Schneider Electric LXM32M User Manual

LXM32M

Modbus-TCP module

Fieldbus manual

V1.01, 01.2012

ETH

0198441113843, V1.01, 01.2012

www.schneider-electric.com

Important information LXM32M

Important information

This manual is part of the product.

Carefully read this manual and observe all instructions.

Keep this manual for future reference.

Hand this manual and all other pertinent product documentation over

to all users of the product.

Carefully read and observe all safety instructions and the chapter

"Before you begin - safety information".

Some products are not available in all countries.

For information on the availability of products, please consult the catalog.

Subject to technical modifications without notice.

All details provided are technical data which do not constitute warranted qualities.

Most of the product designations are registered trademarks of their

respective owners, even if this is not explicitly indicated.

2 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M Table of contents

Table of contents

Important information 2

Table of contents 3

About this manual 7

Further reading 8

1 Introduction 9

2 Before you begin - safety information 11

2.1 Qualification of personnel 11

2.2 Intended use 11

2.3 Hazard categories 12

2.4 Basic information 13

2.5 Standards and terminology 14

3 Basics 15

3.1 Modbus TCP technology 15

3.1.1 Function principle 15

3.1.2 Bus topology 15

3.1.3 Client / server model 16

3.1.4 Network service SNMP 16

3.2 Modbus TCP protocol 17

3.2.1 MBAP header 18

3.3 Modbus TCP communication 19

3.3.1 Connection management 19

3.3.2 Modbus response to a Modbus request 20

3.3.3 Reading and writing parameters 21

3.3.4 I/O scanning to "Drive Profile Lexium" 22

3.3.4.1 I/O scanning Output 23

3.3.4.2 I/O scanning Input 24

3.3.4.3 Parameter channel 26

3.4 Modbus services - "Function Code" 28

3.4.1 "Function Code" 3 (Read Multiple Registers) 28

3.4.2 "Function Code" 8 (Diagnostics) 29

3.4.3 "Function Code" 16 (Write Multiple Registers) 30

3.4.4 "Function Code" 23 (ReadWrite Multiple Registers) 31

3.4.5 "Function Code" 43 (Encapsulated Interface Transport) 32

3.4.6 Examples 33

3.4.6.1 Example of "Function Code" 3 33

3.4.6.2 Example of "Function Code" 16 33

4 Installation 35

0198441113843, V1.01, 01.2012

Modbus-TCP module 3

Table of contents LXM32M

4.1 Installation of the module 35

4.2 Electrical installation 36

5 Commissioning 37

5.1 Commissioning the device 37

5.2 "First Setup" 38

5.2.1 Manual assignment of the network address 39

5.2.2 Assignment of the network address via BOOTP 41

5.2.3 Assignment of the network address via DHCP 42

5.3 Setting the transmission rate 43

5.4 Setting the protocol 43

5.5 Setting the gateway 44

5.6 Master with Word Swap 45

5.7 Setting I/O-Scanning 46

5.7.1 Activating I/O scanning 46

5.7.2 Setting the master for I/O scanning 46

5.7.3 Setting the mapping for I/O scanning 47

5.7.4 Setting communication monitoring for I/O scanning 49

5.8 Setting the web server 49

6 Operation 51

6.1 Operating states 52

6.1.1 Indication of the operating state 52

6.1.2 Changing the operating state 53

6.2 Operating modes 54

6.2.1 Indicating and monitoring the operating mode 54

6.2.2 Starting and changing an operating mode 55

6.2.3 Overview of operating modes 56

6.2.4 Operating mode Jog 57

6.2.5 Operating mode Electronic Gear 58

6.2.6 Operating mode Profile Torque 59

6.2.7 Operating mode Profile Velocity 60

6.2.8 Operating mode Profile Position 61

6.2.9 Operating mode Homing 62

6.2.10 Operating mode Motion Sequence 63

6.3 Extended settings 64

6.3.1 Web server 64

6.3.1.1 Setting the web server 64

6.3.1.2 Accessing the web server 64

6.3.1.3 User interface 65

6.3.2 FTP server 66

6.3.2.1 Accessing the FTP server 66

6.3.2.2 User-specific adaptation of the website 66

6.3.3 FDR service (Fast Device Replacement) 67

7 Diagnostics and troubleshooting 69

7.1 Fieldbus communication error diagnostics 69

4 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M Table of contents

7.2 Status LEDs 70

7.3 Error indication 72

8 Accessories and spare parts 75

8.1 Cables 75

9 Glossary 77

9.1 Units and conversion tables 77

9.1.1 Length 77

9.1.2 Mass 77

9.1.3 Force 77

9.1.4 Power 77

9.1.5 Rotation 78

9.1.6 Torque 78

9.1.7 Moment of inertia 78

9.1.8 Temperature 78

9.1.9 Conductor cross section 78

9.2 Terms and Abbreviations 79

10 Index 81

0198441113843, V1.01, 01.2012

Modbus-TCP module 5

LXM32M

6 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

About this manual

About this manual

This manual applies to the module Modbus TCP for the product

LXM32M, module identification ETH.

The information provided in this manual supplements the product

manual.

Source manuals The latest versions of the manuals can be downloaded from the Inter-

net at:

http://www.schneider-electric.com

Source CAD data For easier engineering, CAD data (EPLAN macros or drawings) are

available for download from the Internet at:

http://www.schneider-electric.com

Corrections and suggestions We always try to further optimize our manuals. We welcome your sug-

gestions and corrections.

Please get in touch with us by e-mail:

techcomm@schneider-electric.com.

Work steps If work steps must be performed consecutively, this sequence of steps

is represented as follows:

■

Special prerequisites for the following work steps

▶

Step 1

◁

Specific response to this work step

▶

Step 2

If a response to a work step is indicated, this allows you to verify that

the work step has been performed correctly.

Unless otherwise stated, the individual steps must be performed in the

specified sequence.

Making work easier Information on making work easier is highlighted by this symbol:

Sections highlighted this way provide supplementary information on

making work easier.

Parameters In text sections, parameters are shown with the parameter name, for

example _IO_act. A list of the parameters can be found in the product manual in the chapter Parameters.

SI units SI units are the original values. Converted units are shown in brackets

behind the original value; they may be rounded.

Example:

Minimum conductor cross section: 1.5 mm2 (AWG 14)

Inverted signals Inverted signals are represented by an overline, for example STO_A or

STO_B.

Glossary Explanations of special technical terms and abbreviations.

0198441113843, V1.01, 01.2012

Modbus-TCP module 7

About this manual

Further reading

User Association http://www.modbus.org

LXM32M

Index List of keywords with references to the corresponding page numbers.

8 Modbus-TCP module

0198441113843, V1.01, 01.2012

L

N

LXM32M

1 Introduction

1 Introduction

1

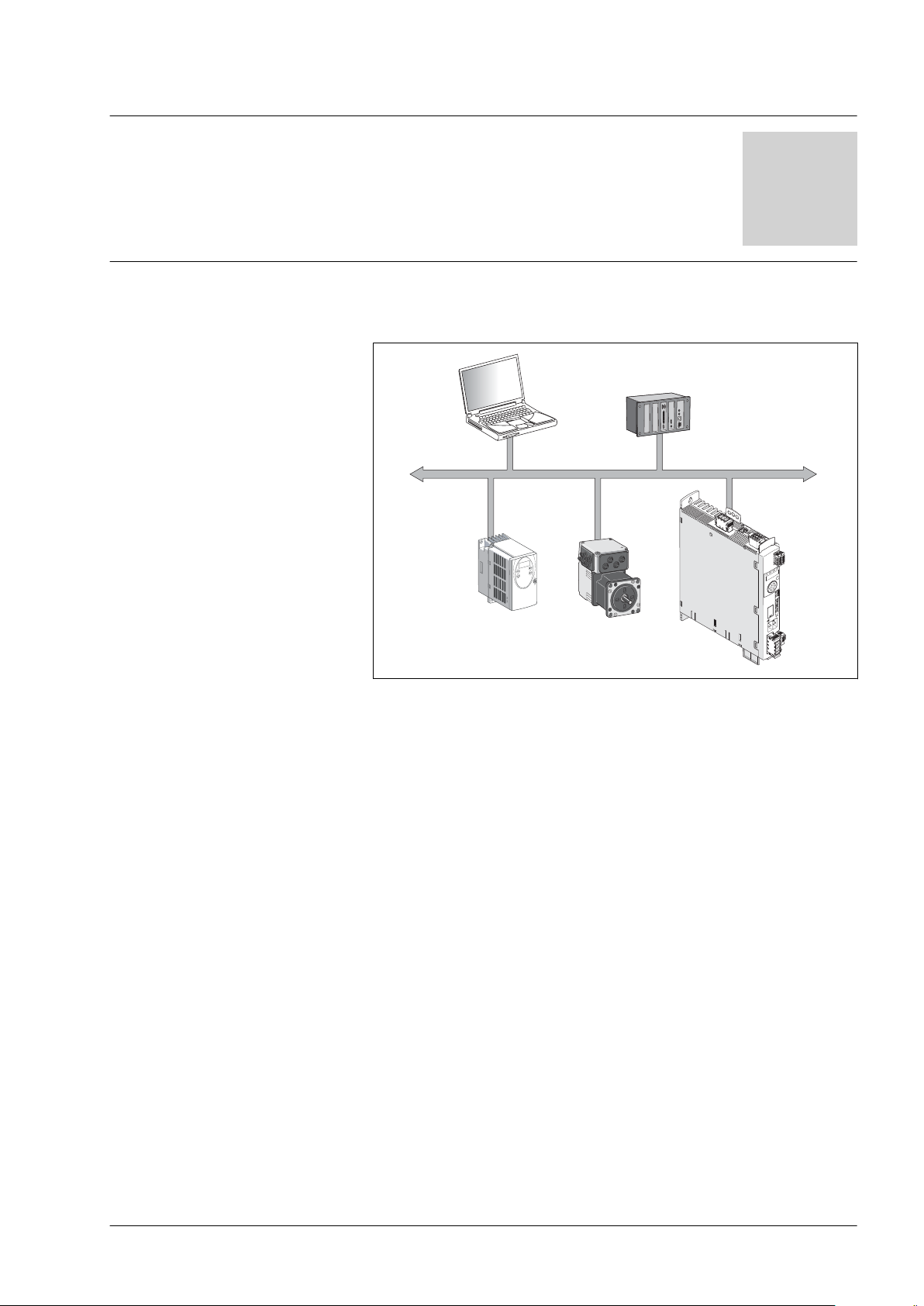

Different products with a Modbus TCP interface can be operated in

the same fieldbus. Modbus TCP provides a common basis for interchanging commands and data between the network devices.

Figure 1: Fieldbus products on the network

Features The product supports the following functions via Modbus TCP:

•

Automatic IP address assignment via BOOTP or DHCP

•

Automatically obtaining configuration data via the FDR (Fast

Device Replacement) service

•

Commissioning via commissioning software

•

Diagnostics and configuration via integrated web server

•

Reading and writing parameters

•

Controlling the drive

•

Monitoring inputs and outputs

•

Diagnostics and monitoring functions

0198441113843, V1.01, 01.2012

Modbus-TCP module 9

1 Introduction

LXM32M

10 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

2 Before you begin - safety information

2 Before you begin - safety information

2.1 Qualification of personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and all other pertinent product documentation are authorized to work on and with this product. In addition,

these persons must have received safety training to recognize and

avoid hazards involved. These persons must have sufficient technical

training, knowledge and experience and be able to foresee and detect

potential hazards that may be caused by using the product, by changing the settings and by the mechanical, electrical and electronic equipment of the entire system in which the product is used.

All persons working on and with the product must be fully familiar with

all applicable standards, directives, and accident prevention regulations when performing such work.

2

2.2

Intended use

The functions described in this manual are only intended for use with

the basic product; you must read and understand the appropriate

product manual.

The product may only be used in compliance with all applicable safety

regulations and directives, the specified requirements and the technical data.

Prior to using the product, you must perform a risk assessment in view

of the planned application. Based on the results, the appropriate

safety measures must be implemented.

Since the product is used as a component in an entire system, you

must ensure the safety of persons by means of the design of this

entire system (for example, machine design).

Operate the product only with the specified cables and accessories.

Use only genuine accessories and spare parts.

Any use other than the use explicitly permitted is prohibited and can

result in hazards.

Electrical equipment should be installed, operated, serviced, and

maintained only by qualified personnel.

The product must NEVER be operated in explosive atmospheres

(hazardous locations, Ex areas).

0198441113843, V1.01, 01.2012

Modbus-TCP module 11

2 Before you begin - safety information

2.3 Hazard categories

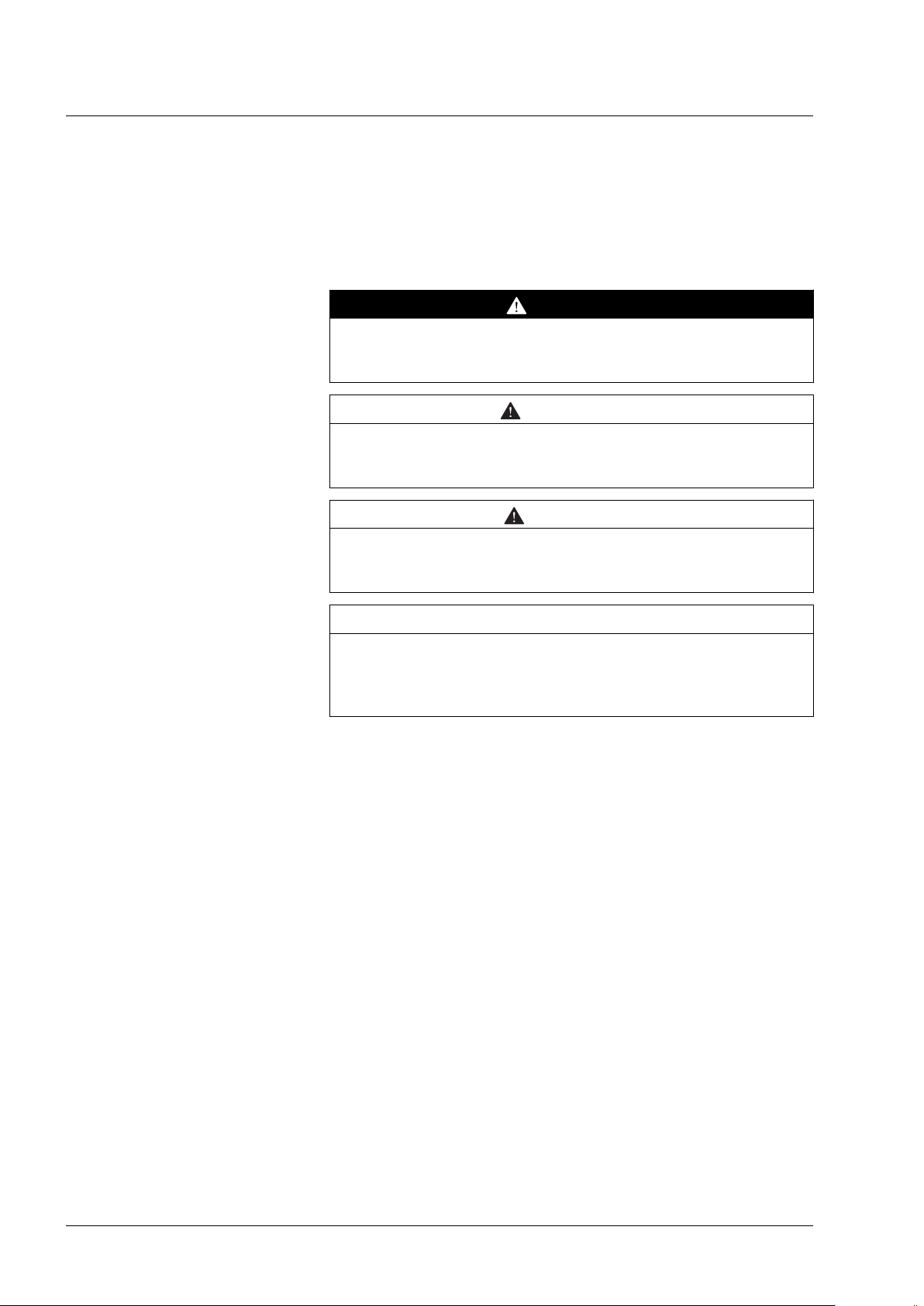

Safety instructions to the user are highlighted by safety alert symbols

in the manual. In addition, labels with symbols and/or instructions are

attached to the product that alert you to potential hazards.

Depending on the seriousness of the hazard, the safety instructions

are divided into 4 hazard categories.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not

avoided, can result in death, serious injury, or equipment damage.

CAUTION indicates a potentially hazardous situation, which, if not

avoided, can result in injury or equipment damage.

LXM32M

DANGER

WARNING

CAUTION

CAUTION

CAUTION used without the safety alert symbol, is used to address

practices not related to personal injury (e.g. can result in equipment

damage).

12 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

2.4 Basic information

2 Before you begin - safety information

WARNING

LOSS OF CONTROL

•

The designer of any control scheme must consider the potential

failure modes of control paths and, for certain critical functions,

provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop,

overtravel stop, power outage and restart.

•

Separate or redundant control paths must be provided for critical

functions.

•

System control paths may include communication links. Consideration must be given to the implication of unanticipated transmission delays or failures of the link.

•

Observe all accident prevention regulations and local safety

guidelines.

•

Each implementation of the product must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death or serious injury.

1)

1)

For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), “Safety

Guidelines for the Application, Installation, and Maintenance of Solid State Control”

and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide

for Selection, Installation and Operation of Adjustable-Speed Drive Systems”.

0198441113843, V1.01, 01.2012

Modbus-TCP module 13

2 Before you begin - safety information

2.5 Standards and terminology

Technical terms, terminology and the corresponding descriptions in

this manual are intended to use the terms or definitions of the pertinent standards.

In the area of drive systems, this includes, but is not limited to, terms

such as "safety function", "safe state", "fault", "fault reset", "failure",

"error", "error message", "warning", "warning message", etc.

Among others, these standards include:

•

IEC 61800 series: "Adjustable speed electrical power drive systems"

•

IEC 61158 series: "Industrial communication networks - Fieldbus

specifications"

•

IEC 61784 series: "Industrial communication networks - Profiles"

•

IEC 61508 series: "Functional safety of electrical/electronic/

programmable electronic safety-related systems"

Also see the glossary at the end of this manual.

LXM32M

14 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

3 Basics

3.1 Modbus TCP technology

3.1.1 Function principle

Modbus TCP is an Ethernet fieldbus. Modbus TCP describes the

transmission of the Modbus protocol via the Ethernet interface and the

TCP/IP transport and network layers.

The Modbus TCP client (master) connects to the Modbus TCP server

(slave). Once the connection is established, the client sends Modbus

requests to the server. These requests are processed by the server.

The result is returned to the client as a Modbus response.

3 Basics

3

3.1.2 Bus topology

The Modbus TCP services are identical to the Modbus RTU services.

Star and tree topologies can be used. It is possible to use hubs or

switches. In the case of high bus loads with many devices, it is recommended to use a switches.

The maximum length of a segment is 100 m. A segment consists of

devices and hubs. A network can be subdivided into several segments

by means of gateways or switches. Short cables and a star topology

are recommended to achieve a fast bus cycle.

The transmission rate is 10 or 100 MBit/s in half-duplex mode. If

switches are used, transmission is also possible in full duplex mode.

0198441113843, V1.01, 01.2012

Modbus-TCP module 15

Modbus Client

Modbus Server

Request Indication

Response

Confirmation

3 Basics

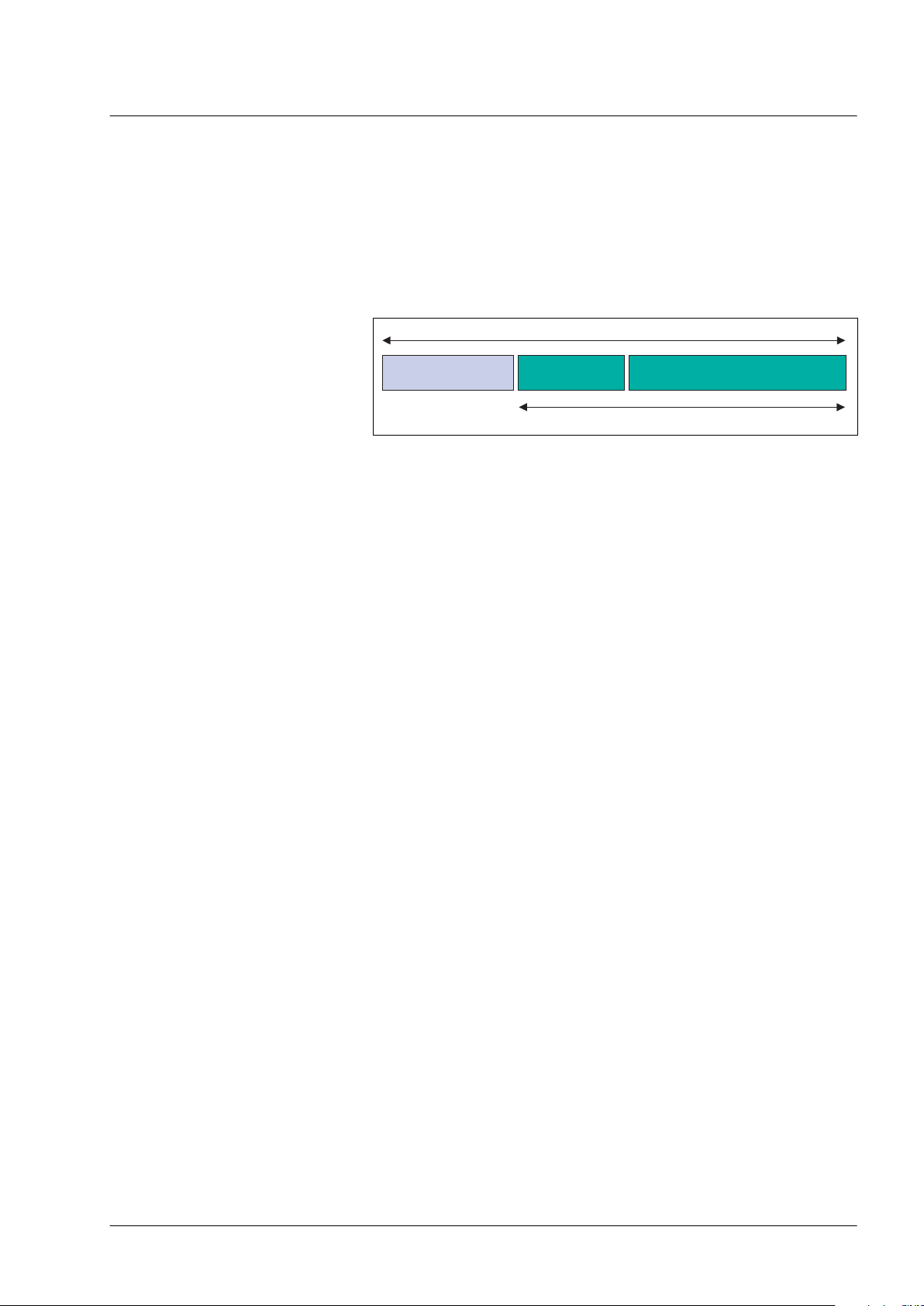

3.1.3 Client / server model

LXM32M

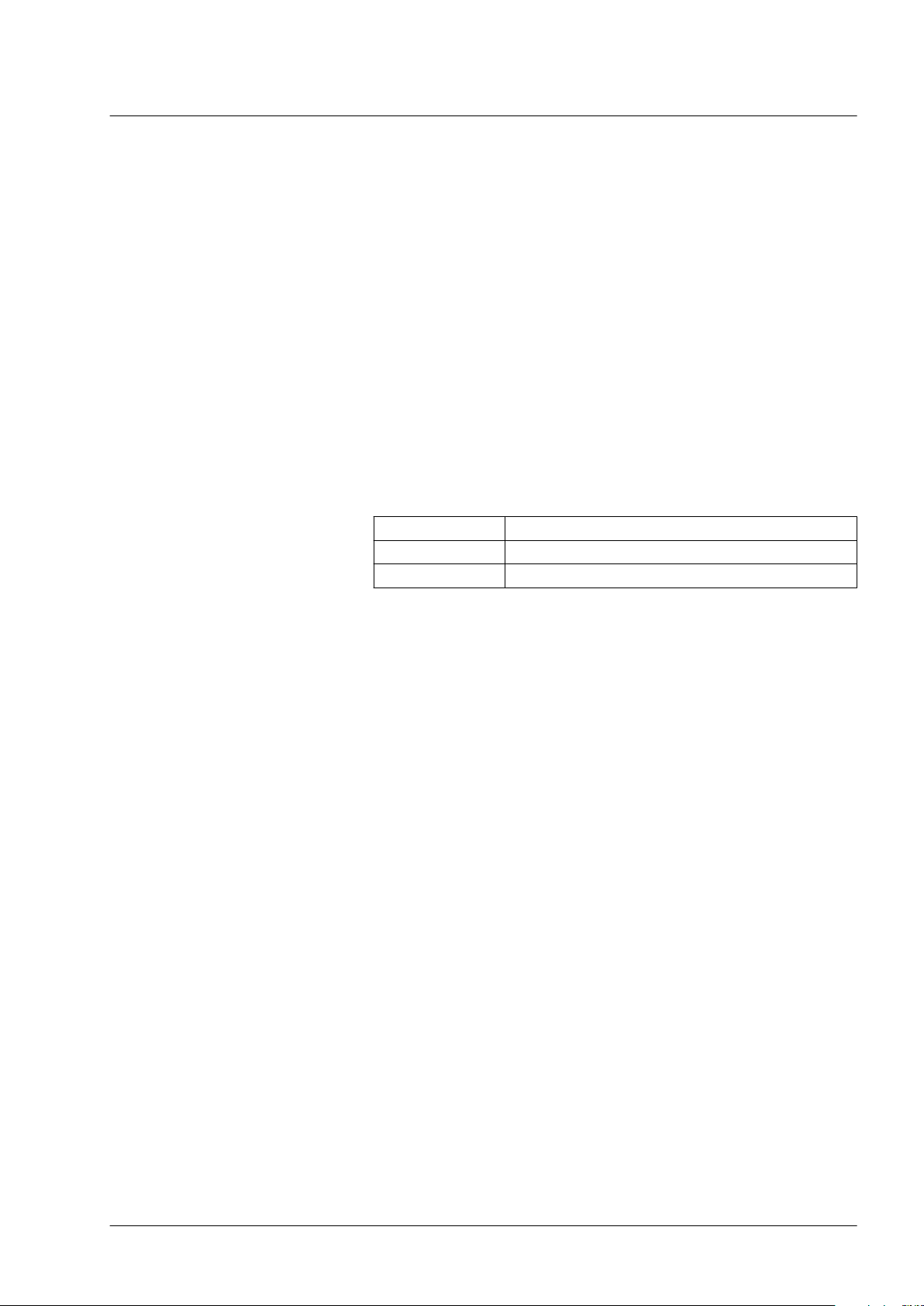

Figure 2: Client / server model

The Modbus messaging service implements client/server communication between devices connected by means of a TCP/IP network. Modbus TCP does not use an object dictionary.

The client/server model is based on 4 types of messages:

•

Request: Message sent by the client to initiate a transaction.

•

Indication: Request as received by the server.

•

Response: Response message to the request sent by the server.

•

Confirmation: Response as received by the client.

A communication cycle consists of the request from the client (request

from the fieldbus master) and a response from the server (response

from the fieldbus slave). Modbus request and Modbus response have

the same structure. If an error occurs on receipt of the Modbus

request or if the slave cannot execute the action, the slave sends an

error message in the Modbus response.

3.1.4 Network service SNMP

SNMP agent ConneXview The product supports SNMP version 1.0. An SNMP agent must be

The product analyzes the Modus requests received. Depending on the

Modbus request, the product triggers actions or provides requested

data.

The Internet community has developed the SNMP standard "Simple

Network Management Protocol" to support the management of different network devices by means of a single system.

The Network Management System can exchange data with SNMP

devices. The tasks of the network management system comprise

monitoring, control and configuration of network components as well

as error detection and error messaging.

used to monitor a network with SNMP. Schneider Electric offers the

tool ConneXview for such purposes.

16 Modbus-TCP module

0198441113843, V1.01, 01.2012

Function code DataMBAP Header

MODBUS PDU

MODBUS TCP/IP ADU

LXM32M

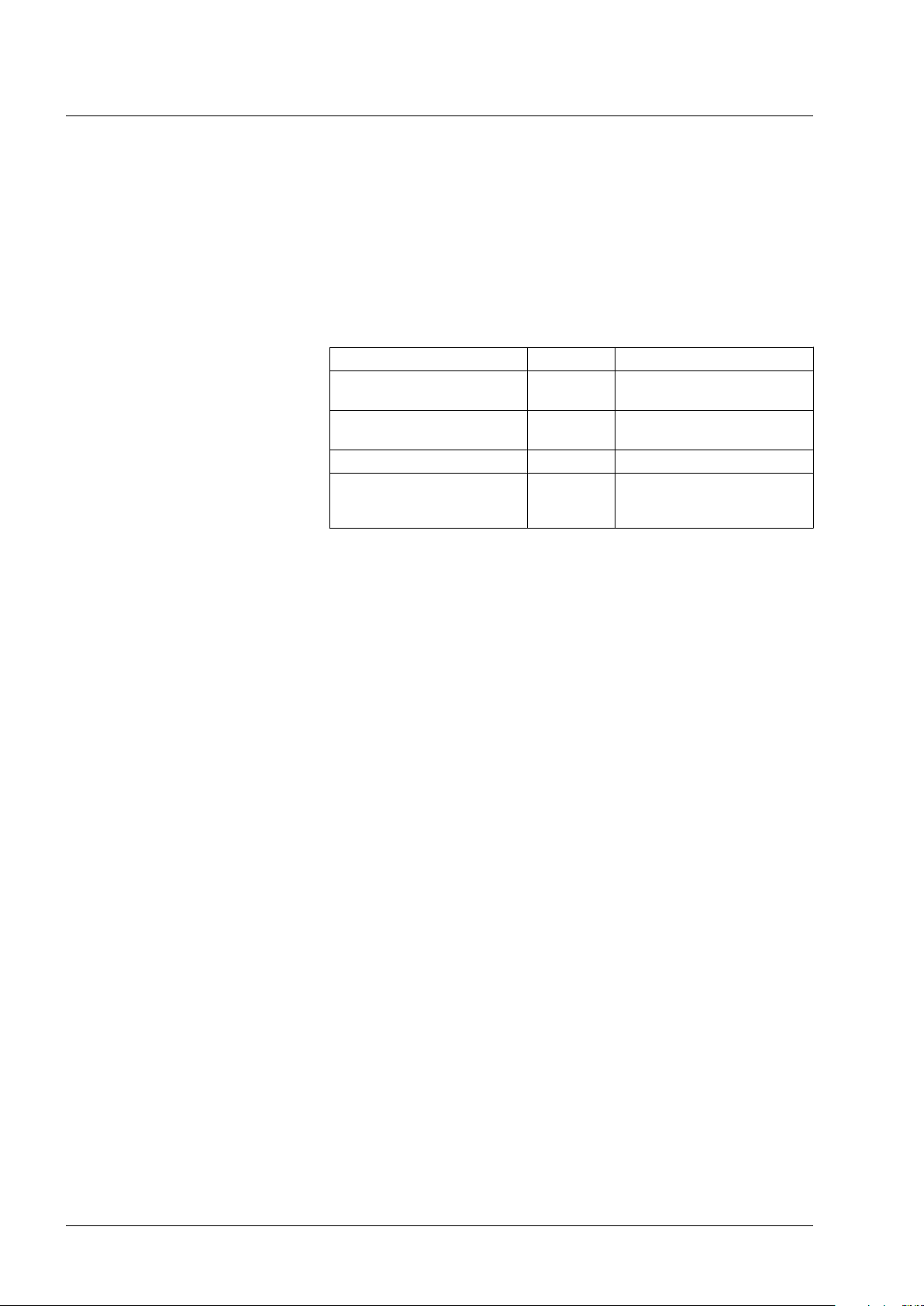

3.2 Modbus TCP protocol

The Modbus protocol defines a so-called Modbus PDU (Protocol Data

Unit) which is independent of the underlying communication layers.

This Modbus PDU consists of the fields "Function Code" and "Data".

Depending on the mapping to the different network protocols, the

Modbus PDU is extended by additional fields in the so-called Modbus

ADU (Application Data Unit). The Modbus PDU and the Modbus ADU

constitute the Modbus message, also referred to as "Frame".

Figure 3: Structure of a Modbus message

The "Function Code" of a message specified the Modbus service to be

triggered. The "Data" field can contain additional information, depending on the "Function Code".

3 Basics

Due to the encapsulation of "Function Code" and "Data" in the Modbus PDU, the Modbus services and the object model can be the same

in the case of all Modbus versions.

In the case of a "Function Code" for which the "Data" field in the Modbus PDU has a fixed length, the "Function Code" is sufficient.

In the case of a "Function Code" for which the "Data" field in the Modbus request or the Modbus response has a variable amount of data,

the "Data" field contains a byte counter.

The maximum size of a Modbus ADU is 260 bytes. The size of an

embedded Modbus PDU is 253 bytes.

NOTE: The fields are encoded in Big Endian format (highest-value

byte first).

0198441113843, V1.01, 01.2012

Modbus-TCP module 17

3 Basics

3.2.1 MBAP header

LXM32M

The MBAP header contains the information allowing the recipient to

uniquely identify a message. This is even possible if a message is split

into several packets for transmission.

Explicit and implicit length rules as well as the use of a CRC-32 error

check code (on Ethernet) results in an infinitesimal chance of undetected corruption to a request or response message.

Design The MBAP header has a length of 7 bytes and contains the following

fields:

Field Length Description

Transaction Identifier 2 bytes Identification of a Modbus

request or Modbus response.

Protocol Identifier 2 bytes Value 0 means Modbus proto-

col.

Length 2 bytes Number of bytes to follow.

Unit Identifier 1 byte Identification of a slave con-

nected to another bus via a

serial line.

•

Transaction Identifier

The field "Transaction Identifier" is used for "Pairing". The server

copies the "Transaction Identifier" of the Modbus request to the

Modbus response.

•

Protocol Identifier

The field "Protocol Identifier" is used to identify the protocol. The

Modbus protocol is identified by the value 0.

•

Length

The "Length" field is a byte counter for the following fields ("Unit

Identifier", "Function Code" and "Data").

•

Unit Identifier

The field "Unit Identifier" is used to identify the server in the slave.

18 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

3.3 Modbus TCP communication

3.3.1 Connection management

Establishing of a connection The Modbus TCP server allows for TCP connections via the default

port 502. A client can establish a new connection via this port. If the

client is to exchange data with a remote server, a new client connection via remote port 502 must be established.

Modbus data transfer A Modbus request is sent via a suitable, open connection. This TCP

connection is found using the IP address of the remote device. The

connection remains open for all Modbus communication. Up to 8

simultaneous connections are possible.

As described in the next chapter, a Modbus client can initialize several

Modbus transactions without having to wait for the previous transaction to be finished.

Closing a connection After the Modbus communication between the client and a server is

finished, the client causes the connection used to be closed.

The server does not close the connection under normal circumstances.

3 Basics

However, when errors occur and in special cases, the server closes

the connection, for example:

•

Communication errors

•

Communication inactivity

•

Maximum number of connections reached

The product can manage up to 8 TCP connections. If an attempt is

made to establish a further connection beyond this maximum, the oldest unused connection is closed. If it is impossible to close the oldest

unused connection, the new connection is refused.

0198441113843, V1.01, 01.2012

Modbus-TCP module 19

3 Basics

3.3.2 Modbus response to a Modbus request

The Modus server generates a Modbus response after having processed a Modbus request.

Depending on the type of processing, two types of Modbus responses

are possible:

•

Positive Modbus response

-

The "Function Code" in the Modbus response corresponds to

the "Function Code" in the Modbus request.

•

Negative Modbus response

-

The client receives pertinent information on error detection during processing;

-

The "Function Code" in Modbus response corresponds to the

"Function Code" in the Modbus request + 80h.

-

The "Exception Code" indicates the cause of the error.

If a syntactically incorrect Modbus PDU (Protocol Data Unit) is transmitted, the connection is terminated. In the case of other other error, a

negative Modbus response is sent.

LXM32M

Exception Code

01 Illegal Function Code The "Function Code" is unknown to the

02 Illegal Data Address Depends on the Modbus request

03 Illegal Data Value Depends on the Modbus request

04 Server Failure The server was unable to properly termi-

05 Acknowledge The server has accepted the Modbus

06 Server Busy The server was unable to accept the

0A Gateway Problem The gateway path is unavailable.

0B Gateway Problem The targeted device does not respond.

Name Description

server.

nate processing.

request. However, the execution takes a

relatively long time. The server therefore

only returns an acknowledgement confirming receipt of the service request.

Modbus request. It is the responsibility of

the application on the client to determine

whether and when to re-send the request.

The gateway generates this error.

20 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

3.3.3 Reading and writing parameters

Parameters are processed as 32 bit values. 16 bit values must also be

processed as 32 bit values. Two consecutive 16 bit parameters must

be read or written to process a 16 bit parameter. The first Modbus

address must be specified.

If several consecutive parameters are to be processed, a single Modbus command with the corresponding Modbus address and the length

indication is sufficient.

NOTE: This does not apply to reading and writing parameters with

addresses in the range from 17408 (4400h) to 17663 (44FFh). In this

range, only a single parameter can be addressed with one Modbus

command.

Example Reading the parameter CTRL1_KPp "Position controller P gain"

Modbus address 4614

When the parameter CTRL1_KPp with the Modbus parameter address

4614 and length 2 is read, the two parameter addresses 4614 and

4615 are read. Result:

Address Value

4614 0000

4615 00C8

3 Basics

h

h

0198441113843, V1.01, 01.2012

Modbus-TCP module 21

3 Basics

3.3.4 I/O scanning to "Drive Profile Lexium"

I/O scanning is used for cyclic interchange of data between master

and slave.

I/O scanning must be configured on the master. The master can use 2

different approaches for of I/O scanning:

•

"Function Code" 23 (17h), Read-Write Mulitple Registers

•

"Function Code" 3 (03h), Read Multiple Registers and "Function

Code" 16 (10h), Write Multiple Registers

NOTE: The read value is 0 until the first write command is executed.

Settings The following setting must be made on the master before you can use

I/O scanning:

•

The "Unit Identifier" is 255.

•

The Modbus parameter address is 0.

•

The data length is 13.

In addition, you can use up to 3 mappable parameters. If these

parameters are used, the data length changes to 15, 17 or 19.

LXM32M

The Modbus addresses for I/O scanning do not differ from the

addresses for normal Modbus access.

Output - Input Output and input refer to the direction of data transmission from the

perspective of the master.

•

Output: Commands from the master to the slave

•

Input: Status messages from the slave to the master

22 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

3.3.4.1 I/O scanning Output

3 Basics

The table below shows the structure of the cyclic data for the commands from the master to the product. See the product manual for a

description of the parameters.

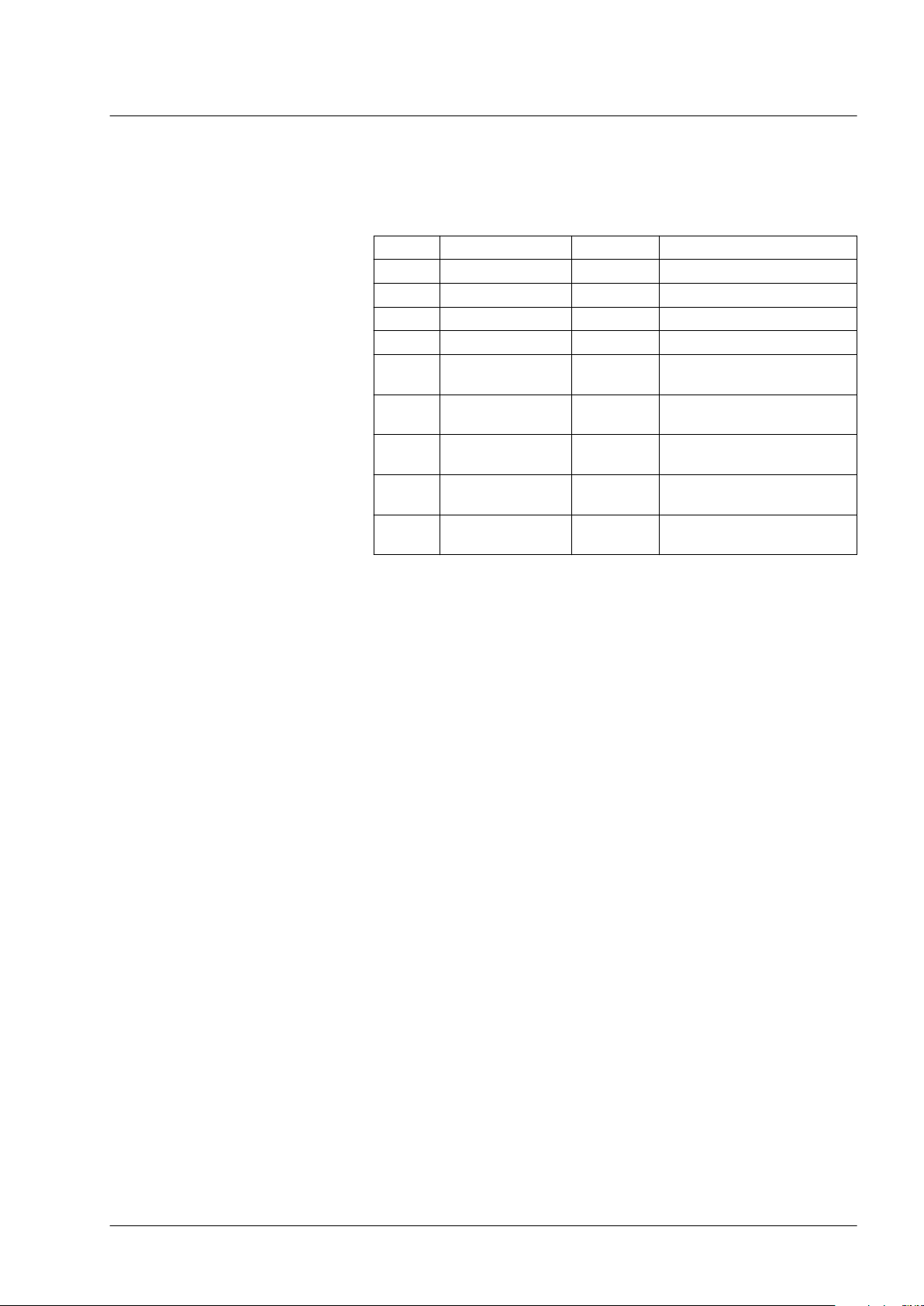

Byte Meaning Data type Parameter address

0 ... 7 ParCh - Parameter channel

8 ... 9 dmControl INT -

10 ... 13 RefA32 DINT -

14 ... 17 RefB32 DINT -

18 ... 21 Ramp_v_acc DINT Parameter Ramp_v_acc

Modbus 1556

22 ... 25 Ramp_v_dec DINT Parameter Ramp_v_dec

Modbus 1558

26 ... 29 EthOptMapOut1 DINT Parameter EthOptMapOut1

Modbus 17500

30 ... 33 EthOptMapOut2 DINT Parameter EthOptMapOut2

Modbus 17502

34 ... 37 EthOptMapOut3 DINT Parameter EthOptMapOut3

Modbus 17504

ParCh Parameters can be read or written via "ParCh", see chapter

"3.3.4.3 Parameter channel".

dmControl The word "dmControl" is used to set the operating state and the oper-

ating mode.

See chapters "6.1.2 Changing the operating state" and

"6.2.2 Starting and changing an operating mode" for a detailed

description of the bits.

RefA32, RefB32 The two double words "RefA32" and "RefB32" are used to set two val-

ues for the operating mode. The meaning depends on the operating

mode; it is described in the chapters on the individual operating

modes.

Ramp_v_acc / Ramp_v_dec The double words "Ramp_v_acc" and "Ramp_v_dec" are used to set

the acceleration and the deceleration. They correspond to the parameters of the same name. See the product manual for a description.

EthOptMapOut1 ... EthOptMap-

Out3

The double words EthOptMapOut1 ... EthOptMapOut3 contain selectable parameters, see chapter

"5.7.3 Setting the mapping for I/O scanning".

0198441113843, V1.01, 01.2012

Modbus-TCP module 23

3 Basics

3.3.4.2 I/O scanning Input

LXM32M

The table below shows the structure of the cyclic data for the status

messages from the product to the master. See the product manual for

a description of the parameters.

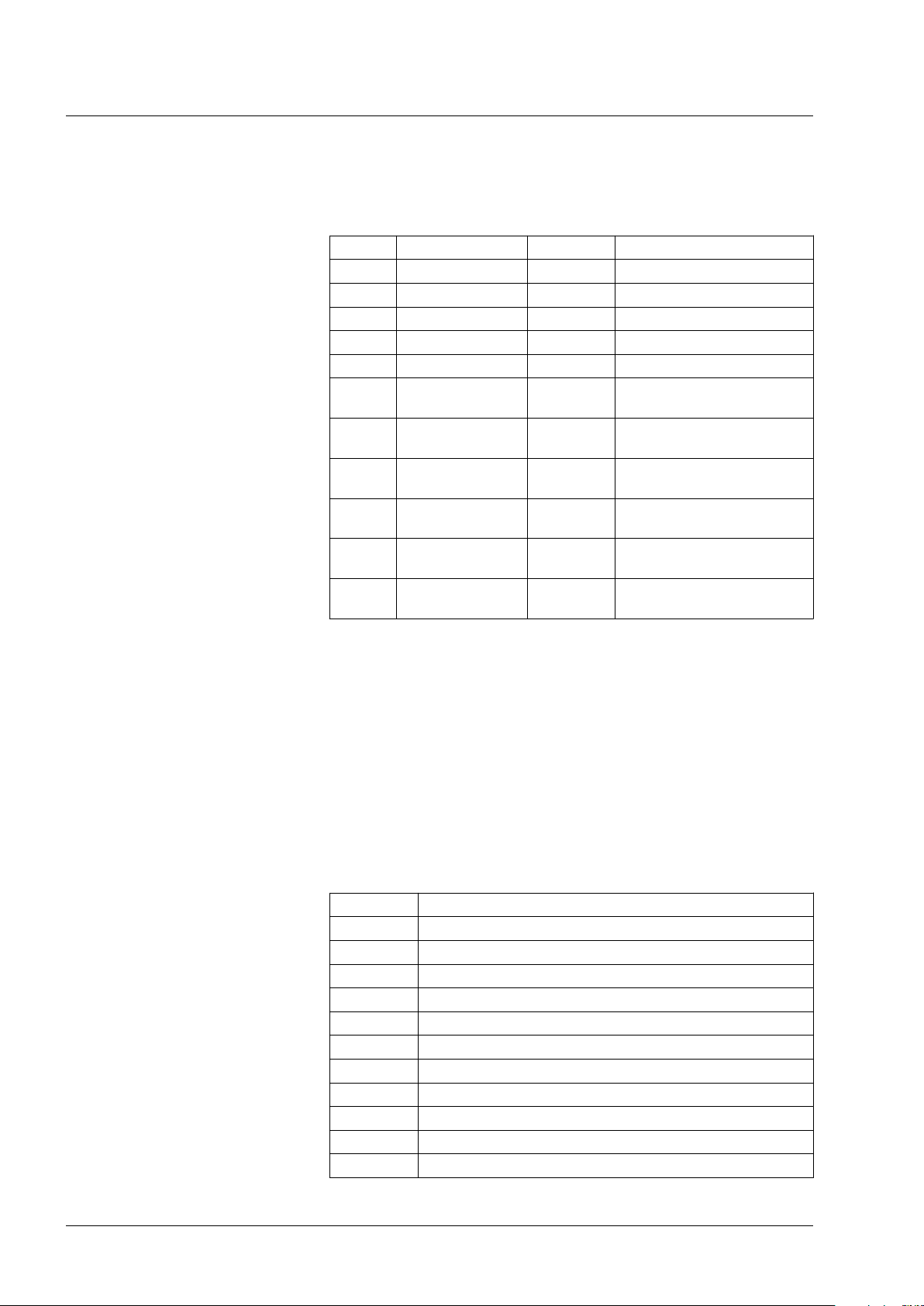

Byte Meaning Data type Parameter address

0 ... 7 ParCh - Parameter channel

8 ... 9 driveStat INT -

10 ... 11 mfStat INT -

12 ... 13 motionStat INT -

14 ... 15 driveInput INT -

16 ... 19 _p_act DINT Parameter _p_act

Modbus 7706

20 ... 23 _v_act DINT Parameter _v_act

Modbus 7744

24 ... 25 _I_act INT Parameter _I_act

Modbus 7686

26 ... 29 EthOptMapInp1 DINT Parameter EthOptMapInp1

Modbus 17512

30 ... 33 EthOptMapInp2 DINT Parameter EthOptMapInp2

Modbus 17514

34 ... 37 EthOptMapInp3 DINT Parameter EthOptMapInp3

Modbus 17516

ParCh Parameters can be read or written via "ParCh", see chapter

"3.3.4.3 Parameter channel".

driveStat The current operating state is indicated with the "driveStat" word.

For a detailed description of the bits, see chapter

"6.1.1 Indication of the operating state".

mfStat The word "mfStat" is used to indicate the current operating mode.

For a detailed description of the bits, see chapter

"6.2.1 Indicating and monitoring the operating mode".

motionStat The word "motionStat" is used to provide information on the motor and

profile generator.

bit Meaning

0 ... 5 Reserved

6 MOTZ: Motor at a standstill

7 MOTP: Motor movement in positive direction

8 MOTN: Motor movement in negative direction

9 PWIN: Motor within position window

10 Reserved

11 TAR0: Profile generator at standstill

12 DEC: Profile generator decelerates

13 ACC: Profile generator accelerates

14 CNST: Profile generator moves at constant velocity

15 Reserved

24 Modbus-TCP module

0198441113843, V1.01, 01.2012

LXM32M

3 Basics

driveInput The word "driveInput" is used to indicate the status of the digital signal

inputs.

bit Signal Factory setting

0

1

2

3

4

5

6 ... 15

_p_act The double word "_p_act" indicates the actual position. The value cor-

responds to the parameter _p_act.

_v_act The double word "_v_act" indicates the actual velocity. The value cor-

responds to the parameter _v_act.

_I_act The word "_I_act" is used to provide information on the total motor

current. The value corresponds to the parameter _I_act.

DI0

DI1

DI2

DI3

DI4

DI5

-

Signal input function Freely Available

Signal input function Reference Switch (REF)

Signal input function Positive Limit Switch (LIMP)

Signal input function Negative Limit Switch (LIMN)

Signal input function Freely Available

Signal input function Freely Available

Reserved

EthOptMapInp1 ... EthOptMapInp3 The double words EthOptMapInp1 ... EthOptMapInp3 contain selecta-

ble parameters. The product manual provides descriptions of the

parameters EthOptMapInp1 ... EthOptMapInp3 which explain parameter mapping.

0198441113843, V1.01, 01.2012

Modbus-TCP module 25

Loading...

Loading...