_

_

_

_

_

_

_

_

_

SINUMERIK SINUMERIK 840D sl/840Di sl/828D/802D sl ISO Milling

SINUMERIK

SINUMERIK 840D sl/840Di sl/ 828D/802D sl ISO Milling

Programming Manual

Principles of programming

_____________

Drive commands

_____________

Motion commands

_____________

Additional functions

_____________

Abbreviations

_____________

G code table

_____________

Data Description

_____________

Data lists

_____________

Interrupts

_____________

1

2

3

4

A

B

C

D

E

Valid for

Software Version

SINUMERIK 802D sl 1.4

SINUMERIK 828D 2.6

SINUMERIK 840D sl/DE sl 2.6

SINUMERIK 840Di sl/DiE sl 1.4

06/09

6FC5398-7BP10-1BA0

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ordernumber: 6FC5398-7BP10-1BA0

Ⓟ 07/2009

Copyright © Siemens AG 2009.

Technical data subject to change

Table of contents

1 Principles of programming .........................................................................................................................

1.1 Introductory comments ..................................................................................................................

1.1.1 Siemens mode ...............................................................................................................................

1.1.2 ISO dialect mode ...........................................................................................................................

1.1.3 Switching between the modes .......................................................................................................

1.1.4 Display of the G code.....................................................................................................................

1.1.5 Maximum number of axes/axis identifiers......................................................................................

1.1.6 Decimal point programming...........................................................................................................

1.1.7 Comments....................................................................................................................................

1.1.8 Skip block.....................................................................................................................................

1.2 Preconditions for the feed............................................................................................................

1.2.1 Rapid traverse..............................................................................................................................

1.2.2 Path feed (F function) ..................................................................................................................

1.2.3 Fixed feedrates F0 to F9..............................................................................................................

1.2.4 Linear feed (G94).........................................................................................................................

1.2.5 Inverse-time feed (G93) ...............................................................................................................

1.2.6 Revolutional feedrate (G95).........................................................................................................

2 Drive commands......................................................................................................................................

2.1 Interpolation commands...............................................................................................................

2.1.1 Rapid traverse (G00) ...................................................................................................................

2.1.2 Linear interpolation (G01) ............................................................................................................

2.1.3 Circular interpolation (G02, G03).................................................................................................

2.1.4 Contour definition programming and addition of chamfers or radiuses.......................................

2.1.5 Helical interpolation (G02, G03)...................................................................................................

2.1.6 Involute interpolation (G02.2, G03.2)...........................................................................................

2.1.7 Cylindrical interpolation (G07.1)...................................................................................................

7

7

7

7

7

8

8

8

10

10

11

11

11

13

15

15

16

17

17

17

18

19

22

25

26

27

2.2 Reference point approach with G functions.................................................................................

2.2.1 Reference point approach with intermediate point (G28)............................................................

2.2.2 Checking the reference position (G27) ........................................................................................

2.2.3 Reference point approach with reference point selection (G30) .................................................

3 Motion commands ...................................................................................................................................

3.1 The coordinate system.................................................................................................................

3.1.1 Machine coordinate systems (G53) .............................................................................................

3.1.2 Workpiece coordinate system (G92) ...........................................................................................

3.1.3 Resetting the tool coordinate system (G92.1) .............................................................................

3.1.4 Selection of a workpiece coordinate system................................................................................

3.1.5 Writing work offset/tool offsets (G10)...........................................................................................

3.1.6 Local coordinate system (G52)....................................................................................................

3.1.7 Selection of the plane (G17, G18, G19) ......................................................................................

3.1.8 Parallel axes (G17, G18, G19).....................................................................................................

3.1.9 Rotation of the coordinate system (G68, G69) ............................................................................

3.1.10 3D rotation G68/G69....................................................................................................................

3.2 Defining the input modes of the coordinate values......................................................................

3.2.1 Absolute/incremental dimensioning (G90, G91) ..........................................................................

3.2.2 Inch/metric input (G20, G21)........................................................................................................

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

30

30

32

33

35

35

36

37

38

38

38

40

41

42

43

45

46

46

47

3

Table of contents

3.2.3 Scaling (G50, G51) ..................................................................................................................... 48

3.2.4 Programmable mirroring (G50.1, G51.1) ....................................................................................

51

3.3 Time-controlled commands.........................................................................................................

3.3.1 Dwell time (G04) .........................................................................................................................

3.4 Tool offset functions ....................................................................................................................

3.4.1 Tool offset data memory .............................................................................................................

3.4.2 Tool length compensation (G43, G44, G49)...............................................................................

3.4.3 Cutter radius compensation (G40, G41, G42) ............................................................................

3.4.4 Collision detection .......................................................................................................................

3.5 S-, T-, M- and B functions ...........................................................................................................

3.5.1 Spindle function (S function) .......................................................................................................

3.5.2 Tool function................................................................................................................................

3.5.3 Additional function (M function)...................................................................................................

3.5.4 M functions of spindle control......................................................................................................

3.5.5 M functions for subroutine calls ..................................................................................................

3.5.6 Macro call via M function.............................................................................................................

3.5.7 M functions..................................................................................................................................

3.6 Controlling the feedrate...............................................................................................................

3.6.1 Automatic corner override G62 ...................................................................................................

3.6.2 Compressor in the ISO dialect mode ..........................................................................................

3.6.3 Exact stop (G09, G61), Continuous-path mode (G64), tapping (G63) .......................................

4 Additional functions..................................................................................................................................

4.1 Program supporting functions .....................................................................................................

4.1.1 Fixed drilling cycles .....................................................................................................................

4.1.2 Deep hole drilling cycle with chip breakage (G73)......................................................................

4.1.3 Fine drilling cycle (G76) ..............................................................................................................

4.1.4 Drilling cycle, preboring (G81) ....................................................................................................

4.1.5 Drilling cycle, preboring (G82) ....................................................................................................

4.1.6 Deep hole drilling cycle with chip removal (G83)........................................................................

4.1.7 Drilling cycle (G85)......................................................................................................................

4.1.8 Boring cycle (G86) ......................................................................................................................

4.1.9 Boring cycle, reverse countersinking (G87)................................................................................

4.1.10 Drilling cycle (G89), return with G01...........................................................................................

4.1.11 Cycle "Tapping without compensating chuck" (G84) ..................................................................

4.1.12 "Drilling a left-hand thread without compensating chuck" cycle (G74) .....................................

4.1.13 Left or right tapping cycle (G84 or G74)....................................................................................

4.1.14 Deselection of a fixed cycle (G80) ............................................................................................

4.1.15 Program example with a tool length compensation and fixed cycles .......................................

4.1.16 Multiple-start threads with G33 .................................................................................................

53

53

54

54

54

57

61

65

65

65

65

66

67

67

68

69

69

71

72

73

73

73

78

81

84

85

87

90

91

93

96

98

101

103

106

107

109

4.2 Programmable data input (G10) ...............................................................................................

4.2.1 Changing the tool offset value...................................................................................................

4.2.2 Working area limitation (G22, G23) ..........................................................................................

4.2.3 M function for calling subroutines (M98, M99)..........................................................................

4.3 Eight-digit program number.......................................................................................................

4.4 Polar coordinates (G15, G16) ...................................................................................................

4.5 Polar coordinates interpolation (G12.1, G13.1) ........................................................................

4.6 Measuring functions ..................................................................................................................

4.6.1 Rapid lift with G10.6 ..................................................................................................................

4.6.2 Measuring with "delete distance-to-go" (G31) ..........................................................................

4.6.3 Measuring with G31, P1 - P4 ....................................................................................................

ISO Milling

110

110

110

111

113

115

116

118

118

118

121

4 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Table of contents

4.6.4 Interrupt program with M96, M97...............................................................................................122

4.6.5 "Tool life control" function ..........................................................................................................

124

4.7 Macro programs.........................................................................................................................

4.7.1 Differences with subroutines......................................................................................................

4.7.2 Macro program call (G65, G66, G67) ........................................................................................

4.7.3 Macro call via G function............................................................................................................

4.8 Special functions........................................................................................................................

4.8.1 Contour repetition (G72.1, G72.2) .............................................................................................

4.8.2 Switchover modes for DryRun and skip levels ..........................................................................

A Abbreviations.........................................................................................................................................

B G code table ..........................................................................................................................................

C Data Description....................................................................................................................................

C.1 General machine data................................................................................................................

C.2 Channel-specific machine data..................................................................................................

C.3 Axis-specific setting data ...........................................................................................................

C.4 Channel-specific setting data.....................................................................................................

D Data lists................................................................................................................................................

D.1 Machine data..............................................................................................................................

D.2 Setting data................................................................................................................................

D.3 Variables ....................................................................................................................................

E Interrupts ...............................................................................................................................................

125

125

125

132

135

135

137

139

147

151

151

164

177

178

181

181

183

184

187

Glossary ................................................................................................................................................

Index......................................................................................................................................................

189

213

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

5

Table of contents

ISO Milling

6 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Principles of programming

1.1 Introductory comments

1.1.1 Siemens mode

The following conditions are valid in the Siemens mode:

● The default of the G commands can be defined for each channel via the machine data

20150 $MC_GCODE_RESET_VALUES.

● No language commands from the ISO dialects can be programmed in the Siemens mode.

1.1.2 ISO dialect mode

The following conditions are valid in the active ISO dialect mode:

● The ISO dialect mode can be set with machine data as the default setting of control

system. The control system reboots by default in the ISO dialect mode subsequently.

● Only G functions from the ISO dialect can be programmed; the programming of Siemens

G functions is not possible in the ISO Mode.

1

● Mixing of ISO dialect and Siemens language in the same NC block is not possible.

● Switching between ISO Dialect M and ISO Dialect T with a G command is not possible.

● Subroutines that are programmed in the Siemens mode can be called.

● If Siemens functions are to be used, one must first switch to the Siemens mode.

1.1.3 Switching between the modes

The following G functions can be used to switch between the Siemens mode and the ISO

dialect mode:

● G290 - Siemens NC programming language active

● G291 - ISO Dialect NC Programming language active

The active tool, the tool offsets and work offsets are not influenced by the switchover.

G290 and G291 must be programmed alone in an NC block.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

7

Principles of programming

1.1 Introductory comments

1.1.4 Display of the G code

The G code is displayed in the same language (Siemens or ISO Dialect) as the relevant

current block. If the display of the blocks is suppressed with DISPLOF, the G codes continue

to be displayed in the language in which the active block is displayed.

Example

The G functions of the ISO dialect mode are used to call the Siemens standard cycles. To do

this, DISPLOF is programmed at the start of the relevant cycle; this way the G functions that

are programmed in the ISO dialect language continue to be displayed.

PROC CYCLE328 SAVE DISPLOF

N10 ...

...

N99 RET

Procedure

The Siemens shell cycles are called via main programs. The Siemens mode is selected

automatically by calling the shell cycle.

With DISPLOF, the block display is frozen on calling the cycle; the display of the G code

continues in the ISO Mode.

The G codes that were changed in the shell cycle, are reset to their original status at the end

of the cycle with the "SAVE" attribute.

1.1.5 Maximum number of axes/axis identifiers

The maximum number of axes in the ISO dialect mode is 9. The axis identifiers for the first

three axes are defined permanently with X, Y and Z. All other axes can be identified with the

letters A, B, C, U, V and W.

1.1.6 Decimal point programming

In the ISO dialect mode, there are two notations for evaluating programmed values without

decimal point:

● Pocket calculator notation

Values without decimal points are interpreted as mm, inch or degree.

● Standard notation

Values without decimal point are multiplied by a conversion factor.

The setting is done over MD10884 $MN_EXTERN_FLOATINGPOINT_PROG.

There are two different conversion factors, IS-B and IS-C. This weighting is related to the

addresses X Y Z U V W A B C I J K Q R and F.

Example:

Linear axis in mm:

ISO Milling

8 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Principles of programming

1.1 Introductory comments

● X 100.5

corresponds to a value with decimal point: 100.5 mm

● X 1000

– Pocket calculator notation: 1,000 mm

– Standard notation:

IS-B: 1,000* 0.001= 1 mm

IS-C: 1,000* 0.0001= 0.1 mm

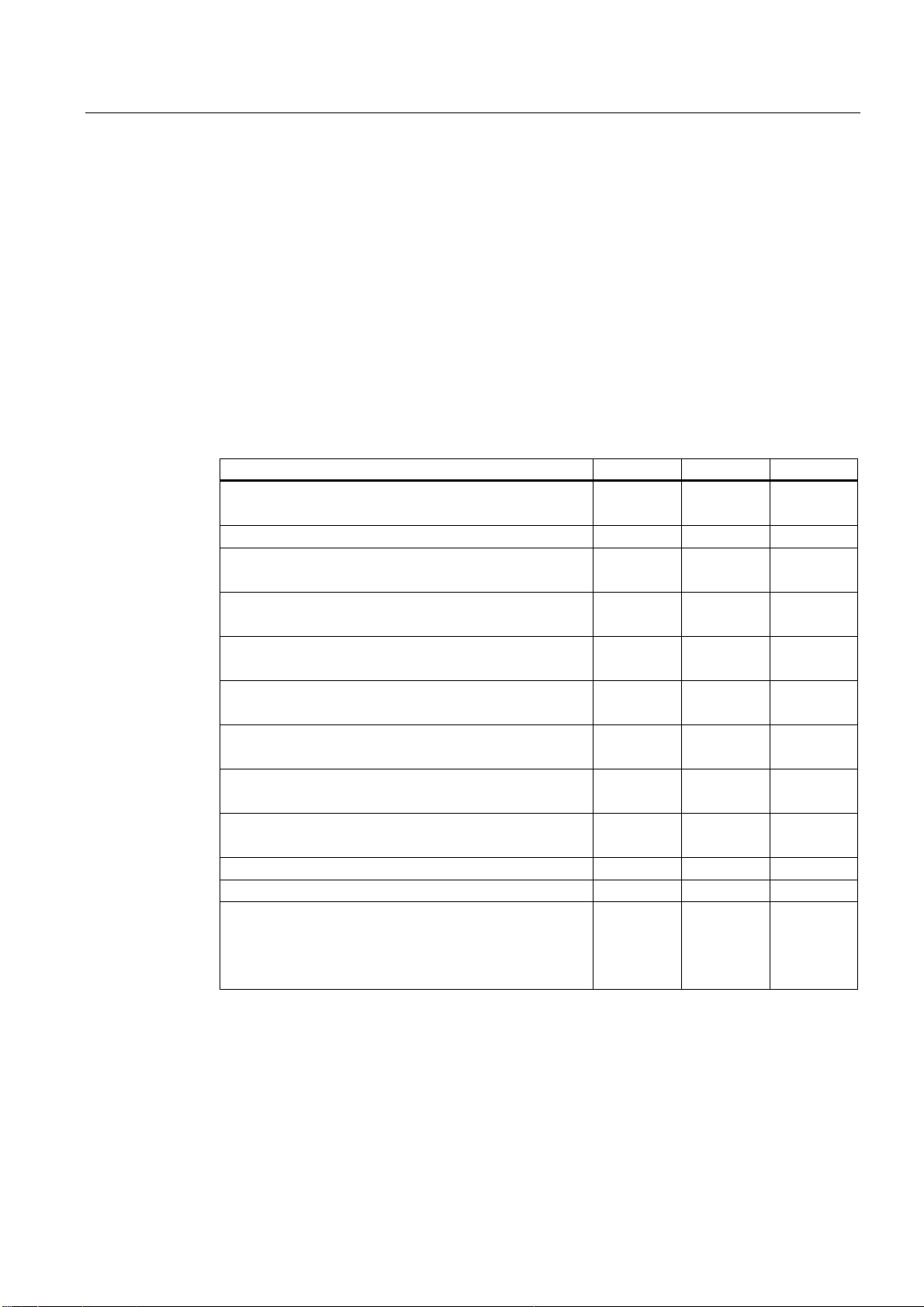

ISO dialect milling

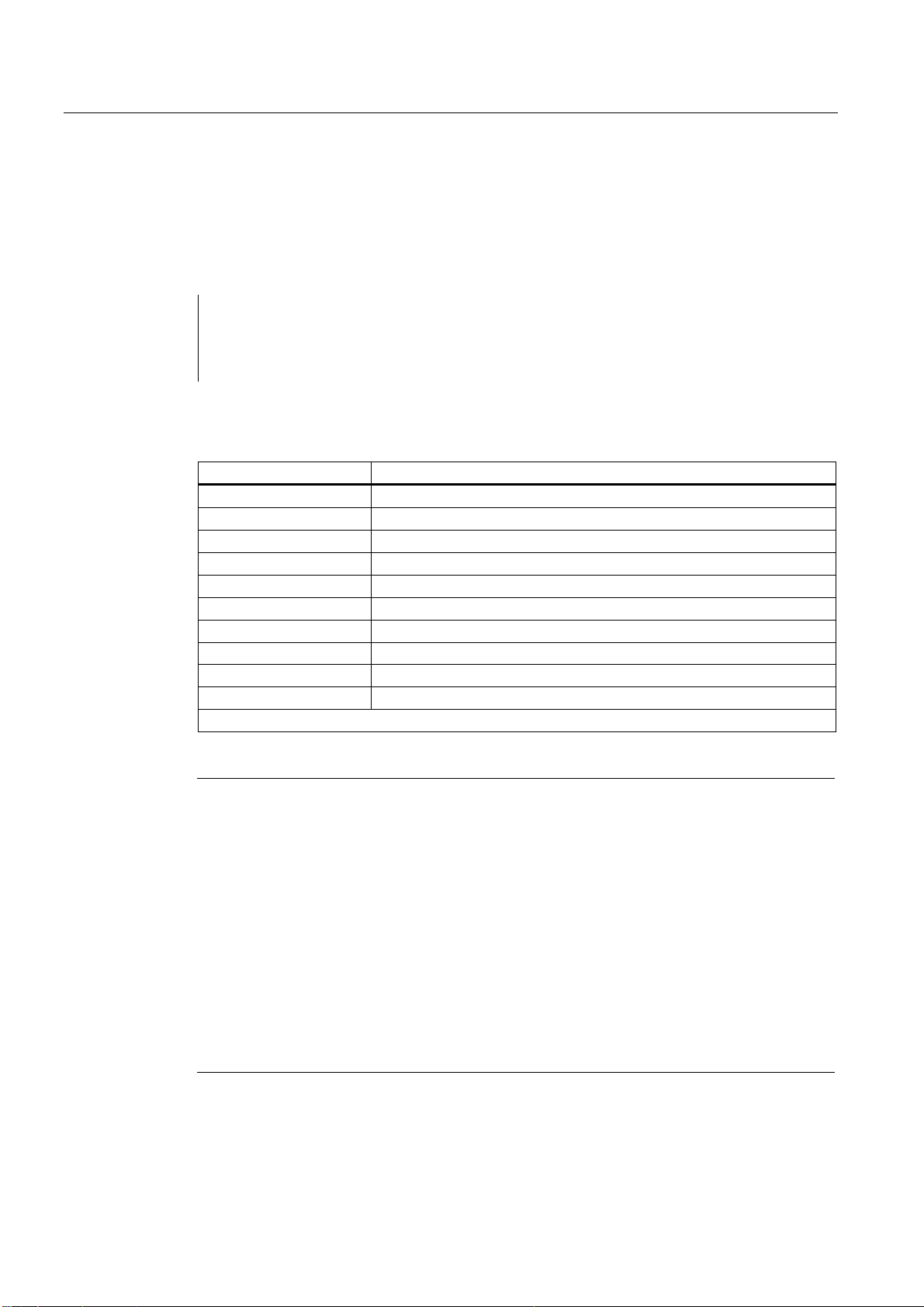

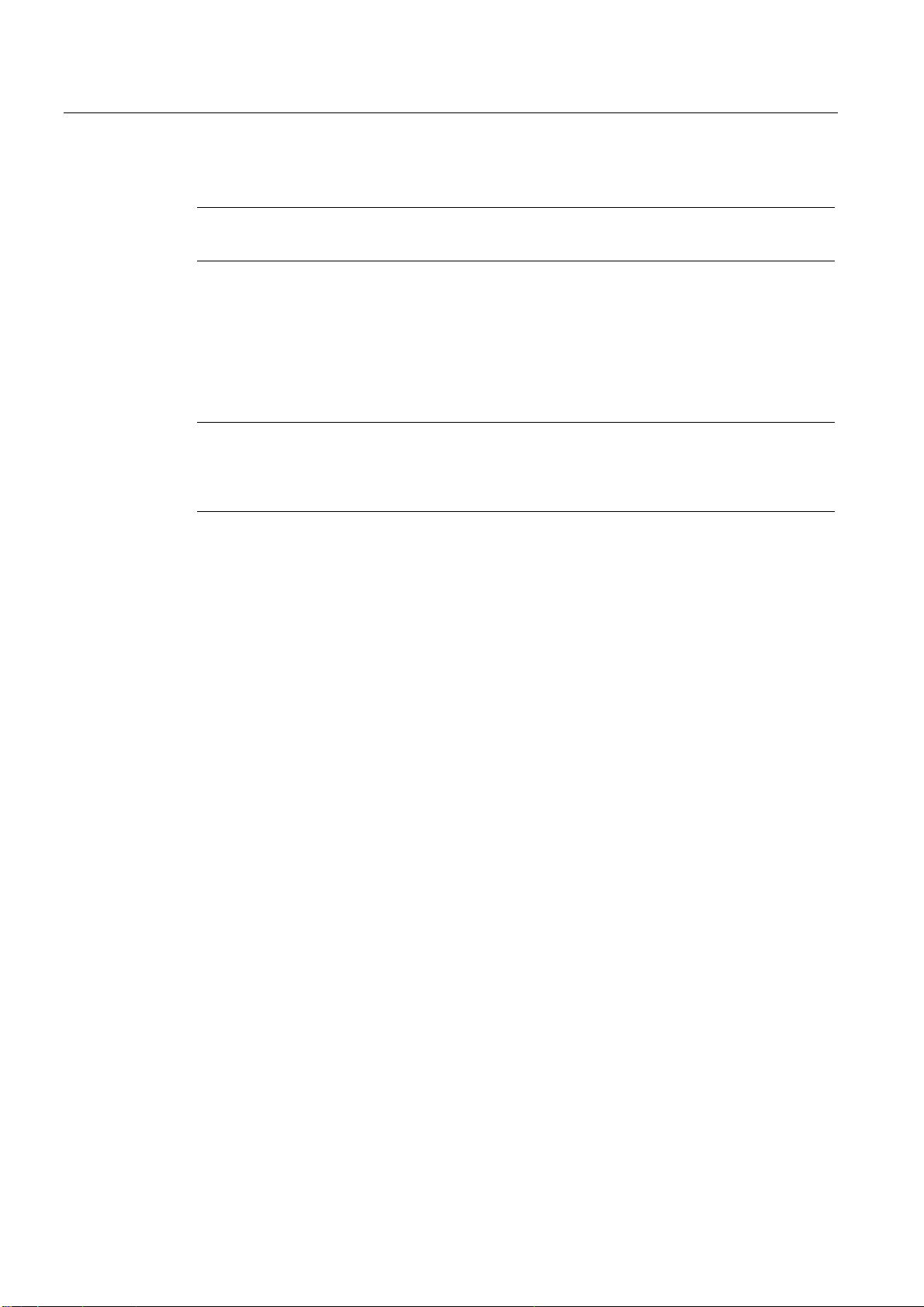

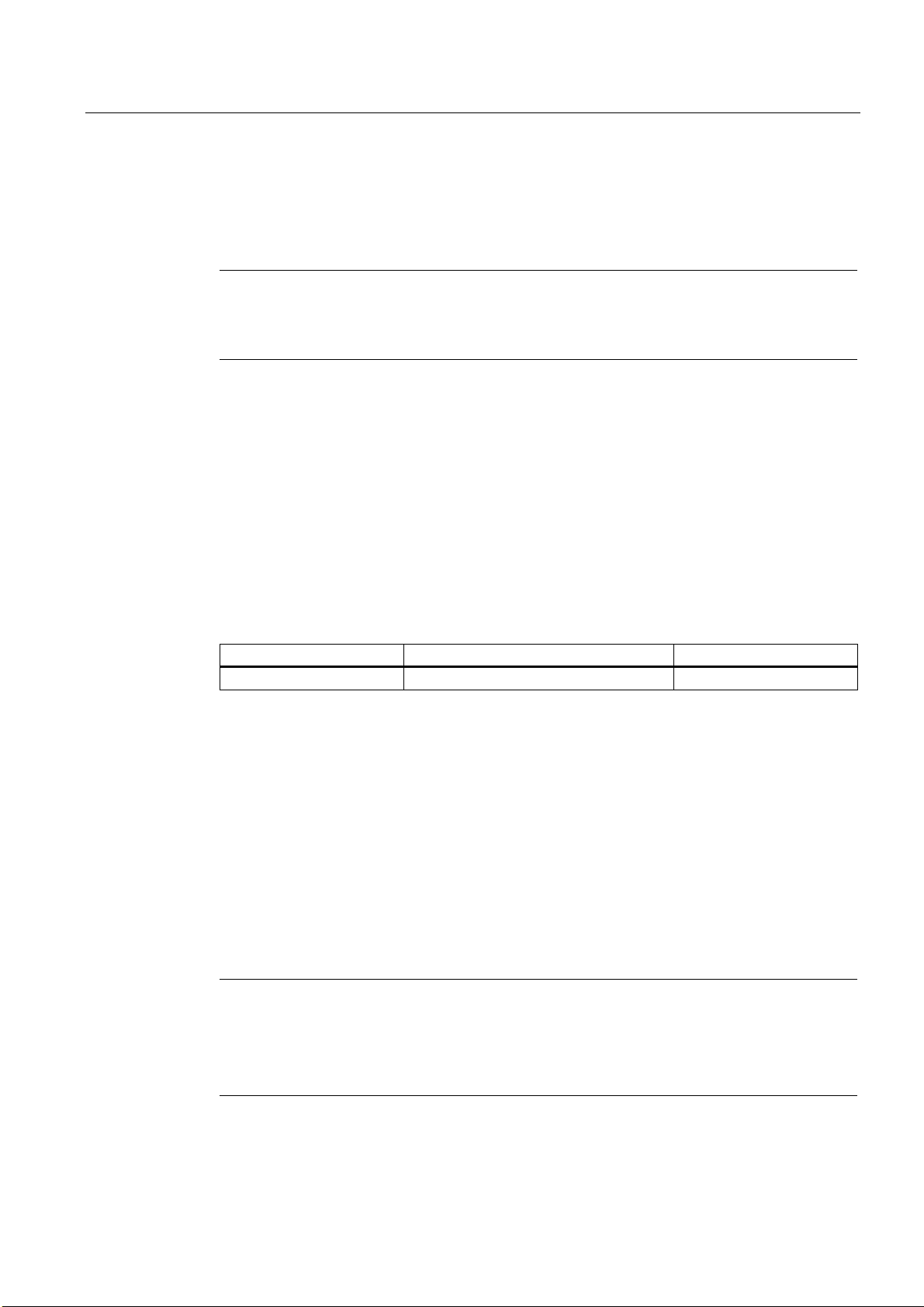

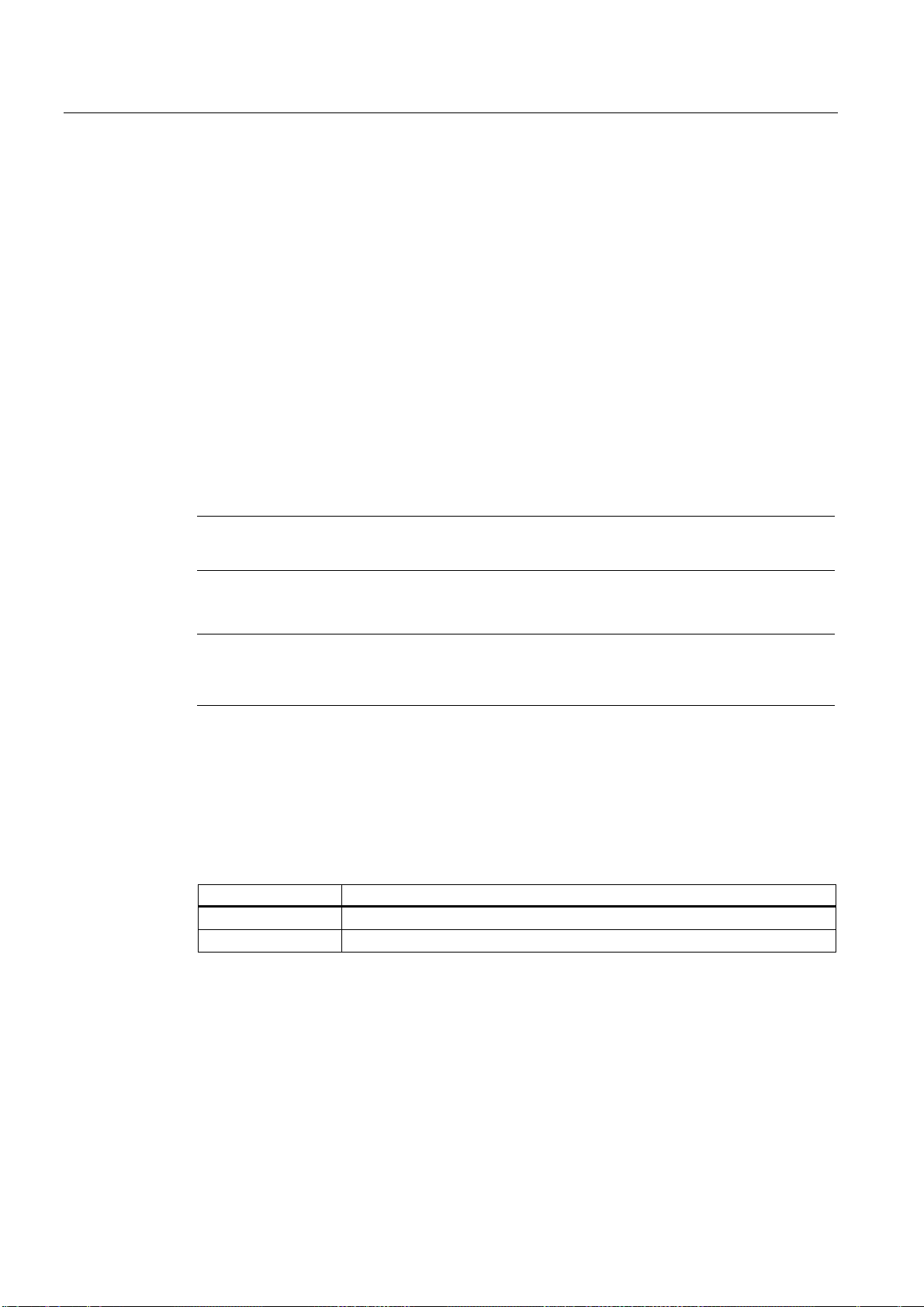

Table 1- 1 Different conversion factors for IS-B and IS-C

Address Unit IS-B IS-C

Linear axis mm

inch

Rotary axis Degree 0,001 0,0001

F feed G94 (mm/inch per min.) mm

inch

F feed G95 (mm/inch per min.) mm

inch

F thread lead mm

inch

C chamfer mm

inch

R radius, G10 toolcorr mm

inch

Q mm

inch

I, J, K IPO parameters mm

inch

G04 X or U s 0,001 0,001

A angle contour definition Degree 0,001 0,0001

G74, G84 tapping cycles

$MC_EXTERN_FUNCTION_MASK

Bit8 = 0 F as feed such as G94, G95

Bit8 = 1 F as thread lead

0,001

0,0001

1

0,01

0,01

0,0001

0,01

0,0001

0,001

0,0001

0,001

0,0001

0,001

0,0001

0,001

0,0001

0,0001

0,00001

1

0,01

0,01

0,0001

0,01

0,0001

0,0001

0,00001

0,0001

0,00001

0,0001

0,00001

0,0001

0,00001

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

9

Principles of programming

1.1 Introductory comments

1.1.7 Comments

In the ISO dialect mode, brackets are interpreted as comment signs. In the Siemens mode,

";" is interpreted as comment. To simplify matters, an ";" is also understood as comment in

the ISO dialect mode.

If the comment start sign '(' is used inside a comment again, the comment is ended only if all

the open brackets are closed again.

Example:

N5 (comment) X100 Y100

N10 (comment(comment)) X100 Y100

N15 (comment(comment) X100) Y100

X100 Y100 is executed in block N5 and N10, but only Y100 in block N15, because the first

bracket is closed only after X100. Everything up to that point is interpreted as comment.

1.1.8 Skip block

The sign of skipping or suppression of blocks "/" can be used at any convenient position in a

block, i.e. even in the middle of the block. If the programmed block skip level is active on the

date of the compilation, the block is not compiled from this point up to the end of the block.

An active block skip level has the same effect as a block end.

Example:

N5 G00 X100. /3 YY100 --> Alarm 12080 "Syntax error"

N5 G00 X100. /3 YY100 --> no alarm, if block skip level 3 is active

Block skip signs within a comment are not interpreted as block skip signs

Example:

N5 G00 X100. ( /3 Part1 ) Y100

;the Y axis is traversed even when the block skip level 3 is active

The block skip levels /1 to /9 can be active. Block skip values <1 and >9 lead to alarm 14060

"Impermissible skip level for differential block skip".

The function is mapped to the existing Siemens skip levels. Unlike the ISO Dialect original,

"/" and "/1" are separate skip levels that must also be activated separately.

Note

The "0" in "/0" can be omitted.

ISO Milling

10 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Principles of programming

1.2 Preconditions for the feed

1.2 Preconditions for the feed

The following Section describes the feed function with which the feedrate (covered path per

minute or per rotation) of a cutting tool is defined.

1.2.1 Rapid traverse

Rapid traverse is used for positioning (G00) as well as for manual traverse with rapid

traverse (JOG). In rapid traverse, each axis is traversed with the rapid traverse rate set for

the individual axes. The rapid traversing rate is defined by the machine manufacturer and it

is specified by the machine data for the individual axes. As the axes traverse independently

of each other, each axis reaches its target point at a different time. Hence, the resulting tool

path is generally not a straight line.

1.2.2 Path feed (F function)

Note

Unless something else is specified, the unit "mm/min" always stands for feedrate of the

cutting tool in this documentation.

The feed with which a tool should be traversed in linear interpolation (G01) or circular

interpolation (G02, G03) is designated with the address character "F".

The feed of the cutting tool in "mm/min" is specified after the address character "F".

The permissible range of F values is specified in the documentation of the machine

manufacturer.

Possibly, the feed is limited by the servo system and the mechanical system in the upward

direction. The maximum feed is set in the machine data and limited to the value defined

there before an overshoot.

The path feed is generally composed of the individual speed components of all geometry

axes participating in the movement and refers to the cutter center (see the two following

figures).

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

11

Principles of programming

1.2 Preconditions for the feed

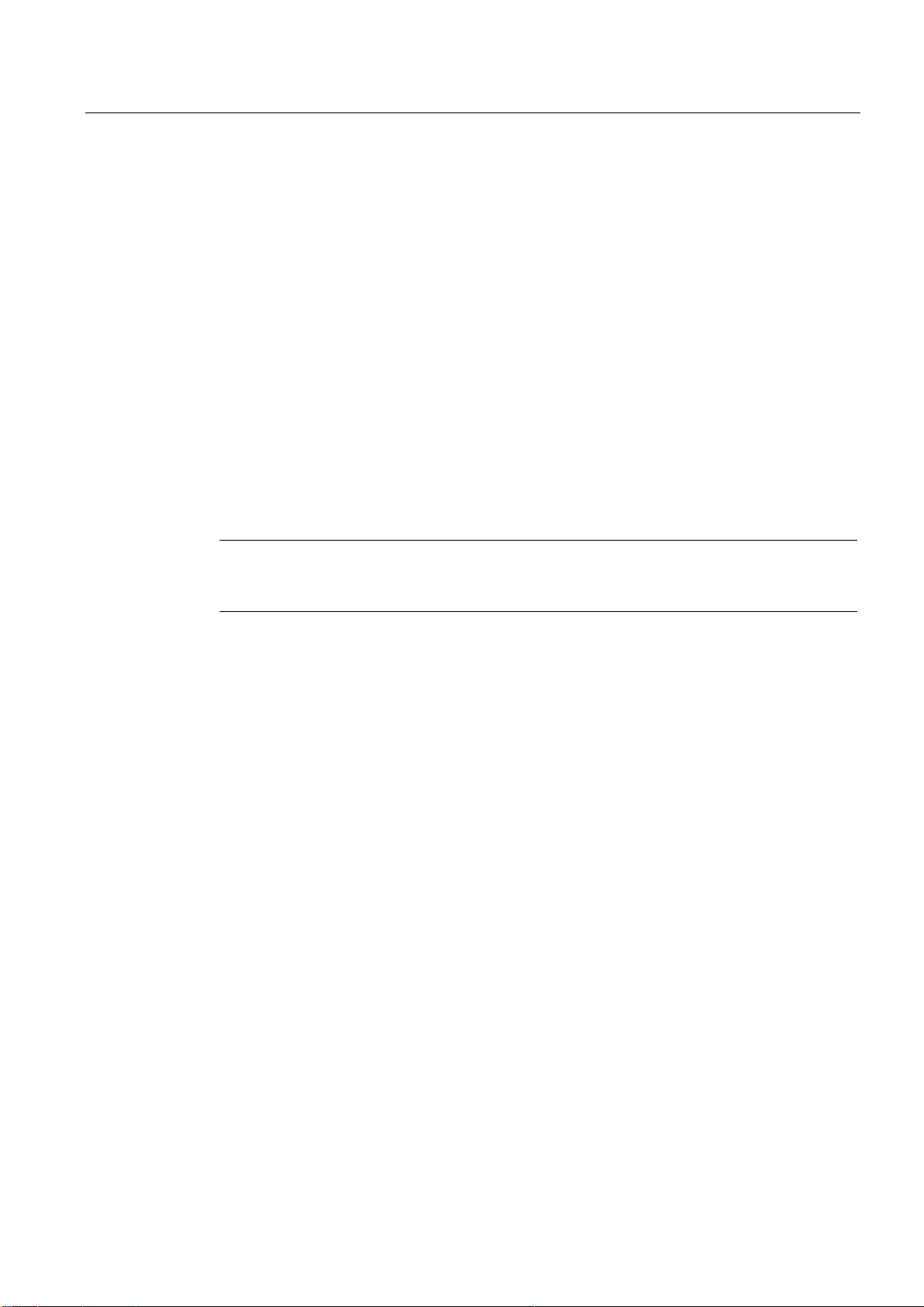

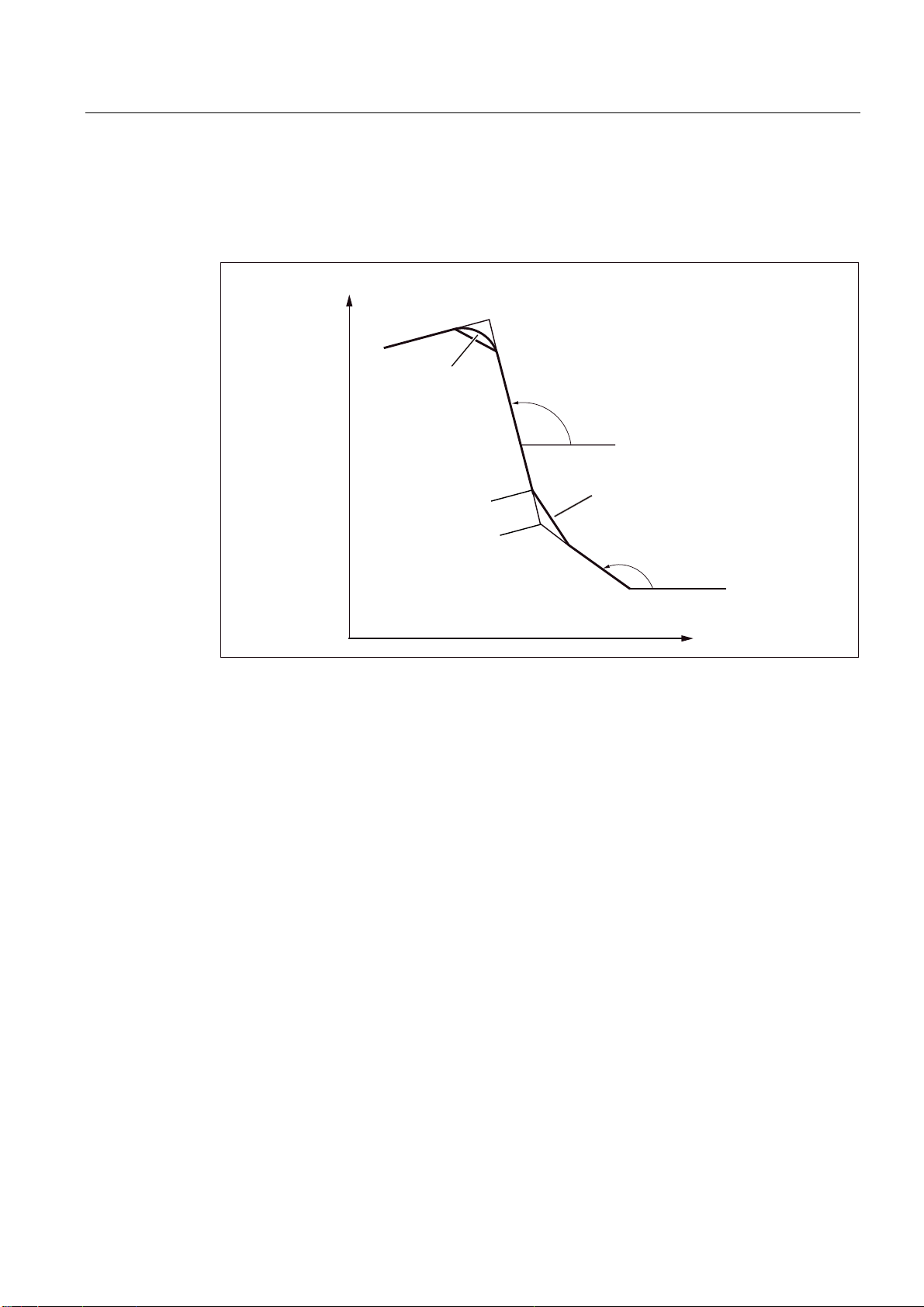

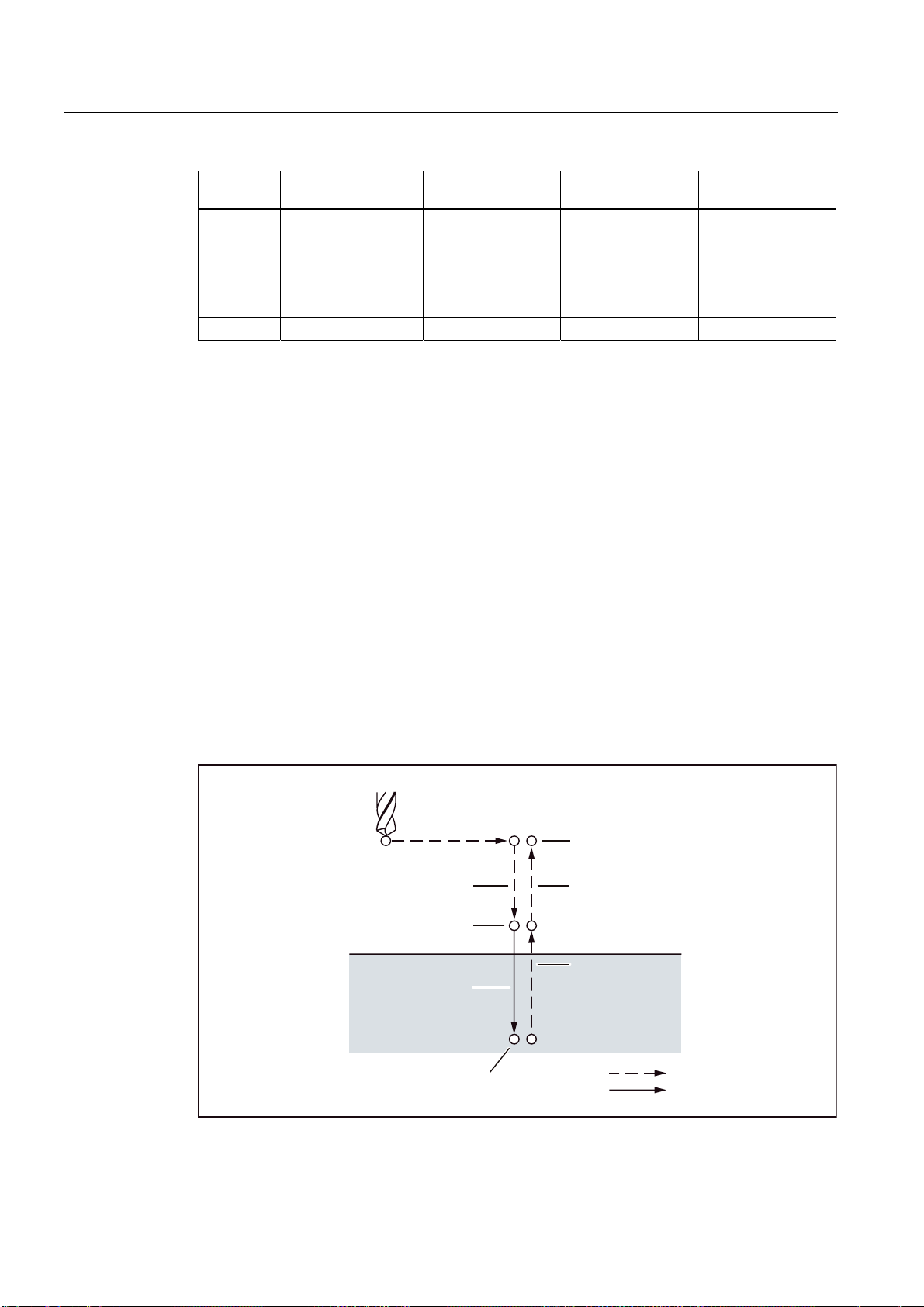

3URJUDPPLQJH[DPSOHZLWKWKH

IROORZLQJSURJUDP

*,QFUHPHQWDOGLPHQVLRQLQJ

*;<)

3DWKYHORFLW\LQ

WDQJHQWLDOGLUHFWLRQ

PPPLQ

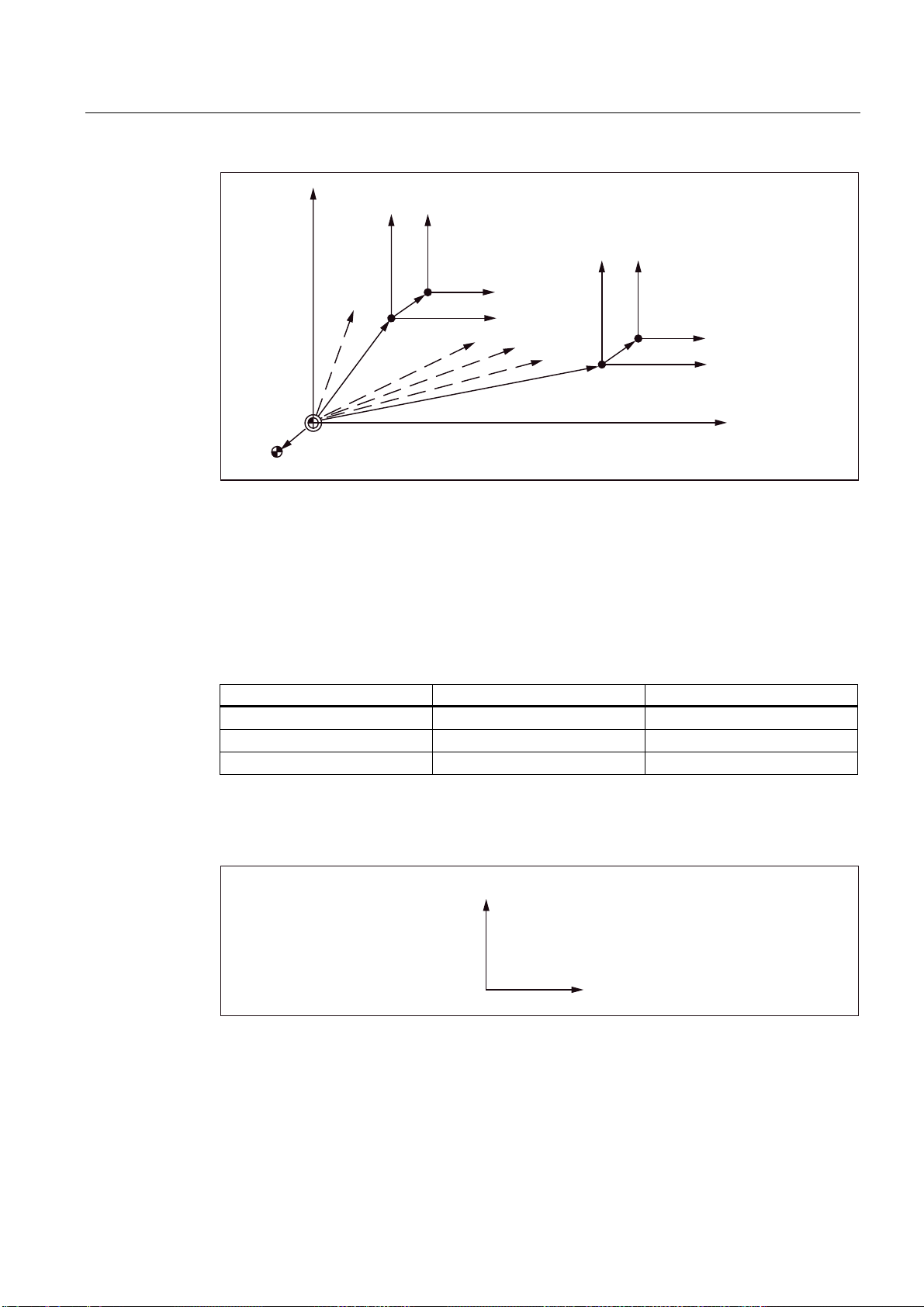

Figure 1-1 Linear interpolation with 2 axes

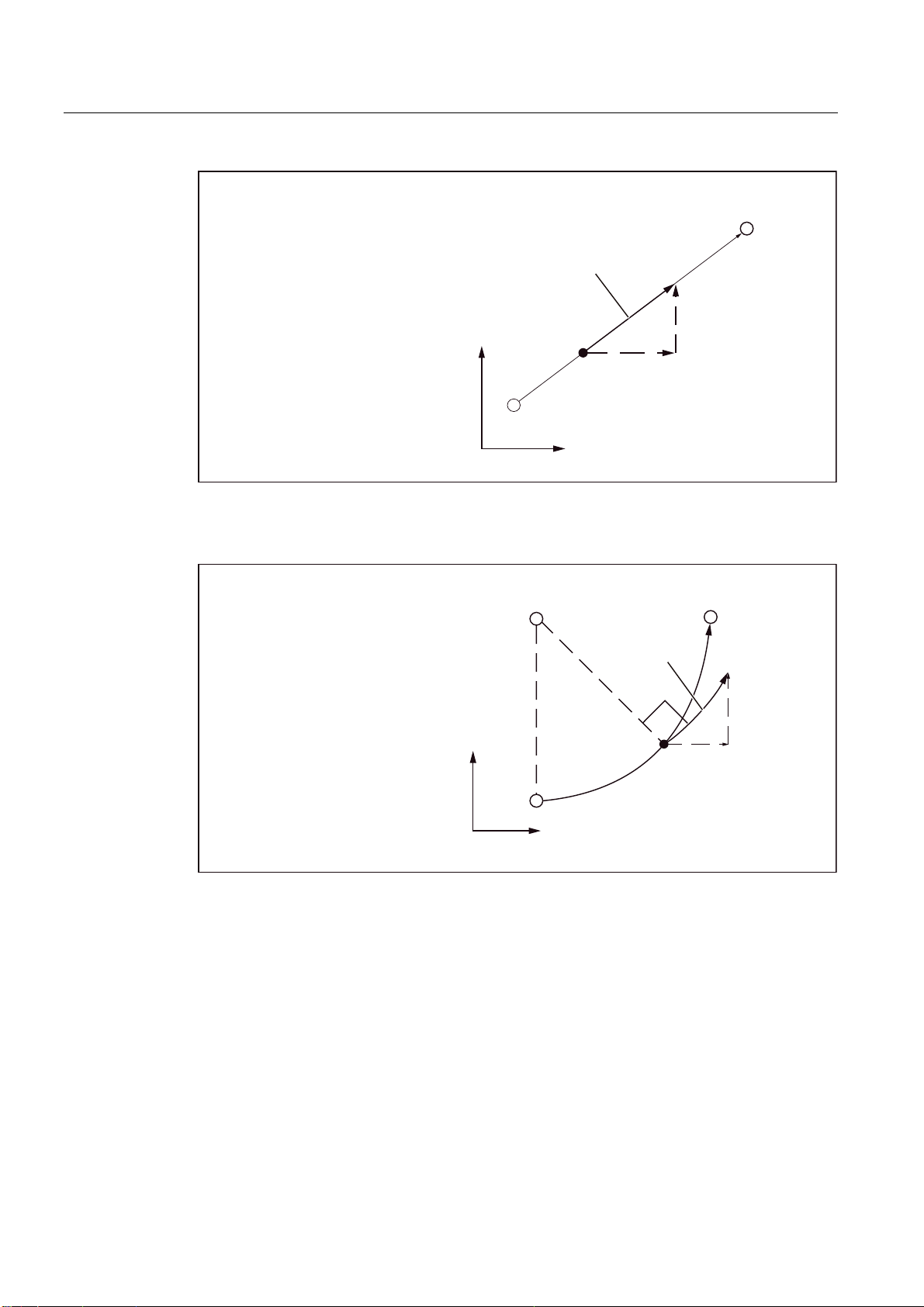

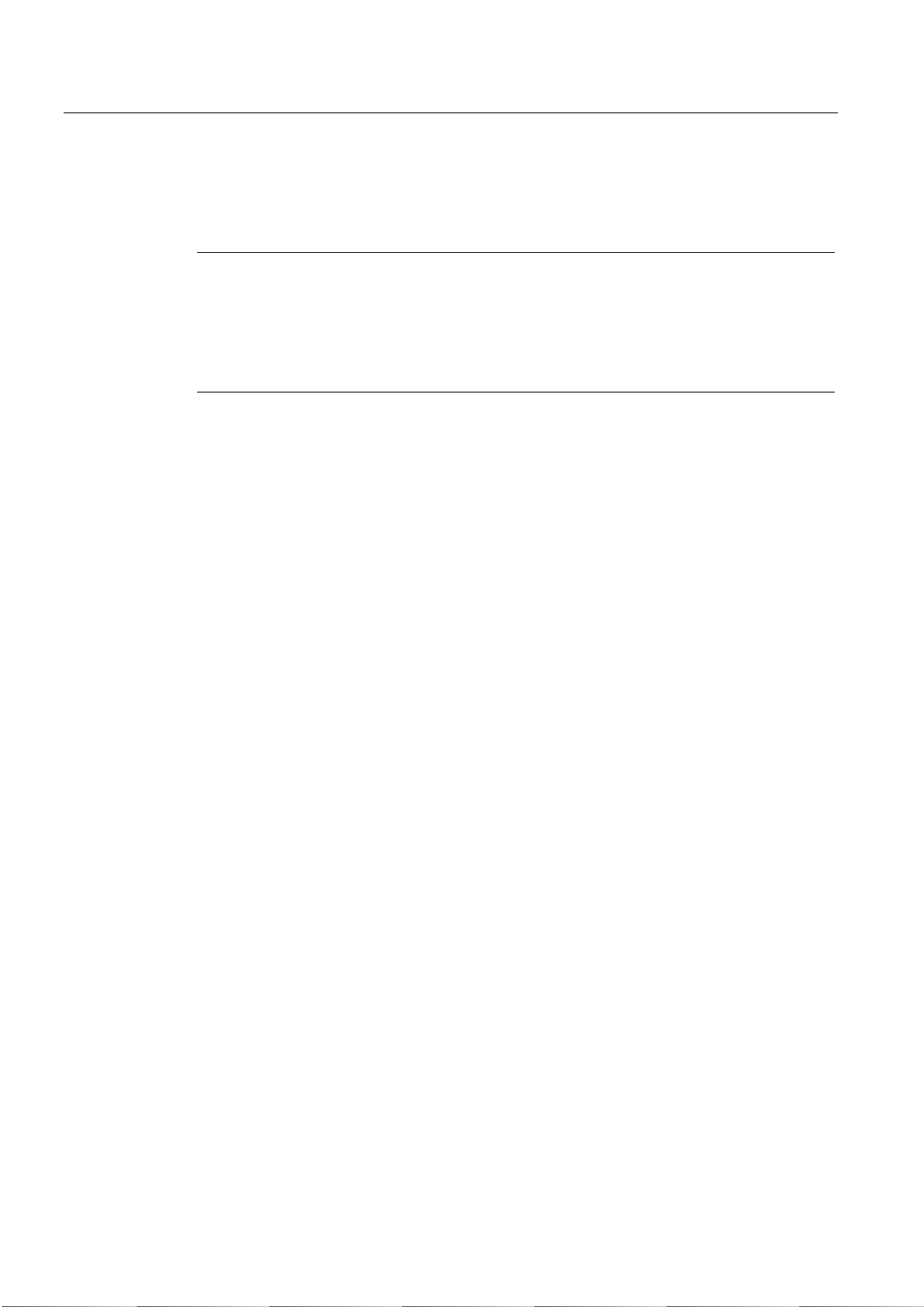

3URJUDPPLQJH[DPSOHZLWKWKH

IROORZLQJSURJUDP

*,QFUHPHQWDOGLPHQVLRQLQJ

*;<,)

<

<

PPPLQ

PPPLQ

;

&HQWHUSRLQW

PPPLQ

)\

)[

;

Figure 1-2 Circular interpolation with 2 axes

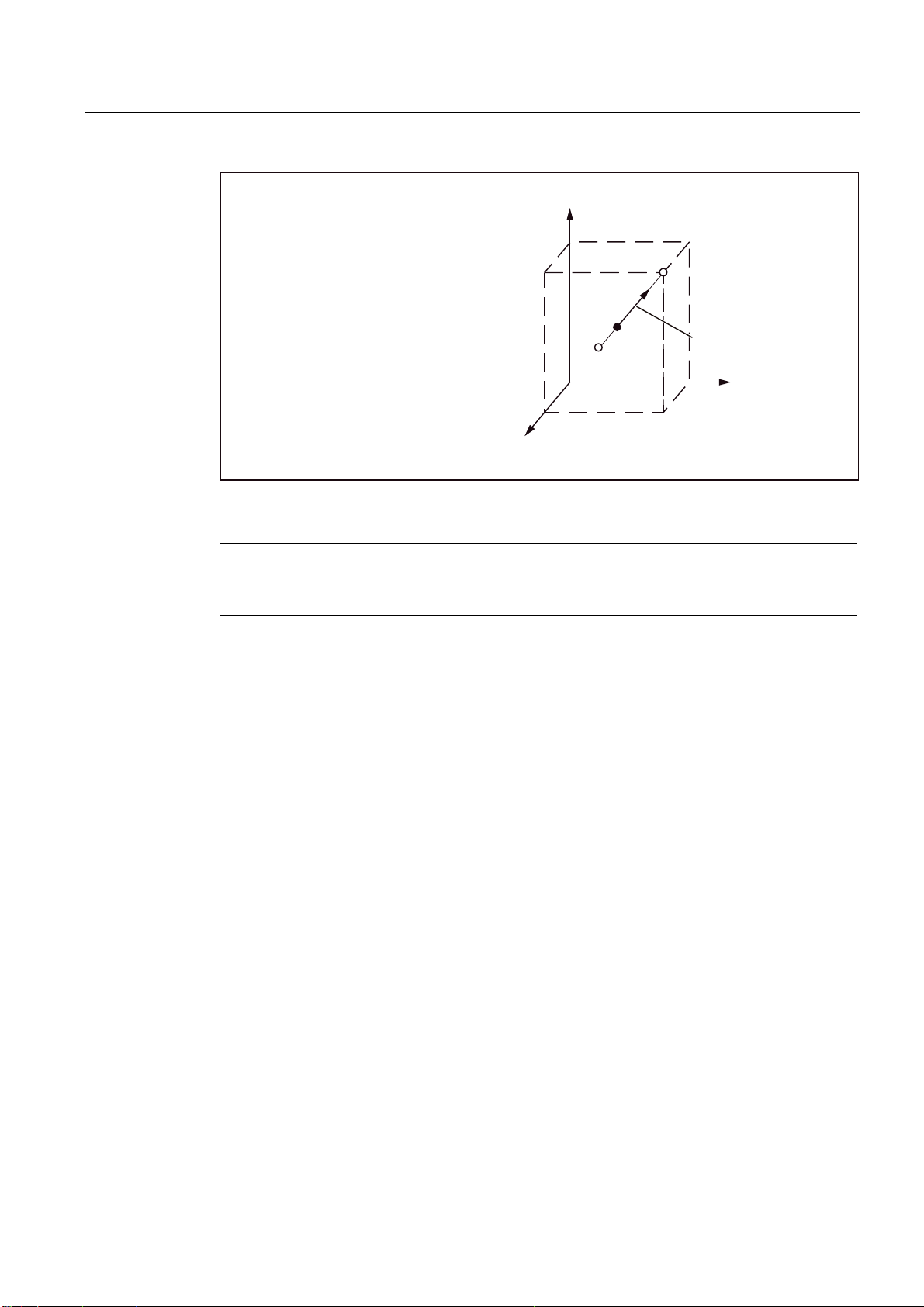

In 3D interpolation, the feed of the resulting straight lines programmed with F are maintained

in the space.

ISO Milling

12 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Principles of programming

1.2 Preconditions for the feed

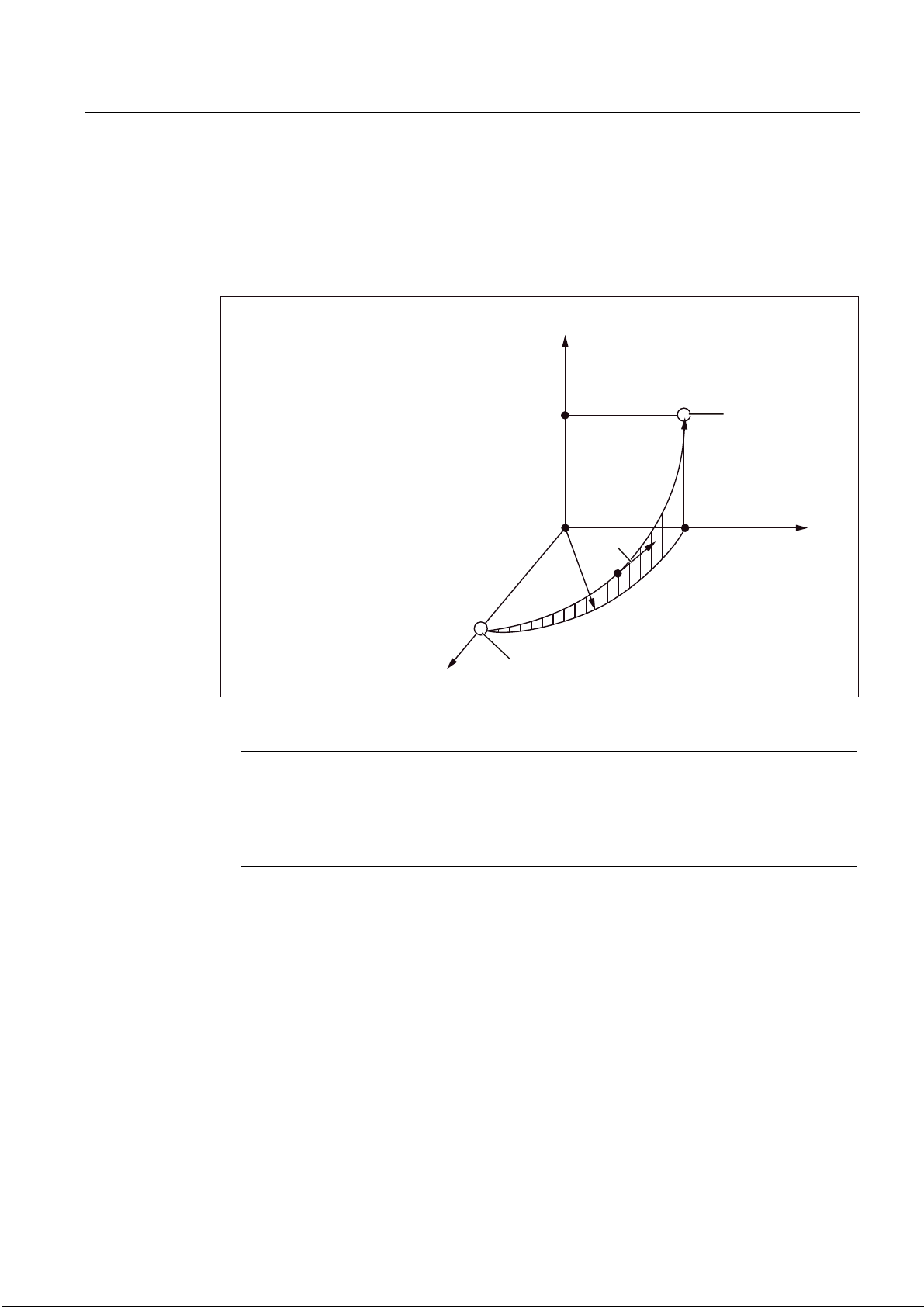

3URJUDPPLQJH[DPSOHZLWK

WKHIROORZLQJSURJUDP

*;<=)

=

<

(QGSRLQW

PPPLQ

6WDUWSRLQW

;

Figure 1-3 Feed in case of 3D interpolation

Note

If "F0" is programmed and the function "Fixed feedrate" is not active, then the Alarm 14800

"Programmed path velocity less than or equal to zero" is output.

1.2.3 Fixed feedrates F0 to F9

Activate feed values

Ten different feed values pre-set via setting data can be activated with F0 to F9. To activate

the rapid traverse rate with F0, the corresponding speed must be entered in the setting data

42160 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[0].

The feed values for F0 to F9 are entered in the setting data as real values. An evaluation of

the input values is not undertaken.

The function is activated via the machine data 22920

$MC_EXTERN_FIXED_FEEDRATE_F1_ON. If the machine data is set to FALSE, F1 - F9 is

interpreted as normal feed programming, e.g. F2 = 2 mm/min, F0=0 mm/min.

If the machine data = TRUE, the feed values for F0 - F9 are fetched from the setting data

42160 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[ ]. If the value 0 exists in one of the

setting data, then the corresponding address extension of feed 0 is activated during the

programming.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

13

Principles of programming

1.2 Preconditions for the feed

Example

$SC_FIXED_FEEDRATE_F1_F9[0] = 5000

$SC_FIXED_FEEDRATE_F1_F9[1] = 1000

$SC_FIXED_FEEDRATE_F1_F9[2] = 500

N10 X10 Y10 Z10 F0 G94 ;Approach position at 5000 mm/min

N20 G01 X150 Y30 F1 ;Feed 1000 mm/min active

N30 Z0 F2 ;Position approached at 500 mm/min

N40 Z10 F0 ;Approach position at 5000 mm/min

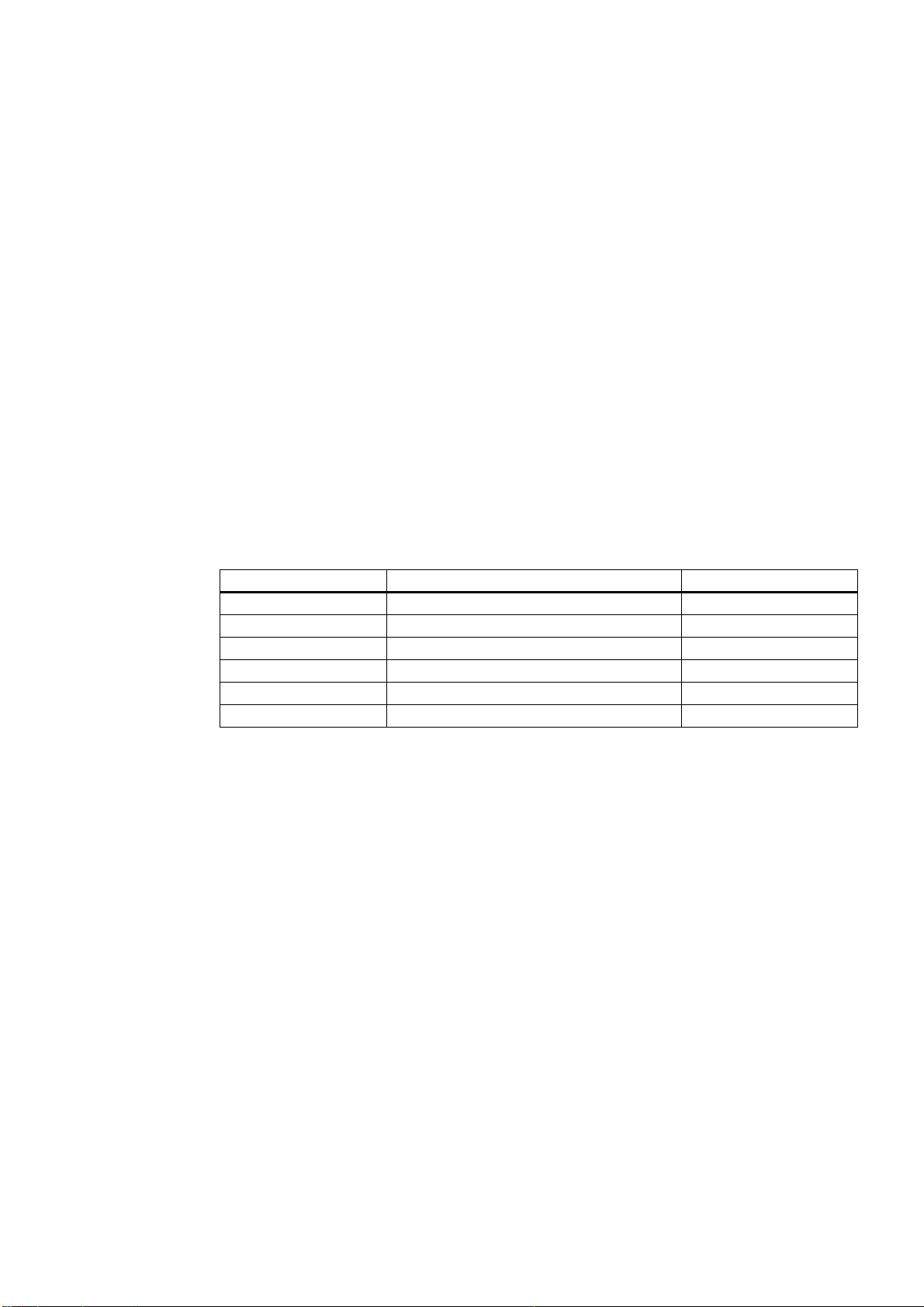

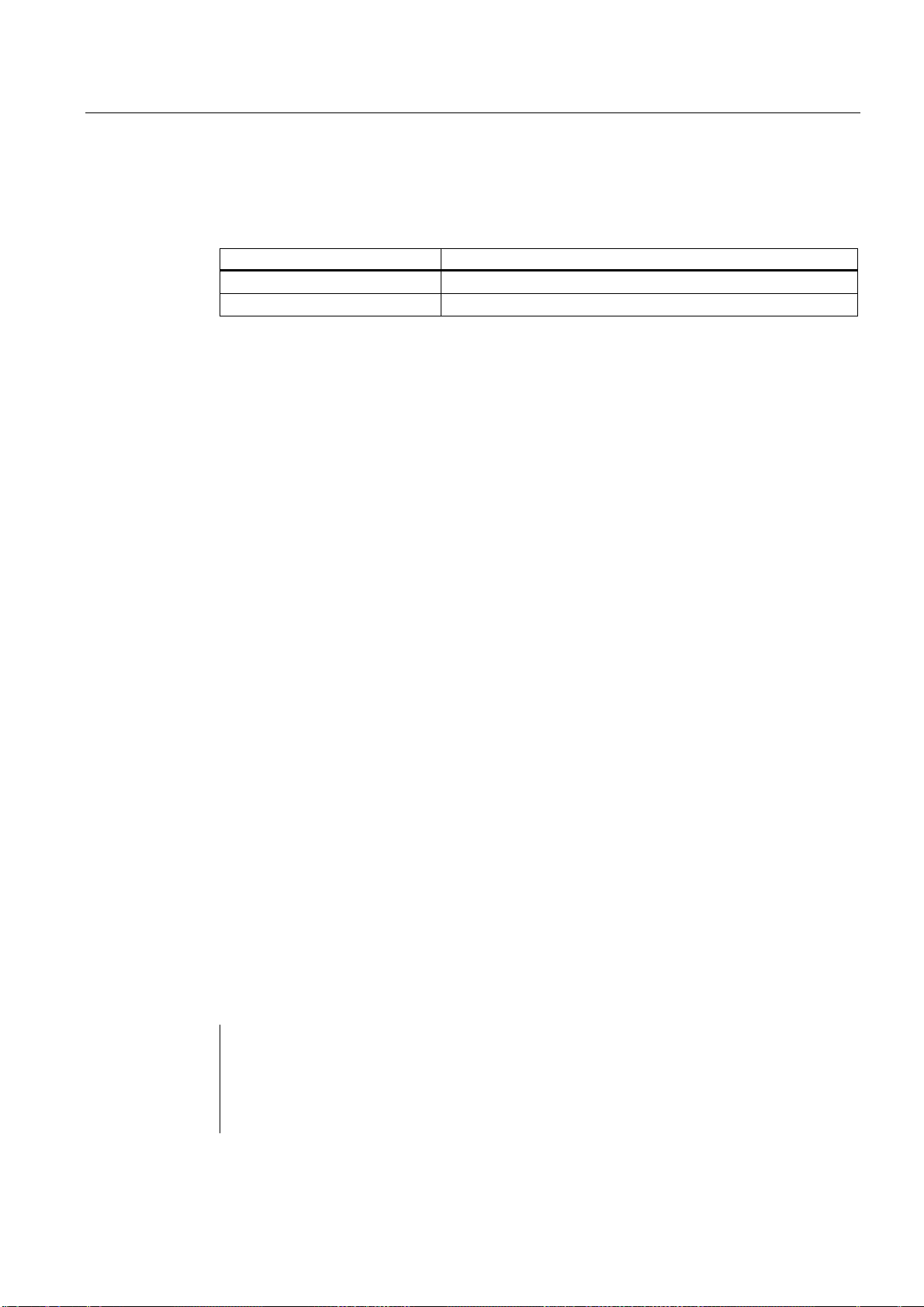

Table 1- 2 Setting data for the default setting of feedrate F

F function Setting Data

F0 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[0]

F1 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[1]

F2 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[2]

F3 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[3]

F4 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[4]

F5 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[5]

F6 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[6]

F7 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[7]

F8 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[8]

F9 $SC_EXTERN_FIXED_FEEDRATE_F1_F9[9]

Note: Input format = REAL

Note

If the function is activated with MD $MC_EXTERN_FIXED_FEEDRATE_F1_ON and if the

feed value from the setting data is not to be active with F1 to F9, then the feed value is

programmed as actual value. If, for instance, a feed value should be programmed at 1

mm/min, the feed must be programmed with F1.0 instead of F1.

If the "DRY RUN" (test run) switch is set to "ON", all the feed commands are traversed at the

feed set for the test run.

The Feed Override function is effective even for the fixed feedrates F0 to F9.

The feed set in the setting data is stored even after the control system is switched off.

In a macro call with G65/G66, the value programmed with F is stored in the system variable

$C_F, i.e. the numeric values 0 to 9 are stored.

If, in a cycle call, a fixed feed (F0 - F9) is programmed in a machining program, the feed

value is read from the relevant setting data and stored in the variable $C_F.

ISO Milling

14 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Principles of programming

1.2 Preconditions for the feed

Example

$SC_FIXED_FEEDRATE_F1_F9[0] = 1500.0

$SC_FIXED_FEEDRATE_F1_F9[1] = 550.0

N10 X10 Y10 Z10 F0 G94 ;Positioning with 1500

N20 G01 X150 Y30 F1 ;Feed 550 mm/min active

N40 Z10 F0 ;Positioning with 1500

Note

While macroprogramming with G65/66, the programmed value for the address F is always

stored in the cycle system variable. For F1 to F9, for example, the value 1 to 9 is entered in

the cycle system variable $C_F. The address signifies a transfer variable here and has no

direct reference to the feed.

The same is true of the thread lead programming in G33 - G34 with the address F. No feed

is programmed with F here, instead the distance between two threads during a spindle

revolution.

In cycle programming (e.g., G81 X.. Y.. Z.. R.. P.. Q.. F..), the feed is always programmed

under the address F. In a part program block with a cycle call over a G function (G81 - G87

etc.), the corresponding feed value during the programming of F1 to F9 is written from the

corresponding setting data in the variable $C_F.

Restriction

In the ISO dialect mode, the feed values are changed in the setting data with a handwheel.

In the Siemens mode, the feeds can be influenced only like a directly programmed feed, e.g.

through the override switch.

1.2.4 Linear feed (G94)

On specifying G94, the feed given after the address character F is executed in the mm/min,

inch/min or degree/min unit.

1.2.5 Inverse-time feed (G93)

On specifying G93, the feed given after the address character F is executed in the 1/min

unit. G93 is a modally effective G function.

Example

N10 G93 G1 X100 F2 ;

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

15

Principles of programming

1.2 Preconditions for the feed

Note

The time inverse feed 1/min G93 is not implemented for SINUMERIK 802D.

i.e., the programmed path is traversed within half a minute.

1.2.6 Revolutional feedrate (G95)

On entering G95, the feed is executed in the mm/revolution unit or inch/revolution related to

the master spindle.

Note

All of the commands are modal. If the G feed command is switched among G93, G94 or

G95, the path feed must be reprogrammed. The feed can also be specified in

degree/revolution for the machining with rotary axes.

ISO Milling

16 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.1 Interpolation commands

The positioning and interpolation commands, with which the tool path along the programmed

contour, such as a straight line or a circular arc, is monitored, are described in the next

Section.

2.1.1 Rapid traverse (G00)

You can use rapid traverse to position the tool rapidly, to traverse around the workpiece or to

approach tool change points.

The following G functions can be used to call the positioning (refer to following table):

Table 2- 1 G function for positioning

G function Function G group

G00 Rapid traverse 01

G01 Linear movement 01

G02 Circle/helix in the clockwise direction 01

G02.2 Involute in the clockwise direction 01

G03 Circle/helix in the counterclockwise direction 01

G03.2 Involute in the counterclockwise direction 01

2

Positioning (G00)

Format

G00 X... Y... Z... ;

Explanation

The tool movement programmed with G00 is executed at the highest possible traversing

speed (rapid traverse). The rapid traverse rate is defined separately for each axis in machine

data. If the rapid traverse movement is executed simultaneously on several axes, the rapid

traverse rate is determined by the axis which requires the most time for its section of the

path.

Axes that are not programmed in a G00 block are not traversed. In positioning, the individual

axes traverse independently of each other with the rapid traverse rate specified for each

axis. The precise speeds of your machine can be consulted in the documentation of the

manufacturer.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

17

Drive commands

2.1 Interpolation commands

3URJUDPPLQJH[DPSOH

*;<=

=D[LV

<D[LV

5DSLGWUDYHUVHUDWH

;D[LVPPPLQ

<D[LVPPPLQ

=D[LVPPPLQ

;D[LV

Figure 2-1 Positioning in the run state with 3 simultaneously controllable axes

Note

As in positioning with G00, the axes traverse independently of each other (not interpolated),

each axis reaches its end point at a different time. Hence, one must be very careful in

positioning with several axes, so that a tool does not collide with a workpiece of the tool

during the positioning.

Linear interpolation (G00)

Linear interpolation with G00 is defined by setting the machine data 20732

$MC_EXTERN_GO_LINEAR_MODE. Here, all programmed axes traverse in rapid traverse

with linear interpolation and reach their target positions simultaneously.

2.1.2 Linear interpolation (G01)

With G01 the tool travels on paraxial, inclined or straight lines arbitrarily positioned in space.

Linear interpolation permits machining of 3D surfaces, grooves, etc.

Format

G01 X... Y... Z... F... ;

In G01, the linear interpolation is executed with the path feed. The axes that are not

specified in the block with G01 are not traversed. The linear interpolation is programmed as

in the example given above.

ISO Milling

18 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

A

2.1 Interpolation commands

Feed F for path axes

The feedrate is specified under the address F. Depending on the default setting in the

machine data, the units of measurement specified with the G commands (G93, G94, G95)

are either in mm or inch.

One F value can be programmed per NC block. The unit of feedrate is defined over one of

the mentioned G commands. The feed F acts only on path axes and remains active until a

new feed value is programmed. Separators are permitted after address F.

Note

n alarm is triggered while executing a G01 block if no feed was programmed in a block with

G01 or in the previous blocks.

The end point can be specified either as absolute or as incremental. Details are available in

Chapter "Absolute/incremental dimensioning".

3URJUDPPLQJH[DPSOH

*;<=)

=D[LV

Figure 2-2 Linear interpolation

<D[LV

PPPLQ

7DQJHQWLDOYHORFLW\

;D[LV

2.1.3 Circular interpolation (G02, G03)

Format

To start the circular interpolation, please execute the commands specified in the following

table.

Table 2- 2 Commands to be executed for circular interpolation

Element Command Description

Designation of the plane G17 Circular arc in Plane X-Y

G18 Circular arc in Plane Z-X

G19 Circular arc in Plane Y-Z

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

19

Drive commands

2.1 Interpolation commands

Element Command Description

Direction of rotation G02 clockwise

G03 counterclockwise

End-point position Two axes from X, Y

or Z

Two axes from X, Y

or Z

Distance between start point center

Radius of circular arc R Radius of circular arc

Feed F Speed along the circular arc

Two axes from I, J or K Distance start point - circle center with sign

End-point position in a workpiece coordinate

system

Distance of start point - end point with sign

Designation of the plane

With the commands specified below, a tool traverses along the specified circular arc in the

plane X-Y, Z-X or Y-Z, so that the feed specified with "F" is maintained on the circular arc.

● in Plane X-Y:

G17 G02 (or G03) X... Y... R... (or I... J... ) F... ;

● in Plane Z-X:

G18 G02 (or G03) Z... X... R... (or K... I... ) F... ;

● in the Plane Y-Z:

G19 G02 (or G03) Y... Z... R... (or J... K... ) F... ;

Before the circle radius programming (with G02, G03), one must first select the desired

interpolation plane with G17, G18 or G19. Circular interpolation is not allowed for the 4th and

5th axes, if these are linear axes.

Plane selection is also used to select the plane in which the tool radius compensation

(G41/G42) is performed. The Plane X-Y (G17) is automatically set after activating the control

system.

G17 X-Y plane

G18 Z-X plane

G19 Y-Z plane

The working planes should be specified, in general.

Circles can also be created outside the selected working plane. In this case, the axis

addresses (specification of circle end positions) determine the circular plane.

Circular interpolation is possible in the Xβ, Zβ or Yβ plane while selecting an optional 5th

linear axis, which also contains a 5th axis besides the X-Y, Y-Z and Z-X planes (β=U, V or

W)

● Circular interpolation in the Xβ plane

G17 G02 (or G03) X... β... R... (or I... J... ) F... ;

● Circular interpolation in the Zβ plane

G18 G02 (or G03) Z... β... R... (or K... I... ) F... ;

ISO Milling

20 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.1 Interpolation commands

● Circular interpolation in the Yβ plane

G19 G02 (or G03) Y... β... R... (or J... K... ) F... ;

● If the address characters for the 4th and 5th axes are omitted - such as in the commands

"G17 G02 X... R... (or I... J... ) F... ;", then the X-Y plane is selected automatically as the

interpolation plane. Circular interpolation with the 4th and 5th axes is not possible if these

additional axes are rotary axes.

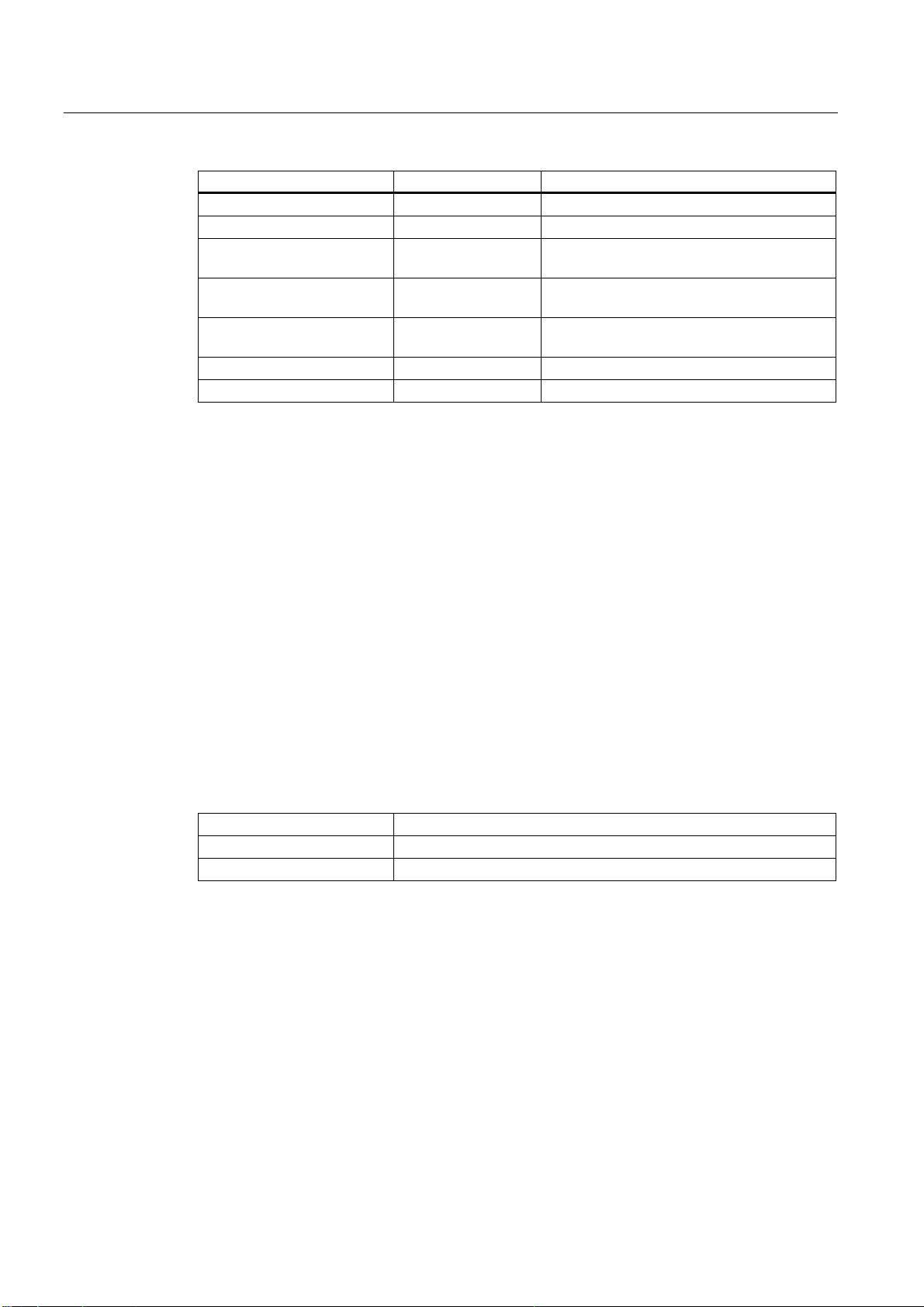

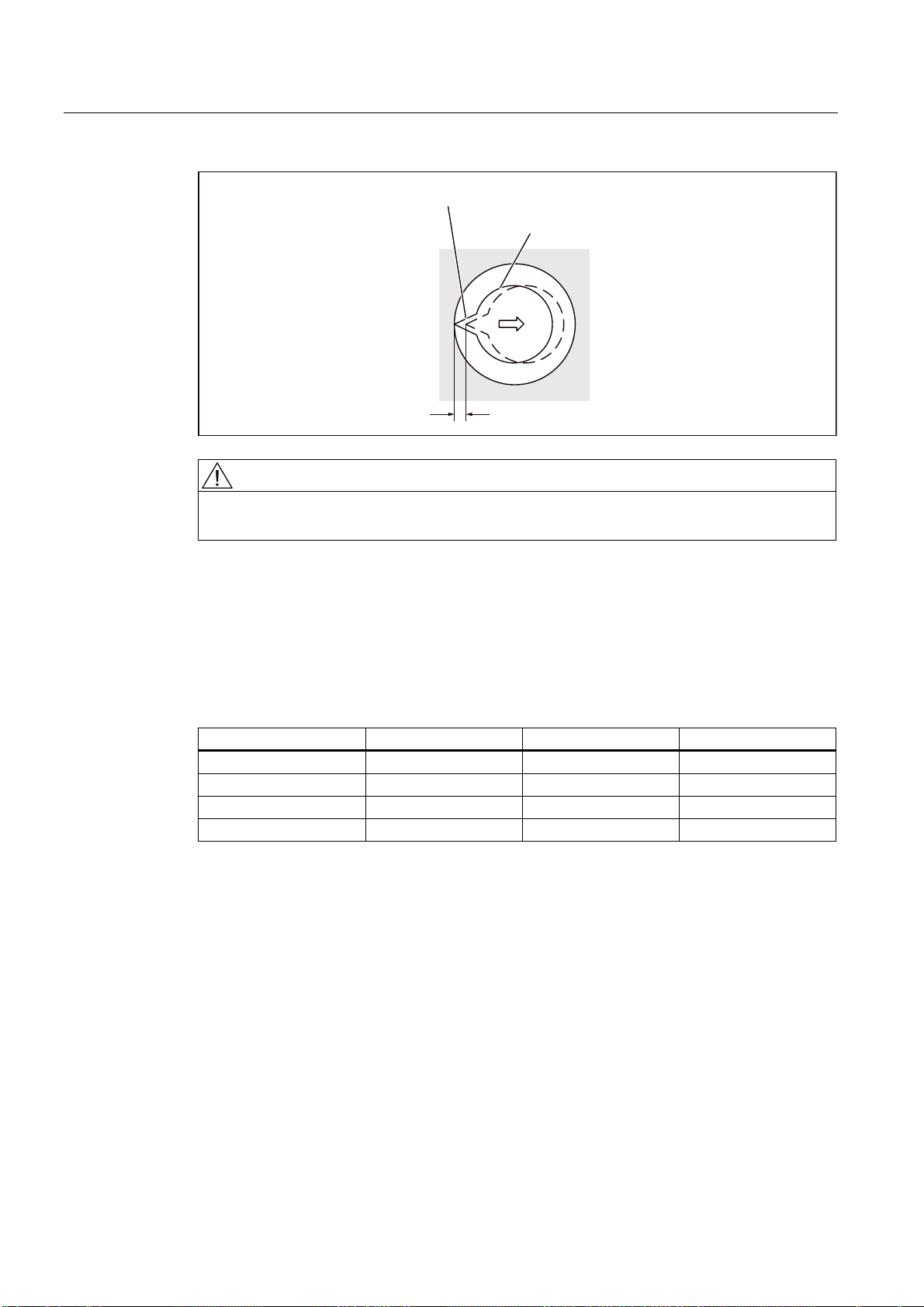

Direction of rotation

The direction of rotation of the circular arc is to be specified as given in the following figure.

G02 clockwise

G03 counterclockwise

<D[LV =D[LV

*

*

3ODQH;<* 3ODQH=;*

Figure 2-3 Direction of rotation of the circular arc

;D[LV =D[LV <D[LV

End point

The end point can be specified corresponding to the definition with G90 or G91 as absolute

or incremental (not in G Code System A!).

If the specified end point does not lie on the circular arc, the system outputs Alarm 14040

"Error in end point of circle".

Possibilities of programming circular movements

The control system offers two options of programming circular movements.

;D[LV

*

*

*

*

3ODQH<=*

The circular motion is described by the:

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

21

Drive commands

2.1 Interpolation commands

● Center point and end point in the absolute or incremental dimension (default)

● Radius and end point in Cartesian coordinates

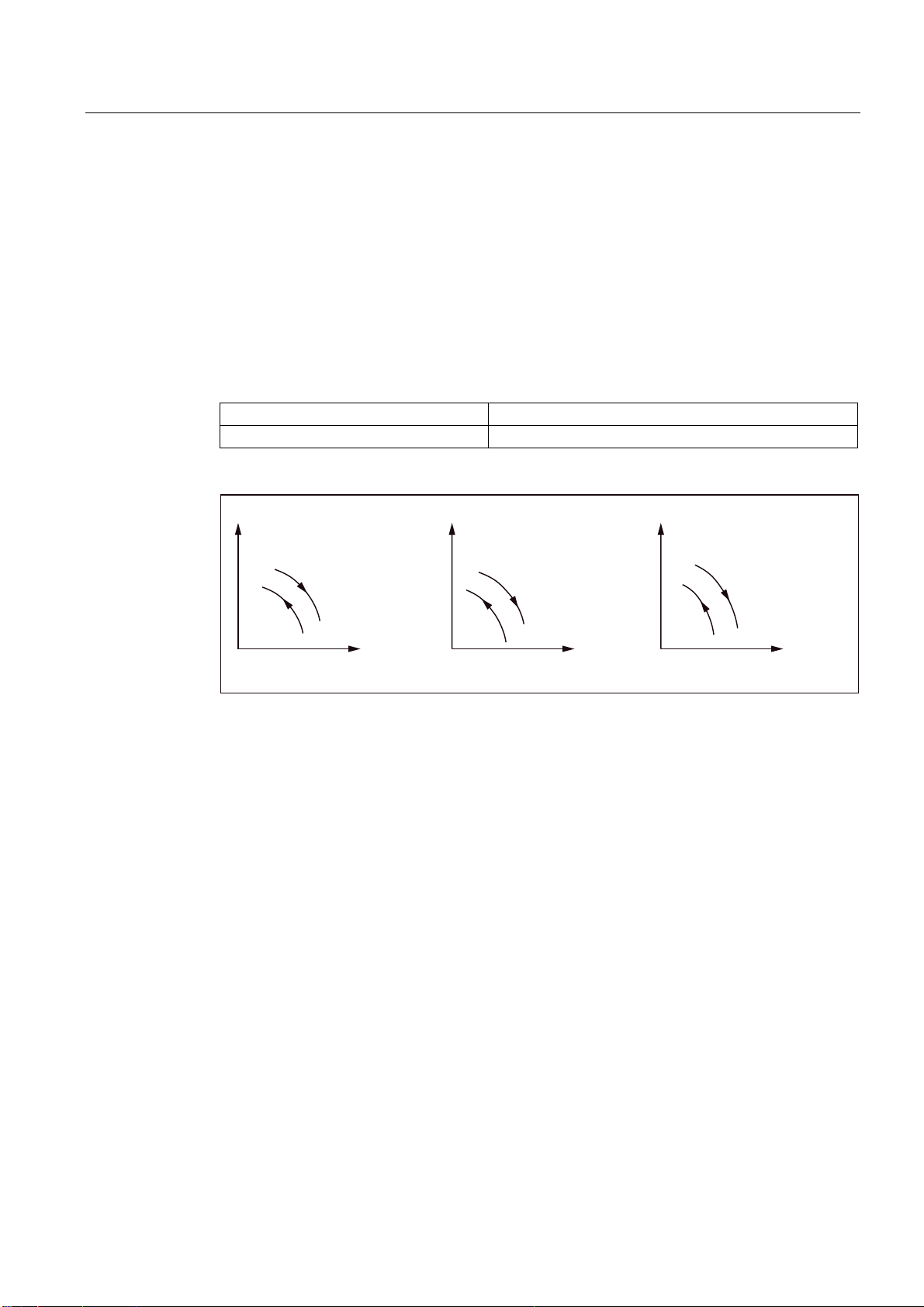

For a circular interpolation with a central angle <= 180 degree, the programming should

be "R > 0" (positive).

For a circular interpolation with a central angle > 180 degree, the programming should be

"R < 0" (negative).

3URJUDPPLQJH[DPSOH

**;<5s)

rRUJUHDWHU

(QGSRLQW

rRUOHVVHU

5

5!

6WDUWSRLQW

Figure 2-4 Circular interpolation with specification of Radius R

Feed

During the circular interpolation, the feed can be specified exactly as during linear

interpolation (see Chapter "Linear interpolation (G01)").

2.1.4 Contour definition programming and addition of chamfers or radiuses

Chamfers or radiuses can be added after each traversing block between linear and circular

contours. For example, to grind sharp edges of workpieces.

The following combinations are possible during addition:

● between two straight lines

● between two circular arcs

● between a circular arc and a straight line

● between a straight line and a circular arc

Format

, C...; Chamfer

, R...; Rounding

ISO Milling

22 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.1 Interpolation commands

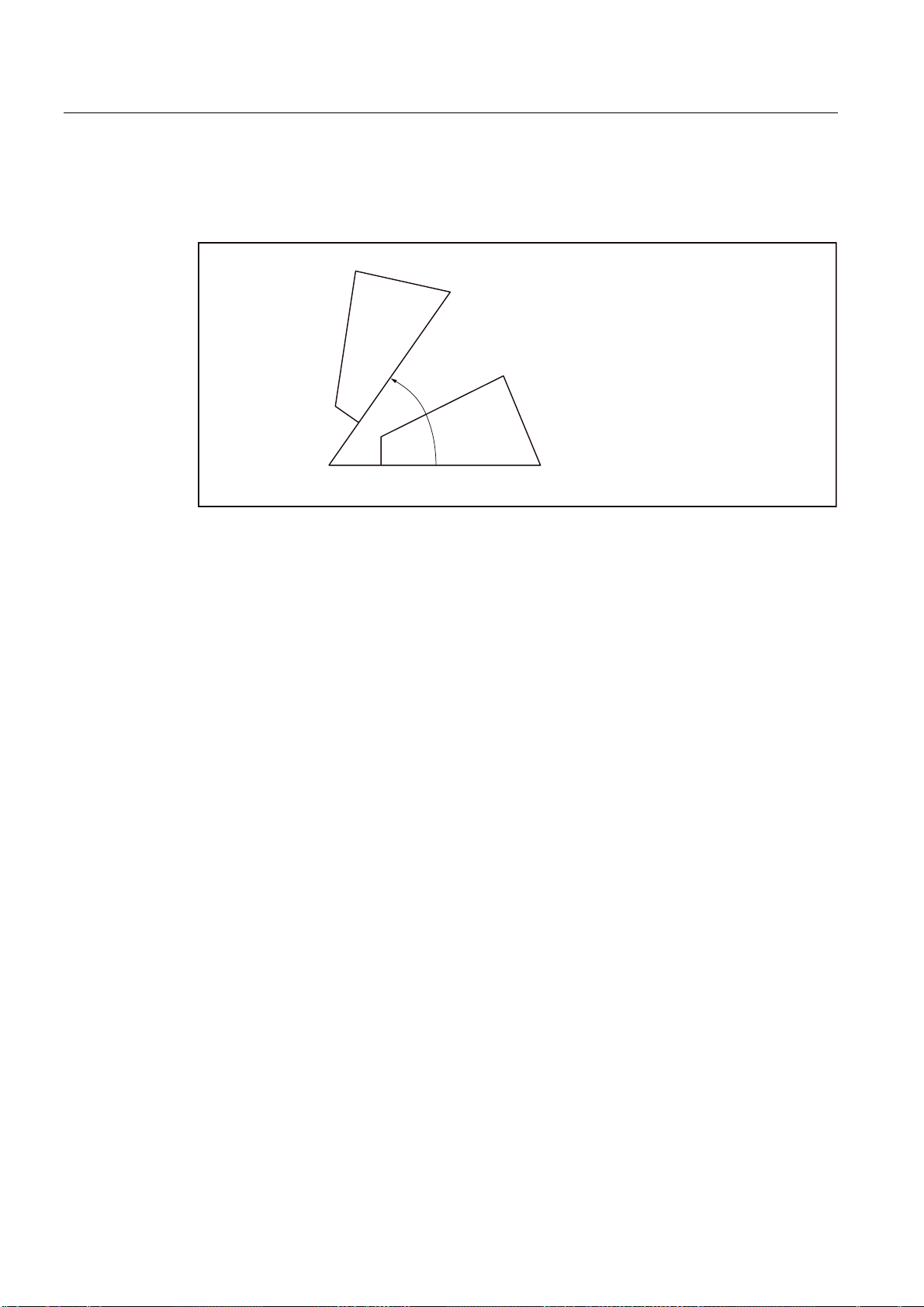

Example

N10 G1 X10. Y100. F1000 G18

N20 A140 C7.5

N30 X80. Y70. A95.824, R10

;

;=

;=

ISO dialect mode

5DGLXV

&KDPIHU

;=

Figure 2-5 3 straight lines

r

5

r

;=

=

In the ISO dialect original, the C address can be used as axis name as well as for denoting a

chamfer on the contour.

The Address R can either be a cycle parameter or an identifier of the radius of a contour.

To differentiate between these two possibilities, a comma "," must be used while

programming the contour definition before the address "R" or "C".

Siemens mode

The identifiers of chamfer and radius are defined in the Siemens mode using the machine

data. Name conflicts can be avoided this way. There should be no comma before the

identifier of the radius or chamfer. The following machine data (MD) is used:

MD for the radius: $MN_RADIUS_NAME

MD for the chamfer: $MN_CHAMFER_NAME

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

23

Drive commands

2.1 Interpolation commands

Selection of plane

Chamfer or fillet is possible only in the plane specified through the plane selection (G17, G18

or G19). These functions cannot be used on parallel axes.

Note

No chamfer/rounding is inserted, if

• No straight- or circular contour is available in the plane,

• a movement takes place outside the plane,

• The plane is changed or a number of blocks specified in the machine data, that do not

Coordinate system

After a block that changes the coordinate system (G92 or G52 to G59) or that contains a

command of reference point approach (G28 to G30), should not contain any command for

chamfering or rounding of corners.

Thread cutting

The specification of fillet in thread cutting blocks is not permissible.

contain any information about traversing (e.g., only command outputs), is exceeded.

ISO Milling

24 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.1 Interpolation commands

2.1.5 Helical interpolation (G02, G03)

With helical interpolation, two motions are superimposed and executed in parallel:

● A plane circular motion on which

● A vertical linear motion is superimposed.

3URJUDPPLQJH[DPSOH

**;<5=)

6WDUWSRLQW

;

=

(QGSRLQW

)

5

<

Figure 2-6 Helical interpolation

Note

G02 and G03 are modal. The circular motion is performed in those axes that are defined

by the specification of the working plane.

For detailed description of the interpolation parameters in case of helical interpolation,

refer to "Programming Manual Fundamentals".

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

25

Drive commands

2.1 Interpolation commands

2.1.6 Involute interpolation (G02.2, G03.2)

Overview

The involute of a circle is a curve traced out from the end point on a "piece of string"

unwinding from the curve. The involute interpolation allows trajectories along an involute. It is

executed in the plane in which the base circle is defined. If the starting point and the end

point are not in this plane, then, analogous to the helical interpolation for circles, there is a

superimposition to a curve in space.

Format

<

&5

1HQGSRLQW

; <

1VWDUWSRLQW

; <

1

1

;

An involute can be traversed in space in case of additional specification of paths vertical to

the active plane.

G02.2 X... Y... Z... I... J... K... R

G03.2 X... Y... Z... I... J... K... R

G02.2: Travel on an involute in clockwise direction

G03.2: Travel on an involute in counterclockwise direction

X Y Z: End point in Cartesian coordinates

I J K: Center of the base circle in cartesian coordinates

R: Radius of the base circle

ISO Milling

26 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.1 Interpolation commands

Supplementary conditions

Both the starting point and the end point must be outside the area of the base circle of the

involute (circle with radius R around the center point specified by I, J, K). If this condition is

not satisfied, an alarm is generated and the program execution is aborted.

Note

For more information about machine data and supplementary conditions that are relevant to

involute interpolation, please see References: /FB1/, A2 Chapter "Settings for involute

interpolation".

2.1.7 Cylindrical interpolation (G07.1)

Randomly running grooves can be cut on cylindrical workpieces with Function G07.1

(cylindrical interpolation). The path of the grooves is programmed with reference to the

unwinded, plane surface of the cylinder.

The G functions specified below can be used to switch the operation of cylindrical

interpolation on or off.

Table 2- 3 G functions for activating/deactivating the cylindrical interpolation

G function Function G group

G07.1 Operation with cylindrical interpolation 16

Format

G07.1 A (B, C) r ;Activation of operation with cylindrical interpolation

G07.1 A (B, C) 0 ;Deselection of operation with cylindrical interpolation

A, B, C: Address of the rotary axis

r: Radius of the cylinder

No other commands should be present in the block containing G07.1.

The G07.1 command is modal. Once G07.1 is specified, the cylindrical interpolation remains

active till G07.1 A (B, C) is deselected. The cylindrical interpolation is deactivated in closed

position or after NC RESET.

Note

G07.1 is based on the Siemens option TRACYL. Appropriate machine data is to be set for

this.

The corresponding data on this is available in the manual "Extended Functions", Section M1,

TRACYL.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

27

Drive commands

2.1 Interpolation commands

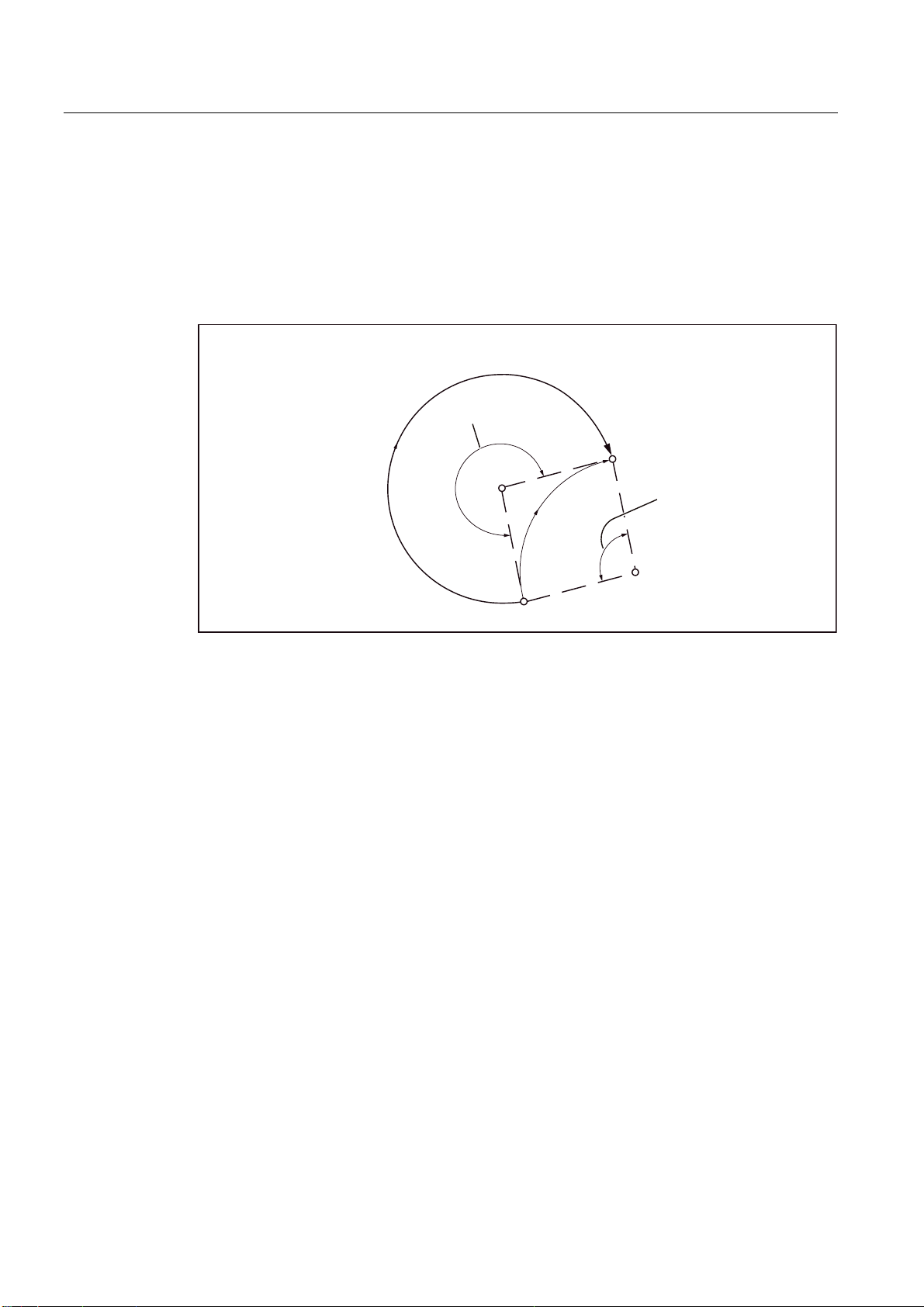

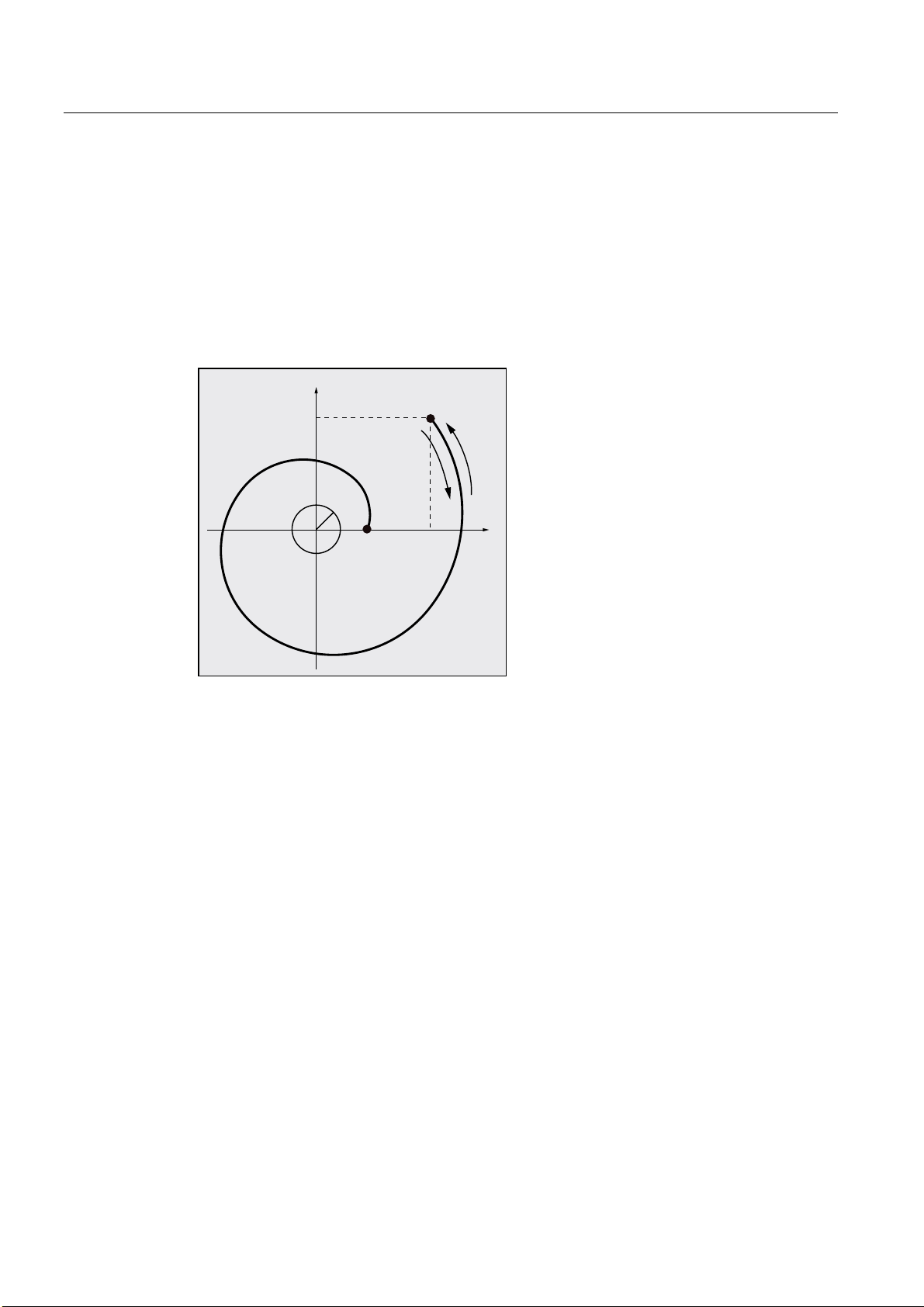

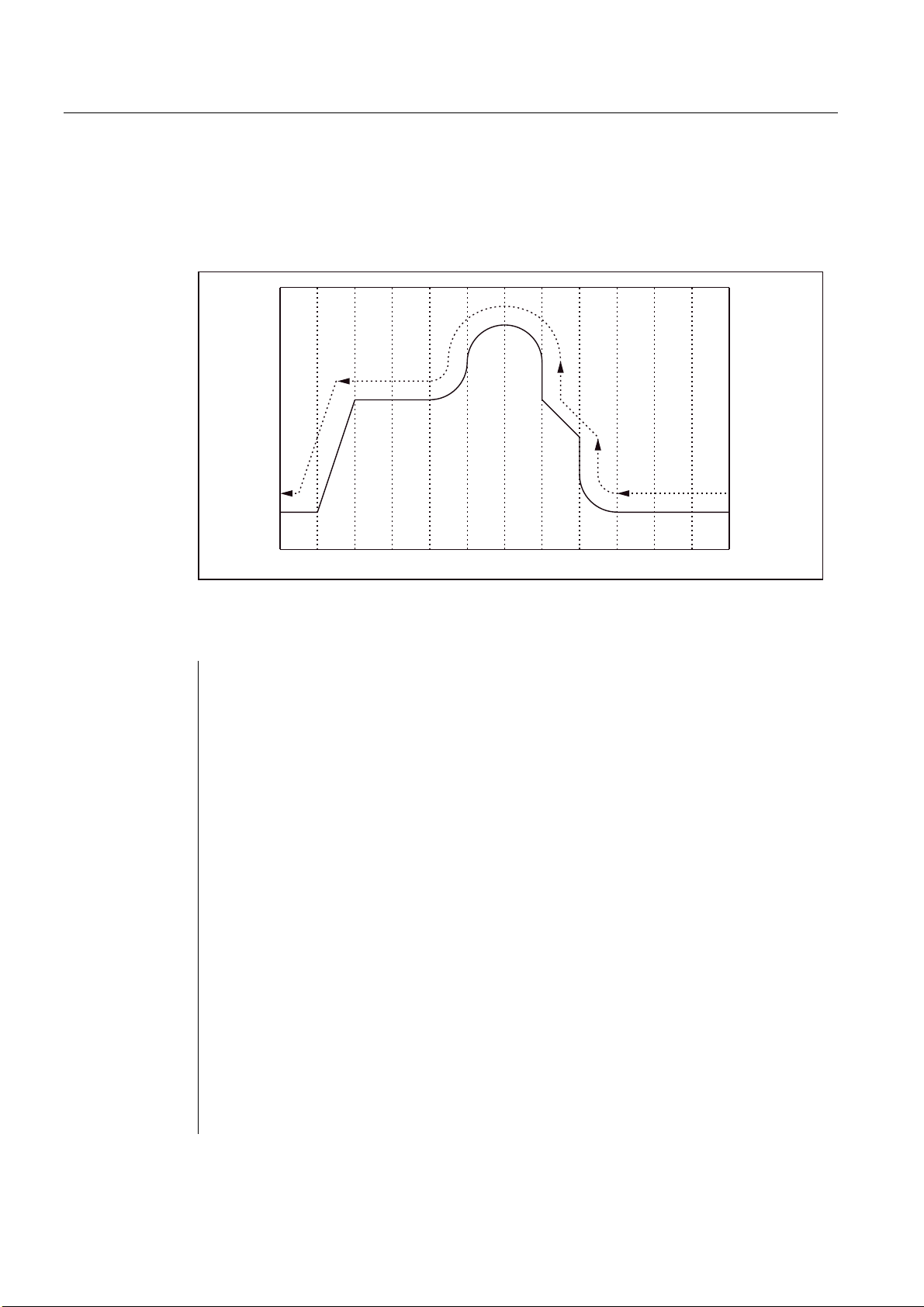

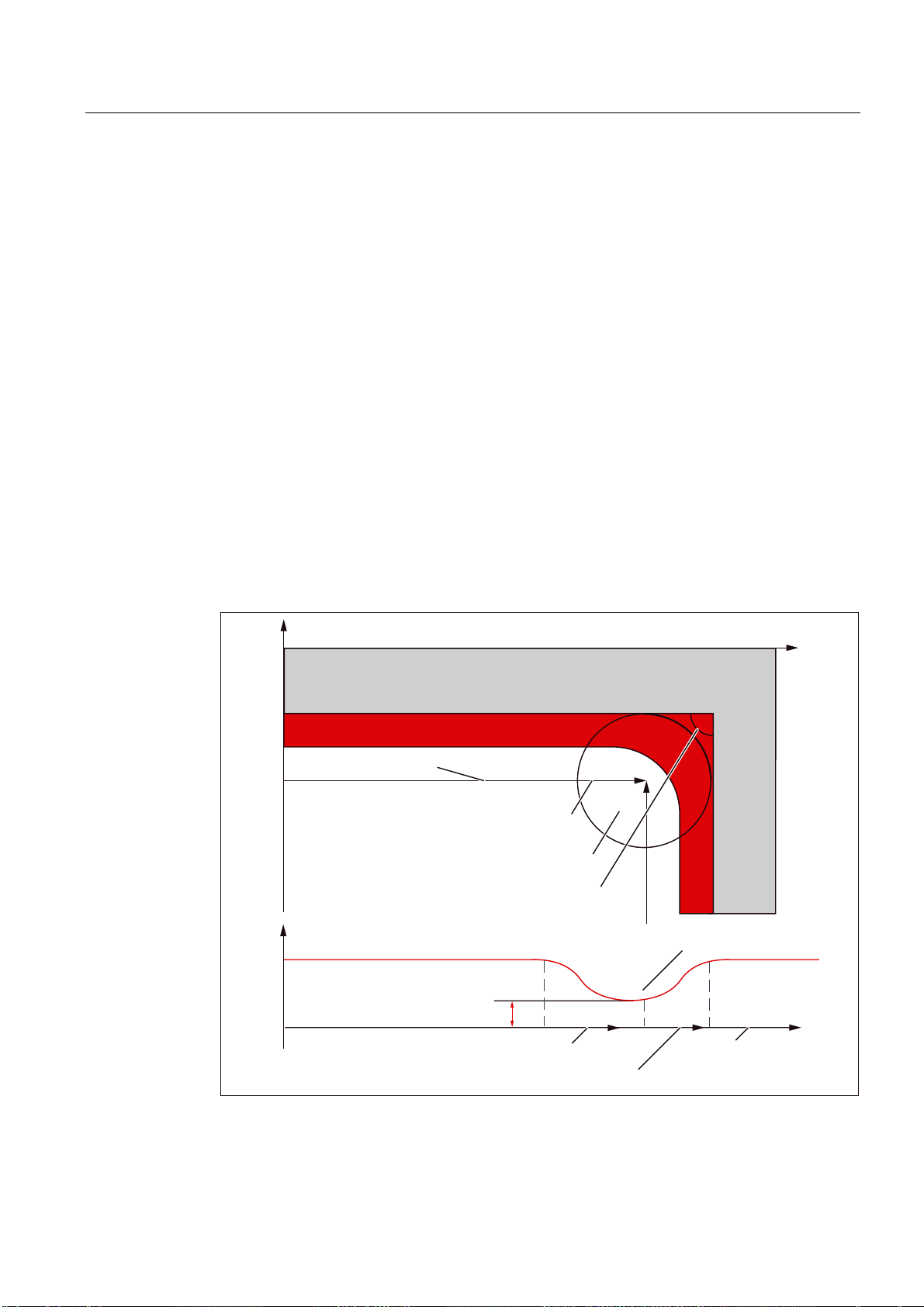

Programming example

At the cylindrical plane (it arises because the circumference of a cylindrical workpiece is

rolled off), in which the Z-axis is accepted as the linear axis and the A-axis as the rotary axis,

the following program is written:

Program

Figure 2-7 G07.1 - Programming example

M19

G40

G00 Z30. A-10.

G07.1 A57.296 ;Operation with cylindrical interpolation ON

;(workpiece radius = 57.926)

G90

G42 G01 A0 F200

G00 X50.

G01 A90. F100

G02 A120. Z60. R30

G01 Z90.

Z120. A150.

Z150.

G03 Z150. A210. R30.

G02 Z120. A240. R30

G01 A300.

Z30. A330.

A360.

G00 X100.

G40 G01 A370.

G07.1 A0 ;Operation with cylindrical interpolation OFF

G00 A0

ISO Milling

28 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.1 Interpolation commands

Programming in operation with cylindrical interpolation

Only the following G functions can be used in cylindrical interpolation: G00, G01, G02, G03,

G04, G40, G41, G42, G65, G66, G67, G90, G91 and G07.1. In operation with G00 only

those axes can be used that are not involved at the cylindrical plane.

The following axes cannot be used as a positioning axis or a reciprocating axis:

1. The geometry axis in the peripheral direction of the surface of the cylinder (Y axis)

2. The additional linear axis for groove side offset (Z axis)

Relations between the cylindrical interpolation and operations with reference to the coordinate system

● The functions mentioned below should not be used in operation with cylindrical

interpolation.

– Mirroring

– Scaling (G50, G51)

– Rotation of the coordinate system (G68)

– Setting the basic coordinate system

● The relevant overrides (rapid traverse, JOG, spindle speed) are effective.

● On deselecting this operation with cylindrical interpolation, the interpolation plane that

was selected before the operation with the cylindrical interpolation was called becomes

active again.

● To perform the tool length compensation, the command for the tool length compensation

is to be written before specifying the G07.1 command.

● The work offset (G54 - G59) is also to be written before specifying the G07.1 command.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

29

Drive commands

2.2 Reference point approach with G functions

2.2 Reference point approach with G functions

2.2.1 Reference point approach with intermediate point (G28)

Format

G28 X... Y... Z... ;

The commands "G28 X... Y... Z... ;" can be used to traverse the programmed axes to their

reference point. Here, the axes are first traversed to the specified position with rapid

traverse, and from there to the reference point automatically. The axes not programmed in

the block with G28 are not traversed to their reference point.

Reference position

When the machine has been powered up (where incremental position measuring systems

are used), all the axes must approach their reference mark. Only then can traversing

movements be programmed. The reference point can be approached in the NC program with

G28. The reference point coordinates are defined with the machine data 34100

$_MA_REFP_SET_POS[0] up to [3]). A total of four reference positions can be defined.

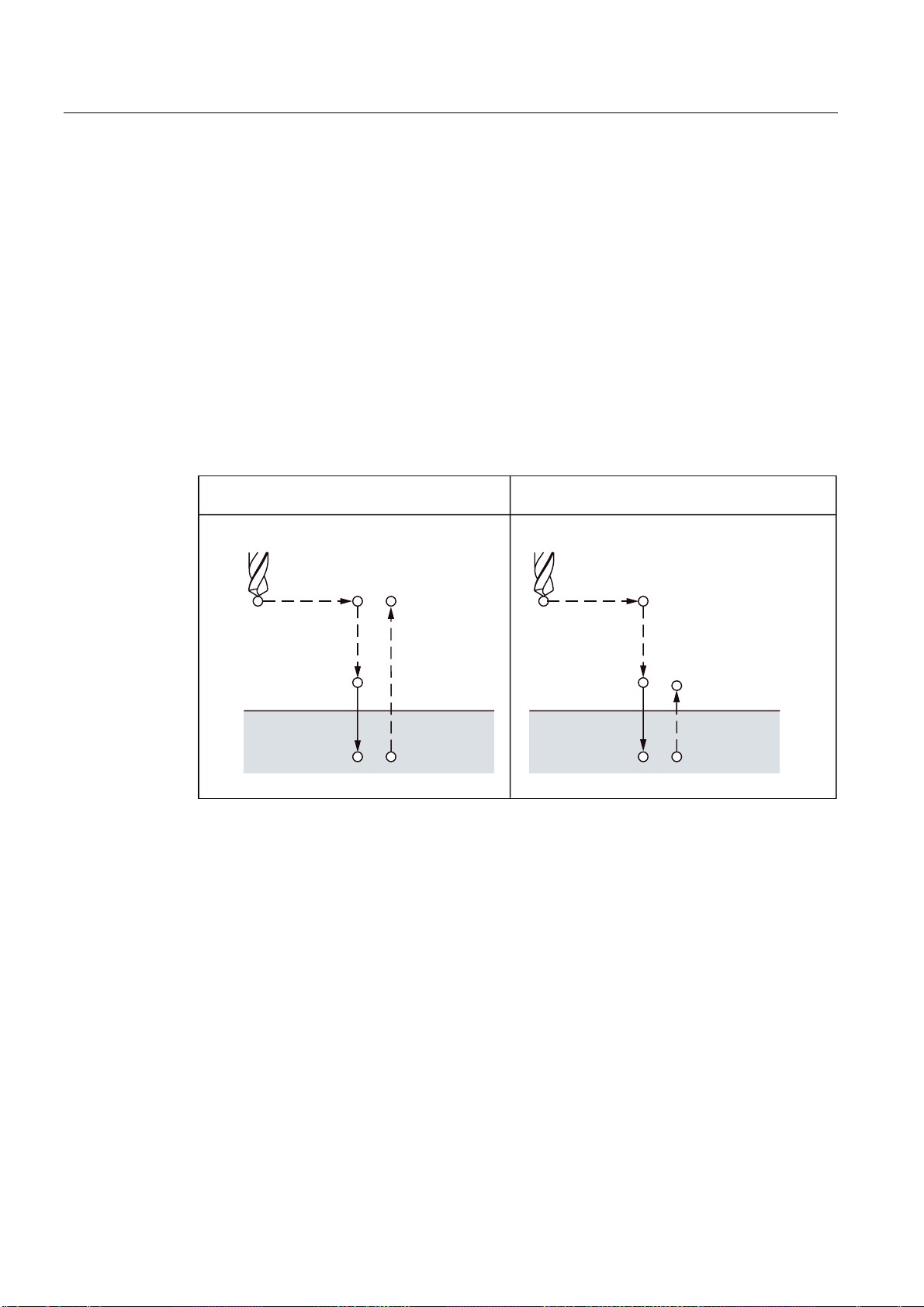

3URJUDPPLQJH[DPSOH

***;<=

=D[LV

3RVLWLRQLQJ

$

6WDUWSRLQW

=

Figure 2-8 Automatic reference point approach

%

'HOD\RI<D[LV/6

<

5HIHUHQFHSRLQW

DIL[HGSRLQWLQWKHPDFKLQH

'HOD\RI=D[LV/6

5HWXUQWRUHIHUHQFHSRLQW

,QWHUSRODWLRQSRLQWDVLQWHUPHGLDWHSRLQW

GXULQJSRVLWLRQLQJ

<D[LV

ISO Milling

30 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.2 Reference point approach with G functions

Return to reference point

Note

The G28 function is implemented with the shell cycle cycle328.spf. A transformation must

not be programmed for an axis which is to approach the reference point with G28 which

must approach the reference mark. The transformation is deactivated in cycle328.spf with

command TRAFOOF.

Automatic reference point approach for rotary axes

Rotary axes can be used for automatic reference point approach exactly as linear axes. The

approach direction of the reference traverse is defined with the machine data 34010

MD_$MA_REFP_CAM_DIR_IS_MINUS.

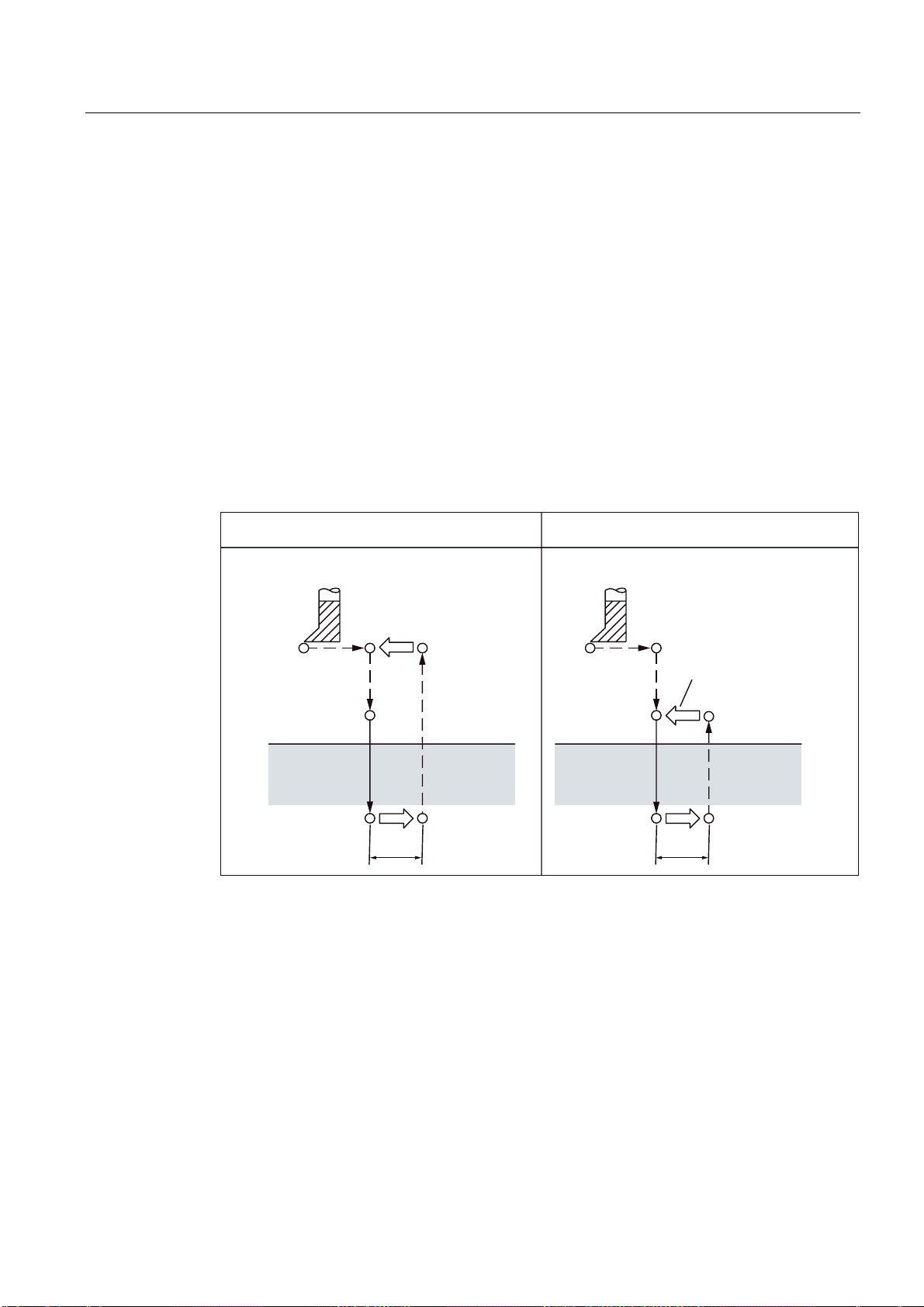

%% $$

r

5HWXUQWRUHIHUHQFHSRLQW7KHSRVLWLYHWUDYHUVLQJGLUHFWLRQZDVVHOHFWHGDVWKH

GLUHFWLRQRIUHWXUQWRWKHUHIHUHQFHSRLQW

Figure 2-9 Return to reference point - rotary axes

r

r r

Additions to the commands for automatic reference point approach:

Tool radius compensation and defined cycles

G28 should not be used in operation with tool radius compensation (G41, G42) or in a

defined cycle!

WARNING

G28 is used to interrupt the tool radius compensation (G40) with eventual axis traverse

movement to the reference point. Hence, tool radius compensation is to be deactivated

before G28 is issued.

Tool offset in G28

In G28, the interpolation point is approached with the current tool offset. The tool offset is

deselected when the reference point is finally approached.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

31

Drive commands

2.2 Reference point approach with G functions

2.2.2 Checking the reference position (G27)

Format

G27 X... Y... Z... ;

This function is used to check whether the axes are on their reference point.

Test procedure

If the check with G27 is successful, the processing is continued with the next part program

block. If one of the axes programmed with G27 is not on the reference point, Alarm 61816

"Axes not on reference point" is triggered and the Automatic mode is interrupted.

Note

Function G27 is implemented with the cycle cycle 328.spf as with G28.

To avoid a positioning error, the function "mirroring" should be deselected before executing

G27.

ISO Milling

32 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Drive commands

2.2 Reference point approach with G functions

2.2.3 Reference point approach with reference point selection (G30)

Format

G30 Pn X... Y... Z... ;

For the commands "G30 Pn X... Y... Z;" the axes are positioned on the specified

intermediate point in the continuous-path mode, and finally traversed to the reference point

selected with P2 - P4. With "G30 P3 X30. Y50.;", The X- and Y-axes return to the third

reference point. The second reference point is selected on omitting "P". Axes that are not

programmed in a G30 block are also not traversed.

Reference point positions

The positions of all the reference points are always determined in relation to the first

reference point. The distance of the first reference point from all subsequent reference points

is set in the following machine data:

Table 2- 4 Reference points

Element MD

2. Reference point $_MA_REFP_SET_POS[1]

3. Reference point $_MA_REFP_SET_POS[2]

4. Reference point $_MA_REFP_SET_POS[3]

Note

Further details of the points that were considered in the programming of G30 are available in

the Chapter "Reference point approach with intermediate point (G28)". Function G30 is

implemented with the cycle 328.spf as with G28.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

33

Drive commands

2.2 Reference point approach with G functions

ISO Milling

34 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

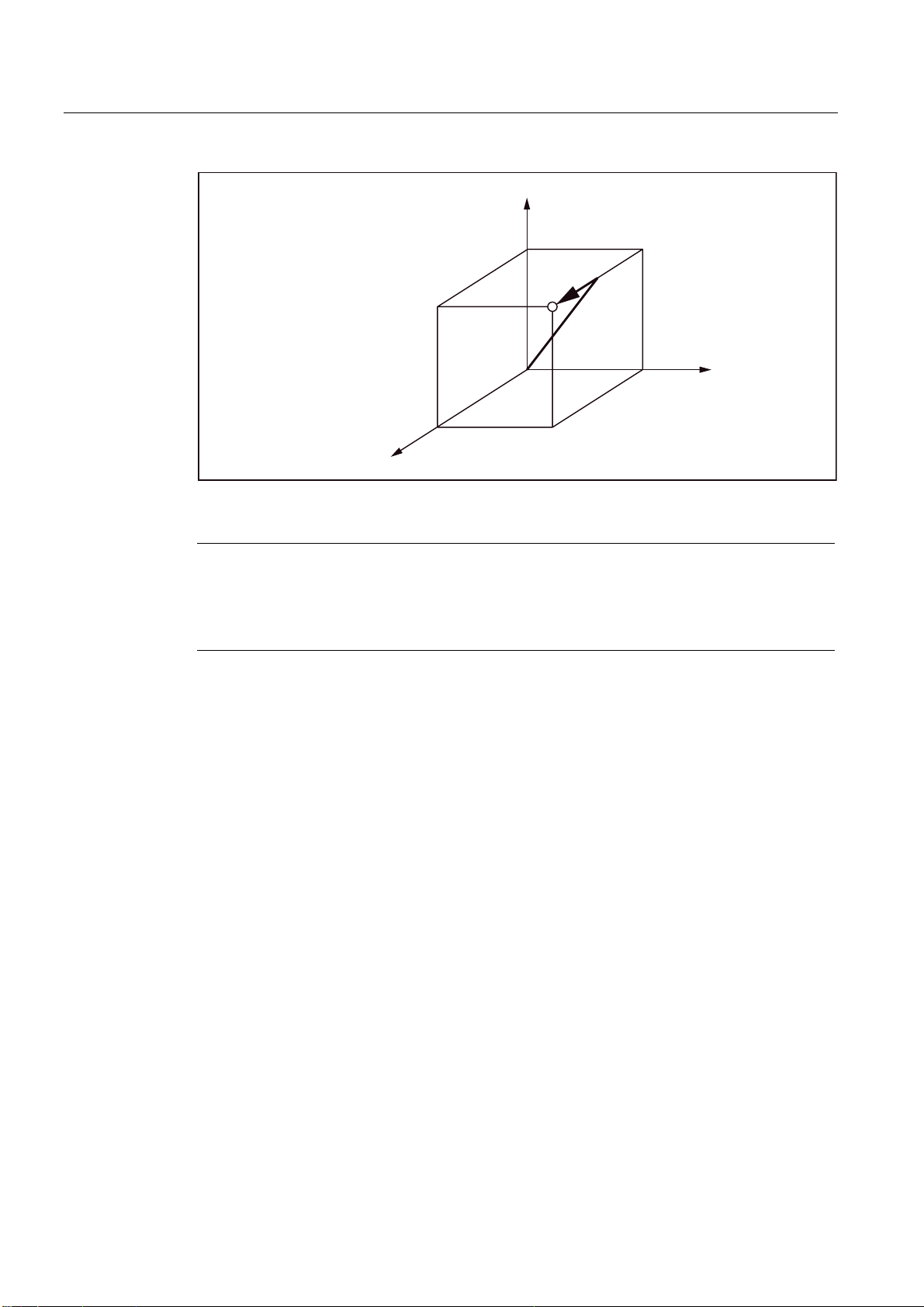

Motion commands

3.1 The coordinate system

The position of a tool is defined uniquely by its coordinates in the coordinate system. These

coordinates are defined through axis positions. If, for instance, the three involved Axes are

denoted by X, Y and Z, the coordinates are specified as follows:

X... Y... Z...

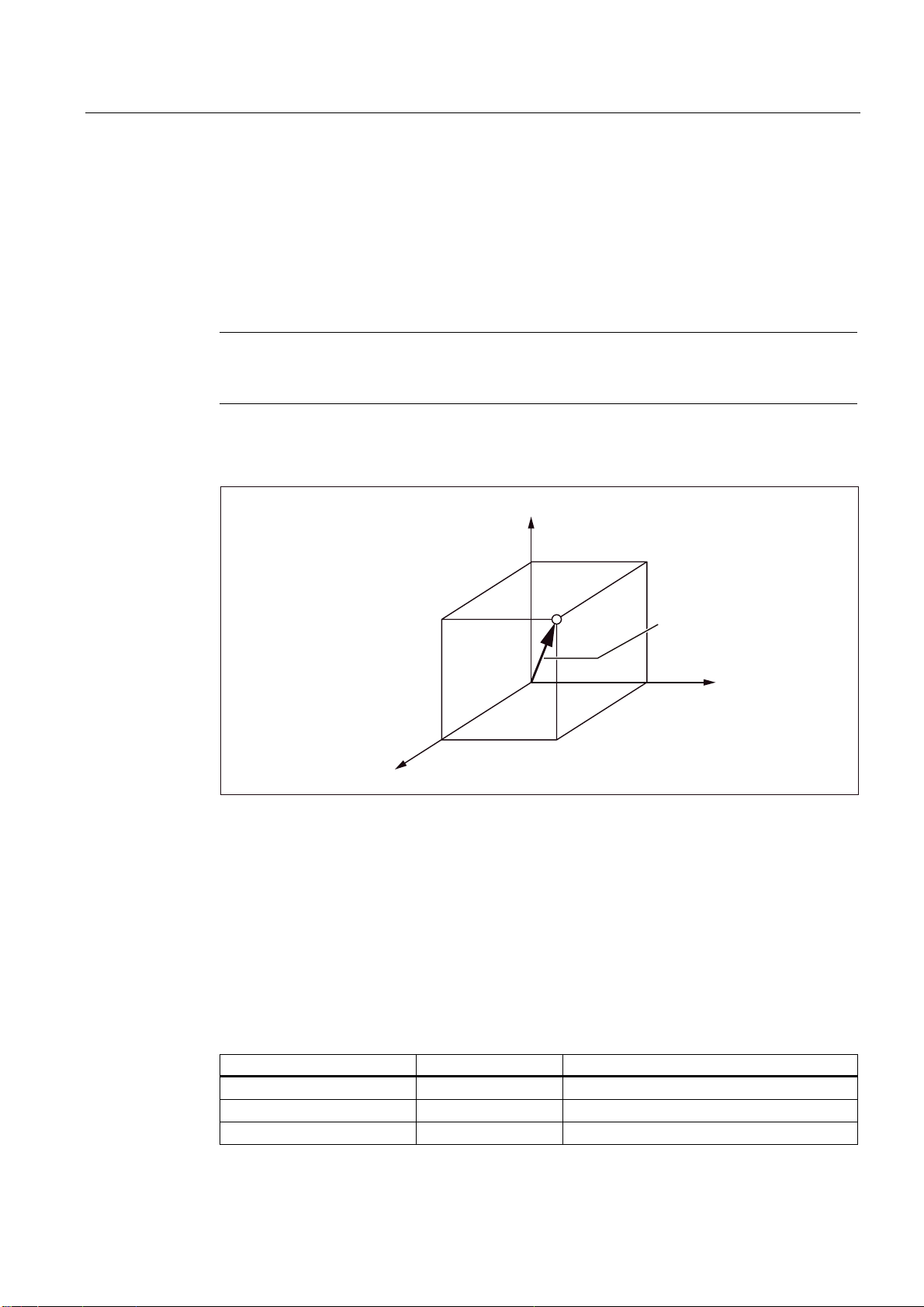

3

=

<

;

Figure 3-1 Tool positions specified with X... Y... Z...

The following coordinate systems are used to specify the coordinates:

1. Machine coordinate systems (G53)

2. Workpiece coordinate system (G92)

3. Local coordinate system (G52)

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

35

Motion commands

3.1 The coordinate system

3.1.1 Machine coordinate systems (G53)

Defining machine coordinate system

The machine zero defines the machine coordinate system MCS. All other reference points

refer to the machine zero.

The machine zero is a fixed point on the machine tool which can be referenced by all

(derived) measuring systems.

This is not necessary if an absolute measuring system is used.

Format

(G90) G53 X... Y... Z... ;

X, Y, Z: absolute dimension word

Selection of machine coordinate system (G53)

G53 suppresses the programmable and adjustable work offset . Traversing in the machine

coordinate system on the basis of G53 are always programmed if the tool is to traverse to a

machine-specific position.

Compensation deselection

If MD10760 $MN_G53_TOOLCORR = 0, then the active tool length and tool radius

compensation remains active in a block with G53

If MD10760 $MN_G53_TOOLCORR = 1, then the active tool length and tool radius

compensations in a block are suppressed with G53.

Reference

MD24004 $MC_CHBFRAME_POWERON_MASK, Bit 0 is used to define whether channelspecific basic frames during Power On are to be reset.

Displacements and rotations are set to 0, scalings to 1.

Mirroring is switched off.

Value = 0: Basic frame is retained at Power ON

Value = 1: Basic frame is reset at Power On.

ISO Milling

36 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Motion commands

3.1 The coordinate system

0DFKLQHFRRUGLQDWHV\VWHP

0DFKLQH]HUR

˟

˞

5HIHUHQFHSRVLWLRQ

Figure 3-2 Reference

3.1.2 Workpiece coordinate system (G92)

Before machining, you must create a coordinate system for the workpiece, the so-called

work piece coordinate system. This section describes different methods of setting, selecting

and changing a workpiece coordinate system.

Setting a tool coordinate system

The following two methods can be used to set a tool coordinate system:

1. With G92 in the part program

2. manually through the HMI operator panel

Format

(G90) G92 X... Y... Z... ;

The base point traverses to the specified position on outputting an absolute command. The

difference between tool tips and the base point is compensated through the tool length

compensation; this way the tool tip can traverse to the target position in any case.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

37

Motion commands

3.1 The coordinate system

3.1.3 Resetting the tool coordinate system (G92.1)

With G92.1 X.. (G Code System A with G50.3 P0) one can reset a shifted coordinate system

before the shift. The tool coordinate system is reset to the coordinate system that is defined

by the active adjustable work offsets (G54-G59). The tool coordinate system is set to the

reference position if no adjustable work offset is active. G92.1 resets shifts carried out

through G92 or G52. However, only the axes that are programmed, are reset.

Example 1:

N10 G0 X100 Y100 ;Display: WCS: X100 Y100 MCS: X100 Y100

N20 G92 X10 Y10 ;Display: WCS: X10 Y10 MCS: X100 Y100

N30 G0 X50 Y50 ;Display: WCS: X50 Y50 MCS: X140 Y140

N40 G92.1 X0 Y0 ;Display: WCS: X140 Y140 MCS: X140 Y140

Example 2:

N10 G10 L2 P1 X10 Y10

N20 G0 X100 Y100 ;Display: WCS: X100 Y100 MCS: X100 Y100

N30 G54 X100 Y100 ;Display: WCS: X100 Y100 MCS: X110 Y110

N40 G92 X50 Y50 ;Display: WCS: X50 Y50 MCS: X110 Y110

N50 G0 X100 Y100 ;Display: WCS: X100 Y100 MCS: X160 Y160

N60 G92.1 X0 Y0 ;Display: WCS: X150 Y150 MCS: X160 Y160

3.1.4 Selection of a workpiece coordinate system

As mentioned above, the user can select one of the already set workpiece coordinate

systems.

1. G92

Absolute commands function in connection with a workpiece coordinate system only if a

workpiece coordinate system was selected earlier.

2. Selection of a workpiece coordinate system from a selection of specified workpiece

coordinate systems via the HMI operator panel

A workpiece coordinate system can be selected by specifying a G function in the area

G54 to G59 and G54 P{1...100}.

Workpiece coordinate systems are setup after the reference point approach after Power

On. The closed position of the coordinate system is G54.

3.1.5 Writing work offset/tool offsets (G10)

The workpiece coordinate systems defined through G54 to G59 or G54 P{1 ... 93} can be

changed with the following two processes.

1. Data inputting at HMI operator panel

2. with the program commands G10 or G92 (setting actual value, spindle speed limitation)

ISO Milling

38 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Motion commands

3.1 The coordinate system

Format

Modified by G10:

G10 L2 Pp X... Y... Z... ;

p=0: External workpiece work offset

p=1 to 6: The value of the workpiece work offset corresponds to the workpiece

coordinate system G54 to G59 (1 = G54 to 6 = G59)

X, Y, Z: Workpiece work offset for each axis during an absolute command (G90).

Value that must be added during an incremental command (G91) for each

axis to the specified workpiece work offset.

G10 L20 Pp X... Y... Z... ;

p=1 to 93: The value of the workpiece work offset corresponds to the workpiece

coordinate system G54 P1 ... P93. The number of work offsets (1 to 93)

can be set through MD18601 $MN_MM_NUM_GLOBAL_USER_FRAMES

or MD28080 $MC_MM_NUM_USER_FRAMES.

X, Y, Z: Workpiece work offset for each axis during an absolute command (G90).

Value that must be added during an incremental command (G91) for each

axis to the specified workpiece work offset.

Explanations

Modified by G92:

G92 X... Y... Z... ;

Modified by G10:

G10 can be used to change each workpiece coordinate system individually. If the work offset

with G10 is to be written only when the G10 block is executed on the machine (main run

block), then MD20734 $MC_EXTERN_FUNCTION_MASK, Bit 13 must be set. An internal

STPPRE is executed in that case with G10. The machine data bits affect all G10 commands

in the ISO Dialect T and ISO Dialect M.

Modified by G92:

By specifying G92 X... Y... Z..., a workpiece coordinate system that was selected earlier with

a G command G54 to G59 or G54 P{1 ...93}, can be shifted and thus a new workpiece

coordinate system can be set. If X, Y and Z are programmed incrementally, the workpiece

coordinate system is defined in such a way that the current tool position matches the total of

the specified incremental value and the coordinates of the previous tool position (shift of

coordinate system). Finally, the value of the coordinate system shift is added to each

individual value of the workpiece work offset. To put it another way: All workpiece coordinate

systems are shifted systematically by the same value.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

39

Motion commands

3.1 The coordinate system

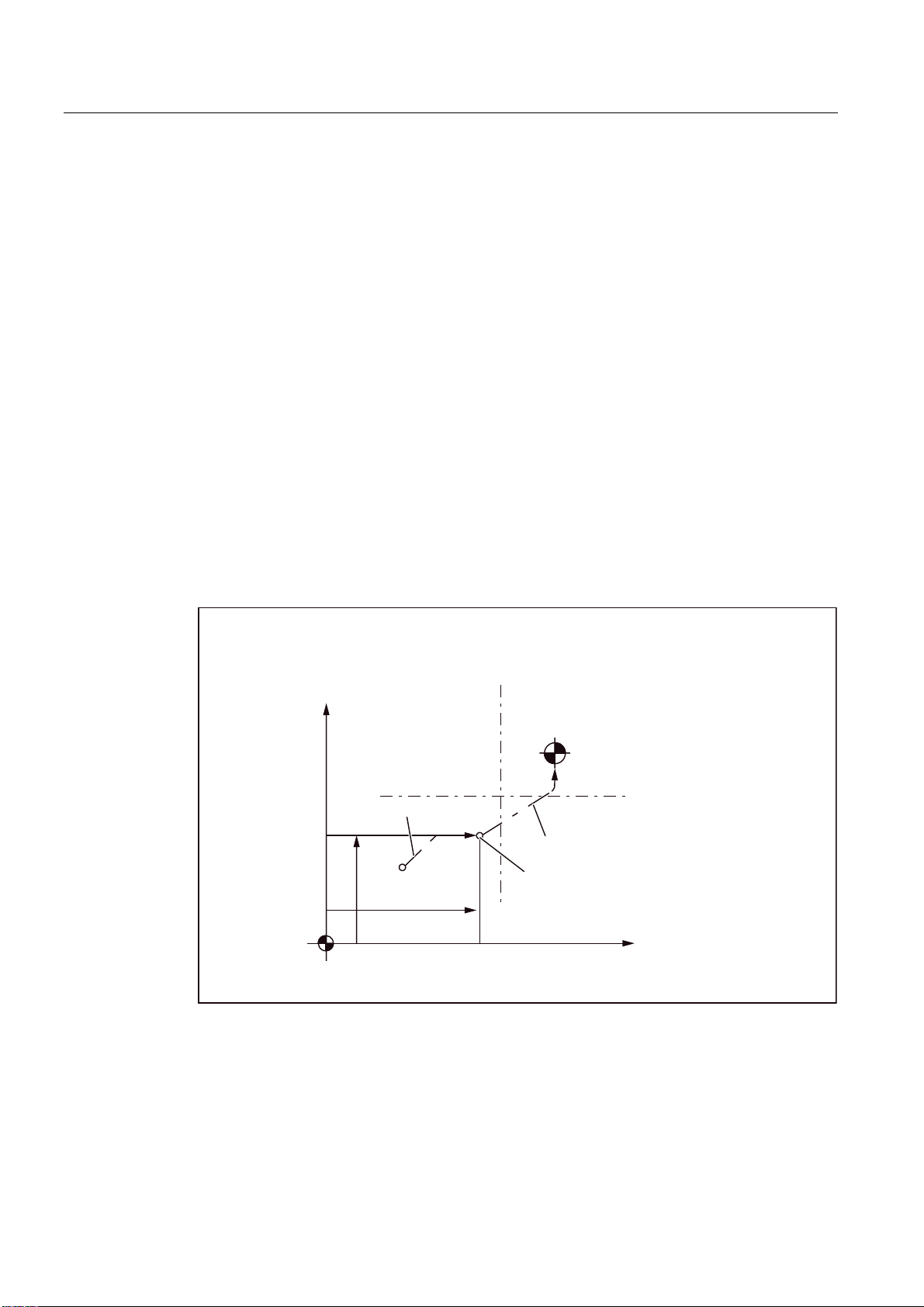

Example

The tool in operation with G54 is positioned at (190, 150), and the workpiece coordinate

system 1 (X' - Y') is created each time in G92X90Y90 with a shift of Vector A.

<<ಫ

*:RUNSLHFHFRRUGLQDWHV\VWHP

Figure 3-3 Example of setting coordinates

3.1.6 Local coordinate system (G52)

For programming simplification, a type of workpiece coordinate system can be setup to

create a program in the workpiece coordinate system. This part coordination system is also

called local coordinate system.

Format

G52 X... Y... Z... ; Setting the local coordinate system

7RROSRVLWLRQ

;ಫ

;

$

G52 X0 Y0 Z0 ; Deselection of the local coordinate system

X, Y, Z: Origin of the local coordinate system

Explanations

G52 can be used to program work offsets for all path and positioning axes in the direction of

the specified axis. This way one can work with changing zero points, e.g. during repetitive

machining operations at different workpiece positions.

G52 X... Y... Z... is a work offset around the offset values programmed in the relevant

specified axis directions. The last specified adjustable work offset (G54 to G59, G54 P1 P93) serves as reference.

ISO Milling

40 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Motion commands

3.1 The coordinate system

*:RUNSLHFHFRRUGLQDWHV\VWHP

ORFDOFRRUGLQDWHV\VWHP

*

*

2ULJLQRIPDFKLQHFRRUGLQDWHV\VWHP

*

*

0DFKLQHFRRUGLQDWHV\VWHP

ORFDOFRRUGLQDWHV\VWHP

*:RUNSLHFHFRRUGLQDWHV\VWHP

5HIHUHQFHSRLQW

Figure 3-4 Setting the local coordinate system

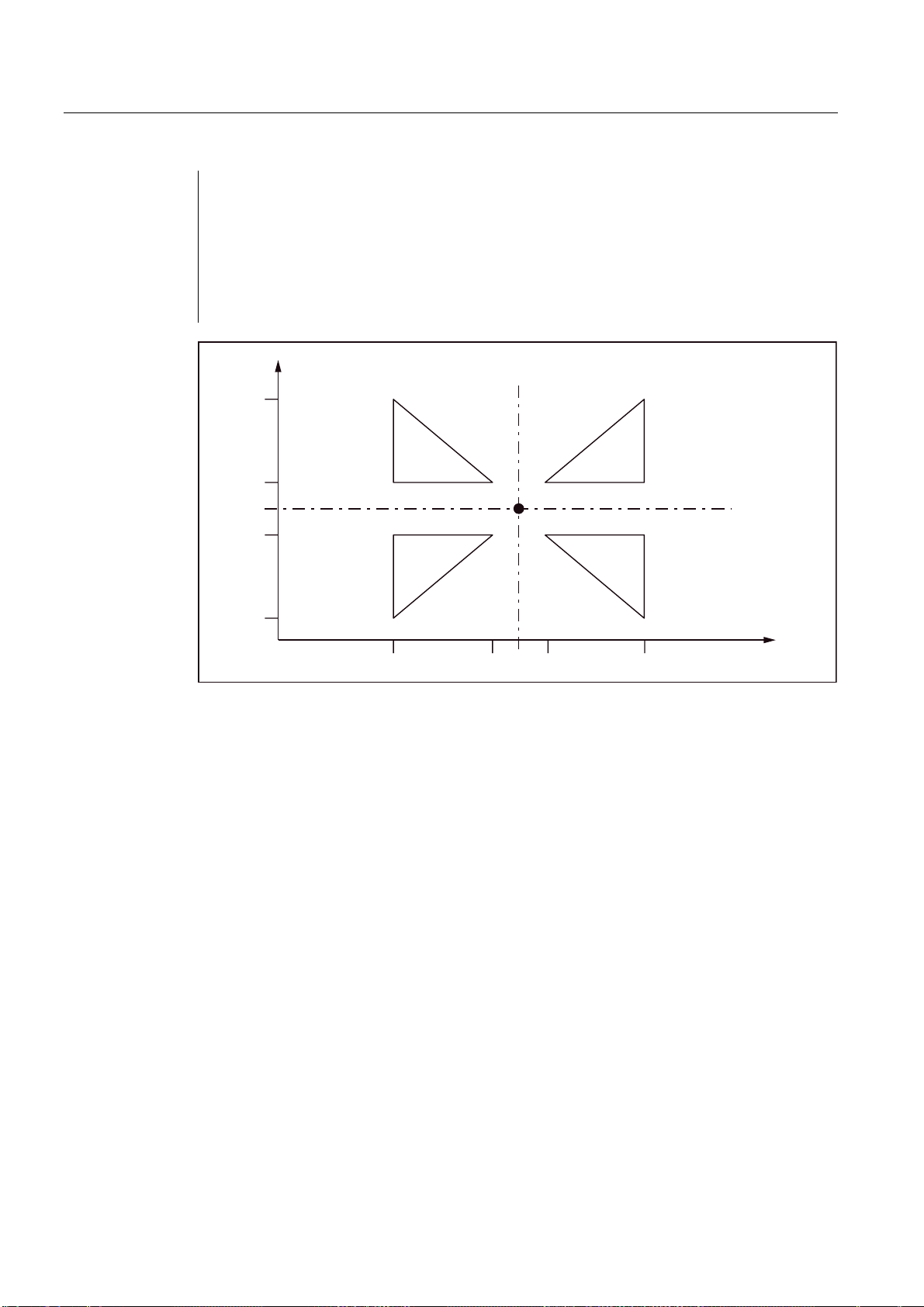

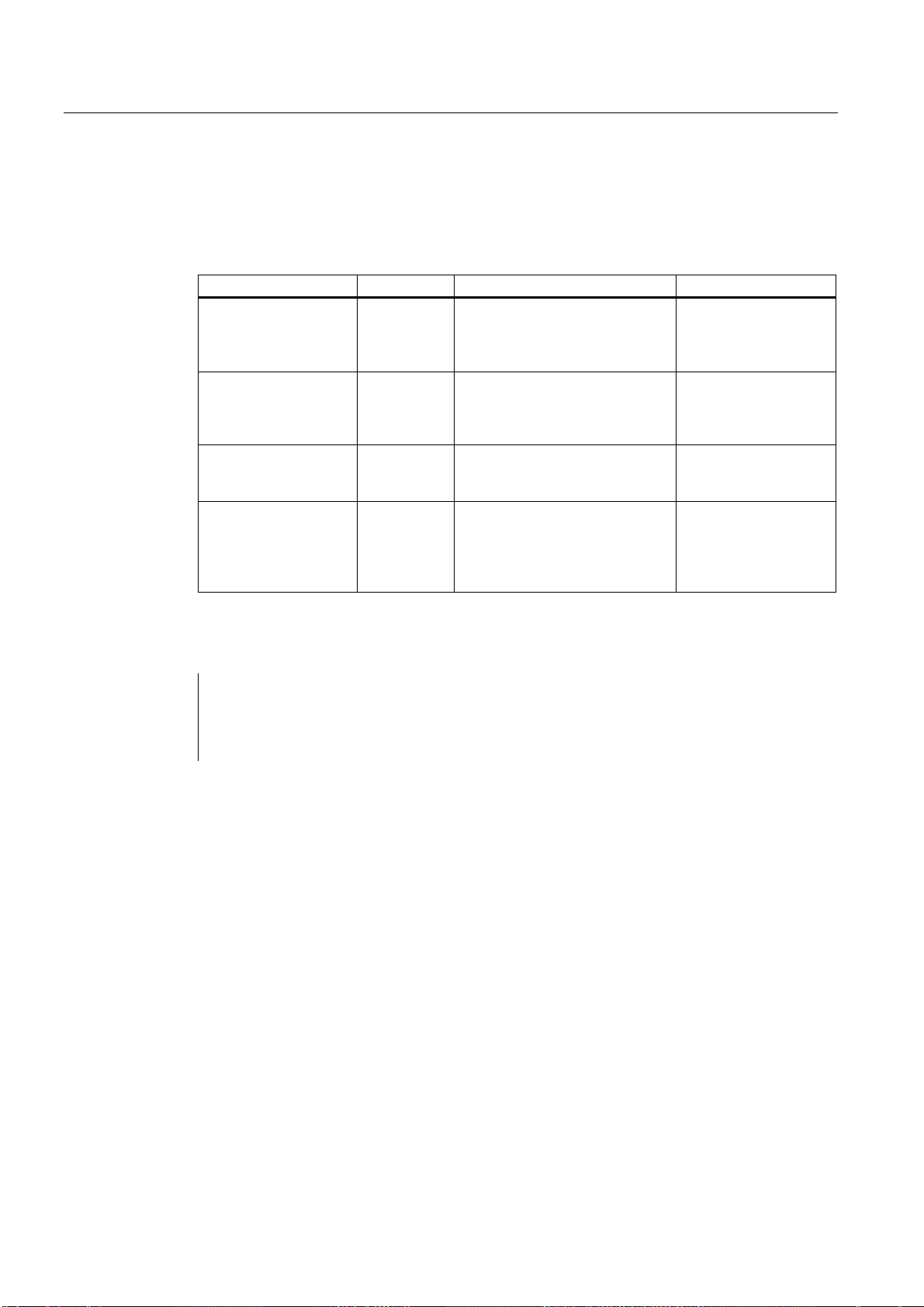

3.1.7 Selection of the plane (G17, G18, G19)

The selection of the plane in which the circular interpolation, tool radius compensation and

rotation of the coordinate system took place is done by specifying the following G functions.

Table 3- 1 G functions for selecting the plane

G function Function G group

G17 X-Y plane 02

G18 Z-X plane 02

G19 Y-Z plane 02

The plane is defined as described below (with the help of the example of Plane X-Y):

The horizontal axis in the first quadrant is the Axis +X, and the vertical axis in the same

quadrant is Y-.

<D[LV

Figure 3-5 Selection of plane

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

;D[LV

41

Motion commands

3.1 The coordinate system

● The Plane X-Y (G17) is selected automatically after activating the control system.

● The command for moving an individual axis can be specified independently of the plane

selection by G17, G18 or G19. Thus for instance, the Z axis can be shifted by specifying

"G17 Z ....;".

● The plane in which the tool radius compensation is executed with G41 or G42 is defined

by specifying G17, G18 or G19.

3.1.8 Parallel axes (G17, G18, G19)

An axis located parallel to one of the three main axes of the coordinate system can be

activated by using the function G17 (G18, G19) <Axis name>.

The three main axes are, e.g., X, Y and Z.

Example

G17 U0 Y0

The parallel axis U is activated when the X axis in the G17 plane is replaced.

Explanations

● An associated parallel axis can be defined for each geometry axis with machine data

$MC_EXTERN_PARALLEL_GEOAX[ ].

● Only geometry axes from a plane defined with (G17, G18, G19) can be replaced.

● On replacing the axes, normally all shifts (frames) - with the exception of the handwheel

and external shifts, the working area limitation and the protection areas - are deleted. The

following machine data is to be set to prevent the values from being deleted:

Shifts (frames)

$MN_FRAME_GEOAX_CHANGE_MODE

Protection areas

$MC_PROTAREA_GEOAX_CHANGE_MODE

Working area limitation

$MN_WALIM_GEOAX_CHANGE_MODE

● Details are available in the machine data description.

● Alarm 12726 "Impermissible plane selection with parallel axes" is output if a main axis is

programmed along with the associated parallel axis with a command for selecting the

plane.

ISO Milling

42 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Motion commands

3.1 The coordinate system

3.1.9 Rotation of the coordinate system (G68, G69)

Properties of G68 and G69

A coordinate system can be rotated with the following G functions.

Table 3- 2 G functions for rotating a coordinate system

G function Function G group

G68 Rotation of the coordinate system 16

G69 Deselection of Rotation of the coordinate system 16

G68 and G69 are modal G functions of the G group 16. G69 is set automatically on

activating the control system and resetting the NC.

The blocks containing G68 and G69 should not contain any other G functions.

The rotation of the coordinate system is called with G68 and deselected with G69.

Format

G68 X_ Y_ R_ ;

X_, Y_ :

Absolute coordinate values of the rotation center. The actual position is accepted as the

rotation center if these are omitted.

R_ :

Angle of rotation as a function of G90/G91 absolute or incremental. If R is not specified, the

value of the channel-specific setting from the setting data 42150

$SC_DEFAULT_ROT_FACTOR_R is used as angle of rotation.

ISO Milling

Programming Manual, 06/09, 6FC5398-7BP10-1BA0

43

Motion commands

3.1 The coordinate system

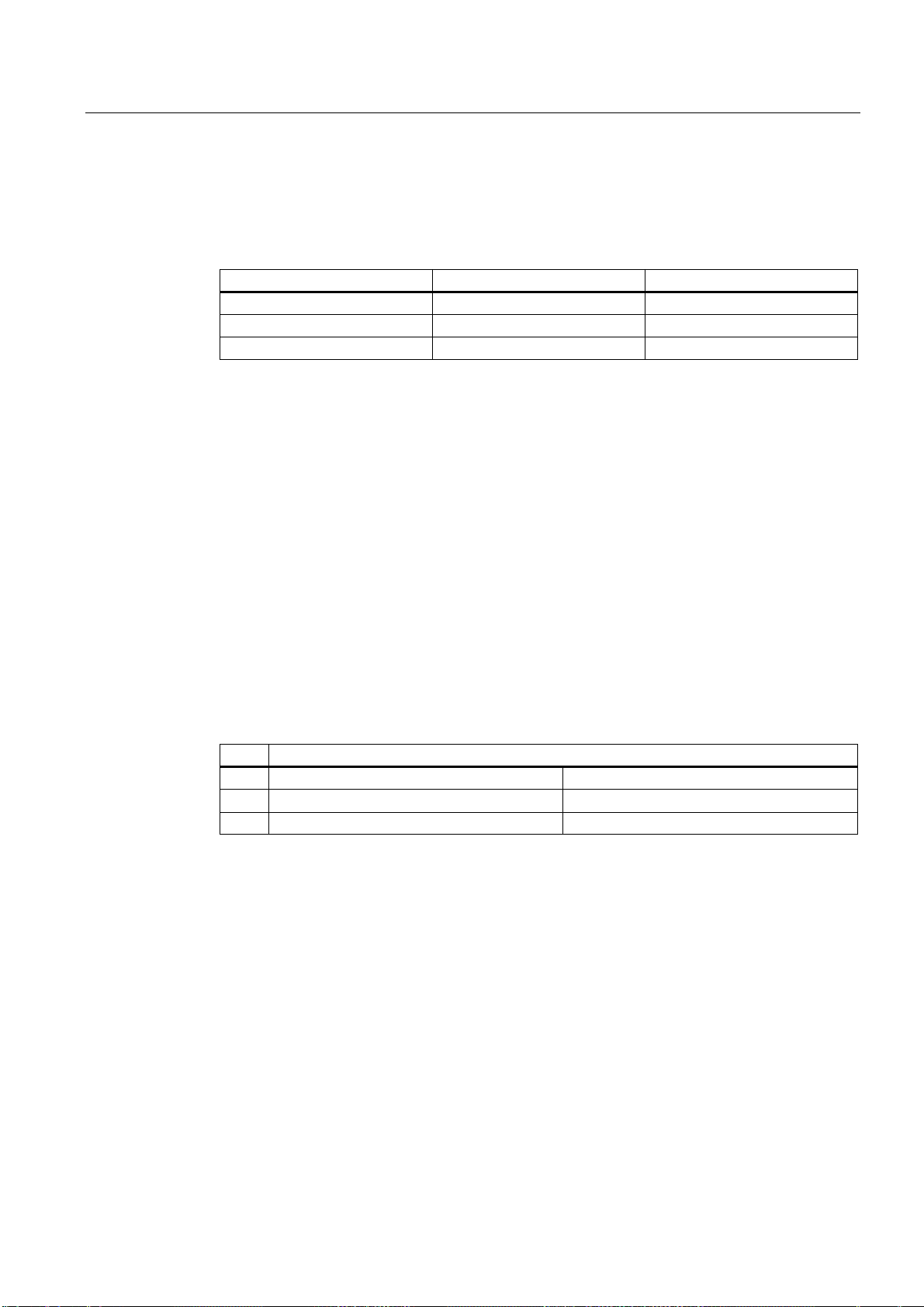

● By specifying G17 (or G18, G19) G68 X... Y... R... ; " the commands specified in the

following blocks are rotated by the angle specified with R around the point (X, Y). The

angle of rotation can be specified in units of 0.001 degree.

;<&HQWHURIURWDWLRQ

5$QJOHRIURWDWLRQಯಯPHDQVURWDWLRQLQ

FRXQWHUFORFNZLVHGLUHFWLRQLVWREH

VSHFLILHGDVDEVROXWHYDOXH

5

;<

Figure 3-6 Rotation of a coordinate system

● The deselection of the coordinate system rotation takes place through G69.

● G68 is executed in the plane that was selected through G68. The 4th and 5th axes must

be linear axes.

G17: X-Y plane

G18: Z-X plane

G19: Y-Z plane

Additions to the commands for rotating the coordinate systems

● To rotate a coordinate system, MD28081 $MC_MM_NUM_BASE_FRAMES must be set

to a value of >= 3.

● If "X" and "Y" are omitted, the current position is used as the rotation center for the

coordinate rotation.

● The positional data for the rotation of a coordinate system are specified in the rotated

coordinate system.

● If you program a change of plane (G17 to G19) after a rotation, the angles of rotation

programmed for the axes are retained and continue to apply in the new working plane. It

is therefore advisable to deactivate the rotation before a change of plane.

ISO Milling

44 Programming Manual, 06/09, 6FC5398-7BP10-1BA0

Motion commands

3.1 The coordinate system

3.1.10 3D rotation G68/G69

The G code G68 is extended for 3D rotation.

Format

G68 X.. Y.. Z.. I.. J.. K.. R..

X.. Y.. Z..: Coordinates of the pivot point related to the current workpiece zero. If no

coordinate is programmed, the pivot point lies in the workpiece zero. The

value is always interpreted as absolute. The coordinates of the pivot point

act as a work offset. G90/G91 in the block does not affect the G68

command.

I.. J.. K..: Vector in pivot point. The coordinate system is rotated around this vector at

angle R.

R..: Angle of rotation. The angle of rotation is always absolute. If no angle is

programmed, the angle from the setting data 42150

$SA_DEFAULT_ROT_FACTOR_R is active. G68 must be alone in the block.

The 2D or 3D rotation differentiation takes place only through the programming of the vector

I, J, K. If there is no vector in the block, G68 2DRot is selected. If there is a vector in the

block, G68 3DRot is selected.

If a vector is programmed with the length 0 (I0, Y0, K0), the Alarm 12560 "Programmed

value outside the permissible limits" is triggered.

Two rotations can be switched one after the other with G68. If so far no G68 is active in a

block containing G68, then the rotation is written to the channel-specific basic frame 2. If