Daikin FTXB09AXVJURXB09AXVJU, FTKB12AXVJURKB12AXVJU, FTKB18AXVJURKB18AXVJU, FTXB24AXVJURXB24AXVJU, FTXB12AXVJURXB12AXVJU Installation Manual

...

INSTALLATION MANUAL

R410A SPLIT SERIES

MODELS

FTXB09A RXB09A

FTXB12A RXB12A

FTXB18A RXB18A

FTXB24A RXB24A

FTKB09A RKB09A

FTKB12A RKB12A

FTKB18A RKB18A

FTKB24A RKB24A

Installation Manual |

English |

|

R410A Split Series |

||

|

||

Manuel d’installation |

|

|

|

||

Français |

||

Série split R410A |

||

|

||

Manual de instalación |

|

|

|

||

Español |

||

Serie Split R410A |

||

|

||

|

|

IM-5WMYJ(R)-0617(0)-DAIKIN USA

Part Number.: R08019046594

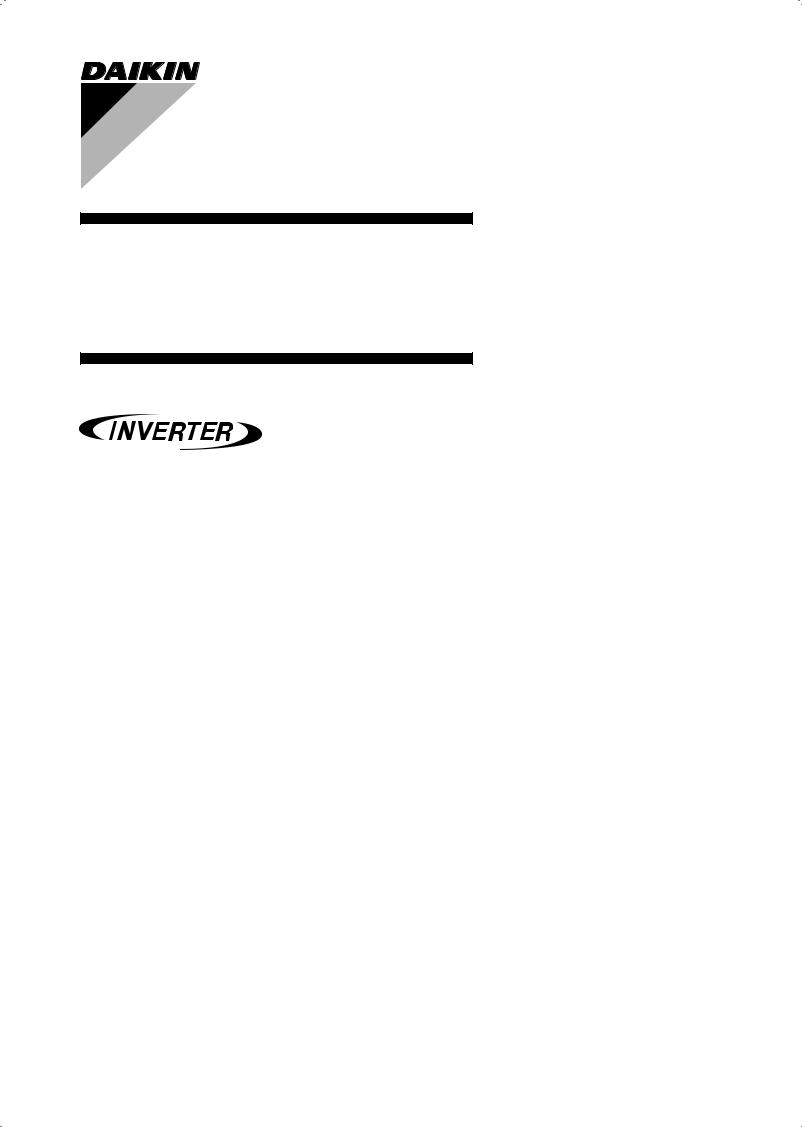

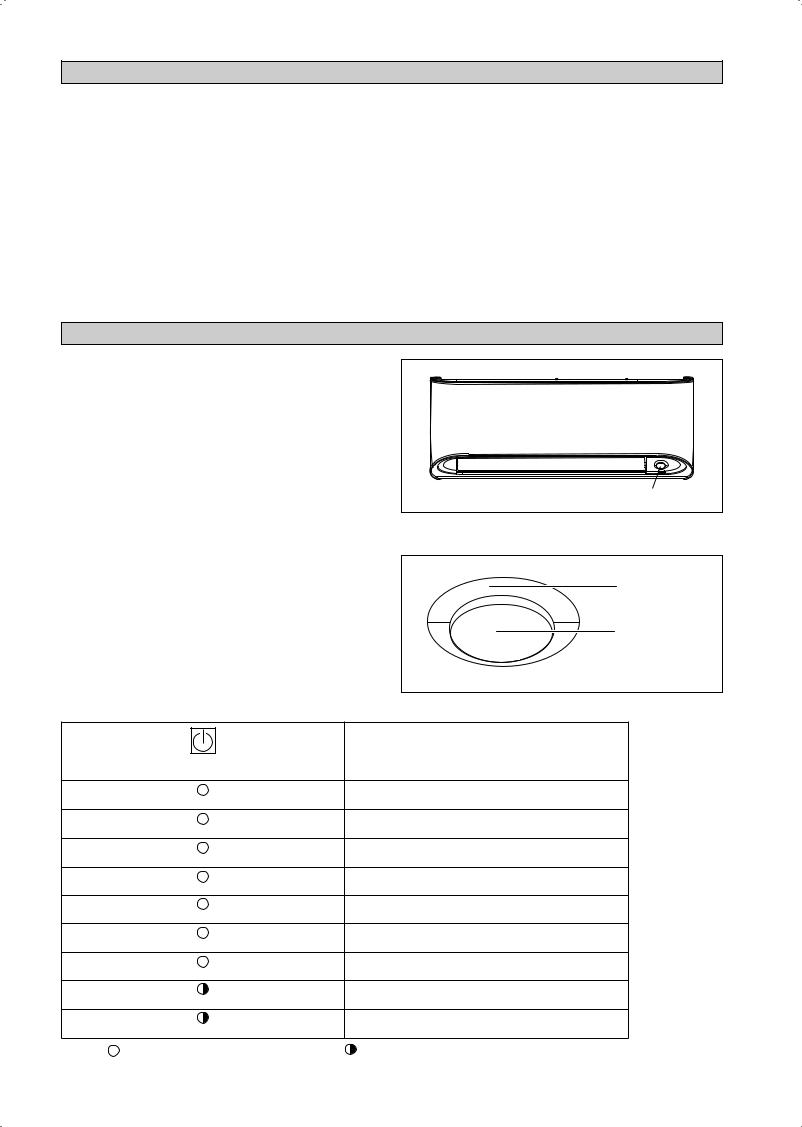

OUTLINE AND DIMENSIONS

Indoor Unit [FTXB/FTKB]

THE MARK |

SHOWS PIPING DIRECTION |

|

|

|

|

A |

|

|

|

REAR |

REAR |

|

|

|

LEFT |

|

RIGHT |

|

|

|

|

|

C |

|

|

TOP VIEW |

|

|

|

|

|

SIGNAL RECEIVER |

B |

NAME PLATE |

B |

|

|

||

|

|

TERMINAL |

||

|

|

|

|

|

|

|

|

|

BLOCK |

|

|

INDOOR UNIT |

|

WITH EARTH |

BOTTOM |

BOTTOM |

ON/OFF SWITCH |

SIDE VIEW |

TERMINAL |

ROOM TEMPERATURE THERMISTOR |

|

|||

|

|

|

||

LOUVER FRONT GRILLE FIXED SCREWS |

(INSIDE) |

|

|

|

|

(INSIDE) |

|

|

|

FRONT VIEW

Original Instruction English

1-1

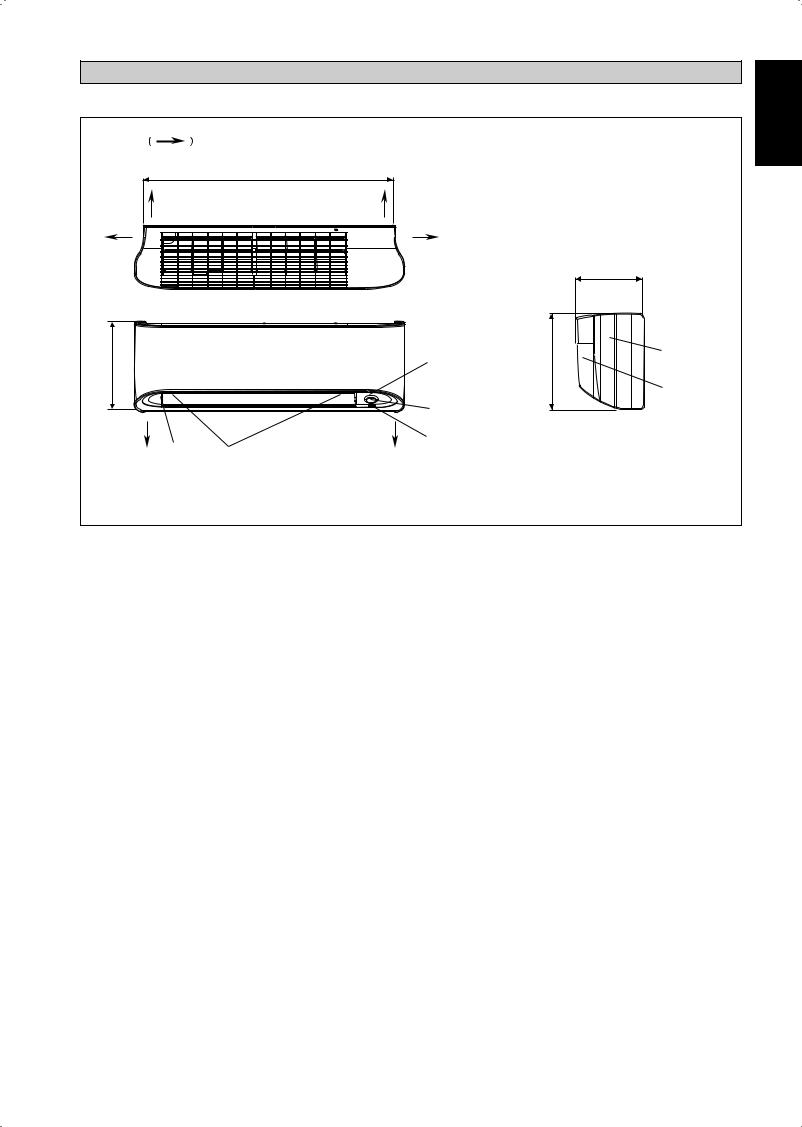

Indoor Unit [FTXB/FTKB]

F

B

G

«Recommended mounting plate retention spots (5 spots in all)

D E

H J

L |

|

|

M |

|

K |

|

I |

|

|

|

|

A |

|

||

Liquid pipe end |

|

Gas pipe end |

|

||||

|

|

|

|

INSTALLATION PLATE 09/12 |

|

||

F

Through the wall hole Ø 2-9/16" (65mm)

G

Drain hose position

All dimensions are in Inch (mm)

|

Dimension |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

Model |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

09/12 |

|

35-1/16 |

11-11/16 |

8-1/4 |

4-1/16 |

5-9/16 |

1-3/16 |

1-13/16 |

2-3/16 |

2-3/16 |

6 |

7-1/8 |

8-1/8 |

2-1/16 |

|

|

(890) |

(297) |

(210) |

(104) |

(141) |

(30) |

(46) |

(55) |

(56) |

(153) |

(181) |

(207) |

(52) |

«Recommended mounting plate retention spots (7 spots in all)

D |

E |

F |

F |

B

|

|

|

|

|

|

Through the wall hole |

|

|

|

|

|

|

Ø 2-9/16" (65mm) |

G |

|

|

|

|

|

G |

H |

J |

Liquid pipe end |

Gas pipe end |

K |

I |

Drain hose position |

|

|

L |

M |

|

|

|

|

|

|

A |

|

|

|

|

|

|

INSTALLATION PLATE 18/24 |

|

|

|

All dimensions are in Inch (mm)

|

Dimension |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

Model |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18/24 |

|

46-1/8 |

12-5/8 |

9-1/2 |

7-1/2 |

6-13/16 |

2-3/8 |

1-9/16 |

1-3/4 |

1-7/8 |

3-9/16 |

8-5/8 |

22-13/16 |

1-3/4 |

|

|

(1172) |

(320) |

(242) |

(190) |

(173) |

(61) |

(40) |

(45) |

(48) |

(91) |

(219) |

(580) |

(45) |

1-2

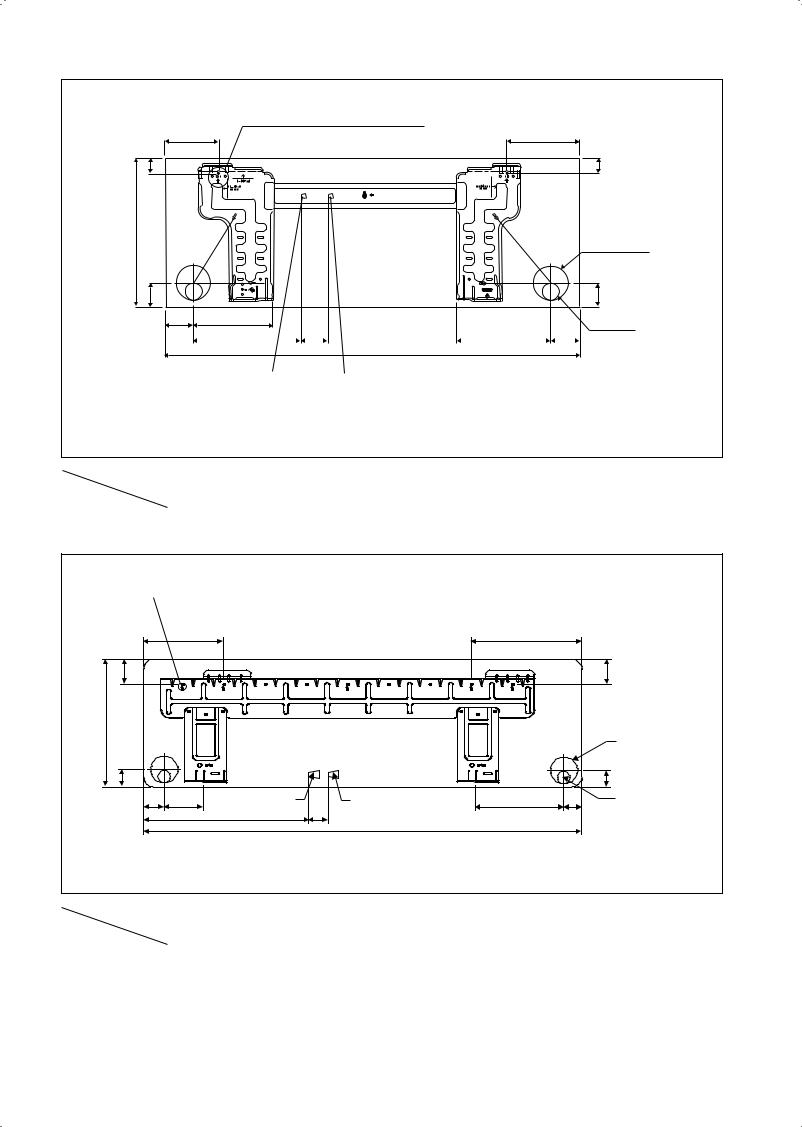

Outdoor Unit [RXB/RKB]

|

|

|

|

|

J |

|

|

H |

|

I |

|

All dimensions are in Inch (mm) |

English |

||||||

|

|

|

|

|

G |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

N |

O |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Q |

|

|

|

|

|

|

|

|

|

|

|

|

5/64 |

|

|

|

|

|

|

|

P |

|

|

|

|

|

|

|

|

|

E |

F |

D |

|

|

B |

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

(2) |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M |

|

|

|

|

|

|

|

|

Model |

Dimension |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

N |

O |

P |

Q |

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

09/12 |

|

21-5/8 |

25-15/16 |

2 |

7/16 |

10-3/4 |

5/8 |

9/16 |

18-1/2 |

3-3/4 3-11/16 |

3-11/16 2-3/8 9/16 |

5-1/4 |

5/16 |

3/8 |

11-3/4 |

|

|||

|

|

(550) |

(658) |

(51) |

(11) |

(273) |

(16) |

(14) |

(470) |

(96) |

(93) |

(94) |

(60) |

(14) |

(133) |

(8) |

(10) |

(299) |

|

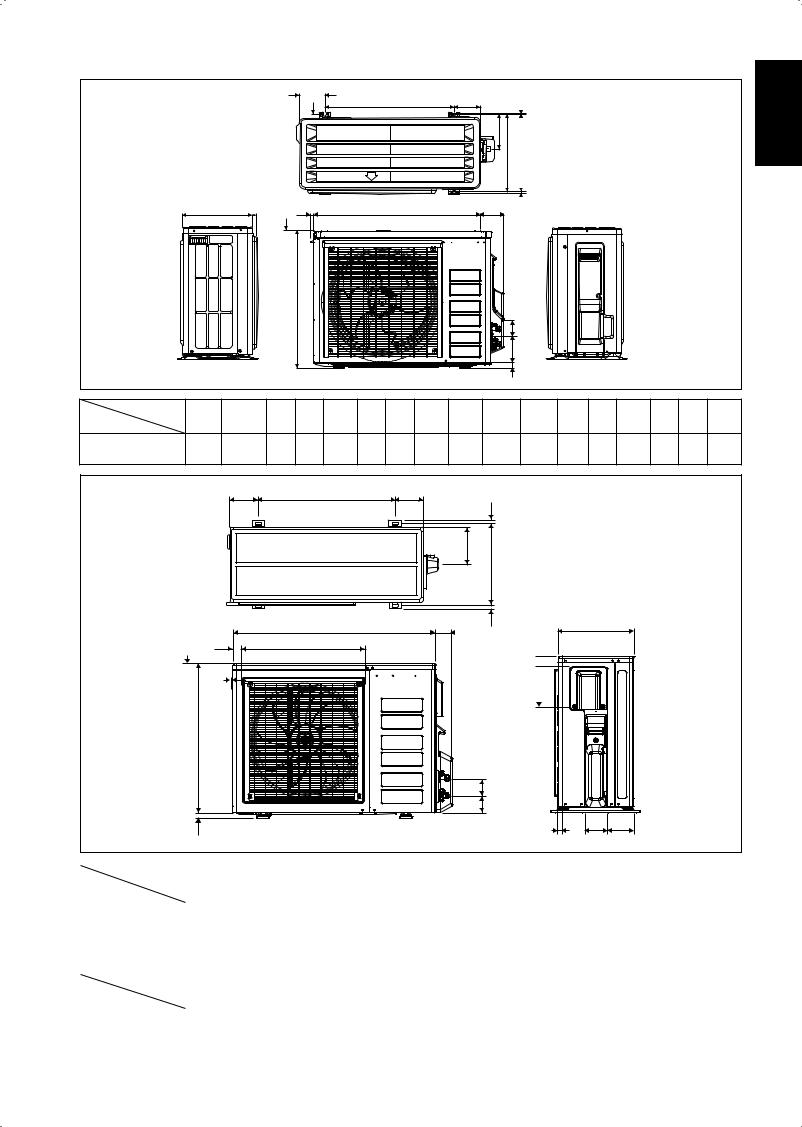

J I J

L

|

|

|

|

K |

|

|

|

|

O |

|

|

A |

S |

L |

|

|

|

||

1/8 |

M |

D |

|

|

(3) |

|

|

|

|

|

T |

|

|

|

B |

|

|

|

|

|

|

|

|

Q |

|

|

|

|

P |

N

All dimensions are in Inch (mm)

C

E F

G H

R

|

Dimension |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

N |

O |

Model |

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

33-11/16 |

24-3/4 |

12-15/16 |

20-1/2 |

7-1/16 |

1-13/16 |

4 |

4-7/16 |

23-3/4 |

4-15/16 |

6-7/16 |

9/16 |

1-5/16 |

15/16 |

14-1/4 |

|

|

(855) |

(628) |

(328) |

(520) |

(179) |

(46) |

(101) |

(113) |

(603) |

(126) |

(164) |

(15) |

(34) |

(23) |

(362) |

24 |

|

33-11/16 |

28-3/4 |

12-15/16 |

20-1/2 |

7-1/16 |

1-13/16 |

4 |

4-7/16 |

23-3/4 |

4-15/16 |

6-7/16 |

9/16 |

1-5/16 |

15/16 |

14-1/4 |

|

|

(855) |

(730) |

(328) |

(520) |

(179) |

(46) |

(101) |

(113) |

(603) |

(126) |

(164) |

(15) |

(34) |

(23) |

(362) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Dimension |

P |

Q |

R |

S |

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

2-7/8 |

2-15/16 |

5/16 |

2-5/8 |

1/4 |

|

|

|

|

|

|

|

|

|

|

|

|

(73) |

(75) |

(8) |

(67) |

(7) |

|

|

|

|

|

|

|

|

|

|

24 |

|

2-7/8 |

2-15/16 |

5/16 |

2-5/8 |

1/4 |

|

|

|

|

|

|

|

|

|

|

|

|

(73) |

(75) |

(8) |

(67) |

(7) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-3 |

|

|

|

|

|

|

|

|

|

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air conditioner unit. Special adjustment may be necessary to suit local requirement.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial use by lay persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

SAFETY PRECAUTIONS

!WARNING

•Only qualified personnel must carry out the installation work. Installation must be done in accordance with this installation manual. Improper installation may result in water leakage, electric shock, or fire.

•When installing the unit in a small room, take measures to keep the refrigerant concentration from exceeding allowable safety limits. Excessive refrigerant leaks, in the event of an accident in a closed ambient space, can lead to oxygen deficiency.

•Use only specified accessories and parts for installation work. Failure to use specified parts may result in water leakage, electric shock, fire, or the unit falling.

•Install the air conditioner or heat pump on a foundation strong enough to withstand the weight of the unit. A foundation of insufficient strength may result in the unit falling and causing injuries.

•Take into account strong winds, typhoons, or earthquakes when installing. Improper installation may result in the unit falling and causing accidents.

•Make sure that a separate power supply circuit is provided for this unit and that all electrical work is carried out by qualified personnel according to local, state, and national regulations. An insufficient power supply capacity or improper electrical construction may lead to electric shock or fire.

•Make sure that all wiring is secured, that specified wires are used, and that no external forces act on the terminal connections or wires. Improper connections or installation may result in fire.

•When wiring, position the wires so that the electrical wiring box cover can be securely fastened. Improper positioning of the electrical wiring box cover may result in electric shock, fire, or the terminals overheating.

•Before touching electrical parts, turn off the unit.

•It is recommended to install a ground fault circuit interrupter if one is not already available. This helps prevent electric shock or fire.

•Securely fasten the outdoor unit terminal cover (panel). If the terminal cover/panel is not installed properly, dust or water may enter the outdoor unit causing fire or electric shock.

•When installing or relocating the system, keep the refrigerant circuit free from substances other than the specified refrigerant (R410A) such as air. Any presence of air or other foreign substance in the refrigerant circuit can cause an abnormal pressure rise or rupture, resulting in injury.

•Do not change the setting of the protection devices. If the pressure switch, thermal switch, or other protection device is shorted and operated forcibly, or parts other than those specified by Daikin are used, fire or explosion may occur.

!CAUTION

•Do not touch the switch with wet fingers. Touching a switch with wet fingers can cause electric shock.

•Do not allow children to play on or around the unit to prevent injury.

•The heat exchanger fins are sharp enough to cut. To avoid injury wear gloves or cover the fins while working around them.

•Do not touch the refrigerant pipes during and immediately after operation as the refrigerant pipes may be hot or cold, depending on the condition of the refrigerant flowing through the refrigerant piping, compressor, and other refrigerant cycle parts. Your hands may suffer burns or frostbite if you touch the refrigerant pipes. To avoid injury, give the pipes time to return to normal temperature or, if you must touch them, be sure to wear proper gloves.

•Install drain piping to proper drainage. Improper drain piping may result in water leakage and property damage.

•Insulate piping to prevent condensation.

•Be careful when transporting the product.

•Do not turn off the power immediately after stopping operation. Always wait for at least 5 minutes before turning off the power. Otherwise, water leakage may occur.

•Do not use a charging cylinder. Using a charging cylinder may cause the refrigerant to deteriorate.

•Refrigerant R410A in the system must be kept clean, dry, and tight.

(a)Clean and Dry -- Foreign materials (including mineral oils such as SUNISO oil or moisture) should be prevented from getting into the system

(b)Tight -- R410A does not contain any chlorine, does not destroy the ozone layer, and does not reduce the earth’s protection again harmful ultraviolet radiation. R410A can contribute to the greenhouse effect if it is released. Therefore, take proper measures to check for the tightness of the refrigerant piping installation. Read the chapter Refrigerant Piping and follow the procedures.

•Since R410A is a blend, the required additional refrigerant must be charged in its liquid state. If the refrigerant is charged in a state of gas, its composition can change and the system will not work properly.

•The indoor unit is for R410A. See the catalog for indoor models that can be connected. Normal operation is not possible when connected to other units.

1-4

•Remote controller (wireless kit) transmitting distance can be shorter than expected in rooms with electronic fluorescent lamps (inverter or rapid start types). Install the indoor unit far away from fluorescent lamps as much as possible.

•Indoor units are for indoor installation only. Outdoor units can be installed either outdoors or indoors. This unit is for indoor use.

•Do not install the air conditioner or heat pump in the following locations:

(a)Where a mineral oil mist or oil spray or vapor is produced, for example, in a kitchen. Plastic parts may deteriorate and fall off or result in water leakage.

(b)Where corrosive gas, such as sulfurous acid gas, is produced. Corroding copper pipes or soldered parts may result in refrigerant leakage.

(c)Near machinery emitting electromagnetic waves. Electromagnetic waves may disturb the operation of the control system and cause the unit to malfunction.

(d)Where flammable gas may leak, where there is carbon fiber, or ignitable dust suspension in the air, or where volatile flammables such as thinner or gasoline are handled. Operating the unit in such conditions can cause a fire.

•Take adequate measures to prevent the outdoor unit from being used as a shelter by small animals. Small animals making contact with electrical parts can cause malfunctions, smoke, or fire. Instruct the user to keep the area around the unit clean.

!NOTE

•Install the power supply and inter-unit wires for the indoor and outdoor units at least 3.5ft away from televisions or radios to prevent image interference or noise. Depending on the radio waves, a distance of 3.5ft may not be sufficient to eliminate the noise.

•Dismantling the unit, treatment of the refrigerant, oil and additional parts must be done in accordance with the relevant local, state, and national regulations.

•Do not use the following tools that are used with conventional refrigerants: gauge manifold, charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge, or refrigerant recovery equipment.

•If the conventional refrigerant and refrigerator oil are mixed in R410A, the refrigerant may deteriorate.

•This air conditioner or heat pump is an appliance that should not be accessible to the general public.

•As design pressure is 536 psi, the wall thickness fieldinstalled pipes should be selected in accordance with the relevant local, state, and national regulations.

!DANGER

•Refrigerant gas is heavier than air and replaces oxygen. A massive leak can lead to oxygen depletion, especially in basements, and an asphyxiation hazard could occur leading to serious injury or death.

•Do not ground units to water pipes, gas pipes, telephone wires, or lightning rods as incomplete grounding can cause a severe shock hazard resulting in severe injury or death. Additionally, grounding to gas pipes could cause a gas leak and potential explosion causing severe injury or death.

•If refrigerant gas leaks during installation, ventilate the area immediately. Refrigerant gas may produce toxic gas if it comes into contact with fire. Exposure to this gas could cause severe injury or death.

•After completing the installation work, check that the refrigerant gas does not leak throughout the system.

•Do not install unit in an area where flammable materials are present due to risk of explosions that can cause serious injury or death.

•Safely dispose all packing and transportation materials in accordance with federal/state/local laws or ordinances. Packing materials such as nails and other metal or wood parts, including plastic packing materials used for transportation may cause injuries or death by suffocation.

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the refrigerant, of oil and of other parts must be done by a qualified installer in accordance with relevant local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring this product is disposed of correctly, you will help to prevent potential negative consequences for the environment and human health. Please contact the installer or local authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local and national legislation.

English

1-5

INSTALLATION DIAGRAM

Indoor Unit

2-3/16" (55mm) or more from ceiling

Front panel

1-15/16" (50mm) or more from walls (on both sides)

M4 x 12L |

Service lid |

Air filter |

n Opening service lid |

|

|

|

Service lid is removeable. |

|

n Opening method |

1) Remove the service lid screws.

2) Pull out the service lid diagonally down in the direction of the arrow.

3) Pull down.

Caulk pipe hole gap with putty.

Cut thermal insulation pipe to an appropriate length and wrap it with tape, making sure that no gap is left in the insulation pipe’s cut line.

Wrap the insulation pipe with the finishing tape from bottom to top.

Outdoor Unit

19- |

|

11/16" (500mm) |

from wall |

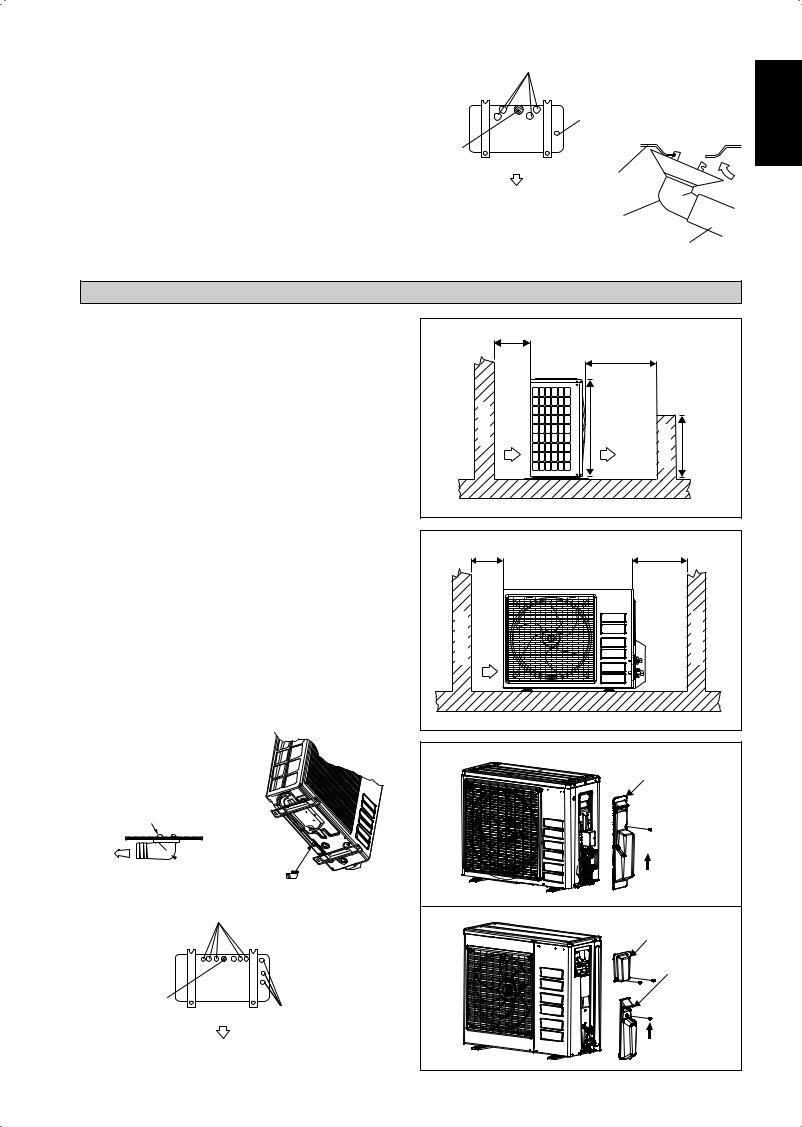

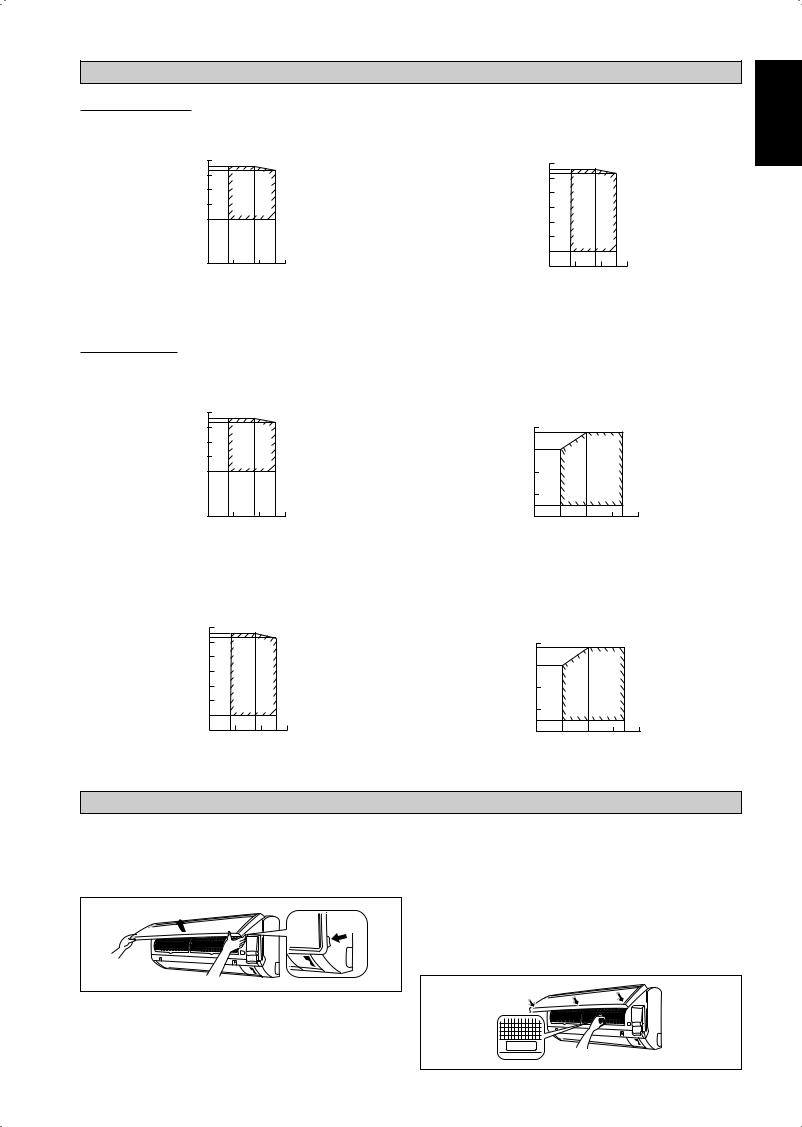

INSTALLATION OF THE OUTDOOR UNIT (09/12)

•Where a wall or other obstacle is in the path of outdoor unit’s intake or exhaust airflow, follow the installation guidelines below.

•For any of the below installation patterns, the wall height on the exhaust side should be 47-1/4" (1200mm) or less.

|

Wall facing one side |

|

|

Wall facing two sides |

More than 1-15/16 (50) |

More than 3-15/16 (100) |

|||

47-1/4 |

More than |

(1200) |

3-15/16 (100) |

or less |

|

|

More than 1-15/16 (50) |

More than |

5-7/8 (150) |

More than 1-15/16 (50) |

Side View |

Top View |

Wall facing three sides

More than 5-15/16 (150)

More than 11-13/16 (300)

More than 1-15/16 (50)

Top View

Unit : Inch (mm)

1-6

Drain work. (Heat Pump Unit Only) |

Drain plug |

|

1) |

Use drain elbow for drainage. |

|

2) |

If the drain port is covered by a mounting base or floor |

|

|

surface, place additional foot bases of at least 1-3/16" |

Drain plug |

|

(30mm) in height under the outdoor unit’s feet. |

|

3) |

In cold areas, do not use a drain elbow, drain plugs and a |

Drain elbow |

|

drain hose with the outdoor unit. (Otherwise, drain water |

|

|

Air outlet side |

|

|

may freeze, impairing heating performance.) |

|

|

Bottom frame |

|

Drain Elbow

Hose (available commercially, inner dia. 5/8" (16mm))

INSTALLATION OF THE OUTDOOR UNIT (18/24)

The outdoor unit must be installed in such a way, so as to prevent short circuit of the hot discharged air or obstruction to the smooth air flow. Please follow the installation clearances shown in the figure. Select the coolest possible place where intake air temperature is not greater than the outside air temperature (Refer to operating range).

Installation clearances

Dimension |

A |

B |

C |

D |

|

|

|

|

|

Minimum Distance, |

11-13/16 |

39-3/8 |

11-13/16 |

19-11/16 |

Inch (mm) |

(300) |

(1000) |

(300) |

(500) |

Note: If there is any obstacle higher than half, of the unit’s height (H), please allow more space than the figure indicated in the above table.

Condensed Water Disposal Of Outdoor Unit

(Heat Pump Unit Only)

•There are 10 holes on the base of Outdoor Unit for condensed water to flow out. Insert the drain elbow to one of the holes.

•To install the drain elbow, first insert one portion of the hook to the base (portion A), then pull the drain elbow in the direction shown by the arrow while inserting the other portion to the base. After installation, check to ensure that the drain elbow clings to base firmly.

•If the unit is installed in a snowy and chilly area, condensed water may freeze in the base. In such case, please remove plug at the bottom of unit to smooth the drainage.

A

BASE

DRAIN ELBOW

DRAIN ELBOW

DRAIN ELBOW

Drain plug

Drain elbow

Drain plug

Air outlet side

A

|

|

|

B |

|

|

Obstacle |

Return air |

H |

Dischargeair |

Obstacle |

H/2 |

|

|

|

|

|

|

C |

D |

|

Obstacle |

Return air |

Service access |

Obstacle |

09/12 |

Please remove |

|

side plate when |

|

connecting |

|

the piping and |

|

connecting cord |

|

PUSH & PULL UP |

|

18/24 |

Please remove |

|

side plate when |

||

|

||

|

connecting |

|

|

the piping and |

|

|

connecting cord |

PUSH & PULL UP

English

1-7

INSTALLATION OF THE OUTDOOR UNIT

1. Precautions for Selecting a Location

1)Choose a place solid enough to bear the weight and vibration of the unit, where the operating sound will not be amplified.

2)Choose a location where the hot air discharged from the unit or the operating sound will not cause a nuisance to the neighbors of the user.

3)Avoid locations, such as near bedrooms, where the operating sound may cause disturbance.

4)There must be sufficient space to carry the unit into and out of the site.

5)There must be sufficient space for air passage and no obstructions around the air inlet and the air outlet.

6)The site must not be prone to flammable gas leaks in the surrounding area.

7)Install units, power cords and inter-unit wire at least 10ft (3m) away from television and radio sets. (This is to prevent interference to images and sounds. Noise may be produced even if they are more than 10ft (3m) away depending on radio wave conditions.)

8)In coastal areas or other places with a salty atmosphere or one containing sulfate gas, corrosion may shorten the life of the air conditioner.

9)Since water will flow from the drain of the outdoor unit, do not place under the unit anything which must be kept away from moisture.

NOTE

Cannot be installed suspended from a ceiling or stacked.

! CAUTION

When operating the air conditioner in a low outdoor ambient temperature, be sure to follow the instructions described below.

•To prevent exposure to wind, install the outdoor unit with its suction side facing the wall.

•Never install the outdoor unit at a site where the suction side may be exposed directly to wind.

•To prevent exposure to wind, it is recommended to install a baffle plate on the air discharge side of the outdoor unit.

•In heavy snow areas, select an installation site where the snow will not affect the unit.

•If there is a likelihood of snow accumulating on the outdoor unit, attach a snow protection hood.

•In high humidity areas or heavy snow areas, it is recommended to attach a drain pan heater to

prevent ice build-up from the bottom frame.

•Construct a large canopy.

•Construct a pedestal.

Install the unit high enough off the ground to prevent burying in snow

1-8

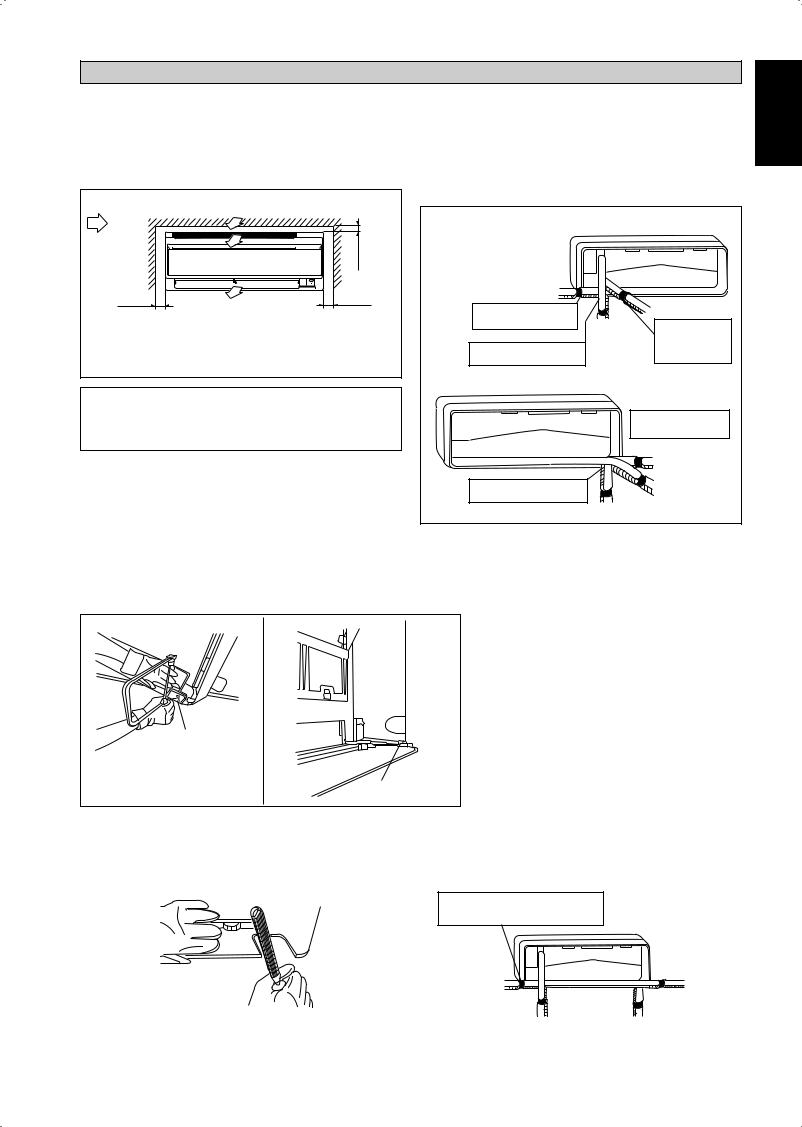

INSTALLATION OF THE INDOOR UNIT

The indoor unit must be installed in such a way so as to prevent short circuit of the cool discharged air with the hot return air. Please follow the installation clearance shown in the figure. Do not place the indoor unit where there could be direct sunlight shining on it. Also, this location must be suitable for piping and drainage, and be away from doors or windows.

Air flow |

|

min. 2-3/16" (55) (Space for performance) |

(Indoor) |

|

|

|

|

|

min. 2" (50) |

Required space |

min. 2" (50) |

(Space for |

(Space for |

|

maintenance) |

|

maintenance) |

All dimensions are in Inch (mm)

!CAUTION

•Must be mounted with the lowest moving parts at least 8ft (2.4m) above floor or grade level.

The refrigerant piping can be routed to the unit in a number of ways (left or right from the back of the unit), by using the cut-out holes on the casing of the unit. Bend the pipes carefully to the required position in order to align it with the holes. For the side and bottom out, hold the bottom of the piping and then position it to the required direction. The condensation drain hose can be taped to the pipes.

Right-side, right-back or right-bottom piping

Right-side piping |

|

|

|

Remove pipe port cover |

|

Right-back piping |

|

here for right-side piping |

Right-bottom |

Bind coolant pipe |

|

|

and drain hose |

||

|

piping |

||

Remove pipe port cover here |

together with |

||

|

|||

for right-bottom piping |

|

insulating tape. |

Left-side, left-back or left-bottom piping

|

Remove pipe port cover |

|

here for left-side piping |

|

Left-side piping |

Remove pipe port cover here |

Left-back piping |

for left-bottom piping |

|

|

Left-bottom piping |

Bottom or side piping

1)Cut off pipe port cover with a copping saw.

üFor bottom piping: On the bottom of the front grille

üFor side piping: On the side cover (front grille side and unit side)

Apply the blade of the copping saw to the notch, and cut off the pipe port cover along the uneven inner surface.

English

Front grille side

The figure shows the case of left bottom piping

Side cover (front grille side)

2)After cutting off the pipe cover, perform filing.

Remove the burrs along the cut section using a half round needle file.

3)Wrap the inter-unit wire, refrigerant pipes and drain hose together with insulation tape.

Then, insert the drain hose and refrigerant pipes into the wall hole after inserting them into the cut out piping hole opened.

NOTE

üBe careful not to let chips enter the driving section of the arm.

üBe careful not to put pressure on the lower front panel.

Bind refrigerant pipe and drain hose together with adhesive vinyl tape.

Right-side |

Left-side |

piping |

piping |

Right-bottom piping |

Left-bottom piping |

1-9

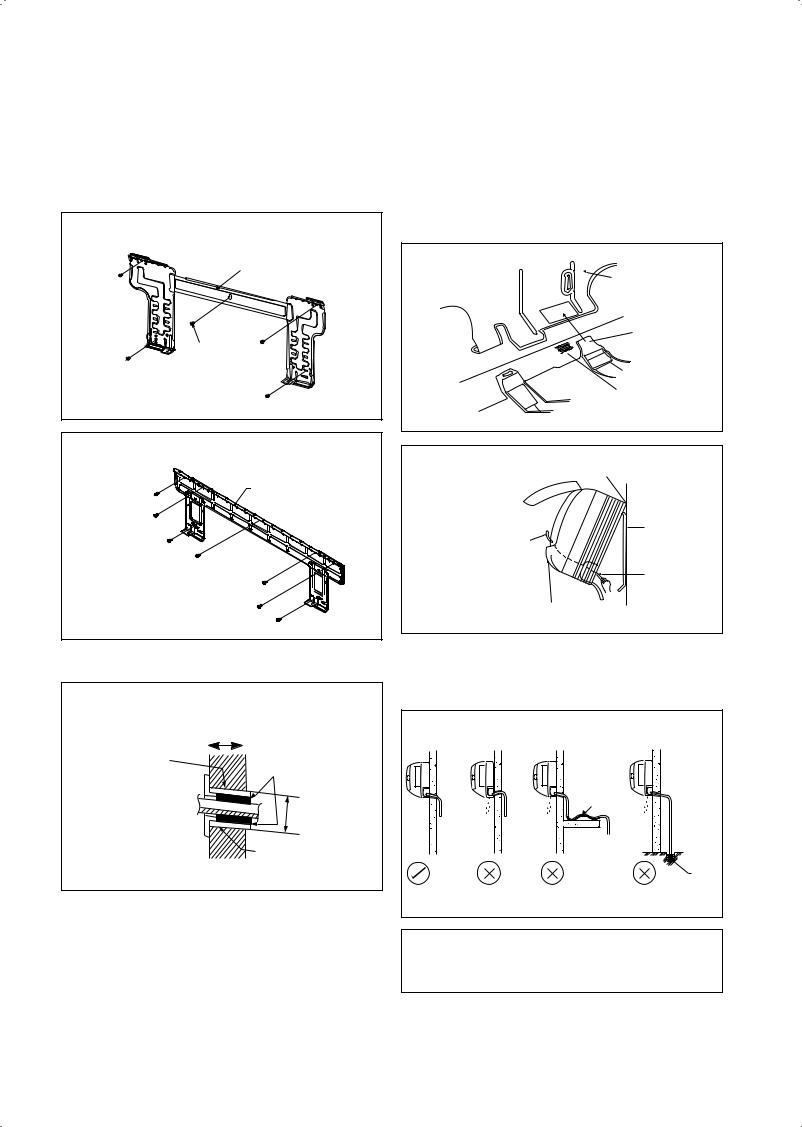

Mounting Installation Plate

Ensure that the wall is strong enough to withstand the weight of the unit. Otherwise, it is necessary to reinforce the wall with plates, beams or pillars.

Use the level gauge for horizontal mounting, and fix it with 5 suitable screws for FTXB/FTKB 09/12 and 7 suitable screws for FTXB/FTKB 18/24.

In case the rear piping draws out, drill a hole 2-9/16" (65mm) in diameter with a cone drill, slightly lower on the outside wall (see figure).

FTXB/FTKB 09/12

Mounting plate

Mounting plate fixing screw

FTXB/FTKB 18/24

Mounting plate

Mounting plate  fixing screw

fixing screw

Mount The Unit Onto The Installation Plate

Hook the indoor unit onto the upper portion of the installation plate (Engage the two hooks at the rear top of the indoor unit with the upper edge of the installation plate). Ensure that the hooks are properly seated on the installation plate by moving it to the left and right.

How To Attach The Indoor Unit

Hook the claws of the bottom frame to the mounting plate.

How To Remove The Indoor Unit

Push up the marked area (at the lower part of the front grille) to release the claws.

Mounting plate

Clip

Bottom frame

Front grille |

Mark (Rear side) |

Hand indoor unit’s hook here.

When stripping the ends |

Mounting plate |

|

of interconnecting wires in |

||

|

||

advance, bind right ends of |

|

|

wires with insulating tape. |

Interconnecting |

|

|

||

|

wires |

|

|

Wire guide |

Drilling a Wall Hole and Installing Wall Embedded

Pipe

Hole With Cone Drill

Inside |

Outside |

Wall embedded pipe |

Caulking |

(Field supply) |

|

Wall hole cover |

Ø 2-9/16" (65mm) |

|

|

(Field supply) |

|

|

Wall embedded pipe |

|

(Field supply) |

Water Drainage Piping

The indoor drain pipe must be in a downward gradient for smooth drainage. Avoid situations that are likely to cause water to leak.

Water Drainage

|

|

Water |

|

|

|

|

retention |

End |

|

|

|

|

||

Water |

Water |

Water |

dipped |

|

into |

||||

leaking |

leaking |

leaking |

||

water |

||||

|

|

|

Drain

Correct |

Wrong |

Wrong |

Wrong |

!CAUTION

•Do not install the unit at altitude over 6560ft (2000m) for both indoor & outdoor.

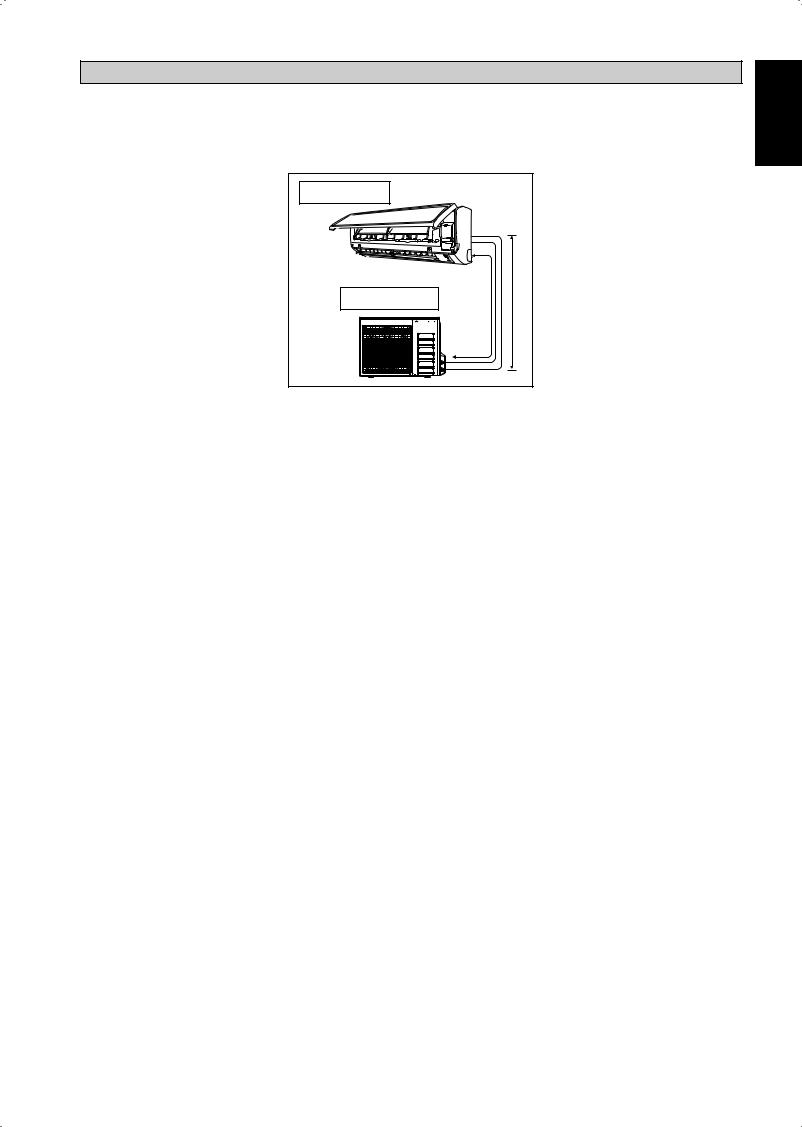

1-10

REFRIGERANT PIPING

Allowable Piping Length

If the pipe is too long, both the capacity and reliability of the unit will drop. As the number of bends increases, resistance to the flow of refrigerant system increases, thus lowering cooling capacity. As a result, the compressor may become defective. Always choose the shortest path and follow the recommendations as tabulated below:

Indoor Unit |

|

|

Outdoor Unit |

L |

E |

|

Model |

Indoor |

(FTXB/FTKB) |

09 |

|

12 |

18 |

24 |

|

|

|

|

|

|

|

|

Outdoor |

(RXB/RKB) |

09 |

|

12 |

18 |

24 |

|

|

|

||||||

|

|

|

|

|

|

|

|

Min. Allowable Length (L), ft/(m) |

|

9.84' (3) |

9.84' (3) |

||||

|

|

|

|

||||

Max. Allowable Length (L), ft/(m) |

|

65.6' (20) |

98.4' (30) |

||||

|

|

|

|

||||

Max. Allowable Elevation (E), ft/(m) |

|

32.8' (10) |

32.8' (10) |

||||

|

|

|

|

|

|

||

Gas Pipe Size, in/(mm) |

|

|

3/8" (9.52) |

1/2" (12.70) |

5/8" (15.88) |

||

|

|

|

|

|

|

||

Liquid Pipe Size, in/(mm) |

|

|

1/4" (6.35) |

1/4" (6.35) |

|||

|

|

|

|

|

|

|

|

*Be sure to add the proper amount of additional refrigerant. Failure to do so may result in reduced performance.

Remark: The refrigerant pre-charged in the outdoor unit is for piping length up to 25ft (7.6m).

Equivalent length for various fitting [Feet (meter)]

Pipe Size |

L joint |

||

|

|

|

|

|

|

|

|

|

|

|

|

3/8" (OD9.52mm) |

0.59' (0.18) |

||

|

|

|

|

1/2" (OD12.7mm) |

0.66' (0.20) |

||

|

|

|

|

5/8" (OD15.9mm) |

0.82' (0.25) |

||

|

|

|

|

3/4" (OD19.1mm) |

1.15' (0.35) |

||

|

|

|

|

7/8" (OD22.2mm) |

1.31' (0.40) |

||

|

|

|

|

1" (OD25.4mm) |

1.48' (0.45) |

||

|

|

|

|

1 1/8" (OD28.6mm) |

1.64' (0.50) |

||

|

|

|

|

1 3/8" (OD34.9mm) |

1.97' (0.60) |

||

|

|

|

|

Notes:

1.Equivalent piping length is obtained with actual length of gas piping.

2.90° bend of piping is equivalent to L joint.

Bending must be carefully made so as not to crush the pipe. Use a pipe bender to bend a pipe where possible.

English

1-11

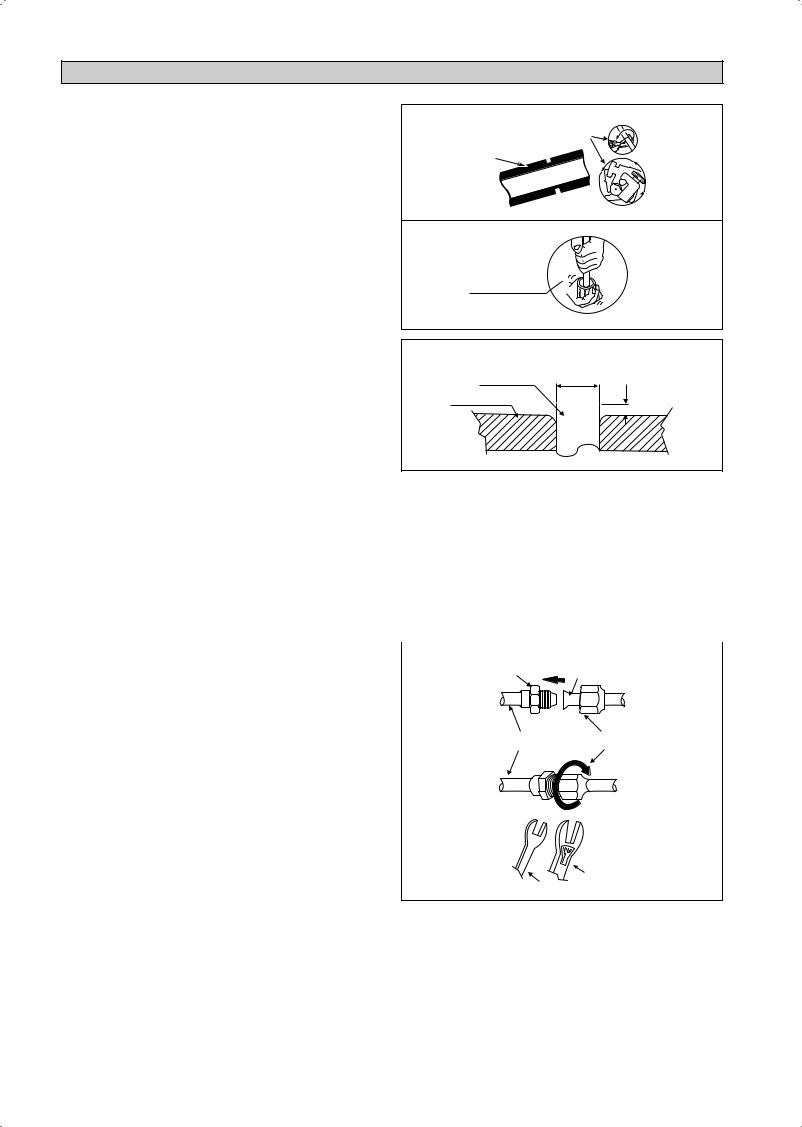

REFRIGERANT PIPING

Piping Works And Flaring Technique

•Do not use contaminated or damaged copper tubing. If any piping, evaporator or condenser had been exposed or had been opened for 15 seconds or more, the system must be vacuumed. Generally do not remove plastic, rubber plugs and brass nuts from the valves, fittings, tubing and coils until it is ready to connect suction or liquid line into valves or fittings.

•If any brazing work is required, ensure that nitrogen gas is passed through coil and joints while the brazing work is being done. This will eliminate soot formation on the inside wall of copper tubings.

•Cut the pipe stages by stages, advancing the blade of pipe cutter slowly. Extra force and a deep cut will cause more distortion of pipe and therefore extra burr. See Figure I.

•Remove burrs from cut edges of the pipes with remover. See Figure II. Hold the pipe on top position and burr remover at lower position to prevent metal chips from entering the pipe. This will avoid unevenness on the flare faces which will cause gas leak.

•Insert the flare nuts, mounted on the connection parts of both the indoor unit and outdoor unit, into the copper pipes.

•The exact length of pipe protruding from the top surface of the swaging block is determined by the flaring tool. See Figure III.

•Fix the pipe firmly on the swaging block. Match the centers of both the swaging block and the flaring punch, then tighten the flaring punch fully.

•The refrigerant pipe connection are insulated by closed cell polyurethane.

Piping Connection To The Units

•Align the center of the piping and tighten the flare nut sufficiently with fingers. See Figure IV.

•Finally, tighten the flare nut with torque wrench until the wrench clicks.

•When tightening the flare nut with the torque wrench, ensure that the tightening direction follows the arrow indicated on the wrench.

•The refrigerant pipe connection are insulated by closed cell polyurethane.

Pipe Size, in (mm) |

Torque, ft-lb (Nm) |

|

|

1/4" (6.35) |

13.3 (18) |

|

|

3/8" (9.52) |

31.0 (42) |

|

|

1/2" (12.70) |

40.6 (55) |

|

|

5/8" (15.88) |

48.0 (65) |

|

|

3/4" (19.05) |

57.6 (78) |

|

|

Figure I

Cutting Copper Tube

1/4t

Figure II

Remove Burr

Figure III

Copper Tube |

D |

Swaging Block |

A |

|

Ø Tube, D |

|

A (Inch/mm) |

||||

Inch |

|

mm |

|

Imperial |

|

Rigid |

|

|

|

(Wing-nut Type) |

|

(Clutch Type) |

|

1/4" |

|

6.35 |

|

0.051" (1.3) |

|

0.028" (0.7) |

3/8" |

|

9.52 |

|

0.063" (1.6) |

|

0.039" (1.0) |

1/2" |

|

12.70 |

|

0.075" (1.9) |

|

0.051" (1.3) |

5/8" |

|

15.88 |

|

0.087" (2.2) |

|

0.067" (1.7) |

|

|

|

|

|

|

|

3/4" |

|

19.05 |

|

0.098" (2.5) |

|

0.079" (2.0) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure IV |

Flare Joint |

Flared Tube |

|

|||

|

|

|

||||

Indoor Piping |

Flare Nut |

Torque Wrench

Spanner

1-12

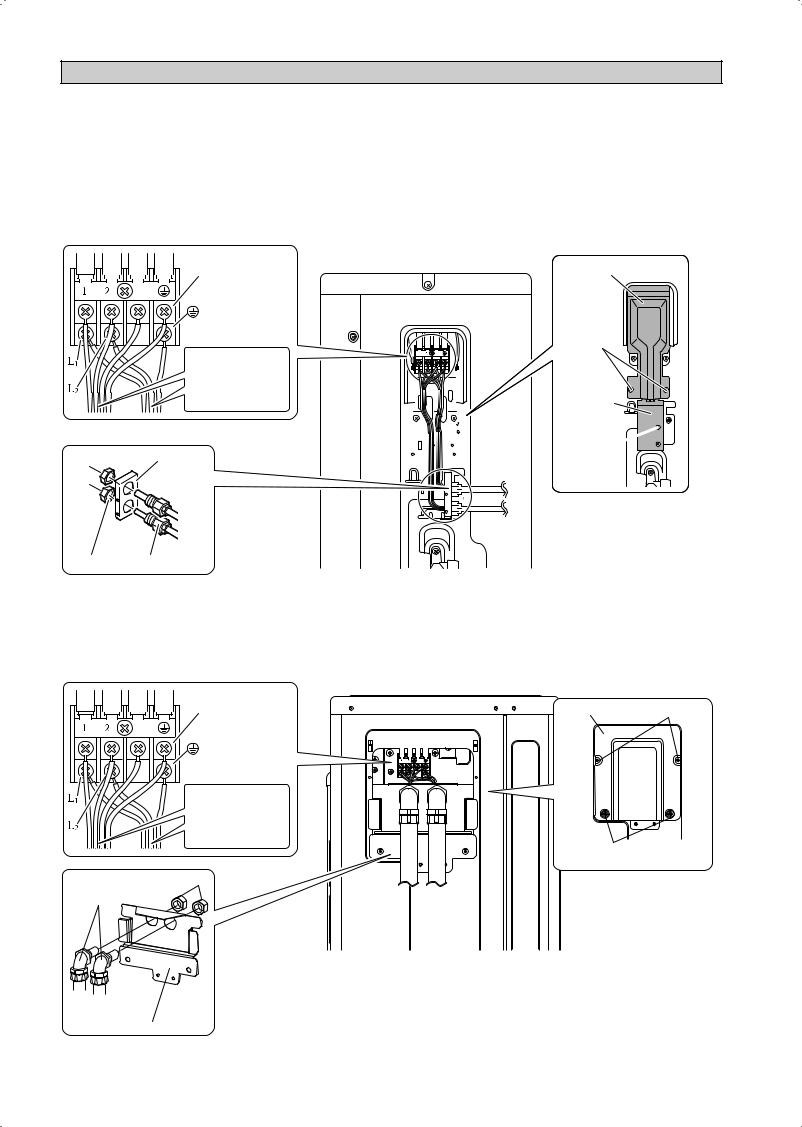

ELECTRICAL WIRING CONNECTION

IMPORTANT : * The figures shown in the table are for information purpose only. They should be checked and selected to comply with the local/national codes of regulations. This is also subject to the type of installation and conductors used.

** The appropriate voltage range should be checked with label data on the unit.

Back

Conduit mounting plate

Conduit

Lock nut

Lock nut

Firmly fix the wires with the terminal screws.

Outdoor unit

Recommend using AWG14, stranded and insulated |

1 2 |

SIG |

L1 L2 GR |

||

wire for connections between indoor and outdoor units. |

|||||

|

|

|

|||

Local code always supersedes recommendation. |

|

|

|

||

Indoor |

1 |

|

|

|

|

2 |

|

|

|

||

unit |

SIG |

|

|

|

|

|

Firmly fix the |

|

|

|

|

|

wires with the |

|

|

Ground |

|

|

terminal screws. |

|

|

|

|

Safety devices in |

|

|

accordance with |

|

Power supply |

local and national |

|

|

|

60Hz 208-230V |

|

codes, i.e. a |

|

|

|

|

|

circuit breaker |

|

|

|

|

|

Note: Take care to ensure that all wiring between indoor unit and outdoor unit has a consistent connection. Any splices can cause communication errors.

! CAUTION |

|

RXB09/12*, RKB09/12* |

15A |

|

RXB18/24*, RKB18/24* |

20A |

|

• Entire PCB replacement required if fuse failure occurs. |

|

||

|

|

|

|

• All wires must be firmly connected.

• Make sure all the wire do not touch the refrigerant pipings, compressor or any moving parts.

• Make sure no external pressure is applied to the terminal connectors and wires.

• Make sure all the covers are properly fixed to avoid any gap.

• Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching to the indication on terminal block. (Refer to the wiring diagram attached on the unit).

Attach insulation sleeve

English

Electric wire

Round crimp-style terminal

•Use the correct screwdriver for terminal screws tightening. Unsuitable screwdrivers can damage the screw head.

•Over tightening can damage the terminal screws.

•Do not connect wire of different gauge to same terminal.

•Keep wiring in an orderly manner. Prevent the wiring from obstructing other parts and the terminal box cover.

Connect wires of the |

Do not connect wires of the |

Do not connect wires |

same gauge to both side. |

same gauge to one side. |

of different gauges. |

|

|

|

1-13

ELECTRICAL WIRING CONNECTION

09/12 class

[Method of mounting conduit]

• A protection plate is fixed for protection from the high-voltage section.

1)Dismount the stop valve cover by removing the screw.

2)Dismount the protection plate by removing the 2 screws.

3)Dismount the conduit mounting cover by removing the 2 screws.

4)Pass wires through the conduit and secure them with a lock nut.

5)After completing the work, reattach the stop valve cover, the conduit mounting cover, and the protection plate to its original position.

SIG |

Power supply terminal block

Shape wires so that the proctection plate and conduit mounting plate fit securely.

Conduit mounting plate

SIG |

Protection plate

Screws

Conduit mounting cover

Screws

Lock nut |

Conduit |

18/24 class

[Method of mounting conduit]

1)Dismount the service lid by removing the screws.

2)Pass wires through the conduit and secure them with a lock nut.

3)After completing the work, reattach the service lid to its original position.

Power supply

terminal block

SIG

Shape wires so that the proctection plate and conduit mounting plate fit securely.

Lock nut

Conduit

SIG |

Service lid |

Screws |

Screws

Conduit mounting plate

1-14

SPECIAL PRECAUTIONS WHEN DEALING WITH R410A UNIT

R410A is a new HFC refrigerant which does not damage the ozone layer. The working pressure of this new refrigerant is 1.6 times higher than conventional refrigerant (R22), thus proper installation/servicing is essential.

•Never use refrigerant other than R410Ain an air conditioner which is designed to operate with R410A.

•POE or PVE oil is used as lubricant for R410A compressor, which is different from the mineral oil used for R22 compressor. During installation or servicing, extra precaution must be taken not to expose the R410A system too long to moist air. Residual POE or PVE oil in the piping and components can absorb moisture from the air.

•To prevent mischarging, the diameter of the service port on the flare valve is different from that of R22.

•Use tools and materials exclusively for refrigerant R410A. Tools exclusively for R410A are manifold valve, charging hose, pressure gauge, gas leak detector, flare tools, torque wrench, vacuum pump and refrigerant cylinder.

•As an R410A air conditioner incurs higher pressure than R22 units, it is essential to choose the copper pipes correctly.

•If the refrigerant gas leakage occurs during installation/ servicing, be sure to ventilate fully. If the refrigerant gas comes into contact with fire, a poisonous gas may occur.

•When installing or removing an air conditioner, do not allow air or moisture to remain in the refrigerant cycle.

VACUUMING AND CHARGING

Vacuuming is necessary to eliminate all moisture and air from the system.

Vacuuming The Piping And The Indoor Unit

Except for the outdoor unit which is pre-charged with refrigerant, the indoor unit and the refrigerant connection pipes must be air-purged because the air containing moisture that remains in the refrigerant cycle may cause malfunction of the compressor.

•Remove the caps from the valve and the service port.

•Connect the center of the charging gauge to the vacuum pump.

•Connect the charging gauge to the service port of the 3-way valve.

•Start the vacuum pump. Evacuate for approximately 30 minutes. The evacuation time varies with different vacuum pump capacity. Confirm that the charging gauge needle has moved towards -14.7psi (-760mmHg).

Caution

•If the gauge needle does not move to -14.7psi (-760mmHg), be sure to check for leakage at flare type connection of the indoor and outdoor unit and repair the leak before proceeding to the next step.

•Close the valve of the changing gauge and stop the vacuum pump.

•On the outdoor unit, open the suction valve (3 way) and liquid valve (2 way) (in anti-clockwise direction) with 5/32" (4mm) key for hexagon sacked screw.

Charge Operation

This operation must be done by using a gas cylinder and a precise weighing machine. The additional charge is topped-up into the outdoor unit using the suction valve via the service port.

•Remove the service port cap.

•Connect the low pressure side of the charging gauge to the suction service port center of the cylinder tank and close the high pressure side of the gauge. Purge the air from the service hose.

•Start the air conditioner unit.

•Open the gas cylinder and low pressure charging valve.

•When the required refrigerant quantity is pumped into the unit, close the low pressure side and the gas cylinder valve.

•Disconnect the service hose from service port. Put back the service port cap.

Allen key |

Refrigerant Piping |

Flare nut |

Service Port

Outdoor Unit 3 ways valve

LOW PRESSURE GAUGE |

HIGH PRESSURE GAUGE |

|

-14.7psi (-760mmHg) |

GAUGE MANIFOLD |

|

HANDLE LO |

HANDLE HI (ALWAYS CLOSED) |

|

CHARGE HOSE |

CHARGE HOSE |

|

VACUUM PUMP |

||

|

||

|

ADAPTER FOR |

|

|

COUNTER FLOW |

|

|

PREVENTION |

|

LIQUID VALVE |

CHECK VALVE |

|

|

||

GAS VALVE |

|

|

(3-WAY) |

|

|

|

CONFIGURATION OFAIR |

|

|

PURGE BY CHARGING |

LOW PRESSURE GAUGE |

HIGH PRESSURE GAUGE |

-14.7psi (-760mmHg) |

GAUGE MANIFOLD |

HANDLE LO |

HANDLE HI (ALWAYS CLOSED) |

CHARGE HOSE |

CHARGE HOSE |

|

|

|

CHECK VALVE |

LIQUID VALVE |

|

GAS VALVE |

|

(3-WAY) |

|

|

CONFIGURATION OFAIR |

|

PURGE BY CHARGING |

English

1-15

ADDITIONAL CHARGE

The refrigerant is pre-charged in the outdoor unit. If the piping length is less than 25ft (7.6m), then additional charge after vacuuming is not necessary. If the piping length is more than 25ft (7.6m), then use the additional charge value as indicated in the table.

Additional refrigerant charge [oz (g)] per additional 3.28ft (1m) length as tabulated.

Model |

Indoor |

(FTXB/FTKB) |

09 |

12 |

18 |

24 |

|

Outdoor |

(RXB/RKB) |

09 |

12 |

18 |

24 |

||

|

|||||||

|

|

|

|

|

|

||

Additional charge [oz/ft (g/m)] |

0.21 (20) |

0.21 (20) |

0.21 (20) |

0.21 (20) |

|||

|

|

|

|

|

|

|

|

Example: |

|

|

|

|

|

||

FTXB09 & RXB09 with 39.4ft (12m) piping length, additional piping length is 14.4ft (4.4m). Thus, Additional charge = 14.4ft (4.4m)x 0.21oz/ft [20g/m]

= 3.024oz [88.0g]

INDICATOR LIGHTS

IR Signal Receiver

When an infrared remote control operating signal has been transmitted, the signal receiver on the indoor unit will respond as below to confirm acceptance of the signal transmission.

ON to OFF |

1 Long Beep |

|

|

OFF to ON |

2 Short Beep |

Pump down / Cool force on |

|

|

|

Others |

1 Short Beep |

|

|

Cooling Unit/Heat Pump Unit

The table shows the LED indicator lights for the air conditioner unit under normal operation and fault conditions. The LED indicator lights are located at the side of the air conditioner unit.

The heat pump units are equipped with an “auto” mode sensor whereby it will provide reasonable room temperature by switching automatically to either “cool” or “heat” mode according to the temperature set by the user.

IR Receiver |

LED Indicator Lights for Cooling Unit/Heat Pump Unit

Cool/Heat/Timer

IR Receiver

ON/OFF ON/OFF switch

ON/OFF switch

LED Indicator Lights: Normal Operation And Fault Conditions For Cooling/Heat Pump Unit

Operation

COOL/HEAT/TIMER

(BLUE/RED/VIOLET)

Cool mode

BLUE

Heat mode

RED

Auto mode in Heating operation

RED

Auto mode in Cooling operation

BLUE

Timer on

VIOLET

Fan mode on

BLUE

Dry mode on

BLUE

Defrost operation

RED

Unit error

BLUE

ON |

Blinking |

1-16

OPERATING RANGE

Cooling Only Model |

|

|

|

Model: FTKB 09/12 |

RKB 09/12 |

Model: FTKB 18/24 |

RKB 18/24 |

(°F/°CDB) |

COOLING |

(°F/°CDB) |

COOLING |

||||||

122/50 |

|

|

|

122/50 |

|

|

|

||

|

114.8/46 |

|

|

|

|

|

|

|

|

|

|

|

|

|

114.8/46 |

|

|

|

|

|

109.4/43 |

|

|

|

|

|

|

|

|

|

|

|

|

|

109.4/43 |

|

|

|

|

|

104/40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

104/40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

86/30 |

|

|

|

|

86/30 |

|

|

|

TEMP |

|

|

|

|

TEMP |

|

|

|

|

68/20 |

|

|

|

68/20 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

50/10 |

|

|

|

|

50/10 |

|

|

|

OUTDOOR |

|

|

|

|

OUTDOOR |

|

|

|

|

|

|

|

|

32/0 |

|

|

|

||

|

|

|

|

|

|

14/-10 |

|

|

|

|

32/0 |

57.2/14 |

66.2/19 |

73.4/23 |

|

-4/-20 |

|

|

|

|

|

|

57.2/14 |

66.2/19 |

73.4/23 |

||||

|

50/10 |

59/15 |

68/20 |

77/25 |

|

|

|||

|

|

50/10 |

59/15 |

68/20 |

77/25 |

||||

|

|

|

|

|

|

||||

INDOOR TEMP (°F/°CWB) |

INDOOR TEMP (°F/°CWB) |

DB: Dry bulb |

WB: Wet bulb |

Heat Pump Model |

|

|

|

|

|

|

|

|

|

|

Model: FTXB 09/12 |

|

RXB 09/12 |

|

|

|

|

|

|

||

(°F/°CDB) |

COOLING |

(°F/°CWB) |

|

HEATING |

|

|||||

122/50 |

|

|

|

|

|

|

|

|

||

|

114.8/46 |

|

|

|

|

|

|

|

|

|

|

109.4/43 |

|

|

|

|

|

|

|

|

|

|

104/40 |

|

|

|

|

68/20 |

|

|

|

|

|

|

|

|

|

|

64.4/18 |

|

|

|

|

|

86/30 |

|

|

|

|

|

|

|

|

|

TEMP |

|

|

|

|

TEMP |

50/10 |

|

|

|

|

68/20 |

|

|

|

|

|

|

|

|

||

OUTDOOR |

50/10 |

|

|

|

OUTDOOR |

32/0 |

|

|

|

|

|

|

|

|

14/-10 |

|

|

|

|

||

|

|

|

|

|

|

5/-15 |

|

|

|

|

|

32/0 |

57.2/14 |

66.2/19 |

73.4/23 |

|

-4/-20 |

|

|

80.6/27 |

|

|

|

|

|

|

|

|

||||

|

50/10 |

59/15 |

68/20 |

77/25 |

|

50/10 |

59/15 |

68/20 |

77/25 |

86/30 |

INDOOR TEMP (°F/°CWB) |

INDOOR TEMP (°F/°CDB) |

DB: Dry bulb |

WB: Wet bulb |

Model: FTXB 18/24 |

|

|

RXB 18/24 |

|

|

|

|

|

|

|

(°F/°CDB) |

COOLING |

(°F/°CWB) |

|

HEATING |

|

|||||

122/50 |

|

|

|

|

|

|

|

|

||

|

114.8/46 |

|

|

|

|

|

|

|

|

|

|

109.4/43 |

|

|

|

|

|

|

|

|

|

|

104/40 |

|

|

|

|

68/20 |

|

|

|

|

|

|

|

|

|

|

64.4/18 |

|

|

|

|

TEMP |

86/30 |

|

|

|

TEMP |

|

|

|

|

|

|

|

|

|

50/10 |

|

|

|

|

||

|

68/20 |

|

|

|

|

|

|

|

|

|

|

50/10 |

|

|

|

|

32/0 |

|

|

|

|

OUTDOOR |

|

|

|

|

OUTDOOR |

|

|

|

|

|

32/0 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

14/-10 |

|

|

|

|

|

14/-10 |

|

|

|

|

5/-15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-4/-20 |

57.2/14 |

66.2/19 |

73.4/23 |

|

-4/-20 |

|

|

80.6/27 |

|

|

50/10 |

|

50/10 |

59/15 |

68/20 |

86/30 |

||||

|

59/15 |

68/20 |

77/25 |

|

77/25 |

|||||

INDOOR TEMP (°F/°CWB) |

|

INDOOR TEMP (°F/°CDB) |

||||||||

|

|

|

|

DB: Dry bulb |

WB: Wet bulb |

|

|

|

|

|

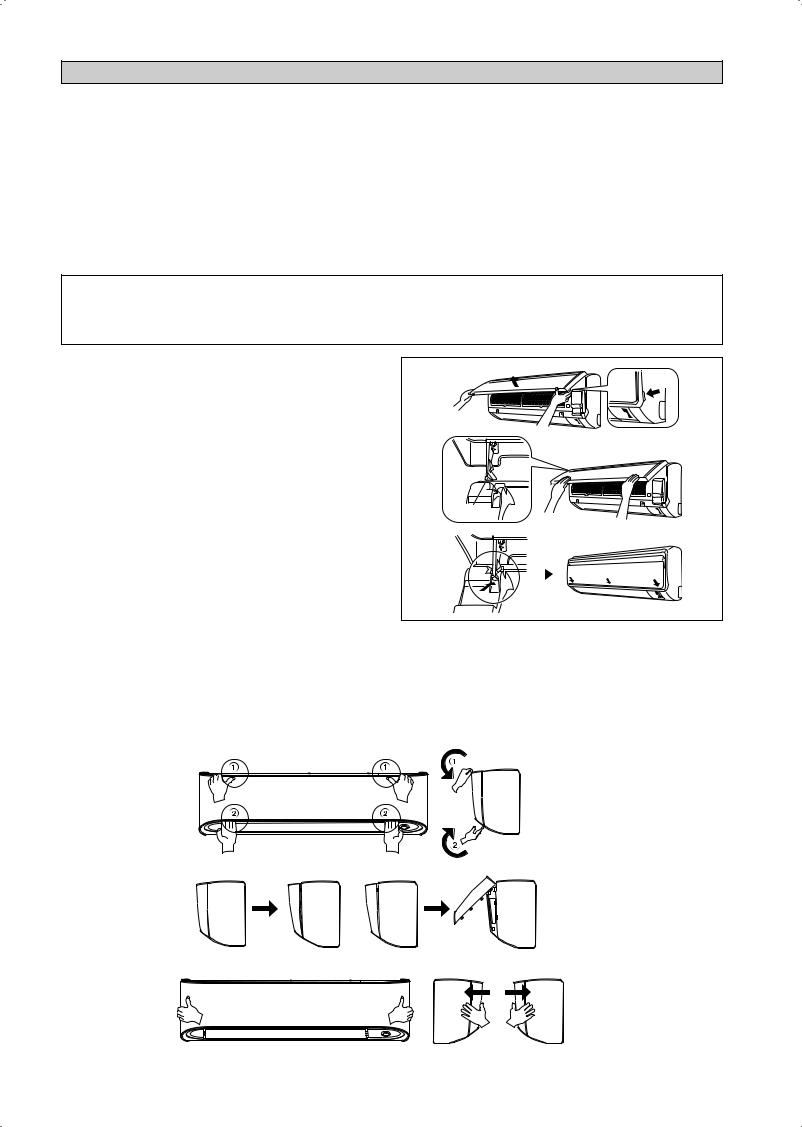

AIR FILTER

1.Open the front panel.

•Hold the panel at the recesses on the main unit (2 recesses on right and left sides) and lift it until it stops.

Recess on main unit

3.Clean or replace each filter.

•When shaking off remaining water, do not wring the filter.

4.Set the air filter and close the front panel.

•Insert claws of the filters into slots of the front panel. Close the front panel slowly and push the panel at the 3 points. (1 on each side and 1 in the middle.)

•The air filter have a symmetrical form in the horizontal direction.

2. Pull out the air filters.

•Push a little upwards the tab at the center of each air filter, then pull it down.

FRONT

English

1-17

SERVICE AND MAINTENANCE

Service Parts |

|

Maintenance Procedures |

Period |

|

|

|

|

Indoor air filter |

1. Remove any dust adhering to the filter by using a vacuum cleaner or wash in lukewarm |

At least once |

|

|

|

water (below 40°C/104°F) with a neutral cleaning detergent. |

every 2 weeks. |

|

2. |

Rinse the filter well and dry before placing it back onto the unit. |

More frequently |

|

3. |

Do not use gasoline, volatile substances or chemicals to clean the filter. |

if necessary. |

|

|

|

|

Indoor unit |

1. Clean any dirt or dust on the grille or panel by wiping it with a soft cloth soaked in |

At least once |

|

|

|

lukewarm water (below 40°C/104°F) and a neutral detergent solution. |

every 2 weeks. |

|

2. |

Do not use gasoline, volatile substances or chemicals to clean the indoor unit. |

More frequently |

|

|

|

if necessary. |

|

|

|

|

!CAUTION

•Avoid direct contact of any coil treatment cleaners on plastic part. This may cause plastic part to deform as a result of chemical reaction.

1.Open the front panel.

•Hold the panel at the recesses on the main unit (2 recesses on right and left sides) and lift it until it stops.

2.Remove the front panel.

•While lifting the front panel further, slide it to the right and pull it to the front side. The left rotating shaft is detached. Slide the right rotating shaft to the left and pull it to the front side to remove it.

3.Attach the front panel.

•Align the right and left rotating shafts of the front panel with the grooves and push them all the way in.

•Gently close the front panel. (Push both ends and the center on the front panel.)

Front Panel Opening & Closing Sequence

Rotating shaft

Recess on main unit

To open the front panel

1)Lift up the two tips of front panel 1 until it stops at the pre-fix position.

2)Lift up the two tips of front panel 2 to open it and access to inner parts.

To close the front panel, reverse the steps of opening sequence. Slot in the ribs (4 ribs at each side, total 8 ribs), carefully at both left and right. Then, press the panel forward till it closes tight. Refer to 3

Step 1 |

Step 2 |

Step 3 |

Step 3 |

1-18

Loading...

Loading...