Schneider Electric PM5100 User Manual

PQS

PowerLogic™ PM5100 Series Power and

Energy Meter

User Guide

EAV15105 - EN03

04/2014

Safety Information

Important Information

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service or maintain it.

The following special messages may appear throughout this manual or on

the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure .

The addition of either symbol to a “Danger” or “Warning” safety label indicates that

an electrical hazard exists which will result in personal injury if the instructions are

not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Please note

WARNING indicates a potentially hazardous situation which, if not avoided, can

result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, can

result in minor or moderate injury.

NOTICE is used to address practices not related to physical injury. The safety

alert symbol shall not be used with this signal word.

Electrical equipment should be installed, operated, serviced and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training

to recognize and avoid the hazards involved.

PowerLogic™ PM5100 series user guide Table of Contents

Chapter 1: Introduction Power and Energy Meter Hardware ................................................................................. 9

Parts and Accessories .................................................................................................. 9

Box Contents ................................................................................................................ 9

Firmware .......................................................................................................................... 9

Chapter 2: Safety Precau-

tions

Chapter 3: Hardware Refer-

ence

Chapter 4: Front panel dis-

play and meter

setup

Before You Begin ........................................................................................................... 11

Notices ........................................................................................................................... 11

Models, Features and Options ....................................................................................... 13

Functions and Characteristics ........................................................................................ 13

Technical Specifications ................................................................................................. 14

Before you begin ............................................................................................................ 16

Safety precautions .......................................................................................................... 16

Dimension ......................................................................................................................17

Meter mounting .............................................................................................................. 17

Mounting the PM5100 ................................................................................................. 18

Meter wiring .................................................................................................................... 19

Recommended cables ................................................................................................ 20

Wiring Diagrams ............................................................................................................. 21

Power system ................................................................................................................. 22

Direct connect voltage limits ....................................................................................... 22

Voltage and current input wiring ................................................................................. 24

Balanced system considerations ................................................................................ 25

Control power wiring ....................................................................................................... 25

Communications ............................................................................................................. 25

Serial communications ................................................................................................ 25

Digital outputs ................................................................................................................. 27

LED indicators ................................................................................................................ 29

Heartbeat / communications LED ............................................................................... 29

Alarm / energy pulsing LED modes ............................................................................ 29

Notification icons ............................................................................................................ 30

Meter screen menus ....................................................................................................... 30

Menu tree .................................................................................................................... 31

Meter setup screen navigation .................................................................................... 32

Front panel meter setup ................................................................................................. 32

Configuring the basic setup parameters ..................................................................... 32

Communications setup ................................................................................................... 34

Setting up serial communications ............................................................................... 34

HMI settings ...................................................................................................................35

Setting up the display .................................................................................................. 35

Setting up regional settings ......................................................................................... 35

Setting up the screen passwords ................................................................................... 36

Lost password ............................................................................................................. 37

Setting the clock ............................................................................................................. 37

Advanced setup .............................................................................................................. 38

Setting up the alarm / energy pulsing LED ..................................................................... 39

Output setup ...................................................................................................................40

Demand setup ................................................................................................................ 40

Alarms setup .................................................................................................................. 41

Remote Meter Setup ...................................................................................................... 41

Chapter 5: Viewing Meter

Data

Viewing meter data from the front panel ........................................................................ 43

Meter data display screens ............................................................................................ 43

Using ION Setup to view or modify configuration data ................................................... 46

Using software to view meter data ................................................................................. 46

Chapter 6: Input / Output Digital output applications ........................................................................................... 47

Digital output setup ..................................................................................................... 47

Alarm / energy pulsing LED setup .................................................................................. 48

© 2014 Schneider Electric All Rights Reserved

5

Table of Contents PowerLogic™ PM5100 series user guide

Chapter 7: Alarms About Alarms ..................................................................................................................51

1-Second Alarms ......................................................................................................... 51

Unary Alarms ...............................................................................................................53

Alarm Priorities ............................................................................................................53

Alarm Setup ...................................................................................................................54

Setting Up 1-Second Alarms .......................................................................................55

Setting Up Unary Alarms .............................................................................................57

Viewing Alarm Activity and History ................................................................................. 57

Viewing Active Alarms and Alarm Counters ................................................................58

Viewing Unacknowledged Alarms and the Alarm History Log .................................... 59

Chapter 8: Measurements

and calculations

Real-time readings ..........................................................................................................61

Energy ............................................................................................................................ 61

Min/max values ............................................................................................................... 61

Power factor ....................................................................................................................61

Power factor min/max convention ...............................................................................62

Power factor sign convention ......................................................................................62

Demand .......................................................................................................................... 63

Power demand calculation methods ...........................................................................63

Current demand ..........................................................................................................65

Predicted demand .......................................................................................................65

Peak demand ..............................................................................................................66

Chapter 9: Power quality Harmonics overview .......................................................................................................67

Total Harmonic Distortion and Total Demand Distortion ............................................. 67

Displaying harmonics data ..............................................................................................68

Viewing harmonics using the front panel .....................................................................68

Viewing TDD ...............................................................................................................69

Viewing THD/thd using the front panel ........................................................................ 69

Chapter 10: Verifying accura-

cy

Testing overview ............................................................................................................. 71

Accuracy test requirements .........................................................................................71

Verifying accuracy test ....................................................................................................73

Energy pulsing considerations ....................................................................................75

Test points ...................................................................................................................76

Typical sources of test errors ......................................................................................76

Chapter 11: Meter resets Front panel meter reset screens ..................................................................................... 77

Global resets ................................................................................................................... 77

Single resets ................................................................................................................... 78

Chapter 12: Maintenance and

Upgrades

Password Recovery ........................................................................................................ 81

Power Meter Memory .....................................................................................................81

Identifying the Firmware Version, Model, and Serial Number ........................................81

Additional Meter Status Information ................................................................................82

Downloading Firmware ...................................................................................................82

Troubleshooting .............................................................................................................. 83

Heartbeat/Comms LED ...............................................................................................83

Getting Technical Support ..............................................................................................84

Register List ....................................................................................................................84

Chapter 13: MID Compliance MID overview ..................................................................................................................85

MID compliance for the meter .........................................................................................85

Specifications relevant to MID ........................................................................................ 85

Safety precautions ..........................................................................................................86

Installation and wiring .....................................................................................................86

Installing the terminal covers ..........................................................................................87

PM5111 default screen ...................................................................................................87

© 2014 Schneider Electric All Rights Reserved6

PowerLogic™ PM5100 series user guide Table of Contents

Meter firmware version ................................................................................................... 88

MID-protected setup parameters .................................................................................... 88

Lock-protected setup parameters ................................................................................... 88

Lock-protected functions ................................................................................................ 88

Setting up the PM5111 ................................................................................................... 89

Basic setup menu ....................................................................................................... 89

Advanced setup menu ................................................................................................ 89

Clock setup menu ....................................................................................................... 89

Passwords setup menu ............................................................................................... 89

Initializing the meter ....................................................................................................... 89

Locking or unlocking the meter ...................................................................................... 89

Setting up lock password ............................................................................................ 90

Glossary Terms ............................................................................................................................. 91

Abbreviations ..................................................................................................................93

© 2014 Schneider Electric All Rights Reserved

7

Table of Contents PowerLogic™ PM5100 series user guide

© 2014 Schneider Electric All Rights Reserved8

PowerLogic™ PM5100 user guide Chapter 1—Introduction

Chapter 1—Introduction

This user guide explains how to operate and configure a PowerLogic™ PM5100 Series

Power and Energy Meter.

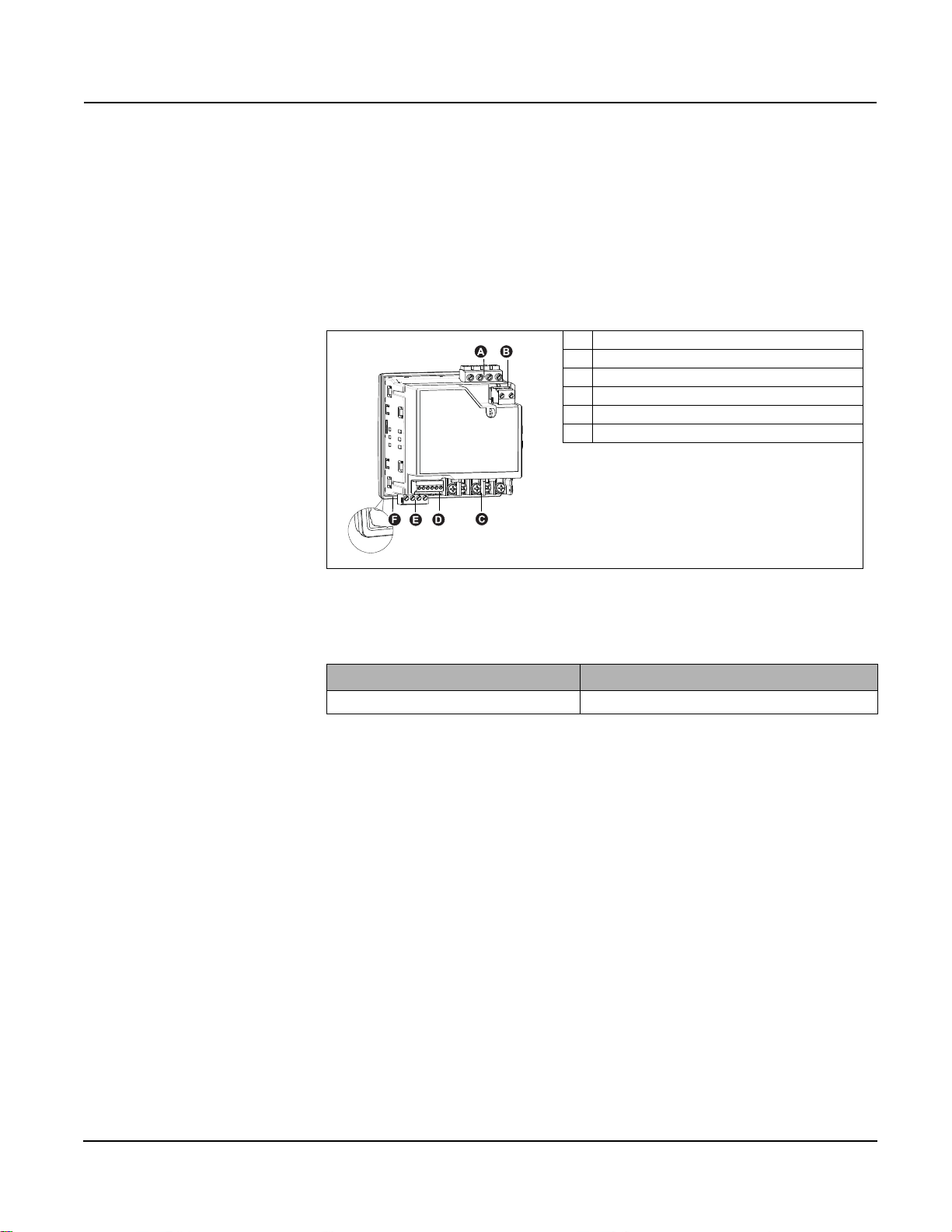

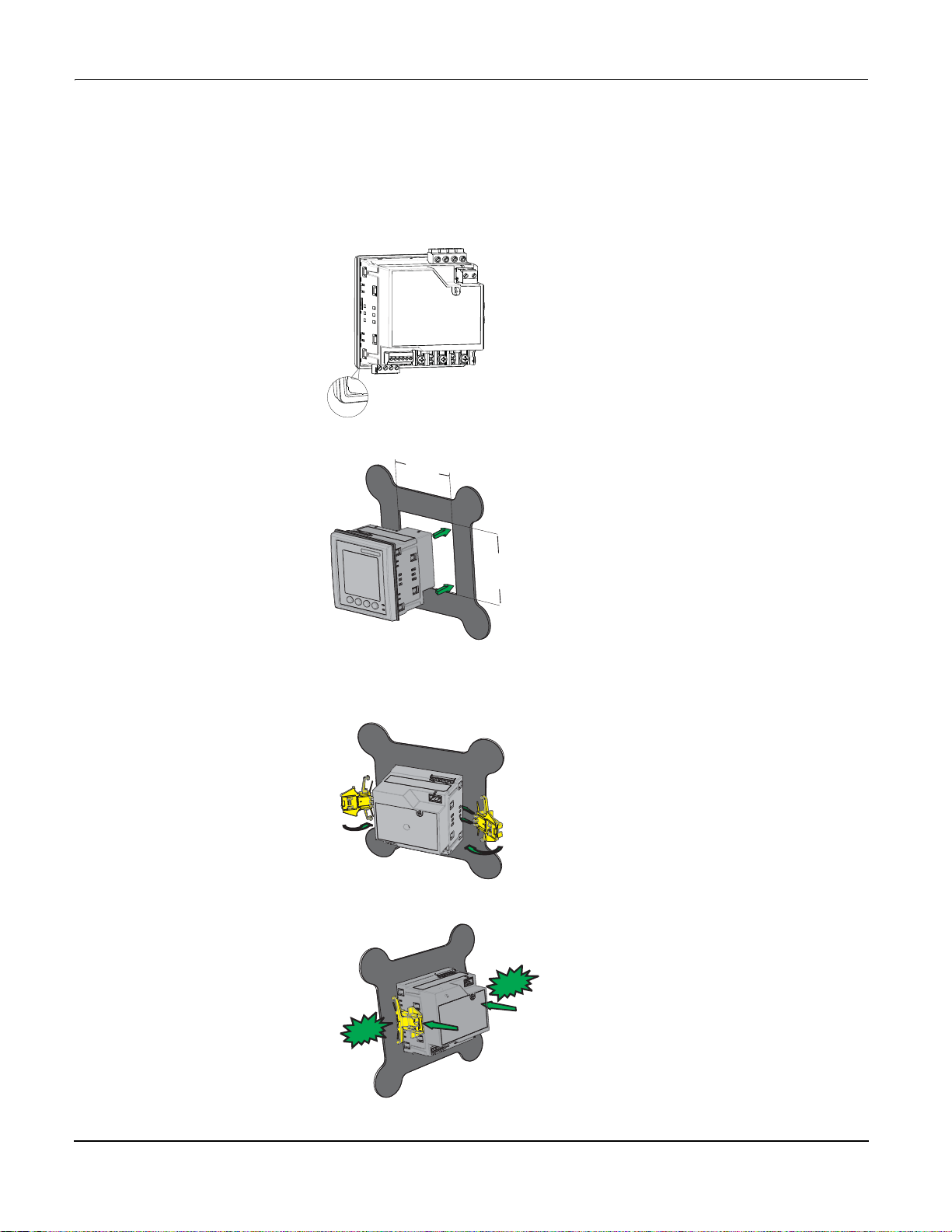

Power and Energy Meter Hardware

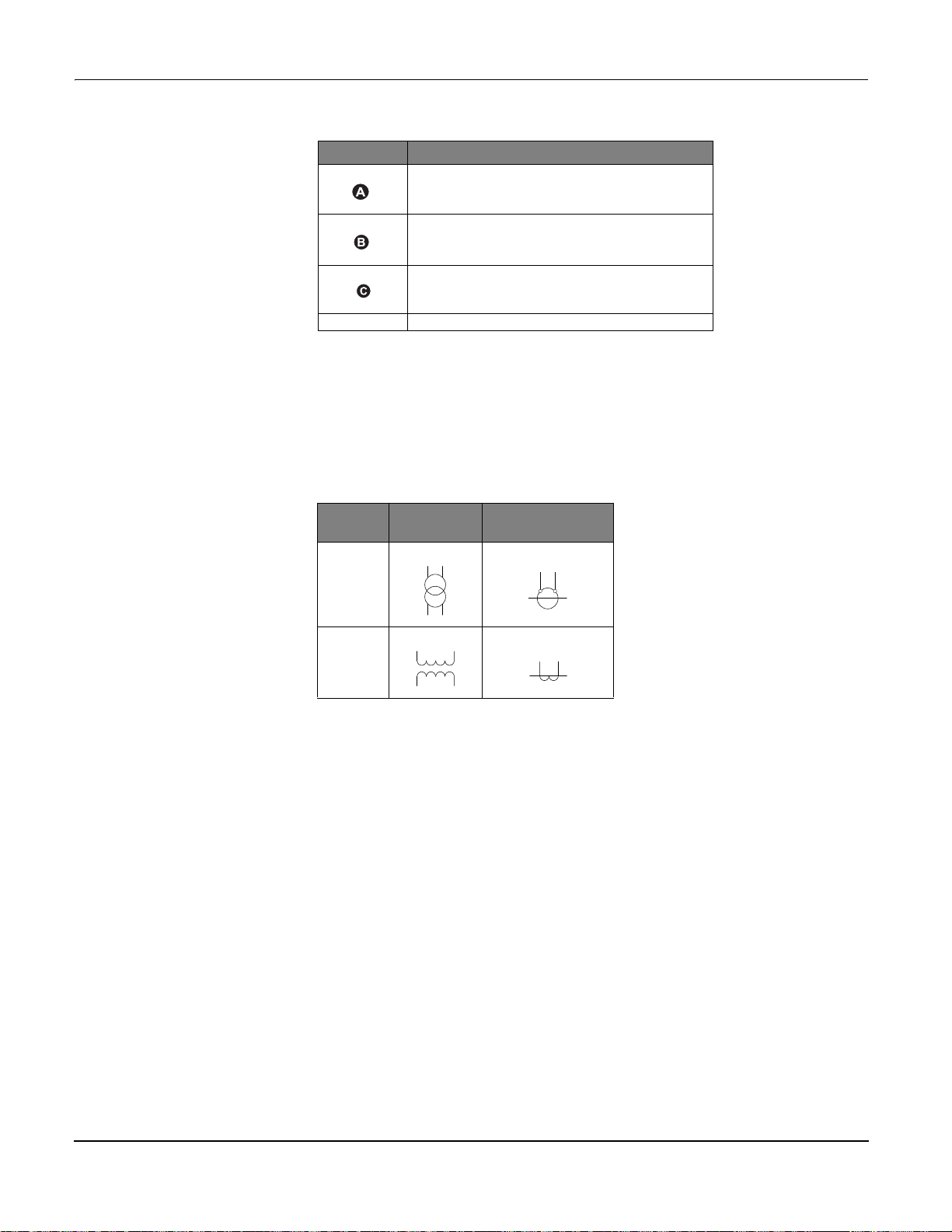

Parts of the meter (rear view)

A Voltage inputs

B Control power

C Current inputs

D Digital output

E Communications port - RS-485(optional)

FGasket

Parts and Accessories

Box Contents

Firmware

Table 1– 1 Meter Models

Description Model Numbers

Power and Energy meter with Integrated Display

PowerLogic

TM

PM5100, PM5110, and PM5111

1. Power and Energy Meter (1)

2. Installation Guide (1)

3. Calibration Certificate (1)

4. Connectors

5. Retainer Clips (2)

This user guide is written to be used with firmware version 01.00.0 and higher. See

“Identifying the Firmware Version, Model, and Serial Number” on page 81 for instructions

on determining the firmware version.

© 2014 Schneider Electric All Rights Reserved

9

Chapter 1—Introduction PowerLogic™ PM5100 user guide

© 2014 Schneider Electric All Rights Reserved10

PowerLogic™ PM5100 series user guide Chapter 2—Safety Precautions

Chapter 2—Safety Precautions

Before You Begin

Installation, wiring, testing and service must be performed in accordance with all local and

national electrical codes.

This section contains important safety precautions that must be followed before

attempting to install, service, or maintain electrical equipment. Carefully read and follow

the safety precautions outlined below.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical

work practices. In the USA, see NFPA 70E or CSAZ462.

• Only qualified electrical workers should install this equipment. Such work should be

performed only after reading this entire set of instructions.

• If the equipment is not used in a manner specified by the manufacturer, the protection

provided by the equipment may be impaired.

• NEVER work alone.

• Before performing visual inspections, tests, or maintenance on this equipment,

disconnect all sources of electric power. Assume that all circuits are live until they

have been completely de-energized, tested, and tagged. Pay particular attention to

the design of the power system. Consider all sources of power, including the

possibility of back feeding.

• Turn off all power supplying the meter and the equipment in which it is installed before

working on it.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Before closing all covers and doors, inspect the work area for tools and objects that

may have been left inside the equipment.

• When removing or installing panels, do not allow them to extend into the energized

bus.

• The successful operation of this equipment depends upon proper handling,

installation, and operation. Neglecting fundamental installation requirements may

lead to personal injury as well as damage to electrical equipment or other property.

• Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the

energy meter is installed, disconnect all input and output wires to the energy meter.

High voltage testing may damage electronic components contained in the meter.

• This equipment should be installed in a suitable electrical enclosure.

Failure to follow these instructions will result in death or serious injury.

Notices

FCC PART 15 NOTICE This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

© 2014 Schneider Electric All Rights Reserved

11

PowerLogic™ PM5100 series user guide Chapter 2—Safety Precautions

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

© 2014 Schneider Electric All Rights Reserved12

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

Chapter 3—Hardware Reference

This section supplements the meter’s installation sheet and provides additional

information about the meter’s physical characteristics and capabilities.

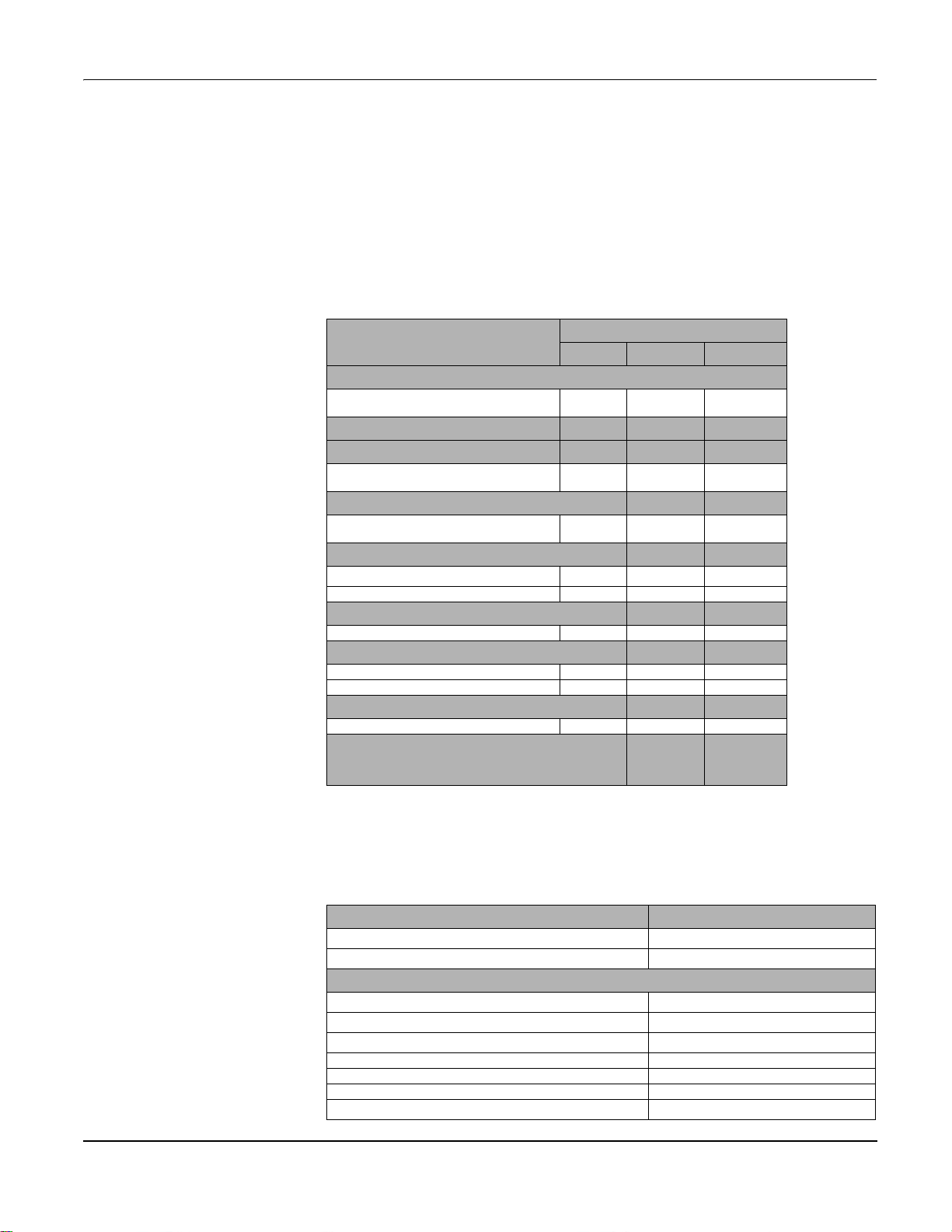

Models, Features and Options

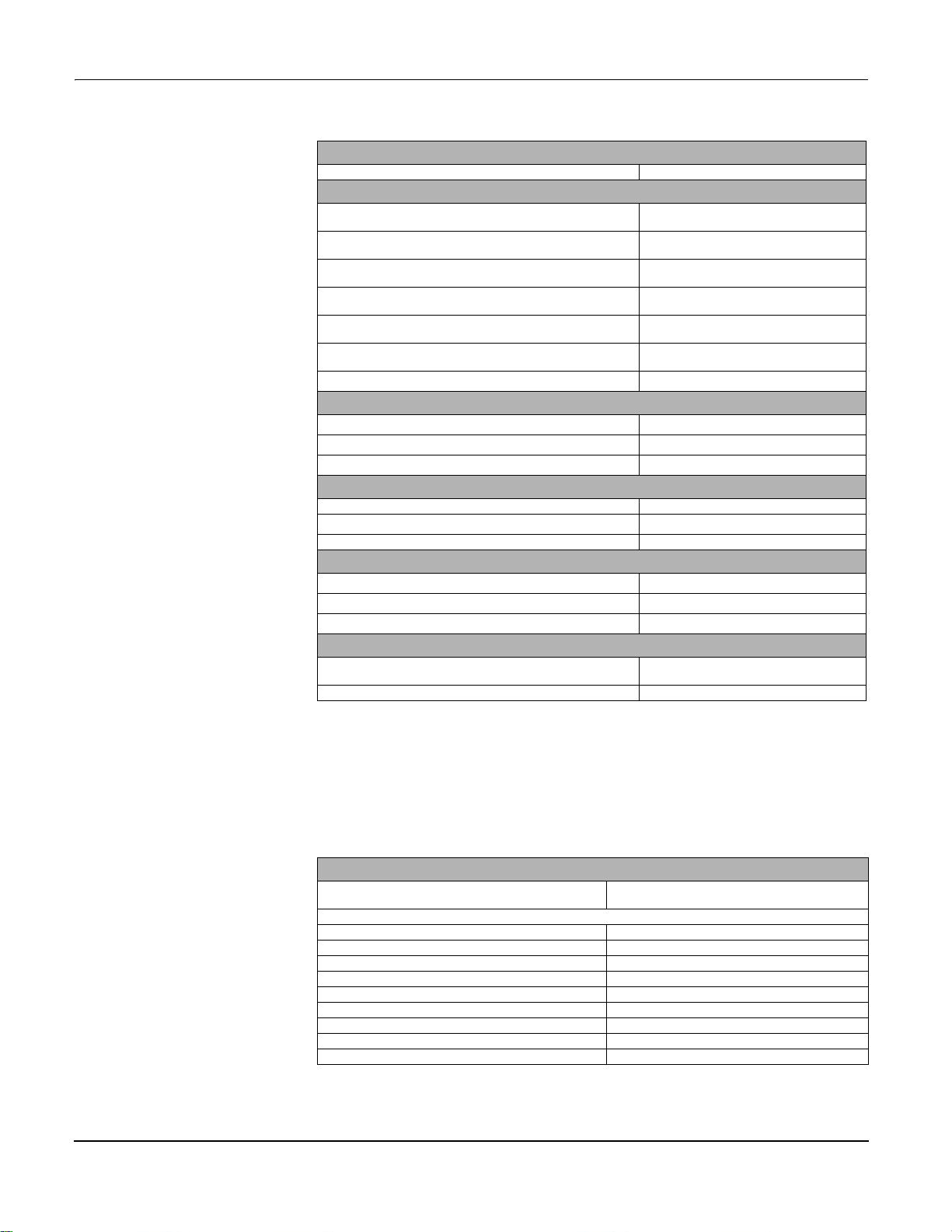

Table 3 –1: PM5100 Series - Models, Features and Options

Features and Options

Installation

Fast installation, panel mount with integrated

display

Accuracy Cl 0.5S Cl 0.5S Cl 0.5S

Display

Backlit LCD, multilingual, bar graphs, 6 lines, 4

concurrent values

Power and energy metering

3-phase voltage, current, power, demand,

energy, frequency, power factor

Power quality analysis

THD, thd, TDD

Harmonics, individual (odd) up to 15th 15th 15th

I/Os

Digital output 1DO 1DO 1DO

Alarms and control

Alarms 33 33 33

Set point response time, seconds 1 1 1

Communications

Serial ports with modbus protocol 0 1 1

MID ready compliance,

EN50470-1/3, Annex B and Annex D

Class C

PM5100 PM5110 PM5111

PM5100 series

Functions and Characteristics

Table 3 –2: Functions and Characteristics

General PM5100 Series

Use on LV and MV systems

Basic metering with THD and min/max readings

Instantaneous rms values

Current (per phase and neutral)

Voltage (total, per phase L-L and L-N)

Frequency

Real, reactive, and apparent power (Total and per phase) Signed, Four Quadrant

True Power Factor (Total and per phase) Signed, Four Quadrant

Displacement PF (Total and per phase) Signed, Four Quadrant

% Unbalanced I, V L-N, V L-L

© 2014 Schneider Electric All Rights Reserved 13

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

Energy Values*

Accumulated Active, Reactive and Apparent Energy Received/Delivered; Net and absolute

Demand Values*

Current average

Active power

Reactive power

Apparent power

Demand calculation (Sliding, fixed and rolling block, thermal

methods)

Synchronization of the measurement window to input,

communication command or internal clock

Settable Demand intervals

Present, Last, Predicted, Peak, and Peak

Date Time

Present, Last, Predicted, Peak, and Peak

Date Time

Present, Last, Predicted, Peak, and Peak

Date Time

Present, Last, Predicted, Peak, and Peak

Date Time

Other Measurements*

Operating timer

Load timer

Alarm counters and alarm logs

Power Quality Measurements

THD, thd (Total Harmonic Distortion) I, V L-N, V L-L per phase I, V L-N, V L-L

TDD (Total Demand Distortion)

Individual harmonics (odds) 15th

Data Recording

Min/max of instantaneous values, plus phase identification*

Alarms with 1s timestamp*

Min/max log

I/Os

Digital output

Timestamp resolution in seconds 1

1

(kWh only)

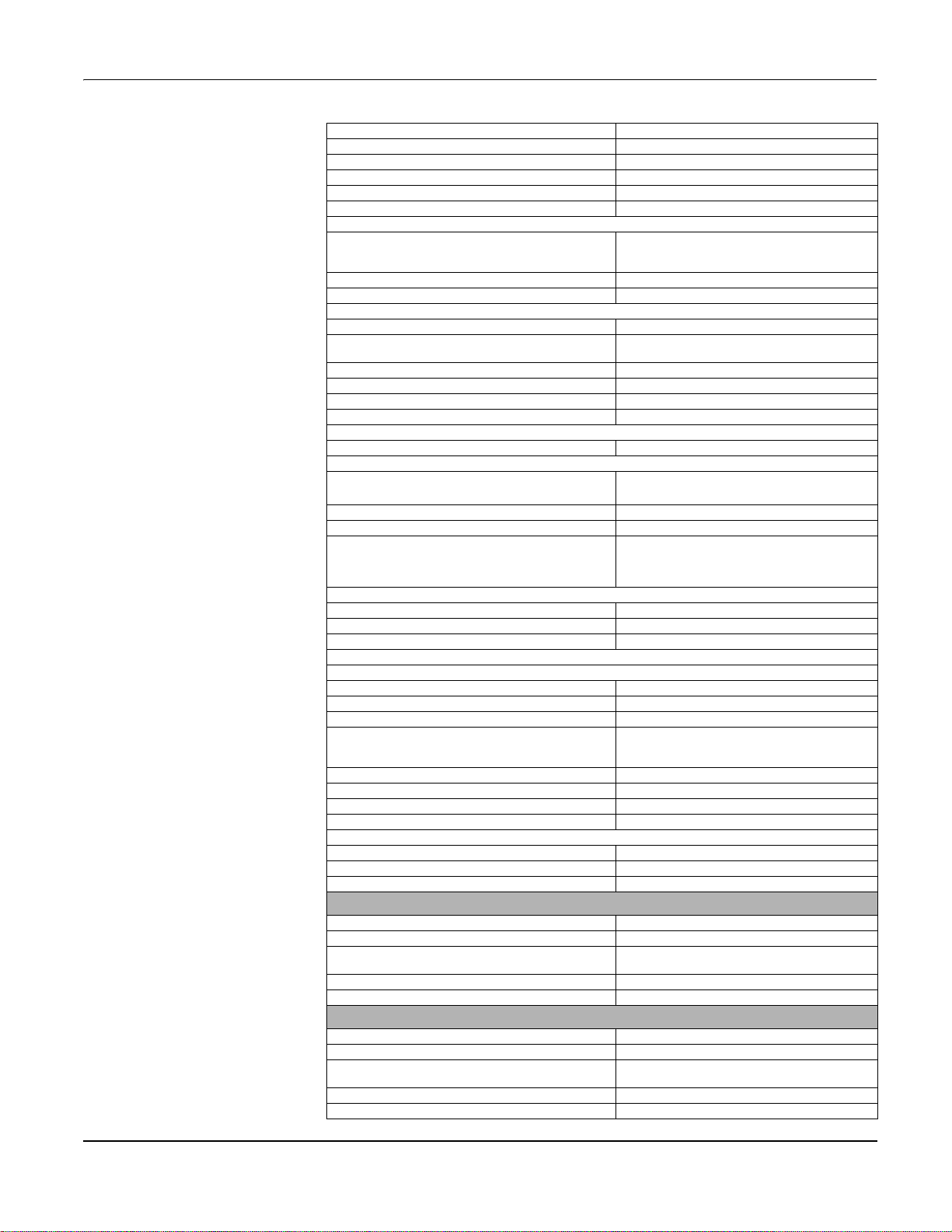

Technical Specifications

NOTE: *Stored in non-volatile memory

Electrical Characteristics

Type of measurement: True rms on three-phase

(3P, 3P + N), zero blind

Measurement accuracy

IEC 61557-12

Active Energy

Reactive Energy

Active Power Class 0.5 as per IEC 61557-12

Reactive Power Class 2 as per IEC 61557-12

Apparent Power Class 0.5 as per IEC 61557-12

Current, Phase Class 0.5 as per IEC 61557-12

Voltage, L-N Class 0.5 as per IEC 61557-12

Frequency Class 0.05 as per IEC 61557-12

1

2

2

64 samples per cycle

PMD/[SD|SS]/K70/0.5

Class 0.5S as per IEC 62053-22

Class 2S as per IEC 62053-23

© 2014 Schneider Electric All Rights Reserved14

1

1

1

1

1

1

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

Power Factor Class 0.5 as per IEC 61557-12

Voltage Harmonics Class 5 as per IEC 61557-12

Voltage THD/thd Class 5 as per IEC 61557-12

Current Harmonics Class 5 as per IEC 61557-12

Current THD/thd Class 5 as per IEC 61557-12

1

1

1

1

1

MID Directive (2004/22/EC) Annex B and Annex D (PM5111) Class C

Input-voltage (up to 1.0 MV AC max, with voltage transformer)

UL: 20-347 V L-N/35-600 V L-L

Nominal Measured Voltage range

IEC: 20-400 V L-N/35-690 V L-L

(absolute range 35 V L-L to 760 V L-L)

Impedance 5 M Ω

F nom 50/60 Hz

Input-current (configurable for 1 or 5 A secondary CTs)

I nom 5 A

Measured Amps with over range and Crest Factor

Starting current: 5mA

Operating range: 50mA to 8.5A

Withstand Continuous 20 A,10s/hr 50 A, 1s/hr 500 A

Impedance < 0.3 m Ω

F nom 50/60 Hz

Burden <0.026VA at 8.5A

Frequency measurement

Measurement range 45 to 65 Hz

AC control power

Operating range

100 - 277 V AC L-N / 415 V L-L +/-10%

CAT III 300V class per IEC 61010

Burden <5 W,11 VA at 415 V L-L

Frequency 45 to 65 Hz

80 mS typical at 120V AC and maximum burden.

Ride-through time

100 mS typical at 230 V AC and maximum burden

100 mS typical at 415 V AC and maximum burden

DC control power

Operating range 125-250 V DC ±20%

Burden <4 W at 250 V DC

Ride-through time 50 mS typical at 125 V DC and maximum burden

Outputs

Digital output

Max load voltage 40 V DC

Max load current 20 mA

On Resistance 50 Ω max

Meter constant

from 1 to 9,999,999 pulses per k_h (k_h = kWh,

kVARh or kVAh depending on the energy parameter

selected)

Pulse width for Digital Output 50% duty cycle

Pulse frequency for Digital Output 25 Hz max.

Leakage current 0.03 micro Amps

Isolation 5 kV rms

Optical outputs

Pulse width (LED) 200

s

Pulse frequency 50 Hz. max.

Meter constant from 1 to 9,999,999 pulses per k_h

Mechanical Characteristics

Product weight 380 g

IP degree of protection (IEC 60529) IP52 front display, IP30 meter body

Dimensions W x H x D [protrusion from cabinet]

96 x 96 x 72mm (depth of meter from housing

mounting flange) [13mm]

Mounting position Vertical

Panel thickness 6 mm maximum

Environmental Characteristics

Operating temperature

Meter -25 °C to +70 °C

Display (Display functions to -25º with reduced

performance)

Storage temp. -40 °C to +85 °C

Humidity range 5 to 95% RH at 50 °C (non-condensing)

-25 °C to +70 °C

© 2014 Schneider Electric All Rights Reserved 15

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

Pollution degree 2

Altitude 2000 m CAT III / 3000 m CAT II

For indoor use only

Electromagnetic Compatibility

Electrostatic discharge IEC 61000-4-2

Immunity to radiated fields IEC 61000-4-3

Immunity to fast transients IEC 61000-4-4

Immunity to surge IEC 61000-4-5

Conducted immunity 150kHz to 80MHz IEC 61000-4-6

Immunity to magnetic fields IEC 61000-4-8

Immunity to voltage dips IEC 61000-4-11

Radiated emissions FCC part 15, EN 55022 Class B

Conducted emissions FCC part 15, EN 55022 Class B

3

Safety

Europe

U.S. and Canada

Measurement category (Voltage and Current inputs) CAT III up to 400 V L-N / 690 V L-L

Dielectric As per IEC/UL 61010-1 (3rd Edition)

Protective Class II, Double insulated for user accessible parts

CE, as per IEC 61010-1 (3rd Edition), IEC 62052-11

& IEC61557-12

cULus as per UL61010-1 (3rd Edition)

CAN/CSA-C22.2 No. 61010-1 (3rd Edition)

1

Communication

RS-485 port Modbus RTU, Modbus ASCII (7 or 8 bit),

JBUS

Firmware and language file update Meter firmware update via the communication ports

Isolation 2.5 kVrms, double insulated

2-Wire, 9600,19200 or 38400 baud, Parity - Even,

Odd, None, 1 stop bit if parity Odd or Even, 2 stop

bits if None; (Optional)

Human Machine Interface

Display type Monochrome Graphics LCD

Resolution 128 x 128

Backlight White LED

Viewable area (W x H) 67 x 62.5 mm

Keypad 4-button

Indicator Heartbeat / Comm activity Green LED

Energy pulse output / Active alarm indication (configurable) Optical, amber LED

Wavelength 590 to 635 nm

Maximum pulse rate 2.5 kHz

Before you begin

Safety precautions

1

For firmware version 1.1.1 and higher

2

For 1A nominal CT when I > 0.15A

3

Tests are conducted as per IEC 61557-12 (IEC 61326-1), 62052-11 and EN50470

Carefully read and follow the safety precautions before working with the meter.

Installation, wiring, testing and service must be performed in accordance with all local and

national electrical codes.

© 2014 Schneider Electric All Rights Reserved16

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

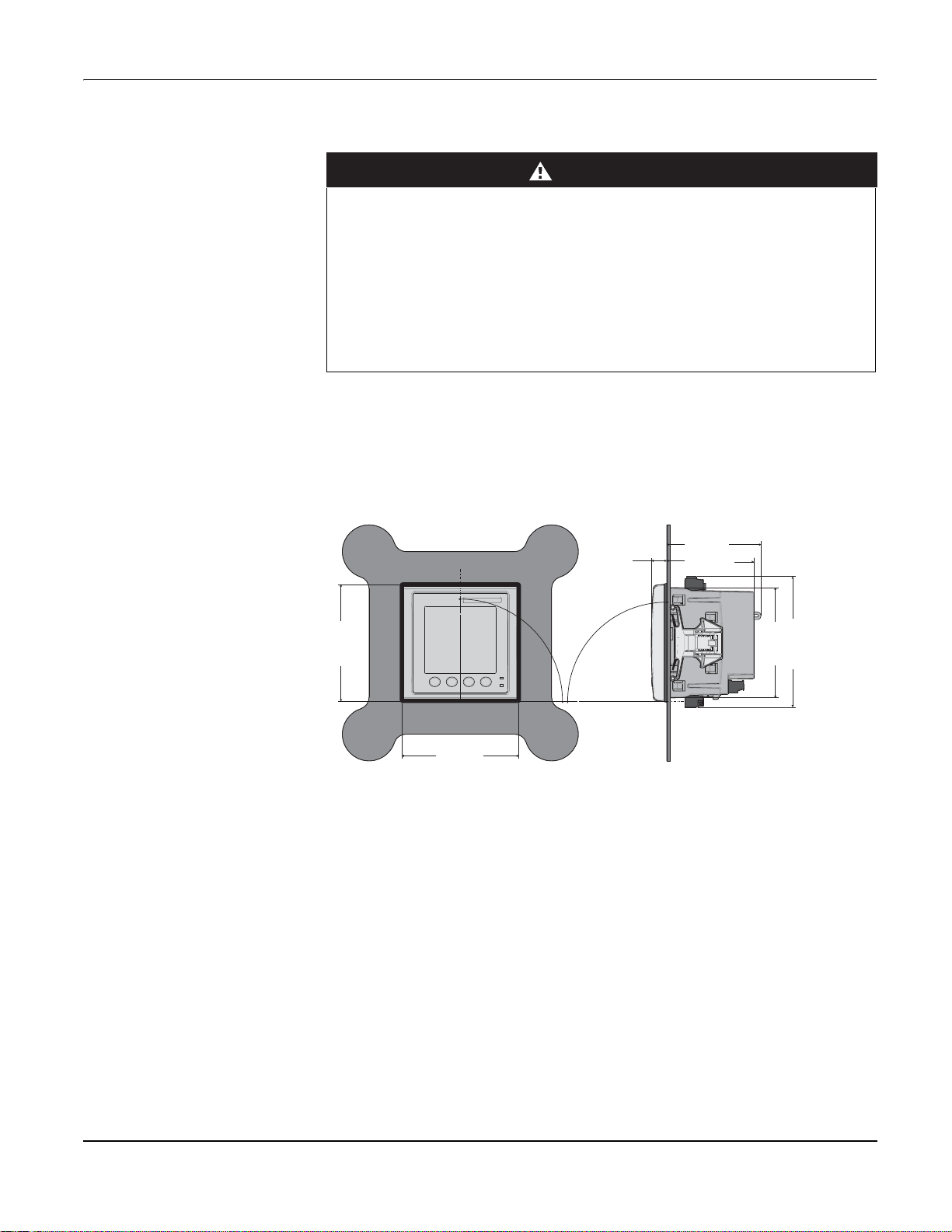

DANGER

90.00°

90.00°

96.00mm

96.00

mm

78.5 mm

12.8 mm

107.4

mm

90.6

mm

72.00 mm

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical

work practices. See NFPA 70E in the USA or applicable local standards.

• Turn off all power supplying this device before working on it.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Do not exceed the device’s ratings for maximum limits.

• Always use grounded external CTs for current inputs.

Failure to follow these instructions will result in death or serious injury.

1. Turn off all power supplying this device before working on it.

2. Always use a properly rated voltage sensing device to confirm that all power is off.

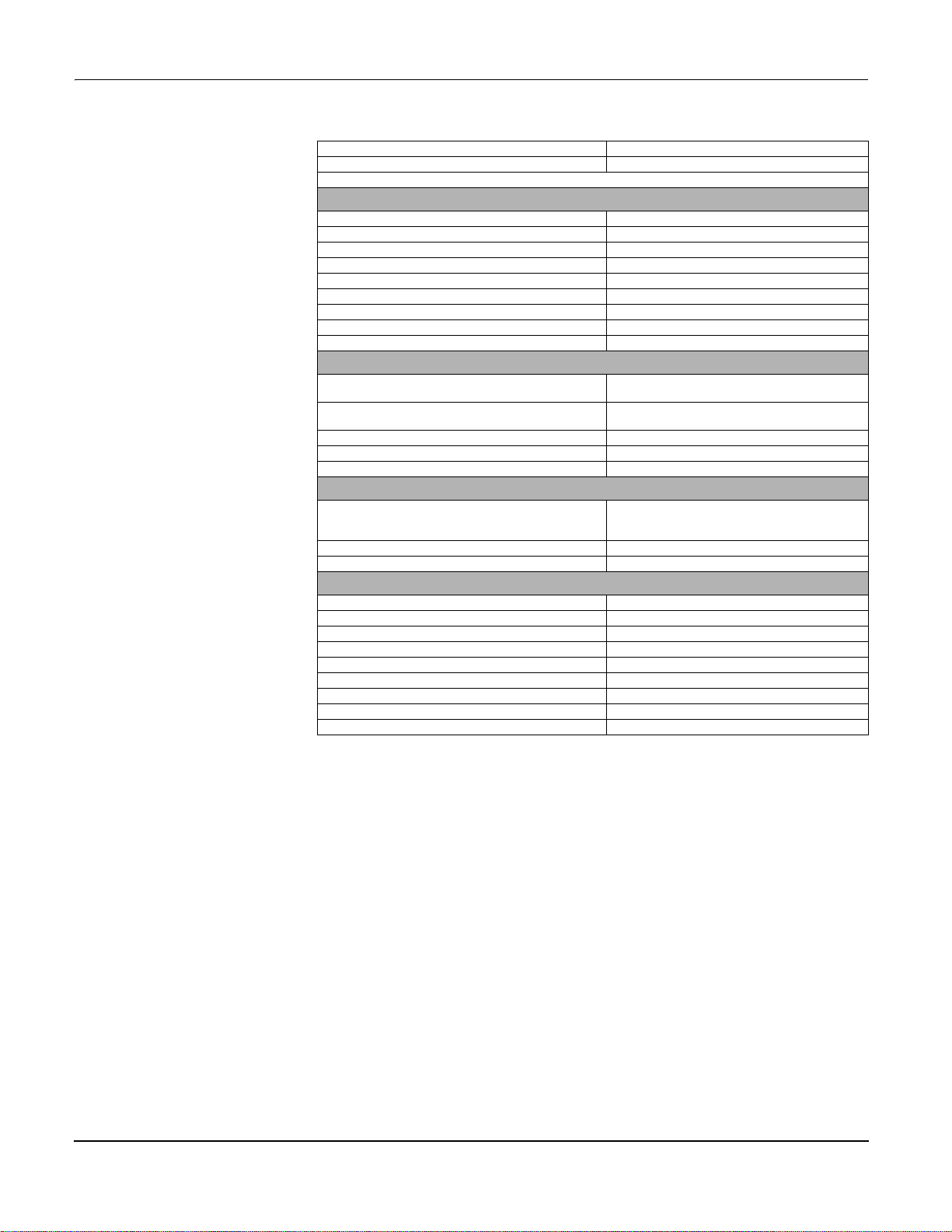

Dimension

Figure 3–1: Dimension

Meter mounting

This section describes how to mount the meter.

© 2014 Schneider Electric All Rights Reserved 17

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

92.0

mm

+0.8

-

0.0

92.0

mm

+0.8

-

0.0

CLICK

CLIC

K

Mounting the PM5100

The meter is designed to be mounted inside a 1/4-DIN panel cutout.

1. Inspect the gasket (installed around the perimeter of the front display) and make sure

it is secured properly and not damaged.

2. Insert the meter through the mounting hole.

3. Line up the tabs of the retainer clips with the slots on either side of the meter. While

holding the retainers at a slight angle, push the retainers in and forward to position

them in place. In situations where the spacing between meters is tight, use a flat-head

screwdriver with a long, narrow shaft to help secure the clips.

4. Push the middle of the clip assembly to lock the retainer in place and secure the

meter.

© 2014 Schneider Electric All Rights Reserved18

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

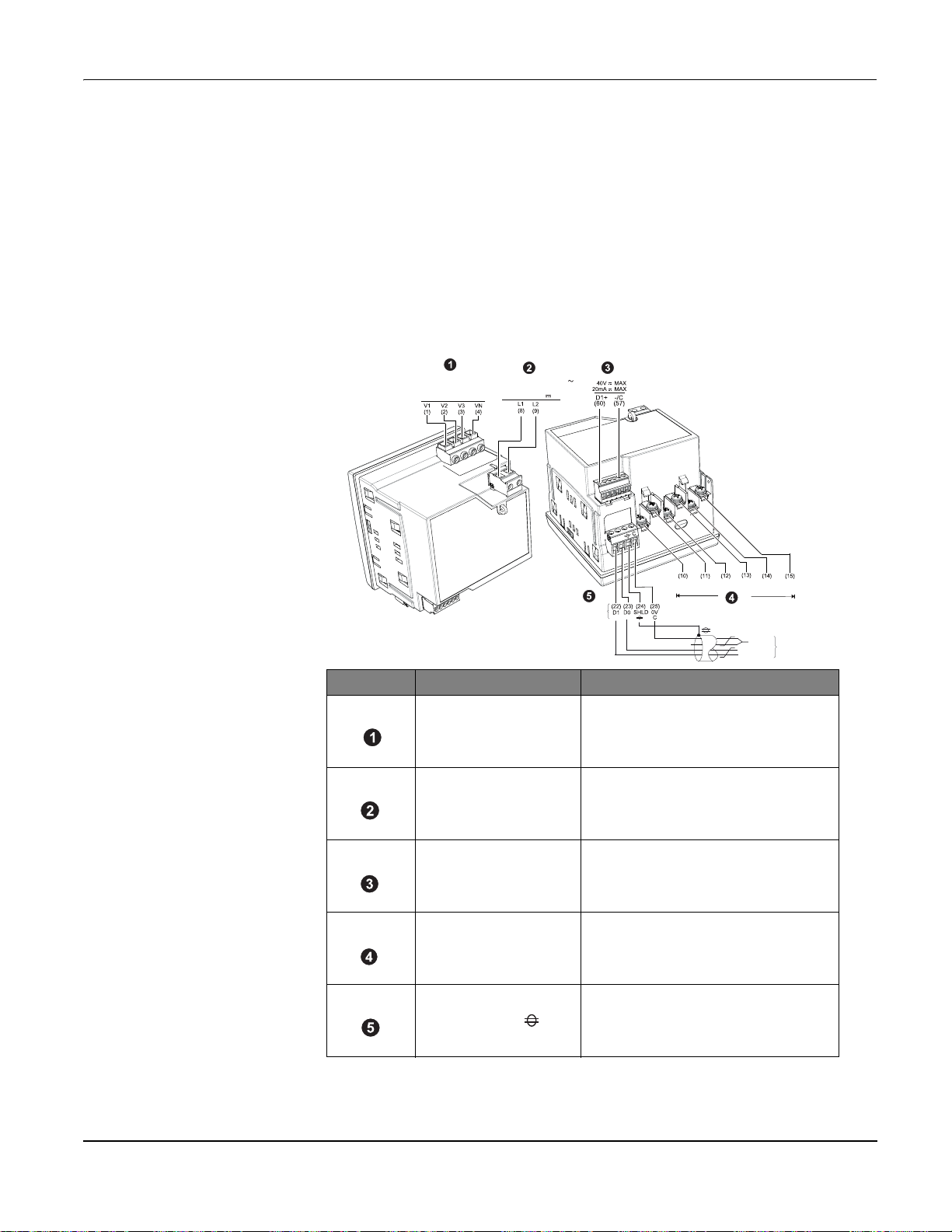

Meter wiring

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

• Wire connections to the meter’s voltage inputs, control power, digital output, and RS-

485 communications are terminated using the supplied pluggable wire connectors.

• When wiring the meter’s current inputs, terminate the wire ends with ring or split-ring

crimp connectors.

Use the meter installation sheet when wiring the meter.

UL: CAT III

20-347VLN/35-600VLL

IEC: CAT III

20-400VLN/35-690VLL

9/19//s

s+]9$

9s:

_

+

Modbus

RS-485

_

+

Serial No. Description Specification

• Wire size: 0.82 - 3.31 mm

Voltage Inputs (V1, V2, V3, VN)

Control Power (L1, L2)

Digital Output (D1+, -/C)

Current Inputs

, I1-, I2+, I2-, I3+, I3-)

(I

1+

Modbus RS-485 (+,-, , C)

• Wire strip length: 0.28 in (7 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M3

• Wire size: 0.82 - 3.31 mm

• Wire strip length: 0.28 in (7 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M3

• Wire size: 0.33 - 3.31 mm

• Wire strip length: 0.24 in (6 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M2

• Wire size: 0.82 - 3.31 mm

• Wire strip length:0.28 in (7 mm)

• Torque: 0.9 - 1.0 N·m (8.0 - 9.0 in·lb)

• Screw driver type: PH1

• Wire size: 0.33 - 3.31 mm

• Wire strip length: 0.24 in (6 mm)

• Torque: 0.5 - 0.6 N·m (4.4 - 5.3 in·lb)

• Screw driver type: M3

I

I

I

1+

2+

1-

$$120$

2

2

2

2

2

I

I

I

2-

3+

3-

0V

Modbus

RS-485

D0 = Rx-, TxD1 = Rx+,Tx+

(18 - 12 AWG)

(18 - 12 AWG)

(22 - 12 AWG)

(18 - 12 AWG)

(22 - 12 AWG)

© 2014 Schneider Electric All Rights Reserved 19

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

Recommended cables

Communication Make Part code Description

RS-485 Belden

3105A Multi-Conductor - EIA Industrial RS-485 PLTC/CM

3106A Multi-Conductor - EIA Industrial RS-485 PLTC/CM

© 2014 Schneider Electric All Rights Reserved20

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

B

A

+

-

+

-

+

-

+

L

B

A

(I1) (I2) (I3)

V1 V2 V3VN

+

-

+

-

+

-

+

A

B

+

-

+

-

+

-

+

B

A

+

-

+

-

+

-

+

A

B

+

-

+

-

+

-

+

B

A

+-+-+

-

+

+

L

B

A

(I1) (I2) (

V1 V2 V3VN

+

-

+

-

+

+

A B

+-+-+

-

+

+

+

B

A

+

-

+

-

+

-

+

L1

L2

L3

A B

V1 V2 V3VN

(I1) (I2) (I3)

+-+-+

-

+

+

A B

+-+-+

-

+

C

A

B

+-+-+

-

+

+

+

C

A

B

+-+-+

-

+

+

C

L1

A

V1 V2 V3VN

B

(I1) (I2) (I3)

+-+-+

-

+

C

L1

L2

L3

A

V1 V2 V3VN

B

(I1) (I2) (I3)

+

+

-

+-+

-

L1

L2

L3

N

A

B

V1 V2 V3VN

(I1) (I2) (I3)

+-+-+

-

+

+

+

L1

L2

L3

N

B

V1 V2 V3VN

(I1) (I2) (I3)

A

+-+-+

-

+

L1

L2

L3

N

A

C

V1 V2 V3VN

B

(I1) (I2) (I3)

+

+

+

+

-

+-+

-

L1

L2

L3

N

A

C

V1 V2 V3VNB(I1) (I2) (I3)

+-+-+

-

+

+

L1

L2

L3

N

A

C

V1 V2 V3VN

B

(I1) (I2) (I3)

+-+-+

-

+

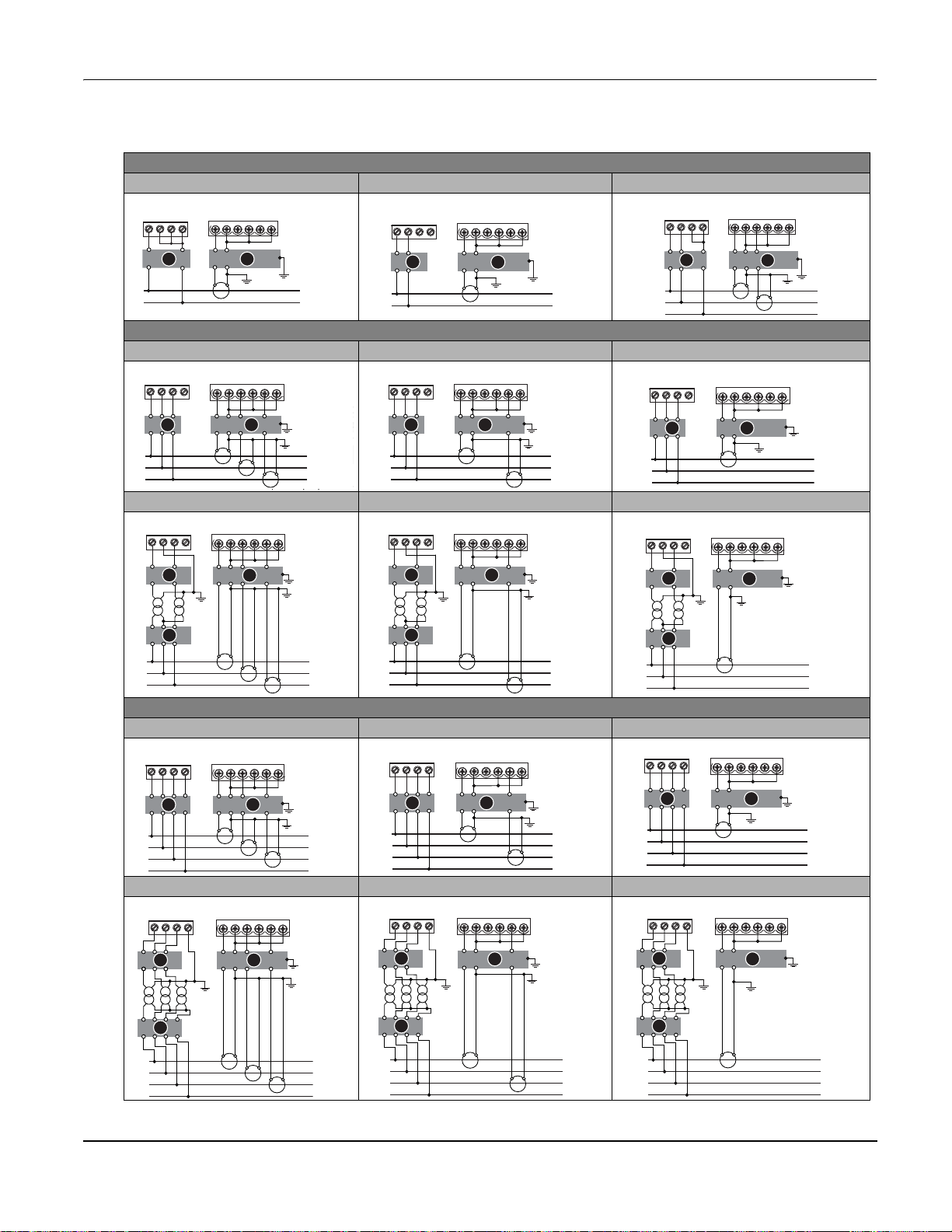

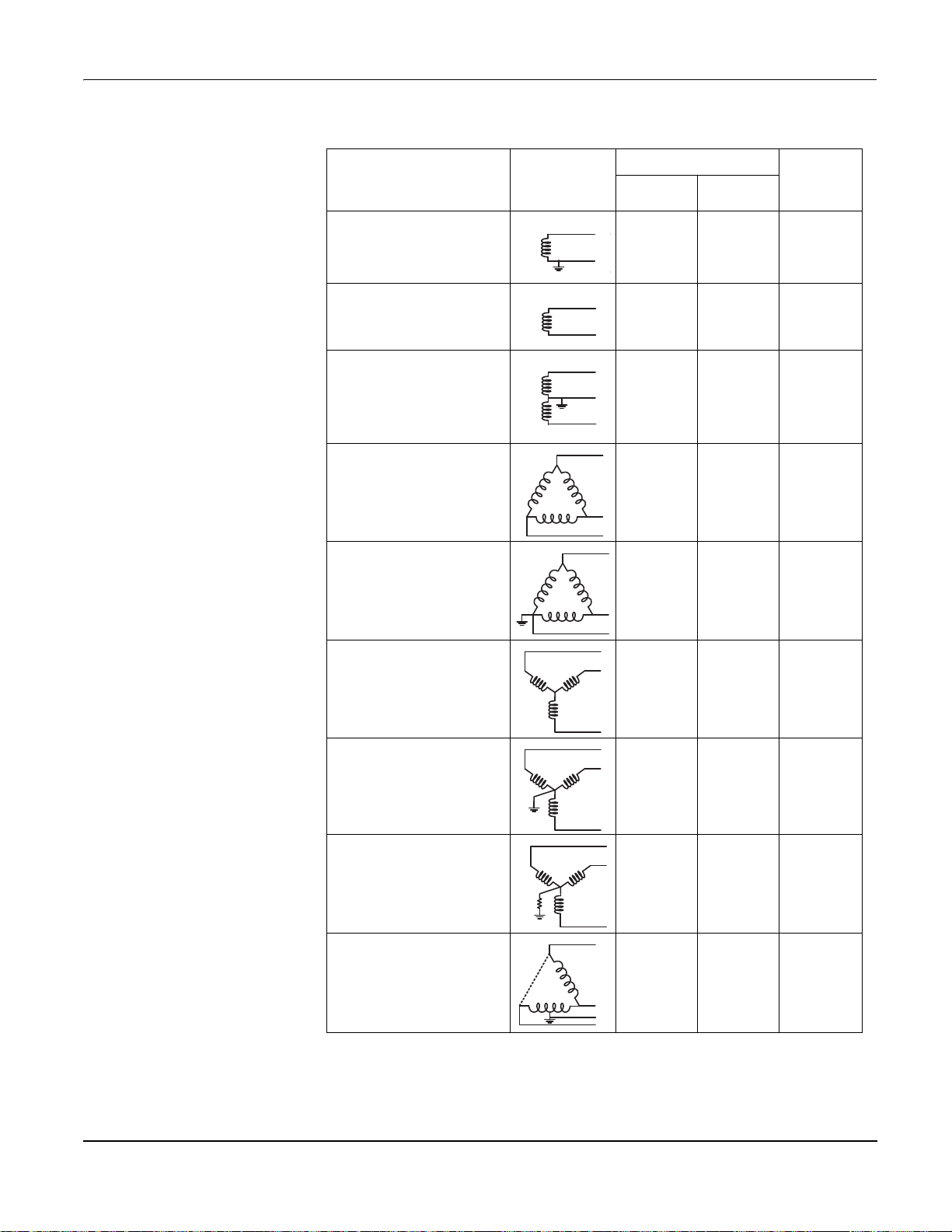

Wiring Diagrams

1PH

1PH2WLN 1PH2WLL 1PH3WLL with N

V1 V2 V3VN

L

N

(I1) (I2) (I3)

3PH3W

3CT 2CT 1CT *

V1 V2 V3VN (I1) (I2) (I3)

L1

L2

L3

2VT, 3CT 2VT, 2CT 2VT, 1CT *

V1 V2 V3VN

L1

L2

L3

(I1) (I2) (I3)

3PH4W

3CT 2CT * 1CT *

V1 V2 V3VN

L1

L2

V1 V2 V3VN

L

N

V1 V2 V3VN

L1

L2

L3

(I1) (I2) (I3)

(I1) (I2) (I3)

(I1) (I2) (I3)

V1 V2 V3VN

V1 V2 V3VN

V1 V2 V3VN

L1

L1

L2

L

L2

N

N

V1 V2 V3VN (I1) (I2) (I3)

L1

L2

L3

(I1) (I2) (I3)

(I1) (I2) (I3)

(I1) (I2) (I3)

© 2014 Schneider Electric All Rights Reserved 21

V1 V2 V3VN

L1

L2

L3

N

A

(I1) (I2) (I3)

+-+-+

B

+

-

+

3VT, 3CT 3VT, 2CT * 3VT, 1CT *

NOTE: According to Blondel's theorem, in an N wire system a minimum of N-1 measuring elements are required for correct measurement.

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

Symbol Description

500 mA fused disconnect / circuit breaker (not supplied)

Shorting block (not supplied)

PT primary fuses and disconnect switch (not supplied)

*

Indicates wiring for a balanced system

NOTE:

• Clearly label the device’s disconnect circuit mechanism and install it within easy reach

of the operator.

• The fuses / circuit breakers must be rated for the installation voltage and sized for the

available fault current.

• Fuse for neutral terminal is required if the source neutral connection is not grounded.

Potential

Transformer

IEC

ANSI

Current Transformer

Power system

Direct connect voltage limits

This section outlines typical requirements for wiring the voltage and current inputs of the

meter to the electrical power system.

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

You can connect the meter’s voltage inputs directly to the phase voltage lines of the

power system if the power system’s line-to-line or line-to-neutral voltages do not exceed

the meter’s direct connect maximum voltage limits. The meter's voltage measurement

inputs are rated by the manufacturer for up to 400 V L-N / 690 V L-L. However, the

maximum voltage allowed for direct connection may be lower, depending on the local

electrical codes and regulations. In US and Canada the maximum voltage on the meter

voltage measurement inputs may not exceed 347 V L-N / 600 V L-L.

If your system voltage is greater than the specified direct connect maximum voltage, you

must use VTs (voltage transformers) to step down the voltages.

© 2014 Schneider Electric All Rights Reserved22

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

N

Power system setup parameters

Power system description

—

Meter setting

Single-phase 2-wire line-to-neutral

—

1PH2W LN

Single-phase 2-wire line-to-line

—

1PH2W LL

Single-phase 3-wire line-to-line with

neutral

—

1PH3W LL with N

3-phase 3-wire Delta ungrounded

—

3PH3W Dlt Ungnd

3-phase 3-wire Delta corner

grounded

—

3PH3W Dlt Crnr Gnd

Symbol

Direct connect maximum

UL IEC

347 V L-N 400 V L-N 1 VT

600 V L-L 600 V L-L 1VT

347 V L-N /

600 V L-L

600 V L-L 600 V L-L 2 VT

600 V L-L 600 V L-L 2 VT

400 V L-N /

690 V L-L

# of VTs

(if required)

2VT

3-phase 3-wire Wye ungrounded

—

3PH3W Wye Ungnd

3-phase 3-wire Wye grounded

—

3PH3W Wye Gnd

3-phase 3-wire Wye resistancegrounded

—

3PH3W Wye Res Gnd

3-phase 4-wire open Delta centertapped

—

3PH4W Opn Dlt Ctr Tp

600 V L-L 600 V L-L 2 VT

600 V L-L 600 V L-L 2 VT

600 V L-L 600 V L-L 2 VT

240 V L-N /

415 V L-N /

480 V L-L

240 V L-N /

415 V L-N /

480 V L-L

3 VT

© 2014 Schneider Electric All Rights Reserved 23

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

N

N

N

Power system setup parameters (continued)

Power system description

—

Meter setting

3-phase 4-wire Delta center-tapped

—

3PH4W Dlt Ctr Tp

3-phase 4-wire ungrounded Wye

—

3PH4W Wye Ungnd

3-phase 4-wire grounded Wye

—

3PH4W Wye Gnd

3-phase 4-wire resistance-grounded

Wye

—

3PH4W Wye Res Gnd

Symbol

Direct connect maximum

UL IEC

240 V L-N /

415 V L-N /

480 V L-L

347 V L-N /

600 V L-L

347 V L-N /

600 V L-L

347 V L-N /

600 V L-L

240 V L-N /

415 V L-N /

480 V L-L

347 V L-N /

600 V L-L

400 V L-N /

690 V L-L

347 V L-N /

600 V L-L

# of VTs

(if required)

3 VT

3 VT or 2 VT

3 VT or 2 VT

3 VT or 2 VT

Voltage and current input wiring

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

Voltage input protection

The meter’s voltage inputs must be wired to fuses/breakers and a disconnect switch. If

using a voltage transformer (VT), both primary and secondary sides of the VT must be

wired to fuses/breakers and disconnect switches.

• Clearly label the device’s disconnect circuit mechanism and install it within easy reach

of the operator.

• The fuses / circuit breakers must be rated for the installation voltage and sized for the

available fault current.

• Fuse for neutral terminal is required if the source neutral connection is not grounded.

See the meter installation sheet for fuse ratings.

Current input protection

For all connected current inputs, use a CT shorting block to short-circuit the secondary

leads of the CTs before removing the current input connections to the meter.

NOTE: Ground any unused current inputs.

© 2014 Schneider Electric All Rights Reserved24

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

Balanced system considerations

In situations where you are monitoring a balanced 3-phase load, you may choose to

connect only one or two CTs on the phase(s) you want to measure, and then configure

the meter so it calculates the current on the unconnected current input(s).

NOTE: For a balanced 4-wire Wye system, the meter’s calculations assume that there is

no current flowing through the neutral conductor.

Balanced 3-phase Wye system with 2 CTs

The current for the unconnected current input is calculated so that the vector sum for all

three phase currents equal zero.

Balanced 3-phase Wye or Delta system with 1 CT

The currents for the unconnected current inputs are calculated so that their magnitude

and phase angle are identical and equally distributed, and the vector sum for all three

phase currents equal zero.

NOTE: You must always use 3 CTs for 3-phase 4-wire center-tapped Delta or

center-tapped open Delta systems.

Control power wiring

Communications

Serial communications

For wiring instructions and safety precautions, see the meter installation sheet that was

shipped with your meter, or download a copy at www.schneider-electric.com.

The meter can be powered from an AC or DC power source.

• L1 and L2 are non-polarized. If using an AC power supply with neutral, connect

neutral to the meter’s L2 terminal.

• Always use a fuse on L1. Fuse L2 when connecting an ungrounded neutral to the

control power.

• If using a control power transformer, fuse both primary and secondary sides of the

transformer.

• The fuses / circuit breakers must be rated for the installation voltage and sized for the

available fault current.

This section provides additional information about the communications ports and

topologies supported by the meter. You must wire and configure the RS-485 port in order

to communicate with the meter.

The meter supports serial communications through the RS-485 port. Up to 32 devices can

be connected on a single RS-485 bus.

In an RS-485 network, there is one master device, typically an Ethernet to RS-485

gateway. It provides the means for RS-485 communications with multiple slave devices

(for example, meters). For applications that require only one dedicated computer to

communicate with the slave devices, an RS-232 to RS-485 converter can be used as the

master device.

© 2014 Schneider Electric All Rights Reserved 25

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

+

-

C

D1 (+)

D0 (-)

+

-

C

120 Ω

120 Ω

Master Slaves

RS-485 wiring

Connect the devices on the RS-485 bus in a point-to-point configuration, with the (+) and

(-) terminals from one device connected to the corresponding (+) and (-) terminals on the

next device.

RS-485 wiring

RS-485 cable

Use a shielded 1.5 twisted pair or 2 twisted pair RS-485 cable to wire the devices. Use

one twisted pair to connect the (+) and (-) terminals, and use the other insulated wire to

connect the C terminals.

RS-485 terminals

Common. This provides the voltage reference (zero volts) for the data plus and data minus signals.

C

Shield. Connect the bare wire to this terminal to help suppress signal noise that may be present.

Ground the shield wiring at one end only (either at the master or the last slave device, but not both).

Data minus. This transmits/receives the inverting data signals.

-

Data plus. This transmits/receives the non-inverting data signal.

+

RS-485 maximum cable length

The total distance for devices connected on an RS-485 bus should not exceed 1200 m

(4000 ft).

RS-485 network configuration

After you have wired the RS-485 port and powered up the meter, you must configure the

serial communications port in order to communicate with the meter.

Each device on the same RS-485 communications bus must have a unique address and

all connected devices must be set to the same protocol, baud rate, and parity (data

format).

NOTE: To communicate with the meter using ION Setup, you must set the parity to

“None” for all devices in the RS-485 network.

For meters that do not have a display, you must first wire and configure each one

separately before connecting these meters to the same RS-485 bus.

© 2014 Schneider Electric All Rights Reserved26

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

D1 -/C

(60)

(57)

LOAD

< 20mA

< 40Vdc

Related topics

• To configure RS-485 communications, see “Setting up serial communications” on

page 34.

Digital outputs

The meter is equipped with a digital output port (D1). You can configure the digital output

for use in the following application:

• energy pulsing applications, where a receiving device determines energy usage by

counting the k_h pulses (k_h = kWh, kVARh or kVAh depending on the energy

parameter selected) coming from the meter’s digital output port.

The digital output can handle voltages less than 40 V DC. For higher voltage applications,

use an external relay in the switching circuit.

Digital output connections

Related topics

• See “Digital output applications” on page 47 for digital output use and configuration

details.

© 2014 Schneider Electric All Rights Reserved 27

PowerLogic™ PM5100 series user guide Chapter 3—Hardware Reference

© 2014 Schneider Electric All Rights Reserved28

PowerLogic™ PM5100 series user guide Chapter 4—Front panel display and meter setup

B

A

C

G

E

F

D

C

B

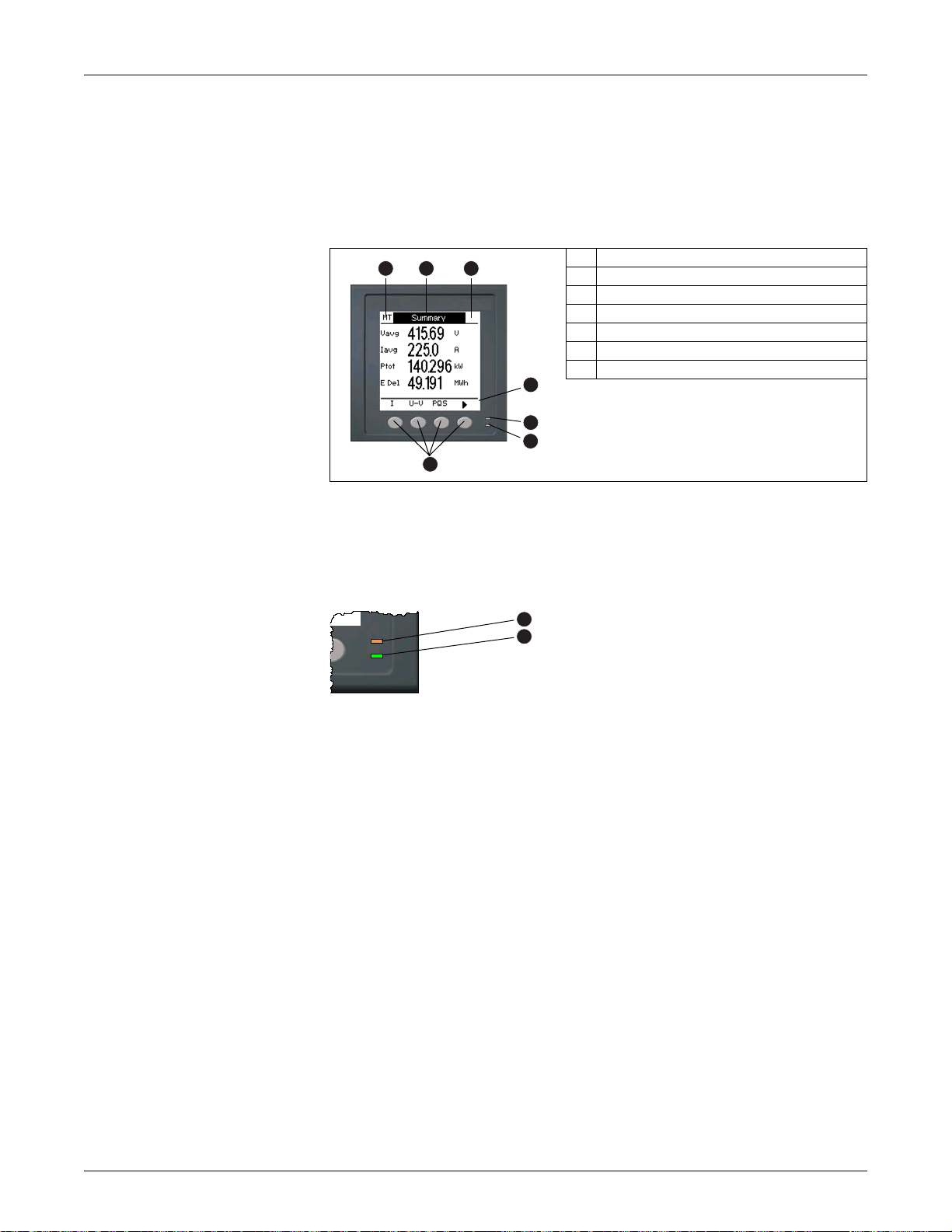

Chapter 4—Front panel display and meter setup

The front panel display lets you use the meter to perform various tasks such as setting

up the meter, displaying data screens, acknowledging alarms, or performing resets.

Parts of the display

A Navigation / menu selection buttons

B Heartbeat / communications LED (green)

C Alarm / energy pulsing LED (orange)

D Navigation symbols or menu options

E Right notification area

F Screen title

G Left notification area

LED indicators

The meter has two LED indicators on the front panel.

Front panel LEDs

Heartbeat / communications LED

The (green) heartbeat / communications LED blinks at a slow, steady rate to indicate

the meter is operational. The LED flashes at a variable, faster rate when the meter is

communicating over a Modbus serial communications port.

You cannot configure this LED for other purposes.

NOTE: A heartbeat LED that remains lit and does not blink (or flash) indicates a

possible hardware problem. In this case, power down the meter and reapply power. If

the LED still does not blink or flash, contact Technical Support.

Alarm / energy pulsing LED modes

The (orange) alarm / energy pulsing LED can be configured for alarm notification or

energy pulsing.

Alarm / energy pulsing LED (orange)

Heartbeat / communications LED (green)

• When configured for alarm notification, this LED flashes when a high, medium or

low priority alarm is active. This provides a visual indication of an active alarm

condition, or an inactive but unacknowledged high priority alarm.

• When configured for energy pulsing, this LED flashes at a rate proportional to the

amount of energy consumed. This is typically used to verify the meter’s accuracy.

© 2014 Schneider Electric All Rights Reserved 29

Loading...

Loading...