *) |

||||||

|

|

|

|

|

|

|

|

|

|

|

1 |

OCT Singleturn |

||||||

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

OCT Multiturn |

||

|

|

|

|

|

|

|

|

|

|

3 |

Hyperface Singleturn (only AM807x) |

|||||||

|

|

|

|

|

|

|

|

|

|

4 |

Hyperface Multiturn (only AM807x) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Winding type |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A…Z |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S = special winding |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shaft |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

smooth shaft |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

feather key groove |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

sealing ring – smooth shaft *) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

sealing ring – feather key groove *) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*) not for AM801x

14 |

Version: 2.4 |

AM8000 and AM8500 |

Drive Technology |

6 Technical description |

6 Technical description

6.1Design of the motors

The synchronous servomotors of the AM8000 and AM8500 series are brushless three-phase motors for demanding servo-applications. In conjunction with our digital servo drives they are particularly suitable for positioning tasks in industrial robots, machine tools, transfer lines etc. with demanding requirements in terms of dynamics and stability.

The servomotors are equipped with permanent magnets in the rotor. This advanced neodymium magnetic material makes a significant contribution to the motors' exceptional dynamic properties. A three-phase winding is housed in the stator, and this is powered by the servo drive. The motor has no brushes, the commutation being implemented electronically in the servo drive.

The winding temperature is measured with a KTY 84.130 PTC silicon sensor and monitored in the servo drive.

The motors are available with or without built-in holding brake. The brake cannot be retrofitted.

The motors have a matt black powder coating (RAL 7016). The finish is not resistant against solvents (e.g. trichlorethylene, thinners or similar).

6.2General technical data

Climate category |

3K3 according to EN 60721 |

|

|

|

|

Ambient temperature |

+5 - +40 °C for site altitudes up to 1000 m amsl |

|

(at rated values) |

It is vital to consult our applications department for ambient temperatures |

|

above 40 °C and encapsulated installation of the motors. |

||

|

||

Permissible humidity |

95% relative humidity, non-condensing |

|

(at rated values) |

|

|

|

|

|

Power derating |

For site altitudes above 1000 m amsl and 40 °C |

|

(currents and torques) |

6% at 2000 m amsl |

|

17% at 3000m amsl |

||

|

||

|

30% at 4000m amsl |

|

|

55% at 5000m amsl |

|

|

No derating for site altitudes above 1000 m amsl with temperature |

|

|

reduction of 10K / 1000m |

|

Ball bearing service life |

≥30.000 operating hours |

|

|

|

|

Technical data |

→ see Section 10 |

|

|

|

|

Storage and transport data |

→ see Section 4 |

|

|

|

AM8000 and AM8500 |

Version: 2.4 |

15 |

6 Technical description |

Drive Technology |

6.3Standard features

6.3.1Style

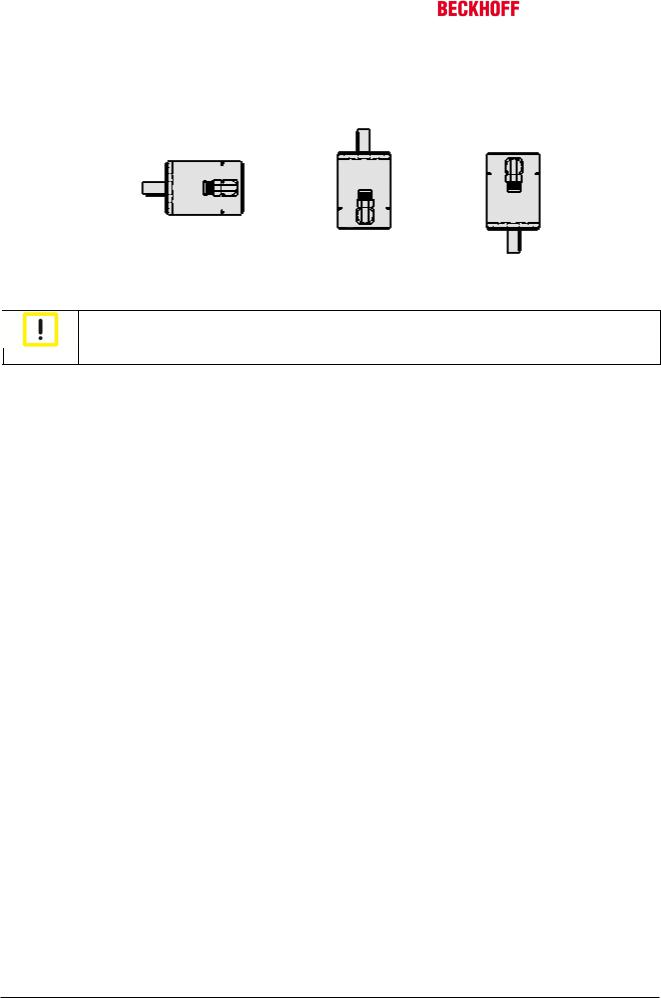

The basic style for the AM8000 and AM8500 synchronous servomotors is IM B5 according to DIN EN 60034-7.

IM B 5 (B5) |

IM V 3 (V3) |

IM V 1 (V1) |

The permitted mounting positions are specified in the technical data.

Motor damage

To avoid liquid entry damaging the motor, fluids (i.e. used for cleaning purposes) must be Attention removed from shaft when motor is mounted according to IM V3.

6.3.2Shaft end, A-side

Load transmission occurs force locked (zero-play) with a clutch on the cylindric end of the shaft A or optionally by keyed connection with feather key groove according to DIN 6885. The lifecycle of the bearings is 30.000 operating hours.

Radial force

If the motors drive via pinions or toothed belts, then high radial forces will occur. The permissible values at the shaft end, depending on the speed, may be read from the diagrams in the Section 10. Please use the force calculation program “Beckhoff AM8000-Motors Radial forces, life cycle” available from our website for exact calculation of the radial forces.

Axial force

Axial forces arise when assembling pinions or pulleys on the shaft and using angular gearheads, for example. Please use the force calculation program “Beckhoff AM8000-Motors Radial forces, life cycle” available from our website for exact calculation of the radial forces.

Coupling

Double-coned collets, possibly in association with metal bellows couplings, have proven themselves as excellent, zero backlash coupling elements.

6.3.3Flange

Flange dimensions according to IEC standard, fit j6 (h7 at AM801x), accuracy according to DIN 42955 Tolerance class: N

6.3.4 |

Protection class |

|

Standard version - housing |

IP65 (IP54 at AM801x) |

|

Standard version - shaft feedthrough |

IP54 |

|

Shaft feedthrough with shaft sealing ring |

IP65 |

|

6.3.5Overtemperature protection

The standard version of each motor (not AM801x) is fitted with a KTY 84.130.

Provided our preassembled motor cable is used, the KTY is integrated into the monitoring system of the digital servo amplifiers. Please configure the servo drive such that a motor temperature warning is issued at 100 °C and the motor is switched off at 140 °C.

6.3.6Insulation material class

The motors conform to insulation material class F according to IEC 60085 (UL 1446 class F).

16 |

Version: 2.4 |

AM8000 and AM8500 |

Drive Technology |

6 Technical description |

6.3.7Vibration class

The motors are made to vibration class A according to DIN EN 60034-14. For a speed range of 600-3600 rpm and a shaft centre height between 54 - 97 mm, this means that the actual value of the permitted vibration severity is 1.6 mm/s.

Speed [rpm] |

Max. rel. vibration |

Max. run-out [µm] |

|

displacement [µm] |

|

<= 1800 |

90 |

23 |

> 1800 |

65 |

16 |

6.3.8Vibrations and shocks

OCT, singleturn and multiturn |

|

Vibration according to EN 60068-2-6 |

50 g / 10…2000 Hz |

Shocks according to EN 60068-2-27 |

100 g / 6 ms |

6.3.9Connection technology

The motors are fitted with rotatable, angular connectors for the power supply and the feedback signals (only resolver).

The mating connectors are not included in the scope of supply. We can supply preassembled feedback (only resolver) and power cables.

6.3.10 Feedback system |

|

|

|

|

|

Feedbacksystem |

|

Impulse per |

System accuracy |

Comment |

|

|

|

rotation |

|

|

|

OCT, Singleturn |

|

33554432 |

± 120 Angle sec. |

ca. 0,03° |

Standard: |

OCT, Multiturn |

|

|

|

|

AM801x – AM8x6x |

Hyperface |

|

|

|

|

Standard: |

|

|

|

|

|

AM807x |

Resolver |

|

16384 |

± 120 Angle sec. |

ca. 0,17° |

Option |

|

|

Feedback exchange |

Note |

|

The feedback system installed can only be replaced with an identical system. Retrofitting a |

|

different system is not possible. |

|

6.3.11 |

Holding brake |

|

|

|

|

|

|

Serious risk of injury! |

The holding brake is not personal safety. If the brake is released then the rotor can be moved WARNING without a remanent torque!

The motors are optionally available with an in-built holding brake. The permanent magnet brake blocks the rotor in de-energised state. The holding brakes are designed as standstill brakes and are not suited for repeated operational braking.

The holding brakes can be controlled directly by the servo drive (no personal safety!). The brake voltage is then switched off in the servo drive — no additional wiring is required.

If the holding brake is not controlled directly by the servo drive, additional circuitry (e.g. varistor) is required. Consult our applications department beforehand.

The maximum number of brake cycles is 10 million.

Motor length

The motor length depends on the built-in holding brake, among other factors. It is not possible to Note fit one at a later date.

AM8000 and AM8500 |

Version: 2.4 |

17 |

Loading...

Loading...