Schneider Electric IP67 User Manual

Advantys FTB CANopen

IP67 monobloc input/output

splitter box

User guide

1606218 02 eng 3.0

1606218 02

www.telemecanique.com

2

1606218 02 08/2006

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Presentation of the CANopen Advantys FTB I/O Splitter Box Range . . . . . . . . . 12

Overview of the Accessories Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installing the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Grounding of the Advantys FTB Splitter Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EMC Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 3 Splitter Box Characteristics and Wiring. . . . . . . . . . . . . . . . . . 27

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Advantys FTB Splitter Box Environment Properties . . . . . . . . . . . . . . . . . . . . . . 28

Electrical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the Actuators and Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Supply Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 4 CANopen Network Interface . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1 Wiring on the CANopen Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction to Wiring on the CANopen Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Choice of system cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting the Field Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configuring the Address and Transmission Speed. . . . . . . . . . . . . . . . . . . . . . . 46

4.2 General Principles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

About CANopen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

The Device Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1606218 02 08/2006 3

CANopen "Boot-Up". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Process Data Object (PDO) Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Inhibit Time and Event Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Access to Data by Explicit Exchanges (SDO) . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

"Node-Guarding" and "Life-Guarding" Monitoring Protocols. . . . . . . . . . . . . . . . 62

The "Heartbeat" Error Monitoring Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.3 Behavior of FTB CANopen Splitter boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Behavior at Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Behavior in the Case of Communication Error. . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Saving / Restoring Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

List of Saved Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Chapter 5 Application-Specific Functions . . . . . . . . . . . . . . . . . . . . . . . . 71

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

List of Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Description of the Discrete Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Description of Discrete Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Description of Configurable Discrete I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

List of Advantys FTB 1CN08E08SP0 Splitter Box I/O Objects . . . . . . . . . . . . . . 78

List of Advantys FTB 1CN12E04SP0 Splitter Box I/O Objects . . . . . . . . . . . . . . 81

List of Advantys FTB 1CN16EP0 and FTB 1CN16EM0 Splitter Box I/O Objects 85

List of Advantys FTB 1CN16CP0 and FTB 1CN16CM0 Splitter Box I/O Objects 87

List of Advantys FTB 1CN08E08CM0 Splitter Box I/O Objects . . . . . . . . . . . . . . 91

Chapter 6 Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.1 Introduction to Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.2 Product Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

At A Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Characteristics of an EDS File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Existing EDS File for CANopen Advantys FTB Splitter Box . . . . . . . . . . . . . . . 103

Creating a New EDS and DCF Configuration File . . . . . . . . . . . . . . . . . . . . . . . 104

6.3 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Setting the Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.4 PLC Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Integration and Use under PL7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Examples of SDO Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Chapter 7 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Power Supply Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Field Bus Status Diagnostics LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

LED Status Diagnostics for I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4 1606218 02 08/2006

CANopen Objects Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Behavior in the Event of Short-circuit / Overload / Under-voltage. . . . . . . . . . . 130

Chapter 8 The Object Dictionary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8.1 The Object Dictionary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

The Object Dictionary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.2 Objects of the Communication Profile 1000H to 1FFFH . . . . . . . . . . . . . . . . . 134

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Object 1000H: Device Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Object 1001H: Error Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Object 1002H: Manufacturer Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Object 1003H: Pre-defined Error Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Object 1005H: COB-ID SYNC Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Object 1006H: Communication Cycle Period . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Object 1008H: Manufacturer Device Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Object 100AH: Manufacturer Software Version (MSV). . . . . . . . . . . . . . . . . . . 143

Object 100CH: Guard Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Object 100DH: Life Time Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Object 1010H: Store Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Object 1011H: Restore Default Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Object 1014H: COB-ID Emergency Message (EMCY) . . . . . . . . . . . . . . . . . . . 150

Object 1016H: Consumer Heartbeat Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Object 1017H: Producer Heartbeat Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Object 1018H: Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Object 1200H: Server SDO Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Object 1400H: 1st Receive PDO Communication Parameter. . . . . . . . . . . . . . 155

Object 1405H: 2nd Receive PDO Communication Parameter . . . . . . . . . . . . . 156

Object 1600H: 1st Receive PDO Mapping Parameter . . . . . . . . . . . . . . . . . . . 157

Object 1605H: 2nd Receive PDO Mapping Parameter. . . . . . . . . . . . . . . . . . . 159

Object 1800H: 1st Transmit PDO Communication Parameter. . . . . . . . . . . . . 161

Object 1805H: 2nd Transmit PDO Communication Parameter . . . . . . . . . . . . 164

Object 1A00H: 1st Transmit PDO Mapping Parameter. . . . . . . . . . . . . . . . . . . 167

Object 1A05H: 2nd Transmit PDO Mapping Parameter . . . . . . . . . . . . . . . . . . 169

8.3 Manufacturer-specific Zone Objects 2000H to 5FFFH . . . . . . . . . . . . . . . . . . . 171

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Object 2000H: Input / Diag Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Object 2001H: Input/Output Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Object 3000H: Manufacturer Specific Diagnostic . . . . . . . . . . . . . . . . . . . . . . . 174

8.4 Hardware Profile Objects 6000H to 9FFFH . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Object 6000H: Read Inputs 8 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Object 6100H: Read Input 16 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Object 6102H: Polarity Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Object 6103H: Filter Constant Input 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Object 6200H: Write Outputs 8 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

1606218 02 08/2006 5

Object 6300H: Write Outputs 16 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Object 6302H: Polarity Outputs 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Object 6306H:Fallback Mode 16 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Object 6307H: Fallback Value 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Object 6308H: Filter Mask Output 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Appendix A IEC Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Glossary of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

6 1606218 02 08/2006

Safety Information

§

Important Information

NOTICE Read these instructions carefully, and look at the equipment to become familiar with

the device before trying to install, operate, or maintain it. The following special

messages may appear throughout this documentation or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates

that an electrical hazard exists, which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can

result in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can

result in injury or equipment damage.

1606218 02 08/2006 7

Safety Information

PLEASE NOTE Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

© 2006 Schneider Electric. All Rights Reserved.

8

1606218 02 08/2006

About the Book

At a Glance

Document Scope This user guide contains the information required to install an Advantys FTB

CANopen monobloc IP67 splitter box.

It has been designed to facilitate rapid familiarization with the system, while

optimizing the system's features for the most advanced technology available.

To install Advantys FTB CANopen splitter boxes, the relevant communication

protocol pre-requisites are necessary, and it should only be installed by qualified

personnel. Special points and warnings regarding safety are highlighted in the

different chapters.

The early chapters provide information for designers and installers on installing the

mechanical and electrical elements of the system.

The following chapters, from the section on "network interface", are specific to the

communication protocol. They contain information on specific wiring for the network

interface and all the necessary information for the software application programmer,

and for the end user (diagnostics).

1606218 02 08/2006 9

About the Book

Chapter Subject covered

Introduction General presentation of system components

Installation Dimensions

Safe practice for installation

I/O splitter box characteristics

and wiring

CANopen network interface Wiring the splitter box on the network

Application functions Description of application functions (Advantys FTB

Software implementation Software installation help

Diagnostics Performing diagnostics

Object dictionary Description of the objects accessible for communication

Appendices Presentation

Glossary Acronyms

Physical and electrical characteristics

Wiring information

Reminder on the communication protocol

System behavior

CANopen splitter box I/O functions)

Appendix A: List of IEC symbols

Definitions

Related

Documents

Title of Documentation Reference Number

Instruction sheet 1693627

CANopen hardware installation manual 35010859

User Comments We welcome your comments about this document. You can reach us by e-mail at

techpub@schneider-electric.com

10

1606218 02 08/2006

Introduction

1

Presentation

Introduction This chapter provides a general overview of Advantys IP 67 FTB CANopen IP67 I/

O splitter boxes.

Advantys FTB CANopen splitter boxes comply with the following specifications:

CiA DS301 V4.02 (CANopen application layer and communication profile)

CiA DS401 V2.1 (CANopen device profile generic I/O modules) (see CANopen

Profiles, p. 50)

Note: The information in this manual is primarily intended for people with some

practical knowledge of the CANopen standard applied to the CANopen field bus.

CANopen equipment installers and users are advised to read the standard

documentation before any equipment installation or handling. All detailed

CANopen specifications may be found at http://www.can-cia.de.

What's in this

Chapter?

1606218 02 08/2006 11

This chapter contains the following topics:

Topic Page

Presentation of the CANopen Advantys FTB I/O Splitter Box Range 12

Overview of the Accessories Range 13

Introduction

Presentation of the CANopen Advantys FTB I/O Splitter Box Range

The CANopen

Advantys FTB

Product Range

Configurable

Connectors

Splitter Box

Inputs and

Outputs

The splitter boxes in the CANopen Advantys FTB ranges come in the following

forms:

CANopen plastic unit

CANopen metal unit

Each CANopen Advantys FTB splitter box contains eight connectors used to link the

sensors or actuators.

Each of these connectors supports two channels. Depending on the splitter box

reference, and on its configuration, each channel is either:

an input channel,

an output channel,

a DESINA standard diagnostics channel.

The configuration of the I/O connector channels depends on the splitter box model.

The table below shows the I/O connector channels available for each model:

Distribution of available inputs/outputs Unit type Product reference

8 input / diagnostics channels + 8 output

channels

4 input channels + 4 output channels + 8 input

/ diagnostics channels

8 input channels + 8 input / diagnostics

channels

8 input / output channels + 8 input / output /

diagnostics channels

8 input / output channels + 8 input /

diagnostics channels

Plastic FTB 1CN08E08SP0

Plastic FTB 1CN12E04SP0

Plastic

Metal

Plastic

Metal

Metal FTB 1CN08E08CM0

FTB 1CN16EP0

FTB 1CN16EM0

FTB 1CN16CP0

FTB 1CN16CM0

12

1606218 02 08/2006

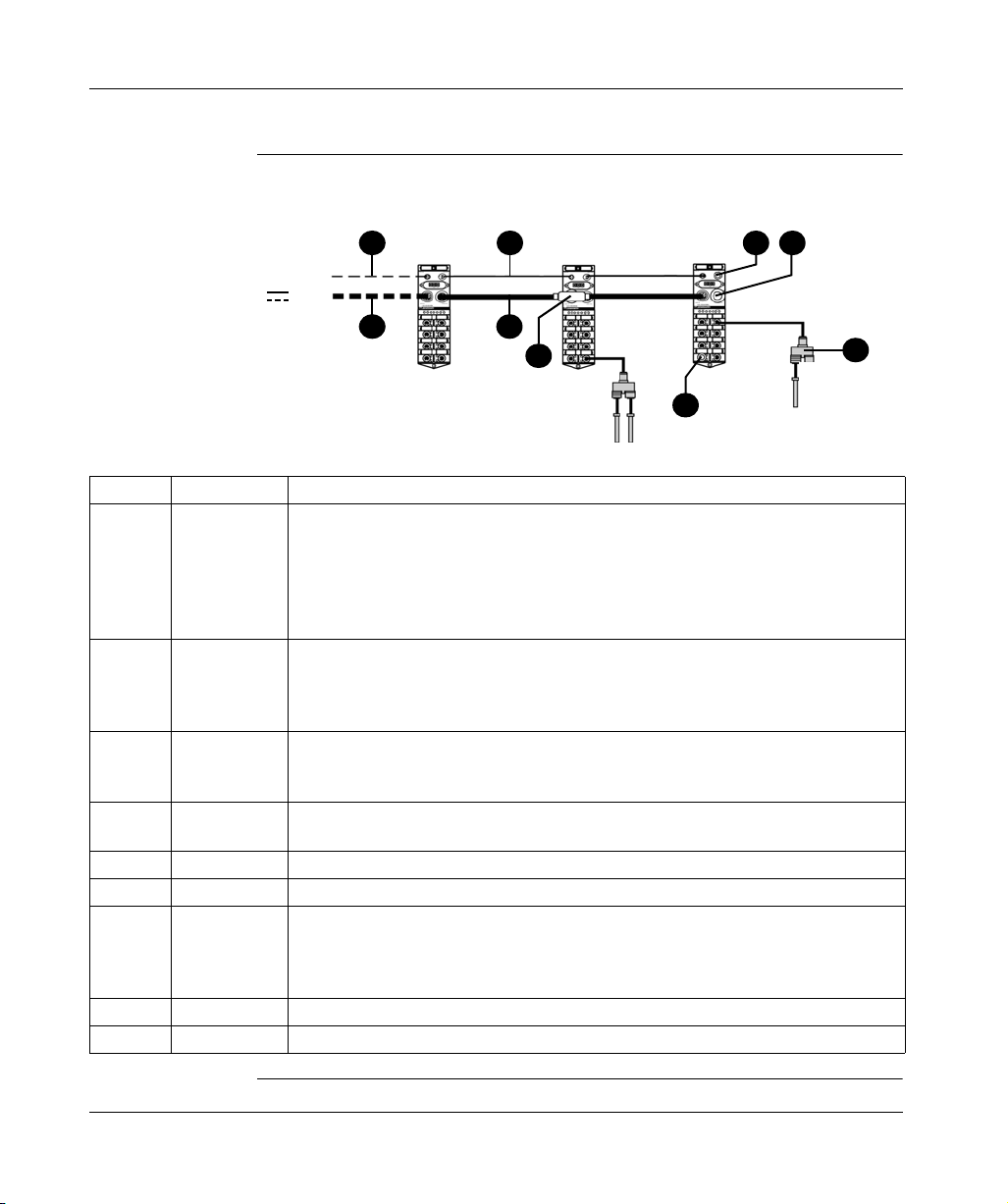

Overview of the Accessories Range

Introduction

Cables for

Connecting the

Bus to the

Splitter Box

Different cables can be used to connect the splitter box to the field bus. These are

available in different lengths.

4

1

6

8

24 V

3 2

5

FTB 1CN

9

Element Reference Function

1 FTX CN3203

FTX CN3206

FTX CN3210

FTX CN3220

FTX CN3230

FTX CN3250

2 FTX DP2206

FTX DP2210

FTX DP2220

FTX DP2250

3 FTX DP2115

FTX DP2130

FTX DP2150

4 FTXCN12M5

FTXCN12F5

5 FTXCNCT1 Connection T fitted with 2 7/8-type connectors, 5 pins, for power supply cables.

6 FTX CNTL12 Line terminators fitted with 1 M12-type connector.

7 FTX CY1208

FTX CY1212

8 FTX C78B Sealing plug for 7/8 connector.

9 FTX CM12B Sealing plugs for M12-type connectors.

Cables fitted with 2 M12-type elbow connectors, 5 pins, at both ends for connecting the

bus between two splitter boxes.

Cables fitted with 2 7/8-type connectors, 5 pins, at both ends for daisy-chaining 24 VDC

supplies to two splitter boxes.

Cables fitted with 1 7/8-type connector, 5 pins, with one free end and the other for

connecting 24 VDC supplies.

Male and female M12-type connectors, 5 pins, for CANopen bus cables (encoding A).

Distribution Y for connecting 2 M8-type connectors to the M12 connector of the splitter

box.

Distribution Y for connecting 2 M12-type connectors to the M12 connector of the splitter

box.

7

1606218 02 08/2006 13

Introduction

14

1606218 02 08/2006

Installation

2

Presentation

Introduction This chapter provides all required information for installing an FTB splitter box on a

field bus.

Note: The graphic representations of the splitter boxes in this chapter may not

correspond to those really used. However, the dimensions are exact whatever the

case.

What's in this

Chapter?

1606218 02 08/2006 15

This chapter contains the following topics:

Topic Page

Overview 16

Installing the Unit 17

Grounding of the Advantys FTB Splitter Box 21

EMC Compatibility 23

Installation

Overview

Introduction This section gives a detailed technical description of the Advantys FTB CANopen

splitter box.

Description The illustrations below show the plastic units (left) and metal units (right) of the

Advantys FTB CANopen splitter.

1

1

2

2

3

3

4

5

6

9

7

8

1

Element Function

1 Mounting holes

2 M12 connector for the inputs and outputs

3 Label

4 Display elements (diagnostics and status LED)

5 Power supply connectors (PWR IN)

6 Power supply distribution connector (PWR OUT)

7 Bus connector (BUS IN)

8 Bus connector (BUS OUT)

9 Transmission speed and addressing rotary selector switch

4

5

6

9

7

8

1

16

1606218 02 08/2006

Installation

Installing the Unit

Introduction This section gives a detailed technical description of Advantys FTB splitter boxes.

Description The Advantys FTB splitter box can be mounted directly onto a wall or a machine.

Two mounting holes have been provided for this purpose inside the splitter box.

Note: When mounting the unit, the support must be flat and smooth so as to

prevent any undue stress on the unit, which may lead to a loss of sealing.

Types of Screws

and Tightening

Torques

Plastic unit

The plastic splitter box is mounted using two 4 mm (0.16 in.) diameter screws and

two washers. The tightening torque is 1.5 Nm (13.3 lb-in).

Metal unit

The metal splitter box is mounted using two 6 mm (0.24 in.) diameter screws and

two washers. The tightening torque is 9 Nm (79.7 lb-in).

Note: For metal units, wire the ground terminal before attaching the splitter box to

its support. See Grounding of the Advantys FTB Splitter Box, p. 21.

1606218 02 08/2006 17

Installation

Plastic Unit

Dimensions

The dimensions of the plastic unit (front and side views) are given in the following

illustrations:

18

1606218 02 08/2006

Installation

Metal Unit

Dimensions

The dimensions of the metal unit (front and side views) are given in the following

illustrations:

1606218 02 08/2006 19

Installation

Method Follow the steps below:

Step Action

1 Position the splitter box on the support.

2 Mount the splitter box using the screws and washers.

RISK OF EQUIPMENT DAMAGE AND NON-COMPLIANCE WITH IP67.

Unused connectors must not be left unprotected. If a connector is not correctly

connected to the end of another connector or to a standard cable, fit a sealing plug

in order to ensure that the product is IP67 standard compliant. To ensure the IP67

protection index, check that the cover is screwed onto the base splitter box and that

all connectors are fitted with cables or sealing plugs.

Failure to follow this instruction can result in injury or equipment damage.

CAUTION

20

1606218 02 08/2006

Installation

Grounding of the Advantys FTB Splitter Box

Description The ground connection is connected internally to pin 1 of the M12 connector of the

field bus connector.

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

Check that the splitter box is correctly connected to the earth in compliance with

the instructions provided in his section. If the splitter box is not grounded, or if the

ground connection is made with an unsuitable cable, the product will be sensitive

to electromagnetic disturbances. See EMC Compatibility, p. 23.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Position of the

Ground

Electrode on the

Plastic Unit

The following figure shows the position of the ground electrode on the plastic boxes.

Note: Use a grounding strip or a conductor with a cross-section of 1 to 1.5 mm2

(AWG18, AWG16) and a length of ≤ 3 m (9.84 ft) long. The maximum

recommended length for the grounding strip is 3 m (9.84 ft).

1606218 02 08/2006 21

Installation

Method for

Plastic Units

Position of the

Ground

Electrode on the

Metal Unit

Follow the steps below to connect the ground to the unit:

Step Action

1 Remove the label located above the symbol representing the ground.

2 Insert the end of the grounding strip into the grounding terminal of the splitter

box.

3 Screw in the ground connection screw.

The following figure shows the position of the ground electrode on the metal boxes.

Note: Use a grounding strip or a conductor with a cross-section of 1 to 1.5 mm2

(AWG18, AWG16) and a length of ≤ 3 m (9.84 ft) long. The maximum

recommended length for the grounding strip is 3 m (9.84 ft).

Method for Metal

Units

Mounting the

Metal Unit

22

Follow the steps below to connect the unit to the ground electrode:

Step Action

1 Crimp the lug on the ground cable.

2 Screw in the lug with the ground conductor connection screw (supplied with the

product).

Once these steps have all been completed (see table above), the product can be

mounted on its support.

1606218 02 08/2006

EMC Compatibility

Installation

Product

Compliance

This product complies with the European directive 89/336/CEE on "electromagnetic

compatibility".

The products described in this manual meet all the conditions regarding

electromagnetic compatibility and are compliant with the applicable standards.

However, this does not mean that the electromagnetic compatibility of your

installation is assured.

This is why it is strongly recommended to follow all indications concerning an EMC

compliant installation. Only in these conditions and thanks to the exclusive use of

CE approved components, will the devices used be deemed as compliant with the

EMC directives.

When handling the products, ensure that all safety measures related to

electromagnetic compatibility and all conditions for the use of the products are

complied with by all persons concerned. This is especially important when handling

products sensitive to electrostatic discharges.

WARNING

RISK OF ELECTROMAGNETIC INTERFERENCE AND UNINTENDED

EQUIPMENT OPERATION

The products described in this manual contain highly complex semiconductors that

can be damaged or destroyed by electrostatic discharges (ESD). If, for example,

they are used within the vicinity of devices rated as class A or B according to IEC

6100-4-4, the level of electromagnetic interference may be enough to cause the

device to operate unexpectedly, and/or to damage it.

Damage may not necessarily cause a failure or malfunction that is immediately

detectable. It may occur sporadically or in a delayed manner.

If there is a risk of electromagnetic interference, the system designer must

implement the necessary protective measures.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

1606218 02 08/2006 23

Installation

Grounding A low impedance connection with a maximum length of 3 m (9.84 ft) must be

installed between the splitter box's ground electrode and the reference ground in

order to discharge the noise voltages. The inductance of standard grounding cables

(PE) presents a risk of high impedance when high frequency noise voltages are

present. It is therefore advisable to use grounding strips. If this solution is not

possible, use a ground conductor with a large cable cross-section and a ground

connection that is as short as possible.

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

If the box is not connected to the ground, or if the ground connection is made using

an inappropriate cable, the product will be sensitive to electromagnetic

disturbances. This may lead to unexpected equipment operation.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Cable Routing Make sure that the following basic wiring rules are followed:

Keep the data wire and the power cables apart from one another, in so far as is

possible.

Make sure there is a space of at least 10 cm (3.94 inches) between the data wires

and the power cables.

The data wires and power cables must only cross at a right angle to one another.

It is advisable to route the data wires and power cables through separate shielded

ducts.

When laying the cables, the noise voltage from other devices or wires must be

considered. This particularly applies to frequency converters, motors and other

devices or cables generating high frequency disturbances. High frequency

sources and the cables described in this manual must be as far apart from each

other as possible.

24

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

Please read and comply with the cabling rules listed above. Failure to comply with

these wiring rules is a common cause of EMC problems! This may lead to

unexpected equipment operation.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

1606218 02 08/2006

Installation

Control of

Inductive Loads

The outputs of the devices described in this manual are equipped with an integrated

protective system against the high noise voltages that may be generated by

inductive loads.

Integrated protective system against the high noise voltages generated by inductive

loads

Varistor

Inductive load

e.g. electromagnetic

valve

The varistor rapidly discharges the energy accumulated in the magnetic field of the

inductive load.

The high voltages arising from the disconnection of inductive loads create large

fields in the wires that may cause disturbances in nearby circuits or devices. It is

advisable to provide an anti-interference device at the load level. In this way, the

voltage peak generated by the inductive load is short-circuited directly at the point

at which it occurs.

1606218 02 08/2006 25

Installation

26

1606218 02 08/2006

Splitter Box Characteristics and Wiring

3

Presentation

Introduction This chapter provides an overall description of all Advantys FTB splitter boxes.

Note: The "-" in the tables corresponds to values that are not applicable.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Advantys FTB Splitter Box Environment Properties 28

Electrical Characteristics 29

Connecting the Actuators and Sensors 30

Power Supply Connection 32

1606218 02 08/2006 27

Splitter Box Characteristics and Wiring

Advantys FTB Splitter Box Environment Properties

Environment

Properties

Characteristic Description Reference standard

Product certification cULus -

Operating temperature -20°C...+60°C (-4°F...+140°F) -

Storage temperature -25°C...+70°C (-13°F...+158°F) -

Degree of protection IP67 According to IEC 60529

Altitude 0m 2,000 m (6,561 ft) -

Vibration withstand capacity

for plastic units

Constant amplitude: 0.35 mm (0.0138 in)

10 Hz≤ f ≤ 57 Hz

Constant acceleration: 5.0 gn

57 Hz≤ f ≤ 150 Hz

Vibration resistance capacity

for metal units

Constant amplitude: 1.5 mm (0.06 in)

5 Hz ≤ f ≤ 70 Hz

Constant acceleration: 15 gn

70 Hz ≤ f ≤ 500 Hz

Shock resistance capacity for

30 gn, duration: 11 ms According to IEC 68-2-27, Fc

plastic units

Shock withstand capacity for

50 gn, duration: 11 ms -

metal units

Resistance capacity for

electrostatic discharges

Withstand capacity for

Contact: +/- 4 kV

Air: +/- 8kV

10 V/m (3.05 V/ft) According to IEC 61000-4-3

radiated fields

Withstand capacity for fast

transients

Withstand capacity for surge

Withstand capacity for duct

Power supply: +/- 2 kV

Signal: +/- 2 kV

Power supply:

symmetrical: +/-500VDC

asymmetrical: +/-1,000 VDC

Signals:

symmetrical: +/-500VDC

asymmetrical: +/-1,000 VDC

Ground : +/-500VDC

10 Vrms According to IEC 61000-4-6

fields

Withstand capacity for 50 Hz

30 A/m (9.15 A/ft) According to IEC 61000-4-8

magnetic fields

Mounting In all positions -

According to IEC 68-2-6, Fc

test

According to IEC 68-2-6, Fc

test

test

According to IEC 61000-4-2

According to IEC 61000-4-4

According to IEC 61000-4-5

28

1606218 02 08/2006

Electrical Characteristics

Splitter Box Characteristics and Wiring

Splitter Box

Characteristics

Input

Characteristics

Output

characteristics

Characteristic Description

Splitter box's internal consumption 120 mA

Splitter power supply voltage 18...30VDC

Splitter and sensor supply current ≤ 8 A

Actuator supply current ≤ 8 A

Under-voltage detection yes

Characteristic Description

Compliance with IEC 1131-2 Type 2

Compliance with 2-wire/3-wire sensor Yes

Rated power voltage 24 VDC

Maximum current 200 mA (for 2 diagnostics input channels)

Logic Positive PNP Sink

Filtering input 1 ms

Protection against reverse polarity and shortcircuit in sensor power supply

Overload and over-voltage protection Yes

Characteristic Description

Output type Transistors

Output voltage 24 VDC

Output current 1.6 A

Over-voltage protection Yes (transient diode)

Maximum switching cycle 20 Hz

Maximum lamp load 10 W

Connection for outputs / cable lengths

Protection against short-circuits yes

Yes

0.75mm2: 10 m maximum (AWG 19 / 32.8 ft)

0.34 mm2: 5 m maximum (AWG 23 / 16.4 ft)

1606218 02 08/2006 29

Splitter Box Characteristics and Wiring

Connecting the Actuators and Sensors

Description The actuators and sensors are connected to the FTB splitter box using M12-type

connectors.

Characteristics

of the

Connections

Assignment of

M12 Connector

Pins

The maximum admissible load for the FTB splitter boxes is limited to:

1.6 A per output (actuator current),

200 mA for both inputs (sensor current).

WARNING

RISK OF EQUIPMENT DAMAGE AND NON-COMPLIANCE WITH IP67

Unused M12 connectors must not be left unprotected. If an M12 connector is not

correctly connected to the end of another connector or standard cable, fit a sealing

plug in order to ensure that the product is IP67 standard compliant. To ensure the

IP67 protection index, check that the cover is screwed onto the base splitter box

and that all connectors are fitted with cables or sealing plugs.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

The following diagram shows the front view of a 5-pin M12 connector and the

convention for numbering the pins:

Pin Assignment

1 +24 VDC

2 Channel 10 to 17: diagnostics input or functional input or output

30 VDC

4 Channel 00 to 07: functional input or output

5 Ground

30

1606218 02 08/2006

Loading...

Loading...