Konica Minolta ISW TRANSFER/TOOL Manual

SERVICE MANUAL

ISW

Transfer/Tool

MAY 2001

CSM-ISW

KONICA BUSINESS TECHNOLOGIES, INC.

ISW

Transfer/Tool

May 2001

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced person servicing this equipment, as well as the risk of damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to improve its performance after this service manual was printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either expressed or implied, that the information contained in this service manual is complete or accurate. It is understood that the user of this manual must assume all risks or personal injury and/or damage to the equipment while servicing the equipment for which this service manual is intended.

Corporate Publications Department

© 2001, KONICA BUSINESS TECHNOLOGIES, INC. All rights reserved.

Printed in U.S.A.

CONTENTS

CONTENTS

ISW |

|

|

PREFACE ........................................................................ |

1 |

|

INTRODUCING ISW ........................................................ |

3 |

|

WHAT IS ISW Trns (ISW TRANSFER)? .......................... |

3 |

|

WHAT IS ISW TOOL? ...................................................... |

3 |

|

SPECIFICATIONS ........................................................... |

4 |

|

[1] ISW Trns (PC Software) ................................... |

4 |

|

[2] ISW Tool (Dedicated Tool) ............................... |

5 |

|

UPDATING WITH ISW Trns ............................................. |

6 |

|

[1] Setting Up ISW Trns ......................................... |

6 |

|

[2] Copying Transfer Data (Update Data) ........... |

11 |

|

[3] |

Connecting ..................................................... |

12 |

[4] |

Updating ......................................................... |

12 |

UPDATING WITH ISW TOOL ........................................ |

17 |

|

[1] |

Kinds of Updating ........................................... |

17 |

[2] Setting Up ISW Tool ....................................... |

18 |

|

[3] |

Connecting ..................................................... |

20 |

[4] Updating Type A Models ................................ |

21 |

|

[5] Updating Type B Models ................................ |

24 |

|

[6] Updating Type C Models ................................ |

28 |

|

[7] |

Error indications ............................................. |

32 |

ISW Trns MESSAGES ................................................... |

33 |

|

TROUBLESHOOTING ISW Trns ................................... |

35 |

|

iii

CONTENTS

Blank

iv

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward machine design and the possibility of human error. In addition, the environment in which a machine is operated must not be overlooked as a potential safety hazard.

Most electrical equipment is safe when installed in a normal environment. However, if the environment is different from what most people consider to be normal, it is conceivable that the combination of the machine and the room air could present a hazardous combination. This is because heat (such as from fusing units) and electrical arcs (which can occur inside switches) have the ability to ignite flammable substances, including air.

When installing a machine, check to see if there is anything nearby which suggests that a potential hazard might exist. For example, a laboratory might use organic compounds which, when they evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate action, such as one of the following suggestions.

∙Determine that the environment is controlled (such as through the use of an exhaust hood) so that an offending substance or its fumes cannot reach the machine.

∙Remove the offending substance.

∙Install the machine in a different location.

The specific remedy will vary from site to site, but the principles remain the same. To avoid the risk of injury or damage, be alert for changes in the environment when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica equipment has gained a reputation for being reliable products. This has been attained by a combination of outstanding design and a knowledgeable service force.

The design of the equipment is extremely important. It is the design process that determines tolerances and safety margins for mechanical, electrical, and electronic aspects. It is not reasonable to expect individuals not involved in product engineering to

know what effect may be caused by altering any aspect of the machine’s design. Such changes have the potential of degrading product performance and reducing safety margins.

For these reasons, installation of any modification not specifically authorized by Konica Business Machines U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclu- sive, but demonstrates the intent of this policy.

∙Using an extension cord or any unauthorized power cord adapter.

∙Installing any fuse whose rating and physical size differs from that originally installed.

∙Using wire, paper clips, solder, etc., to replace or eliminate any fuse (including temperature fuses).

∙Removing (except for replacement) any air filter.

∙Defeating the operation of relays by any means (such as wedging paper between contacts).

∙Causing the machine to operate in a fashion other than as it was designed.

∙Making any change which might have a chance of defeating built-in safety features.

∙Using any unspecified replacement parts.

General Safety Guidelines

This equipment has been examined in accordance with the laws pertaining to various product safety regulations prior to leaving the manufacturing facility to protect the operators and service personnel from injury.However, as with any operating device, components will break down through the wear-and-tear of everyday use, as will additional safety discrepancies be discovered. For this reason, it is important that the technician periodically performs safety checks on the equipment to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be made during each service call:

CAUTION: Avoid injury. Ensure that the equipment is disconnected from its power source before continuing.

∙Look for sharp edges, burrs, and damage on all external covers and copier frame.

∙Inspect all cover hinges for wear (loose or broken).

∙Inspect cables for wear, frays, or pinched areas.

v

SAFETY PRECAUTIONS

∙Ensure that the power cord insulation is not damaged (no exposed electrical conductors).

∙Ensure that the power cord is properly mounted to the frame by cord clamps.

∙Check the continuity from the round lug (GND) of the power cord to the frame of the copier -- ensure continuity. An improperly grounded machine can cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are removed during maintenance are installed in their original positions.

∙When disconnecting connectors, do not pull the wiring, particularly on AC line wiring and high voltage parts.

∙Do not route the power cord where it is likely to be stepped on or crushed.

∙Carefully remove all toner and dirt adhering to any electrical units or electrodes.

∙After part replacement or repair work, route the wiring in such a way that it does not contact any burrs or sharp edges.

∙Do not make any adjustments outside of the specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to clean parts, observe the following precautions:

∙Remove power from the equipment.

∙Use alcohol in small quantities to avoid spillage or puddling. Any spillage should be cleaned up with rags and disposed of properly.

∙Be sure that there is adequate ventilation.

∙Allow a surface which has been in contact with alcohol to dry for a few minutes to ensure that the alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There are no short cuts to high-quality service. Each piece of equipment must be thoroughly inspected with respect to safety considerations as part of every routine service call. The operability of the copier, and more importantly, the safety of those who operate or service the equipment, are directly dependent upon the conscientious effort of each and every technician.

Remember...when performing service calls, use good judgment (have a watchful eye) to identify safety hazards or potential safety hazards that may be present, and correct these problem areas as they are identified -- the safety of those who operate the equipment as well as those who service the copier depend on it!

vi

ISW

ISW

PREFACE

This operation manual discribes the operating procedure of rewriting the flash ROMs in the copier using the ISW Trns (ISW Transfer: a software utility that urns under Windows) or ISW Tool.

Be sure to read this manual and the service handbook of the copier thoruoughly before rewiting the flash ROMs using the ISW Trns or ISW Tool.

1

ISW

Blank

2

ISW

INTRODUCINGISW

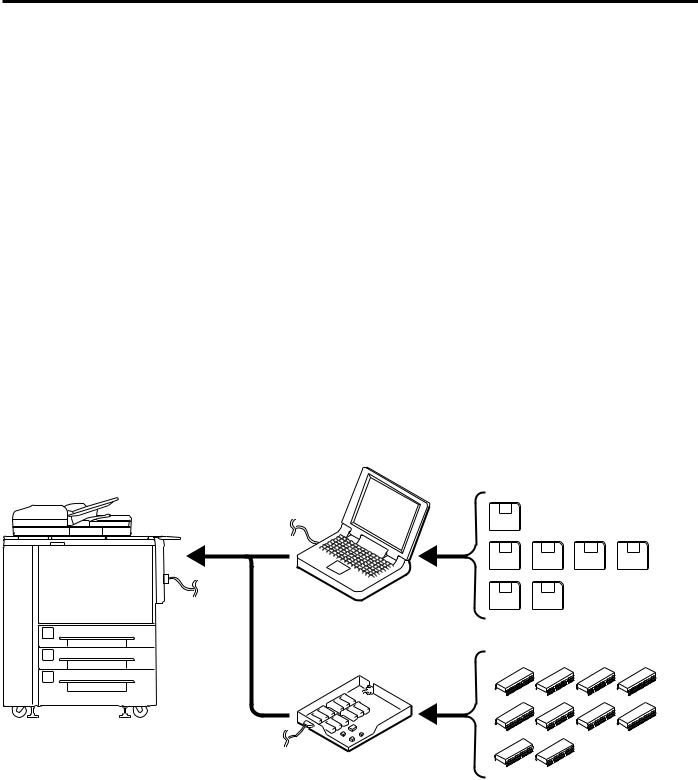

ISW (In-System Writer) is a process of updating the control programs stored in flash ROM mounted on various control boards in a Konica digital copier without isolating the boards or the ROM from the copier. Running ISW enables you to upgrade control programs without replacing the boards and maintain the boards during their replacement.

Tools available for running ISW include ISW Trns (PC software), which connects a personal computer (PC) to the digital copier, and ISW Tool, which is a dedicated tool using EPROM.

These tools can be plugged into the ISW connector of the digital copier to update the control programs in flash ROM assembled in the copier unit and its options.

WHAT IS ISW TRNS (ISW TRANSFER)?

ISW Trns is a software utility that runs under Windows to rewrite the flash ROMs in the copier. Connect the copier to a personal computer using a parallel cable and execute this utility to rewrite the flash ROMs with data transferred from the personal computer.

WHAT IS ISW Tool?

ISW Tool is a ROM writer device dedicated for rewriting the flash ROMs in the copier without using a personal computer. Attach EPROMs to the ISW Tool to rewrite the flash ROMs with data transferred from the EPROMs.

Parallel |

Windows PC |

|

cable |

||

|

Copier

ISW Tool

3

ISW

SPECIFICATIONS

[1] ISW Trns (PC Software)

1.ISW Trns disk organization

• |

Setup disk: |

2 disks |

• |

Update disk: |

Dependent on the copier. |

2.Software environment

• OS: |

Windows 95/98 |

• CPU: |

Pentium 75 MHz or faster |

• RAM: |

16 MB or more |

• Hard disk |

100 MB or more |

space: |

|

• Others: |

PC supporting a parallel (printer) |

|

interface port |

3.Transfer time

Dependent on the copier and personal computer.

4.Prerequisites to running ISW

•Personal computer (PC):1 unit

IBM compatible (PC/AT with a D-sub 25 pin

|

Parallel (printer) interface) |

|

• |

ISW Trns setup disk: |

2 disks |

• |

Update ROM data: |

Dependent on the |

|

|

copier. |

•Parallel cable: 1 (Anphenol 36-pin-D-sub 25-pin; Centronics; within 2 meters in length)

Windows 95/98 is a registered trademark of Microsoft Corporation.

Pentium is a registered trademark of Intel Corporation.

4

ISW

[2] ISW Tool (Dedicated Tool) |

6. Prerequisites to running ISW |

1.ISW EPROM configuration

Dependent on the copier.

Refer to the service manual supplied with the copier.

2. EPROM specifications

4M bits

M27C4001-12F1 (SGS-THOMSON) equivalent: Part No. 943010900

• ISW Tool: ............................................. |

1 pc. |

3.Transfer time

Dependent on the copier.

4.Mechanical specifications

Input power requirement: 5 VDC (supplied from the copier)

Maximum power consumption: |

2.5 W or less |

|

Weight: About 1 lb. (without EPROM installed) |

|

|

Physical dimensions: |

|

|

5. Operating environment |

• Parallel interface cable: ........................ |

1 pc. |

Same as the operating environment for the copier unit.

Unit: inches |

|

|

(approx.) |

|

|

9.5 |

|

|

7.7 |

|

|

|

• Power cable: ........................................ |

1 pc. |

7. |

Safety |

|

|

Use of this equipment may give electromagnetic |

|

1.7 |

interference to surrounding devices. |

|

|

|

|

|

Note: Specifications are subject to change without |

|

|

notice. |

|

5

ISW

UPDATING WITH ISWTrns

[1] Setting Up ISW Trns

1.Installing the application program

Install the ISW Trns on the PC.

Step |

Procedure |

1Boot the PC.

2Mount setup disk 1 on the PC and double-click the [Setup.exe] icon to start the installer.

Caution: If an old version ISW Trns program is present, uninstall it first, then start the setup operation.

3[ISW Trns setup window]

Confirm the installation folder as instructed by on-screen guidance and click Next.

Note 1: By default, the program installs in [C:\Program Files\konica\ ISWTrns].

Note 2: To change the installation folder, click Browse and type a new folder name.

4[Program folder confirmation window] Confirm the ISW Trns program installation folder as instructed by onscreen guidance and click Next.

Note 1: By default, the ISW Trns program installs in [ISWTrns].

Note 2: To change the installation folder, either type a new folder name or select one from the list of existing folders on display.

5[Next disk insertion request window] Mount setup disk 2 as instructed by onscreen guidance and click OK.

6[Information dialog box]

Click OK as instructed by on-screen guidance.

Note: This procedure will add an ISW Trns icon to the Start menu.

7[Setup completion window]

Click Complete as instructed by onscreen guidance.

8The ISW Trns install exits automatically.

2.Setting up ISW Trns

When the ISW Trns program has been installed on the PC, run it to set up a folder in which the transfer file (update data) is stored. When this setting completes, the ISW Trns program is ready to run.

Step |

Procedure |

|

|

|

|

1 |

Boot the PC. |

|

|

|

|

2 |

Select [ISW Trns] from the start menu |

|

|

to run the ISW Trns program. |

|

|

|

|

3 |

[ISW Trns dialog box] |

|

|

Click OK to set up a folder in which the |

|

|

transfer file (update data) is stored. |

|

|

Note: This dialog box will not appear |

|

|

when ISW Trns is run next time. |

|

|

|

|

4 |

[Option window] |

|

|

Set up a folder in which the transfer file |

|

|

(update data) is stored and click Make |

|

|

Folder. |

|

|

Note 1: By default, the folder in which |

|

|

the ISW Trns program has |

|

|

installed |

(C:\Program |

|

Files\konica\ISWTrns) has |

|

|

been set up as a storage folder |

|

|

(data folder). |

|

|

Note 2: To change the storage folder, |

|

|

click Browse and select a new |

|

|

folder or type its full-path name |

|

|

directly in the edit box. |

|

|

|

|

6

Loading...

Loading...