JLG G12-55A Service Manual

Service Manual

Models

G10-55A

&

G12-55A AccuPlace

31200452

Original

January 20, 2009

An Oshkosh Corporation Company

EFFECTIVITY PAGE

January 20, 2009 - A - Original Issue Of Manual

31200452 |

G10-55A & G12-55A AccuPlace |

i |

EFFECTIVITY PAGE

-ii |

G10-55A & G12-55A AccuPlace |

31200452 |

SECTION CONTENTS

Section Subject Page

Section 1 |

|

|

Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.1 |

|

1.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.2 |

1.2 |

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.2 |

1.3 |

Operation & Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.2 |

1.4 |

Do Not Operate Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.2 |

1.5 |

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.3 |

1.6 |

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.3 |

1.7 |

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.4 |

Section 2 |

|

|

General Information and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.1 |

|

2.1 |

Replacement Parts and Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.2 |

2.2 |

Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.3 |

2.3 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.6 |

2.4 |

Fluid and Lubricant Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.8 |

2.5 |

Service and Maintenance Schedules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.9 |

2.6 |

Lubrication Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.11 |

Section 3 |

|

|

Boom . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.1 |

3.1 |

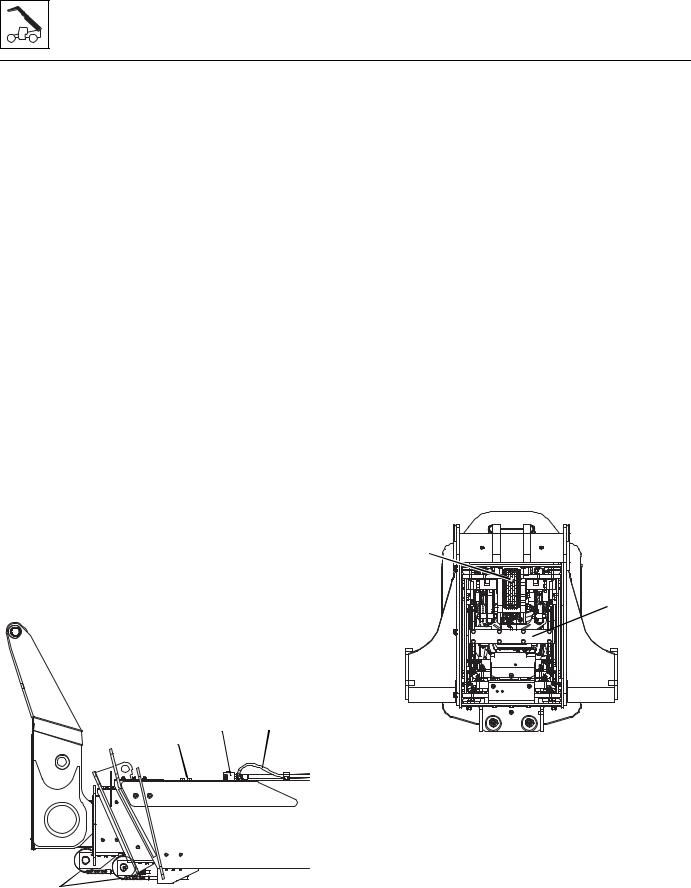

Boom System Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.2 |

3.2 |

Boom System - Four Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.3 |

3.3 |

Boom Assembly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.3 |

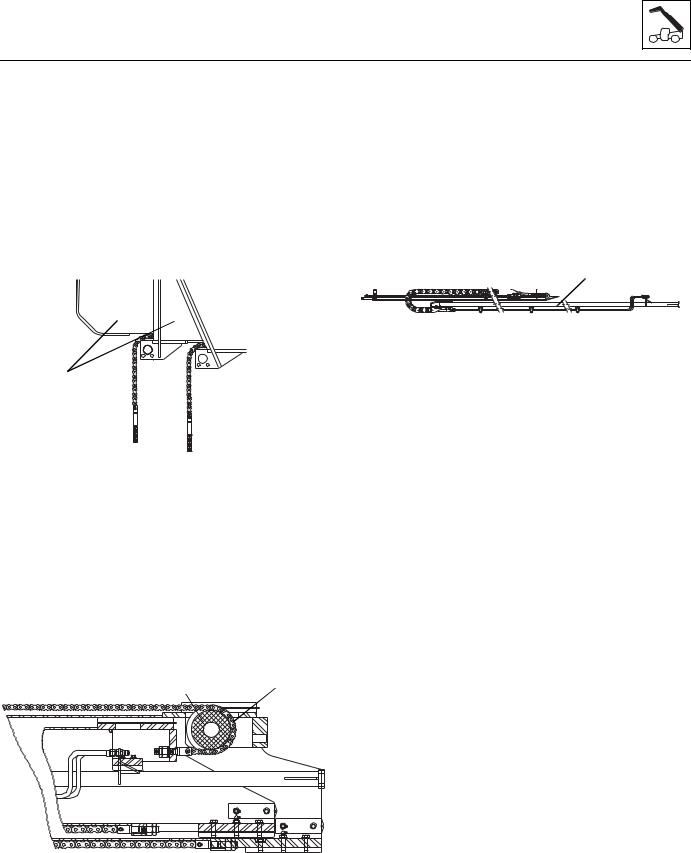

3.4 |

Boom Extend and Retract Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.9 |

3.5 |

Boom Section Separation Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.14 |

3.6 |

Hydraulic Sub-Assembly Removal/Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.14 |

3.7 |

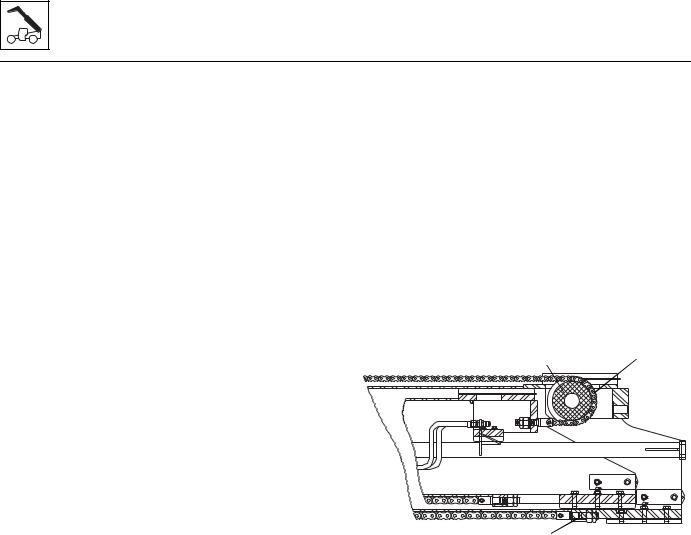

Boom Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.17 |

3.8 |

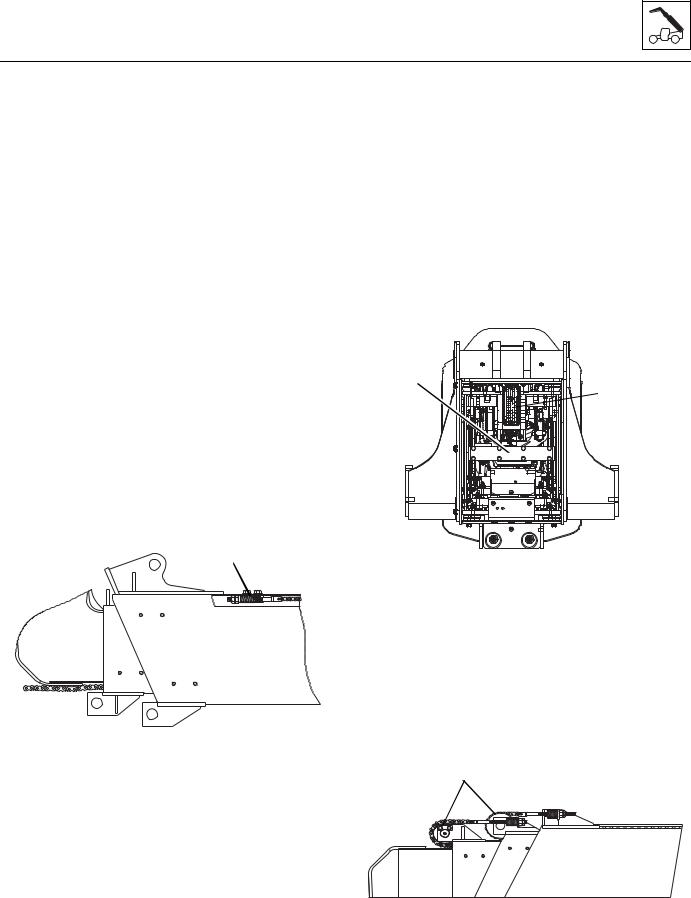

Quick Switch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.18 |

3.9 |

Forks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.18 |

3.10 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.19 |

Section 4 |

|

|

Cab and Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4.1 |

|

4.1 |

Operator’s Cab and Covers Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . |

4.2 |

4.2 |

Operator’s Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4.3 |

4.3 |

Cab Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4.3 |

4.4 |

Cab Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4.7 |

4.5 |

Cab Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4.9 |

Section 5 |

|

|

Axles, Drive Shafts, Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5.1 |

|

5.1 |

Axle, Drive Shaft and Wheel Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . |

5.2 |

5.2 |

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5.3 |

5.3 |

Axle Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5.3 |

5.4 |

Drive Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5.9 |

5.5 |

Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5.10 |

5.6 |

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5.11 |

G10-55A & G12-55A AccuPlace |

i |

Section |

Subject |

Page |

|

|

|

|

|

|

5.7 |

Towing a Disabled machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5.11 |

Section 6 |

|

|

Transmission . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6.1 |

6.1 |

Transmission Assembly Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6.2 |

6.2 |

Transmission Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6.3 |

6.3 |

Transmission Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6.3 |

6.4 |

Transmission Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6.3 |

6.5 |

Transmission Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6.3 |

6.6 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6.7 |

Section 7 |

|

|

Engine . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.1 |

7.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.2 |

7.2 |

Engine Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.4 |

7.3 |

Engine Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.6 |

7.4 |

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.6 |

7.5 |

Engine Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.8 |

7.6 |

Air Cleaner Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.9 |

7.7 |

Engine Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.9 |

7.8 |

Torque Convertor Diaphragm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.11 |

7.9 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7.12 |

Section 8 |

|

|

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.1 |

|

8.1 |

Hydraulic Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.2 |

8.2 |

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.3 |

8.3 |

Hydraulic Pressure Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.4 |

8.4 |

Hydraulic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.5 |

8.5 |

Hydraulic System Schematics and Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.7 |

8.6 |

Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.12 |

8.7 |

Engine Implement Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.13 |

8.8 |

Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.14 |

8.9 |

Hydraulic Piston Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.22 |

8.10 |

Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8.24 |

Section 9 |

|

|

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.1 |

|

9.1 |

Electrical Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.3 |

9.2 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.4 |

9.3 |

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.4 |

9.4 |

Fuses and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.4 |

9.5 |

Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.7 |

9.6 |

Electrical System Schematics And Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.15 |

9.7 |

Engine Start Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.23 |

9.8 |

Charging Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.24 |

9.9 |

Window Wiper/Washer Windshield Wiper Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.25 |

9.10 |

Cab Heater and Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.26 |

9.11 |

Solenoids, Senders and Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.27 |

9.12 |

Display Monitor and Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.35 |

9.13 |

Dash Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.36 |

9.14 |

Engine Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.38 |

9.15 |

Hand Held Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9.39 |

ii |

G10-55A & G12-55A AccuPlace |

Section 1

Safety Practices

Contents

PARAGRAPH |

TITLE |

PAGE |

|

1.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.2 |

|

1.3 |

Operation & Safety Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.2 |

|

1.4 |

Do Not Operate Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.2 |

|

1.5 |

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.3 |

|

|

1.5.1 |

Safety Alert System and Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.3 |

1.6 |

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.3 |

|

|

1.6.1 |

Personal Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.3 |

|

1.6.2 |

Equipment Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.3 |

|

1.6.3 |

General Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.4 |

|

1.6.4 |

Operational Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.4 |

1.7 |

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1.4 |

|

G10-55A & G12-55A AccuPlace |

1.1 |

Safety Practices

1.1INTRODUCTION

This service manual provides general directions for accomplishing service and repair procedures. Following the procedures in this manual will help assure safety and equipment reliability.

Read, understand and follow the information in this manual, and obey all locally approved safety practices, procedures, rules, codes, regulations and laws.

These instructions cannot cover all details or variations in the equipment, procedures, or processes described, nor provide directions for meeting every possible contingency during operation, maintenance, or testing. When additional information is desired consult the local JLG distributor.

Many factors contribute to unsafe conditions: carelessness, fatigue, overload, inattentiveness, unfamiliarity, even drugs and alcohol, among others. For optimal safety, encourage everyone to think, and to act, safely.

Appropriate service methods and proper repair procedures are essential for the safety of the individual doing the work, for the safety of the operator, and for the safe, reliable operation of the machine. All references to the right side, left side, front and rear are given from the operator’s seat looking in a forward direction.

Supplementary information is available from JLG in the form of Service Bulletins, Service Campaigns, Service Training Schools, the JLG website, other literature, and through updates to the manual itself.

1.2

1.2DISCLAIMER

All information in this manual is based on the latest product information available at the time of publication. JLG reserves the right to make changes and improvements to its products, and to discontinue the manufacture of any product, at its discretion at any time without public notice or obligation.

1.3OPERATION & SAFETY MANUAL

The mechanic must not operate the machine until the Operation & Safety Manual has been read & understood, training has been accomplished and operation of the machine has been completed under the supervision of an experienced and qualified operator.

An Operation & Safety Manual is supplied with each machine and must be kept in the manual holder located in the cab. In the event that the Operation & Safety Manual is missing, consult the local JLG distributor before proceeding.

1.4DO NOT OPERATE TAGS

Place Do Not Operate Tags on the ignition key switch and the steering wheel before attempting to perform any service or maintenance. Remove key and disconnect battery leads.

G10-55A & G12-55A AccuPlace

Safety Practices

1.5SAFETY INFORMATION

To avoid possible death or injury, carefully read, understand and comply with all safety messages.

In the event of an accident, know where to obtain medical assistance and how to use a first-aid kit and fire extinguisher/fire suppression system. Keep emergency telephone numbers (fire department, ambulance, rescue squad/paramedics, police department, etc.) nearby. If working alone, check with another person routinely to help assure personal safety.

1.5.1Safety Alert System and Signal Words

DANGER

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

G10-55A & G12-55A AccuPlace

1.6SAFETY INSTRUCTIONS

Following are general safety statements to consider before performing maintenance procedures on the telehandler. Additional statements related to specific tasks and procedures are located throughout this manual and are listed prior to any work instructions to provide safety information before the potential of a hazard occurs.

For all safety messages, carefully read, understand and follow the instructions before proceeding.

1.6.1Personal Hazards

PERSONAL SAFETY GEAR: Wear all the protective clothing and personal safety gear necessary to perform the job safely. This might include heavy gloves, safety glasses or goggles, filter mask or respirator, safety shoes or a hard hat.

LIFTING: NEVER lift a heavy object without the help of at least one assistant or a suitable sling and hoist.

1.6.2Equipment Hazards

LIFTING OF EQUIPMENT: Before using any lifting equipment (chains, slings, brackets, hooks, etc.), verify that it is of the proper capacity, in good working order, and is properly attached.

NEVER stand or otherwise become positioned under a suspended load or under raised equipment. The load or equipment could fall or tip.

DO NOT use a hoist, jack or jack stands only to support equipment. Always support equipment with the proper capacity blocks or stands properly rated for the load.

HAND TOOLS: Always use the proper tool for the job; keep tools clean and in good working order, and use special service tools only as recommended.

1.3

Safety Practices

1.6.3General Hazards

SOLVENTS: Only use approved solvents that are known to be safe for use.

HOUSEKEEPING: Keep the work area and operator’s cab clean, and remove all hazards (debris, oil, tools, etc.).

FIRST AID: Immediately clean, dress and report all injuries (cuts, abrasions, burns, etc.), no matter how minor the injury may seem. Know the location of a First Aid Kit, and know how to use it.

CLEANLINESS: Wear eye protection, and clean all components with a high-pressure or steam cleaner before attempting service.

When removing hydraulic components, plug hose ends and connections to prevent excess leakage and contamination. Place a suitable catch basin beneath the machine to capture fluid run-off.

Check and obey all Federal, State and/or Local regulations regarding waste storage, disposal and recycling.

1.6.4Operational Hazards

ENGINE: Stop the engine before performing any service unless specifically instructed otherwise.

VENTILATION: Avoid prolonged engine operation in enclosed areas without adequate ventilation.

SOFT SURFACES AND SLOPES: NEVER work on a machine that is parked on a soft surface or slope. The machine must be on a hard level surface, with the wheels blocked before performing any service.

FLUID TEMPERATURE: NEVER work on a machine when the engine, cooling or hydraulic systems are hot. Hot components and fluids can cause severe burns. Allow systems to cool before proceeding.

FLUID PRESSURE: Before loosening any hydraulic or diesel fuel component, hose or tube, turn the engine OFF. Wear heavy, protective gloves and eye protection. NEVER check for leaks using any part of your body; use a piece of cardboard or wood instead. If injured, seek medical attention immediately. Diesel fluid leaking under pressure can explode. Hydraulic fluid and diesel fuel leaking under pressure can penetrate the skin, cause infection, gangrene and other serious personal injury.

Relieve all pressure before disconnecting any component, part, line or hose. Slowly loosen parts and allow release of residual pressure before removing any part or component. Before starting the engine or applying pressure, use components, parts, hoses and pipes that are in good condition, connected properly and are tightened to the proper torque. Capture fluid in an

appropriate container and dispose of in accordance with prevailing environmental regulations.

RADIATOR CAP: The cooling system is under pressure, and escaping coolant can cause severe burns and eye injury. To prevent personal injury, NEVER remove the radiator cap while the cooling system is hot. Wear safety glasses. Turn the radiator cap to the first stop and allow pressure to escape before removing the cap completely. Failure to follow the safety practices could result in death or serious injury.

FLUID FLAMABILTITY: DO NOT service the fuel or hydraulic systems near an open flame, sparks or smoking materials.

NEVER drain or store fluids in an open container. Engine fuel and hydraulic fluid are flammable and can cause a fire and/or explosion.

DO NOT mix gasoline or alcohol with diesel fuel. The mixture can cause an explosion.

PRESSURE TESTING: When conducting any test, only use test equipment that is correctly calibrated and in good condition. Use the correct equipment in the proper manner, and make changes or repairs as indicated by the test procedure to achieve the desired result.

LEAVING MACHINE: Lower the forks or attachment to the ground before leaving the machine.

TIRES: Always keep tires inflated to the proper pressure to help prevent tipover. DO NOT over-inflate tires.

NEVER use mismatched tire types, sizes or ply ratings. Always use matched sets according to machine specifications.

MAJOR COMPONENTS: Never alter, remove, or substitute any items such as counterweights, tires, batteries or other items that may reduce or affect the overall weight or stability of the machine.

BATTERY: DO NOT charge a frozen battery.Charging a frozen battery may cause it to explode. Allow the battery to thaw before jump-starting or connecting a battery charger.

1.7SAFETY DECALS

Check that all safety decals are present and readable on the machine. Refer to the Operation & Safety Manual supplied with machine for information.

1.4 |

G10-55A & G12-55A AccuPlace |

Section 2

General Information and Specifications

Contents

PARAGRAPH |

TITLE |

PAGE |

|

2.1 |

Replacement Parts and Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.2 |

|

2.2 |

Torques |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.3 |

|

2.2.1 |

ASTM Fastener Torque Chart (English) . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.3 |

|

2.2.2 |

ASTM Fastener Torque Chart (Metric) . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.4 |

|

2.2.3 |

Metric Fastener Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.5 |

2.3 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.6 |

|

|

2.3.1 |

Travel Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.6 |

|

2.3.2 |

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.6 |

|

2.3.3 |

Engine Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.6 |

|

2.3.4 |

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.7 |

2.4 |

Fluid and Lubricant Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.8 |

|

2.5 |

Service and Maintenance Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.9 |

|

|

2.5.1 |

10, 1st 100 & 50 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.9 |

|

2.5.2 |

250, 500, 1000 & 1500 Hour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.10 |

2.6 |

Lubrication Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2.11 |

|

G10-55A & G12-55A AccuPlace |

2.1 |

General Information and Specifications

2.1REPLACEMENT PARTS AND WARRANTY INFORMATION

Before ordering parts or initiating service inquiries, make note of the machine serial number. The machine serial number plate (1) is located as indicated in the figure.

MY1000

1

Note: The replacement of any part on this machine with any other than JLG authorized replacement parts can adversely affect the performance, durability, or safety of the machine, and will void the warranty. JLG disclaims liability for any claims or damages, whether regarding property damage, personal injury or death arising out of the use of unauthorized replacement parts.

A warranty registration form must be filled out by the JLG distributor, signed by the purchaser and returned to JLG when the machine is sold and/or put into use.

Registration activates the warranty period and helps to assure that warranty claims are promptly processed. To guarantee full warranty service, verify that the distributor has returned the business reply card of the warranty registration form to JLG.

2.2

G10-55A & G12-55A AccuPlace

55A-G10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.2.2 |

2.2 |

|

|

|

|

|

|

|

VALUES FOR ZINC PLATED / YELLOW CHROMATE FASTENERS ONLY |

|

UNPLATED CAP SCREWS |

|

|

|

|||||||||||||

AccuPlace55A-G12& |

|

|

|

|

|

|

TORQUES |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FastenerASTM |

|

||||

40 |

|

0.00604 |

380 |

8 |

6 |

|

— |

— |

540 |

12 |

9 |

— |

— |

— |

— |

— |

|

|

||||

|

|

|

|

|

|

SAE GRADE 5 BOLTS & |

|

SAE GRADE 8 BOLTS & GRADE 8 NUTS |

UNBRAKO 1960 SERIES |

|

|

|

|

|||||||||

|

|

|

|

|

|

GRADE 2 NUTS |

|

|

& SOCKET HEAD CAP SCREWS |

SOCKET HEAD |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BOLT |

TENSILE |

CLAMP |

|

TORQUE |

|

CLAMP |

|

TORQUE |

|

CLAMP |

TORQUE |

|

|

|

|

||||

|

|

THDS. |

DRY OR |

|

|

LOCTITE |

LOCTITE |

DRY OR |

|

LOCTITE |

LOCTITE |

WITHOUT |

WITH |

|

|

|

|

|||||

|

SIZE |

PER |

DIA. |

STRESS |

LOAD |

LOCTITE |

LUB |

|

242 OR |

LOAD |

LOCTITE |

LUB |

242 OR |

LOAD |

LOC-WEL |

LOC-WEL |

|

|

|

|

||

|

AREA |

|

262 |

262 |

|

|

|

|

||||||||||||||

|

|

INCH |

|

|

263 |

|

|

271 |

|

263 |

|

271 |

|

PATCH |

PATCH |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

IN |

SQ. IN. |

LB. |

IN-LB |

IN-LB |

|

IN-LB |

IN-LB |

LB. |

IN-LB. |

IN-LB |

IN-LB |

IN-LB |

LB. |

IN-LB |

IN-LB |

|

|

|

|

|

4 |

|

0.1120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

48 |

0.00661 |

420 |

9 |

7 |

|

— |

— |

600 |

13 |

10 |

— |

— |

— |

— |

— |

Torque |

|

|

|

||

|

|

|

|

|

|

|

||||||||||||||||

|

8 |

32 |

0.1640 |

0.00909 |

580 |

16 |

12 |

|

— |

— |

820 |

23 |

17 |

— |

— |

— |

— |

— |

|

|

|

|

|

6 |

40 |

0.1380 |

0.01015 |

610 |

18 |

13 |

|

— |

— |

920 |

25 |

19 |

— |

— |

— |

— |

— |

|

|

|

|

|

|

32 |

|

0.01400 |

900 |

30 |

22 |

|

— |

— |

1260 |

41 |

31 |

— |

— |

— |

— |

— |

|

|

|

|

|

|

36 |

|

0.01474 |

940 |

31 |

23 |

|

— |

— |

1320 |

43 |

32 |

— |

— |

— |

— |

— |

Chart |

|

|

|

|

|

20 |

|

0.0318 |

2020 |

96 |

75 |

|

— |

105 |

2860 |

144 |

108 |

— |

160 |

3180 |

160 |

168 |

|

|

|

|

|

10 |

24 |

0.1900 |

0.01750 |

1120 |

43 |

32 |

|

— |

— |

1580 |

60 |

45 |

— |

— |

— |

— |

— |

|

|

|

|

|

32 |

0.02000 |

1285 |

49 |

36 |

|

— |

— |

1800 |

68 |

51 |

— |

— |

— |

— |

— |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

1/4 |

|

0.2500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(English) |

|

|

|

|

28 |

0.0364 |

2320 |

120 |

86 |

|

— |

135 |

3280 |

168 |

120 |

— |

185 |

3640 |

168 |

178 |

|

|

|

|||

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

IN |

SQ. IN. |

LB. |

FT-LB |

FT-LB |

|

FT-LB |

FT-LB |

LB. |

FT-LB |

FT-LB |

FT-LB |

FT-LB |

LB. |

FT-LB |

FT-LB |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

5/16 |

18 |

0.3125 |

0.0524 |

3340 |

17 |

13 |

|

16 |

19 |

4720 |

25 |

18 |

22 |

30 |

5240 |

25 |

28 |

|

|

|

|

|

24 |

0.0580 |

3700 |

19 |

14 |

|

17 |

21 |

5220 |

25 |

20 |

25 |

30 |

5800 |

27 |

30 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

3/8 |

16 |

0.3750 |

0.0775 |

4940 |

30 |

23 |

|

28 |

35 |

7000 |

45 |

35 |

40 |

50 |

7750 |

45 |

50 |

|

|

|

|

|

24 |

0.0878 |

5600 |

35 |

25 |

|

32 |

40 |

7900 |

50 |

35 |

45 |

55 |

8780 |

50 |

55 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

7/16 |

14 |

0.4375 |

0.1063 |

6800 |

50 |

35 |

|

45 |

55 |

9550 |

70 |

55 |

63 |

80 |

10630 |

70 |

77 |

|

|

|

General |

|

20 |

0.1187 |

7550 |

55 |

40 |

|

50 |

60 |

10700 |

80 |

60 |

70 |

90 |

11870 |

75 |

82 |

|

|

|

|||

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||

|

1/2 |

13 |

0.5000 |

0.1419 |

9050 |

75 |

55 |

|

68 |

85 |

12750 |

110 |

80 |

96 |

120 |

14190 |

110 |

120 |

|

|

|

|

|

20 |

0.1599 |

10700 |

90 |

65 |

|

80 |

100 |

14400 |

120 |

90 |

108 |

130 |

15990 |

115 |

127 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

9/16 |

12 |

0.5625 |

0.1820 |

11600 |

110 |

80 |

|

98 |

120 |

16400 |

150 |

110 |

139 |

165 |

18200 |

155 |

170 |

|

|

|

|

|

18 |

0.2030 |

12950 |

120 |

90 |

|

109 |

135 |

18250 |

170 |

130 |

154 |

190 |

20300 |

165 |

182 |

|

|

|

Information |

||

|

|

|

|

|

|

|

||||||||||||||||

|

5/8 |

11 |

0.6250 |

0.2260 |

14400 |

150 |

110 |

|

135 |

165 |

20350 |

220 |

170 |

180 |

240 |

22600 |

210 |

231 |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

18 |

0.2560 |

16300 |

170 |

130 |

|

153 |

190 |

23000 |

240 |

180 |

204 |

265 |

25600 |

220 |

242 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

3/4 |

10 |

0.7500 |

0.3340 |

21300 |

260 |

200 |

|

240 |

285 |

30100 |

380 |

280 |

301 |

420 |

33400 |

365 |

400 |

|

|

|

|

|

16 |

0.3730 |

23800 |

300 |

220 |

|

268 |

330 |

33600 |

420 |

320 |

336 |

465 |

37300 |

400 |

440 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

7/8 |

9 |

0.8750 |

0.4620 |

29400 |

430 |

320 |

|

386 |

475 |

41600 |

600 |

460 |

485 |

660 |

46200 |

585 |

645 |

|

|

|

|

|

14 |

0.5090 |

32400 |

470 |

350 |

|

425 |

520 |

45800 |

660 |

500 |

534 |

725 |

50900 |

635 |

700 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

1 |

8 |

1.0000 |

0.6060 |

38600 |

640 |

480 |

|

579 |

675 |

51500 |

900 |

680 |

687 |

990 |

60600 |

865 |

950 |

|

|

|

and |

|

12 |

0.6630 |

42200 |

700 |

530 |

|

633 |

735 |

59700 |

1000 |

740 |

796 |

1100 |

66300 |

915 |

1000 |

|

|

|

|||

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||

|

1-1/8 |

7 |

1.1250 |

0.7630 |

42300 |

800 |

600 |

|

714 |

840 |

68700 |

1280 |

960 |

1030 |

1400 |

76300 |

1240 |

1365 |

|

|

|

|

|

12 |

0.8560 |

47500 |

880 |

660 |

|

802 |

925 |

77000 |

1440 |

1080 |

1155 |

1575 |

85600 |

1380 |

1520 |

|

|

|

Specifications |

||

|

|

|

|

|

|

|

||||||||||||||||

|

Note: |

These torque values |

do not apply to cadmium plated |

fasteners. |

|

1009 |

1175 |

87200 |

1820 |

1360 |

1453 |

2000 |

96900 |

1750 |

1925 |

|

|

|

||||

|

1-1/4 |

7 |

1.2500 |

0.9690 |

53800 |

1120 |

840 |

|

|

|

|

|

||||||||||

|

|

12 |

|

1.0730 |

59600 |

1240 |

920 |

|

1118 |

1300 |

96600 |

2000 |

1500 |

1610 |

2200 |

107300 |

1880 |

2070 |

|

|

|

|

|

1-3/8 |

6 |

1.3750 |

1.1550 |

64100 |

1460 |

1100 |

|

1322 |

1525 |

104000 |

2380 |

1780 |

1907 |

2625 |

115500 |

2320 |

2550 |

|

|

|

|

|

|

12 |

|

1.3150 |

73000 |

1680 |

1260 |

|

1506 |

1750 |

118100 |

2720 |

2040 |

2165 |

3000 |

131500 |

2440 |

2685 |

|

|

|

|

|

1-1/2 |

6 |

1.5000 |

1.4050 |

78000 |

1940 |

1460 |

|

1755 |

2025 |

126500 |

3160 |

2360 |

2530 |

3475 |

140500 |

3040 |

3345 |

|

|

|

|

|

12 |

1.5800 |

87700 |

2200 |

1640 |

|

1974 |

2300 |

142200 |

3560 |

2660 |

2844 |

3925 |

158000 |

3270 |

3600 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

3.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

|

|

|

|

|

|

|

|

|

|

VALUES FOR ZINC PLATED / YELLOW CHROMATE FASTENERS ONLY |

|

|

UNPLATED CAP SCREWS |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

SAE GRADE 5 BOLTS & |

|

SAE GRADE 8 BOLTS & GRADE 8 NUTS |

UNBRAKO 1960 SERIES |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

GRADE 2 NUTS |

|

|

& SOCKET HEAD CAP SCREWS |

SOCKET HEAD |

(Metric)ChartTorqueFastenerASTM |

|

SpecificationsandInformationGeneral |

||||||||

|

|

|

|

|

TENSILE |

|

|

TORQUE |

|

|

|

TORQUE |

|

|

TORQUE |

|

||||||

|

|

|

THDS. |

BOLT |

CLAMP |

DRY OR |

|

|

|

LOCTITE |

CLAMP |

DRY OR |

|

|

LOCTITE |

CLAMP |

WITHOUT |

WITH |

|

|||

|

|

|

STRESS |

|

|

LOCTITE |

|

LOCTITE |

|

|||||||||||||

|

|

SIZE |

PER |

DIA. |

LOAD |

LOCTITE |

LUB |

|

242 OR |

LOAD |

LOCTITE |

LUB |

242 OR |

LOAD |

LOC-WEL |

LOC-WEL |

|

|||||

|

|

AREA |

|

262 |

262 |

|

||||||||||||||||

|

|

|

INCH |

|

|

263 |

|

|

271 |

|

263 |

|

271 |

|

PATCH |

PATCH |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

IN |

SQ. IN. |

LB. |

N, m |

N, m |

|

N, m |

N, m |

LB. |

N, m |

N, m |

N, m |

N, m |

LB. |

N, m |

N, m |

|

|

|

|

|

4 |

40 |

0.1120 |

0.00604 |

380 |

.8 |

.8 |

|

— |

— |

540 |

1.4 |

1.0 |

— |

— |

— |

— |

— |

|

|

|

|

|

48 |

0.00661 |

420 |

1.0 |

.8 |

|

— |

— |

600 |

1.5 |

1.0 |

— |

— |

— |

— |

— |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

6 |

32 |

0.1380 |

0.00909 |

580 |

1.8 |

1.4 |

|

— |

— |

820 |

2.6 |

2.0 |

— |

— |

— |

— |

— |

|

|

|

|

|

40 |

0.01015 |

610 |

2.0 |

1.6 |

|

— |

— |

920 |

2.8 |

2.2 |

— |

— |

— |

— |

— |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

8 |

32 |

0.1640 |

0.01400 |

900 |

3.4 |

2.4 |

|

— |

— |

1260 |

4.6 |

3.4 |

— |

— |

— |

— |

— |

|

|

|

|

|

36 |

0.01474 |

940 |

3.4 |

2.6 |

|

— |

— |

1320 |

5 |

3.6 |

— |

— |

— |

— |

— |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

10 |

24 |

0.1900 |

0.01750 |

1120 |

5 |

3.6 |

|

— |

— |

1580 |

7 |

5 |

— |

— |

— |

— |

— |

|

|

|

|

|

32 |

0.02000 |

1285 |

6 |

4 |

|

— |

— |

1800 |

8 |

6 |

— |

— |

— |

— |

— |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

1/4 |

20 |

0.2500 |

0.0318 |

2020 |

11 |

8 |

|

— |

12 |

2860 |

16 |

12 |

— |

18 |

3180 |

18 |

19 |

|

|

|

|

|

28 |

0.0364 |

2320 |

14 |

10 |

|

— |

15 |

3280 |

19 |

14 |

— |

21 |

3640 |

19 |

20 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

IN |

SQ. IN. |

LB. |

N, m |

N, m |

|

N, m |

N, m |

LB. |

N, m |

N, m |

N, m |

N, m |

LB. |

N, m |

N, m |

|

|

|

|

|

5/16 |

18 |

0.3125 |

0.0524 |

3340 |

23 |

18 |

|

22 |

26 |

4720 |

34 |

24 |

30 |

41 |

5240 |

34 |

38 |

|

|

|

|

|

24 |

0.0580 |

3700 |

26 |

19 |

|

23 |

28 |

5220 |

34 |

27 |

34 |

41 |

5800 |

37 |

41 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

3/8 |

16 |

0.3750 |

0.0775 |

4940 |

41 |

31 |

|

38 |

47 |

7000 |

61 |

47 |

54 |

68 |

7750 |

61 |

68 |

|

|

|

|

|

24 |

0.0878 |

5600 |

47 |

34 |

|

43 |

54 |

7900 |

68 |

47 |

61 |

75 |

8780 |

68 |

75 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

7/16 |

14 |

0.4375 |

0.1063 |

6800 |

68 |

47 |

|

61 |

75 |

9550 |

95 |

75 |

85 |

108 |

10630 |

95 |

104 |

|

|

|

|

|

20 |

0.1187 |

7550 |

75 |

54 |

|

68 |

81 |

10700 |

108 |

81 |

95 |

122 |

11870 |

102 |

111 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

1/2 |

13 |

0.5000 |

0.1419 |

9050 |

102 |

75 |

|

92 |

115 |

12750 |

149 |

108 |

130 |

163 |

14190 |

149 |

163 |

|

|

|

|

|

20 |

0.1599 |

10700 |

122 |

88 |

|

108 |

136 |

14400 |

163 |

122 |

146 |

183 |

15990 |

156 |

172 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

9/16 |

12 |

0.5625 |

0.1820 |

11600 |

149 |

108 |

|

133 |

163 |

16400 |

203 |

149 |

188 |

224 |

18200 |

210 |

230 |

|

|

|

|

|

18 |

0.2030 |

12950 |

163 |

122 |

|

148 |

183 |

18250 |

230 |

176 |

209 |

258 |

20300 |

224 |

247 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

5/8 |

11 |

0.6250 |

0.2260 |

14400 |

203 |

149 |

|

183 |

224 |

20350 |

298 |

230 |

244 |

325 |

22600 |

285 |

313 |

|

|

|

|

|

18 |

0.2560 |

16300 |

230 |

176 |

|

207 |

258 |

23000 |

325 |

244 |

277 |

359 |

25600 |

298 |

328 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

3/4 |

10 |

0.7500 |

0.3340 |

21300 |

353 |

271 |

|

325 |

386 |

30100 |

515 |

380 |

408 |

569 |

33400 |

495 |

542 |

|

|

|

|

|

16 |

0.3730 |

23800 |

407 |

298 |

|

363 |

447 |

33600 |

569 |

434 |

456 |

630 |

37300 |

542 |

597 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

7/8 |

9 |

0.8750 |

0.4620 |

29400 |

583 |

434 |

|

523 |

644 |

41600 |

813 |

624 |

658 |

895 |

46200 |

793 |

874 |

|

|

|

|

|

14 |

0.5090 |

32400 |

637 |

475 |

|

576 |

705 |

45800 |

895 |

678 |

724 |

983 |

50900 |

861 |

949 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

1 |

8 |

1.0000 |

0.6060 |

38600 |

868 |

651 |

|

785 |

915 |

51500 |

1220 |

922 |

931 |

1342 |

60600 |

1173 |

1288 |

|

|

|

|

|

12 |

0.6630 |

42200 |

949 |

719 |

|

858 |

997 |

59700 |

1356 |

1003 |

1079 |

1491 |

66300 |

1241 |

1356 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

1-1/8 |

7 |

1.1250 |

0.7630 |

42300 |

1085 |

813 |

|

968 |

1139 |

68700 |

1735 |

1302 |

1396 |

1898 |

76300 |

1681 |

1851 |

|

|

|

|

|

12 |

0.8560 |

47500 |

1193 |

895 |

|

1087 |

1254 |

77000 |

1952 |

1464 |

1566 |

2135 |

85600 |

1871 |

2061 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

1-1/4 |

7 |

1.2500 |

0.9690 |

53800 |

1518 |

1139 |

|

1368 |

1593 |

87200 |

2468 |

1844 |

1970 |

2712 |

96900 |

2373 |

2610 |

|

|

|

|

|

12 |

1.0730 |

59600 |

1681 |

1247 |

|

1516 |

1763 |

96600 |

2712 |

2034 |

2183 |

2983 |

107300 |

2549 |

2807 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||||||||

-G10 |

|

1-3/8 |

6 |

1.3750 |

1.1550 |

64100 |

1979 |

1491 |

|

1792 |

2068 |

104000 |

3227 |

2413 |

2586 |

3559 |

115500 |

3145 |

3457 |

|

|

|

12 |

1.3150 |

73000 |

2278 |

1708 |

|

2042 |

2373 |

118100 |

3688 |

2766 |

2935 |

4067 |

131500 |

3308 |

3640 |

|

|

|

||||

|

|

|

|

|

|

|||||||||||||||||

55A |

1-1/2 |

6 |

1.5000 |

1.4050 |

78000 |

2630 |

1979 |

|

2379 |

2745 |

126500 |

4284 |

3200 |

3430 |

4711 |

140500 |

4122 |

4535 |

|

|

|

|

12 |

1.5800 |

87700 |

2983 |

2224 |

|

2676 |

3118 |

142200 |

4827 |

3606 |

3856 |

5322 |

158000 |

4433 |

4881 |

|

|

|

||||

& |

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AccuPlace 55A-G12 |

|

Note: These torque values do not apply to cadmium plated fasteners. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General Information and Specifications

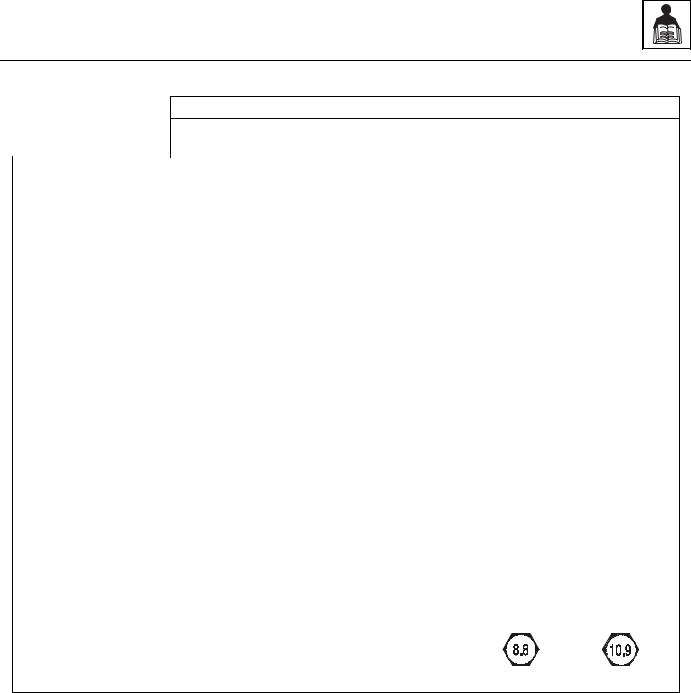

2.2.3Metric Fastener Torque Chart

VALUES FOR ZINC PLATED / YELLOW CHROMATE FASTENERS ONLY

|

|

|

|

CLASS 8.8 METRIC BOLTS & |

|

|

CLASS 10.9 METRIC BOLTS & |

|

|||||

|

|

|

|

CLASS 8 METRIC NUTS |

|

|

CLASS 10 METRIC NUTS |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TENSILE |

|

|

TORQUE |

|

|

|

TORQUE |

|

|||

|

|

CLAMP |

DRY OR |

|

|

LOCTITE |

CLAMP |

DRY OR |

|

|

|

LOCTITE |

|

|

|

STRESS |

|

LOCTITE |

|

LOCTITE |

|

||||||

SIZE |

PITCH |

LOAD |

|

LOAD |

|

|

|||||||

AREA |

LOCTITE |

LUB |

242 OR |

LOCTITE |

LUB |

|

242 OR |

||||||

262 |

262 |

|

|||||||||||

|

|

|

263 |

|

271 |

|

263 |

|

|

271 |

|||

|

|

|

|

|

|

|

|

|

|

||||

|

|

sq. mm |

KN |

N, m |

N, m |

N, m |

N, m |

KN |

N, m |

N, m |

N, m |

|

N, m |

3 |

.5 |

5.03 |

2.19 |

1.3 |

1.0 |

1.2 |

1.4 |

3.13 |

1.9 |

1.4 |

1.5 |

|

2.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.5 |

.6 |

6.78 |

2.95 |

2.1 |

1.6 |

1.9 |

2.3 |

4.22 |

3.0 |

2.2 |

2.4 |

|

3.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

.7 |

8.78 |

3.82 |

3.1 |

2.3 |

2.8 |

3.4 |

5.47 |

4.4 |

3.3 |

3.5 |

|

4.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

.8 |

14.2 |

6.18 |

6.2 |

4.6 |

5.6 |

6.8 |

8.85 |

8.9 |

6.6 |

7.1 |

|

9.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

1 |

20.1 |

8.74 |

11 |

7.9 |

9.4 |

12 |

12.5 |

15 |

11 |

12 |

|

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

1 |

28.9 |

12.6 |

18 |

13 |

16 |

19 |

18 |

25 |

19 |

20 |

|

28 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

1.25 |

36.6 |

15.9 |

25 |

19 |

23 |

28 |

22.8 |

37 |

27 |

29 |

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

1.5 |

58.0 |

25.2 |

50 |

38 |

45 |

55 |

36.1 |

72 |

54 |

58 |

|

79 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

1.75 |

84.3 |

36.7 |

88 |

66 |

79 |

97 |

52.5 |

126 |

95 |

101 |

|

139 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

2 |

115 |

50.0 |

140 |

105 |

126 |

154 |

71.6 |

200 |

150 |

160 |

|

220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

2 |

157 |

68.3 |

219 |

164 |

197 |

241 |

97.8 |

313 |

235 |

250 |

|

344 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

2.5 |

192 |

83.5 |

301 |

226 |

271 |

331 |

119.5 |

430 |

323 |

344 |

|

473 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

2.5 |

245 |

106.5 |

426 |

320 |

383 |

469 |

152.5 |

610 |

458 |

488 |

|

671 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

2.5 |

303 |

132.0 |

581 |

436 |

523 |

639 |

189.0 |

832 |

624 |

665 |

|

915 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

3 |

353 |

153.5 |

737 |

553 |

663 |

811 |

220.0 |

1060 |

792 |

845 |

|

1170 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

27 |

3 |

459 |

199.5 |

1080 |

810 |

970 |

1130 |

286.0 |

1540 |

1160 |

1240 |

|

1690 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

3.5 |

561 |

244.0 |

1460 |

1100 |

1320 |

1530 |

349.5 |

2100 |

1570 |

1680 |

|

2310 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

33 |

3.5 |

694 |

302.0 |

1990 |

1490 |

1790 |

2090 |

432.5 |

2600 |

2140 |

2280 |

|

2860 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36 |

4 |

817 |

355.0 |

2560 |

1920 |

2300 |

2690 |

509.0 |

3660 |

2750 |

2930 |

|

4020 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

42 |

4.5 |

1120 |

487.0 |

4090 |

3070 |

3680 |

4290 |

698.0 |

5860 |

4400 |

4690 |

|

6440 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: These torque values do not apply to cadmium plated fasteners.

METRIC CLASS 8.8 METRIC CLASS 10.9

G10-55A & G12-55A AccuPlace |

2.5 |

General Information and Specifications

2.3SPECIFICATIONS

2.3.1Travel Speeds

|

G10-55A |

G12-55A |

|

|

|

First Gear |

3.4 mph (5,4 km/h) |

3.5 mph (5,6 km/h) |

|

|

|

Second Gear |

6.1 mph (9,8 km/h) |

6.3 mph (10,1 km/h) |

|

|

|

Third Gear |

13.8 mph (22,2 km/h) |

14.1 mph (22,7 km/h) |

|

|

|

Fourth Gear |

20.0 mph (32,2 km/h) |

20.4 mph (32,8 km/h) |

|

|

|

2.3.2Electrical System

Battery:

Type, Rating |

12 BCI, Negative (-) Ground, Maintenance Free |

|

|

Quantity |

1 |

|

|

Reserve Capacity |

1,000 Cold Cranking Amps @ 0° F (-18° C) |

|

|

Group/Series |

Group 31 |

|

|

Alternator |

12V, 95 Amps |

|

|

2.3.3Engine Performance Specifications

Description |

G10-55A |

G12-55A |

|

|

|

Engine Make/Model |

Perkins 1104D - 125HP |

Perkins 1104D - 142 HP |

|

|

|

Displacement |

269 in³ (4,4 liters) |

269 in³ (4,4 liters) |

|

|

|

Low Idle |

1000 rpm |

900 rpm |

|

|

|

High Idle |

2,400 to 2,650 rpm |

2,400 to 2,650 rpm |

|

|

|

Horsepower |

125 HP (93 kW) @ 2400 rpm |

142 HP (104 kW) @ 2400 rpm |

|

|

|

Peak Torque |

Not Available at Publication |

410 lb-ft (556 Nm) @ 1400 rpm |

|

|

|

Fuel Delivery |

Fuel Injection |

Fuel Injection |

|

|

|

Air Cleaner |

Dry Type, Replaceable Primary and |

Dry Type, Replaceable Primary and |

|

Safety Elements |

Safety Elements |

|

|

|

2.6 |

G10-55A & G12-55A AccuPlace |

General Information and Specifications

2.3.4Tires

Note: Standard wheel lug nut torque is 350-400 lb-ft (475-542 Nm).

a. G10-55A |

|

|

|

|

|

|

|

|

|

Size |

Tire Type |

Minimum Ply/ |

Fill Type |

Pressure |

|

|

Star Rating |

|

|

|

|

|

|

|

14.00 x 24 |

G-2/L-2 Bias Ply Traction |

12 Ply |

Pneumatic |

65 psi (4,5 bar) |

|

|

|

|

|

|

|

|

approx. 720 lb foam |

|

|

|

|

|

|

14.00 x 24 |

G-3/L-3 Bias Ply Rock |

12 Ply |

Pneumatic |

65 psi (4,5 bar) |

|

|

|

|

|

|

|

|

approx. 720 lb foam |

|

|

|

|

|

|

14.00 x 24 |

G-2/L-2 Radial |

1 Star |

Pneumatic |

70 psi (4,8 bar) |

|

|

|

|

|

|

|

|

approx. 720 lb foam |

|

|

|

|

|

|

14.00 x 24 |

Solid |

N/A |

Solid Rubber |

N/A |

|

|

|

|

|

17.50 x 25 |

G-2/L-2 Bias Ply Traction |

12 Ply |

Pneumatic |

65 psi (4,5 bar) |

|

|

|

|

|

|

|

|

approx. 785 lb foam |

|

|

|

|

|

|

17.50 x 25 |

G-3/L-3 Bias Ply Rock |

12 Ply |

Pneumatic |

65 psi (4,5 bar) |

|

|

|

|

|

|

|

|

approx. 785 lb foam |

|

|

|

|

|

|

17.50 x 25 |

G-2/L-2 Radial |

1 Star |

Pneumatic |

70 psi (4,8 bar) |

|

|

|

|

|

|

|

|

approx. 785 lb foam |

|

|

|

|

|

|

b. G12-55A

Size |

Tire Type |

Minimum Ply/ |

Fill Type |

Pressure |

|

|

Star Rating |

|

|

|

|

|

|

|

14.00 x 24 |

Solid |

N/A |

Solid Rubber |

N/A |

|

|

|

|

|

17.50 x 25 |

G-2/L-2 Bias Ply Traction |

12 Ply |

Pneumatic |

65 psi (4,5 bar) |

|

|

|

|

|

|

|

|

approx. 785 lb foam |

|

|

|

|

|

|

17.50 x 25 |

G-3/L-3 Bias Ply Rock |

12 Ply |

Pneumatic |

65 psi (4,5 bar) |

|

|

|

|

|

|

|

|

approx. 785 lb foam |

|

|

|

|

|

|

17.50 x 25 |

G-2/L-2 Radial |

1 Star |

Pneumatic |

70 psi (4,8 bar) |

|

|

|

|

|

|

|

|

approx. 785 lb foam |

|

|

|

|

|

|

G10-55A & G12-55A AccuPlace |

2.7 |

General Information and Specifications

2.4FLUID AND LUBRICANT CAPACITIES

Engine Crankcase Oil

Capacity with Filter Change - Perkins |

7 quarts (6,5 liters) |

|

|

Oil Type |

15W-40 CE |

|

|

Fuel Tank |

|

|

|

Capacity |

38 gallons (144 liters) |

|

|

Type of Fuel |

Low Sulfur Diesel #2 |

|

|

Cooling System |

|

|

|

System Capacity - Perkins |

20.5 quarts (19,4 liters) |

|

|

Overflow Bottle Capacity |

3 quarts (2,8 liters) |

|

|

Type of Fluid |

50/50 ethylene glycol & water |

|

|

Coolant Conditioner (refer engine manual) |

0.5 quarts (0,47 liters) |

|

|

Transmission |

|

|

|

Capacity with Filter Change |

4.23 gallons (16 liters) |

|

|

Type of Fluid |

Mobilfluid® 424 Tractor Hydraulic Fluid (ISO 46) |

Transfer Case |

|

|

|

Capacity |

1.5 quarts (1,4 liters) |

|

|

Type of Fluid |

Mobilfluid® 424 Tractor Hydraulic Fluid (ISO 46) |

Axles |

|

|

|

Differential Housing Capacity |

Front Axle - 15.8 quarts (15 liters) |

|

Rear Axle - 16.9 quarts (16 liters) |

|

|

Wheel End Capacity |

2 quarts (1,9 liters) |

|

|

Type of Fluid |

Mobilfluid® 424 Tractor Hydraulic Fluid (ISO 46) |

Hydraulic System |

|

|

|

System Capacity |

G10-55A - 63 gallons (238 liters) |

|

G12-55A - 65 gallons (246 liters) |

|

|

Reservoir Capacity |

38 gallons (144 liters) |

|

|

Auxiliary Hydraulic Circuit Max Flow |

16 gpm (72,7 lpm) |

|

|

Type of Fluid |

Mobilfluid® 424 Tractor Hydraulic Fluid |

2.8 |

G10-55A & G12-55A AccuPlace |

General Information and Specifications

2.5SERVICE AND MAINTENANCE SCHEDULES

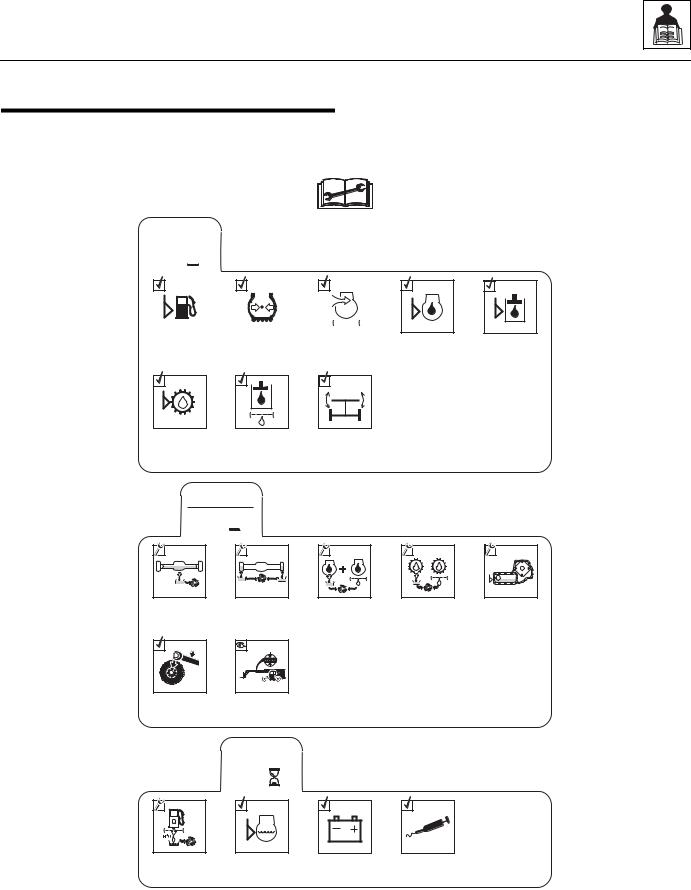

2.5.110, 1st 100 & 50 Hour

EVERY

10

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check Fuel |

|

Check Tire |

|

Air Filter |

|||||||

|

Level |

|

Pressure |

Restriction |

|||||||

|

|

|

|

|

|

|

|

Indicator |

|||

|

|

A |

Check |

Check Hydraulic |

Check Auto- |

Transmission |

Return Filter |

Sway Function |

Oil Level |

Indicator |

|

Check Engine |

Check Hydraulic |

Oil Level |

Oil Level |

1st

100

Change |

Axle Oil |

LB |

/FT ( |

Nm) |

Check Wheel

Lug Nut

Torque

Change Wheel |

End Oil |

Check Boom |

Chain Tension |

|

EVERY |

|

50 |

Drain Fuel/ |

Check Engine |

Water |

Coolant Level |

Separator |

|

Change Engine |

Oil & Filter |

Check |

Battery |

Change |

Transmission |

Oil & Filter |

Lubrication |

Schedule |

Change |

Transfer |

Case Oil |

MY1731

G10-55A & G12-55A AccuPlace |

2.9 |

General Information and Specifications

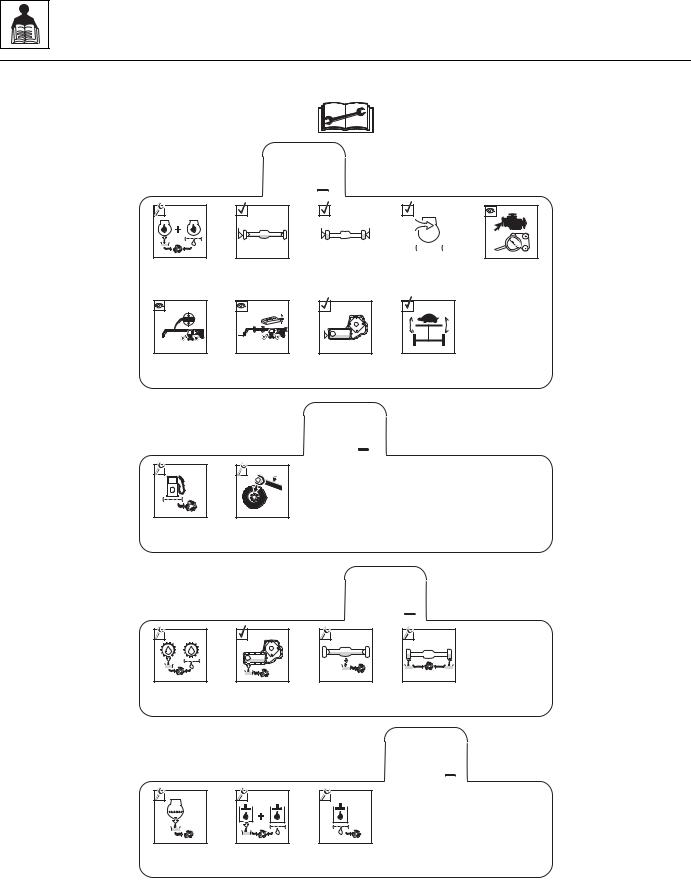

2.5.2250, 500, 1000 & 1500 Hour

Change Engine |

Oil and |

Filter* |

Check Boom |

Chain |

Tension |

EVERY

250

Check Axle

Oil Level

Check Boom |

Bearing |

Pads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check Wheel |

|

Air Filter |

||||

End Oil Levels |

Vacuator |

||||||

|

|

|

|

|

|

Valve |

|

Check Transfer |

Check Rear Axle |

Case Oil Level |

Stabilization |

|

(if equipped) |

Check |

Fan Belt |

Change Fuel |

Filter |

EVERY

500

LB |

/FT ( |

Nm) |

Check Wheel |

Lug Nut |

Torque |

Change |

Transmission |

Oil & Filter |

Change |

Transfer Case |

Oil |

EVERY

1000

Change |

Change Wheel |

Axle Oil |

End Oil |

EVERY

1500

Change |

Change |

Change |

Engine Coolant |

Hydraulic |

Hydraulic Tank |

|

Fluid & Filters |

Breather |

MY0090

Note: Engine oil & filter service interval can be extended. See Engine Manual for details.

2.10 |

G10-55A & G12-55A AccuPlace |

General Information and Specifications

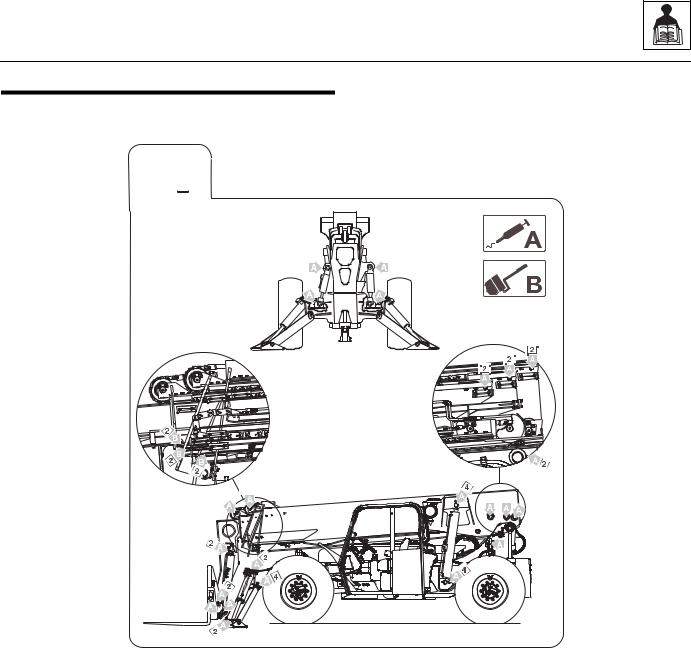

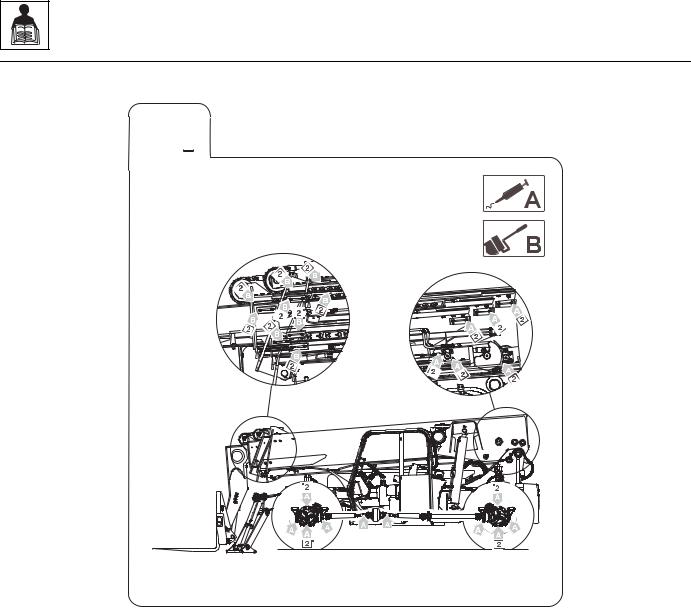

2.6LUBRICATION SCHEDULES

a. 50 Hour

EVERY

50

OY1630

G10-55A & G12-55A AccuPlace |

2.11 |

General Information and Specifications

b. 250 Hour

EVERY

250

OW1210

2.12 |

G10-55A & G12-55A AccuPlace |

Section 3

Boom

Contents

PARAGRAPH |

TITLE |

PAGE |

|

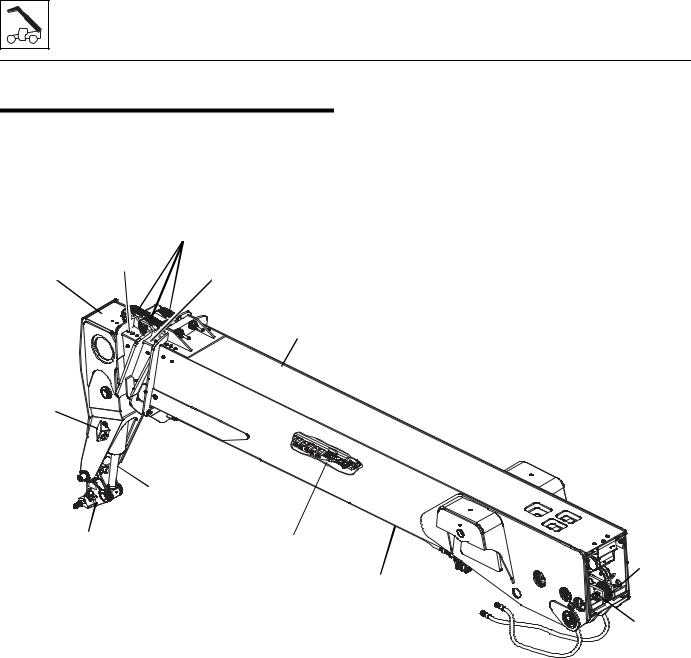

3.1 |

Boom System Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.2 |

|

3.2 |

Boom System - Four Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.3 |

|

|

3.2.1 |

Boom System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.3 |

3.3 |

Boom Assembly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.3 |

|

|

3.3.1 |

Boom Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3.3 |

|

3.3.2 |