User’s manual

LUFP7

Telemecanique

Gateway

Profibus-DP / Modbus RTU

LUFP9

Gateway Profibus-DP / Modbus RTU Page 4

3

In spite of all the care taken over the writing of this document, Schneider Electric SA does not give

any guarantees in relation to the information contained in it, and may not be held liable for any

errors, nor for any damage which might result from its use or its application.

The characteristics and operation of the products and additives presented in this document may

change at any time. The description is in no way contractually binding.

4

Table of Contents

1. Introduction............................................................6

1.1. Introduction to the User Guide ...............................................6

1.2. Introduction to the LUFP7 Gateway ....................................... 7

1.3. Terminology............................................................................ 7

1.4. Notational Conventions .......................................................... 8

1.5. Additional Documentation ......................................................9

1.6. Introduction to the Communication “System” Architecture ..... 9

1.7. Principle Used to Configure and Operate the LUFP7 Gateway 10

2. Hardware Implementation of the LUFP7

Gateway ........................................................... 13

2.1. On Receipt ...........................................................................13

2.2. Introduction to the LUFP7 Gateway ..................................... 13

2.3. Mounting the Gateway on a DIN Rail ................................... 14

2.4. Powering the Gateway ......................................................... 14

2.5. Connecting the Gateway to the Modbus Network ................ 15

2.5.1. Examples of Modbus Connection Topologies................ 15

2.5.2. Pin Outs .........................................................................17

2.5.3. Wiring Recommendations for the Modbus Network....... 18

2.6. Connecting the LUFP7 gateway to the Profibus-DP Network

.............................................................................................. 19

2.6.1. Pin Outs .........................................................................19

2.6.2. Wiring Recommendations for the Profibus-DP Network 20

2.7. Configuring the Profibus-DP Communication Features .......22

2.7.1. Encoding the Gateway Address..................................... 22

2.7.2. No Internal Line Termination.......................................... 22

3. Signalling ............................................................ 23

4. Software Implementation of the Gateway........ 24

4.1. Introduction........................................................................... 24

4.1.1. System Architecture....................................................... 24

4.1.2. Configuring the Motor Starters ....................................... 25

4.1.3. Modbus Cycle Time .......................................................25

4.1.4. Managing Degraded Modes........................................... 25

4.2. Gateway Configuration under PL7 PRO and SyCon ........... 26

4.2.1. Setting Up the Hardware Configuration under PL7 PRO

........................................................................................ 26

4.2.2. Creating a Profibus-DP Network under SyCon .............. 27

4.2.3. Selecting and Adding the Profibus-DP Master Station .. 27

4.2.4. Setting up the Gateway Description Files ...................... 28

4.2.5. Selecting and Adding the Gateway to the Profibus-DP

Network ..........................................................................29

4.2.6. Editing and Configuring the Gateway ............................ 29

4.2.7. Saving and Exporting the Profibus-DP Network

Configuration .................................................................. 31

4.2.8. Importing the Configuration of the Profibus-DP Network

under PL7 PRO .............................................................. 31

4.2.9. Configuring the Gateway I/O under PL7 PRO ...............32

4.2.10. Description of Services Assigned to Gateway

Inputs/Outputs ................................................................ 34

4.2.11. Validating and Saving the Configuration of the

TSX BP 100 Coupler ...................................................... 35

4.2.12. Allocating Symbols to the Gateway Inputs and Outputs

........................................................................................ 35

4.2.13. Using and Monitoring the TSX PBY 100 Coupler

Configuration .................................................................. 36

4.2.14. Developing a Profibus-DP Application ......................... 36

5. Gateway Initialization and Diagnostics............ 37

5.1. Full Management.................................................................. 37

5.1.1. Profibus-DP Master Control Word.................................. 38

5.1.2. Gateway Status Word .................................................... 40

5.2. Diagnostic Only .................................................................... 41

5.2.1. Gateway Status Word .................................................... 41

5.2.2. Profibus-DP Master Control Word.................................. 43

5.3. Simplified Operation ............................................................. 43

6. Configuring the Gateway................................... 44

6.1. Connecting the Gateway to the Configuration PC ............... 44

6.1.1. Pin Outs .........................................................................45

6.1.2. RS-232 Link Protocol......................................................45

6.2. Installing AbcConf.................................................................46

6.3. Importing the Gateway Configuration ...................................46

6.4. Transferring a Configuration to the Gateway........................47

6.5. Monitoring the Content of the Gateway’s Memory................47

6.6. Deleting a Modbus Slave......................................................49

6.7. Adding a Modbus Slave........................................................50

6.8. Changing the Periodic Data Exchanged with a Modbus Slave

..............................................................................................52

6.8.1. Replacing a periodic input data element ........................52

6.8.2. Replacing an Output Periodic Data Element ..................53

6.8.3. Increasing the Amount of Periodic Input Data ................54

6.8.4. Increasing the Amount of Periodic Output Data .............58

6.9. Deleting Aperiodic Parameter Data ......................................63

6.10. Changing a Modbus Slave Configuration ...........................67

6.10.1. Changing the name of a Modbus slave ........................67

6.10.2. Changing the Address of a Modbus slave....................67

6.11. Adding and Setting Up a Modbus Command .....................68

6.11.1. With the TeSys U Motor Starters..................................68

6.11.2. With a Generic Modbus Slave ......................................70

6.11.2.1. Managing degraded modes....................................71

6.11.2.2. Configuring the Query ............................................72

6.11.2.3. Configuring the Response......................................75

6.11.2.4. Configuring the Content of the Query Frame .........76

6.11.2.5. Configuring the Content of the Response Frame...78

6.11.3. Adding a Special Modbus Command ...........................80

6.11.3.1. Modbus Commands Based on Standard Commands

...............................................................................80

6.11.3.2. Modbus Commands which Can Be Completely

Changed by the User.............................................80

6.12. Configuring the General Characteristics of the Gateway....81

6.12.1. “Fieldbus” Element .......................................................81

6.12.2. “ABC” Element..............................................................82

6.12.3. “Sub-Network” Element ................................................83

6.13. Adding a Broadcaster Node................................................85

7. Appendix A: Technical Characteristics............ 86

7.1. Environment..........................................................................86

7.2. Communication Characteristics ............................................86

8. Appendix B: LUFP7 Gateway GSD File ............ 90

8.1. Identification Number............................................................90

8.2. GSD File Content..................................................................90

9. Appendix C: Default Configuration................... 93

10. Appendix C: Default Configuration ................ 94

10.1. Configuring Modbus Exchanges.........................................94

10.2. Content of the Gateway’s DPRAM Memory .......................95

10.2.1. Input Data Memory Area ..............................................95

10.2.2. Output Data Memory Area............................................96

10.2.3. Total Number of Modbus Queries and Responses ......96

11. Appendix D: Sample Use under PL7 PRO ..... 97

11.1. Overview of the “LUFP7 - Tutorial Example” ......................97

11.2. LUFP7 Gateway Initialization and Diagnostics ...................98

11.3. Controlling and Supervising the 8 TeSys U Motor Starters

............................................................................................100

11.4. Reading and Writing any TeSys U Motor Starter Parameter

............................................................................................101

12. Appendix E: Profibus-DP Data and Diagnostics

........................................................................ 104

12.1. Gateway Profibus-DP Diagnostics....................................104

12.2. Gateway Configuration Data.............................................105

12.3. General Gateway Information ...........................................106

13. Appendix F: Modbus Commands ................. 108

13.1. “Read Holding Registers” Command (16#03) ..................109

13.2. “Preset Single Register” Command (16#06).....................109

13.3. “Preset Multiple Registers” Command (16#10) ................110

13.4. Modbus Protocol Exception Responses ...........................110

5

1. Introduction

1.1. Introduction to the User Guide

Chapter 1 Introduction (page 6) describes the gateway, the user guide that comes with it and the terms used in it.

Chapter 2 Hardware Implementation of the LUFP7 Gateway (page 13) gives an introduction to the gateway

and describes all the items used when setting it up, both inside (thumb wheels) and outside (cables and

connectors) the gateway.

Chapter 3 Signalling (page 23) describes the six LEDs on the front of the gateway.

Chapter 4 Software Implementation of the Gateway (page 24) describes the successive steps for setting the

gateway up with its default configuration, with a PLC using Profibus-DP. LUFP7 gateways are shipped preconfigured to allow you to interface a Profibus-DP master with 8 predefined Modbus slaves (TeSys U motor

starters).

Chapter 5 Gateway Initialization and Diagnostics (page 37) describes two registers in the gateway’s memory

reserved for initializing and carrying out diagnostics on the gateway. They are only exchanged between the

Profibus-DP master and the gateway.

Chapter 6 Configuring the Gateway (page 44) describes how to use the “ABC-LUFP Configurator” software

application, which allows you to modify or create a new configuration for the gateway and shows the various features of

this software (add or remove a Modbus slave, add or change a Modbus command, etc.).

This chapter also shows the changes to be made to software implementation operations in SyCon and

PL7 PRO.

Appendix A: Technical Characteristics (chapter 7, page 86) describes the technical aspects of both the

gateway and the Profibus-DP and Modbus RTU networks it is interfaced with.

Appendix B: LUFP7 Gateway GSD File (chapter 8, page 90) details and describes the content of the GSD file

shipped with the gateway. The file can be used for the setup tools to recognize the LUFP7 gateway as a

Profibus-DP subscriber with communication features of its own.

Appendix C: Default Configuration (chapter 10, page 94) describes the main features of the default

configuration of the LUFP7 gateway. However, it does not go into AbcConf in detail.

Appendix D: Sample Use under PL7 PRO (chapter 11, page 97) gives an advanced example using the

LUFP7 gateway’s default configuration. This example exploits the command and monitoring registers for

8 TeSys U motor starters and uses the aperiodic read and write services used to access the value of any motor

starter parameter.

Appendix E: Profibus-DP Data and Diagnostics (chapter 12, page 104) repeats the information described in

the Implementation manual of the TSX PBY 100 coupler for Premium PLCs. It also provides the values of

these data and the results of these diagnostics for the LUFP7 gateway.

Appendix F: Modbus Commands (chapter 13, page 108) describes the content of the Modbus command

frames supported by the LUFP7 gateway.

7

1. Introduction

1.2. Introduction to the LUFP7 Gateway

The LUFP7 gateway allows a master located on a Profibus-DP network to enter into a dialogue with the slaves

on a Modbus RTU network. This is a generic protocol converter operating in a way which is transparent to the

user.

This gateway allows you to interface many products marketed by Schneider Electric with a Profibus-DP network.

These include TeSys U motor starters, Altivar drivers and Altistart soft start- soft stop units.

1.3. Terminology

Throughout this document, the term “user” refers to any person or persons who may need to handle or use the

gateway.

The term “RTU”, which refers to the Modbus RTU communication protocol, will be omitted most of the time. As a

result, the simple term “Modbus” will be used to refer to the Modbus RTU communication protocol.

As is still the case with all communication systems, the terms “input” and “output” are somewhat ambiguous. To

avoid any confusion, we use a single convention throughout this document. So the notions of “input” and “output”

are always as seen from the PLC, or the Profibus-DP master.

Hence, an “output” is a command signal sent to a Modbus slave, whereas an “input” is a monitoring signal

generated by this same Modbus slave.

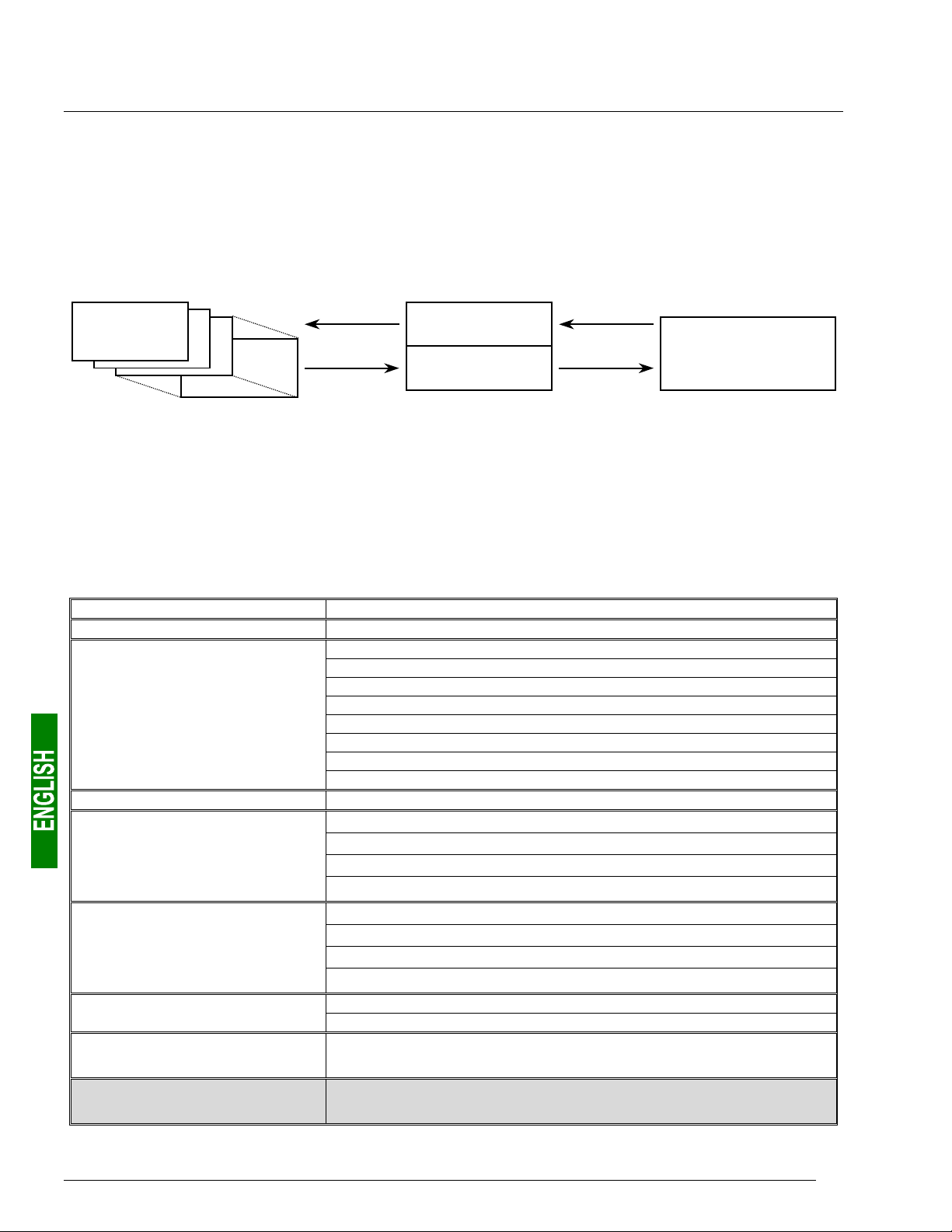

The diagram below shows the flows of “inputs” and “outputs” exchanged between a Profibus-DP master and

Modbus RTU slaves via the LUFP7 gateway:

Profibus-DP Master

INPUTS

OUTPUTS

LUFP7

Gateway

490 NAE 911 00

Altistart 48

Modbus RTU Slaves

8

1. Introduction

1.4. Notational Conventions

16#••••............... Value expressed in hexadecimal, which is equivalent to the H••••, ••••h and 0x•••• notations,

sometimes used in other documents. N.B. The AbcConf softwre uses the 0x•••• notation.

e.g. 16#0100 = 0x0100 = 256.

02#•••• ••••......... Value expressed in binary. The number of ‘•’ digits depends on the size of the item of data

represented. Each nibble (group of 4 bits) is separated from the other nibbles by a space.

Examples: byte 2#0010 0111 = 39, word 2#0110 1001 1101 0001 = 16#69D1 = 27089.

AbcConf............ Abbreviation taht refers to the tool used to configure and implement the LUFP7 gateway: “ABC-

LUFP Configurator”.

ASIC ................. Integrated circuits specific to a given user and application, covering two major families: pre-

characterised processes and pre-distributed networks.

ATS................... Abbreviation of “Altistart” (soft start- soft stop unit).

ATV................... Abbreviation of “Altivar” (drive).

CRC.................. Cyclical Redundancy Check.

LED................... Light-Emitting Diode.

DP..................... Decentralised Periphery (remote I/O). Profibus version or protocol meant for quick communication

with remote I/O. This is the only Profibus protocol supported by the LUFP7 gateway.

DPM1................ Class 1 DP master: the central automatic control of a Profibus-DP network. It resets and controls I/O

transfers and slave diagnostics on the network. One can have several DPM1 stations on a given

Profibus-DP network, each one steering its own slaves.

DPM2................ Class 2 DP master: The programming, configuration, and diagnostic device of a Profibus-DP network.

Fieldbus ............ A term referring to the upstream Profibus-DP network in AbcConf.

FMS .................. Profibus-FMS messaging system that defines the objects and application services applicable to these

objects. By extension, the Profibus version or protocol dedicated to complex and advanced

communication tasks at the cell level. This protocol is not supported by the LUFP7 gateway.

GSD.................. Electronic equipment database, also called GSD file. This term designates the format of the files

(“.gsd” extension) that are used by a Profibus master configuration and adjustment tool to configure

their exchanges according to that same protocol.

Handshake ....... An old term referring to the two registers used for initialising and carrying out diagnostics of the

LUFP7 gateway. This term has been replaced by the expression “Control/Status Byte”.

LRC .................. Longitudinal Redundancy Check.

Node ................. A term referring to the connection point of a Modbus slave under AbcConf.

PA..................... Profibus version or protocol dedicated to process automation. This protocol is not supported by the

LUFP7 gateway.

PDP .................. Profibus-DP (see “DP” above).

LSB:.................. Least significant byte in a 16-bit word.

MSB:................. Most significant byte in a 16-bit word.

PI ...................... Profibus International. This term designates the international organization for users of the Profibus

protocol. It is responsible for federating Profibus skills centres, scattered throughout the 20 largest

industrial countries. The list of user groups of the Profibus protocol is available on the Profibus web

site, at http://www.profibus.com/. To get general-purpose support on Profibus, please email to PI, at:

Profibus_international@compuserve.com.

PNO.................. This term designates the national and local associations of Profibus protocol users.

PPO .................. Parameter Process data Object. This term designates the type and size of the data exchanged

between a Profibus master and slave. In the case of the LUFP7 gateway, PPOs are not used to

configure its exchanges on the Profibus network.

Profibus ............ PROcess Field BUS.

Sub-Network..... A term referring to the downstream Modbus network under AbcConf.

TSDI ................. Initiating station request time.

TSDR................ Answering station response time.

XML .................. EXtensive Markup Language. The language used by AbcConf to import/export the configuration of a

Modbus slave.

9

1. Introduction

A

1.5. Additional Documentation

In the case of Modbus slaves, the features, services and adjustment of the Modbus communications are not

dealt with in this document.

1.6. Introduction to the Communication “System” Architecture

Profibus-DP

Master

Total of 16

motor starters

Upstream network (Profibus-DP)

Downstream

network no.1

(Modbus)

(TeSys U model)

10

Downstream

network no.2

(Modbus)

ATS48

VW33-A48

VW3-G46301

Downstream network no.3 (Modbus)

TS46

1. Introduction

Each LUFP7 Profibus-DP / Modbus RTU gateway allows one of the PLCs on the Profibus-DP network to

command, control and configure up to 8 Modbus slaves. Other Profibus-DP masters on that same network can

only control them. If there are more than 8 Modbus slaves, you will need to use an appropriate number of LUFP7

gateways. In the same way, if the exchanges with the Modbus slaves require more than 25 Modbus commands

(that is to say more than 50 queries and responses), you will have to distribute the Modbus slaves over several

gateways.

The LUFP7 gateway behaves both as a Profibus-DP slave on the upstream network and as a Modbus RTU

master on the downstream network.

See chapter 7.2 Communication Characteristics, page 86 if you would like to read about the technical

communication characteristics of the LUFP7 gateway.

The gateway can carry out its data exchanges (inputs and outputs of all types) with the Modbus slaves cyclically,

aperiodically or in an event-driven way. All of these Modbus exchanges make up the gateway’s “Modbus

scanner” and we use the “ABC-LUFP Configurator” software application to configure this scanner’s exchanges.

Every data element exchanged in that manner is made available for the Profibus-DP master, who may access it

on a periodic basis. The only aperiodic interchange possible with the LUFP7 gateway is the explicit Profibus-DP

diagnostic interchange.

The diagram on the left page illustrates the distribution of several slaves throughout three Modbus RTU

downstream networks, each one being interfaced with the Profibus-DP master PLC using a LUFP7 gateway.

1.7. Principle Used to Configure and Operate the LUFP7 Gateway

The gateway is part of a family of products (referred to as LUFPz) designed to meet generic needs for

connection between two networks using different communication protocols.

The software elements common to all these gateways (a configuration tool known as “ABC-LUFP Configurator”

and the on-board Modbus software) cohabit with the specific features of the network upstream of each of them

(Profibus-DP in the case of the LUFP7 gateway) generically. This is one of the reasons why the interfacing

between the upstream network and the Modbus network is carried out entirely via the gateway’s physical memory.

Ö The exchanges between the gateway (which operates as a Modbus master) and the Modbus slaves are

wholly configured using the “ABC-LUFP Configurator”. This configuration tool goes into great detail (setting

timers for exchanges, communication modes, frame content, etc.), which makes it all the more delicate to

use. So a whole chapter in this guide (chapitre 6 Configuring the Gateway, page 44) has been devoted to this

tool.

By configuring the queries and responses for Modbus commands via this tool the user can create links

between a part of the content of the corresponding Modbus frames and the content of the gateway’s physical

memory (input memory for the content of the Modbus responses and output memory for the content of the

queries).

Ö The exchanges between the Profibus-DP master PLC and the LUFP7 gateway should be configured in such

a way that the Profibus-DP master can read the input data and write the output data from the gateway, but

only the data used for the Modbus exchanges (see previous point).

11

1. Introduction

A

y

)

)

y

)

)

–––––––

–

Ö Each LUFP7 gateway is shipped pre-configured so as to make it easier to operate and the factory settings

can be used as a basis for a configuration which will best meet the user’s expectations. The typical

operations applicable to this default configuration are described in chapter 6 Configuring the Gateway,

page 44.

The Profibus-DP network is totally separate from the Modbus network. The frames on a network are not directly

“translated” by the gateway to generate frames on the other network. Instead, the exchanges between the content

of the gateway’s memory and the Modbus slaves make up a system which is independent of the one which is

entrusted with managing the exchanges between this same memory and the Profibus-DP master.

So the user must ensure that the size of the Profibus-DP data corresponds to the size of the memory used for

the Modbus exchanges, because the gateway configures its Profibus-DP exchanges on the basis of the memory

used by the Modbus frames.

The two synopses which follow illustrate the independent management of each of the two networks:

— Managing Gateway ↔ Modbus slaves exchanges —

ABC Configurator

Slave

Command A1

A1RQ

Quer

Frame

→

• • • Data (Out

Response A1AQ

Trame

→

• • • Data (In

Slave B

Command B1

B1RQ

Quer

Trame →

Response B1AQ

Frame

Slave A Slave B

• • • Data (Out

→

• • • Data (In

Configuration of

Modbus exchanges

by the user

• • •

• • •

• • •

• • •

Transfer of the configuration

LUFP7 gateway

0x0000

:

Input

memory

:

0x00F3

:

0x0200

:

Output

memory

:

0x02F3

Managing

exchanges with the

Modbus slaves

Modbus Network

12

1. Introduction

— Managing Gateway ↔ Profibus-DP master exchanges —

LUFP7 gateway

0x0000

:

:

:

:

0x00F3

:

0x0200

:

:

:

:

0x02F3

Management of the

exchanges with the

Profibus-DP master

Input

Modbus

data

Free

memory

locations

:

Output

Modbus

data

Free

memory

locations

Profibus-DP

network

Configuration of the Profibus-DP exchanges for the

master PLC by the user (excluding programming)

Hilscher

Configuration of Profibus-DP exchanges :

♦ Type and address of the LUFP7 gateway

♦ Size of the input Profibus-DP data

♦ Size of the output Profibus-DP data

Export of the configuration

PL7 PRO

Direct transposition of the content of the gateway's

memory to programming objects :

• Input Modbus data → %IW objects

• Output Modbus data → %QW objects

Transfer of the configuration

Profibus-DP

Master PLC

13

2. Hardware Implementation of the LUFP7 Gateway

2.1. On Receipt

After opening the packaging, check that the following element is there:

• One LUFP7 Profibus-DP / Modbus RTU gateway.

2.2. Introduction to the LUFP7 Gateway

The cables and other accessories for connecting to Profibus-DP and Modbus networks need to be ordered

separately.

f

g

h

cde

Modbus RTUConfiguration

Legend:

c Detachable power connector for the

gateway (

24V ±10%).

d Female RJ45 connector to a PC

running AbcConf configuration

software.

e Female RJ45 connector for the

downstream Modbus RTU network.

f Six diagnostic LEDs.

g Removable cover for the coding

wheels used to configure the gateway,

shown and described in chapter 2.7

Configuring the Profibus-DP

Communication Features, page 22.

The label describing the LEDs is stuck

onto this cover.

h Female Profibus-DP connector.

14

2. Hardware Implementation of the LUFP7 Gateway

2.3. Mounting the Gateway on a DIN Rail

Mounting the gateway

1

2

Start by fitting the rear base of the gateway to the

upper part of the rail, pushing downwards (1) to

compress the gateway’s spring. Then push the

gateway against the DIN rail (2) until the base of the

gateway box fits onto the rail.

Removing the gateway

1

2

Start by pushing the gateway downwards (1) to

compress the gateway’s spring. Then pull the

bottom of the gateway box forwards (2) until the box

comes away from the rail.

N.B. The spring is also used to earth the gateway (Protective Earth).

2.4. Powering the Gateway

Profibus-DP / Modbus RTU gateway – View from underneath

–

+

Power supply

24V isolated (±10%)

95 mA max.

N.B. The negative 24V power supply terminal should be connected to the installation’s earth.

15

2. Hardware Implementation of the LUFP7 Gateway

2.5. Connecting the Gateway to the Modbus Network

Three typical examples of Modbus connection for the gateway and its slaves are shown below. There are many

other possible Modbus connections, but they are not covered in this document.

2.5.1. Examples of Modbus Connection Topologies

• “Star” topology: This topology uses LU9GC03 Modbus hubs, which have 8 female RJ45 connectors.

These hubs should be placed close to the Modbus slaves to which they are connected using

VW3 A8 306 R•• cables. On the other hand, the nature of the cable connecting the LUFP7 gateway to one

of these hubs will depend on the network architecture, so long as there is a male RJ45 connector at each

end. If necessary, one or two line terminations may be directly connected to the hubs.

The connections are shown below:

LUFP7 gateway

Modbus

Line

termination

VW3 A8 306 R••

Modbus hubs

LU9GC03

Line

termination

16

Towards 8 Modbus slaves

2. Hardware Implementation of the LUFP7 Gateway

• “Bus” topology with VW3 A8 306 TF3 drop boxes: This topology uses VW3 A8 306 TF3 drop boxes to

connect each of the Modbus slaves to the main section of the Modbus network. Each box should be placed in

the immediate vicinity of the Modbus slave it is associated with. The cable for the main section of the Modbus

network must have male RJ45 connectors (like the VW3 A8 306 R•• cable used for the “star” topology). The

lead between the drop box and the slave or the Modbus gateway is an integral part of this box. The

connections are shown below:

LUFP7 Gateway

Modbus

VW3 A8 306 TF3

Line

termination

Towards 2 Modbus slaves

Towards 3 Modbus slaves

Towards 3 Modbus slaves

Line

termination

17

2. Hardware Implementation of the LUFP7 Gateway

• “Bus” topology with tap boxes: This topology is similar to the previous one, except that it uses

TSXSCA62 subscriber connectors and/or TSXCA50 subscriber connectors. We recommend using a

VW3 A68 306 connection cable and the TSXCSA•00 Modbus cables. Connect the RJ45 connector on the

VW3 A68 306 cable to the Modbus connector on the LUFP7 gateway.

The connections are shown below:

VW3 A68 306

Modbus

TSXSCA62

LUFP7 Gateway

TSXCSA•00

2.5.2. Pin Outs

In addition to the pin out for the connector on the gateway, the one on the VW3 A68 306 cable is also shown

below, as it is the only Modbus cable which does not exclusively use RJ45 connections.

— LUFP7 connector — ———— VW3 A68 306 cable for TSXSCA62 box ————

Female RJ45 Male RJ45 Male 15-point SUB-D

11

D(B) 4

D(A) 5

0 V 8

2

3

D(B) 4 14 D(B)

D(A) 5 7 D(A)

6

7

2

3

6

7

0 V 8 15 0V

18

2. Hardware Implementation of the LUFP7 Gateway

r

r

2.5.3. Wiring Recommendations for the Modbus Network

• Use a shielded cable with 2 pairs of twisted conductors,

• connect the reference potentials to one another,

• maximum length of line: 1,000 metres

• maximum length of drop line / tap-off: 20 metres

• do not connect more than 9 stations to a bus (slaves and one LUFP7 gateway),

• cable routing: keep the bus away from power cables (at least 30 cm), make crossings at right angles if

necessary, and connect the cable shielding to the earth on each unit,

• adapt the line at both ends using a line terminator (see diagram and VW3 A8 306 RC termination below).

D(B)

D(A)

— Line termination recommended at both ends of the line — — VW3 A8 306 RC line termination —

To make it easier to connect the units using the topologies described in chapter 2.5.1 Examples of Modbus

Connection Topologies, page 15, various accessories are available in the Schneider Electric catalogue:

1) Hubs, drops, taps, and line terminations:

LU9GC03 hub .....................

(“star” topology)

VW3 A8 306 TF3 drop box......................

(“bus” topology with VW3 A8 306 TF3 drop boxes)

2-way TSXSCA62 subscriber connector.

(“bus” topology with tap boxes)

4

120 Ω

1 nF

5

This passive box has 8 female RJ45 connectors. Each of these connectors can

be connected to a Modbus slave, to a Modbus master, to another Modbus hub,

or to a line termination.

This passive box includes a short lead with a male RJ45 connecto

allowing it to be connected directly to a Modbus slave, without

having to use a different cable. It is fitted with 2 female RJ45

connectors for the connection of two Modbus cables of the

VW3 A8 306 R•• type.

This passive box has a printed circuit fitted with screw terminals

and allows the connection of 2 subscribers to the bus (2 female

15 point SUB-D connectors). It includes the line termination when

the connector is located at the end. It is fitted with 2 screw terminals

for the connection of two double twisted pair Modbus cables.

TSXCA50 tap box....................................

(“bus” topology with tap boxes)

VW3 A8 306 RC double termination .......

(all topologies)

This passive box allows a Modbus unit to be connected to a screw

terminal. It includes the line termination when the connector is

located at the end. It is fitted with 2 screw terminals for the

connection of two double twisted pair Modbus cables.

Each of these two red passive boxes is a male RJ45 connecto

3 cm long containing an RC line termination (see diagram and

illustration above). Only the abbreviation “RC” is shown on these

boxes.

19

2. Hardware Implementation of the LUFP7 Gateway

A

–

—

p

(TSX

)

g

q

)

(2)

A

g

g

2) Cables:

VW3 A8 306 R•• Modbus cable...................................

(“star” topology / “bus” topology with tap boxes)

VW3 A68 306 Modbus cable.......................................

(“bus” topology with tap boxes)

Shielded cable with a male RJ45 connector at each

end.

Shielded cable with a male RJ45 connector and a

male 15 point SUB-D connector. It is used to connect

a Modbus subscriber (slave or master) to a

TSXSCA62 or TSXCA50 box.

Shielded double twisted pair Modbus cable ................

(“bus” topology with branch boxes)

Bare cable (without connectors) used to make up the

main section of the Modbus network. There are three

items available: TSXCSA100 (100 m), TSXCSA200

(200 m), and TSXCSA500 (500 m).

2.6. Connecting the LUFP7 gateway to the Profibus-DP Network

Connect the SUB-D 9-point male plug on

the Profibus-DP connector to the

Profibus-DP plug on the LUFP7 gateway.

Connections are illustrated here:

cg

hk

SUB-D

9 points

female

connector

SUB-D 9-point male

490 NAD 911 04 (or 03)

Type

Profibus-DP cables

Ref. : TSX PB SCA100

Modbus

2.6.1. Pin Outs

—— LUFP7 plug ——– — 490 NAD 911 04/03 connector—

9-

oint SUB-D female 9-point SUB-D male

11 Incomin

2

D(B)3

RTS 4

GND 5

+5V 6

2

3 B-line / RxD/TxD +

4Re

uest To Send(1

5 GND Réseau

+5V Réseau (2)

6

—Type A cables ——

PB SCA100

A cable

Outgoing A cable

7

D(A)8

9

Grounding / Shielding

-line / RxD/TxD –

9

Shieldin

/ Groundin

(1) This signal is not mandatory and may be ignored for the LUFP7 gateway.

(2) The “GND” and “+5V” pins are meant to supply the line termination if it is present in the connector being used.

20

2. Hardware Implementation of the LUFP7 Gateway

2.6.2. Wiring Recommendations for the Profibus-DP Network

• Use a shielded cable with a twisted pair of copper conductors, preferably a type A Profibus-DP cable.

• Connect the reference potentials to one another,

• You may choose the transmission rate, within limits ranging from 9.6 kbit/s to 12 Mbit/s. The choice is made

at network startup and applies to all network subscribers.

• The maximum length of the line (segment) is inversely proportional to the transmission rate.

Transmission rate (bit/s) 9,6 k 19,2 k 93,75 k 187,5 k 500 k 1,5 M 3, 6 or 12 M

Distance/segment (m) 1 200 1 200 1 200 1 000 0 400 200 100

With 3 repeaters 4 800 4 800 4 800 4 000 2 000 800 400

Experience shows that these lengths may be doubled using lines with a section of 0.5 mm².

• Do not connect more than 32 master or slave stations per segment without a repeater, 127 maximum

(repeaters included) with the 3 repeaters; don't use more than 3 repeaters

• Cable routing: keep the bus away from power cables (at least 30 cm), make crossings at right angles if

necessary and connect the cable shielding to the earth on each unit,

• The network ends on an active line termination, at each segment end (see diagram below); many suppliers

have provided their cables with switchable line terminations. The LUFP7 gateway has no internal line

termination and therefore applies a 5V voltage between pins 5 and 6 of its Profibus-DP plug in order to allow

for the use of an external line termination when the gateway is at the end of the line.

D(A)

5 3 8 6

390 Ω

220 Ω 390 Ω

D(B)GND

+5V

Active line

termination

recommended

at both ends

N.B. if you use a 490 NAD 911 03 connector on each of the two stations located at segment end, you won't

have to use an external line termination, since a line termination is integrated to that type of connector.

However, if you must disconnect a station to which such a connector is connected, move the connector to

another station on the same network so that the line termination continues to be supplied. If you do not wish

to make that type of arrangement, preferably use connectors featuring a switchable line termination.

21

2. Hardware Implementation of the LUFP7 Gateway

To connect stations to the Profibus-DP network more easily, several accessories are offered in the Schneider

Electric catalogue:

– Single twisted pair type A Profibus-DP cable

(100 m long): TSX PB SCA100. If you use a

different cable, please check that its electric

characteristics are as close as possible to those

of type A cables (see chapter 7.2

Communication Characteristics, page 86).

– Line connector: 490 NAD 911 04. The SUD-D

9-point male plug on that connector should not

be connected to a station located at the

segment end, as the connector has no line

termination. This passive box contains a printed

circuit fitted with one or two terminal boxes with

screws for connecting one incoming ProfibusDP cable and one outgoing Profibus-DP cable.

– End of line connector: 490 NAD 911 03. The

SUB-D 9-point male plug on that connector

must be imperatively connected to a station

located at segment end, since the connector

has a line termination. This passive box

contains a printed circuit fitted with one terminal

box with screws for connecting one incoming

Profibus-DP cable.

490 NAD 911 04 (or 03) connector

A

A

B

B

Red

Green

e

c

Legend:

c Incoming A cable.

d Outgoing A cable (absent in the case of the

490 NAD 911 03 connector).

e Cable collar; the cable sheath must be uninsulated,

at the most, in the middle of the collar.

d

22

2. Hardware Implementation of the LUFP7 Gateway

2.7. Configuring the Profibus-DP Communication Features

This configuration should be carried out when the gateway is powered off.

This task is limited to configuring the gateway's Profibus address, as the communication speed on the Profibus

network (9.6 kbits/s to 12 Mbits/s) is automatically detected by the gateway.

The two coding wheels used for configuring the gateway’s address are hidden behind the gateway cover

illustration in chapter 2.2 Introduction to the LUFP7 Gateway, page 13). To remove this cover, all you have to do

is insert the end of a small flat screwdriver between the top of the hood and the gateway box, and then to pull it

out delicately.

The power supply of the gateway must be turned off before opening the cover.

Once the cover has been removed, make sure that you touch neither the electrical circuits nor

the electronic components.

2.7.1. Encoding the Gateway Address

The LUFP7 gateway is identified on the Profibus-DP bus by its address, ranging from 1 to 99.

Units

Tens

The gateway's Profibus-DP address depends on the position of the two

coding wheels represented on the left, in their factory-setting positions

(default address = 2).

This address is the sum of the decimal values given by the angular

positions of the bottom coding wheel (tens) and the top coding wheel

(units).

g

(see

Any change to the gateway's address shall be taken into account only once it is powered on again.

Examples:

Address = 19 Address = 73

Units

Tens

2.7.2. No Internal Line Termination

The LUFP7 gateway has no active line termination. You must therefore use a Profibus-DP connector with such a

termination if you place the gateway at one of the ends of a bus segment.

Units

Tens

23

3. Signalling

The gateway’s 6 LEDs and the descriptive label on the removable cover which hides its two coding wheels

(gateway address) allow you to diagnose the status of the gateway:

telm

d

c

f

e

h

g

LUFP7

n

p

r

NLINE

1 O

FFLINE

2 O

OT USED

3 N

IELDBUS DIAG

4 F

ODBUS

5 M

ATEWAY

6 G

o

q

s

DEL LED Æ Gateway state

Off: Profibus-DP bus:

Gateway off-line

ONLINE

n

NOT

p

USED

MODBUS

r

(1) Specific errors indicated by the LED q FIELDBUS DIAG:

• Flashing red LED (1 Hz): input and/or output data length is invalid.

Check the overall length of the gateway data, under AbcConf (“Monitor” option from the “S

menu), then adjust exchanges with the gateway accordingly, using the Profibus-DP network configuration

software (e.g.: SyCon).

• Flashing red LED (2 Hz): User parameter data length and/or content is invalid.

• Flashing red LED (4 Hz): Error when resetting the ASIC in charge of Profibus-DP communications.

(2) The LED

queries of the two aperiodic services designed to read/write the value of any parameter of a Modbus slave (see

chapter 4.2.10 Description of Services Assigned to Gateway Inputs/Outputs, page 34). This LED will only revert to

its former green state if you reuse these very same services, but with correct values. More generally, this LED

becomes red, then reverts to a green state, on loss and recovery of the communications with any Modbus slave.

Green: Profibus-DP bus:

Gateway on-line

(exchanges are possible)

Off: —

Off: No power

Flashing (green): No

Modbus communications

Green: Modbus

communications OK

Red: Loss of communication

with at least one Modbus

slave (2)

MODBUS becomes red whenever you use incorrect values in the outputs corresponding to the

r

LED LED Æ Gateway state

Off: Profibus-DP bus: gateway on-line

OFFLINE

o

q

s

FIELDBUS

DIAG

GATEWAY

Red: Profibus-DP bus: Gateway off-line

(exchanges are impossible)

Off: Gateway initialization achieved

Flashing red (1 or 2 Hz): Gateway

configuration error. (1)

Flashing red (4 Hz): Error when resetting the

gateway on Profibus-DP. (1)

Off: No power

Flashing (red/green): Configuration absent / not valid

Use AbcConf to load a valid configuration

Green: Gateway currently being initialized

and configured

Flashing (green): Gateway is in running

order: Configuration OK

ub-Network”

24

N.B. If the LED s DEVICE STATUS is flashing following a sequence beginning with one or

more red flashes, we advise you to note down the order of this sequence and give this

information to the Schneider Electric support service.

4. Software Implementation of the Gateway

4.1. Introduction

This chapter gives an introduction to a quick implementation of the LUFP7 gateway, using its default

configuration. All LUFP7 gateways ship pre-configured.

This pre-configuration means that the user does not have to configure the LUFP7 gateway using AbcConf. This

configuration is described in order to allow the gateway to be used with a configuration tool for Profibus-DP master

PLCs. As an example this implementation will use Sycon (version ≥ V2.5.0.0), the multi-network configuration

software marketed by Hilscher (Réf.: TLX L FBC 10 M), PL7 PRO (version ≥ V3.0) and a Telemecanique PLC

from the Premium range (e.g. TSX 57353 v5.1) to which the appropriate Profibus-DP communication board shall

be added (TSX PBY 100 coupler).

4.1.1. System Architecture

The default configuration for an LUFP7 gateway allows it to control, monitor and configure 8 TeSys U motor

starters:

Configuration

PC

(PL7 PRO

+ SyCon)

490 NAE 911 00

Profibus-DP

master PLC

TSX 57353 v5.1

+ TSX PBY 100

Profibus-DP

(upstream network)

Modbus

addresses

LUFP7

gateway

Total of 8

motor starters

(TeSys U model)

cdefg hij

Modbus (downstream network)

Line

termination

Connection

boxes

Please see chapter 2 Hardware Implementation of the LUFP7 Gateway, page 13, for the hardware

implementation of the default configuration.

If you are using fewer than 8 TeSys U motor starters, you will need to adapt the gateway

configuration using the “ABC-LUFP Configurator” software (see chapter 6 Configuring the

Gateway, page 44, and chapter 6.6 Deleting a Modbus Slave, page 49).

25

4. Software Implementation of the Gateway

4.1.2. Configuring the Motor Starters

Each motor starter should be configured as follows:

Protocol: Modbus RTU slave Start bits 1

Modbus address 1 to 8 Parity None

Bitrate 19,200 bits/s Parity bit 0

Data bits 8 Stop bits 1

When using a TeSys U motor starter with a Modbus communication module (LULC031 module), the

configuration parameters for the RS485 connection are automatically detected, only the Modbus address of the

motor starter needs to be configured.

4.1.3. Modbus Cycle Time

The LUFP7 gateway’s default configuration sets a cycle time of 300 ms on Modbus commands for each of the

8 TeSys U motor starters.

4.1.4. Managing Degraded Modes

The default management for degraded modes is described below. This description only applies to a Premium

PLC fitted with a TSX PBY 100 coupler. Please refer to chapter 6.11.2.1 Managing degraded modes, page 71, if

you want to change the degraded mode management of one or several Modbus commands.

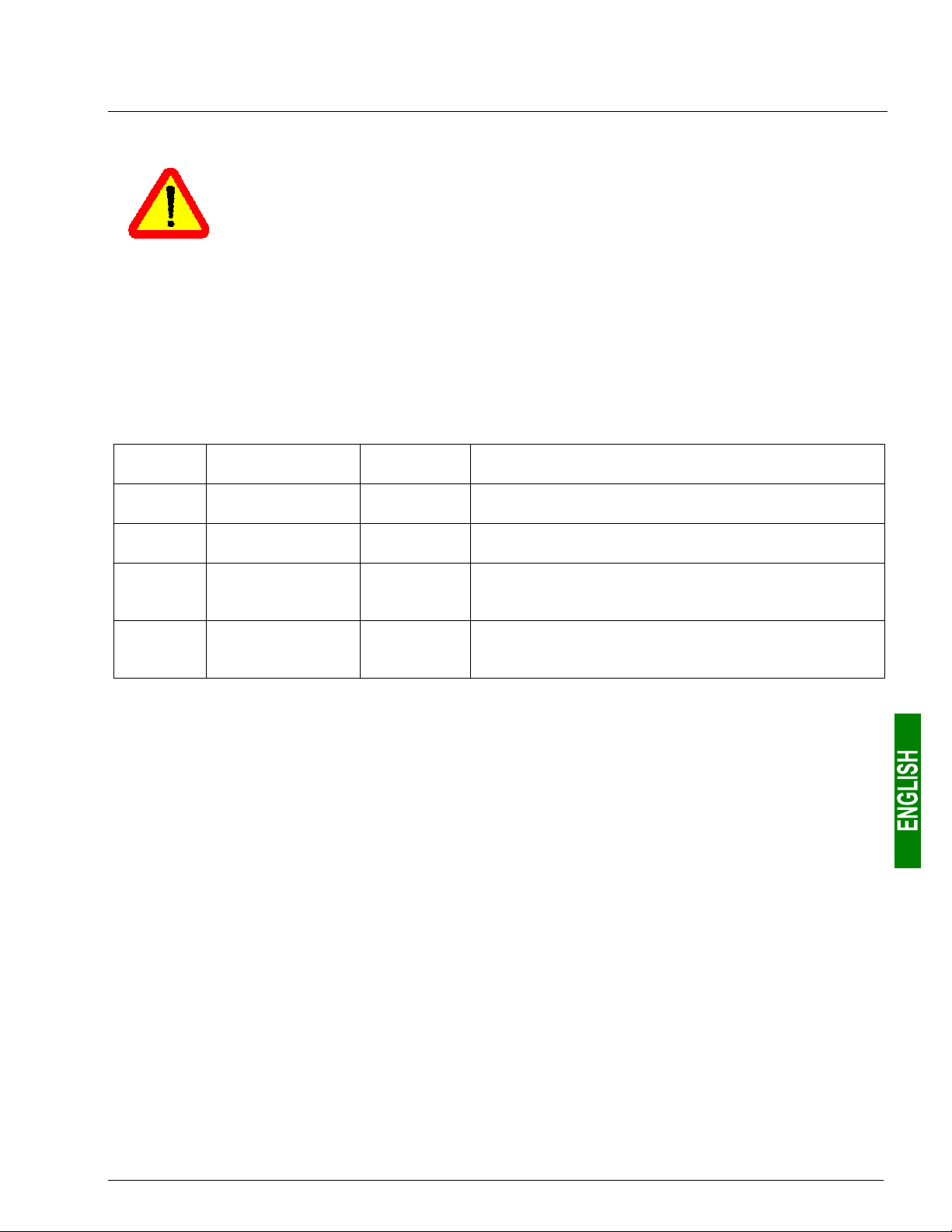

Event

Desired

behaviour

Reset

Output

Hold

Inputs Reset

(1) The “Outputs” option is described in chapter 4.2.8 Importing the Configuration of the Profibus-DP Network under

PL7 PRO, page 31. Under PL7 PRO, it can be accessed from the configuration screen for the TSX PBY 100 board.

(2) The desired behaviour with regard to the outputs should be directly configured on each of the TeSys U motor starters.

Premium PLC:

CPU stop or failure

“Outputs” option

equal to “Reset” (1)

“Outputs” option

equal to “Hold” (1)

—— Yes

Disconnection

of the upstream

Profibus-DP network

Yes

——

Failure of the

LUFP7 gateway

Depending on the configuration of the

TeSys U motor starters (2)

Disconnection of

the downstream

Modbus network

You may also refer to chapter 4.2 Degraded application mode of the Implementation manual – TSX PBY 100 –

PROFIBUS-DP (ref.: TSX DM PBY 100E) for further details regarding the processing of degraded modes by the

TSX PBY 100 board.

26

4. Software Implementation of the Gateway

4.2. Gateway Configuration under PL7 PRO and SyCon

The Profibus-DP master must be configured so that it has access to all of the data described in chapters 10.2.1 Input

Data Memory Area, page 95, and 10.2.2 Output Data Memory Area, page 96.

The following chapters describe the steps in PL7 PRO (version ≥ V3.0) and SyCon (version ≥ V2.5.0.0) which you will

need to go through so that the gateway is correctly recognised by the Profibus-DP master PLC.

The Profibus-DP network which is described in the following chapters only includes one

master (TSX 57353 v5.1 + TSX PBY 100) and one slave (LUFP7 gateway). So you will need

to adapt the addressing of the inputs and outputs shown below (%IW and %QW) according to

any other slaves on the Profibus-DP network which you need to configure.

4.2.1. Setting Up the Hardware Configuration under PL7 PRO

Under PL7 PRO, create a new application or open an application for which you want to add a Profibus-DP

network.

Edit the hardware configuration of this application, add a PBY 100 board and then edit its configuration by

double-clicking on its location in the rack.

Click on the “hilscher” button (enclosed in a red box above) to start the SyCon configuration tool.

N.B. This button is not displayed if you have not installed SyCon on your PC.

27

4. Software Implementation of the Gateway

4.2.2. Creating a Profibus-DP Network under SyCon

Select the “New” option from the “F

configuration, by selecting the “PROFIBUS” network.

This option creates an empty network segment in the SyCon main

window.

In this guide, we shall immediately save this configuration and name

it “LUFP7 - Tutorial Example.pb”.

4.2.3. Selecting and Adding the Profibus-DP Master Station

Select the “Master…” option from

the “Insert” menu (or click on the

button). Move the mouse

pointer (which now looks like a

to the position where you want to

add the Profibus-DP master, and

left-click.

Select the “TSX PBY 100” master,

then click “Add >>”. If need be, edit

its address and name.

ile” menu to create a new

)

Once back to the SyCon main window, the selected master appears in the selected insertion position:

28

4. Software Implementation of the Gateway

Double-click on the line that corresponds to the

Profibus-DP master to open the “Master

Configuration” window.

In the “DP Support” frame, verify that the "Auto

addressing" box has been checked.

Lastly, select the Profibus-DP master and run the “Bus

Parameter…” option from the “Settings” menu to configure the

Profibus-DP network baud rate.

The “Optimize” option must remain equal to

“standard”, except in case of knowledgeable

users who want to edit critical Profibus-DP

network settings (accessible via the “Edit…”

button).

4.2.4. Setting up the Gateway Description Files

The GSD file that describes the gateway must be located on the PC hard drive so that SyCon can access it any

time. Preferably place the file inside the directory that contains all the GSD files used by SyCon. The description

and content of that GSD file are both in chapter 8 Appendix B: LUFP7 Gateway GSD File, page 90.

This file can be found on the CD LU9CD1 : “Tele071F.gsd”.

Î To import that file under SyCon, run the “Copy GSD” option from the “F

mentioned above from the CD. If the command completes successfully, the following message is displayed:

“The import of the GSD file was successful.”

Then, install the symbols representing the gateway under SyCon. The corresponding files are on the CD

LU9CD1 : “LUFP7_S.DIB”, “ LUFP7_R.DIB”, and “ LUFP7_D.DIB”.

Î Copy these files into “C:\Program Files\Hilscher\SyCon\Fieldbus\PROFIBUS\BMP”, if this is the

path where you have installed SyCon on your PC. All these operations should be conducted using Windows

Explorer, for example, as SyCon cannot proceed to their installation.

The symbols that represent each of these three files are given below:

ile” menu and select the GSD file

29

4. Software Implementation of the Gateway

4.2.5. Selecting and Adding the Gateway to the Profibus-DP Network

Run the “Slave…” option from the “I

looks like a ) to the position where you want to add the LUFP7 gateway, then left-click.

In the window that appears,

select the “LUFP7” slave, then

click the “Add >>” button. If

need be, edit its address and

name. Gateway address

configuration is detailed in

chapter 2.7.1 Encoding the

Gateway Address, page 22.

Once back to the SyCon main window, the selected slave appears in the selected insertion position:

nsert” menu (or click on the button). Move the mouse pointer (which now

4.2.6. Editing and Configuring the Gateway

Double-click on the line that corresponds to the LUFP7 gateway. The "Slave Configuration" window appears.

Conduct the following operations:

• In the list of available modules, select the module called “IN/OUT: 32 Byte (16 word)”. Click the “Append

Module” button to add it to the list of modules configured for the gateway. This module occupies one “Slot” and

consists of a 16-word I/O module (both in IW and OW). It is intended to allow the exchange of the various data

presented in chapters 10.2.1 Input Data Memory Area, page 95, and 10.2.2 Output Data Memory Area,

page 96.

30

4. Software Implementation of the Gateway

• In the “Assigned master” frame, check that the Profibus-DP master previously configured is selected. If not,

select it. N.B. Only the "Assigned master" can control the DP slave to which it has been allocated during the

configuration phase. Other DPM1 masters can only read its I/O values.

• In the "General" frame, verify that the two boxes "Activate device in actual configuration" and "Enable

watchdog control" are both checked. If not, please check both.

• Validate the operations conducted by clicking on “OK”.

The left-hand

portion of this area

specifies the

gateway's

maximum capacity,

whilst the right-

hand portion lists

the currently

configured

"Modules".

N.B. Don't use the “Symbolic Names” option to name the I/O exchanged with the gateway. This operation is

useless because the symbols you shall define under SySon would not be exported and retrieved under

PL7 PRO!

If you create or edit a configuration using AbcConf (see chapter 6 Configuring the Gateway,

page 44), you should be aware that the total size of the inputs and outputs, for all the

configured modules, should be identical to the size of the data configured under AbcConf.

They correspond to all the bytes exchanged with the Modbus slaves via the “Data” fields of the

Modbus frames, to the two words reserved for downstream Modbus network management

(see chapter 5 Gateway Initialization and Diagnostics, page 37), if it has not been disabled,

and also to the two read parameter read/write counters . Any “free memory location” inserted

between two data elements, regardless of its size, is included in the bytes exchanged.

N.B. If the "Length of input data" or the "Length of output data" configured for the gateway

(under SyCon) differs from the total size of the gateway input memory area or the total size of

the gateway output memory area (under AbcConf), the gateway shall refuse going on line

(LED n off and LED o red) and the configuration error shall be indicated (LED q flashing

red, at 1 Hz). Please see chapter 3 Signalling, page 23.

31

4. Software Implementation of the Gateway

4.2.7. Saving and Exporting the Profibus-DP Network Configuration

Save the configuration by giving it a name (“Save” or “Save A

of the Profibus-DP network is then saved in a “.pb” file.

In order to export this configuration for PL7 PRO, follow these steps:

• Select the line that corresponds to the Profibus-DP master (TSX PBY 100).

• Run the “Export

N.B. the filename must comply with the “DOS 8.3” format, i.e. it must include a name limited to 8 characters

and a 3-character extension (here, “cnf”).

• Once these operations are completed, quit SyCon.

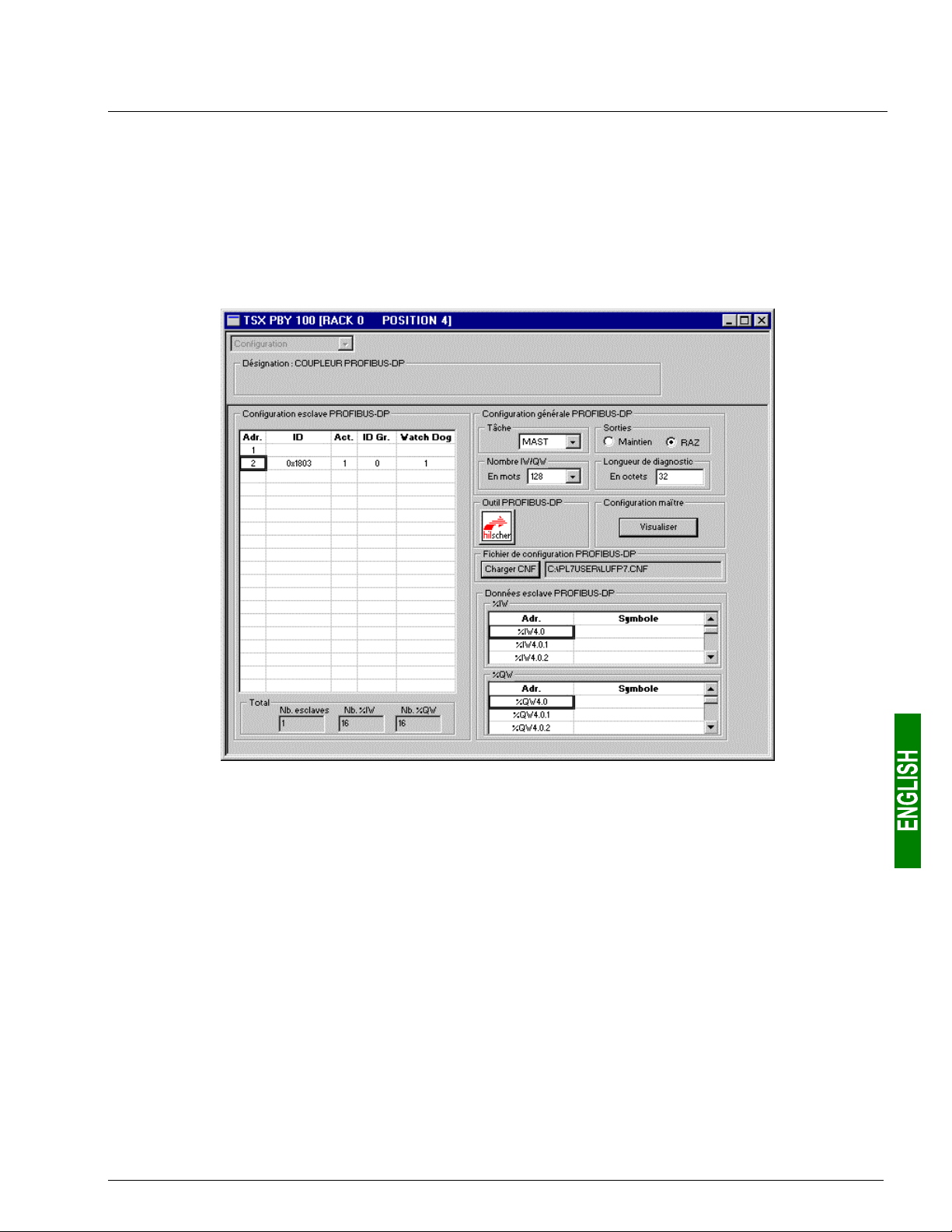

4.2.8. Importing the Configuration of the Profibus-DP Network under PL7 PRO

Back to PL7 PRO (see chapter 4.2.1 Setting Up the Hardware Configuration under PL7 PRO, page 26), click on

the “Load CNF” button. Using the options in the window that appears, select the “cnf” file that was saved

beforehand (see previous chapter).

Once this import is completed, the full path to this file appears on the right of the "Load CNF" button and the

"PROFIBUS-DP slave configuration" frame displays the two configured stations, i.e. “TSX PBY 100”, at the

address 1, and “LUFP7”, at the address 2.

In the case of the LUFP7 gateway, the default values allocated to the configuration options of the "General

PROFIBUS-DP configuration" frame can be kept (see table below). Edit them accordingly if you configure other

slaves on the same Profibus-DP network.

Optional Default value Possible values

Task

Used to select the type of system task that will steer the Profibus-DP network.

N.B. The PL7 PRO application is also subdivided into a “Mast Task” and a “Fast Task”.

Outputs

Determines whether the %QW outputs meant for the Profibus-DP slaves are held or reset to zero when the

associated task (see above) is stopped, as this stop does not cause the TSX PBY 100 board to stop.

N.B. if the gateway’s “Control/Status Byte” option is equal to “Enabled” (which is not the case for its default

configuration), resetting the outputs also resets the “Profibus-DP master control word,” and therefore a

communication disruption request on the Modbus downstream network (see chapter 5.2.1 Profibus-DP Master

Control Word, page 38).

IW/QW number

Determines the number of words used for the input of the TSX PBY 100 board, as well as for its outputs.

The "Total" frame indicates the total number of inputs and outputs, all slaves included. The value allocated to

the “IW/QW number” option should be greater than, or equal to, the greatest of these two numbers.

The LUFP7 gateway only requires 16 words (whether for inputs or for outputs). Therefore, we could use a size

of 32 words. However, it is preferable to keep the default value, should other slaves be configured.

Diagnostic length

Determines the maximum length of a diagnostic on the Profibus-DP network.

N.B. This length should be sufficient to host the longest diagnostic for all the slaves on the network. If the

length is insufficient, the slaves concerned shall not be active on the bus because their diagnostic shall be

invalid. The "diagnostic length" is equal to 6 bytes in the case of the LUFP7 gateway.

► ASCII” option from the “File” menu. The newly-created file bears the “.cnf” extension.

MAST MAST or FAST

Reset Hold or Reset

128 words 32, 64, 128 or 242 words

32 bytes 6 to 244 bytes

s…” option from the “File” menu). The configuration

N.B. You may also request the configuration of the Profibus-DP master by clicking the "View" button in the

"Master configuration" frame.

32

4. Software Implementation of the Gateway

4.2.9. Configuring the Gateway I/O under PL7 PRO

Using the information located in the selected “.cnf” file, PL7 PRO establishes a direct relation between the data

for each Profibus-DP slave and its equivalent I/O.

To view the LUFP7 gateway I/O, click on the line of the address 2 station in the "PROFIBUS-DP slave

configuration" frame.

If you use the vertical sliders in the "PROFIBUS-DP slave data" frame, you can see that the gateway's 16 input

words have been allocated to inputs %IW4.0 to %IW4.0.15 and that its 16 outputs words have been allocated to

outputs %QW4.0 to %QW4.0.15.

N.B.: these allocations are valid only for the gateway's default configuration and for a gateway which is the only

slave on the Profibus-DP network. If you configure other slaves on the same Profibus-DP network, it may be that

gateway input and output allocation, as it is illustrated above, is amended according to the order in which the

slaves and their modules have been declared under SyCon. Then, you can use the PL7 PRO window, presented

above, to check the allocation of the input and output words of the gateway and other Profibus-DP slaves.

33

4. Software Implementation of the Gateway

The correspondence between the content of the gateway's input memory (see chapter 10.2.1 Input Data

Memory Area, page 95) and the PLC inputs “%IW4.0” to “%IW4.0.15” is given in the following table:

Service PLC input

Managing the downstream Modbus network

Periodic communications

—

Monitoring of

TeSys U motor starters

Aperiodic communications

Reading the value of a motor starter

parameter (R

ESPONSE)

Aperiodic communications

Writing the value of a motor starter

parameter (R

ESPONSE)

Aperiodic communications

(“Trigger bytes” for the responses)

%IW4.0.00

%IW4.0.10

%IW4.0.20

%IW4.0.30

%IW4.0.40

%IW4.0.50

%IW4.0.60

%IW4.0.70

%IW4.0.80

%IW4.0.90

%IW4.0.10

%IW4.0.11

%IW4.0.12

%IW4.0.13

%IW4.0.14

%IW4.0.15

Bit 15....................Bit 8 Bit 7......................Bit 0

Value of the motor starter c status register

Value of the motor starter d status register

Value of the motor starter e status register

Value of the motor starter f status register

Value of the motor starter g status register

Value of the motor starter h status register

Value of the motor starter i status register

Value of the motor starter j status register

Free memory location Slave no. (16#01-16#08)

Function No. (16#03) Bytes read (16#02)

Value of the parameter read (16#xxxx)

Slave No. (16#01-16#08) Function No. (16#06)

Address of the parameter written (16#xxxx)

Value of the parameter written (16#xxxx)

Read parameter

response counter

Description

Gateway status word

Write parameter

response counter

The correspondence between the content of the gateway output storage (see chapter 10.2.2 Output Data Memory

Area, page 96) and the outputs of the “%QW4.0” to “%QW4.0.15” automatic controls is as follows:

Service PLC output

Managing the downstream Modbus network

Periodic communications

—

Controlling

TeSys U motor starters

Aperiodic communications

Reading the value of a

motor starter parameter (Q

UERY)

Aperiodic communications

—

Writing the value of a

motor starter parameter (Q

UERY)

Aperiodic communications

(“Trigger bytes” for the queries)

%QW4.0.00

%QW4.0.10

%QW4.0.20

%QW4.0.30

%QW4.0.40

%QW4.0.50

%QW4.0.60

%QW4.0.70

%QW4.0.80

%QW4.0.90

%QW4.0.10

%QW4.0.11

%QW4.0.12

%QW4.0.13

%QW4.0.14

%QW4.0.15

Bit 15....................Bit 8 Bit 7......................Bit 0

Profibus-DP master control word

Value of the motor starter c command register

Value of the motor starter d command register

Value of the motor starter e command register

Value of the motor starter f command register

Value of the motor starter g command register

Value of the motor starter h command register

Value of the motor starter i command register

Value of the motor starter j command register

Slave No. (16#01-16#08) Function No. (16#03)

Address of the parameter to be read (16#xxxx)

Number of parameters to be read (16#0001)

Slave number

(16#01-16#08)

Address of the parameter to be written (16#xxxx)

Value of the parameter to be written (16#xxxx)

Read parameter

query counter

Description

Function number

(16#06)

Write parameter

query counter

34

Whenever you create or change a configuration using AbcConf (see chapter 6 Configuring the

Gateway, page 44), you should be aware that, if you configure an odd number of input (or output)

bytes, PL7 PRO converts the last byte to the 16-bit format instead of leaving it in bits 8-15 of the

last word. Its value is therefore placed into bits 0-7 of the last word.

e.g. If you use 33 input words and the last input word is equal to 16#64 (8-bit format), the word

%IW4.0.16 is therefore equal to 16#0064 (16-bit format) and not 16#64••.

4. Software Implementation of the Gateway

4.2.10. Description of Services Assigned to Gateway Inputs/Outputs

Managing the downstream Modbus network: Refer to chapter 5.3 Diagnostic Only, page 41, for a detailed

description of that service, and to chapter 11.2 LUFP7 Gateway Initialization and Diagnostics, page 98, for an

advanced sample use. In the case of the gateway’s default configuration, under AbcConf, the “Control/Status

Byte” field of the “ABC” element is equal to “Enabled but no startup lock.”

Periodic communications (inputs): The value of each of the 8 words for this service corresponds to teh value

of the status register of a TeSys U motor starter (register located at address 455).

Periodic communications (outputs): The value of each of the 8 words for this service corresponds to the value

to be sent to the command register of a TeSys U motor starter (register located at address 704).

Refer to chapter 11.3 Controlling and Supervising the 8 TeSys U Motor Starters, page 100, for a sample use of

these "periodic communications" services.

Aperiodic communications: Refer to chapter 11.4 Reading and Writing any TeSys U Motor Starter Parameter,

page 101, for a simple example of these "aperiodic communications".

These aperiodic communications services offer functions similar to those of “parameter area PKW” which can be

found on certain Schneider Electric products, such as some ATV drives.

• Sample reading of a motor starter parameter:

Reading of the 1st fault register (address = 452 = 16#01C4) on TeSys U motor starter no. 5.

The initial values of %QW4.0.15 and %IW4.0.15 are equal to 16#0613.

The result of the reading is 16#0002 (magnetic fault).

Output Value Meaning (MSB + LSB) Input Value Meaning (MSB + LSB)

%QW4.0.90

%QW4.0.10

%QW4.0.11

%QW4.0.15

16#0503

16#01C4

16#0001

16#0713

Slave no. + Function no. %IW4.0.90

Parameter address %IW4.0.10

Number of parameters %IW4.0.11

“Trigger byte” for the query (PF)

%IW4.0.15

16#0005

16#0302

16#0002

16#0713

(not used) + Slave no.

Slave no. + Number of bytes

Value read

“Trigger byte” for the response (PF)

• Sample writing of a motor starter parameter:

Writing of the 2nd command register (address = 705 = 16#02C1) on TeSys U motor starter no. 7 at the value

16#0006 (clear statistics + reset thermal memory).

The initial values of %QW4.0.15 and %IW4.0.15 are equal to 16#0713.

The result of the writing is a command echo, that is to say that the values of the “address parameter” and

“value to be written” fields are identical in both the query and the response.

Output Value Meaning (MSB + LSB) Input Value Meaning (MSB + LSB)

%QW4.0.12

%QW4.0.13

%QW4.0.14

%QW4.0.15

16#0706

16#02C1

16#0006

16#0714

Slave no. + Function no. %IW4.0.12

Parameter address %IW4.0.13

Value to be written %IW4.0.14

“Trigger byte” for the query (PF) %I W 4.0.15

16#0706

16#02C1

16#0006

16#0714

Slave no. + Function no.

Parameter address

Written value

“Trigger byte” for the response (PF)

Avoid writing incorrect values in outputs which correspond to the aperiodic communication

services described above, as they would lead to the transmission of an incoherent Modbus

frame. It is therefore up to the Profibus-DP master PLC application to manage them.

In addition, do not ever use these services in “Broadcast” mode (Modbus address = 0).

35

4. Software Implementation of the Gateway

4.2.11. Validating and Saving the Configuration of the TSX BP 100 Coupler

Î Validate the various operations conducted under PL7 PRO using the

Î Close the configuration window of the TSX PBY 100 coupler.

Î In the PLC's hardware configuration window, click on the

Î Save the PL7 PRO application by giving it a name.

4.2.12. Allocating Symbols to the Gateway Inputs and Outputs

Allocating symbols to the gateway I/O is possible only under PL7 PRO, as SyCon does not export such symbols

to the ASCII export file. Once these symbols are defined, they are used in the configuration window of the

TSX PBY 100 coupler previously described.

button again.

button.

36

4. Software Implementation of the Gateway

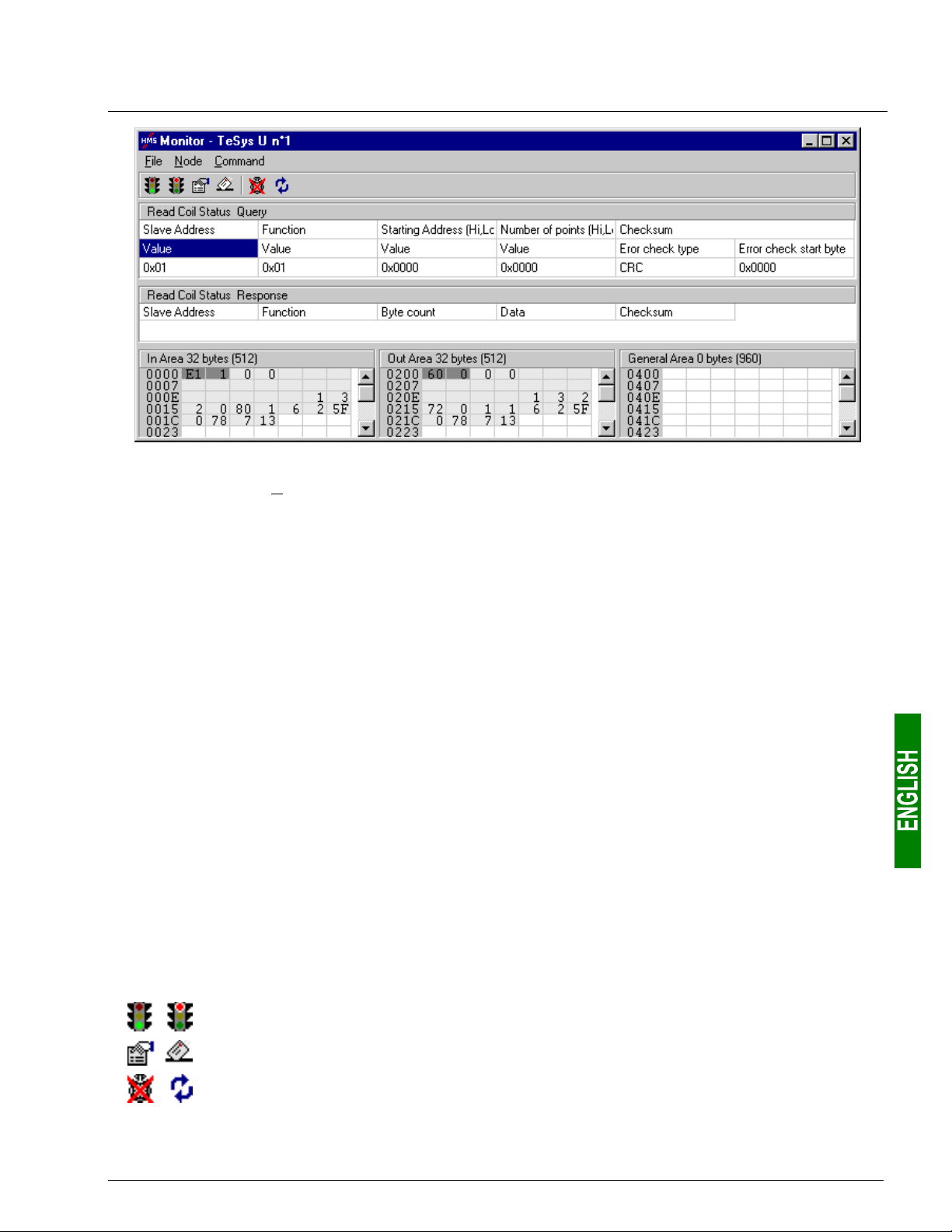

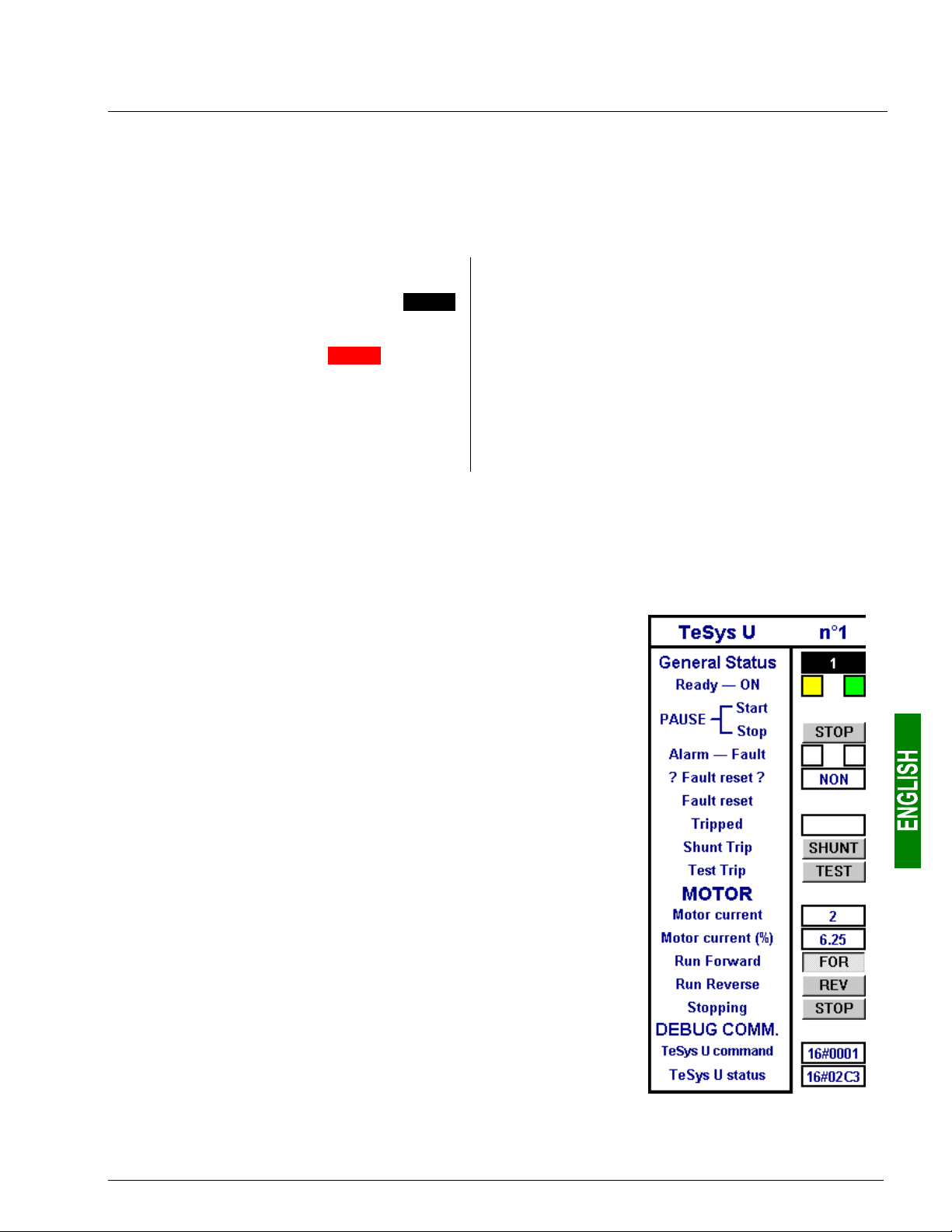

4.2.13. Using and Monitoring the TSX PBY 100 Coupler Configuration

After validating all the changes previously made, you may check the configuration of the TSX PBY 100 coupler,

the Profibus-DP network, and the LUFP7 gateway by downloading the PL7 PRO application to the PLC and

conducting a monitoring operation using the TSX PBY 100 coupler debug screen.

Î Transfer the application from the PC to the PLC by running the “Transfer program…” option from the “P

menu (or click on the button) and selecting “PC -> PLC”.

Î Switch from the OFFLINE to the ONLINE mode by running the “Connect” option from the “PLC” menu (or

click on the button).

Î Initialize and start the PLC application using the “Init…” and “R

Î Open the “Hardware configuration”

and the TSX PBY 100 board

configuration. Then, switch from

“Configuration” to “Debug” and select

the line that corresponds to the

LUFP7 gateway.

The content of the "PROFIBUS-DP

diagnostic data” frame enables you

to view the gateway's Profibus-DP

diagnostics, while the “PROFIBUSDP slave data” frame enables you

to view and change the values of

the gateway I/O. An example is

given on the right.

un…” options from the “PLC” menu.

LC”

4.2.14. Developing a Profibus-DP Application

The Profibus-DP master PLC taken as an example is a TSX 57353 v5.1, marketed by Telemecanique. A sample

PLC application, developed under PL7 PRO, is presented in chapter 11 Appendix D: Sample Use under

PL7 PRO, page 97. This example uses the PLC, the gateway and the 8 TeSys U motor starters shown in the

Software Implementation of the Gateway.

37

5. Gateway Initialization and Diagnostics

Each of the three sub-chapters 5.2, 5.3 and 5.3.2 describes the principle used to initialize and carry out

diagnostics on the gateway using each of the three options offered by the gateway. These options can be

configured via AbcConf, by changing the assignment of the “Control/Status Byte” field for the “ABC” element

(see chapter 6.12.2 “ABC” Element, page 82). The links between these sub-chapters and these options are as

follows:

“Control/Status Byte” field............................. Sub-chapter....................................Page

Enabled ............................................................. 5.2 Full Management......................... 37

Enabled but no startup lock

5.1.1. Disabled 5.3.2 Profibus-DP Master Control Word

The output word located at addresses 16#0200 (MSB) and 16#0201 (LSB) in the gateway’s output memory

constitutes the Profibus-DP master command word. Its structure is described below:

Bits Description

15

0-14 Reserved.

FB_HS_CONFIRM: Acknowledgement bit of a gateway diagnostic

The Profibus-DP master must compare the value of the FB_HS_CONFIRM bit to the value of the

ABC_HS_SEND bit (bit 15 in the gateway’s status word). If these two values are different, this means

that the gateway has transmitted a new diagnostic to the Profibus-DP master.

To tell the gateway that it has read a diagnostic, the Profibus-DP master must copy the value of the

ABC_HS_SEND bit to the FB_HS_CONFIRM bit. This allows the gateway to issue a new diagnostic.

Summary:

• If ( FB_HS_CONFIRM = ABC_HS_SEND ) Æ The gateway’s status word contains a diagnostic

which has already been acknowledged by the Profibus-DP master. So the gateway is free to use

this status word to place another diagnostic there.

• Else Æ A new diagnostic is available in the gateway’s status word. The Profibus-DP master can

read this diagnostic, but must also copy the value of ABC_HS_SEND to FB_HS_CONFIRM in

order to allow the gateway to generate new diagnostics.

............................. 5.3 Diagnostic Only ........................... 41

Simplified Operation ........................................... 43

The option chosen in the default configuration is “Enabled but no startup lock.”

5.2. Full Management

Until it receive an order to start up the Modbus exchanges from the Profibus-DP master, the

LUFP7 gateway does not transmit any queries on the Modbus network. The Profibus-DP

master can then deactivate these exchanges by inverting this startup order. Subsequently

these two orders may be reiterated by the Profibus-DP master.

The Modbus exchange startup order is located in a 16-bit register occupying the addresses 16#0200 and

16#0201 in the gateway’s memory (outputs). A second 16-bit register, located at the addresses 16#0000 and

16#0001 (inputs), allows the gateway to send diagnostics to the Profibus-DP master.

So you must configure your Profibus-DP master so that it has access to the first two bytes of the

gateway’s output data area, as well as to the first two bytes of the gateway’s input data area (see

chapter 4.2 Gateway Configuration under PL7 PRO and SyCon, page 26).

38

5.2.1. Profibus-DP Master Control Word

The output word located at addresses 16#0200 (MSB) and 16#0201 (LSB) in the gateway’s output memory

constitutes the Profibus-DP master command word. Its structure is described below:

Bits Description

15

FB_HS_CONFIRM: Acknowledgement bit of a gateway diagnostic

The Profibus-DP master must compare the value of the FB_HS_CONFIRM bit to the value of the

ABC_HS_SEND bit (bit 15 in the gateway’s status word). If these two values are different, this means

that the gateway has transmitted a new diagnostic to the Profibus-DP master.

To tell the gateway that it has read a diagnostic, the Profibus-DP master must copy the value of the

ABC_HS_SEND bit to the FB_HS_CONFIRM bit. This allows the gateway to issue a new diagnostic.

Summary:

• If ( FB_HS_CONFIRM = ABC_HS_SEND ) Æ The gateway’s status word contains a diagnostic

which has already been acknowledged by the Profibus-DP master. So the gateway is free to use

this status word to place another diagnostic there.

• Else Æ A new diagnostic is available in the gateway’s status word. The Profibus-DP master can

read this diagnostic, but must also copy the value of ABC_HS_SEND to FB_HS_CONFIRM in

order to allow the gateway to generate new diagnostics.

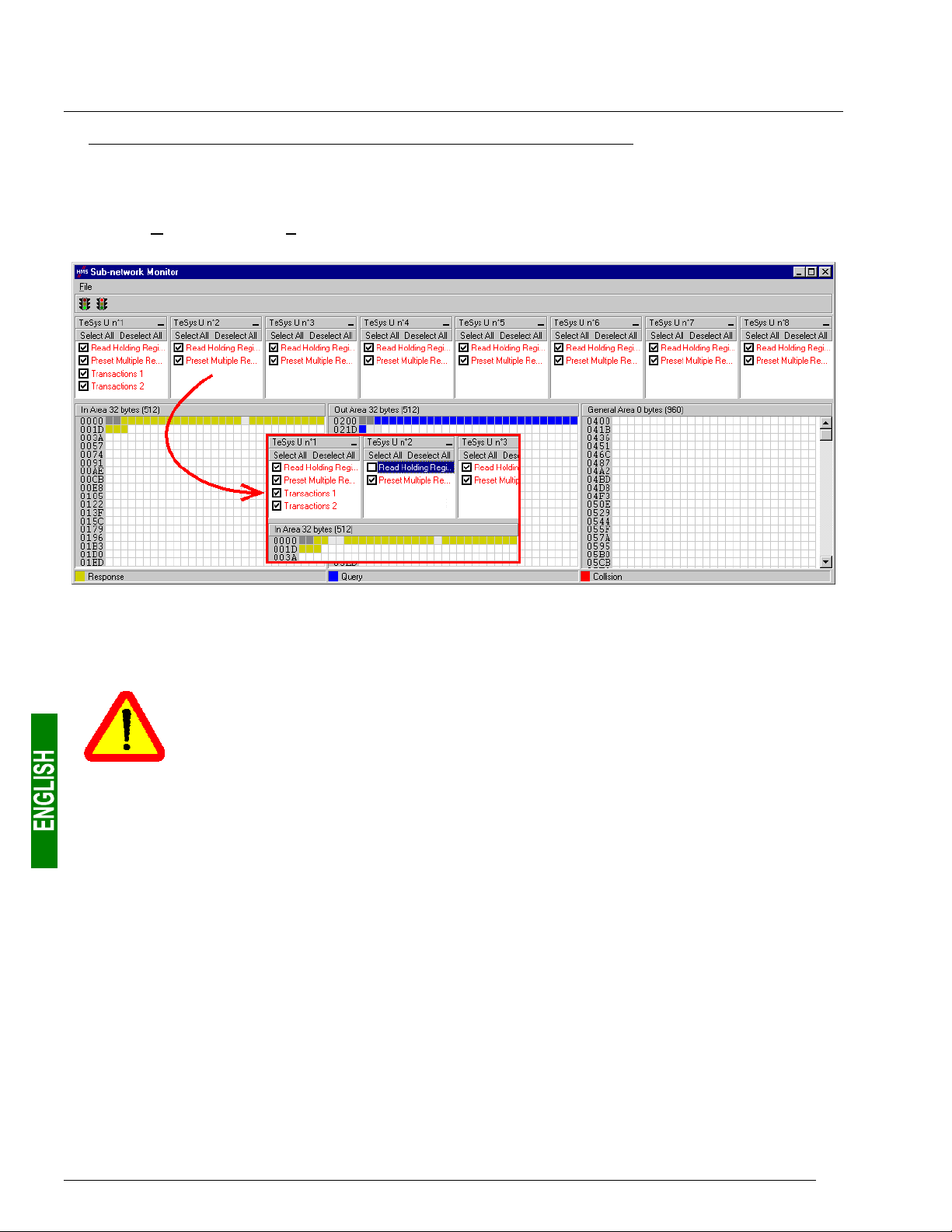

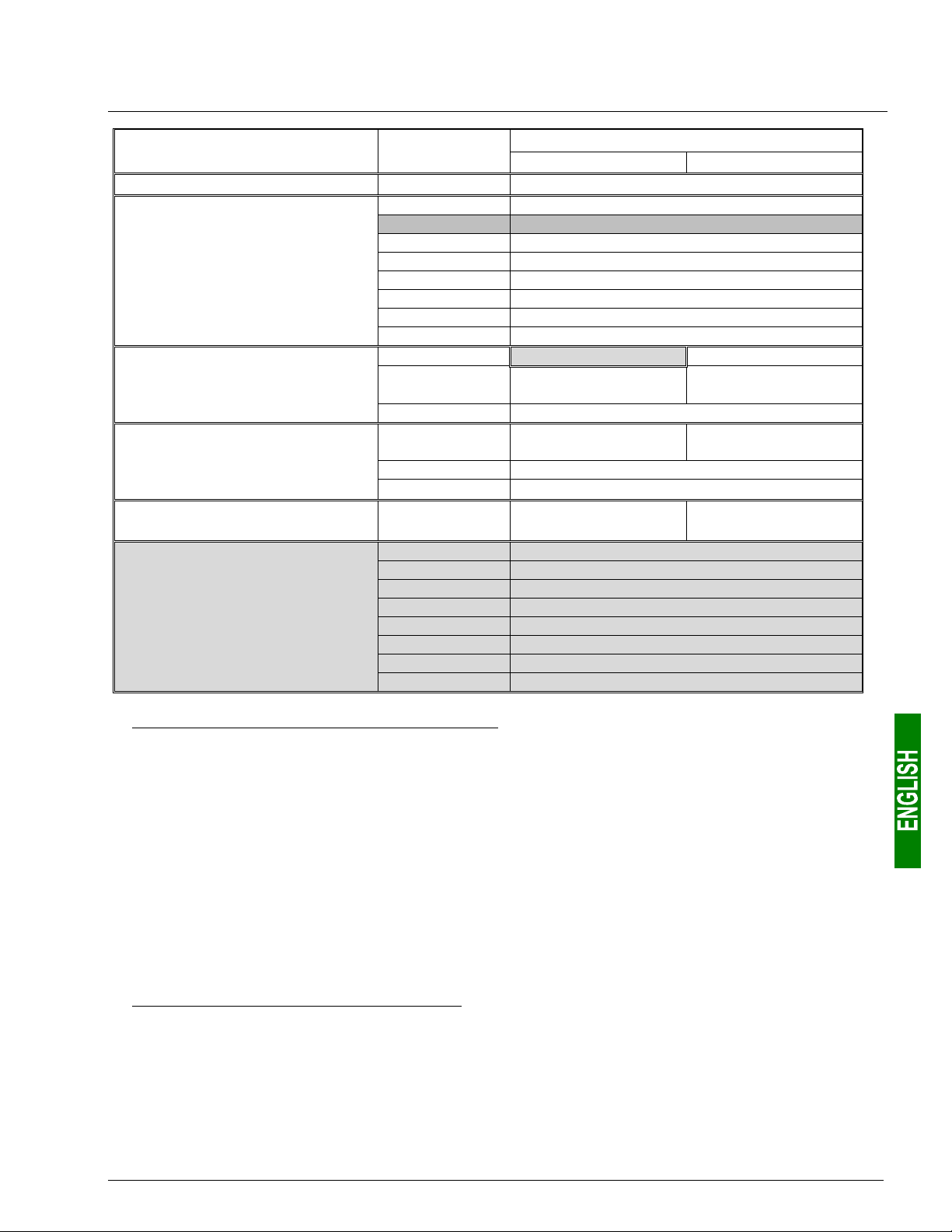

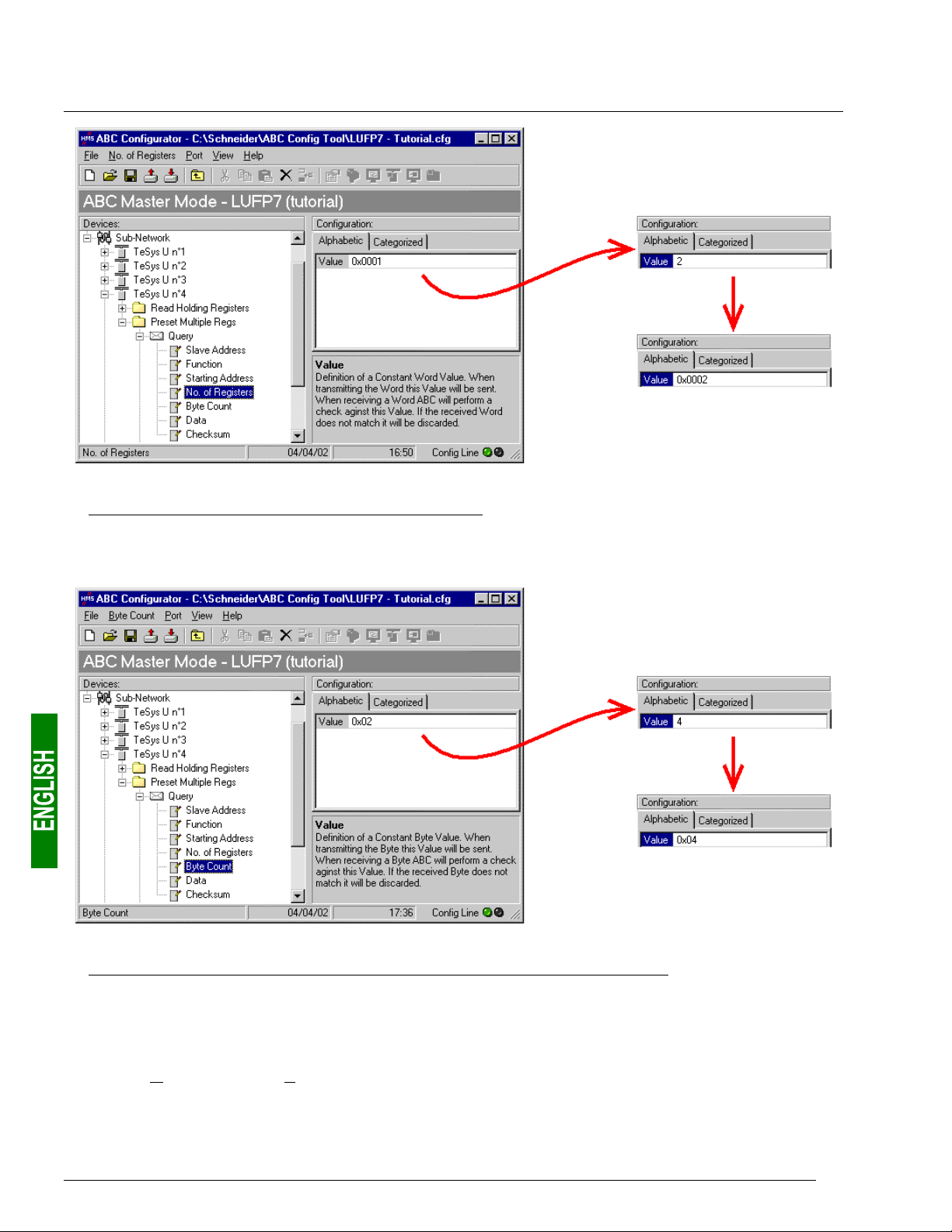

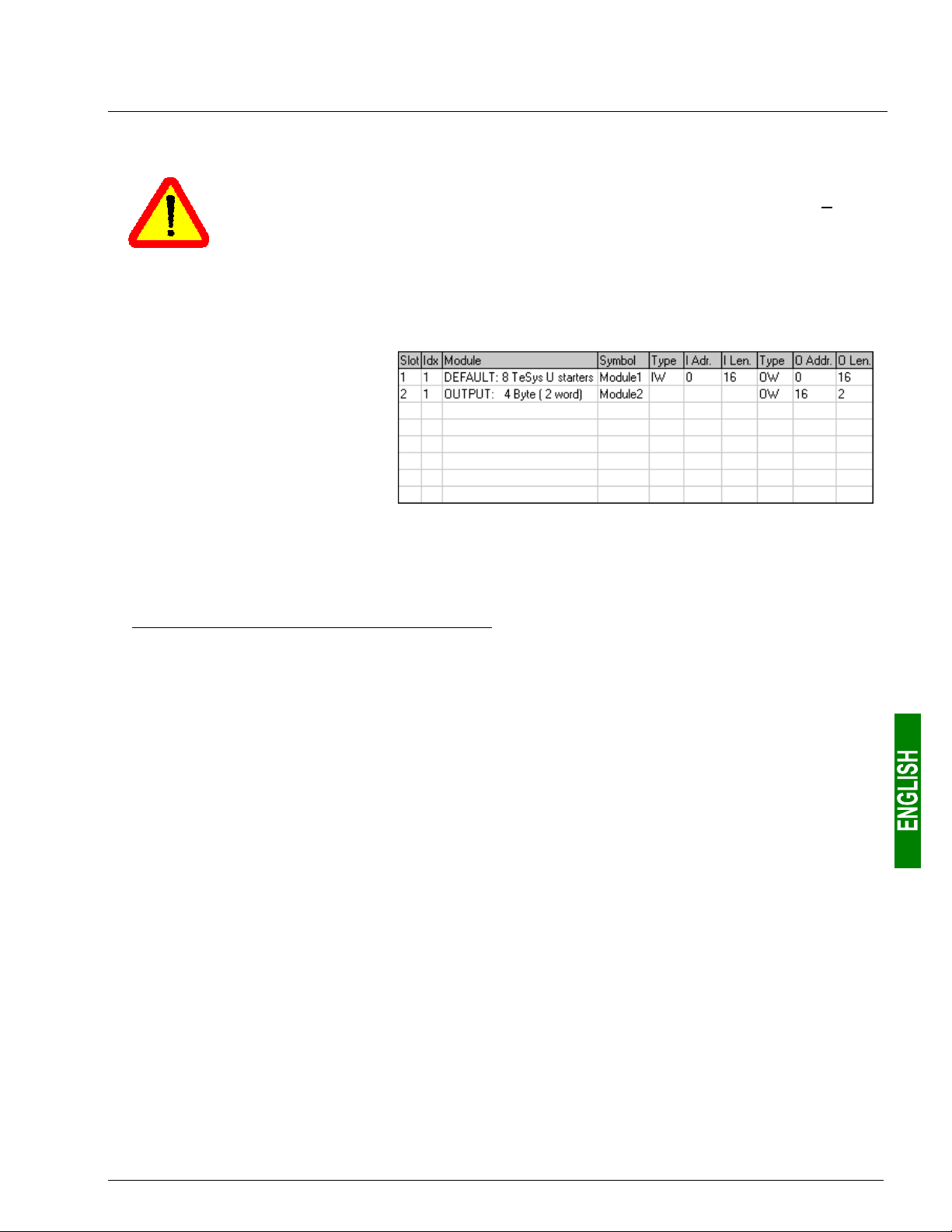

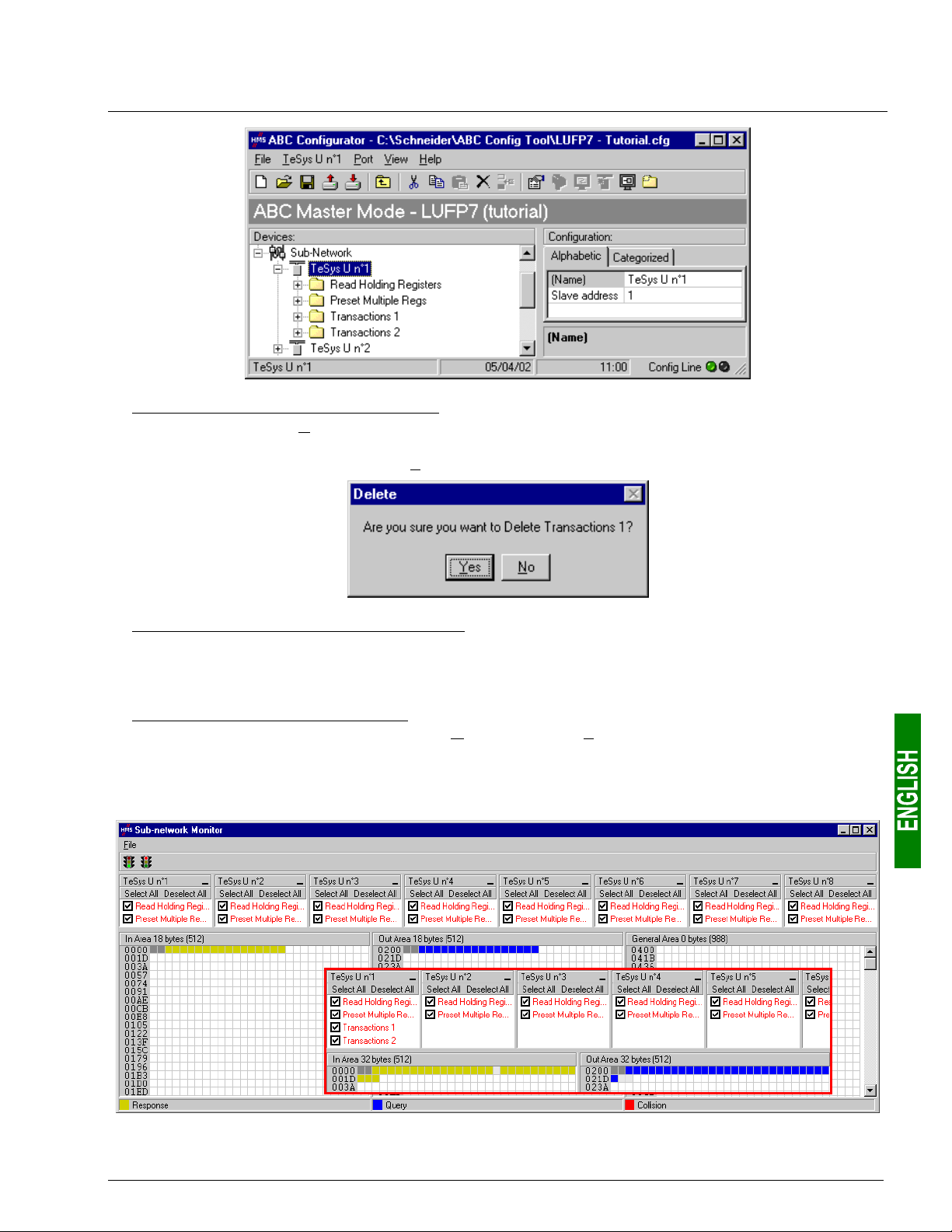

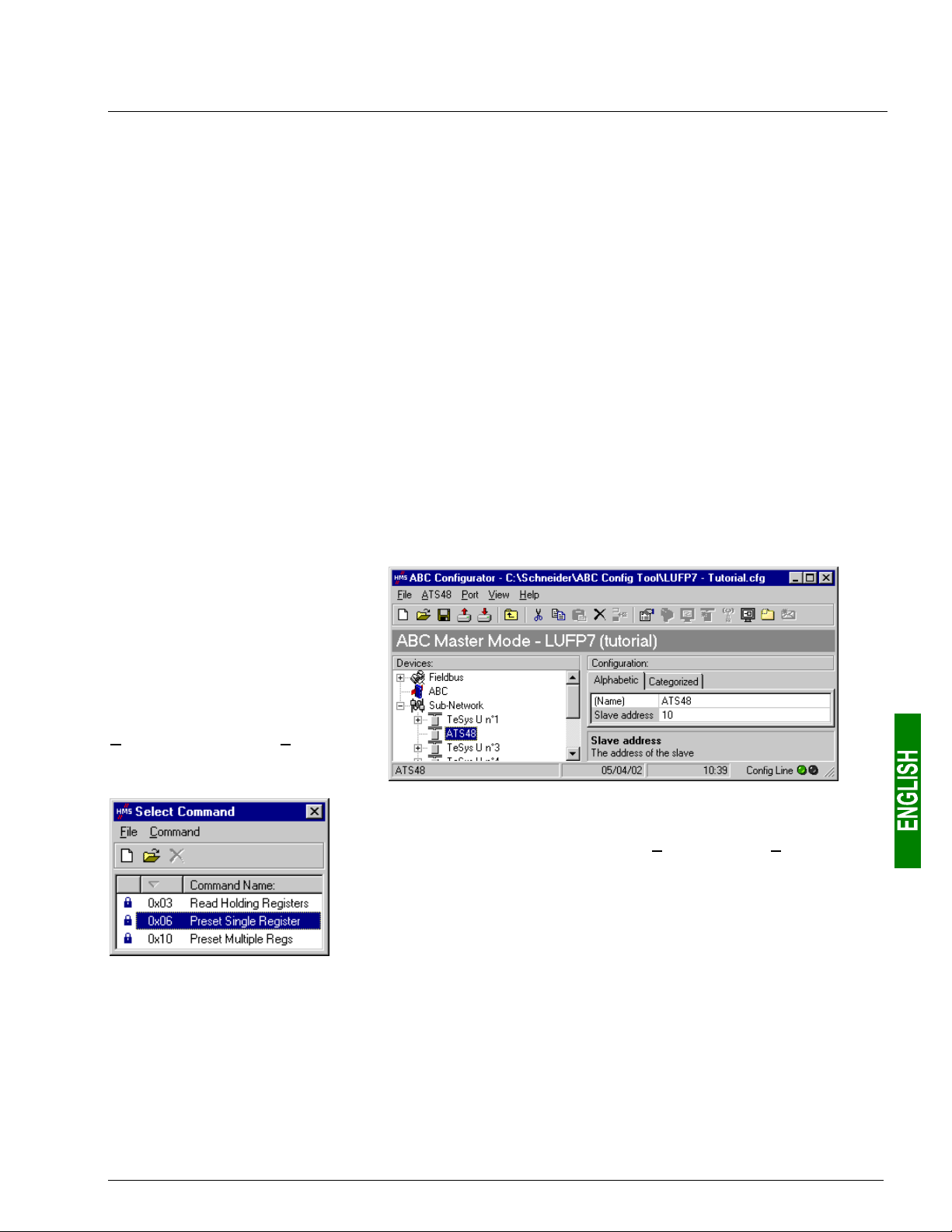

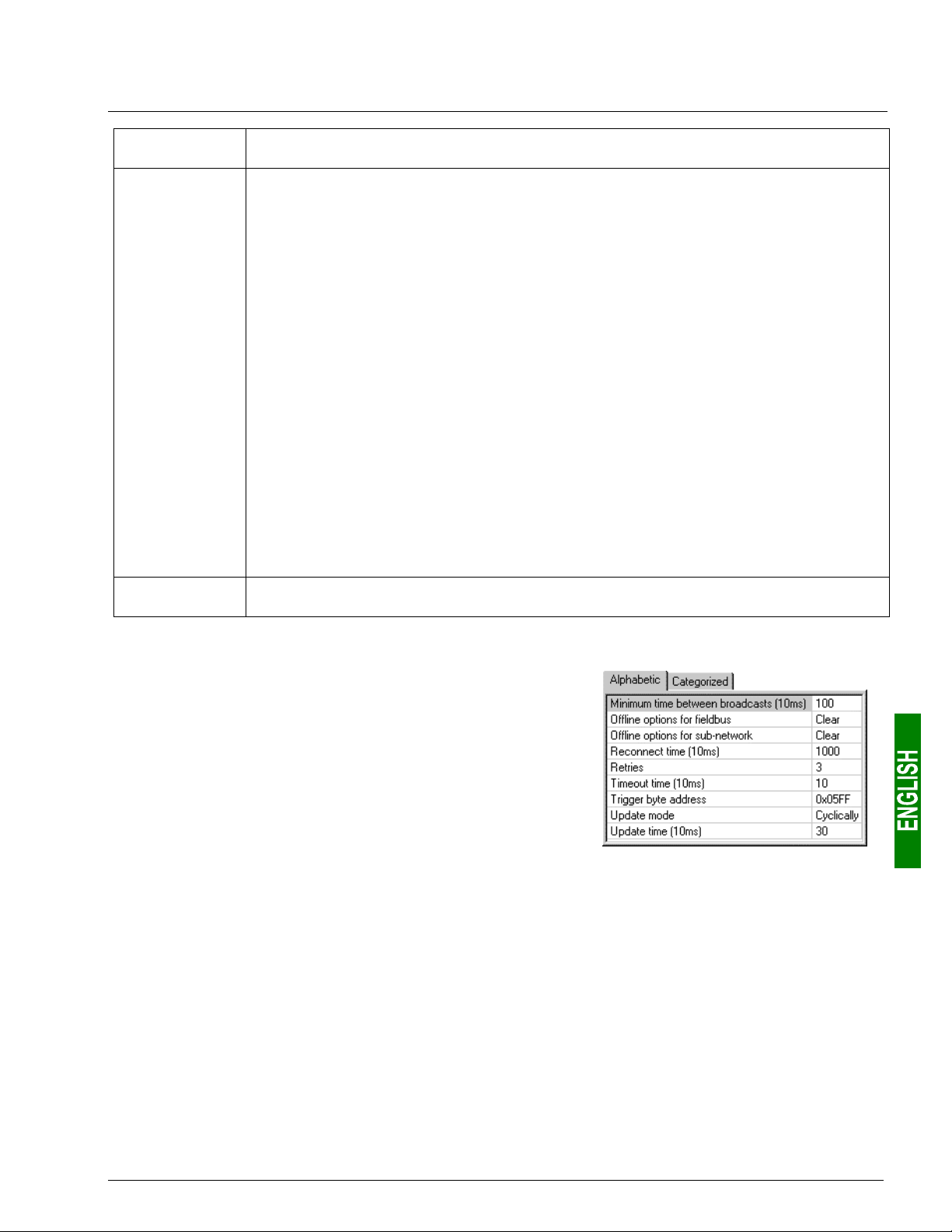

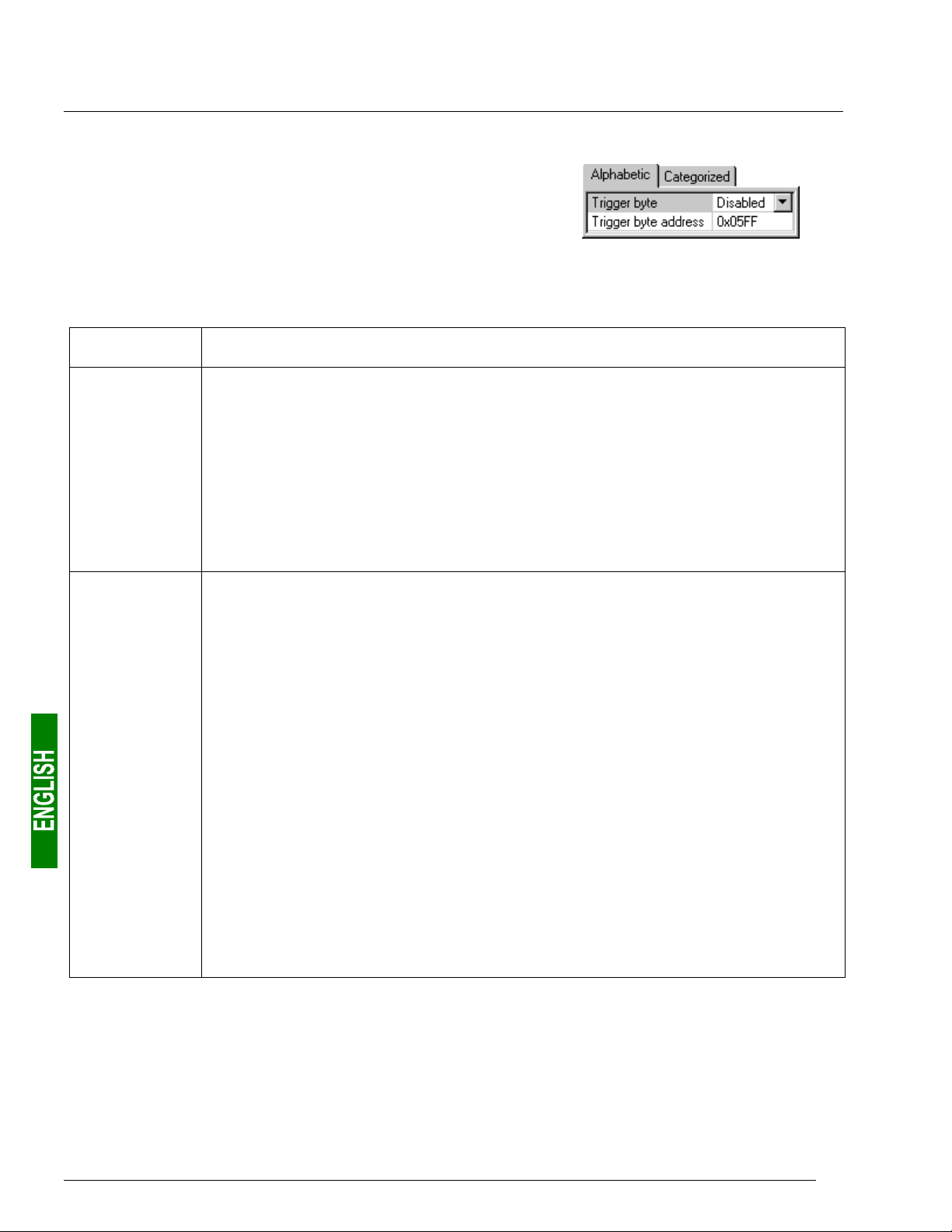

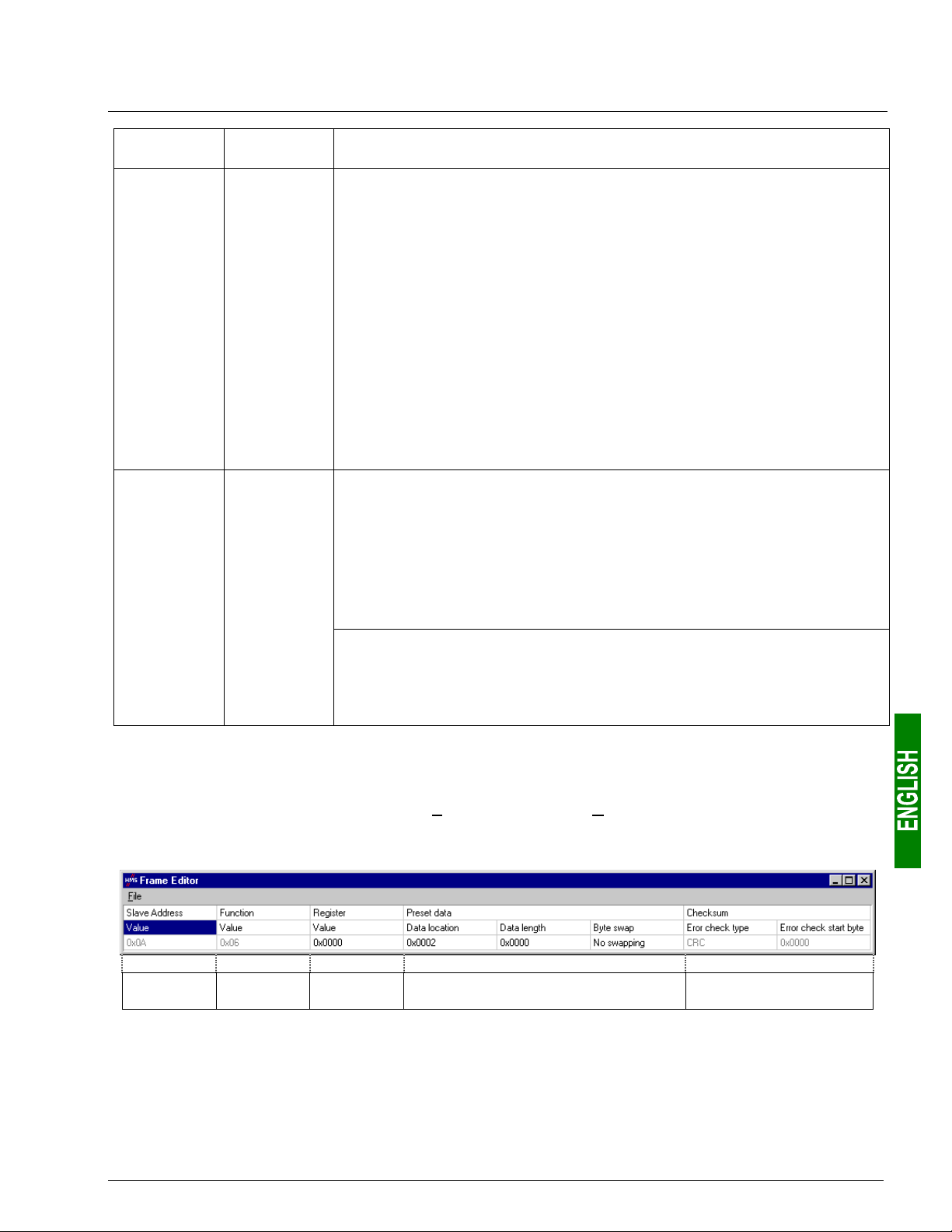

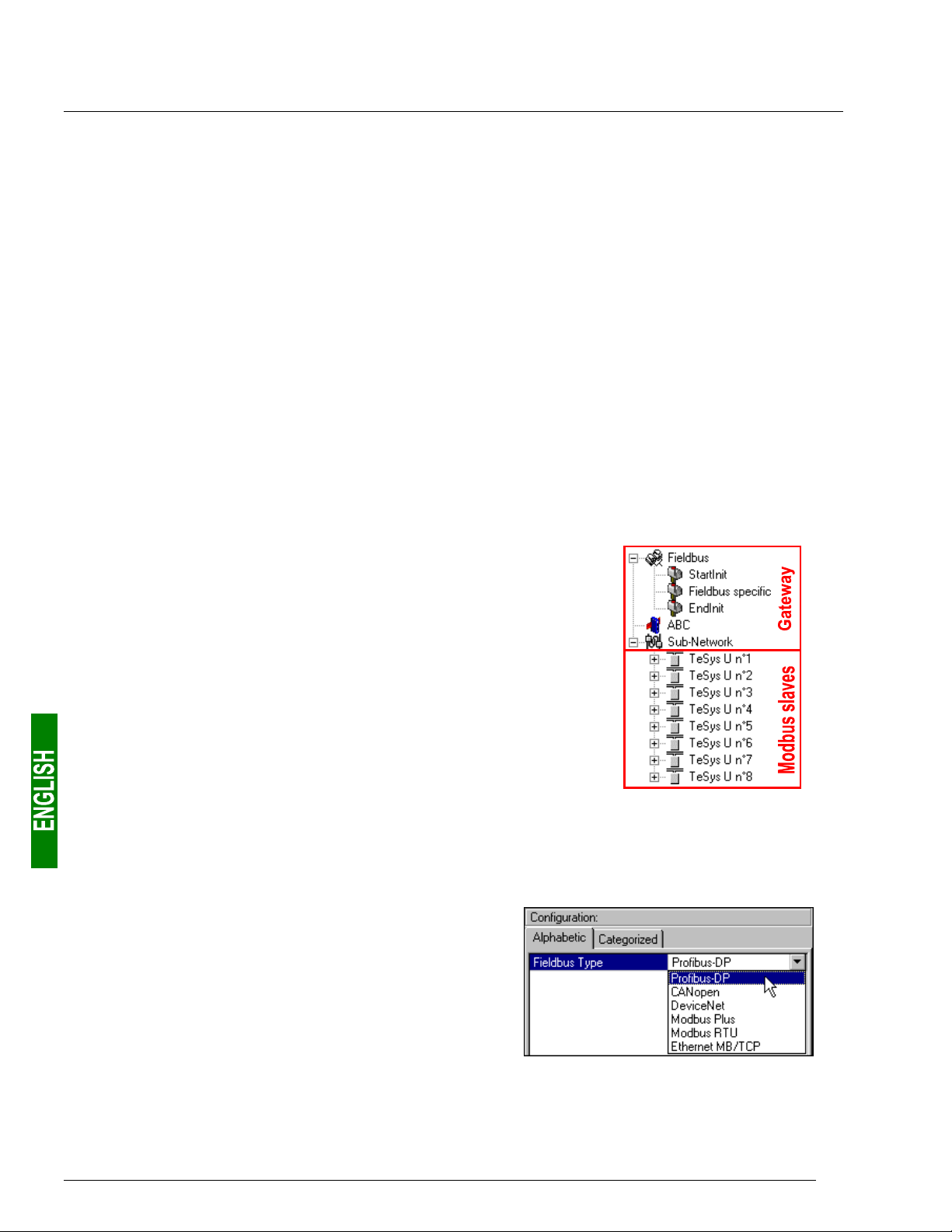

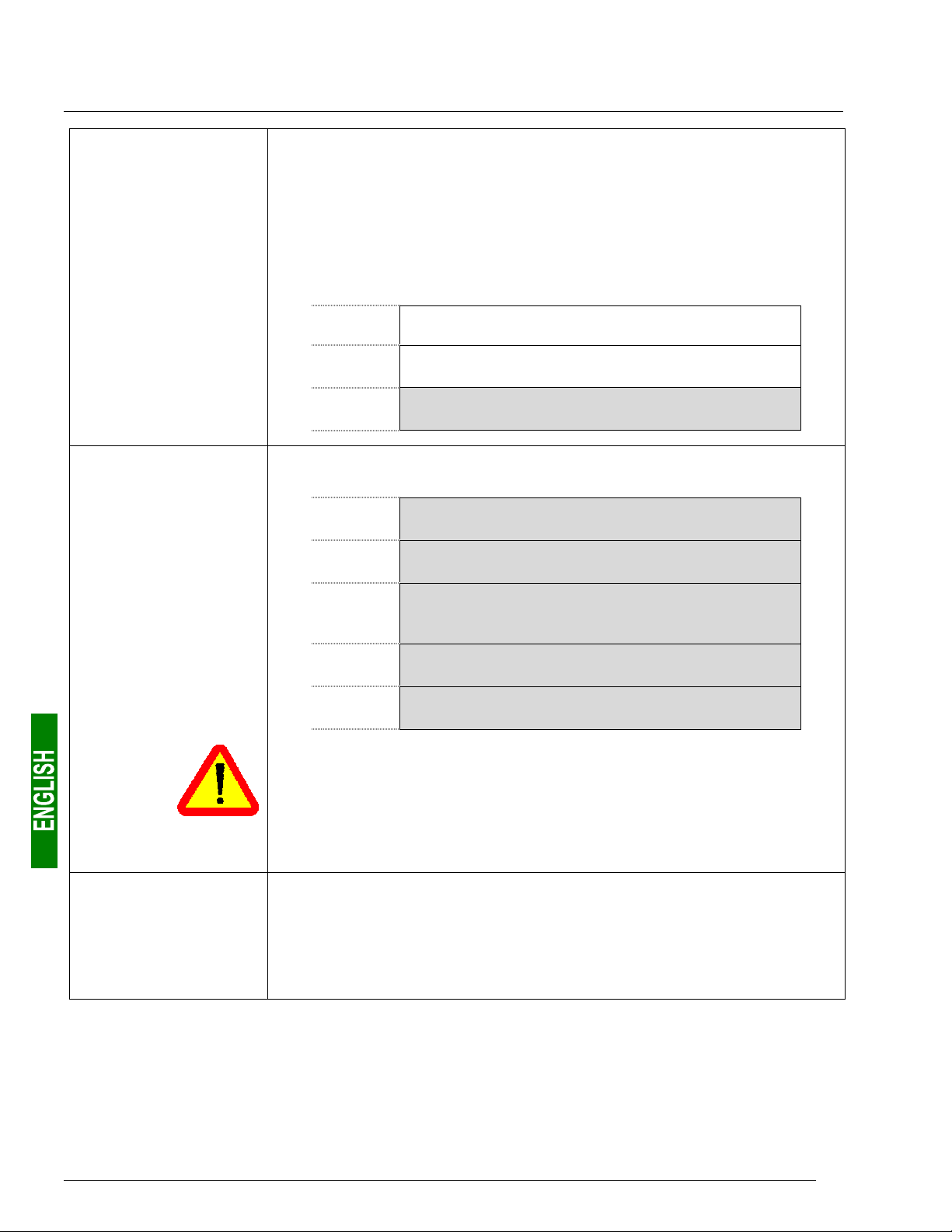

39