siemens 828D User Manual

SINUMERIK 828D

Turning

Control system overview

for machine tools' sales people

09/2009

Preface

Introduction |

1 |

|

|

|

|

System overview |

2 |

|

CNC operation in manual |

|

|

3 |

||

mode (JOG) |

||

|

|

|

Tool Management |

4 |

|

|

|

|

User memory |

5 |

|

|

|

|

Data transfer |

6 |

|

|

|

|

Graphical support functions |

7 |

|

CNC operation in automatic |

|

|

8 |

||

mode (AUTO) |

||

CNC performance capability |

|

|

9 |

||

and optimization functions |

||

|

|

|

CNC programming methods |

10 |

|

|

|

|

Simulation |

11 |

|

|

|

|

CNC technology cycles |

12 |

|

|

|

|

Complete machining |

13 |

|

|

|

|

PC software |

14 |

|

Option list for the |

|

|

15 |

||

SINUMERIK package |

||

|

|

|

Summary of the highlights |

16 |

|

|

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task in accordance with the relevant documentation for the specific task, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG |

|

Copyright © Siemens AG 2009. |

Industry Sector |

09/2009 |

Technical data subject to change |

Postfach 48 48 90026 NÜRNBERG GERMANY

Preface

Scope of validity

This document provides you with an overview of the range of functions included in the SINUMERIK 828D Version 2.6 operator panel controller for turning machines.

The document is focusing on vendors and dealers of machine tools.

Organization of the information

●Of the varied functional features of the SINUMERIK products, only those are listed which are of direct value to the machine user.

●All functions contained in the machine's basic configuration will be identified as follows:

Basic configuration

●All functions not contained in the machine's basic configuration will be identified as follows:

Option: ...

●You can find a summary of the most important unique selling points of the SINUMERIK 828D in the chapter "Summary of highlights".

●For information on marketing options through the machine manufacturer, please see the technical description of each machine.

Subject to change without prior notice

Contact person at machine manufacturer

Marketing & Sales |

|

Phone: |

+49 xxx xxx |

Fax: |

+49 xxx xxx |

Email: |

xxx@machinemanufacturer.com |

Service |

|

Phone: |

+49 xxx xxx |

Fax: |

+49 xxx xxx |

Email: |

xxx@machinemanufacturer.com |

Homepage: |

|

http://www.machinemanufacturer.com |

|

SINUMERIK 828D - Turning |

3 |

Control system overview for machine tools' sales people, 09/2009 |

Preface

Contact person at Siemens

Country |

Name |

Phone |

|||

Argentina |

Santiago Fernandez Veron |

santiago_fernandez.veron@siemens.com |

+54 |

(11) 4738-3348 |

|

Belgium |

Pieter Vanderhaeghen |

pieter.vanderhaeghen@siemens.com |

+32 |

253-69697 |

|

Bosnia and Herzegovina |

Helmut Stralz |

helmut.stralz@siemens.com |

+43 |

51 707 29115 |

|

Brazil |

Gustavo Marino |

marino.gustavo@siemens.com |

+ 55 (11) 3908-1752 |

||

Bulgaria |

Helmut Stralz |

helmut.stralz@siemens.com |

+43 |

51 707 29115 |

|

China |

Yang Yifei |

yifei.yang@siemens.com |

+86 |

10 64765236 |

|

Denmark |

Stefan Karlstrand |

stefan.karlstrand@siemens.com |

+46 |

500 774-148 |

|

Germany (Headquarters) |

Gerhard Micka |

gerhard.micka@siemens.com |

+49 |

9131 98 3314 |

|

Finland |

Juha Meriaho |

juha.meriaho@siemens.com |

+358 |

50 59 26181 |

|

France |

François Chevalier |

francois.chevalier@siemens.com |

+33 |

(0)1 49 22 35 19 |

|

Great Britain |

Tony Bennison |

tony.bennison@siemens.com |

+44 |

780 882 2054 |

|

India |

Narayanan Shankar |

narayanan.shankar@siemens.com |

+91 |

99451 88837 |

|

Indonesia |

Andy Lesmono |

andy_lesmono@cncdesign.com.au |

+62 |

21 7918 6001 |

|

Italy |

Nicodemo Megna |

nicodemo.megna@siemens.com |

+39 |

335 6328927 |

|

Canada |

Sagar Arora |

sagar.arora@siemens.com |

+1 (416) 270-4964 |

||

Korea |

Kim Sung Hyun |

sunghyun.kim@siemens.com |

+ 82 55 268 1906 |

||

Croatia |

Matjaz Mlinsek |

matjaz.mlinsek@siemens.com |

+386 |

1 47 46 152 |

|

Lithuania |

Juha Meriaho |

juha.meriaho@siemens.com |

+358 |

50 59 26181 |

|

Malaysia |

Ridwan Aziz |

ridwan_aziz@cncdesign.com.au |

+603 |

5621 6126 |

|

Mexico |

Marco Lopez |

marco.lopez@siemens.com |

+52 |

(55) 5328-2000 |

|

Netherlands |

Frank de Korte |

frank.de.korte@siemens.com |

+31 |

70 333 1568 |

|

Norway |

Stefan Karlstrand |

stefan.karlstrand@siemens.com |

+46 |

500 774-148 |

|

Austria |

Helmut Stralz |

helmut.stralz@siemens.com |

+43 |

51 707 29115 |

|

Portugal |

Molaguero Godoy |

juan.molaguero.ext@siemens.com |

+34 |

670929001 |

|

Romania |

Matjaz Mlinsek |

matjaz.mlinsek@siemens.com |

+386 |

1 47 46 152 |

|

Russia |

Alexander Kudinov |

alexander.kudinov@siemens.com |

+7 495 737 2442 |

||

Sweden |

Stefan Karlstrand |

stefan.karlstrand@siemens.com |

+46 |

500 774-148 |

|

Switzerland |

Hans-Peter Kueng |

hans-peter.kueng@siemens.com |

+41 |

585 581 524 |

|

Serbia Montenegro |

Helmut Stralz |

helmut.stralz@siemens.com |

+43 |

51 707 29115 |

|

Slovakia |

Matjaz Mlinsek |

matjaz.mlinsek@siemens.com |

+386 |

1 47 46 152 |

|

Slovenia |

Matjaz Mlinsek |

matjaz.mlinsek@siemens.com |

+386 |

1 47 46 152 |

|

Spain |

Molaguero Godoy |

juan.molaguero.ext@siemens.com |

+34 |

670929001 |

|

Taiwan |

Jerry Lin |

jerry.lin@siemens.com |

+886 |

4 2261 9225 |

|

Thailand |

Rajeev Madhyastha |

rajeev_madhyastha@cncdesign.com.au |

+66(0)2993 7485 |

||

Czech |

Eva Klocova |

eva.klocova@siemens.com |

+420 |

605726829 |

|

Turkey |

Taner Okayi |

taner.okayi@siemens.com.tr |

+90 |

216 459 3906 |

|

Hungary |

Istvan Joo |

istvan.joo@siemens.hu |

+36 |

1 471 1598 |

|

USA |

Jon Cruthers |

jon.cruthers@siemens.com |

+1 (847) 952 4124 |

||

Vietnam |

Pham-Vu Trung |

pham-vu.trung@siemens.com |

+84 |

908 346 534 |

|

Homepage:

For further information please visit ...

http://www.siemens.de/cnc4you

http://www.automation.siemens.de/doconweb

4 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

Table of contents

|

Preface |

...................................................................................................................................................... |

3 |

1 |

Introduction................................................................................................................................................ |

9 |

|

|

1.1 |

Application ...................................................................................................................................... |

9 |

|

1.2 .......................................................................................................................... |

Machine spectrum |

9 |

2 |

System ......................................................................................................................................overview |

11 |

|

|

2.1 ....................................................................................................................... |

SINUMERIK 828D |

11 |

|

2.2 ............................................................................................. |

SINUMERIK 828D operator panels |

12 |

|

2.3 .................................................................................................................. |

Performance versions |

13 |

|

2.4 ......................................................................................................... |

Maintenance - free operation |

13 |

|

2.5 ................................................................................................ |

Languages of operating software |

14 |

3 |

CNC operation ....................................................................................................in manual mode (JOG) |

15 |

|

|

3.1 ..................................................................................................................... |

TSM universal cycle |

15 |

|

3.2 .............................................................................................................................. |

Stock removal |

16 |

|

3.3 ................................................................................................................................ |

Measure tool |

17 |

|

3.4 ...................................................................................................................... |

Measure workpiece |

18 |

|

3.5 ................................................................................................................................. |

Work offsets |

19 |

4 |

Tool Management.................................................................................................................................... |

21 |

|

|

4.1 ..................................................................................................................................... |

Tool table |

21 |

|

4.2 ........................................................................ |

Monitoring of tool life and quantity of workpieces |

22 |

|

4.3 ....................................................................................................................... |

Replacement tools |

22 |

5 |

User memory........................................................................................................................................... |

23 |

|

|

5.1 ........................................................................................................ |

Buffered CNC work memory |

23 |

|

5.2 .................................................................................. |

Memory expansion by compact flash card |

23 |

6 |

Data transfer............................................................................................................................................ |

25 |

|

|

6.1 ..................................................................................................................................... |

Interfaces |

25 |

|

6.2 ........................................................................................................................ |

Program manager |

26 |

|

6.3 ................................................................................................... |

Data transfer by serial interface |

27 |

|

6.4 ................................................. |

Data transfer using a USB memory stick or compact flash card |

27 |

|

6.5 ......................................................................................................................... |

RCS Commander |

28 |

|

6.6 ..................................................................................................................... |

Ethernet networking |

29 |

|

6.7 .............................................................................................................................. |

Easy Message |

29 |

SINUMERIK 828D - Turning |

5 |

Control system overview for machine tools' sales people, 09/2009 |

Table of contents

7 |

Graphical support functions..................................................................................................................... |

31 |

|

|

7.1 |

Animated Elements..................................................................................................................... |

31 |

|

7.2 |

Onboard documentation.............................................................................................................. |

32 |

8 |

CNC operation in automatic mode (AUTO).............................................................................................. |

33 |

|

|

8.1 |

Block search................................................................................................................................ |

33 |

|

8.2 |

Program control........................................................................................................................... |

34 |

|

8.3 |

Simultaneous recording .............................................................................................................. |

35 |

9 |

CNC performance capability and optimization functions.......................................................................... |

37 |

|

|

9.1 |

80bit NANO FP accuracy.............................................................................................................. |

37 |

|

9.2 |

Jerk limitation.............................................................................................................................. |

38 |

|

9.3 |

Dynamic feedforward control...................................................................................................... |

38 |

10 |

CNC programming methods.................................................................................................................... |

39 |

|

|

10.1 |

Overview of programming methods............................................................................................ |

39 |

|

10.2 |

programGUIDE and SINUMERIK CNC programming................................................................ |

40 |

|

10.2.1 |

Introduction ................................................................................................................................. |

40 |

|

10.2.2 |

Program editor ............................................................................................................................ |

40 |

|

10.2.3 |

Languages .................................................................................................................................. |

41 |

|

10.2.4 |

programGUIDE input support...................................................................................................... |

42 |

|

10.3 |

ShopTurn..................................................................................................................................... |

43 |

|

10.3.1 |

Introduction ................................................................................................................................. |

43 |

|

10.3.2 |

Sequence editor.......................................................................................................................... |

43 |

|

10.3.3 |

Interlinking of sequences ............................................................................................................ |

44 |

|

10.3.4 |

Broken-line graphics ................................................................................................................... |

45 |

|

10.4 |

Online ISO dialect interpreter...................................................................................................... |

46 |

11 |

Simulation................................................................................................................................................ |

47 |

|

|

11.1 |

2D simulation .............................................................................................................................. |

47 |

|

11.2 |

3D simulation .............................................................................................................................. |

48 |

12 |

CNC technology cycles............................................................................................................................ |

49 |

|

|

12.1 |

CNC technology cycles for programGuide and ShopTurn.......................................................... |

49 |

|

12.2 |

Highlights of machining cycles.................................................................................................... |

50 |

|

12.2.1 |

Stock removal along contour with blank contour........................................................................ |

50 |

|

12.2.2 |

Engraving cycle........................................................................................................................... |

51 |

|

12.2.3 |

Counterspindle cycle................................................................................................................... |

52 |

|

12.2.4 |

Residual material detection during turning.................................................................................. |

53 |

|

12.2.5 |

Detection of residual material when milling................................................................................. |

54 |

|

12.2.6 |

Process measurements for workpieces and tools...................................................................... |

55 |

13 |

Complete machining................................................................................................................................ |

57 |

|

|

13.1 |

End face machining (TRANSMIT)............................................................................................... |

57 |

|

13.2 |

Peripheral surface machining (TRACYL).................................................................................... |

58 |

6 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

|

|

|

Table of contents |

14 |

PC software............................................................................................................................................. |

59 |

|

|

14.1 |

CAD reader for PC....................................................................................................................... |

59 |

|

14.2 |

SinuTrain...................................................................................................................................... |

60 |

|

14.3 |

Computer-based training ............................................................................................................. |

60 |

15 |

Option list for the SINUMERIK package .................................................................................................. |

61 |

|

16 |

Summary of the highlights....................................................................................................................... |

63 |

|

|

Index |

........................................................................................................................................................ |

65 |

SINUMERIK 828D - Turning |

7 |

Control system overview for machine tools' sales people, 09/2009 |

Table of contents

8 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

Introduction |

1 |

1.1Application

With the SINUMERIK 828D you get a CNC system which is customized for the application in turning and milling machines. CNC, PLC, user interface and axis control for six CNC measuring circuits are all combined within a single compact unit. The controller provides comprehensive CNC functions such as support of counterspindle machining and a powerful tool management capability. The SINUMERIK 828D offers comprehensive turning capabilities specially for turning machines as well as drilling and milling operations for face machining and peripheral surface machining of workpieces. The performance of the controller and the new motion control allow you to achieve mirror finish surfaces with a minimum machining time.

The SINUMERIK 828D has eliminated all unnecessary functionalities; this is particularly noticeable in the graphical user interface. This means it is optimally suitable for use in the workshop. Operation, programming and maintenance can quickly be mastered without any heavy training requirement.

●Optimum operator guidance thanks to CNC input screens with animated elements

●Easy data exchange thanks to USB, CF and Ethernet interfaces on the panel front

●Integral mobile radio modem for optimum process monitoring via mobile phone

1.2Machine spectrum

The SINUMERIK 828D is perfectly tailored for equipping horizontal and vertical turning centers with one machining channel and up to eight CNC measuring circuits,

Apart from the main spindle and the geometry axes (X axis and Z axis), further machine units can also be operated:

●CNC controlled turret

●Tailstock axis (with travel to fixed stop)

●Driven tools and C axis mode for end face and peripheral surface machining

●Y axis (orthogonal or oblique)

●Counterspindle with synchronous spindle function for complete machining of workpieces

SINUMERIK 828D - Turning |

9 |

Control system overview for machine tools' sales people, 09/2009 |

Introduction

1.2 Machine spectrum

10 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

System overview |

2 |

2.1SINUMERIK 828D

The SINUMERIK 828D is a complete unit comprising screen, CNC keyboard and CNC electronics.

The motors can be easily connected to the digital drives via DRIVE-CLiQ. In combination with the modular structure of the SINAMICS S120 drive system, this design is conceived to ensure very simple and rugged installation with minimum wiring overhead.

The performance range of the controller has been selected to meet the requirements of standardized turning and milling machines - from one-off production runs to industrial scale manufacture.

●Digital drive controller

●Modular design for drive controller and power unit

●Up to 6 axes/spindles for milling applications

●Intelligent control functions meeting the highest standards of machining technology

Highlights

●Maximum reliability due to compact design with few interfaces

●The same hardware for milling and for turning, leading to optimum spare parts management.

SINUMERIK 828D - Turning |

11 |

Control system overview for machine tools' sales people, 09/2009 |

System overview

2.2 SINUMERIK 828D operator panels

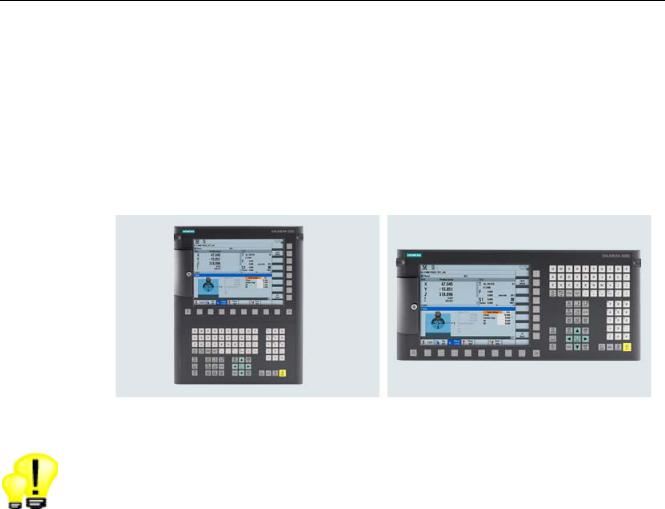

2.2SINUMERIK 828D operator panels

The operator panel consists of a hard-wearing die-cast magnesium alloy and is available in two versions, for horizontal and vertical mounting.

●10.4" TFT color display

●Integrated QWERTY full CNC keyboard with short-stroke keys

●USB, CF card and Ethernet interfaces on the operator panel front

Highlights

●All relevant functions at a glance, thanks to horizontal and vertical softkeys

●Simple data handling using easily accessible sockets for USB and compact flash card storage media on the front panel

12 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

System overview 2.3 Performance versions

2.3Performance versions

The 828D is available in two performance versions: the PPU 260/261 and the PPU 280/281. These allow optimum matching to the demands of the machine.

Scope of performance |

PPU 260 / 261 |

|

PPU 280 / 281 |

Minimum block cycle time |

~6 ms |

|

~6 ms |

CNC work memory |

3 MB |

|

5 MB |

Maximum number of |

|

|

|

tools/cutting edges |

128/256 |

256/512 |

|

Maximum number of |

6 |

8 |

|

axes/spindles |

|

|

|

Highlights

●Outstanding performance even with the standard package

●Complete machining with counterspindle with expansion stage PPU 280/281

2.4Maintenance-free operation

The SINUMERIK 828D offers maintenance-free operation:

●High reliability, as the SINUMERIK 828D does not have a hard disk, battery or fan

●Storage of part programs on a NVRAM, so no loss of data even during an extended loss of power

Highlight

● Highest machine availability thanks to reliable hardware

SINUMERIK 828D - Turning |

13 |

Control system overview for machine tools' sales people, 09/2009 |

System overview

2.5 Languages of operating software

2.5Languages of operating software

Basic configuration

The following languages are available on the operator interfaces of the SINUMERIK 828D. Pressing the CTRL + L keys or by softkey switching you can toggle between between languages.

●Chinese Simplified

●Chinese traditional

●German

●English

●French

●Italian

●Korean

●Portuguese

●Spanish

on request

Language extensions for the HMI sl operating software are available on request for the following languages:

●Danish

●Finnish

●Japanese

●Dutch

●Polish

●Romanian

●Russian

●Swedish

●Slovakian

●Czech

●Turkish

●Hungarian

Highlights

●Operator interface in your language so that the CNC is easy to learn and safe to operate

●All languages are available on the control and can online be changed

14 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

CNC operation in manual mode (JOG) |

3 |

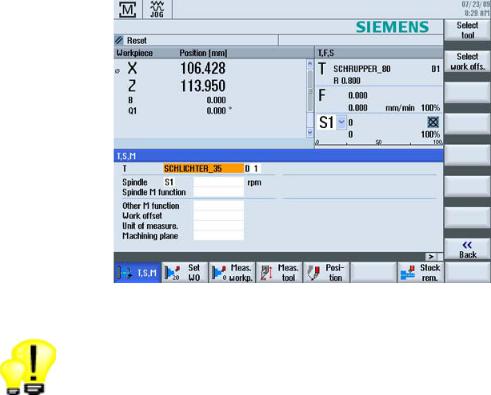

3.1TSM universal cycle

Basic configuration

A universal cycle is available in the setup for the most commonly used machine functions:

●Tool change with direct access via the tool table (T)

●Spindle speed and direction (S)

●M functions (M)

●Activation of work offsets

Highlight

● Take-over and change-in tools directly from the tool table

SINUMERIK 828D - Turning |

15 |

Control system overview for machine tools' sales people, 09/2009 |

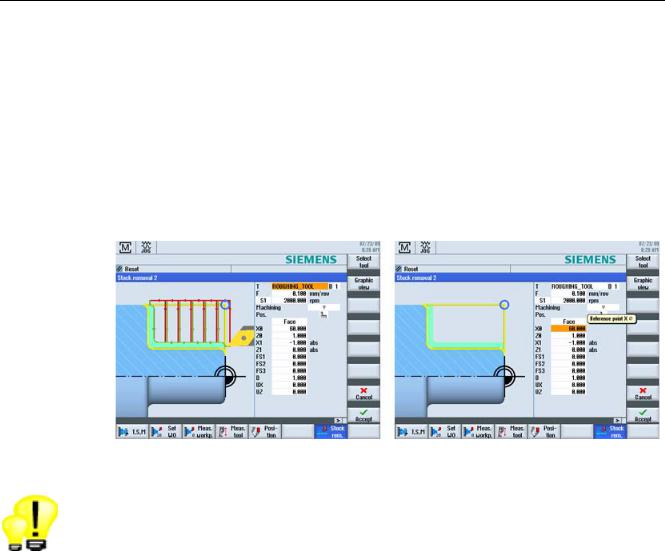

CNC operation in manual mode (JOG) 3.2 Stock removal

3.2Stock removal

Basic configuration

Stock removal is conveniently available in the set-up. Soft collet chucks can, for example, be turned with this cycle.

The following parameters can be specified:

●Roughing or finishing

●Undercut for soft collet chucks

Highlight

● Preparation of workpiece or collet chuck without having to create a part program

16 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

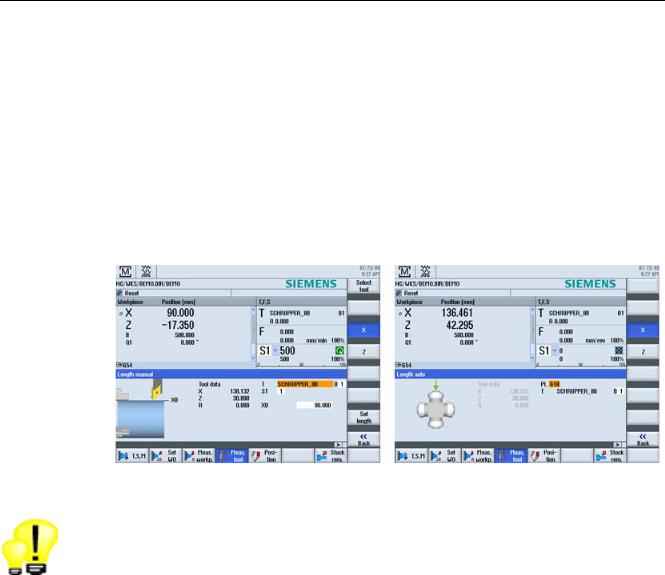

CNC operation in manual mode (JOG) 3.3 Measure tool

3.3Measure tool

Basic configuration

The tool compensation value can be directly determined in the machine set-up.

The following variants are supported:

●Touch chuck

●Determine lengths via reference diameter

●Tool measuring probe (tooleye) or magnifier

Highlight

● User-friendly functions for determining the tool dimensions directly in the machine

SINUMERIK 828D - Turning |

17 |

Control system overview for machine tools' sales people, 09/2009 |

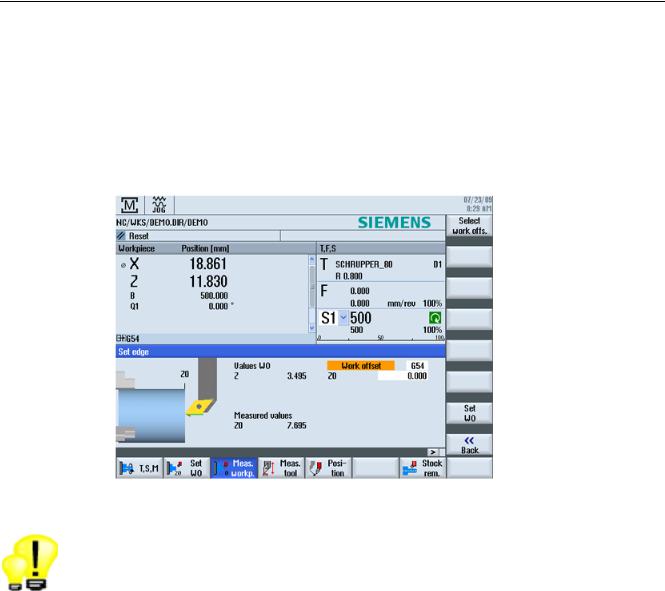

CNC operation in manual mode (JOG) 3.4 Measure workpiece

3.4Measure workpiece

Basic configuration

The workpieces can be measured as follows: ● Reference tool

Highlight

● Fast zero point definition by dialog

18 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

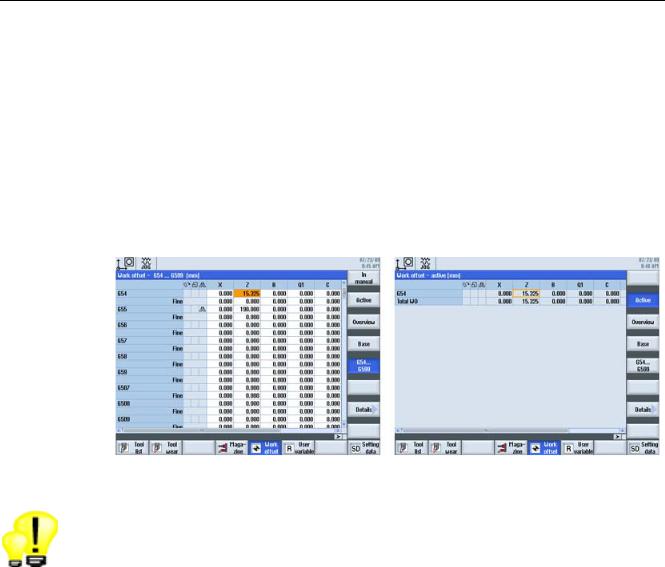

CNC operation in manual mode (JOG) 3.5 Work offsets

3.5Work offsets

Basic configuration

The following adjustable work offsets are available to you:

●A basic offset

●Maximum of 99 work offsets (G54, G55 ...)

●Each work offset with axis rotation and fine offset

Highlights

●Flexible machining due to great number of adjustable work offsets

●Unlimited possibilities of programmable work offsets

SINUMERIK 828D - Turning |

19 |

Control system overview for machine tools' sales people, 09/2009 |

CNC operation in manual mode (JOG) 3.5 Work offsets

20 |

SINUMERIK 828D - Turning |

Control system overview for machine tools' sales people, 09/2009 |

Loading...

Loading...