siemens 828D Parameter Manual

SINUMERIK

SINUMERIK 828D, SINAMICS S120 Parameter description

Parameter Manual

Valid for |

|

SINUMERIK 828D control system |

|

Software |

version |

CNC software |

4.5 |

SINAMICS S120 |

4.5 |

02/2012

6FC5397-8DP40-3BA0

Preface

Explanation of list of |

|

|

1 |

||

parameters |

||

|

|

|

SINAMICS parameters |

2 |

|

|

|

|

Parameters for data sets |

3 |

|

|

|

|

Appendix |

A |

Legal information Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to personswith a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannotbe precludedentirely,wecannotguaranteefullconsistency. However,the informationinthis publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG |

Order number: 6FC5397-8DP40-3BA0 |

Copyright © Siemens AG 2012. |

Industry Sector |

02.2012 Technical data subject to change |

All rights reserved |

Postfach 48 48 |

|

|

90026 NÜRNBERG |

|

|

GERMANY |

|

|

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

•

•

•

General documentation User documentation

Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

•

•

•

Ordering documentation/overview of documentation Additional links to download documents

Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific machine documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

•www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

•www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product Support. http://support.automation.siemens.com

Parameter description |

3 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Preface

SINUMERIK

You can find information on SINUMERIK under the following link: www.siemens.com/sinumerik

Target group

This documentation is intended for project engineers, commissioning engineers, machine operators and service and maintenance personnel.

Benefits

The intended target group can use the Parameter Manual to test and commission the system or the plant professionally and safely.

Utilization phase: Installation and commissioning phase

Standard scope

This documentation only describes the functionality of the standard version. Additions or revisions made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control. This does not, however, represent an obligation to supply such functions with a new control or when servicing.

For the sake of simplicity, this documentation does not contain all detailed information about all types of the product and cannot cover every conceivable case of installation, operation, or maintenance.

Technical Support

You will find telephone numbers for other countries for technical support in the Internet under http://www.siemens.com/automation/service&support

4 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Table of contents

|

Preface......................................................................................................................................................... |

|

3 |

1 |

Explanation of list of parameters ................................................................................................................. |

7 |

|

|

1.1 |

Structure of the parameter descriptions for SINAMICS............................................................... |

7 |

|

1.2 |

Meaning of the parameter descriptions...................................................................................... |

. 8 |

2 |

SINAMICS parameters ............................................................................................................................. |

19 |

|

3 |

Parameters for data sets ......................................................................................................................... |

853 |

|

|

3.1 |

Parameters for drive data sets (DDS) ..................................................................................... |

853 |

|

3.2 |

What parameters are dependent on encoder data sets (EDS) ............................................... |

857 |

|

3.3 |

Parameters for motor data sets (MDS).................................................................................... |

859 |

A |

Appendix |

................................................................................................................................................. |

863 |

|

A.1 |

List of abbreviations................................................................................................................. |

863 |

|

A.2 |

Documentation overview......................................................................................................... |

869 |

Parameter description |

5 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Table of contents

6 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters |

1 |

|

1.1Structure of the parameter descriptions for SINAMICS

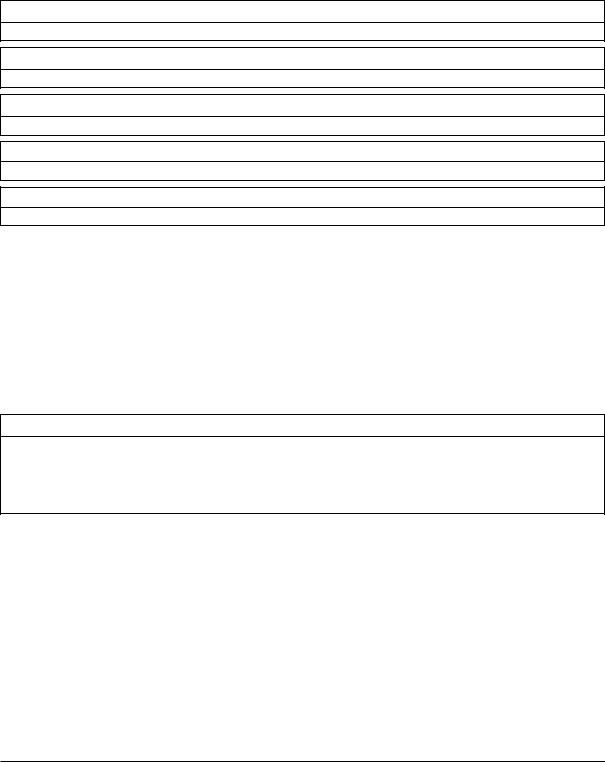

Basic structure of the parameter descriptions

The data in the following example has been chosen at random. The description of a parameter includes as a maximum, the information listed below. Some of the information is optional.

Example

The parameter list (see SINAMICS parameters (Page 19)) has the following structure:

--------------------------------------------- Start of the example --------------------------------------------------

---------------- |

|

|

|

Parameter |

BICO: Full parameter name / abbreviated name |

|

|

number |

|

|

|

pxxxx[0…n] |

|

|

|

Drive object |

Can be changed |

Calculated: - |

Access level: 2 |

(function module) |

into: C1(x) |

|

|

|

Data type: |

Dynamic index: EDS, |

|

|

Unsigned32 |

p140 |

|

|

P group: |

Unit group: - |

Unit selection: p0100 |

|

Not for motor type: |

Scaling: p0200 |

Expert list: 1 |

|

FEM |

|

|

|

Min. |

Max |

Factory setting |

|

0.00 [Nm] |

10.00. [Nm] |

0.00 [Arms] |

Description: |

Text |

|

|

Value: |

0: Name and meaning of value 0 |

|

|

|

1: Name and meaning of value 1 |

|

|

|

2: Name and meaning of value 2 |

|

|

|

etc. |

|

|

Recommendation: |

Text |

|

|

Index: |

[0] = Name and meaning of bit 0 |

|

|

|

[1] = Name and meaning of bit 1 |

|

|

[2] = Name and meaning of bit 2 etc.

Parameter description |

7 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

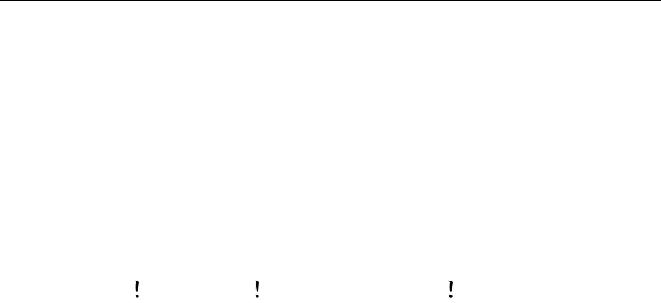

Bit array: |

Bit signal name |

1 signal |

0 signal |

FP |

|

[00] = Name and meaning of |

Yes |

No |

|

|

bit 0 |

Yes |

No |

|

|

[01] = Name and meaning of |

Yes |

No |

|

|

bit 1 |

|

|

|

|

[02] = Name and meaning of |

|

|

|

|

bit 2 |

|

|

|

|

etc. |

|

|

|

Dependency: |

Text |

|

|

|

|

See also: pxxxx,rxxxx |

|

|

|

|

See also: Fxxxxx, Axxxxx |

|

|

|

Danger: |

Warning: |

Caution: |

Safety-related text with |

|

|

|

|

warning triangle |

|

Caution: |

Notice: |

|

Safety-related text |

|

|

|

|

without warning triangle |

|

Note: |

Information which might be useful. |

|

|

|

------------------------------------------------------------ |

End of the example |

--------------------------------------------------- |

|

|

|

|

|

|

|

1.2Meaning of the parameter descriptions

Parameter number

The parameter number consists of a leading "p" or "r", followed by the parameter number and the index (optional).

Examples of the representation in the parameter list:

•

•

•

•

•

•

p...

Adjustable parameter (read and write parameter) r...

Display parameters (read only) p0918

Adjustable parameter 918 p0099[0...3]

Adjustable parameter 99, indices 0 to 3 p1001[0...n]

Adjustable parameter 1001, indices 0 to n (n = configurable) r0944

Display parameter 944

8 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Other examples of the notation used in the documentation:

•p1070[1]

Adjustable parameter 1070, index 1

•p2098[1].3

Adjustable parameter 2098, index 1 bit 3

•r0945[2](3)

Display parameter 945, index 2 of drive object 3

•

•

p0795.4

Adjustable parameter 795, bit 4 r2129.0...15

Display parameter 2129 with bit array (maximum 16 bit)

The following applies to adjustable parameters:

The parameter value "when shipped" is specified under "Factory setting" with the relevant unit in square parentheses. The value can be adjusted within the range defined by "Min" and "Max".

The term "linked parameterization" is used in cases where changes to adjustable parameters affect the settings of other parameters.

Linked parameterization is initiated, for example, as a result of the following actions and parameters:

•

•

•

•

•

Executing macros

p0015, p0700, p1000, p1500

Setting a PROFIBUS telegram (BICO interconnections) p0922

Setting component lists p0230, p0300, p0301, p0400

Automatically calculating and preassigning p0112, p0340, p0578, p3900

Restore factory settings p0970

The following applies to display parameters:

The fields "Min", "Max" and "Factory setting" are specified with a dash "-" and the relevant unit in square parentheses.

Note

The parameter list can contain parameters that are not visible in the expert lists of the respective commissioning software (e.g. parameters for trace functions)

Parameter description |

9 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

BICO: Full parameter name / abbreviated name

The following abbreviations can appear in front of the parameter name:

•BI: Binector Input Binector Input

This parameter selects the source of a digital signal.

•BO: Binector Output Binector Output

This parameter is available as a digital signal for interconnection with other parameters.

•CI: Connector Input Connector Input

This parameter selects the source of an "analog" signal.

•CO: Connector Output Connector Output

This parameter is available as an "analog" signal for interconnection with other parameters.

•CO/BO: Connector/Binector Output Connector/Binector Output

This parameter is available as both an "analog" and a digital signal for interconnection with other parameters.

Note

A Connector Input (CI) cannot be interconnected with just any Connector Output (CO, signal source).

When interconnecting a connector input using the commissioning software, only the signal sources that are actually possible are listed.

Drive object (function module)

A drive object (DO) is an independent, "self-contained" functional unit with its own parameters, faults messages, and alarms.

For each parameter, it is specified in which drive object this parameter is located and for which function module.

A parameter can belong to a single, multiple, or all drive objects.

The following information relating to "Drive object" and "Function module" can be displayed under the parameter number:

Drive object (function module) |

Type |

Meaning |

|

A_INF_828 |

|

103 |

Active Infeed closed-loop control |

|

|

|

Closed-loop controlled, self-commutated infeed/regenerative feedback |

|

|

|

unit for generating |

|

|

|

a constant DC-link voltage. |

A_INF_828 (line transformer) |

|

Active Infeed closed-loop control with "line transformer" function module |

|

A_INF_828 (Brk Mod Ext) |

|

Active Infeed closed-loop control with "Brk Mod Ext?" function module |

|

A_INF_828 |

(Master/Slave) |

|

Active Infeed closed-loop control with "Master/Slave" function module |

A_INF_828 |

(Parallel) |

|

Active Infeed closed-loop control with "Parallel?" function module |

A_INF_828 |

(Recooling unit) |

|

Active Infeed closed-loop control with "Cooling unit" function module |

10 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

|

|

Explanation of list of parameters |

|

|

1.2 Meaning of the parameter descriptions |

|

|

|

Drive object (function module) |

Type |

Meaning |

B_INF_828 |

103 |

Basic Infeed closed loop control |

|

|

Uncontrolled infeed unit (without energy recovery) to |

|

|

rectify the line voltage for the DC link. |

B_INF_828 (Brk Mod Ext) |

|

Basic Infeed closed-loop control with "Brk Mod Ext?" function module |

B_INF_828 (Parallel) |

|

Basic Infeed closed-loop control with "Parallel?" function module |

|

|

Basic Infeed closed-loop control with "Cooling unit" function module |

CU_I_COMBI |

102 |

Control Unit SINAMICS Integrated Combi |

CU_I_828 |

103 |

Control Unit SINAMICS Integrated Booksize |

CU_LINK |

254 |

Object for Controller Extension 32 (CX32) |

CU_NX_828 |

103 |

|

HUB |

150 |

DMC20 DRIVE-CLiQ Hub Module |

SERVO_COMBI |

102 |

Servo drive |

|

|

|

SERVO_COMBI (Safety rot) |

|

Servo drive with "Safety rot?" function module |

SERVO_828 |

103 |

Servo drive |

SERVO_828 (Safety rot) |

|

Servo drive with "Safety rot?" function module |

SI_INF_COMBI |

102 |

|

SI_INF_COMBI (Brk Mod Ext) |

|

|

S_INF_828 (Parallel) |

|

|

S_INF_828 |

103 |

|

S_INF_828 (Brk Mod Ext) |

|

|

S_INF_828 (Recooling unit) |

|

|

TM120 |

207 |

Terminal Module 120 |

TM54F_MA |

205 |

Terminal Module 54F Master |

TM54F_SL |

206 |

Terminal Module 54F Slave |

Can be changed

A "-" character indicates that the parameter can be changed in any object state and that the change will become effective immediately.

The information "C1(x), C2(x), T, U" ((x): optional) means that the parameter can be changed only in the specified drive object state and that the change will not take effect until the object switches to another state. This can be one or more states.

Parameter description |

11 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

The following states may be specified:

• C1(x) Device commissioning C1: Commissioning 1

The device is being commissioned (p0009 > 0). Pulses cannot be enabled.

The parameter can only be changed when the device commissioning settings (p0009 > 0) are as follows:

•C1: Can be changed for all settings p0009 > 0.

•C1(x): Can only be changed when the settings are p0009 = x.

A modified parameter value does not take effect until the device commissioning mode is exited with p0009 = 0.

• C2(x) Drive object commissioning C2: Commissioning 2

The drive is being commissioned (p0009 = 0 and p0010 > 0). Pulses cannot be enabled.

The parameter can only be changed when the drive commissioning settings (p0010 > 0) are as follows:

•C2: Can be changed for all settings p0010 > 0.

•C2(x): Can only be changed when p0010 = x.

A modified parameter value does not take effect until the device commissioning mode is exited with p0010 = 0.

• |

U |

Run |

U: Run |

|

|

Pulses are enabled. |

|

• |

T |

Ready to run |

T: Ready to run |

The pulses are not enabled and the status "C1(x)" or "C2(x)" is not active.

Note

Parameter p0009 is CU specific (belongs to Control Unit).

Parameter p0010 is drive specific (belongs to each drive object).

The operating state of individual drive objects is displayed in r0002.

Calculated

Specifies whether the parameter is influenced by automatic calculations. The calculation attribute defines which activities influence the parameter. The following attributes apply:

•CALC_MOD_ALL

–p0340 = 1

–Project download with commissioning software and send from p0340 = 3

•CALC_MOD_CON

–p0340 = 4

•CALC_MOD_EQU

–p0340 = 2

12 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

•CALC_MOD_LIM_REF

–p0340 = 1, 3, 5

–p0578 = 1

•CALC_MOD_REG

–p0340 = 1, 3

Note

For p3900 > 0, p0340 = 1 is also called automatically.

After p1910 = 1, p0340 = 3 is automatically called.

Access level

Specifies the access level required so that the parameter can be displayed and/or modified. The required access level can be set via parameter p0003.

The system uses the following access levels:

1 = Standard

2 = Extended

3 = Expert

4 = Service

Please contact your local Siemens office for the password for parameters with access

level 4 (Service).

Note

Parameter p0003 is CU-specific (available on the Control Unit).

Data types

The information on the data type can consist of the following two items (separated by a slash):

•First item

Data type of the parameter

•Second item (for binector or connector input only)

Data type of the signal source to be interconnected (binector/connector output)

Parameters can have the following data types:

Data type (abbreviated name) |

Data type (full name) |

Meaning |

I8 |

Integer8 |

8-bit integer number |

I16 |

Integer16 |

16-bit integer number |

I32 |

Integer32 |

32-bit integer number |

Parameter description |

13 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Data type (abbreviated name) |

Data type (full name) |

Meaning |

U8 |

Unsignet8 |

8 bits without sign |

U16 |

Unsignet16 |

16 bits without sign |

U32 |

Unsigned32 |

32 bits without sign |

Float |

FloatingPoint32 |

32-bit floating point number |

Dynamic index

For parameters with a dynamic index [0 to n], the following information is specified here:

•Data set (if this is available).

•Parameter for the number of indices (n = number - 1). The following information can be contained in this field:

•"CDS, p0170" (Command Data Set, CDS count) Example:

p1070[0] -> main setpoint [command data set 0] p1070[1] -> main setpoint [command data set 1], etc.

•"DDS, p0180" (Drive Data Set, DDS count)

•"EDS, p0140" (Encoder Data Set, EDS count)

•"MDS, p0130" (Motor Data Set, MDS count)

•"PDS, p0120" (Power unit Data Set, PDS count)

•"p2615" (traversing blocks count)

Note

Information on the data sets can be taken from the following references: /FH1/ SINAMICS S120 Function Manual Drive Functions Chapter "Data Sets"

P group (only when accessing via BOP (Basic Operator Panel))

Specifies the functional group to which the parameter belongs. The required parameter group can be set via p0004.

Unit, unit group and unit selection

The standard unit of a parameter is specified in square parentheses after the values for "Min", "Max", and "Factory setting".

For parameters where the unit can be changed, "Unit Group" and "Unit Selection" specify which group this parameter belongs and which parameter can be used to change the unit.

Example:

Unit group: 7_1, Unit selection: p0505

14 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

The parameter belongs to Unit Group 7_1 and the unit can be changed using p0505.

Note

Detailed information on changing units can be found in the following references: /FH1/SINAMICS S120 Function Manual

/BA3/SINAMICS S150 Operating Instructions

Parameter values

•Min.

Minimum value of the parameter [unit]

•Max

Maximum value of the parameter [unit]

•Factory setting

Value when delivered [unit]

When commissioned for the first time, it is possible that another value is visible for certain parameters (e.g.p1800).

Reason:

The setting of these parameters is determined by the operating environment of the Control Unit (e.g.depending on the device type, macro, Power Module).

Not for motor type

Specifies for which motor type this parameter has no significance ASM: Asynchronous motor (induction motor)

FEM: Separately excited synchronous motor PEM: Permanent-magnet synchronous motor REL: Reluctance motor/SIEMOSYN motor

Scaling

Specification of the reference variable with which a signal value is automatically converted for a BICO interconnection.

The following reference variables are possible:

•p2000 ... p2007: Reference speed, reference voltage, etc.

•TEMP: 100 °C = 100 %

•PERCENT: 1.0 = 100 %

•4000H: 4000 hex = 100 %

Parameter description |

15 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Expert list

Specifies whether this parameter is available in the expert list of the specified drive objects in the commissioning software.

•

•

1: Parameter does exist in the expert list. 0: Parameter does not exist in the expert list.

NOTICE

Users assume full responsibility for using parameters marked "Expert list: 0" (parameter does not exist in the expert list).

These parameters and their functionalities have not been tested and no further user documentation is available for them (e.g. description of functions).

Further, for these parameters, support through "Technical Support" (hotline) is no longer guaranteed.

Description

Explanation of the function of a parameter.

Values

Lists the possible values of a parameter.

Recommendation

Information about recommended settings.

Index

The name and meaning of each individual index are specified for indexed parameters.

The following applies to the values (Min, Max, Factory setting) of indexed adjustable parameters:

•Min, Max:

The adjustment range and unit apply to all indices.

•Factory setting:

When all indices have the same factory setting, index 0 is specified with the unit to represent all indices.

When the indices have different factory settings, they are all listed individually with the unit.

16 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

Bit array

For parameters with bit arrays, the following information is provided about each bit:

•Bit number and signal name

•Meaning with signal states 0 and 1

Dependency

Conditions that must be fulfilled in conjunction with this parameter.

Also includes special effects that can occur between this parameter and others. See also: List of other additional parameters to be considered.

Parameter description |

17 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Explanation of list of parameters

1.2 Meaning of the parameter descriptions

18 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters |

2 |

|

Product: 828D COMBI, Version: 4502400, Language: eng

Objects: A_INF_828, B_INF_828, CU_I_828, CU_I_COMBI, CU_LINK, CU_NX_828, HUB, S_INF_828, S_INF_COMBI, SERVO_828, SERVO_COMBI, TM120, TM150, TM54F_MA, TM54F_SL

r0002

A_INF_828, S_INF_828, S_INF_COMBI

Description:

Value:

Infeed operating display / INF op_display

Can be changed: - |

Calculated: - |

Access level: 1 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

250 |

- |

Operating display for the infeed.

0:Operation - everything enabled

21:Ready for operation - set "Operation enable" = "1" (p0852)

31:Rdy for sw on - pre-chrg running (p0857)

32:Ready for switching on - set "ON/OFF1" = "0/1" (p0840)

35:Switching on inhibited - carry out first commissioning (p0010)

41:Switching on inhibited - set "ON/OFF1" = "0" (p0840)

42:Switching on inhibited - set "OC/OFF2" = "1" (p0844, p0845)

44:Switching on inhibited - connect 24 V to terminal EP (hardware)

45:Switching on inhibited - remove fault cause, acknowledge fault

46:Switching on inhibited - exit comm mode (p0009, p0010)

60:Infeed de-activated/not operational

70:Initialization

200:Wait for booting/partial booting

250:Device signals a topology error

Dependency: |

Refer to: r0046 |

Notice: |

For several missing enable signals, the corresponding value with the highest number is displayed. |

Note: |

OC: Operating condition |

|

EP: Enable Pulses (pulse enable) |

|

COMM: Commissioning |

r0002 |

Infeed operating display / INF op_display |

|

||

B_INF_828 |

Can be changed: - |

Calculated: - |

Access level: 1 |

|

|

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

|

|

P-Group: - |

Units group: - |

Unit selection: - |

|

|

Not for motor type: - |

Scaling: - |

Expert list: 1 |

|

|

Min |

|

Max |

Factory setting |

|

0 |

|

250 |

- |

Description: |

Operating display for the infeed. |

|

|

|

Value: |

0: |

Operation - everything enabled |

|

|

|

31: |

Rdy for sw on - pre-chrg running (p0857) |

|

|

|

32: |

Ready for switching on - set "ON/OFF1" = "0/1" (p0840) |

|

|

|

35: |

Switching on inhibited - carry out first commissioning (p0010) |

|

|

|

41: |

Switching on inhibited - set "ON/OFF1" = "0" (p0840) |

|

|

|

42: |

Switching on inhibited - set "OC/OFF2" = "1" (p0844, p0845) |

|

|

|

44: |

Switching on inhibited - connect 24 V to terminal EP (hardware) |

|

|

Parameter description |

19 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

45:Switching on inhibited - remove fault cause, acknowledge fault

46:Switching on inhibited - exit comm mode (p0009, p0010)

60:Infeed de-activated/not operational

70:Initialization

200:Wait for booting/partial booting

250:Device signals a topology error

Dependency: |

Refer to: r0046 |

Notice: |

For several missing enable signals, the corresponding value with the highest number is displayed. |

Note: |

OC: Operating condition |

|

COMM: Commissioning |

r0002

CU_I_828, CU_I_COMBI, CU_NX_828

Description:

Value:

Control Unit operating display / CU op_display

Can be changed: - |

Calculated: - |

Access level: 1 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

117 |

- |

Operating display for the Control Unit (CU).

0:Operation

10:Ready

20:Wait for run-up

25:Wait for automatic FW update of DRIVE-CLiQ components

31:Commissioning software download active

33:Remove/acknowledge topology error

34:Exit commissioning mode

35:Carry out first commissioning

70:Initialization

80:Reset active

99:Internal software error

101:Specify topology

111:Insert drive object

112:Delete drive object

113:Change drive object number

114:Change component number

115:Run parameter download

117:Delete component

Notice: For several missing enable signals, the corresponding value with the highest number is displayed.

r0002 |

DRIVE-CLiQ Hub Module operating display / Hub op_display |

|

||

HUB |

Can be changed: - |

Calculated: - |

Access level: 1 |

|

|

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

|

|

P-Group: - |

Units group: - |

Unit selection: - |

|

|

Not for motor type: - |

Scaling: - |

Expert list: 1 |

|

|

Min |

|

Max |

Factory setting |

|

0 |

|

250 |

- |

Description: |

Operating display for the DRIVE-CLiQ Hub Module. |

|

||

Value: |

0: |

Module in cyclic operation |

|

|

|

40: |

Module not in cyclic operation |

|

|

|

50: |

Alarm |

|

|

|

60: |

Fault |

|

|

|

70: |

Initialization |

|

|

|

120: |

Module de-activated |

|

|

|

200: |

Wait for booting/partial booting |

|

|

|

250: |

Device signals a topology error |

|

|

Notice: |

For several missing enable signals, the corresponding value with the highest number is displayed. |

|||

20 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

r0002 |

Drive operating display / Drv op_display |

||

SERVO_828, |

Can be changed: - |

Calculated: - |

|

SERVO_COMBI |

Data type: Integer16 |

Dynamic index: - |

|

|

|||

|

P-Group: - |

Units group: - |

|

|

Not for motor type: - |

Scaling: - |

|

|

Min |

|

Max |

|

0 |

|

250 |

Description: |

Operating display for the drive. |

|

|

Value: |

0: |

Operation - everything enabled |

|

10:Operation - set "enable setpoint" = "1" (p1142, p1152)

11:Operation - set "enable speed controller" = "1" (p0856)

12:Operation - RFG frozen, set "RFG start" = "1" (p1141)

13:Operation - set "enable RFG" = "1" (p1140)

14:Oper. - MotID, excit. running and/or brake opens, SS2, SOS

15:Operation - open brake (p1215)

16:Operation - withdraw braking with OFF1 using "ON/OFF1" = "1"

17:Operation - braking with OFF3 can only be interrupted with OFF2

18:Operation - brake on fault, remove fault, acknowledge

19:Operation - armature short-circ./DC brake act. (p1230, p1231)

21:Ready for operation - set "Operation enable" = "1" (p0852)

22:Ready for operation - de-magnetizing running (p0347)

23:Ready for operation - set "Infeed operation" = "1" (p0864)

31:Ready for switching on - set "ON/OFF1" = "0/1" (p0840)

35:Switching on inhibited - carry out first commissioning (p0010)

41:Switching on inhibited - set "ON/OFF1" = "0" (p0840)

42:Switching on inhibited - set "OC/OFF2" = "1" (p0844, p0845)

43:Switching on inhibited - set "OC/OFF3" = "1" (p0848, p0849)

44:Switching on inhibited - connect 24 V to terminal EP (hardware)

45:Switching on inhibited - rectify fault, acknowledge fault, STO

46:Switching on inhibited - exit comm mode (p0009, p0010)

60:Drive object de-activated/not operational

70:Initialization

200:Wait for booting/partial booting

250:Device signals a topology error

Access level: 1 Func. diagram: - Unit selection: - Expert list: 1

Factory setting

-

Dependency: |

Refer to: r0046 |

Notice: |

For several missing enable signals, the corresponding value with the highest number is displayed. |

Note: |

OC: Operating condition |

|

EP: Enable Pulses (pulse enable) |

|

RFG: Ramp-function generator |

|

COMM: Commissioning |

|

MotID: Motor data identification |

|

SS2: Safe Stop 2 |

|

SOS: Safe Operating Stop |

|

STO: Safe Torque Off |

r0002 |

TM120 operating display / TM120 op_display |

|

|

TM120 |

Can be changed: - |

Calculated: - |

Access level: 1 |

|

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

|

P-Group: - |

Units group: - |

Unit selection: - |

|

Not for motor type: - |

Scaling: - |

Expert list: 1 |

|

Min |

Max |

Factory setting |

|

0 |

250 |

- |

Description: |

Operating display for Terminal Module 120 (TM120) |

|

|

Parameter description |

21 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

Value: |

0: |

Module in cyclic operation |

|

40: |

Module not in cyclic operation |

|

50: |

Alarm |

|

60: |

Fault |

|

70: |

Initialization |

|

120: |

Module de-activated |

|

200: |

Wait for booting/partial booting |

|

250: |

Device signals a topology error |

Notice: |

For several missing enable signals, the corresponding value with the highest number is displayed. |

|

r0002 |

TM150 operating display / TM150 op_display |

|

||

TM150 |

Can be changed: - |

Calculated: - |

Access level: 1 |

|

|

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

|

|

P-Group: - |

Units group: - |

Unit selection: - |

|

|

Not for motor type: - |

Scaling: - |

Expert list: 1 |

|

|

Min |

|

Max |

Factory setting |

|

0 |

|

250 |

- |

Description: |

Operating display for Terminal Module 150 (TM150) |

|

||

Value: |

0: |

Module in cyclic operation |

|

|

|

40: |

Module not in cyclic operation |

|

|

|

50: |

Alarm |

|

|

|

60: |

Fault |

|

|

|

70: |

Initialization |

|

|

|

120: |

Module de-activated |

|

|

|

200: |

Wait for booting/partial booting |

|

|

|

250: |

Device signals a topology error |

|

|

Notice: |

For several missing enable signals, the corresponding value with the highest number is displayed. |

|||

r0002

TM54F_MA, TM54F_SL

TM54F operating display / TM54F op_display

Can be changed: - |

Calculated: - |

Access level: 1 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

250 |

- |

Description: |

Operating display for Terminal Module 54F (TM54F). |

|

Value: |

0: |

Module in cyclic operation |

|

40: |

Module not in cyclic operation |

|

50: |

Alarm |

|

60: |

Fault |

|

70: |

Initialization |

|

120: |

Module de-activated |

|

200: |

Wait for booting/partial booting |

|

250: |

Device signals a topology error |

p0003

CU_I_828, CU_I_COMBI, CU_NX_828

Description:

BOP access level / BOP acc_level

Can be changed: C1, U, T |

Calculated: - |

Access level: 1 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 0 |

Min |

Max |

Factory setting |

1 |

4 |

1 |

Sets the access level for reading and writing parameters via the Basic Operator Panel (BOP).

22 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

Value: |

1: |

Standard |

|

2: |

Extended |

|

3: |

Expert |

|

4: |

Service |

Note: |

Access level 1 (standard): |

|

|

Parameters for simplest possible operations. |

|

|

Access level 2 (extended): |

|

|

Parameters to operate the basic functions of the drive unit. |

|

|

Access level 3 (experts): |

|

|

Expert know-how is required for these parameters (e.g. BICO parameterization). |

|

|

Access level 4 (service): |

|

|

For these parameters, it is necessary that authorized service personnel enter the appropriate password (p3950). |

|

p0005[0...1]

HUB, TM120, TM150, TM54F_MA, TM54F_SL

BOP operating display selection / BOP op_disp sel

Can be changed: U, T |

Calculated: - |

Access level: 2 |

Data type: Unsigned16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

65535 |

[0] 2 |

|

|

[1] 0 |

Description: |

Sets the parameter number and parameter index for display for p0006 = 2, 4 for the Basic Operator Panel (BOP). |

|

Examples for the SERVO drive object: |

|

p0005[0] = 21, p0005[1] = 0: Actual speed smoothed (r0021) |

|

p0005[0] = 25, p0005[1] = 0: Output voltage smoothed (r0025) |

Index: |

[0] = Parameter number |

|

[1] = Parameter index |

Dependency: |

Refer to: p0006 |

Note: |

Procedure: |

|

1. |

|

The parameter number to be displayed should be set in index 0. Only the monitoring parameters (read-only parame- |

|

ters) can be set that actually exist for the actual drive object. |

|

If the set parameter number is not indexed, or if there is an index in index 1 that lies outside the valid range of the set |

|

parameter, then index 1 is automatically set to 0. |

|

2. |

|

The index that belongs to the parameter set in index 0 should be set in index 1. The permissible changes in index 1 |

|

always depend on the parameter number set in index 0. |

p0006

HUB, TM120, TM150, TM54F_MA, TM54F_SL

BOP operating display mode / BOP op_ disp mode

Can be changed: U, T |

Calculated: - |

Access level: 3 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

4 |

4 |

4 |

Description: |

Sets the mode of the operating display for the Basic Operator Panel (BOP) in the operating states "ready for operation" |

|

|

and "operation". |

|

Value: |

4: |

p0005 |

Dependency: |

Refer to: p0005 |

|

Note: |

Mode 0 ... 3 can only be selected if also r0020, r0021 are available on the drive object. |

|

|

Mode 4 is available for all drive objects. |

|

Parameter description |

23 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

p0009

CU_I_828, CU_I_COMBI, CU_NX_828

Description:

Value:

Notice:

Note:

Device commissioning parameter filter / Dev comm par_filt

Can be changed: C1, T |

Calculated: - |

Access level: 1 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

10000 |

1 |

Sets the device and basic drive commissioning.

By appropriately setting this parameter, those parameters are filtered that can be written into in the various commissioning steps.

0:Ready

1:Device configuration

2:Defining the drive type/function module

3:Drive base configuration

4:Data set base configuration

29:Device download

30:Parameter reset

50:OA application configuration

55:OA application installation

101:Topology input

111:Insert drive object

112:Delete drive object

113:Change drive object number

114:Change component number

115:Parameter download

117: Delete component 10000: Ready (asynchron)

For p0009 = 10000 the following applies:

After the value has been modified, no further parameter modifications can be made and the status is shown in r3996. Modifications can be made again when r3996 = 0.

The drives can only be powered up outside the device commissioning (the inverter enabled). In this case, p0009 must be 0 (Ready) and the individual drive objects must have already gone into operation (p0010).

p0009 = 1: Device configuration

At the first commissioning of the device, after booting, the device is in the "device configuration" state. To start the internal automatic first commissioning of the drive unit, p0009 should be set to 0 (Ready) after the ID for the actual topology (r0098) was transferred into the ID for the target topology (p0099). To do this, it is sufficient to set a single index value of p0099[x] the same as r0098[x]. Before the device has been completely commissioned, no other parameter can be changed. After the first commissioning was carried out, in this state, when required, other basic device configuration parameters can be adapted (e.g. the basic sampling time in p0110).

p0009 = 2: Defines the drive type / function module

In this state, the drive object types and/or the function modules can be changed or selected for the individual drive objects. To do this, the drive object type can be set using p0107[0...15] and the function can be set using p0108[0...15] (refer to p0101[0...15]).

p0009 = 3: Drive basic configuration

In this state, after the device has been commissioned for the first time, basic changes can be made for the individual drive objects (e.g. sampling times in p0111, p0112, p0115 and the number of data sets in p0120, p0130, p0140, p0170, p0180).

p0009 = 4: Data set basic configuration

In this state, after the device has been commissioned for the first time, for the individual drive objects changes can be made regarding the assignment of the components (p0121, p0131, p0141, p0151, p0161) to the individual data sets and the assignment of the power unit, motor and encoder to the drive data sets (p0185, ...).

p0009 = 29: Device download

If a download is made using the commissioning software, the device is automatically brought into this state. After the download has been completed, p0009 is automatically set to 0 (ready). It is not possible to manually set p0009 to this value.

24 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

p0009 = 30: Parameter reset

In order to bring the complete unit into the "first commissioning" state or to load the parameters saved using p0977, to start, p0009 must be set to this value. p0976 can then be changed to the required value.

p0009 = 50: OA application configuration

In this state, after the device has been commissioned for the first time, changes can be made for the individual drive objects regarding the activity (p4956) of the OA applications.

p0009 = 55: OA application installation

OA applications can be installed and/or uninstalled in this state. p0009 = 101: Topology input

In this state, the DRIVE-CLiQ target topology can be entered using p9902 and p9903. p0009 = 111: Insert drive object

This state allows a new drive object to be inserted using p9911. p0009 = 112: Delete drive object

This state allows existing drive objects to be deleted using p9912 after the device has been commissioned for the first time.

p0009 = 113: Change drive object number

This state allows the drive object number of existing drive objects to be changed using p9913 after the device has been commissioned for the first time.

p0009 = 114: Change component number

This state allows the component number of existing components to be changed using p9914 after the device has been commissioned for the first time.

p0009 = 115: Parameter download

This state allows the complete device and drive commissioning using the parameter services. p0009 = 117: Delete component

This state allows components to be deleted using p9917 after the device has been commissioned for the first time.

p0010

A_INF_828, B_INF_828, S_INF_828, S_INF_COMBI

Description:

Value:

Note:

Infeed commissioning parameter filter / INF comm par_filt

Can be changed: C2(1), T |

Calculated: - |

Access level: 1 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

30 |

1 |

Sets the parameter filter to commission an infeed unit.

Setting this parameter filters out the parameters that can be written into in the various commissioning steps.

0:Ready

1:Quick commissioning

2:Power unit commissioning

5:Technological application/units

29:Only Siemens int

30:Parameter reset

The drive can only be powered up outside the drive commissioning (inverter enable). To realize this, this parameter must be set to 0.

For p3900 not equal to 0, at the end of the quick commissioning, this parameter is automatically reset to 0. Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1.

Parameter description |

25 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

p0010

SERVO_828, SERVO_COMBI

Drive commissioning parameter filter / Drv comm. par_filt

Can be changed: C2(1), T |

Calculated: - |

Access level: 1 |

Data type: Integer16 |

Dynamic index: - |

Func. diagram: 2800, 2846 |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

10000 |

1 |

Description: |

Sets the parameter filter to commission a drive. |

|

|

Setting this parameter filters out the parameters that can be written into in the various commissioning steps. |

|

Value: |

0: |

Ready |

|

1: |

Quick commissioning |

|

2: |

Power unit commissioning |

|

3: |

Motor commissioning |

|

4: |

Encoder commissioning |

|

5: |

Technological application/units |

|

15: |

Data sets |

|

17: |

Basic positioner commissioning |

|

25: |

Position control commissioning |

|

29: |

Only Siemens int |

|

30: |

Parameter reset |

|

95: |

Safety Integrated commissioning |

|

10000: Ready with immediate feedback signal |

|

Notice: |

For p0010 = 10000 the following applies: |

|

|

After the value has been modified, no further parameter modifications can be made and the status is shown in r3996. |

|

|

Modifications can be made again when r3996 = 0. |

|

Note: |

The drive can only be powered up outside the drive commissioning (inverter enable). To realize this, this parameter |

|

|

must be set to 0. |

|

|

By setting p3900 to a value other than 0, the quick commissioning is completed, and this parameter is automatically |

|

|

reset to 0. |

|

|

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1. |

|

|

p0010 = 10000 corresponds to p0010 = 0. Unlike with p0010 = 0, the parameter modification is applied immediately |

|

|

and the calculations are made in the background. Further parameter modifications cannot be made while the calcula- |

|

|

tions are being performed. |

|

p0010 |

TM120 commissioning parameter filter / TM120 com par_filt |

|

||

TM120 |

Can be changed: C2(1), T |

Calculated: - |

Access level: 1 |

|

|

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

|

|

P-Group: - |

Units group: - |

Unit selection: - |

|

|

Not for motor type: - |

Scaling: - |

Expert list: 1 |

|

|

Min |

|

Max |

Factory setting |

|

0 |

|

30 |

0 |

Description: |

Sets the parameter filter for commissioning a Terminal Module 120 (TM120). |

|

||

|

Setting this parameter filters out the parameters that can be written into in the various commissioning steps. |

|||

|

For the BOP, this setting also causes the read access operations to be filtered. |

|

||

Value: |

0: |

Ready |

|

|

|

29: |

Only Siemens int |

|

|

|

30: |

Parameter reset |

|

|

Dependency: |

Refer to: p0970 |

|

|

|

Note: |

Only the following values are possible: p0010 = 0, 30 |

|

||

|

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1. |

|

||

26 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

|

|

|

|

SINAMICS parameters |

|

|

|

|

|

||

|

|

|

|

||

p0010 |

TM150 commissioning parameter filter / TM150 com par_filt |

|

|

||

TM150 |

Can be changed: C2(1), T |

Calculated: - |

Access level: 1 |

||

|

Data type: Integer16 |

Dynamic index: - |

Func. diagram: - |

||

|

P-Group: - |

Units group: - |

Unit selection: - |

||

|

Not for motor type: - |

Scaling: - |

Expert list: 1 |

||

|

Min |

|

Max |

Factory setting |

|

|

0 |

|

30 |

0 |

|

Description: |

Sets the parameter filter for commissioning a Terminal Module 150 (TM150). |

|

|

||

|

Setting this parameter filters out the parameters that can be written into in the various commissioning steps. |

||||

|

For the BOP, this setting also causes the read access operations to be filtered. |

|

|

||

Value: |

0: |

Ready |

|

|

|

|

29: |

Only Siemens int |

|

|

|

|

30: |

Parameter reset |

|

|

|

Dependency: |

Refer to: p0970 |

|

|

|

|

Note: |

Only the following values are possible: p0010 = 0, 30 |

|

|

||

|

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1. |

|

|

||

|

|

|

|

||

p0010 |

TM54F commissioning parameter filter / TM54F com par_filt |

|

|

||

TM54F_MA |

Can be changed: C2(1), T |

Calculated: - |

Access level: 1 |

||

|

Data type: Integer16 |

Dynamic index: - |

Func. diagram: 2847 |

||

|

P-Group: - |

Units group: - |

Unit selection: - |

||

|

Not for motor type: - |

Scaling: - |

Expert list: 1 |

||

|

Min |

|

Max |

Factory setting |

|

|

0 |

|

95 |

0 |

|

Description: |

Sets the parameter filter for commissioning a Terminal Module 54F (TM54F). |

|

|

||

|

Setting this parameter filters out the parameters that can be written into in the various commissioning steps. |

||||

|

For the BOP, this setting also causes the read access operations to be filtered. |

|

|

||

Value: |

0: |

Ready |

|

|

|

|

29: |

Only Siemens int |

|

|

|

|

30: |

Parameter reset |

|

|

|

|

95: |

Safety Integrated commissioning |

|

|

|

Dependency: |

Refer to: p0970 |

|

|

|

|

Note: |

Procedure for "Reset parameter": Set p0010 to 30 and p0970 to 1. |

|

|

||

p0013[0...49]

HUB, TM120, TM150, TM54F_MA, TM54F_SL

Description:

BOP user-defined list / BOP list

Can be changed: U, T |

Calculated: - |

Access level: 3 |

Data type: Unsigned16 |

Dynamic index: - |

Func. diagram: - |

P-Group: Functions |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

65535 |

0 |

Sets the required parameters to read and write via the Basic Operator Panel (BOP). Activation:

1.p0003 = 3 (expert).

2.p0013[0...49] = requested parameter number

3.If required, enter p0011 = password in order to prevent non-authorized de-activation.

4.p0016 = 1 --> activates the selected user-defined list.

De-activation/change:

1.p0003 = 3 (expert).

2.If required, p0012 = p0011, in order to be authorized to change or de-activate the list.

Parameter description |

27 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

|

3. If required p0013[0...49] = required parameter number. |

|

|

4. p0016 = 1 --> activates the modified user-defined list. |

|

|

5. p0003 = 0 --> de-activates the user-defined list. |

|

Dependency: |

Refer to: p0009, p0976 |

|

Note: |

The following parameters can be read and written on the Control Unit drive object: |

|

|

- p0003 |

(access stage) |

|

- p0009 |

(device commissioning, parameter filter) |

|

- p0012 |

(BOP password acknowledgement (p0013)) |

|

The following applies for the user-defined list: |

|

|

- password protection is only available on the drive object Control Unit and is valid for all of the drive objects. |

|

|

- p0013 cannot be included in the user-defined list for all drive objects. |

|

|

- p0003, p0009, p0011, p0012, p0976 cannot, for the drive object Control Unit, be included in the user-defined list. |

|

|

- the user-defined list can be cleared and de-activated "restore factory setting". |

|

|

A value of 0 means: Entry is empty. |

|

p0015

A_INF_828,

B_INF_828,

S_INF_828, S_INF_COMBI, SERVO_828, SERVO_COMBI, TM120, TM150

Description:

Dependency:

Caution:

Notice:

Note:

Macro drive object / Macro DO

Can be changed: C2(1) |

Calculated: - |

Access level: 1 |

Data type: Unsigned32 |

Dynamic index: - |

Func. diagram: - |

P-Group: Commands |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

999999 |

0 |

Runs the corresponding macro files.

The selected macro file must be available on the memory card/device memory. Example:

p0015 = 6 --> the macro file PM000006.ACX is run. Refer to: p0700, p1000, p1500, r8570

When executing a specific macro, the corresponding programmed settings are made and become active.

After the value has been modified, no further parameter modifications can be made and the status is shown in r3996. Modifications can be made again when r3996 = 0.

No errors were issued during quick commissioning (p3900 = 1) when writing to parameters of the QUICK_IBN group!

The macros in the specified directory are displayed in r8570. r8570 is not in the expert list of the commissioning software.

Macros available as standard are described in the technical documentation of the particular product. The parameter is not influenced by setting the factory setting.

p0015

CU_I_828, CU_I_COMBI, CU_NX_828

Description:

Dependency:

Caution:

Macro drive unit / Macro drv unit

Can be changed: C1 |

Calculated: - |

Access level: 1 |

Data type: Unsigned32 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

999999 |

0 |

Runs the corresponding macro files.

The selected macro file must be available on the memory card/device memory. Example:

p0015 = 6 --> the macro file PM000006.ACX is run. Refer to: p0700, p1000, p1500, r8570

When executing a specific macro, the corresponding programmed settings are made and become active.

28 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

Notice: After the value has been modified, no further parameter modifications can be made and the status is shown in r3996. Modifications can be made again when r3996 = 0.

Note: The macros in the specified directory are displayed in r8570. r8570 is not in the expert list of the commissioning software.

Macros available as standard are described in the technical documentation of the particular product. The parameter is not influenced by setting the factory setting.

r0018

CU_I_828, CU_I_COMBI, CU_NX_828

Description:

Dependency:

Note:

Control Unit firmware version / CU FW version

Can be changed: - |

Calculated: - |

Access level: 1 |

Data type: Unsigned32 |

Dynamic index: - |

Func. diagram: - |

P-Group: - |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: - |

Expert list: 1 |

Min |

Max |

Factory setting |

0 |

4294967295 |

- |

Displays the firmware version of the Control Unit.

Refer to: r0128, r0148, r0158, r0197, r0198

Example:

The value 1010100 should be interpreted as V01.01.01.00.

r0020 |

Speed setpoint smoothed / n_set smth |

|

|

|

SERVO_828, |

Can be changed: - |

Calculated: - |

Access level: 2 |

|

SERVO_COMBI |

Data type: FloatingPoint32 |

Dynamic index: - |

Func. diagram: 5020, 6799 |

|

|

||||

|

P-Group: Displays, signals |

Units group: 3_1 |

Unit selection: p0505 |

|

|

Not for motor type: - |

Scaling: p2000 |

Expert list: 1 |

|

|

Min |

Max |

Factory setting |

|

|

- [rpm] |

- [rpm] |

- [rpm] |

|

Description: |

Displays the currently smoothed speed setpoint at the input of the speed controller or U/f characteristic (after the inter- |

|||

|

polator). |

|

|

|

Dependency: |

Refer to: r0060 |

|

|

|

Note: |

Smoothing time constant = 100 ms |

|

|

|

|

The signal is not suitable as a process quantity and may only be used as a display quantity. |

|||

|

The speed setpoint is available smoothed (r0020) and unsmoothed (r0060). |

|

|

|

r0021 |

CO: Actual speed smoothed / n_act smooth |

|

|

SERVO_828, |

Can be changed: - |

Calculated: - |

Access level: 2 |

SERVO_COMBI |

Data type: FloatingPoint32 |

Dynamic index: - |

Func. diagram: 1580, 1680, |

|

|||

|

|

|

4710, 6799 |

|

P-Group: Displays, signals |

Units group: 3_1 |

Unit selection: p0505 |

|

Not for motor type: - |

Scaling: p2000 |

Expert list: 1 |

|

Min |

Max |

Factory setting |

|

- [rpm] |

- [rpm] |

- [rpm] |

Description: |

Displays the smoothed actual value of the motor speed. |

|

|

Dependency: |

Refer to: r0022, r0063 |

|

|

Note: |

Smoothing time constant = 100 ms |

|

|

|

The signal is not suitable as a process quantity and may only be used as a display quantity. |

||

|

The speed actual value is available smoothed (r0021, r0022) and unsmoothed (r0063). |

||

Parameter description |

29 |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

SINAMICS parameters

r0022 |

Speed actual value rpm smoothed / n_act rpm smooth |

|

|

SERVO_828, |

Can be changed: - |

Calculated: - |

Access level: 2 |

SERVO_COMBI |

Data type: FloatingPoint32 |

Dynamic index: - |

Func. diagram: 1580, 1680, |

|

|||

|

|

|

4710, 6799 |

|

P-Group: Displays, signals |

Units group: - |

Unit selection: - |

|

Not for motor type: - |

Scaling: p2000 |

Expert list: 1 |

|

Min |

Max |

Factory setting |

|

- [rpm] |

- [rpm] |

- [rpm] |

Description: |

Displays the smoothed actual value of the motor speed. |

|

|

|

r0022 is identical to r0021, however, it always has units of rpm and contrary to r0021 cannot be changed over. |

||

Dependency: |

Refer to: r0021, r0063 |

|

|

Note: |

Smoothing time constant = 100 ms |

|

|

|

The signal is not suitable as a process quantity and may only be used as a display quantity. |

||

|

The speed actual value is available smoothed (r0021, r0022) and unsmoothed (r0063). |

||

r0024

A_INF_828, S_INF_828, S_INF_COMBI

Description:

Dependency:

Note:

CO: Line supply frequency smoothed / f_line smooth

Can be changed: - |

Calculated: - |

Access level: 3 |

Data type: FloatingPoint32 |

Dynamic index: - |

Func. diagram: 8850, 8950 |

P-Group: Displays, signals |

Units group: - |

Unit selection: - |

Not for motor type: - |

Scaling: p2000 |

Expert list: 1 |

Min |

Max |

Factory setting |

- [Hz] |

- [Hz] |

- [Hz] |

Displays the smoothed line supply frequency. Refer to: r0066

Smoothing time constant = 300 ms

The signal is not suitable as a process quantity and may only be used as a display quantity. The line frequency is available smoothed (r0024) and unsmoothed (r0066).

A positive sign of the frequency is obtained when the line supply phases U, V and W are connected with the correct phase sequence.

A negative sign of the frequency is obtained when the 3 line phases are interchanged therefore designating a negative direction of the rotating field of the 3-phase line supply voltage.

r0024 |

Output frequency smoothed / f_outp smooth |

|

|

SERVO_828, |

Can be changed: - |

Calculated: - |

Access level: 3 |

SERVO_COMBI |

Data type: FloatingPoint32 |

Dynamic index: - |

Func. diagram: 1690, 5300, |

|

|||

|

|

|

5730, 6799 |

|

P-Group: Displays, signals |

Units group: - |

Unit selection: - |

|

Not for motor type: - |

Scaling: p2000 |

Expert list: 1 |

|

Min |

Max |

Factory setting |

|

- [Hz] |

- [Hz] |

- [Hz] |

Description: |

Displays the smoothed converter frequency. |

|

|

Dependency: |

Refer to: r0066 |

|

|

Note: |

Smoothing time constant = 100 ms |

|

|

|

The signal is not suitable as a process quantity and may only be used as a display quantity. |

||

|

The output frequency is available smoothed (r0024) and unsmoothed (r0066). |

|

|

30 |

Parameter description |

Parameter Manual, 02/2012, 6FC5397-8DP40-3BA0 |

Loading...

Loading...