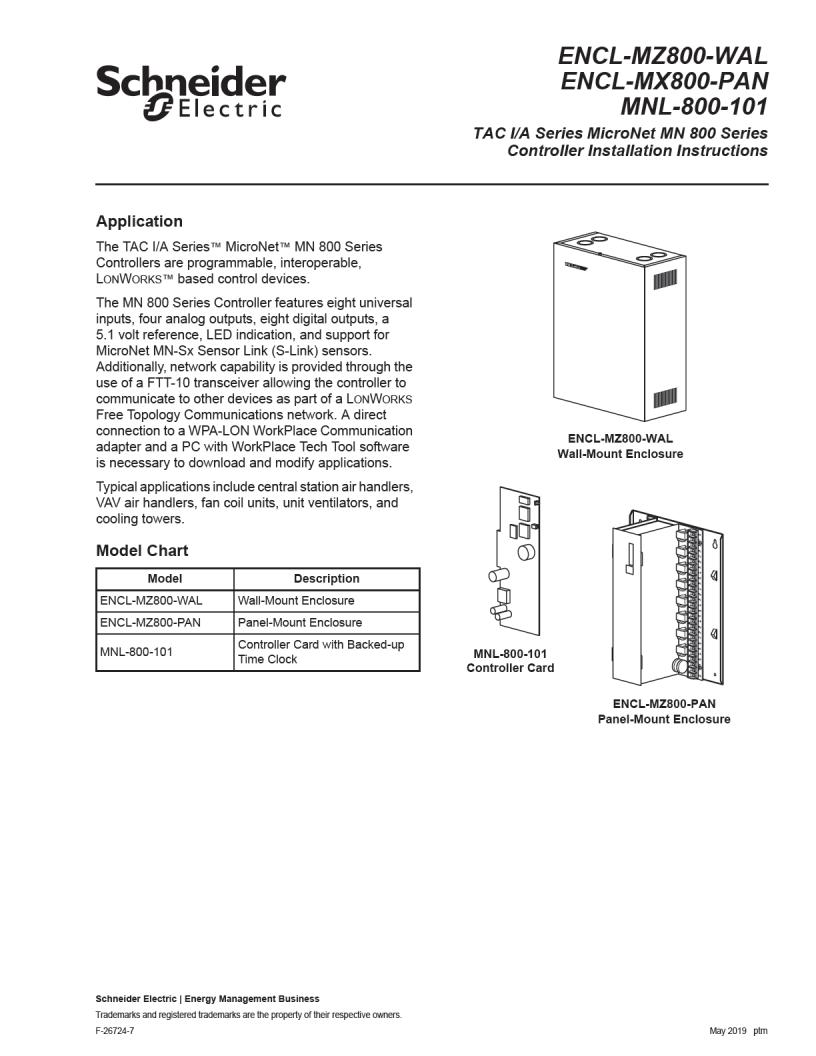

Schneider Electric MNL-800-101, ENCL-MZ800-WAL, ENCL-MX800-PAN Installation Instructions

<![endif]>© 2019 Schneider Electric. All rights reserved.

Applicable Documentation

F-Number |

Description |

|

Audience |

Purpose |

|

|

TAC I/A Series |

– |

Application Engineers |

|

|

|

Micronet |

Provides step-by-step installation and checkout procedures |

|||

|

– |

Installers |

|||

F-26277 |

MN-SX Series |

for TAC I/A Series MicroNet MN-SX Series Sensors. Also |

|||

– |

Service Personnel |

||||

|

Sensors General |

contains instructions for sensor operation. |

|||

|

– |

Start-up Technicians |

|||

|

Instructions |

|

|||

|

|

|

|

||

|

|

|

|

|

|

|

TAC I/A Series |

– |

Application Engineers |

Provides an overview of the TAC I/A Series MicroNet |

|

|

– |

Installers |

System. It includes brief descriptions of the hardware and |

||

F-26303 |

MicroNet |

||||

– |

Start-up Technicians |

software components, and how they may be combined to |

|||

|

System Overview |

||||

|

– |

Service Personnel |

create MicroNet networks and stand-alone systems. |

||

|

|

||||

|

|

|

|

|

|

|

WorkPlace Tech Tool |

– |

Application Engineers |

Provides engineering and technical information for applying |

|

F-26580 |

– |

Installers |

|||

Engineering Guide |

– |

Service Personnel |

and using all aspects of WorkPlace Tech Tool. |

||

|

|||||

|

|

– |

Start-up Technicians |

|

|

|

|

|

|

|

|

|

TAC I/A Series |

– |

Application Engineers |

Provides engineering and technical information to assist in |

|

|

– |

Installers |

|||

F-26507 |

MicroNet System |

designing a complete TAC MicroNet controller system using |

|||

– |

Service Personnel |

||||

|

Engineering Guide |

different architectures, components, and software. |

|||

|

– |

Start-up Technicians |

|||

|

|

|

|||

|

|

|

|

|

|

|

WorkPlace Tech Tool |

– |

Application Engineers |

Provides step-by-step instructions for using WorkPlace |

|

F-26304 |

– |

Installers |

|||

User’s Guide |

– |

Service Personnel |

Tech Tool. |

||

|

|||||

|

|

– |

Start-up Technicians |

|

|

|

|

|

|

|

|

|

EN-206 Guidelines |

|

|

Offers guidelines for avoiding equipment damage |

|

|

for Powering Multiple |

|

|

||

|

|

|

associated with improperly wiring devices of varying |

||

|

Full-Wave and Half- |

– |

Application Engineers |

||

|

rectifier types. Contains instructions for identifying device |

||||

F-26363 |

Wave Rectifier |

– |

Installers |

||

rectifier type, guidelines for correctly powering devices of |

|||||

|

Devices from a |

– |

Service Personnel |

||

|

varying rectifier types, and examples illustrating proper |

||||

|

Common |

|

|

||

|

|

|

power wiring techniques. |

||

|

Transformer |

|

|

||

|

|

|

|

Installation

Inspection |

Inspect carton for damage. If damaged, notify carrier immediately. Inspect controllers for |

|

|

damage. Return damaged products. |

|

Requirements |

• |

Training: Installer must be a qualified, experienced technician. |

|

|

|

|

Note: The following items are not provided. |

|

|

• |

Job wiring diagrams |

|

• |

Tools |

|

|

– Drill and bits for panel mounting screws |

|

|

– Digital Volt-ohm meter (DVM) |

|

|

– Static protection wrist strap |

|

• Class 1 or Class 2 power transformer supplying a nominal 24 Vac (20.4 to 30 Vac) with |

|

|

|

a minimum rating of 20 VA, 50/60 Hz per controller plus Digital Output (DO) loads (if |

|

|

same transformer is used). In European Community, transformer must conform to local |

|

• |

standards. |

|

Terminators |

|

|

|

– One LON-TERM1 terminator required for free topologies |

|

|

– Two LON-TERM2 terminators required for bus topologies |

Schneider Electric | Energy Management Business

Trademarks and registered trademarks are the property of their respective owners.

2 |

F-26724-7 |

Loading...

Loading...