Application

0

10

20

30

40

50

60

70

80

90

100

°F

0

5

10

15

20

25

30

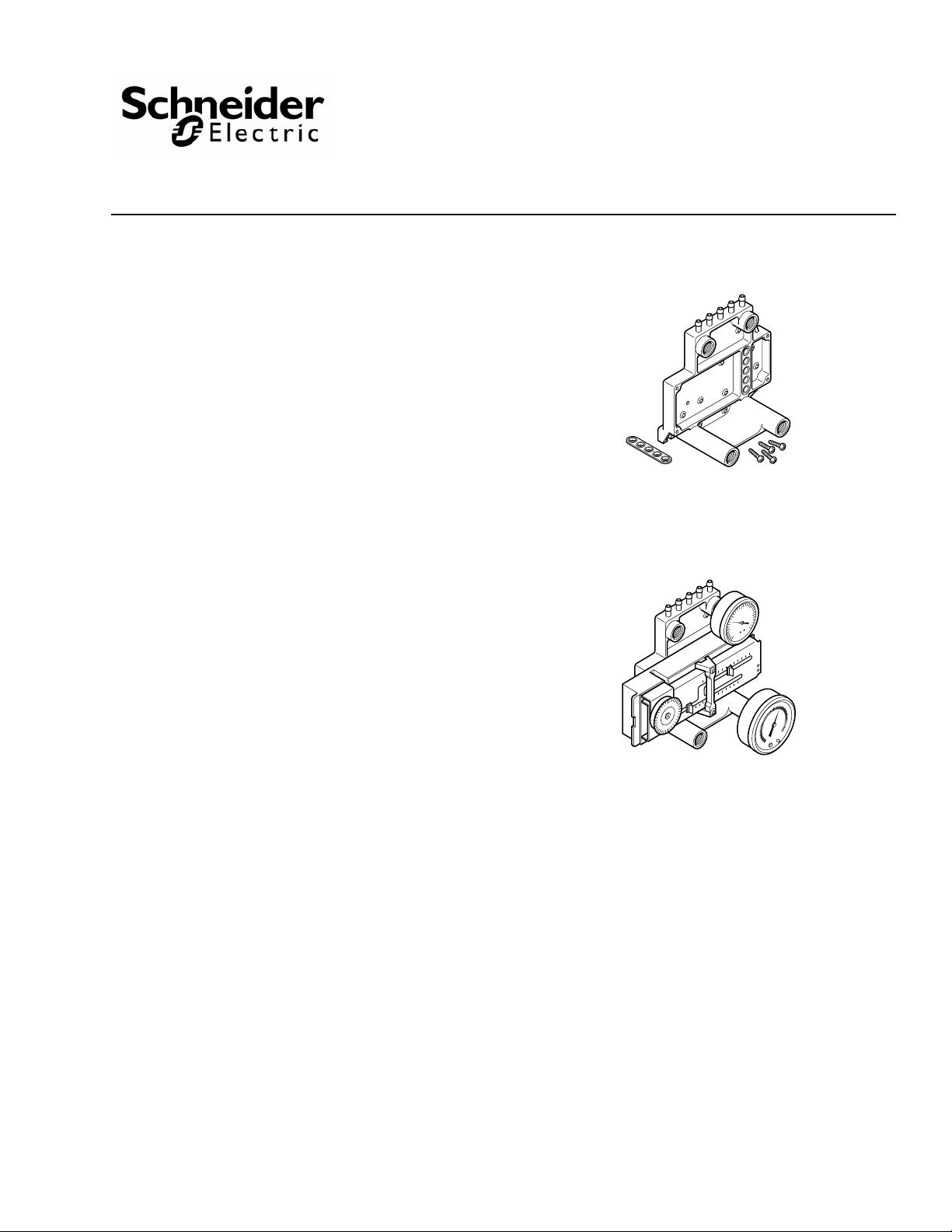

P541-BASE

P541-BASE

with one P-541 Series Receiver-Controller,

one 1-1/2" Pressure Gauge, and one 2"

Receiver-Gauge mounted

The P541-BASE is a mounting base designed to permit

stand-alone field-mounting of either the P541

(2341-501), direct acting — or the P541-RA

(2341-502), reverse acting — three-input

receiver-controller. It also provides for the mounting of

up to two receiver-gauges and two pressure gauges.

P541-BASE

Mounting Base

General Instructions

The compact size, versatility, and ample capabili

ty of a

base-mounted P541 or P541-RA receiver-controller

allows field-mounting of same for either new

construction; additions or modifications to existing

control systems; or the replacement of most existing

receiver-controllers.

Features

• Features compact size and ample capacity when

combined with a mounted P541 seri

re

ceiver-controlle

r

es

• Durable glass-filled nylon construction

• Barbed connections for 1/4 in. (6.8 mm) poly tubing

• Ports for gauges with 1/8 in. MNPT, center-back

con

nections

Applicable Literature

• P541, Receiver-Controller General Instructions,

F-23895

• P341, Receiver-Controller General Instructions,

F-23894

• Pneumatic Products Catalog, F-27383

Printed in U.S.A. 6-10 Copyright 2010 Schneider Electric All Rights Reserved. F-26081-4

SPECIFICATIONS

Construction: : Glass-filled nylon.

Maximum Air Pressure: : 30 psig (207 kPa).

Ambient Temperature Limits: :

Shipping and Storage, , -40 to 140° F (-40 to 60° C).

Operating, , 35 to 140° F (2 to 60° C).

Air Connections: : Five barbed fittings for 1/4 in. (6.4 mm) poly tubing.

Gauge Ports: : Four ports for center-back gauges with 1/8 in. MNPT fittings.

Mounting Dimensions (with P541 Series Controller and Gauges Mounted): :

5-3/8 H x 5-13/16 W x approx. 3-3/4 D in. (137 H x 148 W x approx. 95 D mm).

ACCESSORIES

See Accessories Chart, Table-1.

Table-1 Accessories Chart.

Schneider

Electric

Model No.

K541 22-171 Cover for P541 series receiver-controllers

N100-0010 21-038

N4-32 20-944

N100-2501 21-153

A253-12 2422-003

23-XX NA

A201-02 2420-001

AL-362 NA

M-101 20-983 1/8" MPT plug (for unused gauge ports)

MCS-G 22-133 Gasket (one is included with P541-BASE)

MCS-SCREW 22-134

Schneider

Electric

Uni-Line

Model No.

Description

Restrictor tee for 1/4 in. (6.4 mm) O.D. poly tubing, 1.0 SCFH

(plastic, barbed, red)

Restrictor tee for 1/4 in. (6.4 mm) O.D.copper tubing (brass

compression type)

Restrictor, in-line, for 1/4 in. (6.4 mm) O.D. poly tubing, 1.0 SCFH

(plastic, red)

Receiver-gauge, 2 in. diameter (0 to 100° F). Other ranges may

be displayed with the selection of a 23-XX series adhesive

receiver-gauge dial.

Series of adhesive receiver-gauge dials to fit A253-12 receivergauges, to indicate ranges other than 0 to 100° F (printed on dial

face).

Pressure gauge, 0 to 30 psi scale, 1-1/2 in. diameter

(Robertshaw logo)

Pressure gauge, 0 to 30 psi (0 to 200 kPa), 1-1/2 in. diameter

(Barber-Colman logo)

No. 6, 1/2 in. (13 mm) long, Plastite double-helix screw, for

attaching P541 or P541-RA receiver-controller to P541-BASE

(four included with P541-BASE)

TOOL S

Appropriate drill and drill bit for mounting screws

Appropriate screwdrivers and wrenches

2 Copyright 2010 Schneider Electric All Rights Reserved. F-26081-4

INSTALLATION

Inspection Inspect the package for damage. If damaged, notify the appropriate carrier immediately. If

undamaged, open the package and inspect the device for obvious damage. Return

damaged products.

Requirements • Piping diagrams

• Tools (not provided):

– Appropriate drill and drill bit for mounting screws

– Appropriate screwdrivers and wrenches

• Training: Installer must be a qualified, experienced technician

• Other accessories as appropriate

Caution:

• Use a refrigerated air dryer, particulate filter, and a coalescing filter to provide the

required clean, dry, oil-free air (refer to EN-123).

• The compressor oil must be non-paraffin, mineral base or naphtha base. The use of

synthetic or paraffin base oils will destroy pneumatic controls and void the warranty.

• Make all connections in accordance with the piping diagram.

• Avoid locations where excessive oil, dust, moisture, corrosive fumes or vibration is

present.

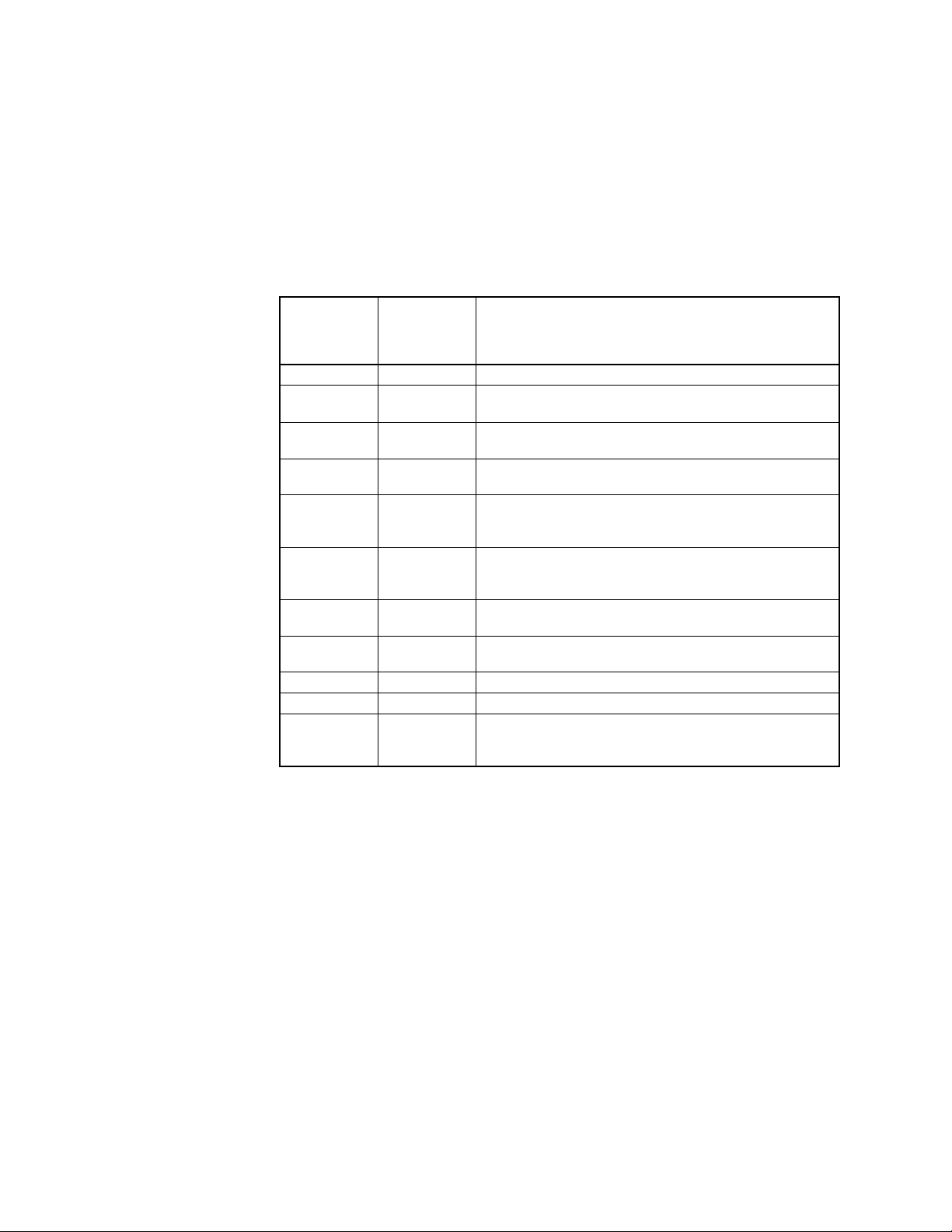

Mounting The mounting base provides for the mounting of one P541 or P541-RA receiver-controller

and four gauges having 1/8 in. MNPT, center-back connections. Refer to Figure-1.

Gauges

A selection of gauges may be installed onto the mounting base. Thread the desired gauges

into the 1/8 in. MNPT fittings and tighten, using an appropriate wrench. Refer to Figure-1.

Caution: Do not overtighten when installing a gauge or plug onto the mounting base.

Overtightening can cause the port to crack.

The gauges, and the ports to which they may be mounted, are as follows:

• Two 2 in. diameter, 3 to 15 psig (21 to 103 kPa) receiver-gauges for the primary (S) and

secondary (R) transmitter input ports.

• Two 1-1/2 in. diameter, 0 to 30 psig (0 to 207 kPa) pressure gauges for the branch output

signal port (B) and the remote con

trol-point adjustment, input signal port (C).

F-26081-4 Copyright 2010 Schneider Electric All Rights Reserved. 3

Figure-1 Installation of Receiver-Controller and Gauges on Mounting Base.

0

5

10

15

20

25

30

0

5

10

15

20

25

30

0

10

20

30

40

50

60

70

80

90

100

°F

0

10

20

30

40

50

60

70

80

90

100

°F

P541-BASE

Mounting Base

Port C

Port B

MCS-G Sealing

Gasket

A201-02 or AL-362

1-1/2 in. Pressure

Gauge

A201-02 or AL-362

1-1/2 in. Pressure

Gauge

A253-12

2 in. Receiver Gauge

P541 or P541-RA

Receiver Controller

MCS-SCREW

Double-Helix

Screw (1 of 4)

Port S

Port R

A253-12

2 in. Receiver Gauge

Barbed Fittings for

1/4 in. (6.4mm) Poly Tubing

C

R

S

M

B

Receiver-Controller

The P541 and P541-RA are both three-input controllers. The choice of a direct- or reverseacting controller is normally determined by the action and use of the final control devices

(valves, dampers, PE switches, etc.). Refer to P541, Receiver-Controller General

Instructions, F-23895, for more detailed information regarding the P541 or P541-RA

controller.

The mounting base is provided with a sealing gasket (MCS-G) and four double-helix screws

(MCS-SCREW). Mount the receiver-controller onto the mounting base as follows:

1. Install the sealing gasket over the barbed fittings on the back of the controller and push gasket down to rear surface of controller. Refer to Figure-1.

2. Install the controller onto the mounting base so that its barbed fittings are inserted into

the five sockets on the base. Internal ports within the base connect the installed

controller to the five fittings at the top of the mounting base and to the four gauge ports.

3. Secure the receiver-controller to the mounting base, using the four double-helix screws.

4 Copyright 2010 Schneider Electric All Rights Reserved. F-26081-4

Replacement of P341 Receiver-Controller

A P541 or P541-RA receiver-controller, mounted onto a P541-BASE mounting base, may

replace an existing P341 receiver-controller. When doing so, note the following:

• The bottom mounting foot position of the mounting base matches that of the P341.

• A new hole must be drilled in the mounting surface, for the upper mounting foot.

• If an existing P341 (or P340) and reversing-relay combination was originally used for

reverse-acting operation, a P541-RA controller, alone, may be used to replace both

devices. Refer to P341, Stand Alone Receiver-Controller General Instructions,

F-23894, for more detailed information regarding the P341 controller.

Connections Note: It is not necessary to cap unused barbed fittings or to plug unused gauge ports if the

corresponding barbed fitting is not used.

The mounting base features five barbed connections for 1/4 in. (6.4 mm) poly tubing. Refer

to Figure-1. The identification letters and functions of these connections are:

C Input from a remote Control point adjuster, if used

R Reset input from a secondary transmitter, if used

S Input Signal from a primary transmitter

M Main air

B Branch output

Note: Identification letters for the R and S gauge terminals are repeated at the gauge port

locations.

MAINTENANCE

FIELD REPAIR

The mounting base requires no maintenance.

Regular maintenance of the total system is recommended to assure sustained, optimum

performance.

None. Replace a damaged mounting base with a functional unit.

F-26081-4 Copyright 2010 Schneider Electric All Rights Reserved. 5

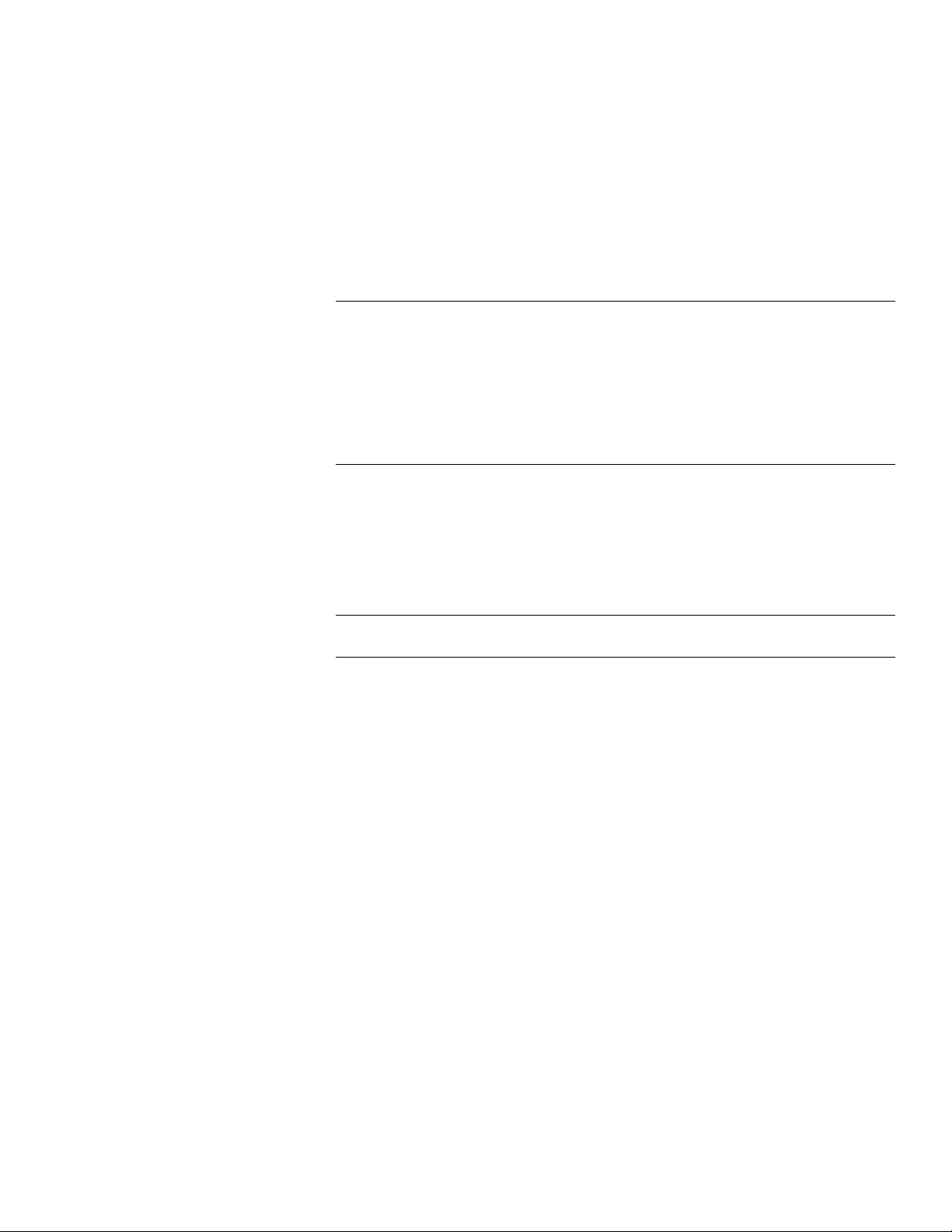

DIMENSIONAL DATA

2-1/4

(57)

1-1/16

(27)

2-3/8

(60)

4-5/8

(117)

2-3/8 (60)

2 (51)

2-5/8 (67)

3-11/16 (94)

4-7/16 (113)

Dimensions shown

are in inches (mm).

SR

RCSMB

Figure-2 Dimensions of P-541-BASE.

6 Copyright 2010 Schneider Electric All Rights Reserved. F-26081-4

3-3/4

(95)

2-9/16

(65)

2-1/2

(64)

5-3/8

(136)

5-13/16 (148)

Dimensions shown

are in inches (mm).

0

5

15

10

20

30

25

0

5

15

10

20

30

25

0

10

20

30

40

50

60

70

80

90

100

°F

0

10

20

30

40

50

60

70

80

90

100

°F

S

Figure-3 Dimensions of P541-BASE with Controller and Four Gauges mounted.

F-26081-4 Copyright 2010 Schneider Electric All Rights Reserved. 7

On October 1st, 2009, TAC became the Buildings business of its parent company Schneider Electric. This document reflects the visual identity of Schneider Electric,

however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate

corporate brand changes.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-26081-4

Loading...

Loading...