P

Q

S

PowerLogic™ PM5300 Series Power and

Energy Meter

User Guide

EAV15107 - EN03

04/2014

Safety Information

Important Information

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service or maintain it.

The following special messages may appear throughout this manual or on

the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure .

The addition of either symbol to a “Danger” or “Warning” safety label indicates that

an electrical hazard exists which will result in personal injury if the instructions are

not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Please note

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

Electrical equipment should be installed, operated, serviced and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

PowerLogic™ PM5300 series user guide Table of Contents

Chapter 1: Introduction Power and Energy Meter Hardware ................................................................................. 9

Parts and Accessories .................................................................................................. 9

Box Contents ................................................................................................................ 9

Firmware .......................................................................................................................... 9

Chapter 2: Safety Precau-

tions

Chapter 3: Hardware Refer-

ence

Chapter 4: Front panel dis-

play and meter

setup

Before You Begin ........................................................................................................... 11

Notices ........................................................................................................................... 11

Models, Features and Options ....................................................................................... 13

Functions and Characteristics ........................................................................................ 13

Technical Specifications ................................................................................................. 15

Before you begin ............................................................................................................ 17

Safety precautions .......................................................................................................... 17

Dimension ......................................................................................................................17

Meter mounting .............................................................................................................. 18

Mounting the PM5300 ................................................................................................. 18

Meter wiring .................................................................................................................... 19

Recommended cables ................................................................................................ 21

Wiring Diagrams ............................................................................................................. 22

Power system ................................................................................................................. 23

Direct connect voltage limits ....................................................................................... 23

Voltage and current input wiring ................................................................................. 25

Balanced system considerations ................................................................................ 26

Control power wiring ....................................................................................................... 26

Communications ............................................................................................................. 26

Serial communications ................................................................................................ 26

Ethernet communications ........................................................................................... 28

Digital outputs ................................................................................................................. 28

Status inputs ................................................................................................................... 29

Relay outputs ................................................................................................................. 29

LED indicators ................................................................................................................ 31

Heartbeat / communications LED ............................................................................... 31

Alarm / energy pulsing LED modes ............................................................................ 31

Notification icons ............................................................................................................ 32

Meter screen menus ....................................................................................................... 32

Menu tree .................................................................................................................... 33

Meter setup screen navigation .................................................................................... 34

Front panel meter setup ................................................................................................. 34

Configuring the basic setup parameters ..................................................................... 34

Communications setup ................................................................................................... 36

Setting up serial communications ............................................................................... 36

Setting up Ethernet communications .......................................................................... 37

HMI settings ...................................................................................................................38

Setting up the display .................................................................................................. 38

Setting up regional settings ......................................................................................... 39

Setting up the screen passwords ................................................................................... 39

Lost password ............................................................................................................. 40

Setting the clock ............................................................................................................. 41

Advanced setup .............................................................................................................. 41

Setting up the alarm / energy pulsing LED ..................................................................... 42

Input / output setup ......................................................................................................... 43

Demand setup ................................................................................................................ 43

Multi-tariff setup .............................................................................................................. 44

Alarms setup .................................................................................................................. 44

Remote Meter Setup ...................................................................................................... 44

Chapter 5: Viewing Meter

Data

© 2014 Schneider Electric All Rights Reserved

Viewing meter data from the front panel ........................................................................ 45

Meter data display screens ............................................................................................ 45

5

PowerLogic™ PM5300 series user guide Table of Contents

Using ION Setup to view or modify configuration data ...................................................48

Using software to view meter data ..................................................................................48

Chapter 6: Input / Output Status input applications .................................................................................................49

Status input setup ........................................................................................................50

Digital output applications ...............................................................................................52

Digital output setup ......................................................................................................52

Relay output applications ................................................................................................57

Relay output setup ......................................................................................................57

Alarm / energy pulsing LED setup .................................................................................. 60

Chapter 7: Alarms About Alarms ..................................................................................................................63

1-Second Alarms ......................................................................................................... 63

Digital Alarms .............................................................................................................. 65

Unary Alarms ...............................................................................................................66

Alarm Priorities ............................................................................................................66

Using an Alarm to Control a Relay and Digital Output ................................................ 66

Alarm Setup ...................................................................................................................66

Setting Up 1-Second Alarms .......................................................................................67

Setting Up Unary Alarms .............................................................................................69

Setting Up Digital Alarms ............................................................................................70

Viewing Alarm Activity and History ................................................................................. 72

Viewing Active Alarms and Alarm Counters ................................................................72

Viewing Unacknowledged Alarms and the Alarm History Log .................................... 73

Chapter 8: Data Logs Data Logs ....................................................................................................................... 75

Memory Allocation for Log Files .....................................................................................76

Alarm Log ....................................................................................................................... 76

Alarm Log Storage ......................................................................................................76

Chapter 9: Measurements

and calculations

Real-time readings ..........................................................................................................77

Energy ............................................................................................................................ 77

Min/max values ............................................................................................................... 77

Power factor ....................................................................................................................77

Power factor min/max convention ...............................................................................78

Power factor sign convention ......................................................................................78

Demand .......................................................................................................................... 79

Power demand calculation methods ...........................................................................79

Current demand ..........................................................................................................81

Predicted demand .......................................................................................................81

Peak demand ..............................................................................................................82

Chapter 10: Multi-tariff feature Multi-tariff feature example ............................................................................................. 83

Multi-tariff feature overview .............................................................................................83

Command mode overview ...........................................................................................84

Time of day mode overview ........................................................................................84

Input mode overview ................................................................................................... 86

Configuring tariffs using the front panel .......................................................................... 87

Configuring time of day mode tariffs using the front panel .......................................... 87

Configuring input mode tariffs using the front panel .................................................... 88

Chapter 11: Power quality Harmonics overview .......................................................................................................89

Total Harmonic Distortion and Total Demand Distortion ............................................. 89

Displaying harmonics data ..............................................................................................90

Viewing harmonics using the front panel .....................................................................90

Viewing TDD ...............................................................................................................91

Viewing THD/thd using the front panel ........................................................................ 91

© 2014 Schneider Electric All Rights Reserved6

PowerLogic™ PM5300 series user guide Table of Contents

Chapter 12: Verifying accura-

cy

Testing overview ............................................................................................................ 93

Accuracy test requirements ........................................................................................ 93

Verifying accuracy test ................................................................................................... 95

Energy pulsing considerations .................................................................................... 97

Test points .................................................................................................................. 98

Typical sources of test errors ...................................................................................... 98

Chapter 13: Meter resets Front panel meter reset screens .................................................................................... 99

Global resets ..................................................................................................................99

Single resets ................................................................................................................. 100

Chapter 14: Maintenance and

Upgrades

Password Recovery ..................................................................................................... 103

Power Meter Memory ................................................................................................... 103

Identifying the Firmware Version, Model, and Serial Number ...................................... 103

Additional Meter Status Information ............................................................................. 104

Downloading Firmware ................................................................................................. 104

Troubleshooting ............................................................................................................ 105

Heartbeat/Comms LED ............................................................................................. 105

Getting Technical Support ............................................................................................ 106

Register List ................................................................................................................. 106

Chapter 15: MID Compliance MID overview ................................................................................................................ 107

MID compliance for the meter ...................................................................................... 107

Specifications relevant to MID ...................................................................................... 107

Safety precautions ........................................................................................................ 108

Installation and wiring ................................................................................................... 108

Installing the terminal covers ........................................................................................ 109

PM5331/PM5341 default screen .................................................................................. 109

Meter firmware version ................................................................................................. 110

MID-protected setup parameters .................................................................................. 110

Lock-protected setup parameters ................................................................................. 110

Lock-protected functions .............................................................................................. 110

Setting up the PM5331/PM5341 .................................................................................. 111

Basic setup menu ..................................................................................................... 111

Advanced setup menu .............................................................................................. 111

Clock setup menu ..................................................................................................... 111

Tariff setup menu ...................................................................................................... 111

Passwords setup menu ............................................................................................. 111

Initializing the meter ..................................................................................................... 111

Locking or unlocking the meter .................................................................................... 112

Setting up lock password .......................................................................................... 112

Glossary Terms ........................................................................................................................... 113

Abbreviations ................................................................................................................ 115

© 2014 Schneider Electric All Rights Reserved

7

PowerLogic™ PM5300 series user guide Table of Contents

© 2014 Schneider Electric All Rights Reserved8

PowerLogic™ PM5300 user guide Chapter 1—Introduction

Chapter 1—Introduction

This user guide explains how to operate and configure a PowerLogic™ PM5300 Series

Power and Energy Meter.

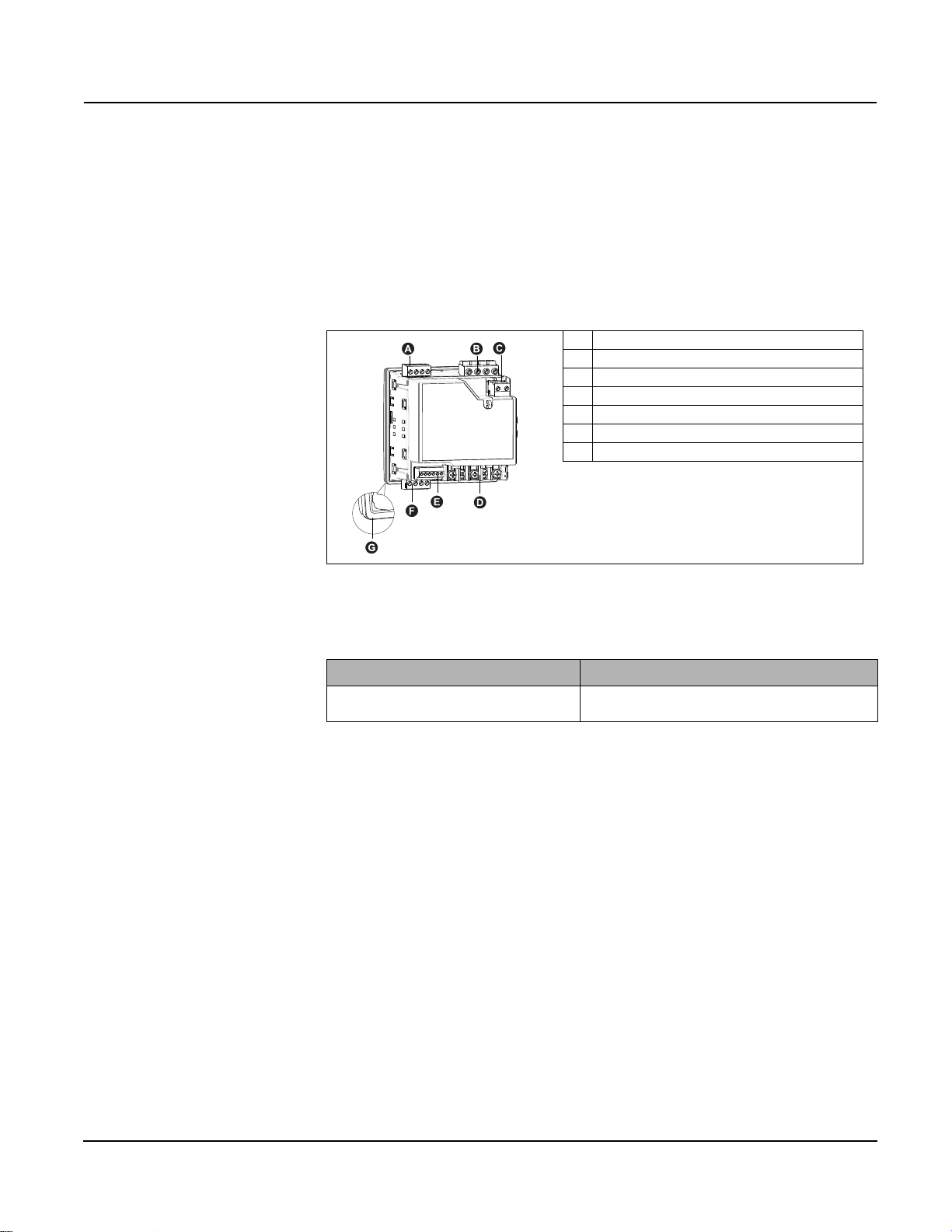

Power and Energy Meter Hardware

Parts of the meter (rear view)

A Relay outputs

B Voltage inputs

C Control power

D Current inputs

E Status inputs/Digital outputs

F Communications port (Ethernet or RS-485)

GGasket

Parts and Accessories

Box Contents

Firmware

Table 1– 1 Meter Models

Description Model Numbers

Power and Energy meter with Integrated Display

PowerLogic

PM5340, and PM5341

TM

PM5310, PM5330, PM5331, PM5320,

1. Power and Energy Meter (1)

2. Installation Guide (1)

3. Calibration Certificate (1)

4. Connectors

5. Retainer Clips (2)

This user guide is written to be used with firmware version 01.00.0 and higher. See

“Identifying the Firmware Version, Model, and Serial Number” on page 103 for

instructions on determining the firmware version.

© 2014 Schneider Electric All Rights Reserved

9

PowerLogic™ PM5300 user guide Chapter 1—Introduction

© 2014 Schneider Electric All Rights Reserved10

PowerLogic™ PM5300 series user guide Chapter 2—Safety Precautions

Chapter 2—Safety Precautions

Before You Begin

Installation, wiring, testing and service must be performed in accordance with all local and

national electrical codes.

This section contains important safety precautions that must be followed before

attempting to install, service, or maintain electrical equipment. Carefully read and follow

the safety precautions outlined below.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical

work practices. In the USA, see NFPA 70E or CSAZ462.

• Only qualified electrical workers should install this equipment. Such work should be

performed only after reading this entire set of instructions.

• If the equipment is not used in a manner specified by the manufacturer, the protection

provided by the equipment may be impaired.

• NEVER work alone.

• Before performing visual inspections, tests, or maintenance on this equipment,

disconnect all sources of electric power. Assume that all circuits are live until they

have been completely de-energized, tested, and tagged. Pay particular attention to

the design of the power system. Consider all sources of power, including the

possibility of back feeding.

• Turn off all power supplying the meter and the equipment in which it is installed before

working on it.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Before closing all covers and doors, inspect the work area for tools and objects that

may have been left inside the equipment.

• When removing or installing panels, do not allow them to extend into the energized

bus.

• The successful operation of this equipment depends upon proper handling,

installation, and operation. Neglecting fundamental installation requirements may

lead to personal injury as well as damage to electrical equipment or other property.

• Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the

energy meter is installed, disconnect all input and output wires to the energy meter.

High voltage testing may damage electronic components contained in the energy

meter.

• This equipment should be installed in a suitable electrical enclosure.

Failure to follow these instructions will result in death or serious injury.

Notices

FCC PART 15 NOTICE This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

© 2014 Schneider Electric All Rights Reserved

11

PowerLogic™ PM5300 series user guide Chapter 2—Safety Precautions

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

© 2014 Schneider Electric All Rights Reserved12

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

Chapter 3—Hardware Reference

This section supplements the meter’s installation sheet and provides additional

information about the meter’s physical characteristics and capabilities.

Models, Features and Options

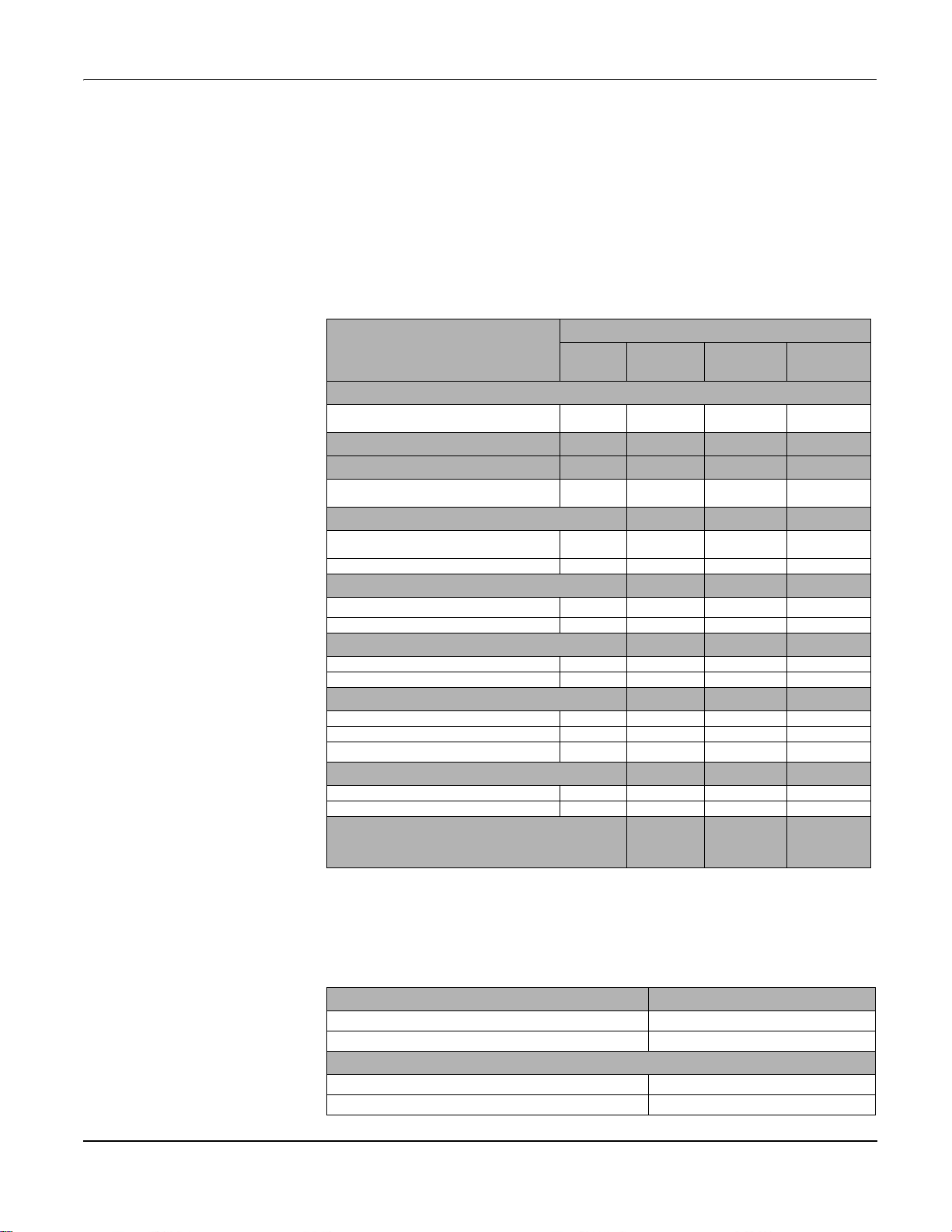

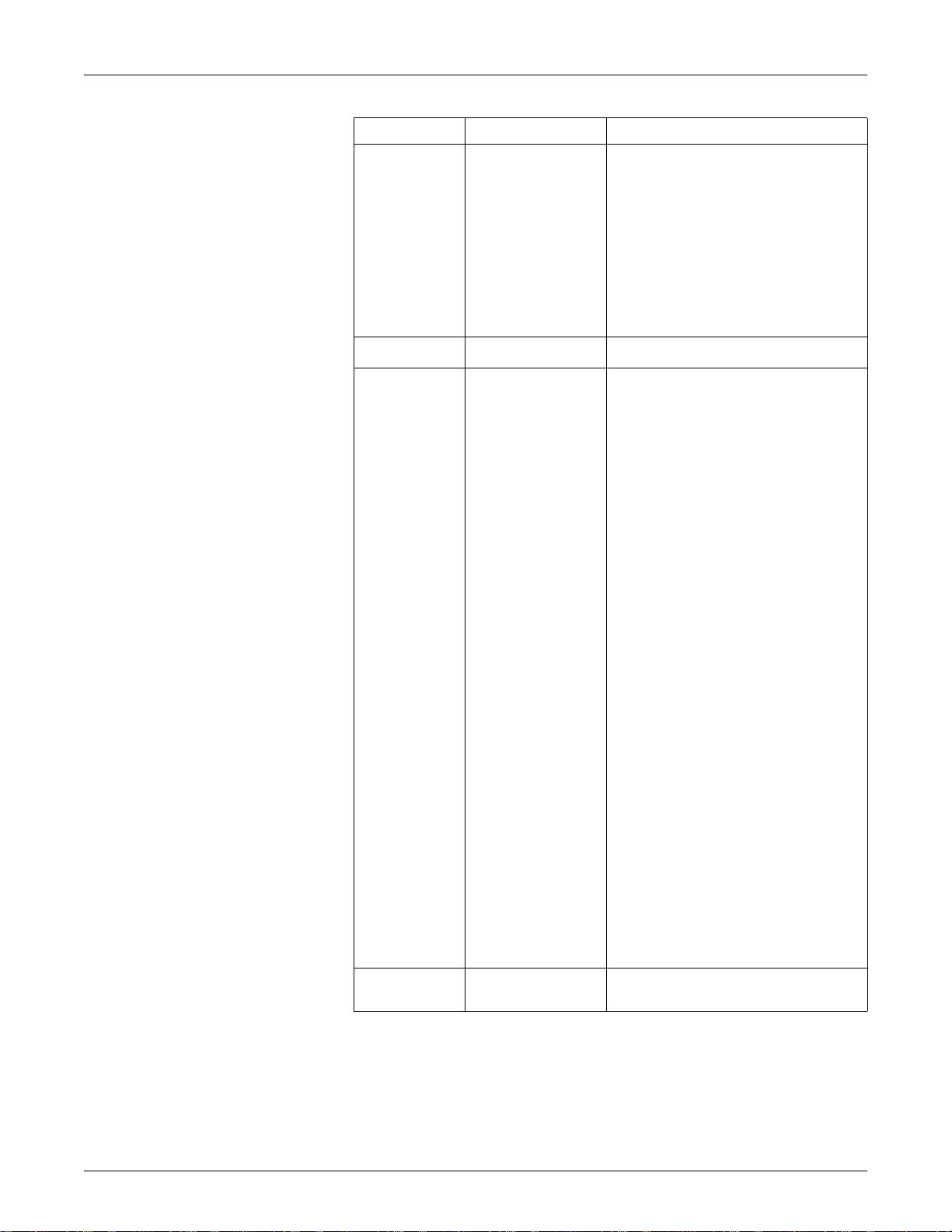

Table 3 –1: PM5300 Series - Models, Features and Options

PM5300 Series

Features and Options

Installation

Fast installation, panel mount with integrated

display

Accuracy Cl 0.5S Cl 0.5S Cl 0.5S Cl 0.5S

Display

Backlit LCD, multilingual, bar graphs, 6 lines, 4

concurrent values

Power and energy metering

3-phase voltage, current, power, demand,

energy, frequency, power factor

Multi-tariff 4 4 4 4

Power quality analysis

THD, thd, TDD

Harmonics, individual (odd) up to 31st 31st 31st 31st

I/Os and relays

I/Os 2SI/2DO 2SI/2DO 2SI/2DO 2SI/2DO

Relays 0 0 2 2

Alarms and control

Alarms 35 35 35 35

Set point response time, seconds 1 1 1 1

Single and multi-condition alarms

Communications

Serial ports with modbus protocol 1 - 1 Ethernet port with Modbus TCP protocol - 1 - 1

MID ready compliance,

EN50470-1/3, Annex B and Annex D

Class C

PM5310 PM5320

PM5330

PM5331

PM5331 PM5341

PM5340

PM5341

Functions and Characteristics

Table 3 –2: Functions and Characteristics

General PM5300 Series

Use on LV and MV systems

Basic metering with THD and min/max readings

Instantaneous rms values

Current (per phase and neutral)

Voltage (total, per phase L-L and L-N)

© 2014 Schneider Electric All Rights Reserved 13

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

Frequency

Real, reactive, and apparent power (Total and per phase) Signed, Four Quadrant

True Power Factor (Total and per phase) Signed, Four Quadrant

Displacement PF (Total and per phase) Signed, Four Quadrant

% Unbalanced I, V L-N, V L-L

Energy Values*

Accumulated Active, Reactive and Apparent Energy Received/Delivered; Net and absolute

Demand Values*

Current average

Active power

Reactive power

Apparent power

Demand calculation (Sliding, fixed and rolling block, thermal

methods)

Synchronization of the measurement window to input,

communication command or internal clock

Settable Demand intervals

Present, Last, Predicted, Peak, and Peak

Present, Last, Predicted, Peak, and Peak

Present, Last, Predicted, Peak, and Peak

Present, Last, Predicted, Peak, and Peak

Date Time

Date Time

Date Time

Date Time

Other Measurements*

I/O timer

Operating timer

Load timer

Alarm counters and alarm logs

Power Quality Measurements

THD, thd (Total Harmonic Distortion) I, V L-N, V L-L per phase I, V L-N, V L-L

TDD (Total Demand Distortion)

Individual harmonics (odds) 31st

Data Recording

Min/max of instantaneous values, plus phase identification*

Alarms with 1s timestamping*

Up to two fixed parameters (e.g., kWh and

Data logging

Memory capacity 256 kB

Min/max log

Maintenance, alarm and event logs

kVAh) with configurable interval and duration

(e.g., 2 parameters for 60 days at 15 minutes

interval)

Inputs/Outputs/Relays

Digital inputs 2

Digital outputs 2

Form A Relay outputs 2

Timestamp resolution in seconds 1

Whetting voltage

NOTE: *Stored in non-volatile memory

© 2014 Schneider Electric All Rights Reserved14

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

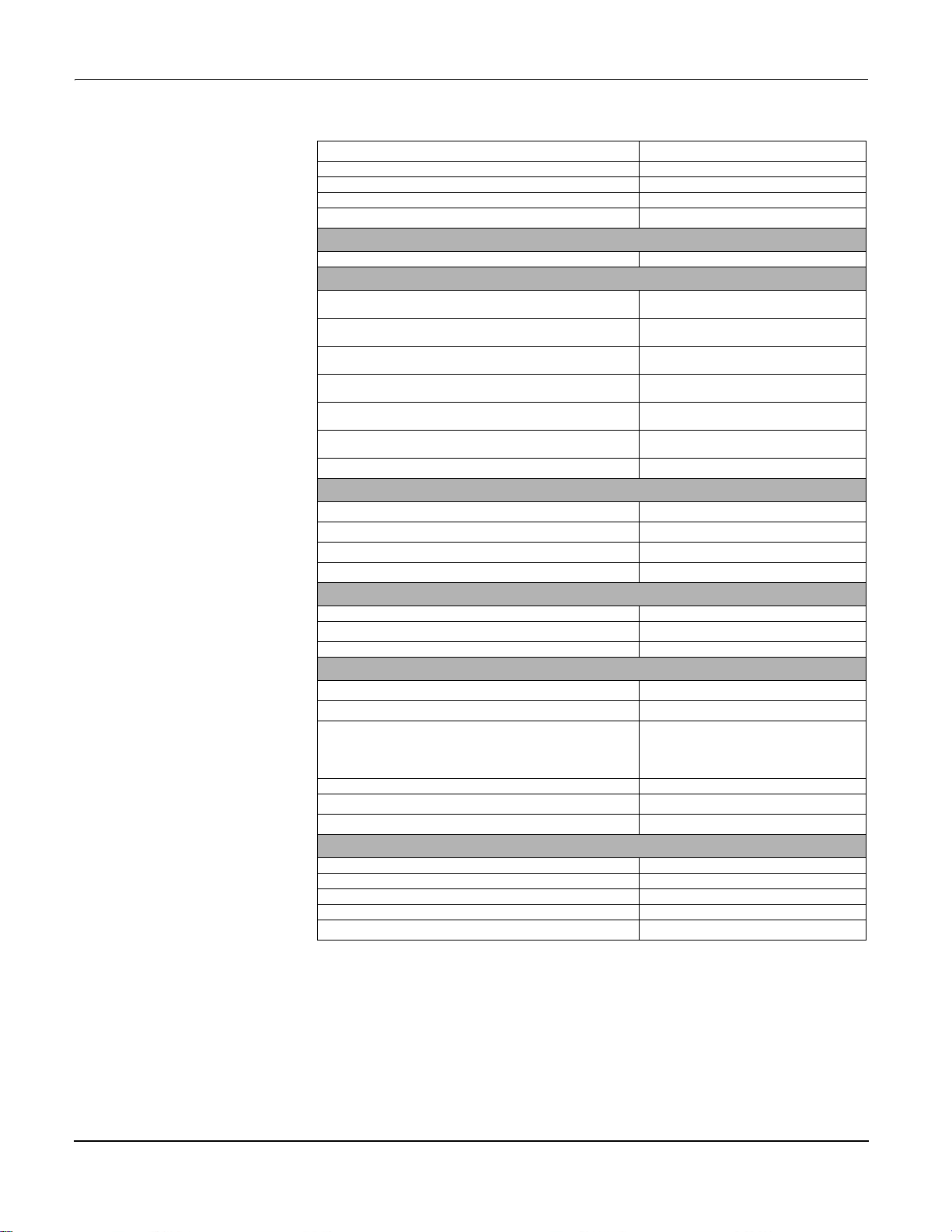

Technical Specifications

Electrical Characteristics

Type of measurement: True rms on three-phase

(3P, 3P + N), zero blind

Measurement accuracy

IEC 61557-12

Active Energy

Reactive Energy

1

2

2

Active Power Class 0.5 as per IEC 61557-12

Reactive Power Class 2 as per IEC 61557-12

Apparent Power Class 0.5 as per IEC 61557-12

Current, Phase Class 0.5 as per IEC 61557-12

Voltage, L-N Class 0.5 as per IEC 61557-12

Frequency Class 0.05 as per IEC 61557-12

Power Factor Class 0.5 as per IEC 61557-12

Voltage Harmonics Class 5 as per IEC 61557-12

Voltage THD/thd Class 5 as per IEC 61557-12

Current Harmonics Class 5 as per IEC 61557-12

Current THD/thd Class 5 as per IEC 61557-12

MID Directive (2004/22/EC)

Input-voltage (up to 1.0 MV AC max, with voltage transformer)

Nominal Measured Voltage range

Impedance 5 M Ω

F nom 50/60 Hz

Input-current (configurable for 1 or 5 A secondary CTs)

I nom 5 A

Measured Amps with over range and Crest Factor

Withstand Continuous 20 A,10s/hr 50 A, 1s/hr 500 A

Impedance < 0.3 mΩ

F nom 50/60 Hz

Burden <0.026VA at 8.5A

Frequency measurement

Measurement range 45 to 65 Hz

AC control power

Operating range

Burden <5 W,11 VA at 415V L-L

Frequency 45 to 65 Hz

Ride-through time

DC control power

Operating range 125-250 V DC ±20%

Burden <4 W at 250 V DC

Ride-through time 50 mS typical at 125 V DC and maximum burden

Outputs

Mechanical

Max output frequency

Switching current

Isolation 2.5 kV rms

Digital outputs

Max load voltage 40 V DC

Max load current 20 mA

On Resistance 50 Ω max

64 samples per cycle

PMD/[SD|SS]/K70/0.5

Class 0.5S as per IEC 62053-22

Class 2S as per IEC 62053-23

1

1

1

1

1

1

1

1

1

1

1

Annex B and Annex D (PM5331 and PM5341)

Class C

UL: 20-347 V L-N/35-600 V L-L

IEC: 20-400 V L-N/35-690 V L-L

(absolute range 35 V L-L to 760 V L-L)

Starting current: 5mA

Operating range: 50mA to 8.5A

100 - 277 V AC L-N / 415 V L-L +/-10%

CAT III 300V class per IEC 61010

80 mS typical at 120V AC and maximum burden.

100 mS typical at 230 V AC and maximum burden

100 mS typical at 415 V AC and maximum burden

0.5 Hz maximum (1 second ON /

1 second OFF - minimum times)

250 V AC at 8.0 Amps, 25 k cycles, resistive

30 V DC at 2.0 Amps, 75 k cycles, resistive

30 V DC at 5.0 Amps,12.5 k cycles, resistive

© 2014 Schneider Electric All Rights Reserved 15

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

Meter constant

Pulse width for Digital Output 50% duty cycle

Pulse frequency for Digital Output 25 Hz max.

Leakage current 0.03 micro Amps

Isolation 5 kV rms

Optical outputs

Pulse width (LED) 200

Pulse frequency 50 Hz. max.

Meter constant from 1 to 9,999,999 pulses per k_h

Status Inputs

ON Voltage 18.5 to 36 V DC

OFF Voltage 0 to 4 V DC

Input Resistance 110 k Ω

Maximum Frequency 2 Hz (T ON min = T OFF min = 250 ms)

Response Time 20 ms

Opto Isolation 5 kV rms

Whetting output 24 V DC/ 8mA max

Input Burden 2 mA @ 24 V DC

from 1 to 9,999,999 pulses per k_h (k_h = kWh,

kVARh or kVAh depending on the energy

parameter selected)

s

Mechanical Characteristics

Product weight 430 g

IP degree of protection (IEC 60529) IP52 front display, IP30 meter body

Dimensions W x H x D [protrusion from cabinet]

Mounting position Vertical

Panel thickness 6 mm maximum

96 x 96 x 72mm (depth of meter from housing

mounting flange) [13mm]

Environmental Characteristics

Operating temperature

Meter -25 °C to +70 °C

Display (Display functions to -25º with reduced

performance)

Storage temp. -40 °C to +85 °C

Humidity range 5 to 95 % RH at 50 °C (non-condensing)

Pollution degree 2

Altitude 2000 m CAT III / 3000 m CAT II

For indoor use only

Electromagnetic Compatibility

Electrostatic discharge IEC 61000-4-2

Immunity to radiated fields IEC 61000-4-3

Immunity to fast transients IEC 61000-4-4

Immunity to surge IEC 61000-4-5

Conducted immunity 150kHz to 80MHz IEC 61000-4-6

Immunity to magnetic fields IEC 61000-4-8

Immunity to voltage dips IEC 61000-4-11

Radiated emissions FCC part 15, EN 55022 Class B

Conducted emissions FCC part 15, EN 55022 Class B

3

-25 °C to +70 °C

Safety

Europe

U.S. and Canada

Measurement category (Voltage and Current inputs) CAT III up to 400 V L-N / 690 V L-L

Dielectric As per IEC/UL 61010-1 (3rd Edition)

Protective Class II, Double insulated for user accessible parts

CE, as per IEC 61010-1 (3rd Edition), IEC 6205211 & IEC61557-12

cULus as per UL61010-1 (3rd Edition)

CAN/CSA-C22.2 No. 61010-1 (3rd Edition)

1

Communication

RS-485 port Modbus RTU, Modbus ASCII (7 or 8 bit), JBUS

Ethernet port: 10/100 Mbps; Modbus TCP/IP 1 (Optional)

Firmware and language file update

2-Wire, 9600,19200 or 38400 baud, Parity - Even,

Odd, None, 1 stop bit if parity Odd or Even, 2 stop

bits if None; (Optional)

Meter firmware update via the communication

ports

© 2014 Schneider Electric All Rights Reserved16

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

DANGER

Isolation 2.5 kVrms, double insulated

Human Machine Interface

Display type Monochrome Graphics LCD

Resolution 128 x 128

Backlight White LED

Viewable area (W x H) 67 x 62.5 mm

Keypad 4-button

Indicator Heartbeat / Comm activity Green LED

Energy pulse output / Active alarm indication (configurable) Optical, amber LED

Wavelength 590 to 635 nm

Maximum pulse rate 2.5 kHz

1

For firmware version 1.1.1 and higher

2

For 1A nominal CT when I > 0.15A

3

Tests are conducted as per IEC 61557-12 (IEC 61326-1), 62052-11 and EN50470

Before you begin

Carefully read and follow the safety precautions before working with the meter.

Safety precautions

Dimension

Installation, wiring, testing and service must be performed in accordance with all local and

national electrical codes.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical

work practices. See NFPA 70E in the USA or applicable local standards.

• Turn off all power supplying this device before working on it.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Do not exceed the device’s ratings for maximum limits.

• Always use grounded external CTs for current inputs.

Failure to follow these instructions will result in death or serious injury.

1. Turn off all power supplying this device before working on it.

2. Always use a properly rated voltage sensing device to confirm that all power is off.

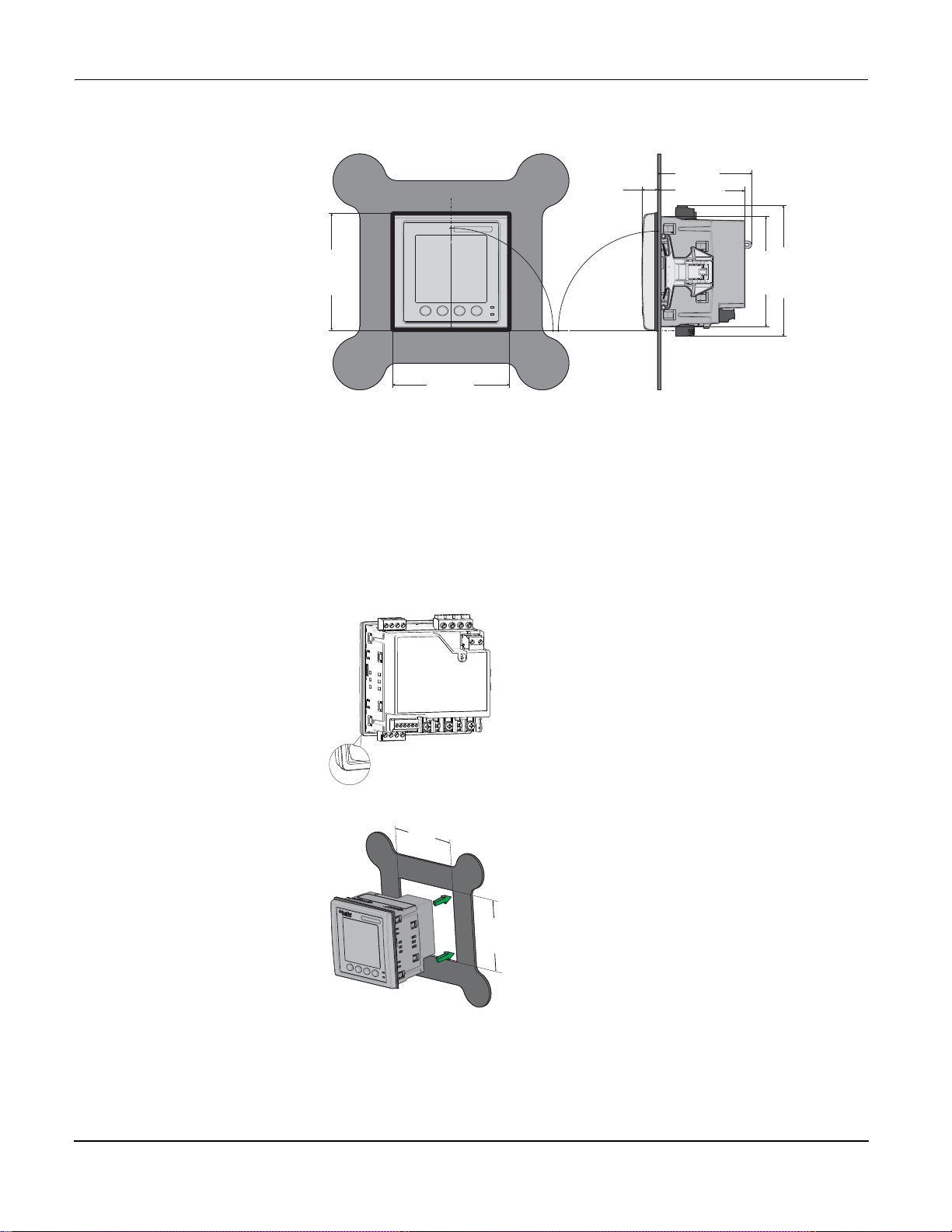

Figure 3–1: Dimension

© 2014 Schneider Electric All Rights Reserved 17

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

90.00°

90.00°

96.00mm

96.00

mm

78.5 mm

12.8 mm

107.4

mm

90.6

mm

72.00 mm

92.0

mm

+0.8

-

0.0

92.0

mm

+0.8

-

0.0

Meter mounting

This section describes how to mount the meter.

Mounting the PM5300

The meter is designed to be mounted inside a 1/4-DIN panel cutout.

1. Inspect the gasket (installed around the perimeter of the front display) and make sure

it is secured properly and not damaged.

2. Insert the meter through the mounting hole.

3. Line up the tabs of the retainer clips with the slots on either side of the meter. While

holding the retainers at a slight angle, push the retainers in and forward to position

them in place. In situations where the spacing between meters is tight, use a flat-head

screwdriver with a long, narrow shaft to help secure the clips.

© 2014 Schneider Electric All Rights Reserved18

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

CLICK

CLICK

4. Push the middle of the clip assembly to lock the retainer in place and secure the

meter.

Meter wiring

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

• Wire connections to the meter’s voltage inputs, control power, digital outputs, digital

(status) inputs and RS-485 communications are terminated using the supplied

pluggable wire connectors.

• When wiring the meter’s current inputs, terminate the wire ends with ring or split-ring

crimp connectors.

Use the meter installation sheet when wiring the meter.

© 2014 Schneider Electric All Rights Reserved 19

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

(30)

Modbus

RS-485

II

IIII

D1 = Rx+,Tx+

RS-485

D0 = Rx-, Tx-

Modbus

0V

(CAT II)

UL: CAT III

20-347VLN/35-600VLL

IEC: CAT III

20-400VLN/35-690VLL

24V

$$120$

8mA MAX

100-277VLN/415VLL ± 10%

50/60 ± 5 Hz < 11VA

125-250V ± 20% < 4W

Modbus TCP/IP

Link

10/100

40V MAX

20mA MAX

36V MAX

250V/8A

30V/5A

RESISTIVE

NO

NO

RELAY1

RELAY2

V1 V2 V3 VN

L1 L2

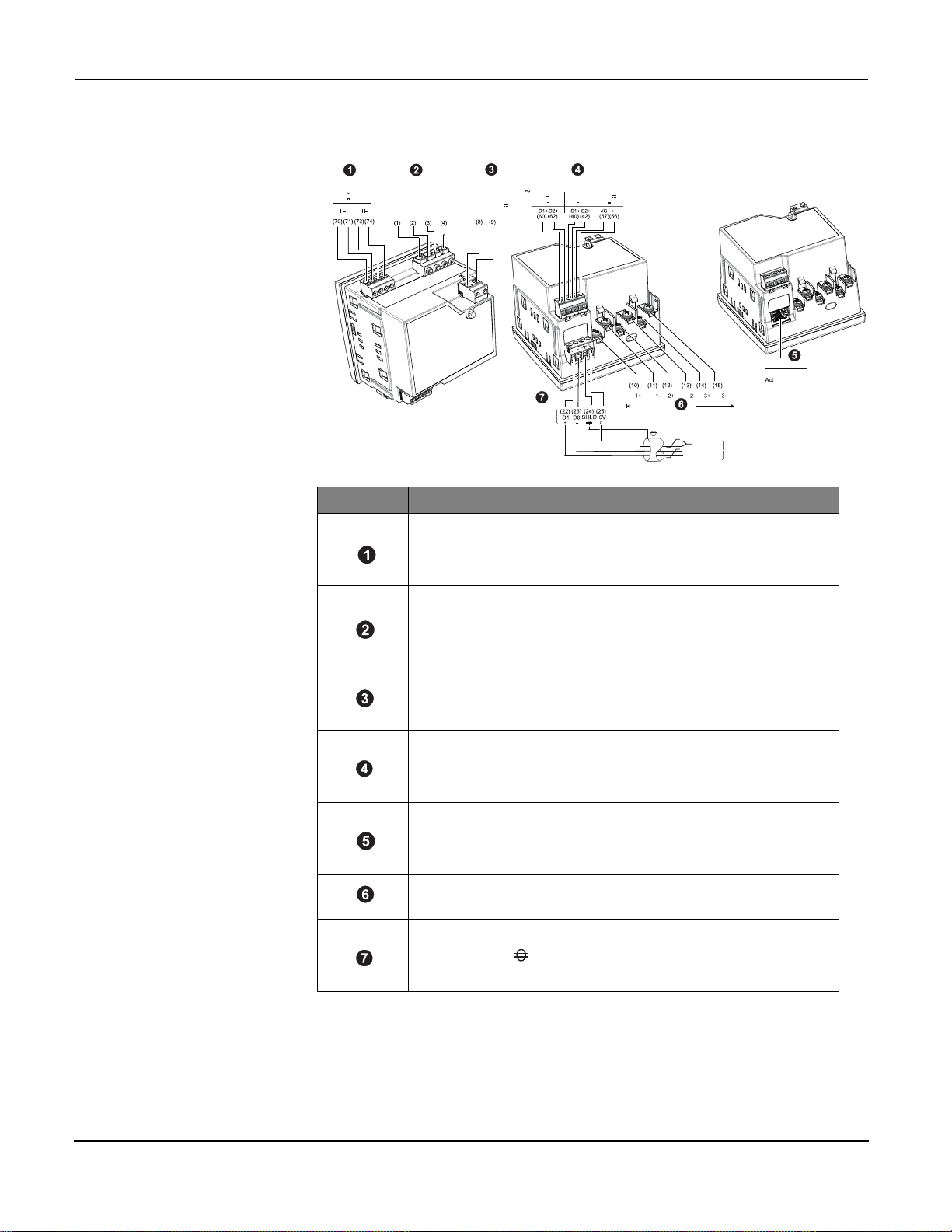

Serial No. Description Specification

2

(22 - 12 AWG)

2

(18 - 12 AWG)

2

(18 - 12 AWG)

2

(22 - 12 AWG)

2

(18 - 12 AWG)

Relay (Relay1, Relay2)

Voltage Inputs (V1, V2, V3, VN)

Control Power (L1, L2)

Digital Output / Status Input (D1+,

D2+, S1+, S2+, -/C, +)

Current Inputs

, I1-, I2+, I2-, I3+, I3-)

(I

1+

• Wire size: 0.33 - 3.31 mm

• Wire strip length: 0.24 in (6 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M3

• Wire size: 0.82 - 3.31 mm

• Wire strip length: 0.28 in (7 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M3

• Wire size: 0.82 - 3.31 mm

• Wire strip length: 0.28 in (7 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M3

• Wire size: 0.33 - 3.31 mm

• Wire strip length: 0.24 in (6 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M2

• Wire size: 0.82 - 3.31 mm

• Wire strip length:0.28 in (7 mm)

• Torque: 0.9 - 1.0 N·m (8.0 - 9.0 in·lb)

• Screw driver type: PH1

Ethernet RJ-45

• Wire size: 0.33 - 3.31 mm

Modbus RS-485 (+,-, ,C)

• Wire strip length: 0.24 in (6 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M3

2

(22 - 12 AWG)

© 2014 Schneider Electric All Rights Reserved20

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

Recommended cables

Communication Make Part code Description

RS-485 Belden

Ethernet Schneider Electric

3105A Multi-Conductor - EIA Industrial RS-485 PLTC/CM

3106A Multi-Conductor - EIA Industrial RS-485 PLTC/CM

DC6PCSRJ01-GY DIGILINK Patch Cord CAT at 6 SFTP Gray 1m

DC6PCSRJ02-GY DIGILINK Patch Cord CAT 6 SFTP Gray 2m

DC6PCSRJ03-GY DIGILINK Patch Cord CAT 6 SFTP Gray 3m

DCECASTP4P3X DIGILINK Solid Cable CAT 5e, 4 pair, SFTP-305m

NOTE: According to Blondel's theorem, in an N wire system a minimum of N-1 measuring elements are required for correct measurement.

© 2014 Schneider Electric All Rights Reserved 21

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

B

A

+

-

+

-

+

-

+

L

B

A

(I1) (I2) (I3)

V1 V2 V3VN

+

-

+

-

+

-

+

A

B

+

-

+

-

+

-

+

B

A

+

-

+

-

+

-

+

A

L1

L2

(I1) (I2) (I3)

V1 V2 V3VN

B

+

-

+

-

+

-

+

B

A

+-+-+

-

+

+

L

B

A

(I1) (I2) (

V1 V2 V3VN

+

-

+

-

+

+

A B

+-+-+

-

+

+

+

B

A

+

-

+

-

+

-

+

L1

L2

L3

A B

V1 V2 V3VN

(I1) (I2) (I3)

+-+-+

-

+

+

A B

+-+-+

-

+

C

A

B

+-+-+

-

+

+

+

C

A

B

+-+-+

-

+

+

C

L1

A

V1 V2 V3VN

B

(I1) (I2) (I3)

+-+-+

-

+

C

L1

L2

L3

A

V1 V2 V3VN

B

(I1) (I2) (I3)

+

+

-

+-+

-

L1

L2

L3

N

A

B

V1 V2 V3VN

(I1) (I2) (I3)

+-+-+

-

+

+

+

L1

L2

L3

N

B

V1 V2 V3VN

(I1) (I2) (I3)

A

+-+-+

-

+

L1

L2

L3

N

A

C

V1 V2 V3VN

B

(I1) (I2) (I3)

+

+

+

+

-

+-+

-

L1

L2

L3

N

A

C

V1 V2 V3VNB(I1) (I2) (I3)

+-+-+

-

+

+

L1

L2

L3

N

A

C

V1 V2 V3VN

B

(I1) (I2) (I3)

+-+-+

-

+

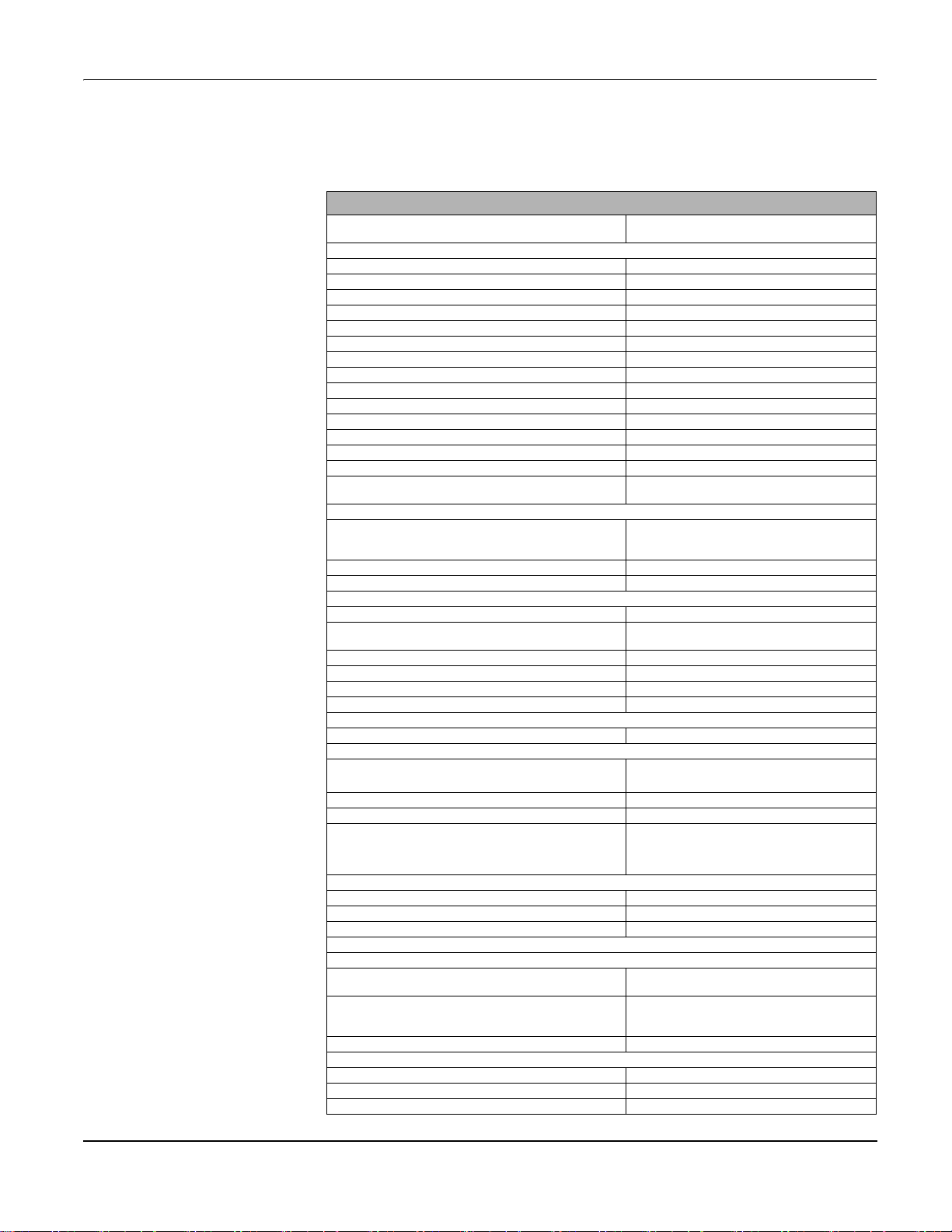

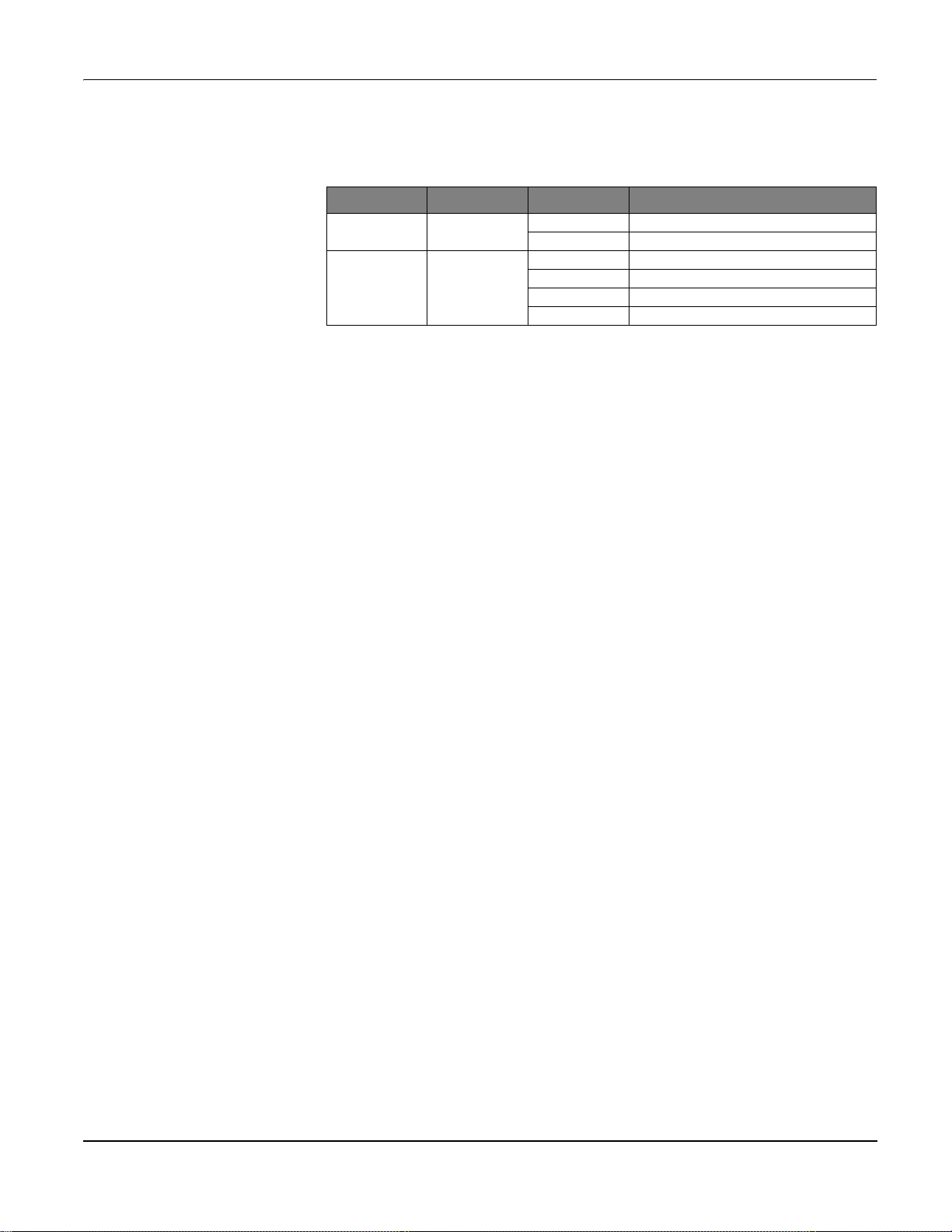

Wiring Diagrams

1PH

1PH2WLN 1PH2WLL 1PH3WLL with N

V1 V2 V3VN

(I1) (I2) (I3)

V1 V2 V3VN

(I1) (I2) (I3)

V1 V2 V3VN

V1 V2 V3VN

(I1) (I2) (I3)

(I1) (I2) (I3)

L

N

L1

L2

L1

L2

L

N

N

3PH3W

3CT 2CT 1CT *

V1 V2 V3VN (I1) (I2) (I3)

L1

L2

L3

V1 V2 V3VN

L

N

(I1) (I2) (I3)

2VT, 3CT 2VT, 2CT 2VT, 1CT *

V1 V2 V3VN

L1

L2

L3

(I1) (I2) (I3)

V1 V2 V3VN

L1

L2

L3

(I1) (I2) (I3)

3PH4W

3CT 2CT * 1CT *

V1 V2 V3VN (I1) (I2) (I3)

L1

L2

L3

V1 V2 V3VN

L1

L2

L3

N

A

(I1) (I2) (I3)

+-+-+

B

+

+

-

3VT, 3CT 3VT, 2CT * 3VT, 1CT *

© 2014 Schneider Electric All Rights Reserved22

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

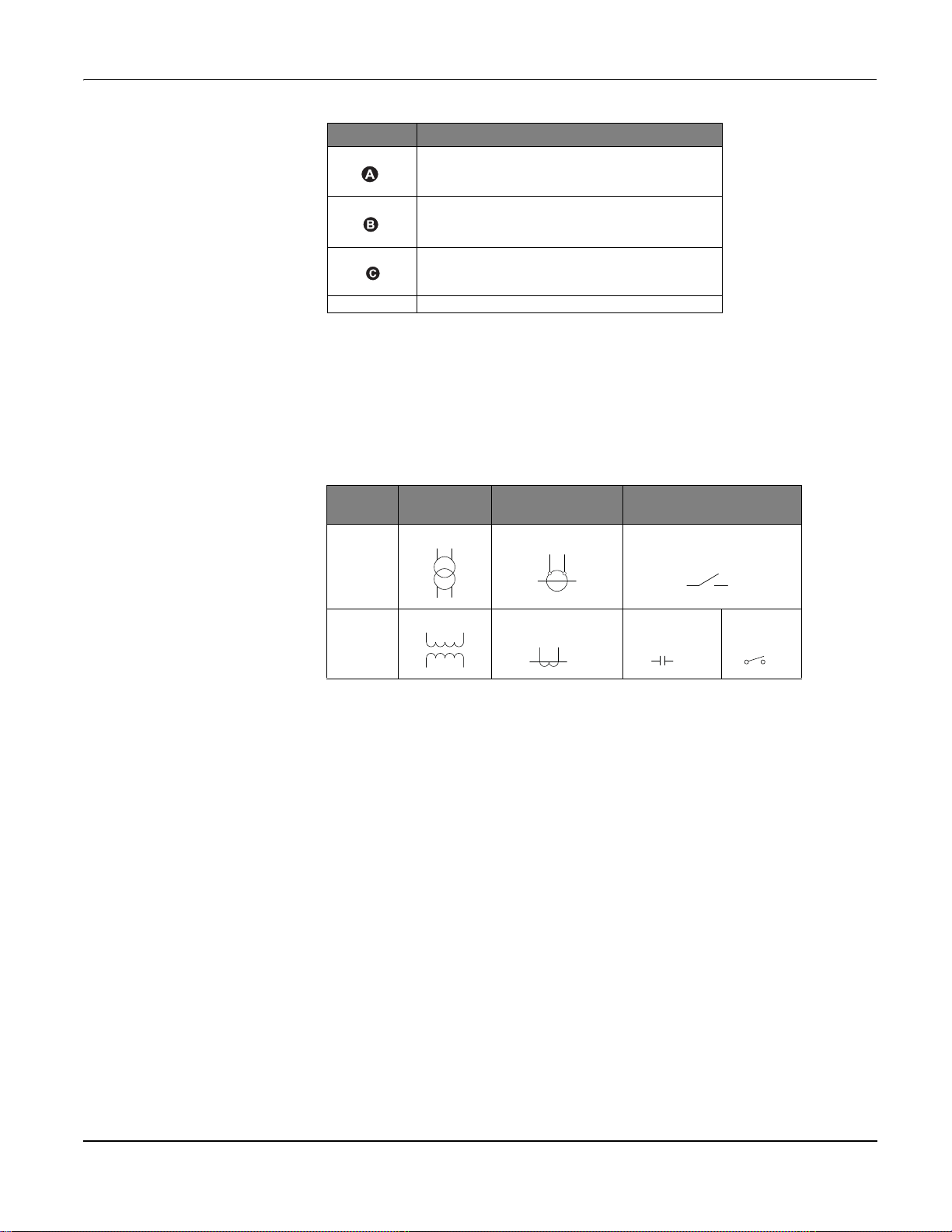

Symbol Description

500 mA fused disconnect / circuit breaker (not supplied)

Shorting block (not supplied)

PT primary fuses and disconnect switch (not supplied)

Power system

*

Indicates wiring for a balanced system

NOTE:

• Clearly label the device’s disconnect circuit mechanism and install it within easy reach

of the operator.

• The fuses / circuit breakers must be rated for the installation voltage and sized for the

available fault current.

• Fuse for neutral terminal is required if the source neutral connection is not grounded.

Potential

Transformer

IEC

ANSI

Current Transformer Voltage disconnect switch

This section outlines typical requirements for wiring the voltage and current inputs of the

meter to the electrical power system.

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

Direct connect voltage limits

You can connect the meter’s voltage inputs directly to the phase voltage lines of the

power system if the power system’s line-to-line or line-to-neutral voltages do not exceed

the meter’s direct connect maximum voltage limits. The meter's voltage measurement

inputs are rated by the manufacturer for up to 400 V L-N / 690 V L-L. However, the

maximum voltage allowed for direct connection may be lower, depending on the local

electrical codes and regulations. In US and Canada the maximum voltage on the meter

voltage measurement inputs may not exceed 347 V L-N / 600 V L-L.

If your system voltage is greater than the specified direct connect maximum voltage, you

must use VTs (voltage transformers) to step down the voltages.

© 2014 Schneider Electric All Rights Reserved 23

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

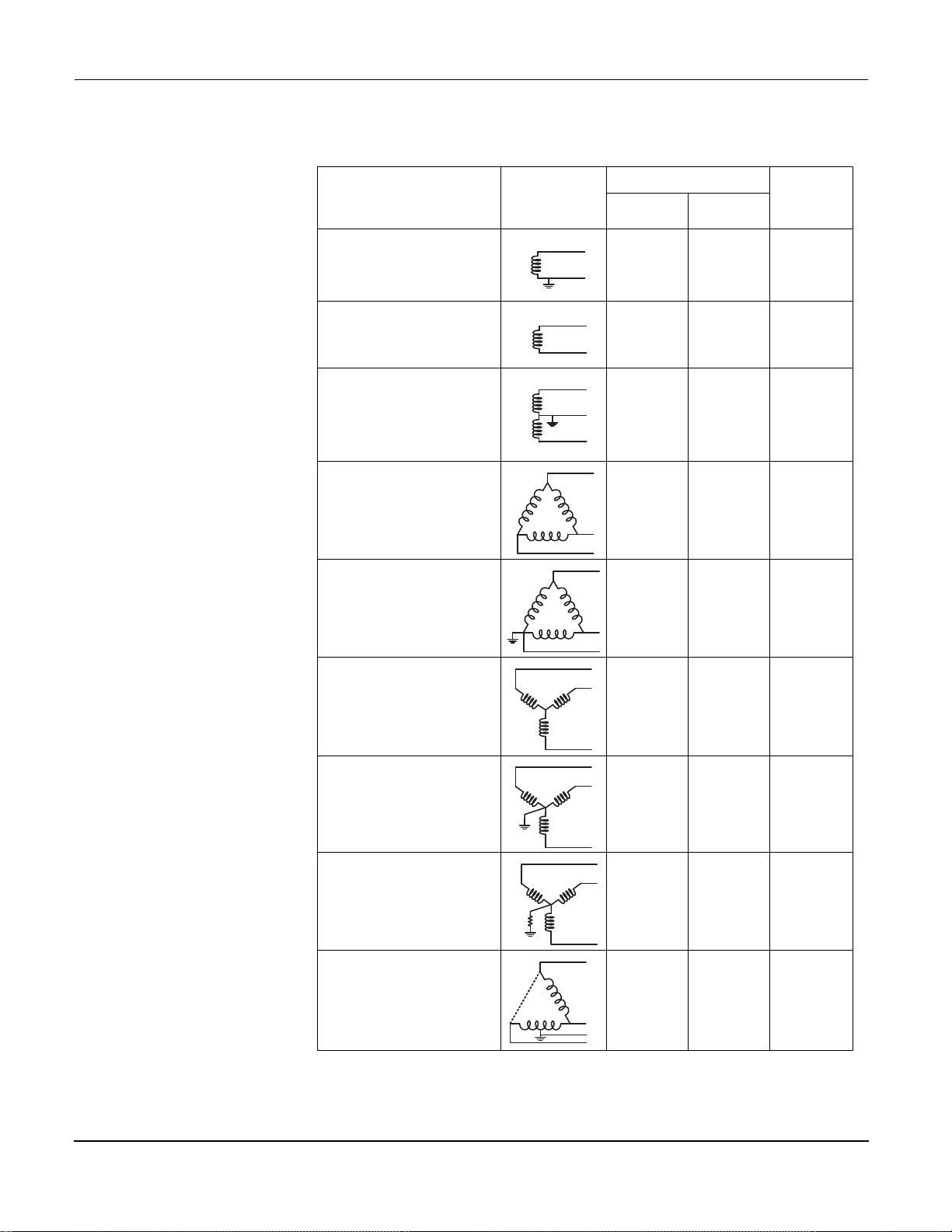

N

Power system setup parameters

Power system description

—

Meter setting

Single-phase 2-wire line-to-neutral

—

1PH2W LN

Single-phase 2-wire line-to-line

—

1PH2W LL

Single-phase 3-wire line-to-line with

neutral

—

1PH3W LL with N

3-phase 3-wire Delta ungrounded

—

3PH3W Dlt Ungnd

3-phase 3-wire Delta corner

grounded

—

3PH3W Dlt Crnr Gnd

Symbol

Direct connect maximum

UL IEC

347 V L-N 400 V L-N 1 VT

600 V L-L 600 V L-L 1VT

347 V L-N /

600 V L-L

600 V L-L 600 V L-L 2 VT

600 V L-L 600 V L-L 2 VT

400 V L-N /

690 V L-L

# of VTs

(if required)

2VT

3-phase 3-wire Wye ungrounded

—

3PH3W Wye Ungnd

3-phase 3-wire Wye grounded

—

3PH3W Wye Gnd

3-phase 3-wire Wye resistancegrounded

—

3PH3W Wye Res Gnd

3-phase 4-wire open Delta centertapped

—

3PH4W Opn Dlt Ctr Tp

600 V L-L 600 V L-L 2 VT

600 V L-L 600 V L-L 2 VT

600 V L-L 600 V L-L 2 VT

240 V L-N /

415 V L-N /

480 V L-L

240 V L-N /

415 V L-N /

480 V L-L

3 VT

© 2014 Schneider Electric All Rights Reserved24

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

N

N

N

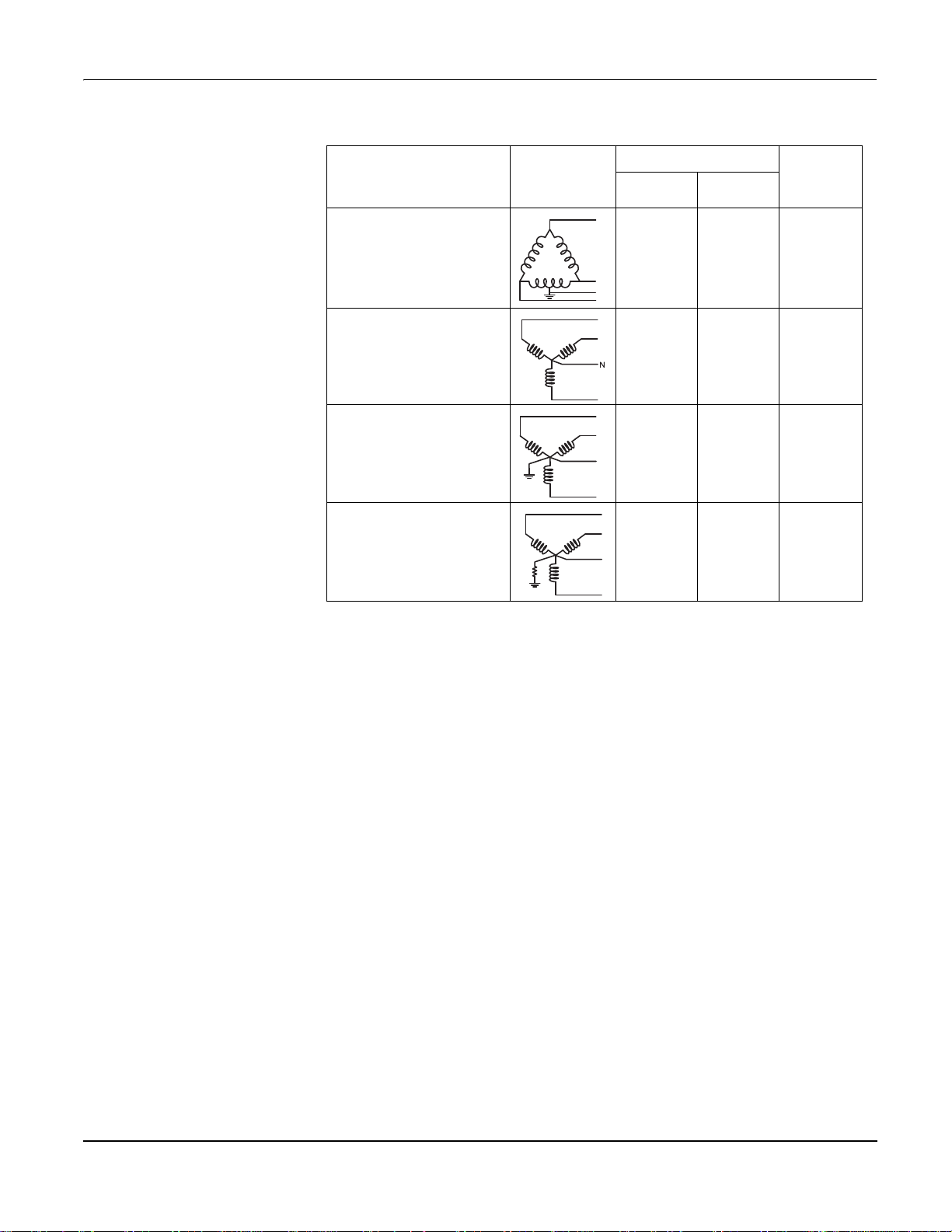

Power system setup parameters (continued)

Power system description

—

Meter setting

3-phase 4-wire Delta center-tapped

—

3PH4W Dlt Ctr Tp

3-phase 4-wire ungrounded Wye

—

3PH4W Wye Ungnd

3-phase 4-wire grounded Wye

—

3PH4W Wye Gnd

3-phase 4-wire resistance-grounded

Wye

—

3PH4W Wye Res Gnd

Symbol

Direct connect maximum

UL IEC

240 V L-N /

415 V L-N /

480 V L-L

347 V L-N /

600 V L-L

347 V L-N /

600 V L-L

347 V L-N /

600 V L-L

240 V L-N /

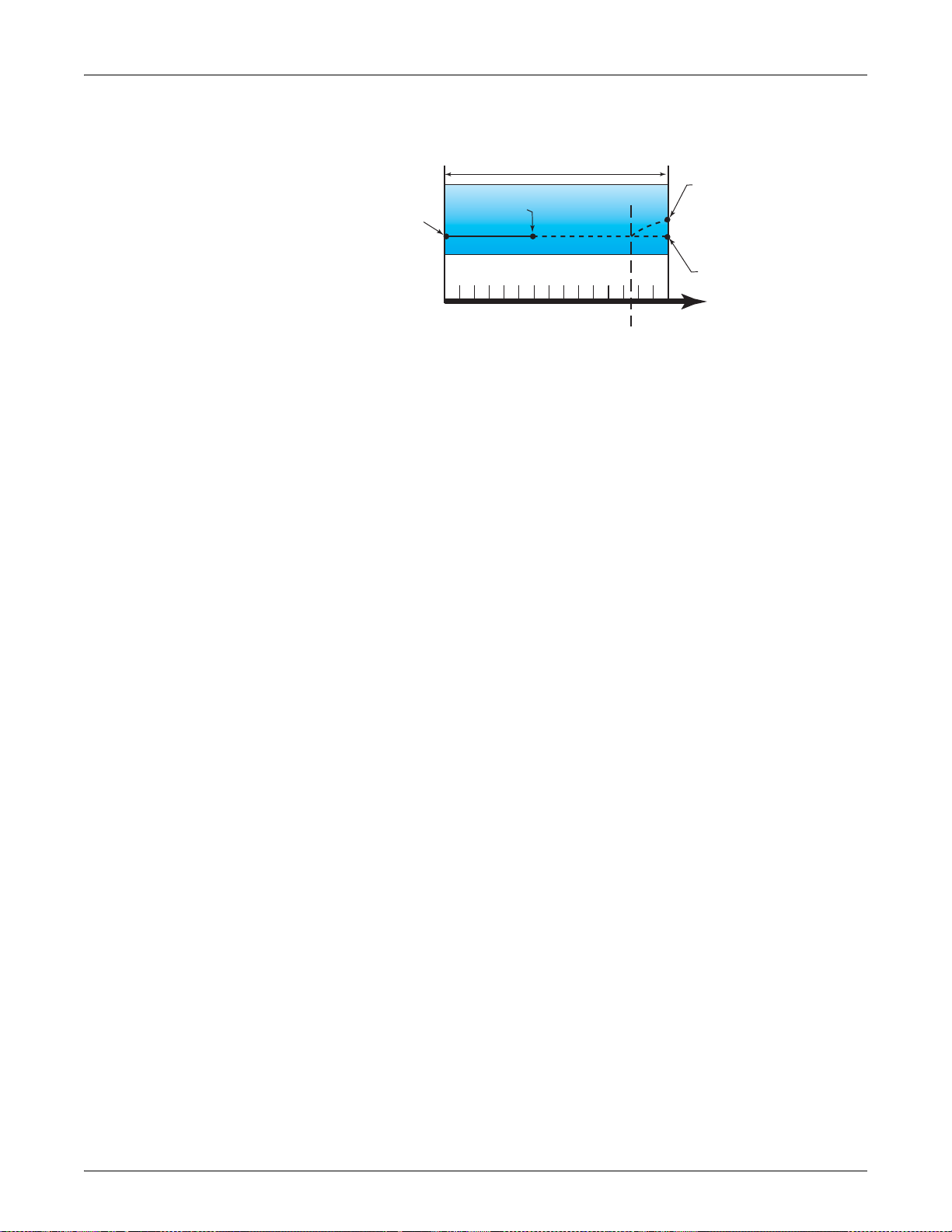

415 V L-N /

480 V L-L

347 V L-N /

600 V L-L

400 V L-N /

690 V L-L

347 V L-N /

600 V L-L

# of VTs

(if required)

3 VT

3 VT or 2 VT

3 VT or 2 VT

3 VT or 2 VT

Voltage and current input wiring

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

Voltage input protection

The meter’s voltage inputs must be wired to fuses/breakers and a disconnect switch. If

using a voltage transformer (VT), both primary and secondary sides of the VT must be

wired to fuses/breakers and disconnect switches.

• Clearly label the device’s disconnect circuit mechanism and install it within easy reach

of the operator.

• The fuses / circuit breakers must be rated for the installation voltage and sized for the

available fault current.

• Fuse for neutral terminal is required if the source neutral connection is not grounded.

See the meter installation sheet for fuse ratings.

Current input protection

For all connected current inputs, use a CT shorting block to short-circuit the secondary

leads of the CTs before removing the current input connections to the meter.

NOTE: Ground any unused current inputs.

© 2014 Schneider Electric All Rights Reserved 25

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

Balanced system considerations

In situations where you are monitoring a balanced 3-phase load, you may choose to

connect only one or two CTs on the phase(s) you want to measure, and then configure

the meter so it calculates the current on the unconnected current input(s).

NOTE: For a balanced 4-wire Wye system, the meter’s calculations assume that there is

no current flowing through the neutral conductor.

Balanced 3-phase Wye system with 2 CTs

The current for the unconnected current input is calculated so that the vector sum for all

three phase currents equal zero.

Balanced 3-phase Wye or Delta system with 1 CT

The currents for the unconnected current inputs are calculated so that their magnitude

and phase angle are identical and equally distributed, and the vector sum for all three

phase currents equal zero.

NOTE: You must always use 3 CTs for 3-phase 4-wire center-tapped Delta or

center-tapped open Delta systems.

Control power wiring

Communications

Serial communications

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

The meter can be powered from an AC or DC power source.

• L1 and L2 are non-polarized. If using an AC power supply with neutral, connect

neutral to the meter’s L2 terminal.

• Always use a fuse on L1. Fuse L2 when connecting an ungrounded neutral to the

control power.

• If using a control power transformer, fuse both primary and secondary sides of the

transformer.

• The fuses / circuit breakers must be rated for the installation voltage and sized for the

available fault current.

This section provides additional information about the communications ports and

topologies supported by the meter. You must wire and configure the RS-485 port or the

Ethernet port in order to communicate with the meter.

The meter supports serial communications through the RS-485 port. Up to 32 devices can

be connected on a single RS-485 bus.

In an RS-485 network, there is one master device, typically an Ethernet to RS-485

gateway. It provides the means for RS-485 communications with multiple slave devices

(for example, meters). For applications that require only one dedicated computer to

© 2014 Schneider Electric All Rights Reserved26

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

Master Slaves

communicate with the slave devices, an RS-232 to RS-485 converter can be used as the

master device.

RS-485 wiring

Connect the devices on the RS-485 bus in a point-to-point configuration, with the (+) and

(-) terminals from one device connected to the corresponding (+) and (-) terminals on the

next device.

RS-485 wiring

C

-

+

C

120 Ω

-

+

D0 (-)

D1 (+)

120 Ω

RS-485 cable

Use a shielded 1.5 twisted pair or 2 twisted pair RS-485 cable to wire the devices. Use

one twisted pair to connect the (+) and (-) terminals, and use the other insulated wire to

connect the C terminals.

RS-485 terminals

Common. This provides the voltage reference (zero volts) for the data plus and data minus signals.

C

Shield. Connect the bare wire to this terminal to help suppress signal noise that may be present.

Ground the shield wiring at one end only (either at the master or the last slave device, but not both).

Data minus. This transmits/receives the inverting data signals.

-

Data plus. This transmits/receives the non-inverting data signal.

+

RS-485 maximum cable length

The total distance for devices connected on an RS-485 bus should not exceed 1200 m

(4000 ft).

RS-485 network configuration

© 2014 Schneider Electric All Rights Reserved 27

After you have wired the RS-485 port and powered up the meter, you must configure the

serial communications port in order to communicate with the meter.

Each device on the same RS-485 communications bus must have a unique address and

all connected devices must be set to the same protocol, baud rate, and parity (data

format).

NOTE: To communicate with the meter using ION Setup, you must set the parity to

“None” for all devices in the RS-485 network.

For meters that do not have a display, you must first wire and configure each one

separately before connecting these meters to the same RS-485 bus.

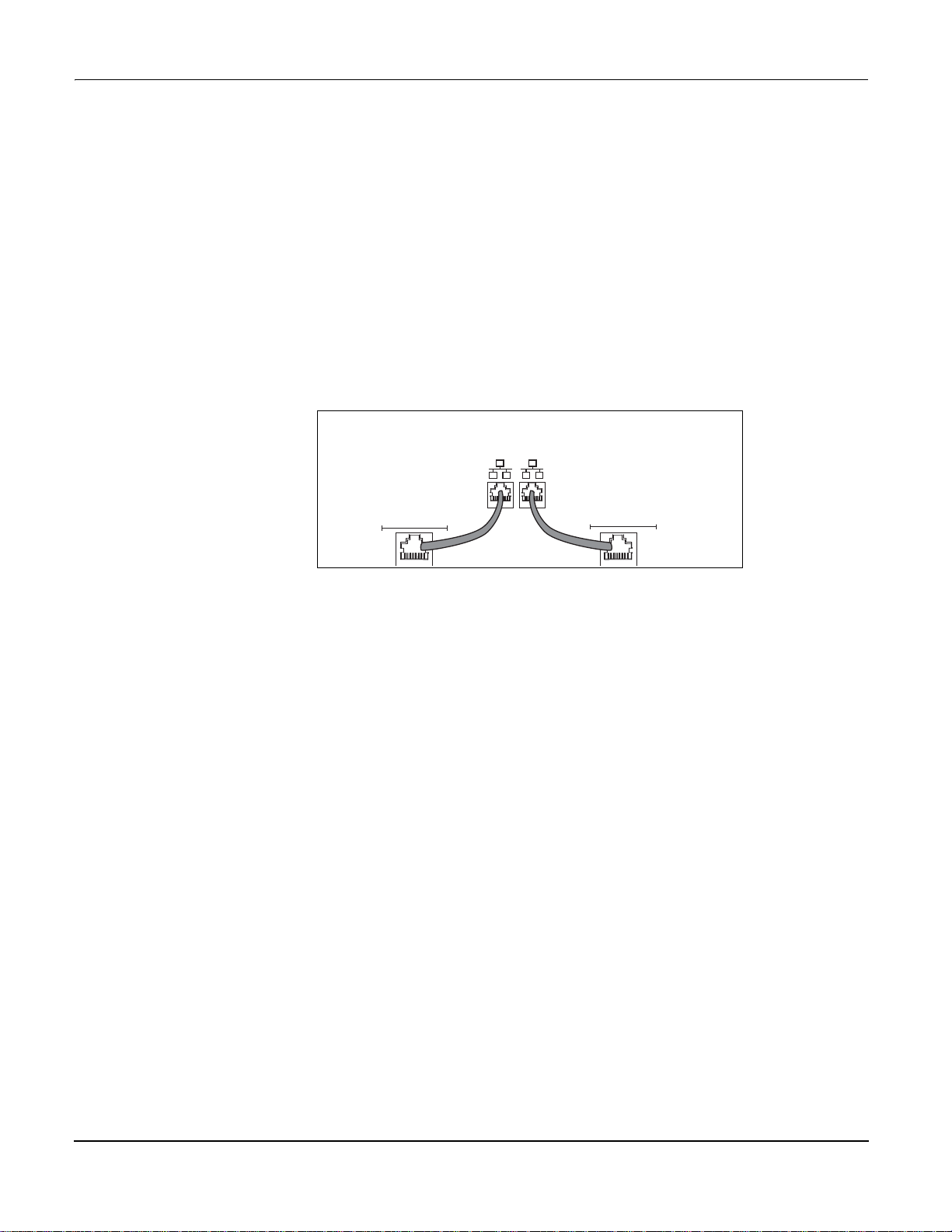

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

ETHERNET

ETHERNET

SWITCH / HUB

ETHERNET

Ethernet

Switch / hub

Ethernet

Ethernet

Related topics

• To configure RS-485 communications, see “Setting up serial communications” on

page 36.

Ethernet communications

The meter uses Modbus TCP protocol to communicate at data speeds up to 100 Mbps

through its Ethernet communications port.

Use a shielded Ethernet cable to connect the meter’s Ethernet port. Ground terminal is

not available on meter, shield should be connected to Ground at the other end. Ethernet

connection source should be installed in a location that minimizes the overall Ethernet

cable routing length.

Ethernet wiring

Digital outputs

Ethernet configuration

To communicate with the meter through Ethernet, all devices must have a unique IP

address and be set to the same subnet mask and gateway.

• To configure Ethernet communications, see “Setting up Ethernet communications” on

page 37.

The meter is equipped with two digital output ports (D1, D2). You can configure the digital

outputs for use in the following applications:

• switching applications, for example, to provide on/off control signals for switching

capacitor banks, generators, and other external devices and equipment

• demand synchronization applications, where the meter provides pulse signals to the

input of another meter to control its demand period

• energy pulsing applications, where a receiving device determines energy usage by

counting the k_h pulses (k_h = kWh, kVARh or kVAh depending on the energy

parameter selected) coming from the meter’s digital output port

The digital outputs can handle voltages less than 40 V DC. For higher voltage

applications, use an external relay in the switching circuit.

© 2014 Schneider Electric All Rights Reserved28

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

S1 S2D1 D2 -/C +

(60) (62)

(40) (42) (57) (56)

Digital output connections

S1 S2D1 D2 -/C +

(40) (42) (57) (56)

(60) (62)

< 20mA < 20mA

LOAD

LOAD

< 40Vdc < 40Vdc

Related topics

• See “Digital output applications” on page 52 for digital output use and configuration

details.

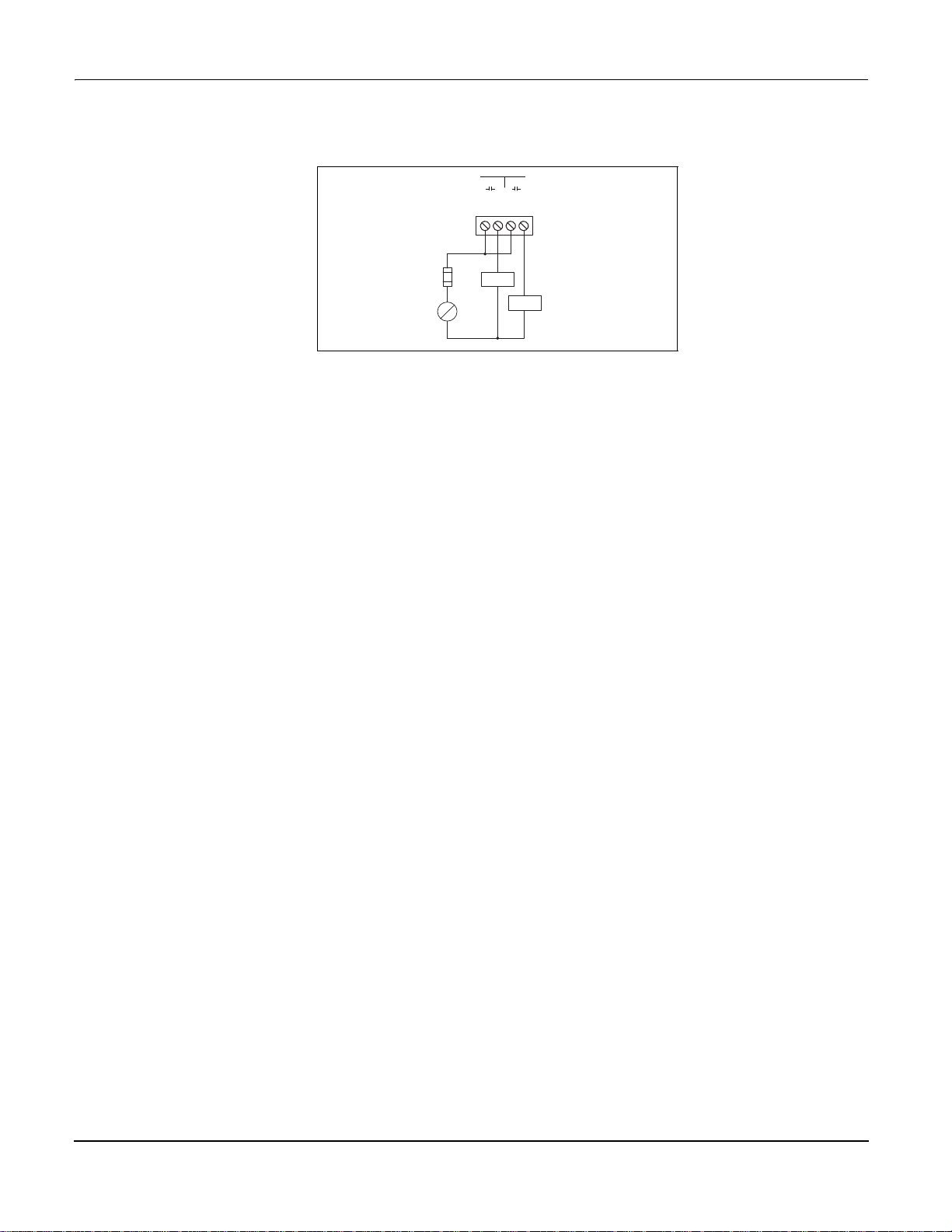

Status inputs

The meter is equipped with two status input ports (S1 and S2). You can configure the

status inputs for use in status monitoring applications.

Relay outputs

The meter’s status inputs require an external voltage source to detect the status input’s

on/off state. The meter detects an ON state if the external voltage appearing at the status

input is within its operating range.

The external voltage can be derived from either the whetting output provided by the meter

or by a voltage source up to 36 V DC external to the meter.

Status input connections

The meter is equipped with two Form A mechanical relay output ports (Relay 1 and Relay

2). Relay outputs can be configured to be used switching applications, for example, to

provide on/off control signals for switching capacitor banks, generators, and other

external devices and equipment.

© 2014 Schneider Electric All Rights Reserved 29

PowerLogic™ PM5300 series user guide Chapter 3—Hardware Reference

LOAD

LOAD

30 Vdc, 5A

250 Vac, 8A Cos

=1

250 Vac, 6A Cos

=0.4

*

RELAY 1 RELAY 2

(70)(71)(73)(74)

NO NO

~

=

Relay output connections

* The overcurrent protective device must be rated for the short-circuit current at the connection point.

© 2014 Schneider Electric All Rights Reserved30

PowerLogic™ PM5300 series user guide Chapter 4—Front panel display and meter setup

B

A

C

G

E

F

D

C

B

Chapter 4—Front panel display and meter setup

The front panel display lets you use the meter to perform various tasks such as setting

up the meter, displaying data screens, acknowledging alarms, or performing resets.

Parts of the display

A Navigation / menu selection buttons

B Heartbeat / communications LED (green)

C Alarm / energy pulsing LED (orange)

D Navigation symbols or menu options

E Right notification area

F Screen title

G Left notification area

LED indicators

The meter has two LED indicators on the front panel.

Front panel LEDs

Heartbeat / communications LED

The (green) heartbeat / communications LED blinks at a slow, steady rate to indicate

the meter is operational. The LED flashes at a variable, faster rate when the meter is

communicating over a Modbus serial communications port.

You cannot configure this LED for other purposes.

NOTE: A heartbeat LED that remains lit and does not blink (or flash) indicates a

possible hardware problem. Please contact Technical Support.

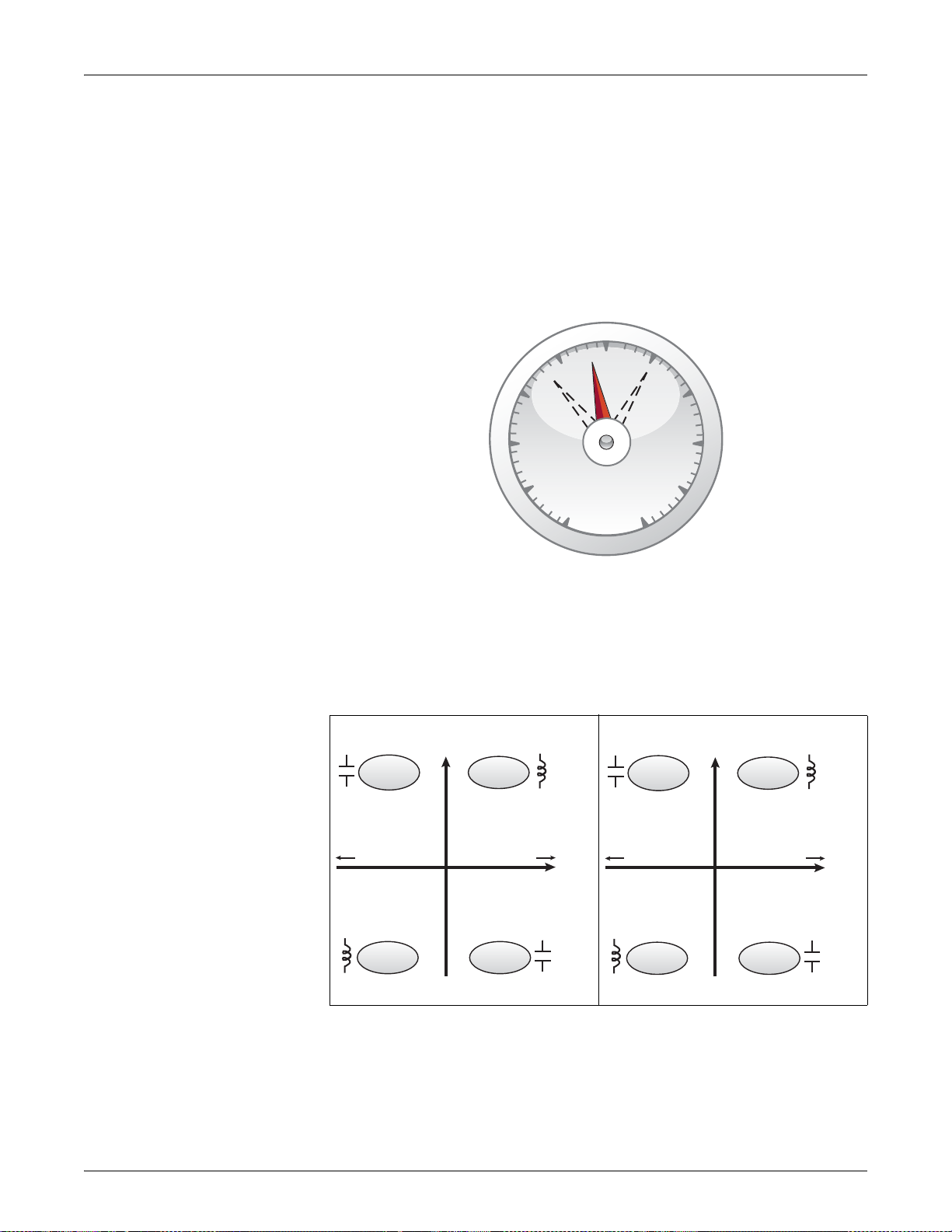

Alarm / energy pulsing LED modes

The (orange) alarm / energy pulsing LED can be configured for alarm notification or

energy pulsing.

Alarm / energy pulsing LED (orange)

Heartbeat / communications LED (green)

• When configured for alarm notification, this LED flashes when a high, medium or

low priority alarm is active. This provides a visual indication of an active alarm

condition, or an inactive but unacknowledged high priority alarm.

• When configured for energy pulsing, this LED flashes at a rate proportional to the

amount of energy consumed. This is typically used to verify the meter’s accuracy.

© 2014 Schneider Electric All Rights Reserved 31

Chapter 4—Front panel display and meter setup PowerLogic™ PM5300 series user guide

Maint

Amps

Volts

PF

Hz

Clock

Energy

Unbal

MnMx

Alarm

I/O

Timer

THD Harm

Power

Maint

I

U-V PQS PF

F

Clock

E

Unbal

MnMx

Alarm

I/O

Timer

THD Harm

Related topics

• See “Setting up the alarm / energy pulsing LED” on page 42 for details on using the

front panel to switch the LED mode for alarming or energy pulsing applications.

• See “Alarm / energy pulsing LED setup” on page 60 for details on using ION Setup

to switch the LED mode for alarming or energy pulsing applications.

• See “Alarm Priorities” on page 66 for a detailed description on the alarm / energy

pulsing LED’s behavior when it is configured for alarm notification.

Notification icons

To alert you about meter state or events, notification icons appear at the top left or top

right corner of the display screen.

Notification icons

Icon Description

The wrench icon indicates that the power meter requires maintenance. See “Maintenance

and Troubleshooting” on page 103.

The alarm icon indicates an alarm condition has occurred. See “About Alarms” on page 63

and “Alarm Priorities” on page 66.

The blinking heartbeat icon indicates that the power meter is in normal operating condition.

Meter screen menus

All meter screens are grouped logically, according to their function. You can access any

available meter screen by first selecting the Level 1 (top level) screen that contains it.

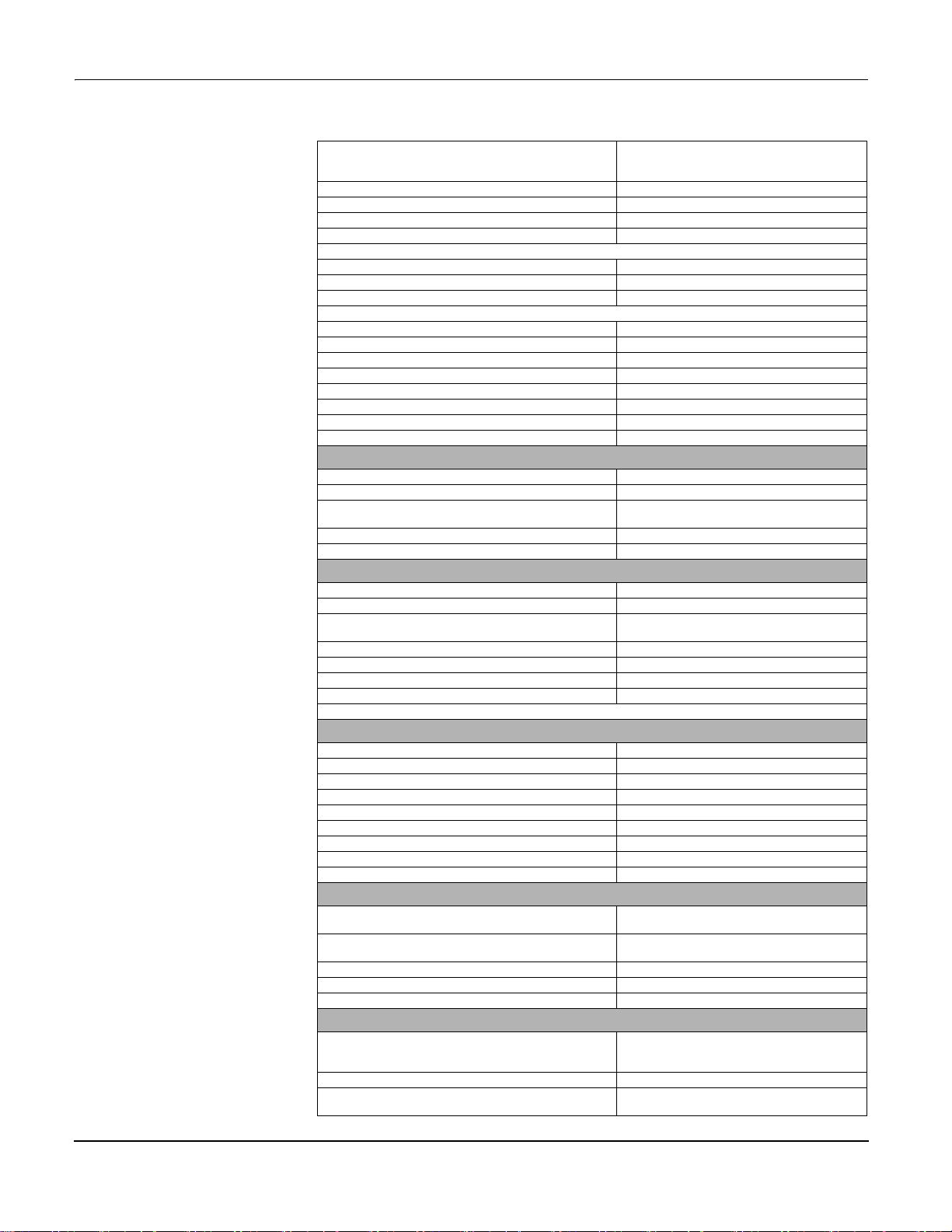

Level 1 screen menus - IEEE display mode

Level 1 screen menus - IEC display mode

Use the buttons to navigate the different meter screens. The navigation symbols and

their functions are explained below:

Navigation symbols

Symbol Description

Scroll right and display more menu items

Exit screen and go up one level

Move cursor down the list of options or display more items below

Move cursor up the list of options or display more items above

Move cursor one character to the left

Increase the highlighted value or show the next item in the list

Show the previous item in the list

Front panel buttons

When you reach the last screen, press again to cycle through the screen menus.

32 © 2014 Schneider Electric All Rights Reserved

PowerLogic™ PM5300 series user guide Chapter 4—Front panel display and meter setup

R1

R2

S1

S2

Volts (U-V)

Maint

Reset

Setup Meter

Comm

Alarm

I/O

HMI

Clock

Basic

Advan

Dmd

Tar i ff

1-Sec Unary

Dig

LED SIn

DOut

Relay

Displ

Region

Pass

Amps

(I)

Dmd Iavg

Volt s

(U-V)

V L-L (U)

V L-N (V)

Power (PQS)

Phase

Power

(PQS)

Dmd

Wd (Pd)

VARd (Qd)

VAd (Sd)

Wh

VAh

Energy

(E)

VAR h

Active (P)

Reac (Q)

Appr (S)

T1

T2

T3

T4

True

Disp

PF

Hz

(F)

THD

thd

THD

Tariff

Unbal

Amps (I)

Power (PQS)

Unbal

MnMx

PF

Hz (F)

THD

Hist

Active

Count

Alarm

Unack

Diag

Info

Clock

DOut

I/O

Oper

Load

Timer

Level 1 Level 2 Level 3

Pk DT

V L-L (U)

V L-N (V)

Harm

Amps (I)

Amps (I)

V L-L (U)

V L-N (V)

Amps (I)

V L-L (U)

V L-N (V)

(% volts line-to-line, volts line-to-neutral, )amps

(frequency, average voltage, average current, power factor)

V L-L (U)

V L-N (V)

Active (P)

Reac (Q)

Appr (S)

True

Disp

THD

Amps (I)

V L-L (U)

V L-N (V)

Amps (I)

Relay

Wd (Pd)

Pk DT

Pk DT

Pk DT

VARd (Qd)

VAd (Sd)

TDD

thd

Amps (I)

V L-L (U)

V L-N (V)

Amps (I)

V L-L (U)

V L-N (V)

S In

D1

D2

Meter

Cl Pwr

PhAng

Rec

Del

Rec

Del

Rec

Del

Rec

Del

Menu tree

© 2014 Schneider Electric All Rights Reserved 33

This summarizes the meter screens (IEEE menus shown, with the corresponding IEC

menus in parentheses — see “Setting up regional settings” on page 39).

PM5300 display screen menus

Chapter 4—Front panel display and meter setup PowerLogic™ PM5300 series user guide

NOTICE

Meter setup screen navigation

The meter’s front panel buttons and display screen allow you to navigate and configure

the meter’s setup parameters. The following illustration shows one of the meter setup

screens.

Basic setup screen

In this example, the down arrow ( ) indicates there are more parameters below the

selected option ( ). Press the down arrow button to display additional parameters. The

down arrow disappears when the last item in the list is selected, and there are no more

parameters to display.

Front panel meter setup

Meter configuration can be performed directly through the front panel buttons or

remotely through software. This section contains instructions on setting up the meter

using the front panel.

Related topics

• See “Remote Meter Setup” on page 44 for remote meter setup details.

Configuring the basic setup parameters

Proper configuration of the meter’s basic setup parameters is essential for accurate

measurement and calculations. Use the Basic Setup screen to define the electrical

power system that the meter is monitoring.

UNINTENDED EQUIPMENT OPERATION

After modifying any basic setup parameter:

• Verify all standard alarms settings are correct and make adjustments as necessary.

• Re-enable all configured alarms.

Failure to follow these instructions can result in incorrect alarm func tions.

If standard (1-sec) alarms have been configured and you make subsequent changes to

the meter’s basic setup, all alarms are disabled to prevent undesired alarm operation.

After saving the changes, confirm all configured standard alarm settings are still valid,

reconfigure them as required, and re-enable the alarms.

34 © 2014 Schneider Electric All Rights Reserved

PowerLogic™ PM5300 series user guide Chapter 4—Front panel display and meter setup

Maint

Reset

Setup

Comm

Meter Basic

Basic setup menu tree

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0000”), then press OK.

3. Navigate to Meter > Basic.

4. Move the cursor to point to the parameter you want to modify, then press Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

Basic setup parameters

Parameter Values Description

Select the power system type (power transformer) the meter is wired to.

1PH2W LN Single-phase 2-wire line-to-neutral

1PH2W LL Single-phase 2-wire line-to-line

1PH3W LL with N Single-phase 3-wire line-to-line with neutral

3PH3W Dlt Ungnd 3-phase 3-wire ungrounded delta

3PH3W Dlt Crnr Gnd 3-phase 3-wire corner grounded delta

Power System

VT Connect

VT Primary (V) 1 to 1000000 Enter the size of the VT primary, in Volts.

VT Secondary (V) 100, 110, 115, 120 Select the size of the VT secondary, in Volts

CT on Terminal

CT Primary (A) 1 to 32767 Enter the size of the CT primary, in Amps.

CT Secondary (A) 1, 5 Select the size of the CT secondary, in Amps.

Sys Frequency (Hz) 50, 60

Phase Rotation ABC, CBA Select the phase rotation of the 3-phase system.

3PH3W Wye Ungnd 3-phase 3-wire ungrounded wye

3PH3W Wye Gnd 3-phase 3-wire grounded wye

3PH3W Wye Res Gnd 3-phase 3-wire resistance-grounded wye

3PH4W Opn Dlt Ctr Tp 3-phase 4-wire center-tapped open delta

3PH4W Dlt Ctr Tp 3-phase 4-wire center-tapped delta

3PH4W Wye Ungnd 3-phase 4-wire ungrounded wye

3PH4W Wye Gnd 3-phase 4-wire grounded wye

3PH4W Wye Res Gnd 3-phase 4-wire resistance-grounded wye

Select how many voltage transformers (VT) are connected to the electrical power

system.

Direct Con Direct connect; no VTs used

2VT 2 voltage transformers

3VT 3 voltage transformers

Define how many current transformers (CT) are connected to the meter, and

which terminals they are connected to.

I1 1 CT connected to I1 terminal

I2 1 CT connected to I2 terminal

I3 1 CT connected to I3 terminal

I1 I2 2 CT connected to I1, I2 terminals

I1 I3 2 CT connected to I1, I3 terminals

I2 I3 2 CT connected to I2, I3 terminals

I1 I2 I3 3 CT connected to I1, I2, I3 terminals

Select the frequency of the electrical power

system, in Hz.

7. Press to exit. Press Yes to save your changes.

© 2014 Schneider Electric All Rights Reserved 35

Chapter 4—Front panel display and meter setup PowerLogic™ PM5300 series user guide

Related topics

• See “Configuring the basic setup parameters” on page 34 for meter basic setup

instructions.

Communications setup

After wiring the meter’s serial and Ethernet communications ports, you can configure

these ports so you can connect to the meter remotely and use device configuration

software such as ION Setup to configure the meter.

Based on the reference model, the meter is equipped with the following communication

ports:

Communication ports

Reference Models Communication

PM5310 RS-485

PM5320 Ethernet

PM5330 RS-485

PM5331 RS-485

PM5340 Ethernet

PM5341 Ethernet

Setting up serial communications

The Serial Port setup screen allows you to configure the meter’s RS-485

communications port so you can use software to access the meter’s data or configure

the meter remotely.

Serial communications setup menu tree

Maint

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0000”), then press OK.

3. Press Comm.

4. Move the cursor to point to the parameter you want to modify, then press Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

Reset

Setup Meter

Comm

36 © 2014 Schneider Electric All Rights Reserved

PowerLogic™ PM5300 series user guide Chapter 4—Front panel display and meter setup

Maint

Reset

Setup Meter

Comm

Communications setup parameters

Parameter Values Description

Protocol Modbus

Address 1 to 247

Baud Rate 9600, 19200, 38400

Parity Even, Odd, None

The communications format used to transmit data. The

protocol must be the same for all devices in a

communications loop.

Set the address for this device. The address must be

unique for each device in a communications loop. For

Jbus protocol, set the device ID to 255.

Select the speed for data transmission. The baud rate

must be the same for all devices in a communications

loop.

Select None if the parity bit is not used. The parity

setting must be the same for all devices in a

communications loop.

7. Press to exit. Press Yes to save your changes.

Setting up Ethernet communications

The Ethernet Port setup screen allows you to assign the meter a unique IP address so

you can use software to access the meter’s data or configure the meter remotely

through the Ethernet port. Before configuring the Ethernet parameters, make sure you

obtain your meter’s IP address information from your network administrator or IT

department.

Ethernet communications setup menu tree

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0000”), then press OK.

3. Press Comm.

4. Move the cursor to point to the parameter you want to modify, then press Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

© 2014 Schneider Electric All Rights Reserved 37

Chapter 4—Front panel display and meter setup PowerLogic™ PM5300 series user guide

Maint

Reset

Meter

Comm

Alarm

I/O

Clock

Region

Pass

Displ

Setup

HMI

Ethernet port settings

Parameter Values Description

IP Address

Subnet

Gateway The Ethernet IP gatway address of your network.

HTTP Server Disabled

Device Name N/A This parameter is read-only for reference purposes.

IP Method

Contact your local

network administrator

for parameter values.

DHCP, BOOTP,

Stored, Default

The internet protocol address of your device.

The Ethernet IP subnetwork address of your

network (subnet mask).

Controls whether your device’s webserver and

webpages are active or not.

This controls the network protocol for your device

(what the meter uses to obtain its IP address).

• DHCP: Dynamic Host Configuration Protocol

• BOOTP: Bootstrap Protocol

• Stored: Use the static value programmed in the

IP Address setup register

• Default: Use 85.16 as the first two values of the

IP address, then convert the last two

hexadecimal values of the MAC address to

decimal and use this as the last two values of

the IP address.

Example: MAC address = 00:80:67:82:B8:C8

Default IP = 85.16.184.200

7. Press to exit. Press Yes to save your changes.

HMI settings

Setting up the display

The HMI (human-machine interface) setup screens allow you to:

• control the general appearance and behavior of the display screens,

• change the regional settings, or

• change the meter passwords.

You can change the display screen’s contrast or the screen backlight and timeout

settings.

Display setup menu tree

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0000”), then press OK.

3. Navigate to HMI > Displ.

4. Move the cursor to point to the parameter you want to modify, then press Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

38 © 2014 Schneider Electric All Rights Reserved

PowerLogic™ PM5300 series user guide Chapter 4—Front panel display and meter setup

Display setup parameters

Parameter Values Description

Contrast 1 - 9

Backlight Timeout (min) 0 - 60

Screen Timeout (min) 0 - 60

Increase or decrease the value to increase or

decrease the display contrast.

Set how long (in minutes) before the backlight

turns off after a period of inactivity. Setting this to

“0” disables the backlight timeout feature (i.e.,

backlight is always on).

Set how long (in minutes) before the screen turns

off after a period of inactivity. Setting this to “0”

disables the screen timeout feature (i.e., display is

always on).

7. Press to exit. Press Yes to save your changes.

Setting up regional settings

You can change the regional settings to localize the meter screens and display data in

a different language, using local standards and conventions.

NOTE: In order to display a different language other than those listed in the Language

setup parameter, you need to download the appropriate language file to the meter

using the appropriate firmware upgrade tool such as DLF3000. See “Downloading

Firmware” on page 104.

Regional settings menu tree

Maint

Reset

Setup

Meter

Comm

Alarm

I/O

HMI

Clock

Displ

Region

Pass

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0000”), then press OK.

3. Navigate to HMI > Region.