JLG 510AJ Parts Manual

3121182 510AJ 3

4 510AJ 3121182

3121182 510AJ 5

6 510AJ 3121182

TABLE OF CONTENTS

3121182 510AJ 7

SECTION 1 - FRAME ........................................................................................................................................................................... 9

FIGURE 1-1. AXLE AND STEERING INSTALLATION ................................................................................................................... 10

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATIONS ........................................................................................................... 14

FIGURE 1-3. DRIVE HUB/BRAKE ASSEMBLY (REAR) ................................................................................................ ................ 18

FIGURE 1-4. DRIVE HUB/BRAKE ASSEMBLY (REAR) ................................................................................................ ................ 22

FIGURE 1-5. DRIVE HUB ASSEMBLY (FRONT)........................................................................................................................... 26

FIGURE 1-6. DRIVE HUB ASSEMBLY (FRONT)........................................................................................................................... 30

FIGURE 1-7. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES) (Prior to SN 1300002249) ........................................ 34

FIGURE 1-8. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN

1300002249 to Present, SN E300000100 through E300001114) ................................................................................................... 36

FIGURE 1-9. DRIVE VALVES INSTALLATIONS ........................................................................................................................... 38

SECTION 2 - TURNTABLE ................................................................................................................................................................ 41

FIGURE 2-1. CONTROL VALVE INSTALLATION.......................................................................................................................... 42

FIGURE 2-2. MAIN CONTROL VALVE ASSEMBLY ...................................................................................................................... 44

FIGURE 2-3. TURNTABLE AND SWING DRIVE INSTALLATIONS .............................................................................................. 46

FIGURE 2-4. SWING MOTOR ASSEMBLY (ORIGINAL EQUIPMENT FOR BELGIUM BUILT MACHINES) (Prior to SN

1300006701) .................................................................................................................................................................................. 50

FIGURE 2-5. SWING MOTOR ASSEMBLY (SERVICE REPLACEMENT FOR BELGIUM BUILT MACHINES AND ORIGINAL

EQUIPMENT FOR BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (Prior to SN 1300006701, SN

1300006701 to Present, SN E300000100 through E300001114) ................................................................................................... 52

FIGURE 2-6. SWING BEARING AND ROTATION BOX ASSEMBLY ............................................................................................ 54

FIGURE 2-7. CATERPILLAR ENGINE INSTALLATION (WITH UGM) ........................................................................................... 58

FIGURE 2-8. 2500W GENERATOR INSTALLATION - CATERPILLAR MACHINES (WITH UGM) (OPTIONAL) .......................... 66

FIGURE 2-9. DEUTZ ENGINE INSTALLATION (BELGIUM BUILT MACHINES) (Prior to SN 1300000981) ................................. 70

FIGURE 2-10. DEUTZ ENGINE INSTALLATION (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN

1300000981 to Present, SN E300000100 through E300001114) ................................................................................................... 76

FIGURE 2-11. 2500W GENERATOR INSTALLATION - DEUTZ MACHINES (OPTIONAL) .......................................................... 84

FIGURE 2-12. PERKINS ENGINE INSTALLATION (WITH ELECTRICAL DRIVEN COOLING FAN) (WITHOUT UGM) .............. 88

FIGURE 2-13. PERKINS ENGINE INSTALLATION (WITH ENGINE DRIVEN COOLING FAN) (WITHOUT UGM) ...................... 96

FIGURE 2-14. PERKINS ENGINE INSTALLATION (WITH UGM) ............................................................................................... 104

FIGURE 2-15. 2500W GENERATOR INSTALLATION - PERKINS MACHINES (OPTIONAL) .................................................... 112

FIGURE 2-16. PISTON PUMP ASSEMBLY ................................................................................................................................. 116

FIGURE 2-17. AUXILIARY PUMP ASSEMBLY ............................................................................................................................ 120

FIGURE 2-18. TANK INSTALLATIONS ........................................................................................................................................ 124

FIGURE 2-19. GROUND CONTROL BOX ASSEMBLY (WITHOUT UGM) ................................................................................. 128

FIGURE 2-20. GROUND CONTROL BOX ASSEMBLY (WITH UGM) ......................................................................................... 132

FIGURE 2-21. ELECTRICAL OPTIONS INSTALLATION (TURNTABLE MOUNTED) ................................................................. 136

FIGURE 2-22. HOODS INSTALLATION (BELGIUM BUILT MACHINES) (Prior to SN 1300006659) .......................................... 140

FIGURE 2-23. HOODS INSTALLATION (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN 1300006659

to Present, SN E300000100 through E300001114)...................................................................................................................... 144

SECTION 3 - BOOM ........................................................................................................................................................................ 149

FIGURE 3-1. TOWER/MID BOOMS AND CYLINDERS INSTALLATION .................................................................................... 150

FIGURE 3-2. MAIN BOOM INSTALLATION ................................................................................................................................. 154

FIGURE 3-3. MAIN BOOM ASSEMBLY ....................................................................................................................................... 158

FIGURE 3-4. ROTATOR ASSEMBLY .......................................................................................................................................... 162

FIGURE 3-5. PLATFORM SUPPORT AND CONTROL VALVES INSTALLATIONS.................................................................... 164

SECTION 4 - PLATFORM ................................................................................................................................................................ 167

FIGURE 4-1. PLATFORM INSTALLATION .................................................................................................................................. 168

FIGURE 4-2. PLATFORM CONSOLE ASSEMBLY ...................................................................................................................... 172

FIGURE 4-3. CONTROLLER ASSEMBLY (LIFT AND SWING) ................................................................................................... 178

FIGURE 4-4. CONTROLLER ASSEMBLY (DRIVE AND STEER)................................................................................................ 182

FIGURE 4-5. SOFT TOUCH SYSTEM INSTALLATION (OPTIONAL) ......................................................................................... 186

SECTION 5 - CYLINDER ................................................................................................................................................................. 189

FIGURE 5-1. AXLE LOCKOUT CYLINDER ASSEMBLY (BELGIUM BUILT MACHINES) (Prior to SN 1300003223) ................. 190

FIGURE 5-2. AXLE LOCKOUT CYLINDER ASSEMBLY (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES)

(SN 1300003223 to Present, SN E300000100 through E300001114) ......................................................................................... 192

FIGURE 5-3. LEVEL (PLATFORM) CYLINDER ASSEMBLY ....................................................................................................... 194

TABLE OF CONTENTS

8 510AJ 3121182

FIGURE 5-4. LIFT (JIB) CYLINDER ASSEMBLY ......................................................................................................................... 196

FIGURE 5-5. LIFT (MAIN BOOM) CYLINDER ASSEMBLY .......................................................................................................... 198

FIGURE 5-6. LIFT (TOWER BOOM) CYLINDER ASSEMBLY ..................................................................................................... 200

FIGURE 5-7. MASTER CYLINDER ASSEMBLY .......................................................................................................................... 202

FIGURE 5-8. STEER CYLINDER ASSEMBLY ............................................................................................................................. 204

FIGURE 5-9. TELESCOPE CYLINDER ASSEMBLY .................................................................................................................... 206

SECTION 6 - HYDRAULIC ............................................................................................................................................................... 209

FIGURE 6-1. AXLE LOCKOUT HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES) (Prior to SN 1300000353) .................. 210

FIGURE 6-2. AXLE LOCKOUT HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES) (SN 1300000353 through 1300003222)

................................................................................................................................................................................................ ...... 212

FIGURE 6-3. AXLE LOCKOUT HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES)

(SN 1300003223 to Present, SN E300000100 through E300001114) ................................................................ .......................... 214

FIGURE 6-4. DRIVE HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES) (Prior to SN 1300003476) .................................. 216

FIGURE 6-5. DRIVE HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN

1300003476 to Present, SN E300000100 through E300001114) ................................................................................................. 220

FIGURE 6-6. STANDARD HYDRAULIC DIAGRAM...................................................................................................................... 222

FIGURE 6-7. HYDRAULIC DIAGRAM LIST .................................................................................................................................. 226

SECTION 7 - ELECTRICAL .............................................................................................................................................................. 227

FIGURE 7-1. ELECTRICAL DIAGRAM LIST ................................................................................................................................ 228

FIGURE 7-2. HARNESS COMPONENTS INSTALLATION (WITHOUT UGM) ............................................................................. 230

FIGURE 7-3. HARNESS COMPONENTS INSTALLATION (WITH UGM) .................................................................................... 244

SECTION 8 - DECALS ..................................................................................................................................................................... 257

FIGURE 8-1. DECALS INSTALLATION - ANSI SPEC .................................................................................................................. 258

FIGURE 8-2. DECALS INSTALLATION - ANSI EXPORT SPECS................................................................................................ 262

FIGURE 8-3. DECALS INSTALLATION - CE AND AUSTRALIAN SPECS ................................................................................... 268

SECTION 9 - RECOMMENDED SERVICE PARTS STOCK ............................................................................................................ 273

FIGURE 9-1. MODEL 510AJ STANDARD PARTS ....................................................................................................................... 274

FIGURE 9-2. MODEL 510AJ VARIABLE PARTS ......................................................................................................................... 276

SECTION 10 - SPECIAL OPTIONS ................................................................................................................................................. 277

FIGURE 10-1. SPECIAL OPTIONS .............................................................................................................................................. 278

PART NUMBER INDEX .................................................................................................................................................................... 283

SECTION 1 - FRAME

3121182 510AJ 9

SECTION 1 - FRAME

SECTION 1 - FRAME

10 510AJ 3121182

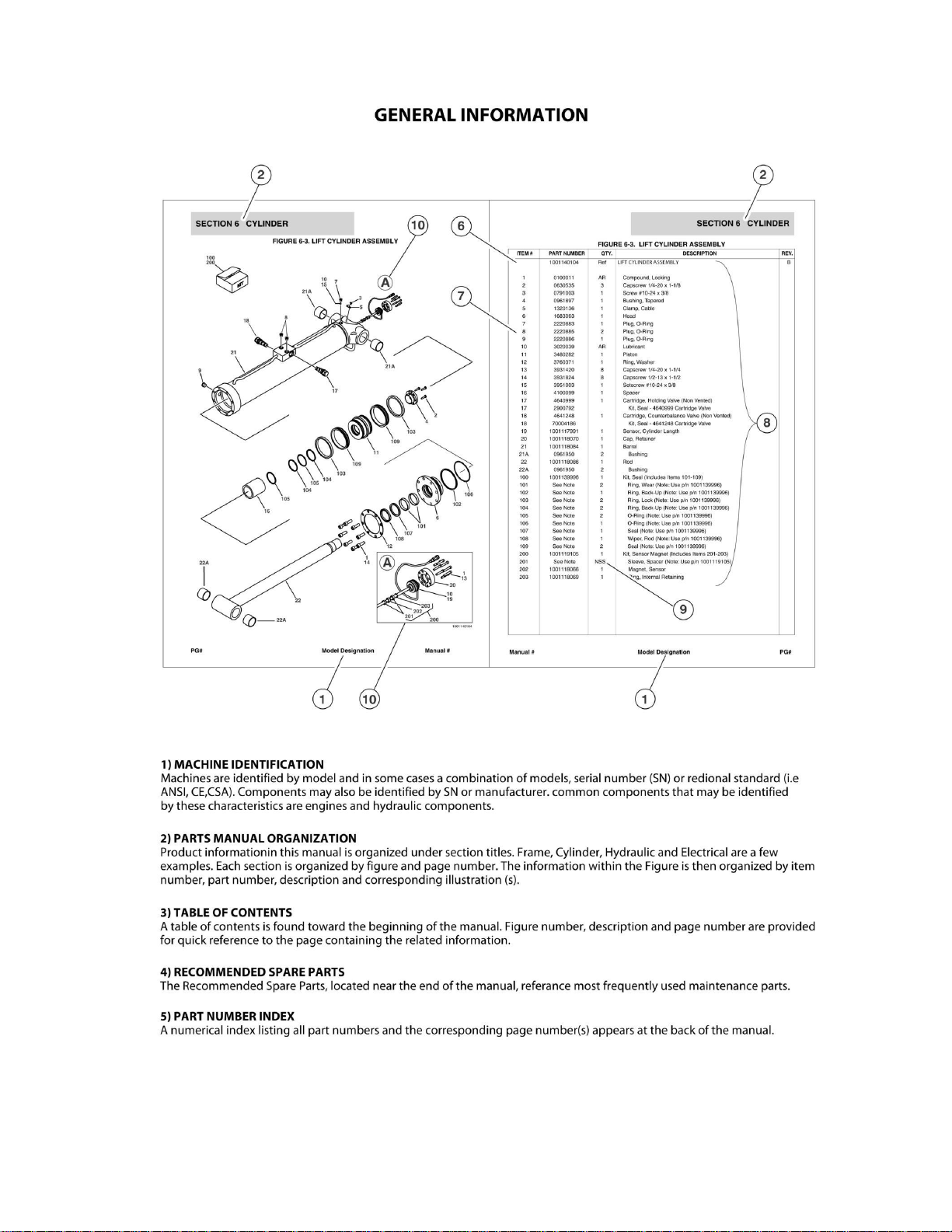

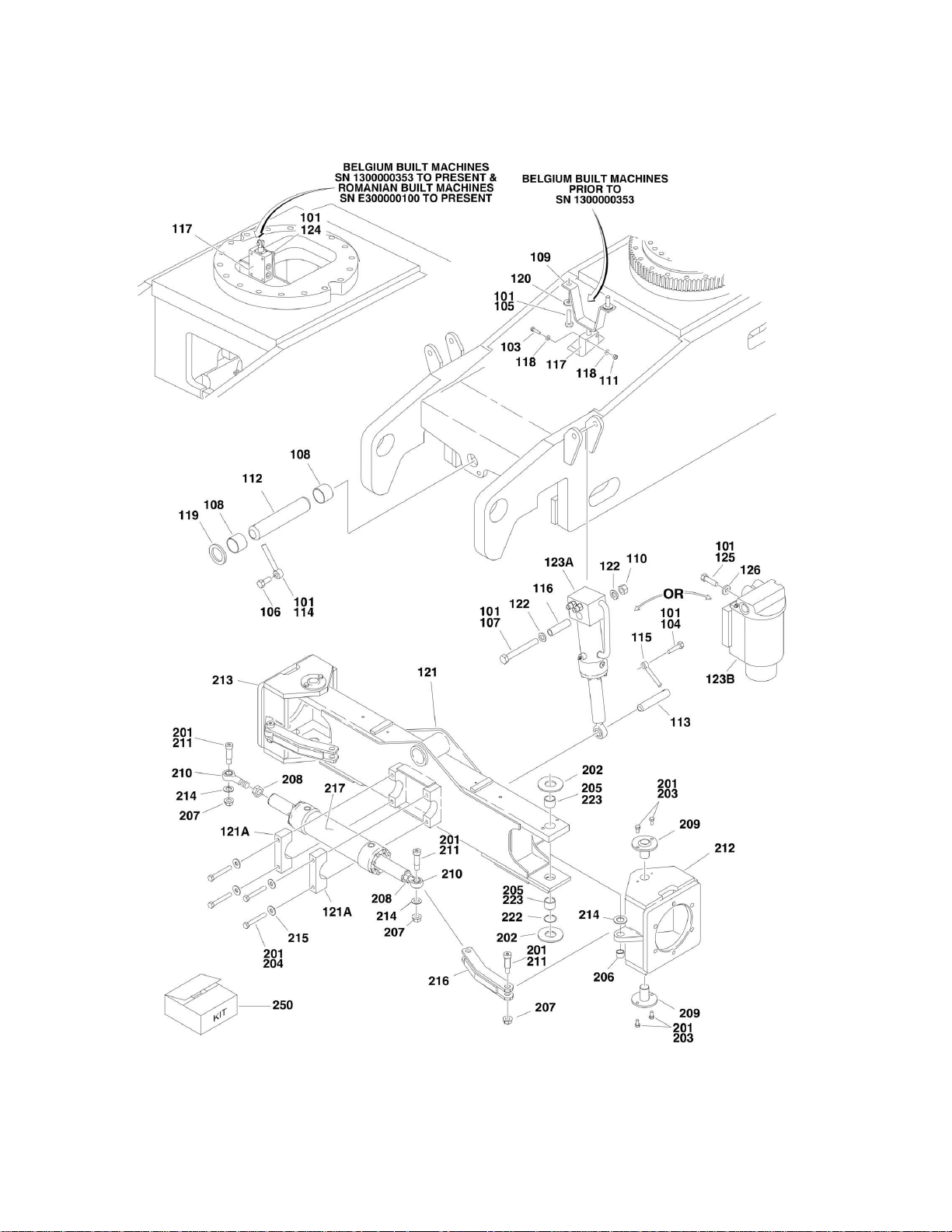

FIGURE 1-1. AXLE AND STEERING INSTALLATION

SECTION 1 - FRAME

3121182 510AJ 11

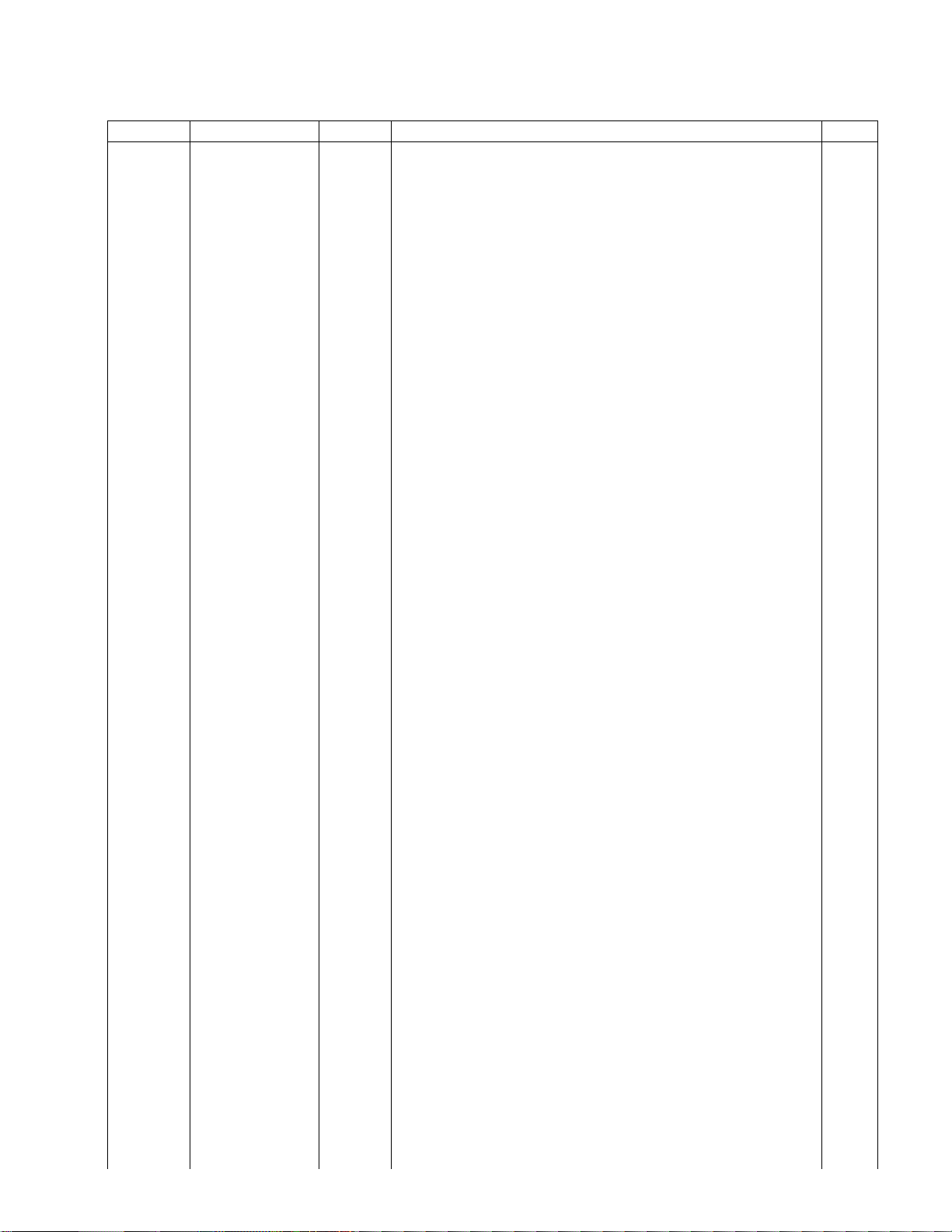

FIGURE 1-1. AXLE AND STEERING INSTALLATION

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

OSCILLATING AXLE INSTALLATIONS

0272424

Ref

Belgium Built Machines (Prior to SN 1300000353)

E

0273497

Ref

Belgium Built Machines (SN 1300000353 through 1300003222)

C

0274753

Ref

Belgium Built Machines (SN 1300003223 to Present)

A

0274753

Ref

Romanian Built Machines (SN E300000100 through

E300001114)

A

101

0100011

AR

Compound, Locking

101

0100019

AR

Compound, Locking

102

0100038

AR

Primer, Locking #7471

103

0641416

4

Bolt 1/4in-20NC x 2in (Belgium Built Machines) (Prior to SN

1300000353)

104

0641607

2

Bolt 3/8in-16NC x 3/4in (Belgium Built Machines) (Prior to SN

1300003223)

105

0641810

2

Bolt 1/2in-13NC x 1-1/4in (Belgium Built Machines) (Prior to SN

1300000353)

106

0642012

1

Bolt 5/8in-11NC x 1-1/2in

107

0682248

2

Bolt 3/4in-10NC x 6in (Belgium Built Machines) (Prior to SN

1300003223)

108

0961950

2

Bushing

109

1100134

1

Cam, Lockout (Belgium Built Machines) (Prior to SN

1300000353)

110

3272201

2

Nut 3/4in-10NC (Belgium Built Machines) (Prior to SN

1300003223)

111

3311405

4

Locknut 1/4in-20NC (Belgium Built Machines) (Prior to SN

1300000353)

112

3422592

1

Pin, Axle Pivot

113

3422520

2

Pin (Belgium Built Machines) (Prior to SN 1300003223)

114

3841258

1

Keeper, Pin

115

3841520

2

Keeper, Pin (Belgium Built Machines) (Prior to SN 1300003223)

116

4567462

2

Tube, Mounting (Belgium Built Machines) (Prior to SN

1300003223)

117

Ref

Lockout Valve Assembly Options:

117

4640871

1

Valve used on Belgium Built Machines (Prior to SN

1300000353)

117

7012693

1

Seal Kit - 4640871 Valve

117

7002840

1

Anti-Rotation Pin Removal Tool

117

4641265

1

Valve used on Belgium Built Machines (SN 1300000353 to

Present)

117

4641265

1

Valve used on Romanian Built Machines (SN E300000100

through E300001114)

118

4711400

4

Flatwasher 1/4in Thin (Belgium Built Machines) (Prior to SN

1300000353)

119

4740158

1

Thrustwasher

120

4752000

4

Flatwasher 5/8in Regular (Belgium Built Machines) (Prior to SN

1300000353)

121

Ref

Axle Weldment Options:

Ref

Note: If kingpin holes in the axle measure 1.503in diameter

or larger in any direction, axle weldment must be replaced.

Ref

Note: See Kit Item 250 and additional notes at end of parts

list before ordering parts.

121

4846660

1

Belgium Built Machines (Prior to SN 1300003223)

121

0280203

1

Belgium Built Machines (SN 1300003223 to Present)

121

0280203

1

Romanian Built Machines (SN E300000100 through

SECTION 1 - FRAME

12 510AJ 3121182

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

E300001114)

121A

0561511

2

Steer Cylinder Mounting Block Assembly

122

4892200

4

Flatwasher 3/4in Hardened (Belgium Built Machines) (Prior to

SN 1300003223)

123

Ref

Lockout Cylinder Assembly Options (See CYLINDER SECTION

for Breakdown):

123A

1684243

2

Belgium Built Machines (Prior to SN 1300003223)

123B

1684465

2

Belgium Built Machines (SN 1300003223 to Present)

123B

1684465

2

Romanian Built Machines (SN E300000100 through

E300001114)

124

0791506

4

Screw 5/16in-18NC x 3/4in (Belgium Built Machines) (SN

1300000353 to Present)

125

0641814

8

Bolt 1/2in-13NC x 1-3/4in (Belgium Built Machines) (SN

1300003223 to Present)

126

4891800

8

Flatwasher 1/2in Hardened (Belgium Built Machines) (SN

1300003223 to Present)

126

4891800

8

Flatwasher 1/2in Hardened (Romanian Built Machines) (SN

E300000100 through E300001114)

0272428

Ref

STEERING INSTALLATION

F

201

0100011

AR

Compound, Locking

202

Ref

Thrustwasher Options:

202

0440161

AR

Belgium Built Machines (Top and Bottom Kingpin Location)

(Note: See Kit Item 250 and additional notes at end of parts list

before ordering parts) (Prior to SN 1300000441)

202

4740537

AR

Belgium Built Machines (.0625) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740537

AR

Romanian Built Machines (.0625) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

4740538

AR

Belgium Built Machines (.125) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740538

AR

Romanian Built Machines (.125) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

4740539

AR

Belgium Built Machines (.188) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740539

AR

Romanian Built Machines(.188) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

4740540

AR

Belgium Built Machines (.250) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740540

AR

Romanian Built Machines (.250) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

0440271

AR

Belgium Built Machines (Bottom Kingpin Location) (SN

1300000441 to Present)

202

0440271

AR

Romanian Built Machines (Bottom Kingpin Location) (SN

E300000100 through E300001114)

203

0641606

16

Bolt 3/8in-16NC x 3/4in

204

0641824

4

Bolt 1/2in-13NC x 3in

205

Ref

Bushing / Bearing Options:

205

0961951

2

Belgium Built Machines (Top and Bottom Kingpin Location)

(Note: See Kit Item 250 and additional notes at end of parts list

before ordering parts) (Prior to SN 1300000441)

205

0961951

2

Belgium Built Machines (SN 1300000441 to Present)

205

0961951

2

Romanian Built Machines Options: (SN E300000100 through

E300001114)

205

0440291

2

Bushing / Bearing (Top Kingpin Location)

205

0440274

2

Bushing / Bearing (Bottom Kingpin Location)

206

0962140

2

Bearing, Garmax

SECTION 1 - FRAME

3121182 510AJ 13

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

207

3312008

4

Nut 5/8in-11NC

208

3322201

2

Nut 3/4in-16NC

209

Ref

Kingpin Options:

209

3422716

4

Belgium Built Machines (2 Bolt Mounting) (Note: See Kit Item 250

and additional notes at end of parts (Prior to SN 1300000441)

209

3423081

4

Belgium Built Machines (4 Bolt Mounting) (SN 1300000441 to

Present)

209

3423081

4

Romanian Built Machines (SN E300000100 through

E300001114)

210

Ref

Rod-End with Grease Fitting

210

3841367

2

Belgium Built Machines (Prior to SN 130005313)

210

3841517

2

Belgium Built Machines (SN 130005313 to Present)

210

3841517

2

Romanian Built Machines (SN E300000100 through

E300001114)

211

3900109

4

Screw, Shoulder

212

Ref

Spindle (Left Side) Options:

212

4130391

1

Belgium Built Machines (Prior to SN 1300000441)

212

4130408

1

Belgium Built Machines (SN 1300000441 to Present)

212

4130408

1

Romanian Built Machines (SN E300000100 through

E300001114)

213

Ref

Spindle (Right Side) Options:

213

4130392

1

Belgium Built Machines (Prior to SN 1300000441)

213

4130407

1

Belgium Built Machines (SN 1300000441 to Present)

213

4130407

1

Romanian Built Machines (SN E300000100 through

E300001114)

214

4740086

4

Thrustwasher

215

4751800

4

Flatwasher 1/2in Regular

216

4846666

2

Tie-Rod

217

1684246

1

Steer Cylinder Assembly (See CYLINDER SECTION for

Breakdown)

222

3780182

2

O-Ring (Belgium Built Machines) (SN 1300003223 to Present)

222

3780182

2

O-Ring (Romanian Built Machines) (SN E300000100 through

E300001114)

223

3020029

AR

Grease, Bearing

250

2902400

1

Kingpin & Bushings Update Kit for Belgium Built Machines Built

Prior to SN 1300000441 (Includes Newer “Belgium Built Machines

SN 1300000441 to Present” Design Items 202, 205, 210 & 222).

Refer to Field Service Bulletin AWP-04-11.

Ref

Note: Newer bushings will fit in "Belgium Built Machines Prior

to SN 1300000441" axles however if kingpin holes measure

1.503in diameter or larger in any direction, axle weldment

must be replaced before installation of kit.

Ref

Note: Spindles require drilling and tapping for 8 additional

kingpin mtg bolts. Newer design kingpins require 4 mtg bolts

each.

Ref

Note: All Romanian Built Machines have the newer design

axle.

SECTION 1 - FRAME

14 510AJ 3121182

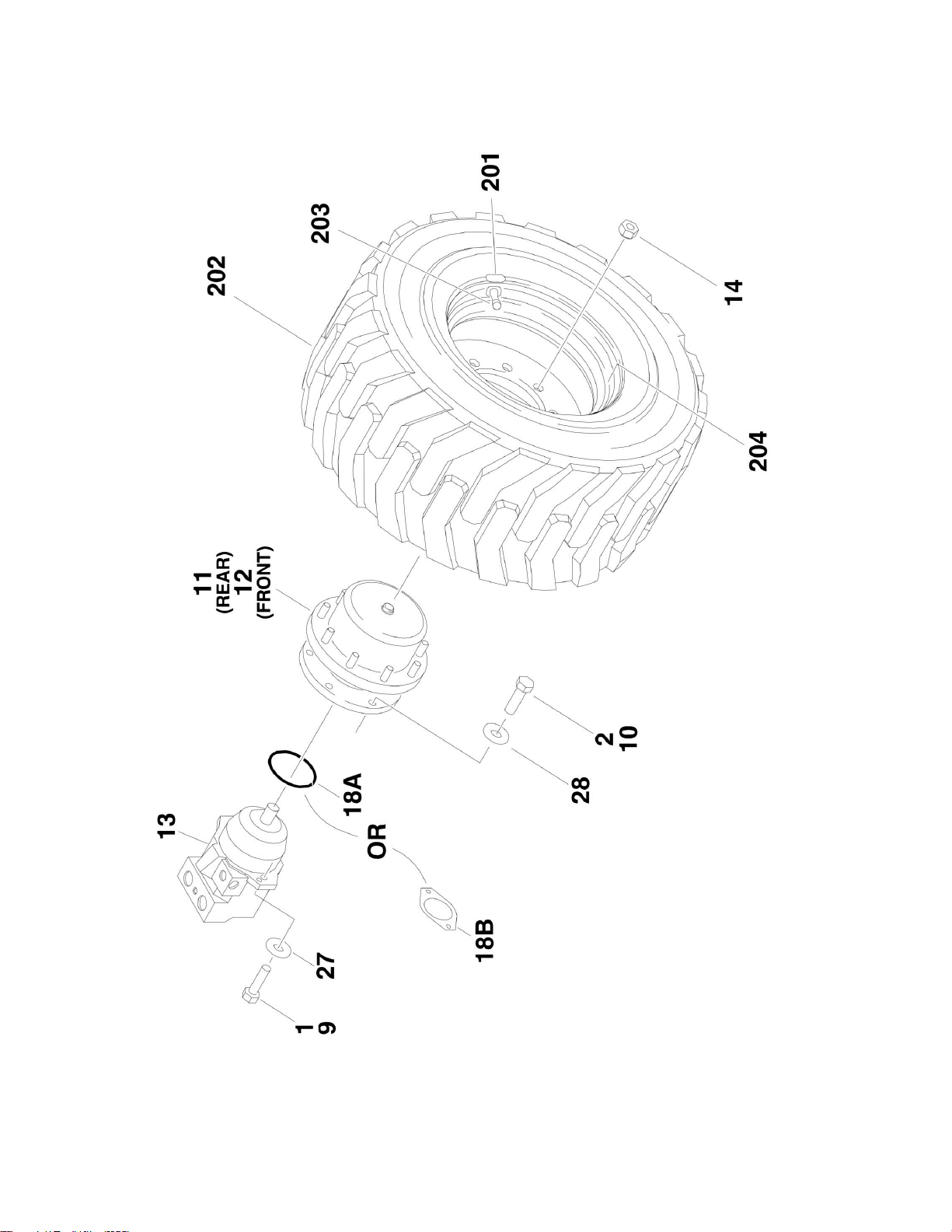

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATIONS

SECTION 1 - FRAME

3121182 510AJ 15

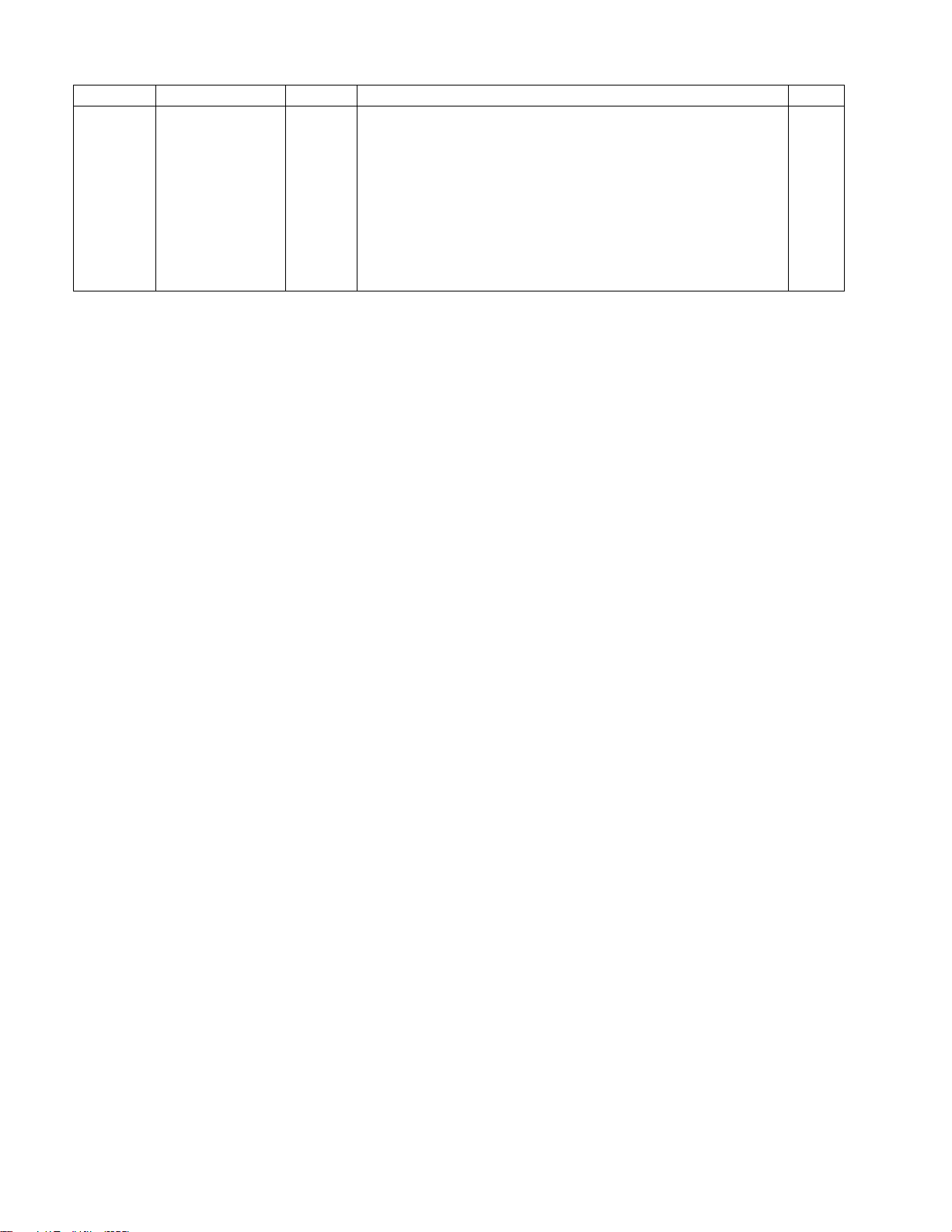

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATIONS

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

WHEEL DRIVE INSTALLATIONS

0272320

Ref

Wheel Drive Installations (Prior to SN 1300000159)

C

0272895

Ref

Wheel Drive Installations (SN 1300000159 through

1300003222)

G

0275854

Ref

Wheel Drive Installations (SN 1300003223 through

E300001114)

C

1

0100011

AR

Compound, Locking

2

0100019

AR

Compound, Locking

9

Ref

Hardware Options:

9

0681810

8

Bolt 1/2in-13NC x 1-1/4in (Grade 8) (Both Front and Rear Axle)

(Belgium Built Machines) (Prior to SN 1300000162)

9

0681810

4

Bolt 1/2in-13NC x 1-1/4in (Grade 8) (Front Axle) (Belgium Built

Machines) (SN 1300000162 to Present)

9

0681810

4

Bolt 1/2in-13NC x 1-1/4in (Grade 8) (Front Axle) (Romanian

Built Machines) (SN E300000100 through E300001114)

9

3311801

4

Nut 1/2in-13NC (Not Shown) (Rear Axle) (Belgium Built

Machines) (SN 1300000162 to Present)

9

3311801

4

Nut 1/2in-13NC (Not Shown) (Rear Axle) (Romanian Built

Machines) (SN E300000100 through E300001114)

10

0682014

24

Bolt 5/8in-11NC x 1-3/4in (Grade 8)

11

Ref

Drive Hub/Brake Assembly (Rear) Options:

11

2780256

2

Belgium Built Machines (See DRIVE HUB/BRAKE ASSEMBLY

(REAR) for Breakdown) (Prior to SN 1300000159)

11

2780267

2

Belgium Built Machines (See DRIVE HUB/BRAKE ASSEMBLY

(REAR) for Breakdown) (SN 1300000159 to Present)

11

2780267

2

Romanian Built Machines (See DRIVE HUB/BRAKE

ASSEMBLY (REAR) for Breakdown) (SN E300000100 through

E300001114)

12

Ref

Drive Hub Assembly (Front) Options:

12

2780257

2

Belgium Built Machines (See DRIVE HUB ASSEMBLY

(FRONT) for Breakdown) (Prior to SN 1300000159)

12

2780268

2

Belgium Built Machines (See DRIVE HUB ASSEMBLY

(FRONT) for Breakdown) (SN 1300000159 to Present)

12

2780268

2

Romanian Built Machines (See DRIVE HUB ASSEMBLY

(FRONT) for Breakdown) (SN E300000100 through

E300001114)

13

Ref

Drive Motor Assembly Options:

13

3160266

4

Belgium Built Machines (Use p/n 3160348 - See DRIVE

MOTOR ASSEMBLY for Breakdown) (For 3160348 Motor - See

DRIVE MOTOR ASSEMBLY for Breakdown) (Prior to SN

1300002249)

13

3160348

4

Belgium Built Machines (See DRIVE MOTOR ASSEMBLY for

Breakdown) (SN 1300002249 to Present)

13

3160348

4

Romanian Built Machines (See DRIVE MOTOR ASSEMBLY for

Breakdown) (SN E300000100 through E300001114)

14

3300106

36

Lugnut

18

Ref

Seal Options:

18A

3790045

2

O-Ring Belgium Built Machines (Prior to SN 1300002638)

18B

3960526

4

Gasket Belgium Built Machines (SN 1300002638 to Present)

18B

3960526

4

Gasket Romanian Built Machines (SN E300000100 through

E300001114)

27

4891800

8

Flatwasher 1/2in Hardened

28

4892000

24

Flatwasher 5/8in Hardened

31

2300016

AR

Fluid, Hydraulic (Not Shown)

SECTION 1 - FRAME

16 510AJ 3121182

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

32

3020008

AR

Lubricant, Mobilube HD 80W - 90 (Not Shown)

Ref

TIRE AND WHEEL INSTALLATION OPTIONS

0258028

Ref

12 x 16.5 Pneumatic (ANSI/ANSI Export/CSA/Japanese Specs

Only. Not Available on CE/Australian Specs)

A

0258030

Ref

12 x 16.5 Foam-Filled (Available on all Specs)

A

0270674

Ref

12 x 16.5 Foam-Filled, Non-Marking (Available on all Specs)

B

0258031

Ref

33/1550 x 16.5 Foam-Filled

B

0258831

Ref

33/16LL x 16.1 Pneumatic (ANSI/ANSI Export/CSA/Japanese

Specs Only. Not Available on CE/Australian Specs) (Requires

special counterweighting)

A

0257740

2

12 x 16.5 Pneumatic Right Side (Not Available on CE/Australian

Specs)

C

0257746

2

12 x 16.5 Pneumatic Left Side (Not Available on CE/Australian

Specs)

C

0258009

2

12 x 16.5 Foam-Filled Right Side

C

0258010

2

12 x 16.5 Foam-Filled Left Side

C

0270675

2

12 x 16.5 Foam-Filled Non-Marking Right Side

A

0270676

2

12 x 16.5 Foam-Filled Non-Marking Left Side

A

0258011

2

33/1550 x 16.5 Foam-Filled Right Side

D

0258012

2

33/1550 x 16.5 Foam-Filled Left Side

D

0258830

4

33/16LL x 16.1 Pneumatic (Not Available on CE/Australian

Specs) (Requires special counterweighting)

Ref

Note: Assemblies may require ballast/foam filling to

manufacture's specifications prior to installing on a

machine. Refer to Operation and Safety or Service and

Maintenance Manuals. Purchase individual tire and/or rim

only if able to foam fill tire and wheel assembly, otherwise,

purchase complete assembly.

201

Ref

Decal Options (Pneumatic Only):

201

1702740

1

Decal - 90PSI

201

1703067

1

Decal - 40PSI

202

Ref

Tire Options:

202

4520216

1

12 x 16.5 NHS (OTR Brand)

202

4520240

1

12 x 16.5 Non-Marking (OTR Brand)

202

4520217

1

33/1550 x 16.5 NHS (OTR Brand)

202

4520212

1

33/16LL x 16.1 (Galaxy Brand)

203

Ref

Valve Stem Options:, Air (Pneumatic Only)

203

4640113

1

All except 33/1550 x 16.5 Foam-Filled Tire and Wheel Assy

203

8786514

1

33/1550 x 16.5 Foam-Filled Tire and Wheel Assy Only

204

Ref

Rim, Wheel Options:

204

4860178

1

16.5 x 12 (Use with 12 x 16.5 Tires)

204

4860179

1

16.5 x 12 (Use with 33/1550 x 16.5 Tires)

204

4860193

1

16.1 x 14 (Use with 33/16LL x 16.1 Tires)

SECTION 1 - FRAME

18 510AJ 3121182

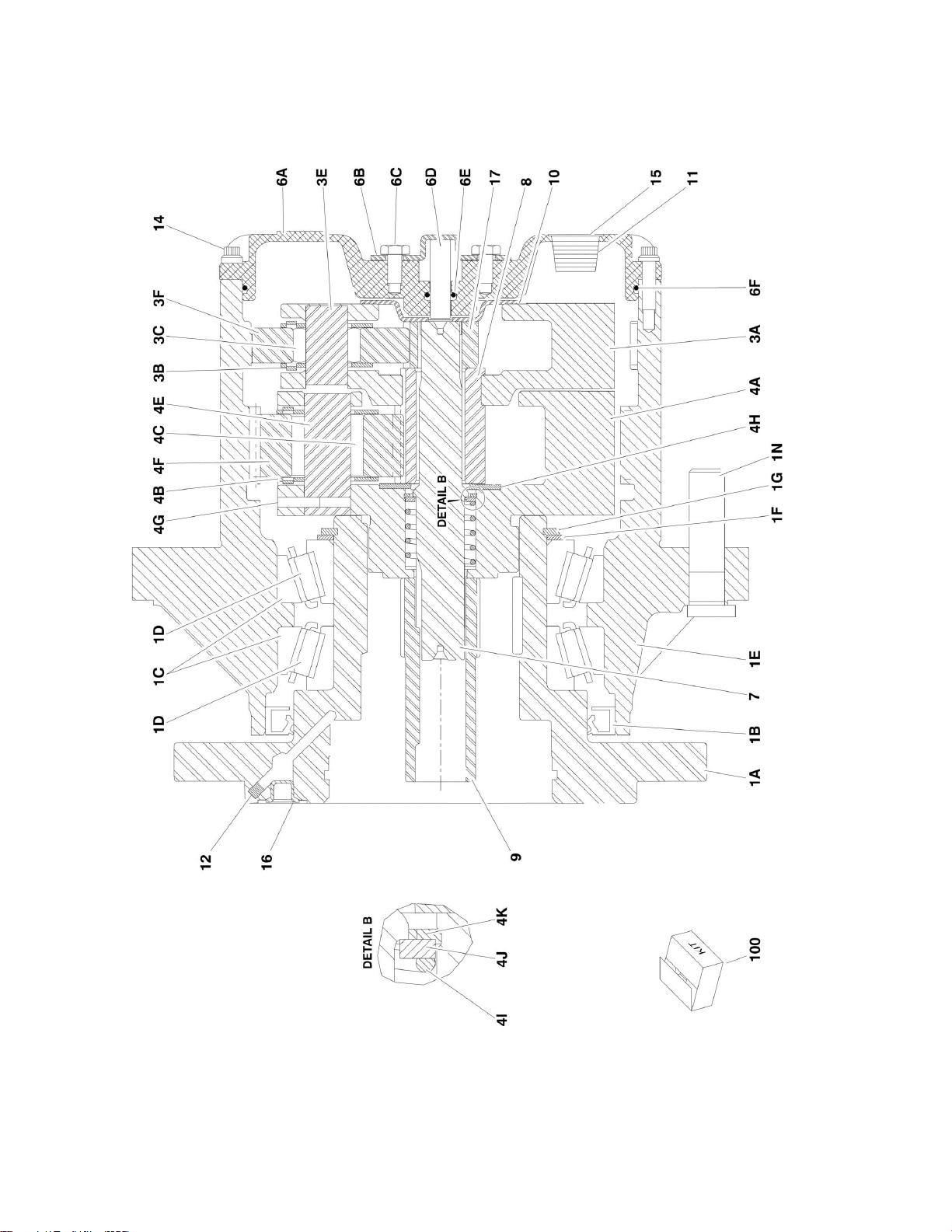

FIGURE 1-3. DRIVE HUB/BRAKE ASSEMBLY (REAR)

SECTION 1 - FRAME

3121182 510AJ 19

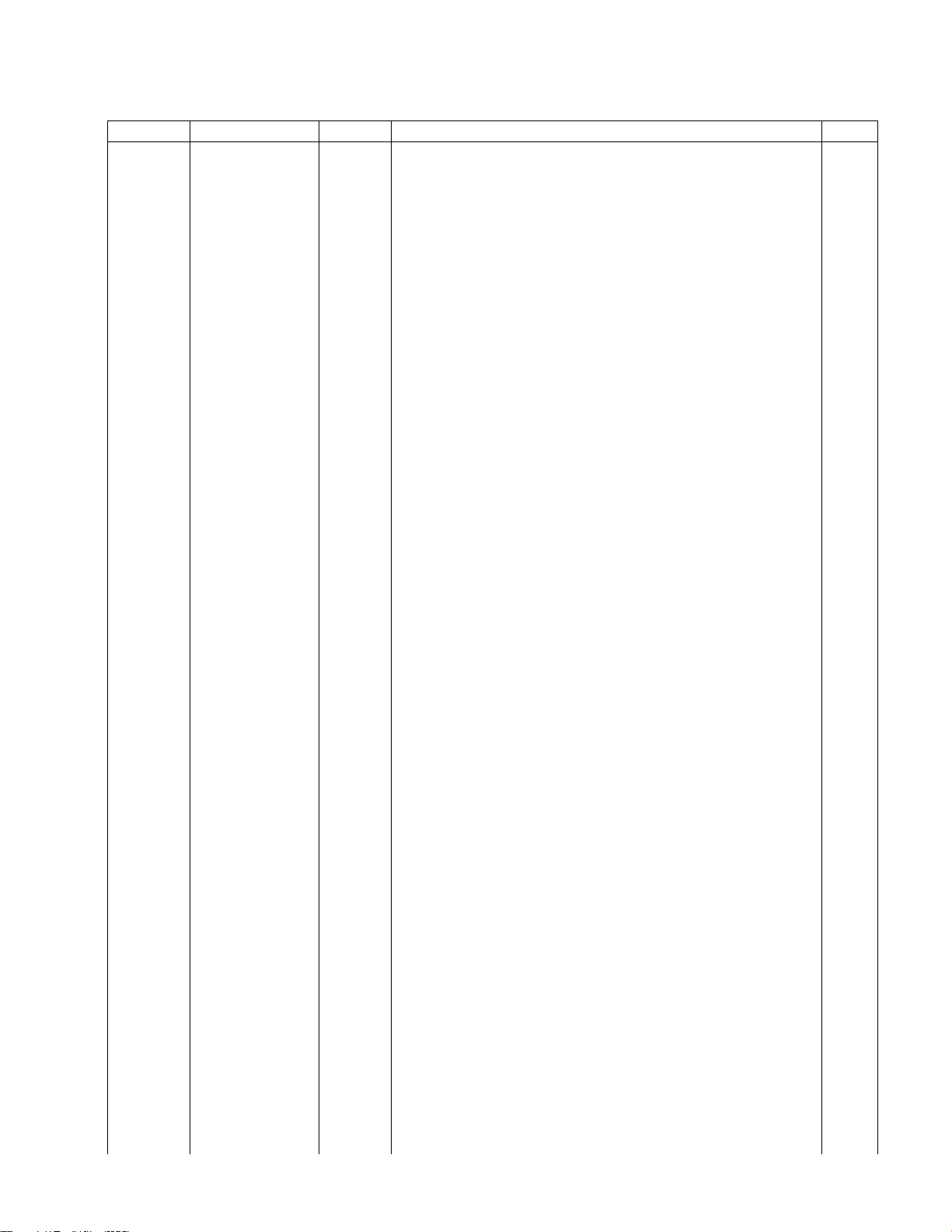

FIGURE 1-3. DRIVE HUB/BRAKE ASSEMBLY (REAR)

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

USAGE: USED BELGIUM BUILT MACHINES (Prior to SN

1300000159)

Ref

NOTE: Hub may have been replaced with Service Kit p/n

1001178138. Kit uses hub p/n 2780267. See next figure for

service parts.

2780256

Ref

DRIVE HUB/BRAKE ASSEMBLY

G

1

See Note

1

Spindle/Housing Assembly (Note: Not Available - Purchase

Individual Components)

1A

7024105

1

Spindle

1B

7024113

1

Seal

1C

7007006

2

Cone, Bearing

1D

7024112

2

Cup, Bearing

1E

7024110

1

Housing/Ring Gear

1F

7024109

1

Thrustwasher

1G

7024107

1

Ring, Retaining

1N

7024111

9

Stud, Wheel

2

7024106

1

Brake, Input

2A

7024710

1

Kit, Brake Lining (Includes Qty 8 Outer Plates and Qty 7 Inner

Plates)

2B

7024709

1

Kit, Brake O-Ring (Includes Qty 2 O-Rings and Back-up Rings)

2C

7024711

1

Kit, Brake Spring (Includes Qty 12 Springs)

2D

7024719

1

Kit, Brake Hardware (Includes End Plate, Spacer and Qty 2 E-

Clips)

3

See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

3A

7024116

1

Carrier

3B

7024127

6

Thrustwasher

3C

7024123

42

Bearing, Needle

3E

7024120

3

Shaft, Planet

3F

7024118

3

Gear, Planet

4

See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

4A

7024117

1

Carrier

4B

7024126

6

Thrustwasher

4C

7024122

45

Bearing, Needle

4E

7024121

3

Shaft, Planet

4F

7024119

3

Gear, Planet

4G

7001913

3

Rollpin

4H

7024128

1

Thrustwasher

4I

7024124

1

Spring

4J

7024129

1

Thrustwasher

4K

7024125

1

Thrustwasher

6

See Note

1

Cover Assembly (Note: Not Available - Purchase Individual

Components)

6A

7024132

1

Plate, Cover

6B

7017093

1

Cap, Disengage

6C

0641404

2

Bolt 1/2in-20NC x 1/2in

6D

7017092

1

Pin, Dowel

6E

7017095

1

O-Ring

6F

7024134

1

O-Ring

7

7024130

1

Shaft, Input

8

7024115

1

Gear, Sun

SECTION 1 - FRAME

20 510AJ 3121182

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

9

7024131

1

Coupling

10

7017097

1

Spacer, Thrust

11

7017094

2

Plug, Pipe

12

7024108

1

Plug, Pressure

14

7024133

12

Bolt 1/4in-20NC x 7/8in (Grade 8)

15

See Note

1

Plate, ID (Not Shown) (Note: Not Available for Purchase)

16

7017082

1

Plug, O-Ring

17

7024114

1

Gear, Sun

100

7024198

1

Seal Kit (Includes Items 1B, 1G & 6F)

SECTION 1 - FRAME

22 510AJ 3121182

FIGURE 1-4. DRIVE HUB/BRAKE ASSEMBLY (REAR)

SECTION 1 - FRAME

3121182 510AJ 23

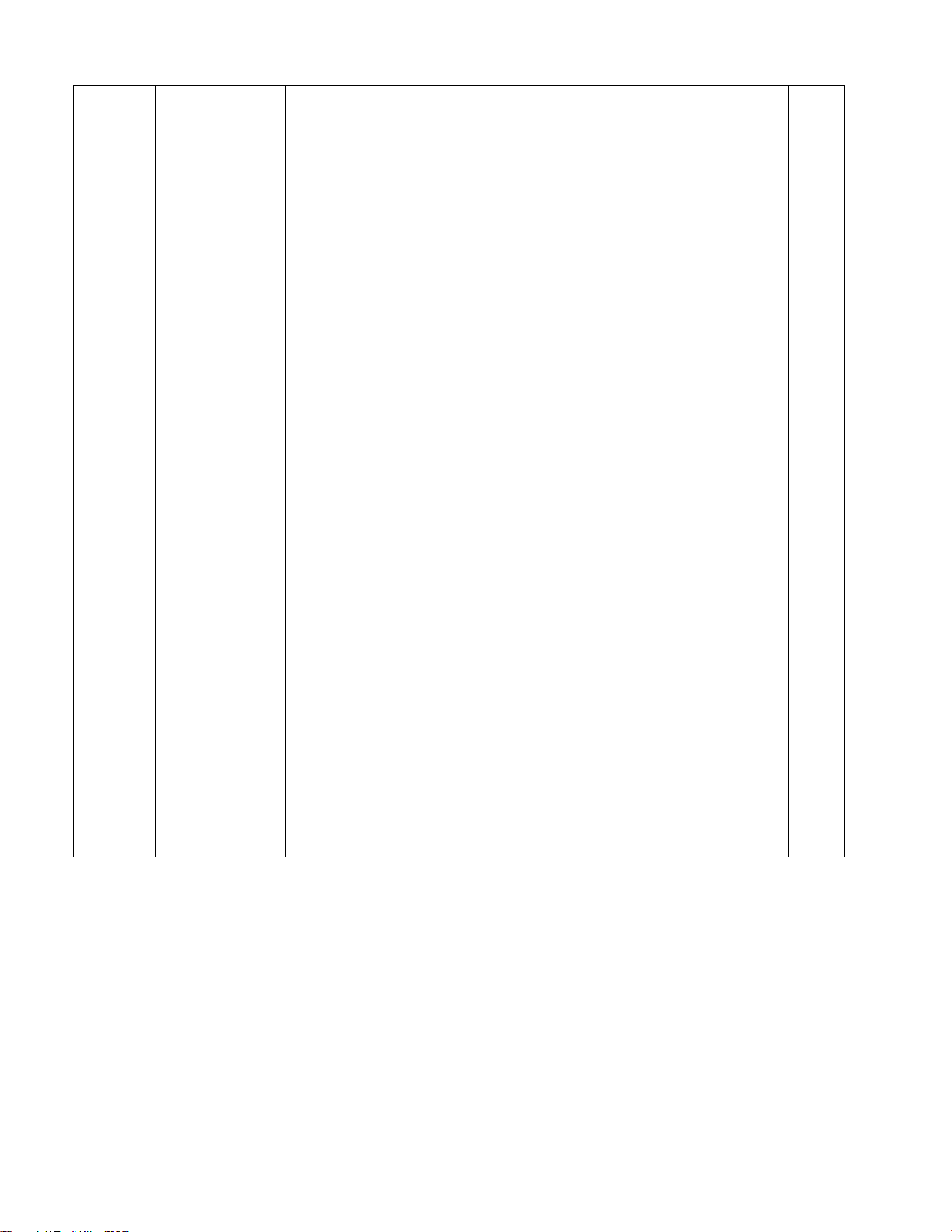

FIGURE 1-4. DRIVE HUB/BRAKE ASSEMBLY (REAR)

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

USAGE: USED BELGIUM BUILT MACHINES (SN 1300000159 to

Present)

Ref

USAGE: USED ROMANIAN BUILT MACHINES (SN E300000100

through E300001114)

2780267

Ref

DRIVE HUB/BRAKE ASSEMBLY

D

1

See Note

1

Spindle/Housing Assembly (Note: Not Available - Purchase

Individual Components)

1A

7017059

1

Spindle

1B

7001998

1

Seal

1C

7010429

1

Cone, Bearing (Includes Item 1D)

1D

7010429

1

Cup, Bearing (Includes Item 1C)

1E

7000257

1

Cup, Bearing

1F

7000258

1

Cone, Bearing

1G

7007601

1

Housing/Ring Gear

1H

7000232

1

Thrustwasher

1I

7000229

1

Ring, Retaining

1N

7007640

9

Stud, Wheel

2

7000246

1

Gear, Internal

3

7024712

1

Carrier Assembly

3A

7024712

1

Carrier

3B

7024712

6

Ring, Retaining

3C

7024712

AR

Bearing, Needle

3D

7024712

3

Thrustwasher

3E

7024712

3

Shaft, Planet

3F

7024712

3

Gear, Planet

3G

7024712

3

Rollpin

4

7000248

1

Ring Gear

5

7000230

1

O-Ring

5A

7017070

1

O-Ring

6

70001349

1

Cover Assembly (was p/n 7017090)

6A

70001349

1

Spacer, Thrust (was p/n 7017097)

6B

70001349

1

Plate, Cover (was p/n 7017091)

6C

70001349

1

O-Ring (was p/n 7017095)

6D

70001349

1

Rod, Disconnect (was p/n 7017092)

6E

70001349

1

Cap, Disengage (was p/n 7017093)

6F

70001349

2

Bolt (was p/n 0641404)

6G

7017094

1

Plug, Pipe

6I

See Note

4

Rivet (Note: Not Available - Purchase Locally)

6J

See Note

1

Plate, ID (Note: Not Available for Purchase)

7

Ref

Input Shaft Assembly

7A

7024714

1

Shaft

7B

7000261

1

Ring, Retaining

7C

7000262

1

Spring

7D

7000263

2

Spacer, Thrust

8

7024713

1

Gear, Sun

11

7000253

1

Thrustwasher

12

7017067

12

Bolt

13

7017080

4

Pin, Dowell

14

7000206

1

Coupling

15

7024715

1

Spacer, Input

SECTION 1 - FRAME

24 510AJ 3121182

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

16

7024716

1

Spacer, Input

17

7024182

1

Brake Assembly (See Items 101-123 for Breakdown)

27

7024705

1

O-Ring

28

7024717

2

Rod, Threaded

29

7024718

2

Nut 1/2in-13NC

30

7000731

1

Gasket

7024182

Ref

BRAKE ASSEMBLY

101

7024189

1

Shaft

102

7024182

1

Housing

103

I7024193

2

Plate, Friction

104

7024193

1

Plate, Pressure

105

7000731

1

Gasket

106

7024193

2

Plate, Outer

107

See Note

1

Gasket (Note: Use Item 150, 153 or 154.)

108

7024191

1

Cylinder

109

7024192

1

Piston

110

7024197

1

Bearing, Ball

111

7024197

1

Ring, Retaining

112

7024197

1

Seal, Shaft

113

See Note

6

Capscrew (Note: Not Available - Purchase Locally)

114

See Note

6

Lockwasher (Note: Not Available - Purchase Locally)

115

7024194

1

O-Ring

116

7024194

1

Ring, Back-up

117

7024194

1

O-Ring

118

7024194

1

Ring, Back-up

119

7024190

2

Pin, Dowel

120

See Note

1

Plug (Note: Not Available - Purchase Locally)

121

See Note

2

Plug (Note: Not Available - Purchase Locally)

122

7024196

10

Spring Kit (Natural)

123

7024196

2

Spring Kit (Blue)

150

7024194

1

Seal Kit, Brake (Includes Items 105, 107 & 115-118)

151

7024196

1

Spring Kit, Brake (Includes 12 Natural Colored Springs Item 122)

(was p/n 7024195)

152

7024196

1

Spring Kit, Brake (Includes 12 Natural Colored Springs Item 122 &

2 Blue Springs Colored Springs Item 123)

153

7024193

1

Friction Disc Kit, Brake (Includes Items 103, 104, 106 & 107)

154

7024197

1

Bearing Kit, Brake (Includes Items 107 & 110-112)

SECTION 1 - FRAME

26 510AJ 3121182

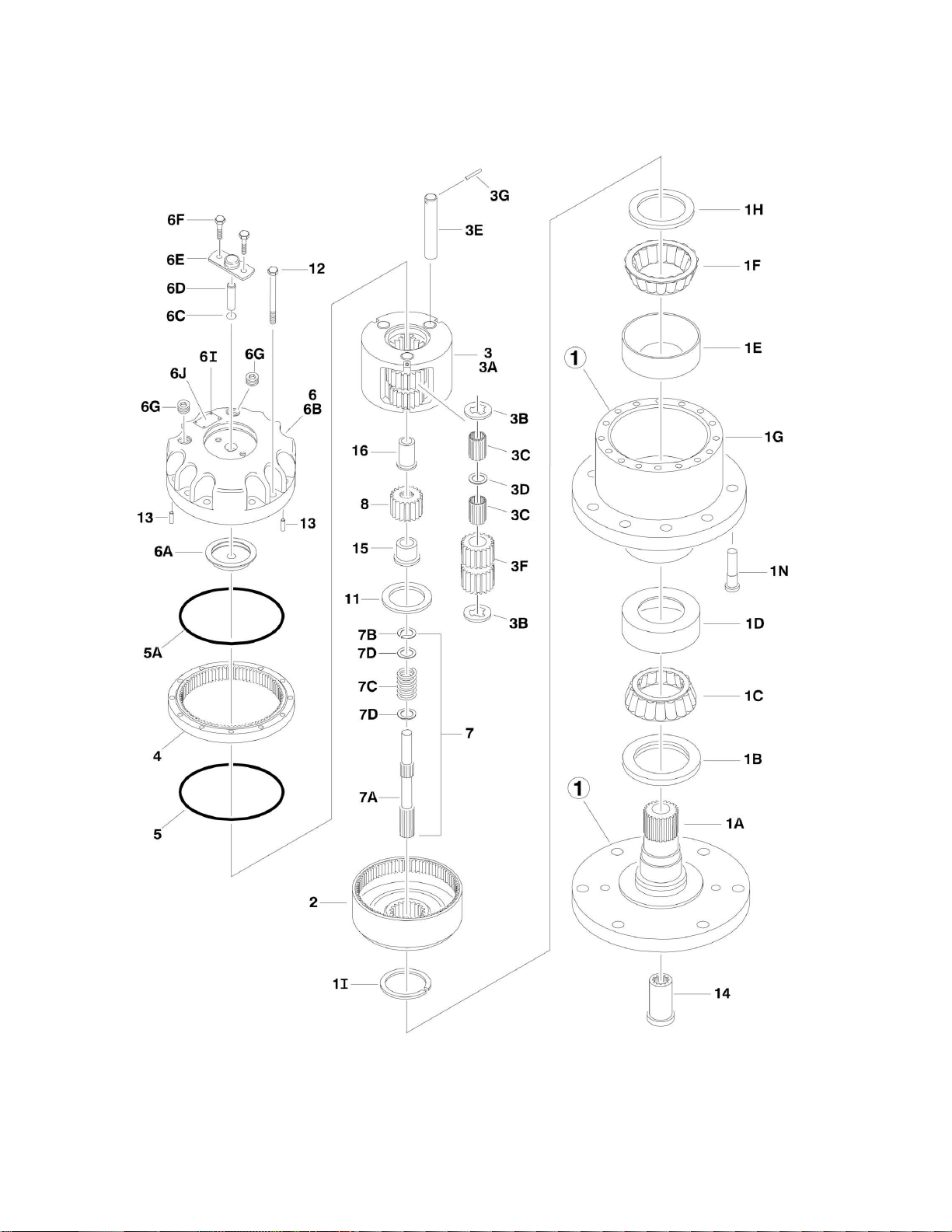

FIGURE 1-5. DRIVE HUB ASSEMBLY (FRONT)

SECTION 1 - FRAME

3121182 510AJ 27

FIGURE 1-5. DRIVE HUB ASSEMBLY (FRONT)

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

USAGE: BELGIUM BUILT MACHINES USED (Prior to SN

1300000064)

Ref

NOTE: Hub may have been replaced with Service Kit p/n

1001178136. Kit uses hub p/n 2780268. See next figure for

service parts.

2780257

Ref

DRIVE HUB ASSEMBLY

F

1

See Note

1

Spindle/Housing Assembly (Note: Not Available - Purchase

Individual Components)

1A

7024105

1

Spindle

1B

7024113

1

Seal

1C

7007006

2

Cone, Bearing

1D

7024112

2

Cup, Bearing

1E

7024110

1

Housing/Ring Gear

1F

7024109

1

Thrustwasher

1G

7024107

1

Ring, Retaining

1N

7024111

9

Stud, Wheel

3

See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

3A

7024116

1

Carrier

3B

7024127

6

Thrustwasher

3C

7024123

42

Bearing, Needle

3E

7024120

3

Shaft, Planet

3F

7024118

3

Gear, Planet

4

See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

4A

7024117

1

Carrier

4B

7024126

6

Thrustwasher

4C

7024122

45

Bearing, Needle

4E

7024121

3

Shaft, Planet

4F

7024119

3

Gear, Planet

4G

7001913

3

Rollpin

4H

7024128

1

Thrustwasher

4I

7024124

1

Spring

4J

7024129

1

Thrustwasher

4K

7024125

1

Thrustwasher

6

See Note

1

Cover Assembly (Note: Not Available - Purchase Individual

Components)

6A

7024132

1

Plate, Cover

6B

7017093

1

Cap, Disengage

6C

0641404

2

Bolt 1/2in-20NC x 1/2in

6D

7017092

1

Pin, Dowel

6E

7017095

1

O-Ring

6F

7024134

1

O-Ring

7

7024130

1

Shaft, Input

8

7024115

1

Gear, Sun

9

7024131

1

Coupling

10

7017097

1

Spacer, Thrust

11

7017094

2

Plug, Pipe

12

7024108

1

Plug, Pressure

14

7024133

12

Bolt 1/4in-20NC x 7/8in (Grade 8)

15

See Note

1

Plate, ID (Not Shown) (Note: Not Available For Purchase)

SECTION 1 - FRAME

28 510AJ 3121182

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

16

7017082

1

Plug, O-Ring

17

7024114

1

Gear, Sun

100

7024198

1

Seal Kit (Includes Items 1B, 1G & 6F)

SECTION 1 - FRAME

30 510AJ 3121182

FIGURE 1-6. DRIVE HUB ASSEMBLY (FRONT)

Loading...

Loading...