siemens 802Dsl User Manual

SINUMERIK 802D sl plus

Manual machine +

Turning

Control system overview

for machine tools' sales people

03/2011

___________________

Foreword

Introduction |

1 |

|

|

|

|

System overview |

2 |

|

|

|

|

Manual Machine |

3 |

|

|

|

|

Programming |

4 |

|

|

|

|

Setup functions |

5 |

|

Program management and |

|

|

6 |

||

user memory |

||

|

|

|

Simulation |

7 |

|

|

|

|

Automatic mode |

8 |

|

|

|

|

Maintenance and diagnostics |

9 |

|

|

|

|

Ordering data |

10 |

|

Summary of unique selling |

|

|

11 |

||

points |

||

|

|

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task in accordance with the relevant documentation for the specific task, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG |

|

Copyright © Siemens AG 2011. |

Industry Sector |

03/2011 |

Technical data subject to change |

Postfach 48 48 90026 NÜRNBERG GERMANY

Foreword

Scope of validity

This document provides you with an overview of the range of functions included in the SINUMERIK 802D solution line plus Version 1.4 operator panel control with the optional package Manual Machine + (MM+) for turning machines.

The document is oriented towards vendors and dealers of machine tools.

Structure of the information

●From the wide variety of functions of the SINUMERIK products, only those that are of direct significance to the machine user are listed.

●All functions contained in the machine's basic configuration are identified as follows:

Basic configuration

●All functions not contained in the machine's basic configuration are identified as follows:

Option: ...

●A summary of the unique selling points of the SINUMERIK 802D sl plus in comparison with competitors, may be found in the chapter "Summary of unique selling points".

●For information on marketing options through the machine manufacturer, please see the technical description of the particular machine.

We reserve the right to make technical changes

Contact person at the machine manufacturer

Sales |

|

Phone: |

+49 xxx xxx |

Fax: |

+49 xxx xxx |

Email: |

xxx@machinemanufacturer.com |

Web: |

http://www.machinemanufacturer.com |

Service |

|

Phone: |

+49 xxx xxx |

Fax: |

+49 xxx xxx |

Email: |

xxx@machinemanufacturer.com |

Web: |

http://www.machinemanufacturer.com |

Homepage: |

|

http://www.machinemanufacturer.com |

|

SINUMERIK 802D sl plus - Turning |

|

Control system overview for machine tools' sales people, 03/2011 |

3 |

Foreword

Contact person at Siemens

Sales / specialist support |

|

Phone: |

+49 xxx xxx |

Fax: |

+49 xxx xxx |

Web: |

http://www4.ad.siemens.de (worldwide) |

Service |

|

Phone: |

+49 xxx xxx |

Fax: |

+49 xxx xxx |

Web: |

http://www4.ad.siemens.de (worldwide) |

Homepage: |

|

Visit the JobShop internet portal: |

|

http://www.siemens.com/jobshop |

|

|

SINUMERIK 802D sl plus - Turning |

4 |

Control system overview for machine tools' sales people, 03/2011 |

Table of contents

|

Foreword |

................................................................................................................................................... |

3 |

1 |

Introduction................................................................................................................................................ |

7 |

|

|

1.1 |

Application...................................................................................................................................... |

7 |

|

1.2 |

Machine spectrum.......................................................................................................................... |

7 |

2 |

System overview........................................................................................................................................ |

9 |

|

|

2.1 |

SINUMERIK 802D sl...................................................................................................................... |

9 |

|

2.2 |

Operator panel............................................................................................................................. |

10 |

3 |

Manual Machine ...................................................................................................................................... |

11 |

|

|

3.1 |

Overview...................................................................................................................................... |

11 |

|

3.2 |

Entry............................................................................................................................................. |

12 |

4 |

Programming........................................................................................................................................... |

13 |

|

|

4.1 |

Machining step program .............................................................................................................. |

13 |

|

4.2 |

Teaching in programs.................................................................................................................. |

14 |

|

4.3 |

MM+ machining cycles................................................................................................................. |

15 |

|

4.3.1 |

Axis-parallel traversal................................................................................................................... |

15 |

|

4.3.2 |

Taper turning................................................................................................................................ |

15 |

|

4.3.3 |

Radius turning.............................................................................................................................. |

16 |

|

4.3.4 |

Drilling - centered......................................................................................................................... |

16 |

|

4.3.5 |

Tapping........................................................................................................................................ |

17 |

|

4.3.6 |

Groove cycles/Parting.................................................................................................................. |

17 |

|

4.3.7 |

Thread cutting.............................................................................................................................. |

18 |

|

4.3.8 |

Rough turning of contours............................................................................................................ |

18 |

|

4.4 |

Free Contour Programming / Contour Calculator........................................................................ |

19 |

|

4.5 |

DIN/ISO language........................................................................................................................ |

21 |

|

4.6 |

DIN/ISO editor.............................................................................................................................. |

22 |

|

4.7 |

Machining Cycles......................................................................................................................... |

23 |

|

4.8 |

On-board user manual................................................................................................................. |

25 |

|

4.9 |

On-board pocket calculator.......................................................................................................... |

26 |

SINUMERIK 802D sl plus, MM+, Turning |

|

Control system overview for machine tools' sales people, 03/2011 |

5 |

Table of contents

5 |

Setup functions........................................................................................................................................ |

27 |

|

|

5.1 |

Work offsets................................................................................................................................ |

27 |

|

5.2 |

ToolMeasuring ............................................................................................................................ |

28 |

|

5.2.1 |

Manual tool measuring - MM+ .................................................................................................... |

28 |

|

5.2.2 |

Measure tools automatically in JOG........................................................................................... |

29 |

|

5.3 |

Tool management....................................................................................................................... |

30 |

|

5.3.1 |

Tool list........................................................................................................................................ |

30 |

|

5.3.2 |

Monitoring of tool life and quantity of workpieces....................................................................... |

31 |

6 |

Program management and user memory ................................................................................................ |

33 |

|

|

6.1 |

Program Manager....................................................................................................................... |

33 |

|

6.2 |

User memory and data management ......................................................................................... |

34 |

|

6.2.1 |

Buffered CNC user memory........................................................................................................ |

34 |

|

6.2.2 |

Compact Flash card.................................................................................................................... |

34 |

|

6.2.3 |

Serial data transfer...................................................................................................................... |

35 |

7 |

Simulation................................................................................................................................................ |

37 |

|

8 |

Automatic mode....................................................................................................................................... |

39 |

|

|

8.1 |

Program control........................................................................................................................... |

39 |

|

8.2 |

Block search................................................................................................................................ |

40 |

9 |

Maintenance and diagnostics .................................................................................................................. |

41 |

|

|

9.1 |

Maintenance-free operation........................................................................................................ |

41 |

|

9.2 |

Diagnostics.................................................................................................................................. |

42 |

10 |

Ordering data........................................................................................................................................... |

43 |

|

11 |

Summary of unique selling points............................................................................................................ |

45 |

|

|

Index |

........................................................................................................................................................ |

47 |

|

SINUMERIK 802D sl plus, MM+, Turning |

6 |

Control system overview for machine tools' sales people, 03/2011 |

Introduction |

1 |

1.1Application

The SINUMERIK 802D sl plus is a customized operator panel control for standard CNC turning machines..

With the Manual Machine + (MM+) package of the SINUMERIK 802D sl plus you can easily operate the machine tool, as all operations are supported by graphical help screens and can be performed just like for a conventional machine tool.

The available functions enable quick and practice-oriented machine setup for machining. More specifically, this consists of calculating the workpiece position in the machine, as well as maintaining and measuring the tools in use.

For programming purposes, you are provided with a DIN/ISO editor that is easy to operate and has a complete G-code in accordance with DIN66025 and ISO dialect. During programming, graphical support is provided for technological machining cycles and contours.

The SINUMERIK 802D sl plus is a powerful complete system, covering all required fields of application without additional commissioning and training costs:

●Easy-to-use interface for all machine functions

●Flexible execution of individual machining steps without programming

●DIN/ISO programming on the machine

●DIN/ISO programming offline via CAD/CAM system

●Automatic tool measuring during setup

1.2Machine spectrum

The SINUMERIK 802D sl plus is particularly recommended for the following machine types:

1.Single-slide turning machines with X and Z axes

–Turning

–Centric drilling on the end face

2.Like 1.) with rotating tools (C axis mode)

SINUMERIK 802D sl plus, MM+, Turning |

|

Control system overview for machine tools' sales people, 03/2011 |

7 |

Introduction

1.2 Machine spectrum

|

SINUMERIK 802D sl plus, MM+, Turning |

8 |

Control system overview for machine tools' sales people, 03/2011 |

System overview |

2 |

2.1SINUMERIK 802D sl

The SINUMERIK 802D sl operator panel controller is the ideal package for use with standardized turning and milling machines. Used in conjunction with the new, compact and reliable SINAMICS S120 drive system, the SINUMERIK 802D sl is a complete package for machine tool applications. These range from low-volume production to medium-volume production to production of more advanced workpieces with any type of hole machining and milling on end face and outer surface.

●Digital drive technology via DRIVE-CLiQ

●Up to 4 interpolating axes and one spindle

●Identical hardware and software for turning and milling

●Powerful PLC based on SIMATIC S7-200 with "ladder logic" programming

●Large, easy-to-read color display

See catalog NC 61 for additional information

See catalog NC 61 for additional information

Highlights

●Powerful and reliable machine package from Siemens

●Extremely dynamic drives and motors

●Matched, complete package

0RGXODU 6,1$0,&6 'ULYH V\VWHP

6,180(5,. ' VO ZLWK 7)7 FRORU GLVSOD\ &1& NH\ERDUG DQG PDFKLQH FRQWURO SDQHO

3+ VSLQGOH PRWRU). VHUYRPRWRUV

SINUMERIK 802D sl plus, MM+, Turning |

|

Control system overview for machine tools' sales people, 03/2011 |

9 |

System overview

2.2 Operator panel

2.2Operator panel

The operator panel front consists of an operator panel with a 10.4 inch color TFT display, 8 + 2 horizontal and 8 vertical softkeys, and a CNC keyboard (horizontal or vertical options available). This facilitates clear and user-friendly operation of the machine functions. We also offer the coordinated machine control panel MCP 802D sl with feed and spindle override.

Highlights

●All relevant functions at a glance, thanks to horizontal and vertical softkeys

●Brilliant color display, balanced and high-quality design of operator components

●Easy data handling thanks to the easily accessible Compact Flash card slot on the front

|

SINUMERIK 802D sl plus, MM+, Turning |

10 |

Control system overview for machine tools' sales people, 03/2011 |

Manual Machine |

3 |

3.1Overview

Basic configuration of MM+

We provide the Manual Machine function for beginners switching over from conventional machines, but also for experienced CNC machine operators who often only perform individual machining steps.

In the manual machine operating area, you can machine workpieces without having to create a specific part program. The

following functions are available:

●Axis-parallel traversal

●Taper turning

●Radius turning

●Drilling - centered

●Tapping

●Groove cycles/Parting

●Thread cutting

●Rough turning of contours

User-friendly input screens with help screens support you in defining/parameterizing the function.

The compound-rest slide is controlled using the handwheels or axis direction switch/acknowledgement button or the axis direction keys. The spindle is controlled using spindle direction switches or the individual keys for preprocessing, stop or ramp down.

Note: The machine manufacturer can specify in which mode the control powers up (MM+ or standard).

Highlights

●Saving time in single machining steps, such as repair or remachining of individual parts, as no part programs are required

●Flexible execution of the steps

●No programming expertise required

SINUMERIK 802D sl plus, MM+, Turning |

|

Control system overview for machine tools' sales people, 03/2011 |

11 |

Manual Machine

3.2 Entry

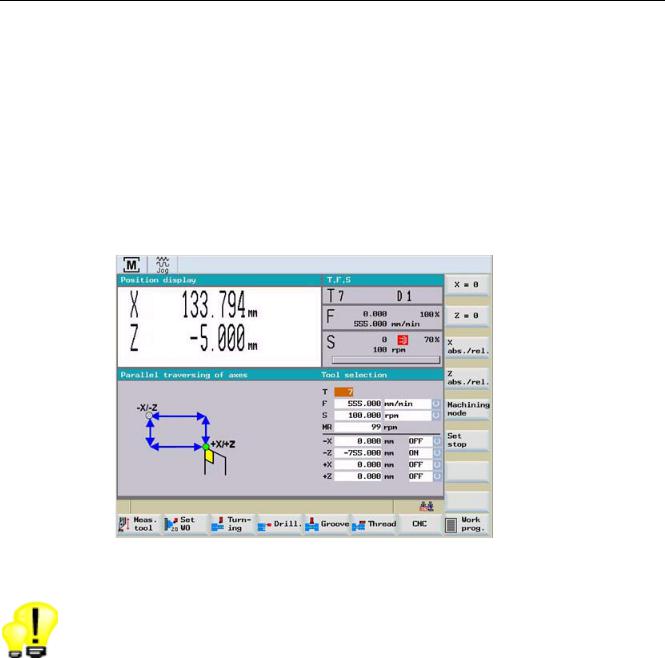

3.2Entry

Basic configuration of MM+

To access the MM+ operating area after machine power up, first select the JOG mode and then press the Manual softkey. By pressing the CNC softkey you can return to the operating area of the NC basic machine.

Note: The machine manufacturer can specify in which mode the control powers up (MM+ or standard).

Highlights

● Easy change between the operating areas using the softkeys

|

SINUMERIK 802D sl plus, MM+, Turning |

12 |

Control system overview for machine tools' sales people, 03/2011 |

Programming |

4 |

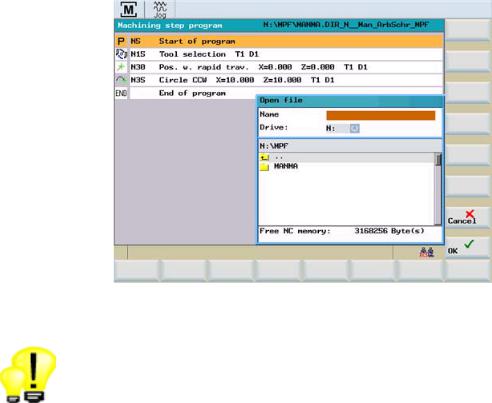

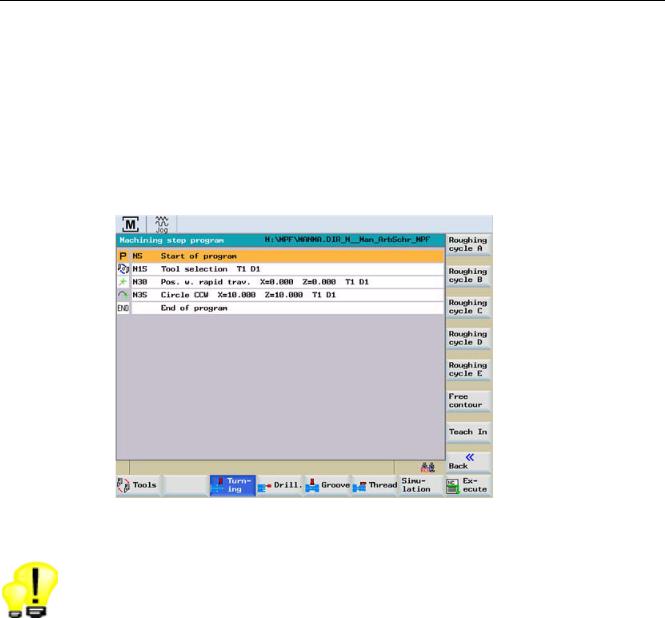

4.1Machining step program

Basic configuration of MM+

This function in the Manual Machine operating area enables you to combine the machining cycles in a list in any order desired. You can include up to 390 machining steps. that are executed in the order specified by the user. The machining step programs can be saved either in the CNC work memory or using external media such as a CF card.

Highlights

●Intuitive program entry even without DIN/ISO expertise

●Interactively created programs can be saved and are thus available for automatic execution

SINUMERIK 802D sl plus, MM+, Turning |

|

Control system overview for machine tools' sales people, 03/2011 |

13 |

Programming

4.2 Teaching in programs

4.2Teaching in programs

Basic configuration of MM+

The "Teach In" function in the Manual Machine operating area enables you to enter an approached axis position directly into a certain traversing block. You can use this function for axis-parallel turning, taper turning and radius turning.

Highlights

● Easy transfer of manually approached positions into the program

|

SINUMERIK 802D sl plus, MM+, Turning |

14 |

Control system overview for machine tools' sales people, 03/2011 |

Programming

4.3 MM+ machining cycles

4.3MM+ machining cycles

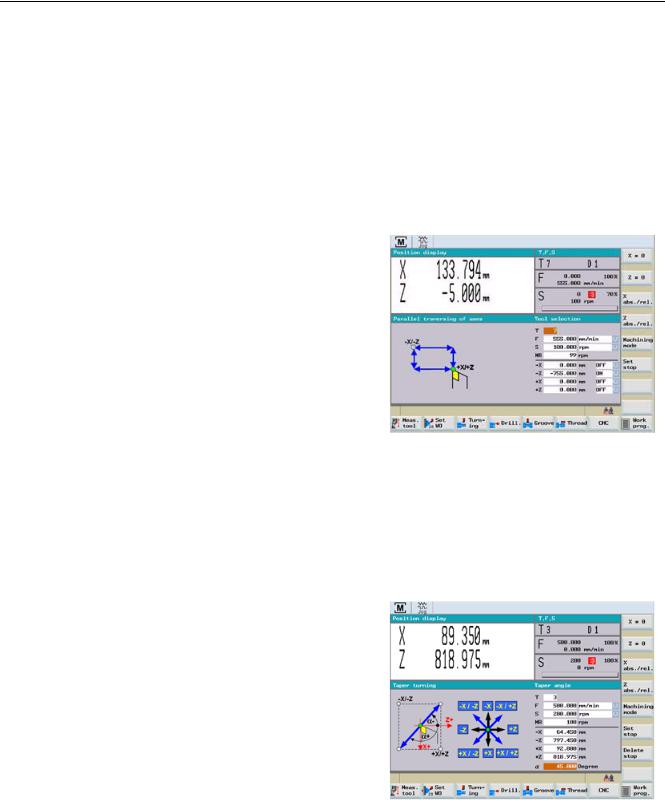

4.3.1Axis-parallel traversal

Basic configuration of MM+

Using the "Axis-parallel traversal" function you can rough turn your workpiece or position the axes.

4.3.2Taper turning

Basic configuration of MM+

Using this function you can easily produce tapered workpieces.

The value you entered for the angle causes the coordinate plane of the control to rotate. During execution the control interpolates the X and Z axis based on this angle value.

SINUMERIK 802D sl plus, MM+, Turning |

|

Control system overview for machine tools' sales people, 03/2011 |

15 |

Loading...

Loading...