JLG 450AJ Operator Manual

Operators and Safety Manual

Model 450A 450AJ

3120748 April 24, 2002

ANSI

– JLG Lift –

FOREWORD

FOREWORD

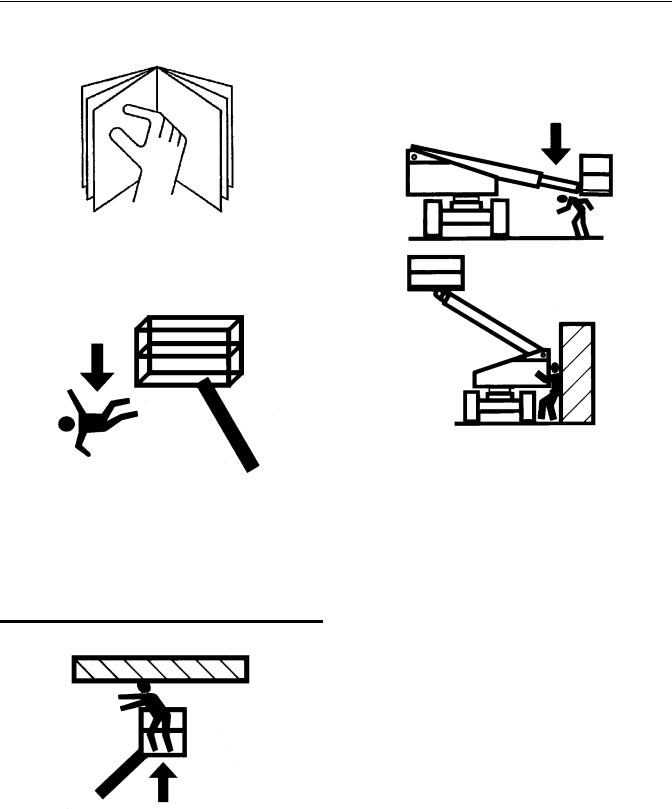

The purpose of this manual is to provide users with the operating procedures essential for the promotion of proper machine operation for its intended purpose. It is important to over-stress proper machine usage. All information in this manual should be READ and UNDERSTOOD before any attempt is made to operate the machine. YOUR OPERATING MANUAL IS YOUR MOST IMPORTANT TOOL - Keep it with the machine.

REMEMBER ANY EQUIPMENT IS ONLY AS SAFE AS THE OPERATOR.

BECAUSE THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND OPERATION, PROPER SAFETY PRACTICES ARE THE RESPONSIBILITY OF THE USER AND HIS OPERATING PERSONNEL.

ALL INSTRUCTIONS IN THIS MANUAL ARE BASED ON THE USE OF THE MACHINE UNDER PROPER OPERATING CONDITIONS, WITH NO DEVIATIONS FROM THE ORIGINAL DESIGN. ALTERATION AND/OR MODIFICATION OF THE MACHINE IS STRICTLY FORBIDDEN, WITHOUT WRITTEN APPROVAL FROM JLG INDUSTRIES, PER OSHA REGULATIONS AND APPLICABLE ANSI STANDARDS.

THIS SAFETY ALERT SYMBOL IS USED TO CALL ATTENTION TO POTENTIAL HAZARDS WHICH MAY LEAD TO SERIOUS INJURY OR DEATH IF IGNORED.

Safety of personnel and proper use of the machine are of primary concern, DANGER, WARNING, CAUTION, IMPORTANT, INSTRUCTIONS and NOTE are inserted throughout this manual to emphasize these areas. They are defined as follows:

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED WILL RESULT IN SERIOUS INJURY OR DEATH.]

CAUTION INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY ALSO BE USED TO ALERT AGAINST UNSAFE PRACTICES

WARNING INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED COULD RESULT IN SERIOUS INJURY OR DEATH.

IMPORTANT OR INSTRUCTIONS INDICATES A PROCEDURES ESSENTIAL FOR SAFE OPERATION AND WHICH, IF NOT FOLLOWED, MAY RESULT IN A MALFUNCTION OR DAMAGE TO THE MACHINE.

JLG INDUSTRIES MAY HAVE ISSUED SAFETY RELATED BULLETINS FOR YOUR JLG PRODUCT. CONTACT JLG INDUSTRIES INC. OR THE LOCAL AUTHORIZED JLG DISTRIBUTOR FOR INFORMATION CONCERNING SAFETY RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR YOUR JLG PRODUCT. ALL ITEMS REQUIRED BY THE SAFETY RELATED BULLETINS MUST BE COMPLETED ON THE AFFECTED JLG PRODUCT

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes without prior notification. Contact JLG Industries, Inc. for updated information.

3120748 |

– JLG Lift – |

a |

FOREWORD

This page left blank intentionally.

b |

– JLG Lift – |

3120748 |

FOREWORD

All procedures herein are based on the use of the machine under proper operating conditions, with no deviations from original design intent... as per OSHA regulations and applicable ANSI standards.

READ & HEED!

The ownership, use, service, and/or maintenance of this machine is subject to various governmental and local laws and regulations. It is the responsibility of the owner/user to be knowledgeable of these laws and regulations and to comply with them. Owner/ user/operator/lessor and lessee must be familiar with Sections 6,7,8,9, and 10 of ANSI A92.5-1992. These sections contain the responsibilities of the owner, users, operators, lessors, and lessees concerning safety, training, inspection, maintenance, application and operation. The most prevalent regulations of this type in the United States are the Federal OSHA Safety Regulations*. Listed below, in abbreviated form are some of the requirements of Federal OSHA regulations in effect as of the date of publication of this handbook.

The listing of these requirements shall not relieve the owner/user of the responsibility and obligation to determine all applicable laws and regulations and their exact wording and requirements, and to comply with the requirements. Nor shall the listing of these requirements constitute an assumption of responsibility of liability on the part of JLG Industries, Inc.

1.Only trained and authorized operators shall be permitted to operate the aerial lift.

2.A malfunctioning lift shall be shut down until repaired.

3.The controls shall be plainly marked as to their function.

4.The controls shall be tested each day prior to use to determine that they are in safe operating condition.

5.All personnel in the platform shall, at all times, wear approved fall protection devices and other safety gear as required.

6.Load limits specified by the manufacturer shall not be exceeded.

7.Instruction and warning placards must be legible.

8.Aerial lifts may be field modified for uses other than those intended by the manufacturer only if certified in writing by the manufacturer to be in conformity to JLG requirements and to be at least as safe as it was prior to modification.

9.Aerial lifts shall not be used near electric power lines unless the lines have been de energized or adequate clearance is maintained (See OSHA 29 CFR 1910.67 and 1926.453).

10.Employees using aerial lifts shall be instructed on how to recognize and avoid unsafe conditions and hazards.

11.Ground controls shall not be operated unless permission has been obtained from personnel in the platform, except in case of an emergency.

12.Regular inspection of the job site and aerial lift shall be performed by competent persons.

13.Personnel shall always stand on the floor of the platform, not on boxes, planks, railing or other devices, for a work position.

*Applicable Federal OSHA regulations for the United States, as of the date of publication of this manual, include, but are not limited to, 29 CFR 1910.67, 29 CFR 1926.20, 29 CFR 1926.21, 29 CFR 1926.28, and 29 CFR 1926.453.

3120748 |

– JLG Lift – |

c |

FOREWORD

|

|

REVISON LOG |

Original Issue |

- |

May, 1998 |

Revised |

|

June 1, 1999 |

3-6 |

- |

Updated 9-21-99 |

3-8 |

- |

Updated 9-21-99 |

3-6 |

- |

Updated 10-14-99 |

2-12 and 2-13 |

- |

Updated 11-8-99 |

5-3 |

- |

Updated 2-2-00 |

Prop 65 page added |

- |

Updated 4-20-00 |

4-1 |

- |

Updated 4-20-00 |

3-6 |

- |

Updated 9-19-00 |

3-11 |

- |

Updated 4-24-02 |

d |

– JLG Lift – |

3120748 |

TABLE OF CONTENTS

|

TABLE OF CONTENTS |

|

SUBJECT - SECTION, PARAGRAPH |

PAGE NO. |

|

SECTION |

- FOREWORD |

|

SECTION |

1 - SAFETY PRECAUTIONS |

|

1.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .1-1 |

1.2 |

Driving/Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .1-1 |

1.3 |

Electrocution Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .1-2 |

1.4 |

Pre-Operational . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .1-2 |

1.5 |

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .1-4 |

1.6 |

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .1-5 |

1.7 |

Towing and Hauling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .1-8 |

SECTION |

2 - PREPARATION AND INSPECTION |

|

2.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .2-1 |

2.2 |

Preparation For Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .2-1 |

2.3 |

Delivery and Frequent Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .2-1 |

2.4 |

Daily Walk-Around Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .2-5 |

2.5 |

Daily Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .2-9 |

2.6 |

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .2-10 |

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Personnel Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Operating Characteristics and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.4 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.5 Placards and Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

SECTION 4 - MACHINE OPERATION

4.1 |

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

4.2 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

4.3 |

Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

4.4 |

Traveling (Driving) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

4.5 |

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

4.6 |

Parking and Stowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

4.7 |

Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

4.8 |

Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

4.9 |

Lift Up and Platform Level Down Disable Switch Functional Check . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

4.10 |

Shut Down and Park . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

4.11 |

Tie Down and Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

4.12 |

Oscillating Axle Lockout Test (If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-9 |

4.13 |

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-10 |

SECTION 5 - OPTIONAL EQUIPMENT

5.1 Dual Fuel System (Gas Engine Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Oscillating Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 Platform W/soft Touch Proximity System Bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.4 Four Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.5 Cold Weather Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.6 Travel Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.7 Electric Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.8 Foam Filled Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.9 Rotating Beacon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

3120748 |

– JLG Lift – |

i |

TABLE OF CONTENTS (Continued)

TABLE OF CONTENTS (continued)

SUBJECT - SECTION, PARAGRAPH |

PAGE NO. |

5.10 Cylinder Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.11 Boom Wipers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.12 Hostile Environment Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.13 Motion Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.14 Semi-Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

SECTION 6 - EMERGENCY PROCEDURES

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Emergency Towing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Emergency Controls and Their Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.4 Emergency Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.5 Incident Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

SECTION 7 - INSPECTION AND REPAIR LOG

|

LIST OF FIGURES |

|

FIGURE NO. |

TITLE |

PAGE NO. |

2-1. Machine Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 2-2. Daily Walk-Around Inspection - Sheet 1 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6 2-3. Daily Walk-Around Inspection - Sheet 2 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7 2-4. Daily Walk-Around Inspection - Sheet 3 of 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8 2-5. Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11 2-6. Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14 3-1. Position of Least Forward Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3 3-2. Position of Least Backward Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 3-3. Ground Control Indicator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6 3-4. Ground Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 3-5. Malfunction Indicator Light and Test Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 3-6. Platform Station - Proportional Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10 3-7. Danger and Warning Decal Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13 3-8. Control Panel Symbols - Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16 3-9. Control Panel Symbols - Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17 4-1. Grade and Sideslope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 4-2. Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 4-3. Machine Tie Down - A Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6 4-4. Machine Tie Down - AJ Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7 4-5. Lifting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8 4-6. Drive Disconnect Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

LIST OF TABLES

TABLE NO. |

TITLE |

PAGE NO. |

1-1 Minimum Safe Approach Distances (M.S.A.D.) to energized (exposed or insulated)

power lines and parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 2-1 Lubrication Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12 7-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

ii |

– JLG Lift – |

3120748 |

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1GENERAL

This section prescribes the proper and safe practices for major areas of machine usage. In order to promote proper usage of the machine, it is mandatory that a daily routine be established based on instructions given in this section. A maintenance program must also be established by a qualified person and must be followed to ensure that the machine is safe to operate.

The owner/user/operator of the machine should not accept operating responsibility until this manual has been read and understood, and operation of the machine, under the supervision of an experienced and qualified person, has been completed. Owner/user/operator must be familiar with Sections 6, 7, 8, 9, and 10 of ANSI A92.5- 1992. These sections contain the responsibilities of the owner, users, operators, lessors and lessees concerning safety, training, inspection, maintenance, application and operation. If there is a question on application and/or operation, JLG Industries Inc., should be consulted.

MODIFICATION OR ALTERATION OF AN AERIAL PLATFORM SHALL BE MADE ONLY WITH PRIOR WRITTEN PERMISSION OF THE MANUFACTURER.

1.2DRIVING/TOWING

Before driving the machine, the user must be familiar with the drive, steer and stopping characteristics. This is especially important when driving in close quarters.

The user should be familiar with the driving surface before driving. The surface should be firm and level and grades should not exceed the allowable grade for the machine.

NOTE: Remember that the key to safe and proper usage is common sense and its careful application.

The machine is not equipped with provisions for towing. Refer to Section 6 for emergency towing procedures.

SPECIAL NOTE:

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN THIS SECTION AND ON THE MACHINE COULD RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH, AND IS A SAFETY VIOLATION.

3120748 |

– JLG Lift – |

1-1 |

SECTION 1 - SAFETY PRECAUTIONS

Table 1-1.Minimum Safe Approach Distances (M.S.A.D.) to energized (exposed or insulated) power lines and parts

Voltage Range |

MINIMUM SAFE APPROACH DISTANCE |

(Phase to Phase) |

in Feet (Meters) |

|

|

0 to 300V |

AVOID CONTACT |

|

|

Over 300V to 50 KV |

10 (3) |

|

|

Over 50KV to 200 KV |

15 (5) |

|

|

Over 200 KV to 350 KV |

20 (6) |

|

|

Over 350 KV to 500 KV |

25 (8) |

|

|

Over 500 KV to 750 KV |

35 (11) |

|

|

Over 750 KV to 1000 KV |

45 (14) |

|

|

DANGER: DO NOT maneuver machine or personnel inside PROHIBITED ZONE. ASSUME all electrical parts and wiring are ENERGIZED unless known otherwise.

1.3ELECTROCUTION HAZARD

•MAINTAIN SAFE CLEARANCE FROM ELECTRICAL LINES AND APPARATUS. ALLOW FOR BOOM SWAY, ROCK OR SAG AND ELECTRICAL LINE SWAYING. THE MACHINE DOES NOT PROVIDE PROTECTION

FROM CONTACT WITH OR PROXIMITY TO AN ELECTRICALLY CHARGED CONDUCTOR.

•MAINTAIN A CLEARANCE OF AT LEAST 10 FEET (3 M) BETWEEN ANY PART OF THE MACHINE OR ITS LOAD AND ANY ELECTRICAL LINE OR APPARATUS CARRYING UP TO 50,000 VOLTS. ONE FOOT ADDITIONAL CLEARANCE IS REQUIRED FOR EVERY ADDITIONAL 30,000 VOLTS OR LESS.

1.4PRE-OPERATIONAL

•READ YOUR MANUAL. UNDERSTAND WHAT YOU’VE READ - THEN BEGIN OPERATIONS.

•ALLOW ONLY AUTHORIZED AND QUALIFIED PERSONNEL TO OPERATE MACHINE WHO HAVE DEMONSTRATED THAT THEY UNDERSTAND SAFE AND PROPER OPERATION AND MAINTENANCE OF THE UNIT.

1-2 |

– JLG Lift – |

3120748 |

SECTION 1 - SAFETY PRECAUTIONS

•AN OPERATOR MUST NOT ACCEPT OPERATING RESPONSIBILITIES UNTIL ADEQUATE TRAINING HAS BEEN GIVEN BY COMPETENT AND AUTHORIZED PERSONS.

•BEFORE OPERATION, CHECK WORK AREA FOR OVERHEAD ELECTRIC LINES, MACHINE TRAFFIC SUCH AS BRIDGE CRANES, HIGHWAY, RAILWAY AND CONSTRUCTION EQUIPMENT.

•PRECAUTIONS TO AVOID ALL KNOWN HAZARDS IN THE WORK AREA MUST BE TAKEN BY THE OPERATOR AND HIS SUPERVISOR BEFORE STARTING THE WORK.

•DO NOT OPERATE THIS MACHINE UNLESS IT HAS BEEN SERVICED AND MAINTAINED ACCORDING TO THE MANUFACTURERS SPECIFICATIONS AND SCHEDULE.

•ENSURE DAILY INSPECTION AND FUNCTION CHECK IS PERFORMED PRIOR TO PLACING MACHINE INTO OPERATION.

•NEVER DISABLE OR MODIFY THE FOOTSWITCH OR ANY OTHER SAFETY DEVICE. ANY UNAUTHORIZED MODIFICATION OF THE MACHINE IS A SAFETY VIOLATION AND IS A VIOLATION OF OSHA REGULATIONS AND ANSI STANDARDS.

•DO NOT OPERATE MACHINE WHEN WIND CONDITIONS EXCEED 30 MPH (48 KMH).

•NEVER OPERATE BOOM FUNCTIONS (TELE, SWING, LIFT) WHEN MACHINE IS ON A TRUCK, OTHER VEHICLE, OR ABOVE GROUND STRUCTURE.

•THIS MACHINE CAN BE OPERATED IN NOMINAL AMBIENT TEMPERATURES OF 0° F TO 104° F (-20°C TO 40°C). CONSULT FACTORY TO OPTIMIZE OPERATION OUTSIDE THIS RANGE.

•APPROVED HEAD GEAR MUST BE WORN BY ALL OPERATING AND GROUND PERSONNEL.

3120748 |

– JLG Lift – |

1-3 |

SECTION 1 - SAFETY PRECAUTIONS

.

•READ AND OBEY ALL DANGERS, WARNINGS, CAU- T I O N S A N D O P E R AT I N G I N S T R U C T I O N S O N MACHINE AND IN THIS MANUAL.

•BE FAMILIAR WITH LOCATION AND OPERATION OF GROUND STATION CONTROLS.

•ALWAYS POSITION BOOM OVER REAR (DRIVE) AXLE IN LINE WITH DIRECTION OF TRAVEL. REMEMBER, IF BOOM IS OVER FRONT (STEER) AXLE, DIRECTION OF STEER AND DRIVE MOVEMENT WILL BE OPPOSITE FROM NORMAL OPERATION.

•ALWAYS USE THREE POINT CONTACT WHEN ENTERING OR EXITING THE MACHINE. FACE THE MACHINE WHEN YOU ENTER OR LEAVE. THREE POINT CONTACT MEANS THAT TWO HANDS AND ONE FOOT OR ONE HAND AND TWO FEET ARE IN CONTACT WITH THE MACHINE AT ALL TIMES DURING MOUNT AND DISMOUNT.

1.5DRIVING

•WATCH FOR OBSTRUCTIONS AROUND MACHINE AND OVERHEAD WHEN DRIVING.

•DO NOT USE DRIVE FUNCTION TO POSITION PLATFORM CLOSE TO OBSTACLES. USE BOOM FUNCTION INSTEAD.

•WHEN DRIVING IN HIGH SPEED, SWITCH TO LOW SPEED BEFORE STOPPING. TRAVEL GRADES IN LOW DRIVE, HIGH ENGINE ONLY.

•DO NOT USE HIGH SPEED DRIVE WHEN IN RESTRICTED OR CLOSE QUARTERS, OR WHEN DRIVING IN REVERSE.

•BE AWARE OF STOPPING DISTANCES WHEN TRAVELING IN HIGH AND LOW SPEEDS.

•ALWAYS POST A LOOKOUT AND SOUND HORN WH E N D RI V IN G IN ARE A S WH E RE V I SI O N I S OBSTRUCTED.

•KEEP NON-OPERATING PERSONNEL AT LEAST 6 FEET (2 M) AWAY FROM MACHINE DURING DRIVING OPERATIONS.

1-4 |

– JLG Lift – |

3120748 |

SECTION 1 - SAFETY PRECAUTIONS

•CHECK TRAVEL PATH FOR PERSONS, DEPRESSIONS, HOLES, BUMPS, DROP-OFFS, OBSTRUCTIONS, DEBRIS, AND COVERINGS WHICH MAY CONCEAL HOLES AND OTHER HAZARDS.

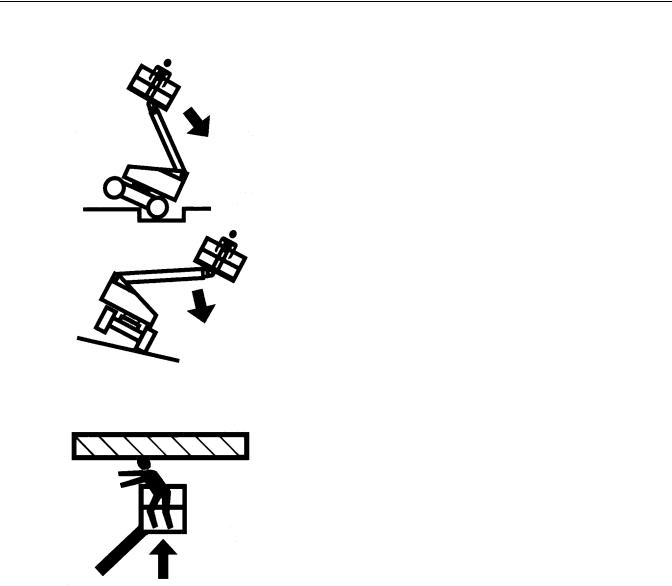

•TRAVEL IS PERMITTED ON GRADES NO GREATER THAN THOSE INDICATED ON THE SERIAL NUMBER PLATE.

•DO NOT DRIVE ON SIDESLOPES WHICH EXCEED 5°.

•OPERATION WITH BOOM RAISED IS RESTRICTED TO FIRM, LEVEL AND UNIFORM SURFACE.

•DO NOT TRAVEL ON SOFT OR UNEVEN SURFACES, AS TIPPING WILL OCCUR.

•ENSURE THAT GROUND CONDITIONS ARE ADEQUATE TO SUPPORT THE MAXIMUM TIRE LOAD.

•DO NOT DRIVE MACHINE NEAR PITS, LOADING DOCKS OR OTHER DROP-OFFS.

1.6OPERATION

•READ YOUR MANUAL. UNDERSTAND WHAT YOU’VE READ - THEN BEGIN OPERATIONS.

•PRIOR TO ENTERING AND EXITING PLATFORM AT G R O U N D L E V E L , F U L LY LO W E R T H E B O O M . EXTEND BOOM UNTIL END OF FLY BOOM CONTACTS GROUND. WITH BOOM LIFT IN THIS CONFIG- U R AT I O N , E N T E R A N D / O R E X I T P L AT F O R M THROUGH GATE OPENING.

•OSHA REQUIRES ALL PERSONS IN THE PLATFORM TO WEAR LANYARDS WITH AN APPROVED FALL PROTECTION DEVICE. SECURE LANYARD TO DESIGNATED LANYARD ATTACH POINT ON PLATFORM. KEEP GATE CLOSED AT ALL TIMES.

•TO AVOID FALLING - USE EXTREME CAUTION WHEN E N T E R I N G O R L E AV I N G P L AT F O R M A B O V E GROUND. ENTER OR EXIT THRU GATE ONLY. PLATFORM FLOOR MUST BE WITHIN 1 FOOT (30 CM) OF ADJACENT - SAFE AND SECURE - STRUCTURE. ALLOW FOR PLATFORM VERTICAL MOVEMENT AS WEIGHT IS TRANSFERRED TO OR FROM PLATFORM.

3120748 |

– JLG Lift – |

1-5 |

SECTION 1 - SAFETY PRECAUTIONS

•TRANSFERS BETWEEN A STRUCTURE AND THE AERIAL PLATFORM EXPOSE OPERATORS TO FALL HAZARDS. THIS PRACTICE SHOULD BE DISCOURAGED WHEREVER POSSIBLE. WHERE TRANSFER MUST BE ACCOMPLISHED TO PERFORM THE JOB TWO LANYARDS WITH AN APPROVED FALL PROTECTION DEVICE WILL BE USED. ONE LANYARD SHOULD BE ATTACHED TO THE AERIAL PLATFORM. THE OTHER TO THE STRUCTURE. THE LANYARD THAT IS ATTACHED TO THE AERIAL PLATFORM SHOULD NOT BE DISCONNECTED UNTIL SUCH TIME AS THE TRANSFER TO THE STRUCTURE IS COMPLETE. OTHERWISE, DO NOT STEP OUTSIDE OF PLATFORM.

•DO NOT ADD NOTICE BOARDS OR SIMILAR ITEMS TO THE PLATFORM. ADDITION OF SUCH ITEMS INCREASES THE EXPOSED WIND AREA OF THE MACHINE.

•NEVER POSITION LADDERS, STEPS, OR SIMILAR ITEMS ON UNIT TO PROVIDE ADDITIONAL REACH FOR ANY PURPOSE.

•WHEN RIDING IN OR WORKING FROM PLATFORM, BOTH FEET MUST BE FIRMLY POSITIONED ON THE FLOOR.

•KEEP OIL, MUD AND SLIPPERY SUBSTANCES CLEANED FROM FOOTWEAR AND PLATFORM FLOOR.

•NEVER "WALK" THE BOOM TO GAIN ACCESS TO OR LEAVE PLATFORM.

•NEVER PLACE HANDS OR ARMS IN TOWER BOOM OR UPRIGHT MECHANISM.

•KEEP ALL NON-OPERATING PERSONNEL AT LEAST 6 FEET (2 M) AWAY FROM THE MACHINE AT ALL TIMES.

•IF PLATFORM OR BOOM IS CAUGHT SO THAT ONE OR MORE WHEELS ARE OFF THE FLOOR, ALL PERSONNEL MUST BE REMOVED FROM PLATFORM BEFORE ATTEMPTING TO FREE MACHINE. USE CRANES, FORKLIFT TRUCKS OR OTHER EQUIPMENT TO REMOVE PERSONNEL AND STABILIZE MACHINE MOTION, IF NECESSARY.

•THE OPERATOR IS RESPONSIBLE TO AVOID OPERATING MACHINE OVER GROUND PERSONNEL AND TO WARN THEM NOT TO WORK, WALK OR STAND UNDER A RAISED BOOM OR PLATFORM. POSITION BARRICADES ON FLOOR IF NECESSARY.

1-6 |

– JLG Lift – |

3120748 |

SECTION 1 - SAFETY PRECAUTIONS

.

•ENSURE MACHINE IS POSITIONED ON A FIRM, LEVEL AND UNIFORM SUPPORTING SURFACE BEFORE RAISING OR EXTENDING BOOM.

•CHECK CLEARANCES ABOVE, ON SIDES AND BOTTOM OF PLATFORM WHEN RAISING, LOWERING, SWINGING, AND TELESCOPING BOOM.

•EXERCISE EXTREME CAUTION AT ALL TIMES TO PREVENT OBSTACLES FROM STRIKING OR INTER-

FERING WITH OPERATING CONTROLS AND PERSONS IN PLATFORM.

•ENSURE THAT OPERATORS OF OTHER OVERHEAD AND FLOOR MACHINES ARE AWARE OF THE AERIAL PLATFORMS PRESENCE. DISCONNECT POWER TO OVERHEAD CRANES. POSITION BARRICADES ON FLOOR IF NECESSARY.

•NEVER "SLAM" A CONTROL SWITCH OR LEVER THROUGH NEUTRAL TO THE OPPOSITE DIRECTION. ALWAYS RETURN SWITCH TO NEUTRAL AND STOP; THEN MOVE SWITCH TO THE DESIRED POSITION. OPERATE LEVERS WITH SLOW, EVEN PRESSURE.

•DO NOT CARRY MATERIALS ON PLATFORM RAILING UNLESS APPROVED BY JLG INDUSTRIES INC.

•NEVER PUSH OR PULL THE MACHINE OR OTHER OBJECTS BY TELESCOPING THE BOOM.

•NEVER USE BOOM FOR ANY PURPOSE OTHER THAN POSITIONING PERSONNEL, THEIR TOOLS AND EQUIPMENT.

•NEVER EXCEED MANUFACTURERS RATED PLATFORM CAPACITY - REFER TO CAPACITY DECAL ON MACHINE. DISTRIBUTE LOADS EVENLY ON PLATFORM FLOOR.

•NEVER OPERATE A MALFUNCTIONING MACHINE. IF A MALFUNCTION OCCURS, SHUT DOWN THE MACHINE , RED TAG IT, AND NOTIFY PROPER AUTHORITIES.

•DO NOT REMOVE, MODIFY, OR DISABLE FOOTSWITCH BY BLOCKING OR ANY OTHER MEANS.

•DO NOT ASSIST A STUCK OR DISABLED MACHINE BY PUSHING OR PULLING EXCEPT BY PULLING AT CHASSIS TIE-DOWN LUGS.

•NEVER ATTEMPT USING BOOM AS A CRANE. STRUCTURAL DAMAGE OR TIPPING MAY OCCUR.

•STOW BOOM AND SHUT OFF ALL POWER BEFORE LEAVING MACHINE.

•NO STUNT DRIVING OR HORSEPLAY IS PERMITTED.

3120748 |

– JLG Lift – |

1-7 |

SECTION 1 - SAFETY PRECAUTIONS

•NEVER ATTEMPT TO FREE A MACHINE STUCK IN SOFT GROUND OR ASSIST A MACHINE UP A STEEP HILL OR RAMP BY USING BOOM "LIFT", "TELESCOPE", OR "SWING" FUNCTIONS.

•NEVER ATTACH WIRE, CABLE, OR ANY SIMILAR ITEMS TO PLATFORM.

•DO NOT PLACE BOOM OR PLATFORM AGAINST ANY STRUCTURE TO STEADY PLATFORM OR SUPPORT STRUCTURES.

•DO NOT USE THE LIFT, SWING, OR TELESCOPE FUNCTIONS FOR THE BOOM, TO MOVE EITHER THE MACHINE OR OTHER OBJECTS.

•HYDRAULIC CYLINDERS SHOULD NEVER BE LEFT FU L LY E XT E N D E D O R R E T RA CT E D F O R A N Y LENGTH OF TIME. ALWAYS "BUMP" CONTROL IN OPPOSITE DIRECTION SLIGHTLY WHEN FUNCTION BEING USED REACHES END OF TRAVEL . THIS APPLIES TO MACHINES IN OPERATION OR IN STOWED MODE.

•DO NOT OPERATE ANY MACHINE ON WHICH DANGER, WARNING, CAUTION OR INSTRUCTION PLACARDS OR DECALS ARE MISSING OR ILLEGIBLE.

•MACHINE MUST ALWAYS BE SHUT DOWN WHEN REFUELING. NO SMOKING IS MANDATORY. NEVER REFUEL DURING AN ELECTRICAL STORM. ENSURE THAT FUEL CAP IS CLOSED AND SECURE AT ALL OTHER TIMES.

1.7TOWING AND HAULING

•DO NOT TOW A MACHINE EXCEPT IN AN EMERGENCY. SEE SECTION 6 FOR EMERGENCY TOWING PROCEDURES.

•LOCK TURNTABLE BEFORE TRAVELING LONG DISTANCES OR BEFORE HAULING MACHINE ON A TRUCK OR TRAILER.

1-8 |

– JLG Lift – |

3120748 |

SECTION 2 - PREPARATION AND INSPECTION

SECTION 2. PREPARATION AND INSPECTION

2.1GENERAL

This section provides the necessary information needed by those personnel that are responsible to place the machine in operation readiness, and lists checks that are performed prior to use of the machine. It is important that the information contained in this section be read and understood before any attempt is made to operate the machine. Ensure that all the necessary inspections have been completed successfully before placing the machine into service. These procedures will aid in obtaining maximum service life and safe operation.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE, SAFETY IS THE RESPONSIBILITY OF THE OWNER/OPERATOR.

2.2PREPARATION FOR USE

Before a new machine is put into operation it must be carefully inspected for any evidence of damage resulting from shipment and inspected periodically thereafter, as outlined in Delivery and Frequent Inspection (see section 2-3). During initial start-up and run, the unit should be thoroughly checked for hydraulic leaks. A check of all components should be made to assure their security.

All preparation necessary to place the machine in operation readiness status is the responsibility of management personnel. Preparation requires good common sense, (i.e. telescope works smoothly and brakes operate properly) coupled with a series of visual inspections. The mandatory requirements are given in the Daily Walk Around Inspection (see section 2-4).

It should be assured that the items appearing in the Delivery and Frequent Inspection and Functional Check are complied with prior to putting the machine into service.

2.3DELIVERY AND FREQUENT INSPECTION

NOTE: This machine requires periodic safety and maintenance inspections by an authorized JLG Dealer. A decal located on the frame provides a place to record (stamp) inspection dates. Check decal and notify dealer if inspection is overdue.

NOTE: An annual inspection shall be performed on the aerial platform no later than thirteen (13) months from the date of the prior annual inspection. The inspection shall be performed by person(s) qualified as a mechanic on the specific make and model of the aerial platform.

The following checklist provides a systematic inspection to assist in detecting defective, damaged, or improperly installed parts. The checklist denotes the items to be inspected and conditions to examine.

Frequent inspection shall be performed every 3 months or 150 hours whichever comes first, or more often when required by environment, severity, and frequency of usage.

This inspection checklist is also applicable and must be followed for all machines that have been in storage or for all machines that will be exposed to harsh or changing climates.

These checks are also to be performed after maintenance has been performed on the machine.

Chassis

1.Check front tires and wheel assemblies for loose or worn spindles, components and hardware for security, tires for wear and damage.

2.Check steering assembly for loose or bent tie rod, cylinder and hydraulic lines for leaks and security, and hardware for proper installation.

3.If equipped with 4WD, check drive hubs, hydraulic motors, brakes and hydraulic lines for damage and leaks.

4.Check rear tires and wheel assemblies for security, tires for wear and damage.

5.Check drive hubs, hydraulic motors, brakes and hydraulic lines for damage and leaks.

6.Check oil level in drive hub by removing pipe plug on side and feeling for oil level. (Contact Service Personnel for assistance if needed).

NOTE: Torque hubs should be one-half full of lubricant.

7.Check oscillating axle (if equipped) for loose, missing and worn parts, pivot pin and lockout cylinder pins for security, lockout cylinders and hydraulic hoses for damage and leaks.

3120748 |

– JLG Lift – |

2-1 |

SECTION 2 - PREPARATION AND INSPECTION

Turntable

1.Check turntable for damage, loose or missing parts, and security. Check swing drive and brake for damage, loose or missing parts, hydraulic lines and component housings for evidence of leakage; worm gear for proper mesh with swing gear.

2.Check swing bearing for damage, wear, lubrication and loose or missing bearing bolts.

3.Check solenoid valves and hydraulic lines for damage, leakage, security and electrical connections for tightness and evidence of corrosion.

4.Check ground controls for damage, loose or missing parts, security, electrical connections for evidence of corrosion and tightness and wiring for insulation damage. Assure that all switches function properly.

5.Check battery for damage, loose or missing vent caps, electrical connections for tightness, and evidence of corrosion, hold-down brackets for tightness, and electrolyte for proper water level. Add only clean distilled water to battery.

6.Check engine tray pivot assembly for damage, loose or missing parts, and security.

7.Check engine and accessories for damage, loose or missing parts, leakage and security. Check throttle solenoid and linkage for damage, electrical connections for tightness, and evidence of corrosion and wiring for insulation damage.

8.Check fuel lines for damage, leakage and security.

9.Check all access doors for damage, proper operation of latches, props and security.

10.Check fuel tank for damage, leakage and filler cap for security.

11.Check hydraulic reservoir and hydraulic lines for damage, leakage and security.

NOTE: JLG recommends replacing the hydraulic filter element after the first 50 hours of operation and then every 300 hours thereafter, unless system indicator require earlier replacement.

12.Check all pin and shaft retaining hardware for security and wear.

13.Check all electrical cables for defects, damage, loose or corroded connections.

Boom

1.Check Lower Boom and leveling link for damage, missing parts and security.

2.Check all pin and shaft retaining hardware for security and wear.

3.Check hydraulic lines and electrical cable for damage, missing parts and security.

4.Check limit switch connections and plunger for corrosion and security.

5.Check Lower Upright, cross pins and hydraulic lines for damage, wear, lubrication, leakage and security.

6.Check Lower Upright for damage, wear, lubrication and security.

7.Check hydraulic lines mounted on upright for damage, leakage and security.

8.Check boom pivot bushings for wear.

9.Check boom lift cylinder and hydraulic lines for damage, leakage and security. Check lift cylinder cross pins for damage, wear and security.

10.Check all pin and shaft retaining hardware for security and wear.

11.Check Upper Upright, cross pins and hydraulic lines for damage, wear, lubrication, leakage and security.

12.Check Upper Upright for damage, wear, lubrication and security.

13.Check hydraulic lines mounted on upright for damage, leakage and security.

14.Check Upper Boom Lift Cylinder and cross pins and hydraulic lines for damage, wear, lubrication, leakage and security.

2-2 |

– JLG Lift – |

3120748 |

SECTION 2 - PREPARATION AND INSPECTION

PLATFORM

CONSOLE

EXTEND-A-REACH or JIB

FLY BOOM

BASE BOOM

MID LIFT CYLINDER

TOWER or

LOWER BOOM

TURNTABLE

PLATFORM

EXTEND-A-REACH

CYLINDER

LEVEL CYLINDER

POWER TRACK

MAIN BOOM ASSEMBLY

UPPER LIFT CYLINDER

MID BOOM

LOWER UPRIGHT

TOWER or LOWER LIFT

CYLINDER

DRIVE WHEELS

STEER WHEELS

Figure 2-1. Machine Nomenclature

3120748 |

– JLG Lift – |

2-3 |

SECTION 2 - PREPARATION AND INSPECTION

15.Check Upper Boom pivot pin for damage, wear, lubrication and security.

16.Check Upper Boom for damage, missing parts and security.

17.Check Upper Boom wear pads for damage, missing parts and security.

18.Check Upper Boom telescope cylinder, cross pins and hydraulic lines for damage, wear, lubrication, leakage and security.

19.Check Platform Leveling Cylinder, cross pins and hydraulic lines for damage, wear, lubrication, leakage and security.

Platform

1.Check platform and control console for damage, loose or missing parts, and security.

2.Check control switches and levers for damage, loose or missing parts and security. Assure that levers function properly.

3.Check control switches, levers and electrical connections for tightness and evidence of corrosion, and wiring for defects and chafing damage. Assure that switches function properly.

4.Check access gate hinges, stop, and latch for proper operation, damage and security.

5.Check platform rotator mechanism for proper operation, damage, security. Check hydraulic lines for leakage, damage and security.

NOTE: Check all DANGER, WARNING, CAUTION and INSTRUCTION placards for legibility and security on the entire machine.

Torque Requirements

The Torque Chart (Figure 2-6.) consists of standard torque values based on bolt diameter and grade, also specifying dry and wet torque values in accordance with recommended shop practices. This chart is provided as an aid to the operator in the event he/she notices a condition that requires prompt attention during the walk-around inspection or during operation, until the proper service personnel can be notified. The Service and Maintenance manual provides specific torque values and periodic maintenance procedures with a listing of individual components. Utilizing this Torque Chart in conjunction with the preventive maintenance section in the Service and Maintenance manual will enhance safety, reliability, and performance of the machine.

2-4 |

– JLG Lift – |

3120748 |

SECTION 2 - PREPARATION AND INSPECTION

2.4DAILY WALK-AROUND INSPECTION

It is the operators responsibility to inspect the machine before the start of each workday. It is recommended that each operator inspect the machine before operation, even if the machine has already been put into service under another operator. This Daily Walk-Around Inspection is the preferred method of inspection.

These checks are also to be performed after maintenance has been performed on the machine.

In addition to the Daily Walk-Around Inspection, be sure to include the following as part of the daily inspection:

1.Overall cleanliness.

Check all standing surfaces for oil, fuel and hydraulic oil spillage and foreign objects. Ensure overall cleanliness.

2.Placards.

Keep all information and operating placards clean and unobstructed. Cover when spray painting or shot blasting to protect legibility.

3.Operator’s and Safety Manual.

Ensure a copy of this manual and the ANSI A92.5- 1992 Responsibilities, are enclosed in the manual storage box.

4.Machine Log.

Ensure a machine operating record or log is kept, check to see that it is current and that no entries

have been left uncleared, leaving machine in an unsafe condition for operation.

5. Start each day with a full fuel tank.

TO AVOID INJURY, DO NOT OPERATE A MACHINE UNTIL ALL MALFUNCTIONS HAVE BEEN CORRECTED. USE OF A MALFUNCTIONING MACHINE IS A SAFETY VIOLATION.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS "OFF" DURING WALK-AROUND INSPECTION.

NOTE: Check boom limit switches on upright for proper operation and security, both visually and manually. The lower switch cuts out drive speed when the lower boom is above horizontal. The upper switch cuts out drive speed when the upper boom is above horizontal. Only creep drive speed will continue to function.

6.Check platform footswitch for proper operation. Switch must be released to start engine and depressed to operate machine.

7.Check that drive brakes hold when machine is driven up a grade not greater than specified on the serial number placard and stopped.

NOTE: On new machines, those recently overhauled, or after changing hydraulic oil, operate all systems a minimum of two complete cycles and recheck oil level in reservoir.

8.Assure that all items requiring lubrication are serviced. Refer to Figure 2-5., Lubrication Diagram for specific requirements.

3120748 |

– JLG Lift – |

2-5 |

Loading...

Loading...