KONICA MINOLTA FS-510, FS-511, SD-502, MT-501, JS-502 Service Manual

Confidential – for internal use only, do not distribute

THEORY OF OPERATION TOTAL CONTENTS |

|

SAFETY AND IMPORTANT WARNING ITEMS .............................................................. |

S-1 |

IMPORTANT NOTICE ................................................................................................ |

S-1 |

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION ......................... |

S-1 |

SAFETY WARNINGS ................................................................................................. |

S-2 |

SAFETY INFORMATION ............................................................................................... |

S-12 |

IMPORTANT NOTICE .............................................................................................. |

S-12 |

INDICATION OF WARNING ON THE MACHINE ..................................................... |

S-13 |

MEASURES TO TAKE IN CASE OF AN ACCIDENT .................................................... |

S-15 |

Composition of the service manual ................................................................................. |

C-1 |

Notation of the service manual ....................................................................................... |

C-2 |

bizhub 500/420/360 Main Body |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION ........................................................................................ |

9 |

* For particulars, see the contents of the main body. |

|

DF-607 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION ........................................................................................ |

5 |

* For particulars, see the contents of DF-607. |

|

PC-202 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION ........................................................................................ |

3 |

* For particulars, see the contents of PC-202. |

|

PC-402 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION ........................................................................................ |

3 |

* For particulars, see the contents of PC-402. |

|

LU-201 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION ........................................................................................ |

3 |

* For particulars, see the contents of LU-201. |

|

Confidential – for internal use only, do not distribute |

i |

FS-510/PU-501/OT-601 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION........................................................................................ |

9 |

* For particulars, see the contents of FS-510/PU-501/OT-601. |

|

FS-511/RU-502 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION........................................................................................ |

7 |

* For particulars, see the contents of FS-511/RU-502. |

|

SD-502 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION........................................................................................ |

3 |

* For particulars, see the contents of SD-502. |

|

MT-501 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION........................................................................................ |

3 |

* For particulars, see the contents of MT-501. |

|

JS-502 |

|

OUTLINE ........................................................................................................................ |

1 |

COMPOSITION/OPERATION........................................................................................ |

3 |

* For particulars, see the contents of JS-502. |

|

ii |

Confidential – for internal use only, do not distribute |

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this product as well as the risk of damage to the product, Konica Minolta Business Technologies, INC. (hereafter called the KMBT) strongly recommends that all servicing be performed only by KMBTtrained service technicians.

Changes may have been made to this product to improve its performance after this Service Manual was printed. Accordingly, KMBT does not warrant, either explicitly or implicitly, that the information contained in this Service Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to the product while servicing the product for which this Service Manual is intended. Therefore, this Service Manual must be carefully read before doing service work both in the course of technical training and even after that, for performing maintenance and control of the product properly.

Keep this Service Manual also for future service.

DESCRIPTION ITEMS FOR DANGER,

WARNING AND CAUTION

In this Service Manual, each of three expressions " DANGER", "

DANGER", " WARNING", and "

WARNING", and " CAUTION" is defined as follows together with a symbol mark to be used in a limited meaning.

CAUTION" is defined as follows together with a symbol mark to be used in a limited meaning.

When servicing the product, the relevant works (disassembling, reassembling, adjustment, repair, maintenance, etc.) need to be conducted with utmost care.

DANGER: Action having a high possibility of suffering death or serious injury

DANGER: Action having a high possibility of suffering death or serious injury

WARNING: Action having a possibility of suffering death or serious injury

WARNING: Action having a possibility of suffering death or serious injury

CAUTION: Action having a possibility of suffering a slight wound, medium trouble and property damage

CAUTION: Action having a possibility of suffering a slight wound, medium trouble and property damage

Symbols used for safety and important warning items are defined as follows:

|

:Precaution when using the |

|

|

|

|

|

|

|

|

|

copier. |

General |

||

|

:Prohibition when using the |

precaution |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

copier. |

General |

||

|

|

prohibition |

||

|

:Direction when using the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General |

|||

|

copier. |

|||

|

|

instruction |

||

|

|

|

|

|

|

|

Electric hazard |

High |

|||||

|

|

|

|

temperature |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Do not touch |

Do not |

|||||

with wet hand |

disassemble |

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

Unplug |

Ground/Earth |

|||||

Confidential – for internal use only, do not distribute |

S-1 |

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNINGS

[1]MODIFICATIONS NOT AUTHORIZED BY KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

Konica Minolta brand products are renowned for their high reliability. This reliability is achieved through high-quality design and a solid service network.

Product design is a highly complicated and delicate process where numerous mechanical, physical, and electrical aspects have to be taken into consideration, with the aim of arriving at proper tolerances and safety factors. For this reason, unauthorized modifications involve a high risk of degradation in performance and safety. Such modifications are therefore strictly prohibited. The points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

Prohibited Actions

DANGER

DANGER

• Using any cables or power cord not specified by KMBT.

• Using any fuse or thermostat not specified by KMBT. Safety will not be assured, leading to a risk of fire and injury.

• Disabling fuse functions or bridging fuse terminals with wire, metal clips, solder or similar object.

• Disabling relay functions (such as wedging paper between relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.) Safety will not be assured, leading to a risk of fire and injury.

• Making any modification to the product unless instructed by KMBT

• Using parts not specified by KMBT

S-2 |

Confidential – for internal use only, do not distribute |

SAFETY AND IMPORTANT WARNING ITEMS

[2] POWER PLUG SELECTION

In some countries or areas, the power plug provided with the product may not fit wall outlet used in the area. In that case, it is obligation of customer engineer (hereafter called the CE) to attach appropriate power plug or power cord set in order to connect the product to the supply.

Power Cord Set or Power Plug

WARNING

WARNING

•Use power supply cord set which meets the following criteria:

-provided with a plug having configuration intended for the connection to wall outlet appropriate for the product's rated voltage and current, and

-the plug has pin/terminal(s) for grounding, and

-provided with three-conductor cable having enough current capacity, and

-the cord set meets regulatory requirements for the area. Use of inadequate cord set leads to fire or electric shock.

•Attach power plug which meets the following criteria:

-having configuration intended for the connection to wall outlet appropriate for the product's rated voltage and current, and

-the plug has pin/terminal(s) for grounding, and

-meets regulatory requirements for the area.

Use of inadequate cord set leads to the product connecting to inadequate power supply (voltage, current capacity, grounding), and may result in fire or electric shock.

•Conductors in the power cable must be connected to terminals of the plug according to the following order:

• |

Black or Brown: |

L (line) |

• White or Light Blue: |

N (neutral) |

|

• |

Green/Yellow: |

PE (earth) |

Wrong connection may cancel safeguards within the product, and results in fire or electric shock.

AC230V

AC208V 240V

240V

Confidential – for internal use only, do not distribute |

S-3 |

SAFETY AND IMPORTANT WARNING ITEMS

[3] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

Konica Minolta brand products are extensively tested before shipping, to ensure that all applicable safety standards are met, in order to protect the customer and CE from the risk of injury. However, in daily use, any electrical equipment may be subject to parts wear and eventual failure. In order to maintain safety and reliability, the CE must perform regular safety checks.

1.Power Supply

Connection to Power Supply

WARNING |

|

|

|

• Check that mains voltage is as specified. |

|

Connection to wrong voltage supply may result in fire or |

|

electric shock. |

? V |

•Connect power plug directly into wall outlet having same configuration as the plug.

Use of an adapter leads to the product connecting to |

kw |

inadequate power supply (voltage, current capacity, grounding), and may result in fire or electric shock.

If proper wall outlet is not available, advice the customer to contact qualified electrician for the installation.

•Plug the power cord into the dedicated wall outlet with a capacity greater than the maximum power consumption.

If excessive current flows in the wall outlet, fire may result.

• If two or more power cords can be plugged into the wall outlet, the total load must not exceed the rating of the wall outlet.

If excessive current flows in the wall outlet, fire may result.

• Make sure the power cord is plugged in the wall outlet securely.

Contact problems may lead to increased resistance, overheating, and the risk of fire.

S-4 |

Confidential – for internal use only, do not distribute |

SAFETY AND IMPORTANT WARNING ITEMS

Connection to Power Supply

WARNING

WARNING

• Check whether the product is grounded properly.

If current leakage occurs in an ungrounded product, you may suffer electric shock while operating the product. Connect power plug to grounded wall outlet.

Power Plug and Cord

WARNING

WARNING

• When using the power cord set (inlet type) that came with this product, make sure the connector is securely inserted in the inlet of the product.

When securing measure is provided, secure the cord with the fixture properly.

If the power cord (inlet type) is not connected to the product securely, a contact problem may lead to increased resistance, overheating, and risk of fire.

•Check whether the power cord is not stepped on or pinched by a table and so on.

Overheating may occur there, leading to a risk of fire.

•Check whether the power cord is damaged. Check whether the sheath is damaged.

If the power plug, cord, or sheath is damaged, replace with a new power cord or cord set (with plug and connector on each end) specified by KMBT.

Using the damaged power cord may result in fire or electric shock.

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

Confidential – for internal use only, do not distribute |

S-5 |

SAFETY AND IMPORTANT WARNING ITEMS

Power Plug and Cord

WARNING

WARNING

•Check whether dust is collected around the power plug and wall outlet.

Using the power plug and wall outlet without removing dust may result in fire.

•Do not insert the power plug into the wall outlet with a wet hand.

The risk of electric shock exists.

•When unplugging the power cord, grasp the plug, not the cable.

The cable may be broken, leading to a risk of fire and electric shock.

Wiring

WARNING

WARNING

•Never use multi-plug adapters to plug multiple power cords in the same outlet.

If used, the risk of fire exists.

•When an extension cord is required, use a specified one. Current that can flow in the extension cord is limited, so using a too long extension cord may result in fire.

Do not use an extension cable reel with the cable taken up. Fire may result.

S-6 |

Confidential – for internal use only, do not distribute |

SAFETY AND IMPORTANT WARNING ITEMS

2.Installation Requirements

Prohibited Installation Places

WARNING

WARNING

•Do not place the product near flammable materials or volatile materials that may catch fire.

A risk of fire exists.

• Do not place the product in a place exposed to water such as rain.

A risk of fire and electric shock exists.

When not Using the Product for a long time

WARNING

WARNING

• When the product is not used over an extended period of time (holidays, etc.), switch it off and unplug the power cord.

Dust collected around the power plug and outlet may cause fire.

Ventilation

CAUTION

CAUTION

•The product generates ozone gas during operation, but it will not be harmful to the human body.

If a bad smell of ozone is present in the following cases, ventilate the room.

a. When the product is used in a poorly ventilated room b. When taking a lot of copies

c. When using multiple products at the same time

Fixing

CAUTION

CAUTION

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the product may slide, leading to a injury.

Confidential – for internal use only, do not distribute |

S-7 |

SAFETY AND IMPORTANT WARNING ITEMS

Inspection before Servicing

CAUTION

CAUTION

•Before conducting an inspection, read all relevant documentation (service manual, technical notices, etc.) and

proceed with the inspection following the prescribed procedure in safety clothes, using only the prescribed tools. Do not make any adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the product may break and a risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect the power plugs from the product and options.

When the power plug is inserted in the wall outlet, some units are still powered even if the POWER switch is turned OFF. A risk of electric shock exists.

•The area around the fixing unit is hot. You may get burnt.

Work Performed with the Product Powered On

WARNING

WARNING

• Take every care when making adjustments or performing an operation check with the product powered.

If you make adjustments or perform an operation check with the external cover detached, you may touch live or high-voltage parts or you may be caught in moving gears or the timing belt, leading to a risk of injury.

•Take every care when servicing with the external cover detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

S-8 |

Confidential – for internal use only, do not distribute |

SAFETY AND IMPORTANT WARNING ITEMS

Safety Checkpoints

WARNING

WARNING

• Check the exterior and frame for edges, burrs, and other damages.

The user or CE may be injured.

•Do not allow any metal parts such as clips, staples, and screws to fall into the product.

They can short internal circuits and cause electric shock or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or fire.

•Carefully remove all toner remnants and dust from electrical parts and electrode units such as a charging corona

unit.

Current can leak, leading to a risk of product trouble or fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or fire.

• Check electrode units such as a charging corona unit for deterioration and sign of leakage.

Current can leak, leading to a risk of trouble or fire.

• Before disassembling or adjusting the write unit (P/H unit) incorporating a laser, make sure that the power cord has been disconnected.

The laser light can enter your eye, leading to a risk of loss of eyesight.

•Do not remove the cover of the write unit. Do not supply power with the write unit shifted from the specified mount-

ing position.

The laser light can enter your eye, leading to a risk of loss of eyesight.

Confidential – for internal use only, do not distribute |

S-9 |

SAFETY AND IMPORTANT WARNING ITEMS

Safety Checkpoints

WARNING

WARNING

•When replacing a lithium battery, replace it with a new lithium battery specified in the Parts Guide Manual. Dispose of the used lithium battery using the method specified by local authority.

Improper replacement can cause explosion.

•After replacing a part to which AC voltage is applied (e.g., optical lamp and fixing lamp), be sure to check the installation state.

A risk of fire exists.

•Check the interlock switch and actuator for loosening and check whether the interlock functions properly.

If the interlock does not function, you may receive an electric shock or be injured when you insert your hand in the product (e.g., for clearing paper jam).

•Make sure the wiring cannot come into contact with sharp edges, burrs, or other pointed parts.

Current can leak, leading to a risk of electric shock or fire.

•Make sure that all screws, components, wiring, connectors, etc. that were removed for safety check and maintenance have been reinstalled in the original location. (Pay special attention to forgotten connectors, pinched cables, forgotten screws, etc.)

A risk of product trouble, electric shock, and fire exists.

Handling of Consumables

WARNING

WARNING

•Toner and developer are not harmful substances, but care must be taken not to breathe excessive amounts or let the substances come into contact with eyes, etc. It may be stimulative.

If the substances get in the eye, rinse with plenty of water immediately. When symptoms are noticeable, consult a physician.

S-10 |

Confidential – for internal use only, do not distribute |

SAFETY AND IMPORTANT WARNING ITEMS

Handling of Consumables

WARNING

WARNING

• Never throw the used cartridge and toner into fire. You may be burned due to dust explosion.

Handling of Service Materials

CAUTION

CAUTION

• Unplug the power cord from the wall outlet.

Isopropyl alcohol and acetone are highly flammable and must be handled with care. A risk of fire exists.

•Do not replace the cover or turn the product ON before any solvent remnants on the cleaned parts have fully

evaporated.

A risk of fire exists.

•Use only a small amount of cleaner at a time and take care not to spill any liquid. If this happens, immediately

wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to discomfort.

Confidential – for internal use only, do not distribute |

S-11 |

SAFETY INFORMATION

SAFETY INFORMATION

IMPORTANT NOTICE

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented regulations for laser products manufactured since August 1, 1976. Compliance is mandatory for products marketed in the United States.

This copier is certified as a "Class 1" laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and Safety Act of 1968. Since radiation emitted inside this copier is completely confined within protective housings and external covers, the laser beam cannot escape during any phase of normal user operation.

S-12 |

Confidential – for internal use only, do not distribute |

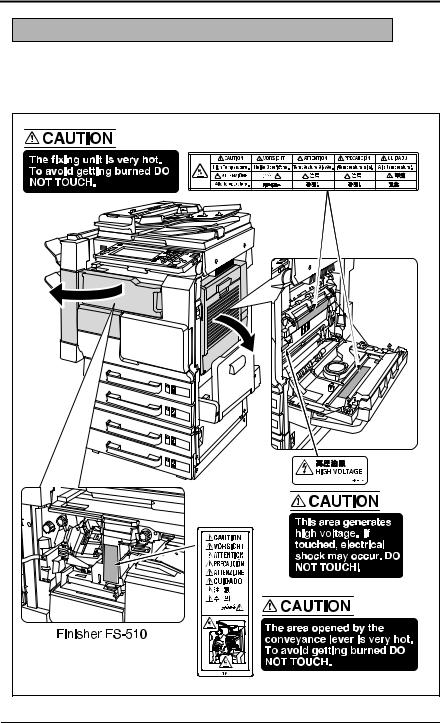

SAFETY INFORMATION

INDICATION OF WARNING ON THE MACHINE

Caution labels shown below are attached in some areas on/in the machine.

When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid burns and electric shock.

50gap0e001na |

Confidential – for internal use only, do not distribute |

S-13 |

SAFETY INFORMATION

50gap0e002na |

CAUTION:

CAUTION:

•You may be burned or injured if you touch any area that you are advised by any caution label to keep yourself away from. Do not remove caution labels. And also, when the caution label is peeled off or soiled and cannot be seen clearly, replace it with a new caution label.

S-14 |

Confidential – for internal use only, do not distribute |

MEASURES TO TAKE IN CASE OF AN ACCIDENT

MEASURES TO TAKE IN CASE OF

AN ACCIDENT

1.If an accident has occurred, the distributor who has been notified first must immediately take emergency measures to provide relief to affected persons and to prevent further damage.

2.If a report of a serious accident has been received from a customer, an on-site evaluation must be carried out quickly and KMBT must be notified.

3.To determine the cause of the accident, conditions and materials must be recorded through direct on-site checks, in accordance with instructions issued by KMBT.

4.For reports and measures concerning serious accidents, follow the regulations specified by every distributor.

Confidential – for internal use only, do not distribute |

S-15 |

MEASURES TO TAKE IN CASE OF AN ACCIDENT

Blank Page

S-16 |

Confidential – for internal use only, do not distribute |

Composition of the service manual

This service manual consists of the following sections and chapters:

<Theory of Operation section>

OUTLINE: |

System configuration, product specifications, |

|

unit configuration, and paper path |

COMPOSITION/OPERATION: Configuration of each unit, explanation of the operating system, and explanation of the control system

This section gives, as information for the CE to get a full understanding of the product, a rough outline of the object and role of each function, the relationship between the electrical system and the mechanical system, and the timing of operation of each part.

<Field service section> |

|

OUTLINE: |

System configuration, and product specifications |

MAINTENANCE: |

Service schedule *, maintenance steps, |

|

list of service tools and directions for use *, |

|

firmware version up method *, |

|

and removal/reinstallation methods of major parts |

ADJUSTMENT/SETTING: |

Utility mode *, service mode *, security and mechanical |

|

adjustment |

TROUBLESHOOTING*: |

List of jam codes, their causes, operation when a jam |

|

occurs and its release method, and list of error codes, |

|

their causes, operation when a warning is issued and esti- |

|

mated abnormal parts. |

APPENDIX*: |

Parts layout drawings, connector layout drawings, timing |

|

chart, overall layout drawing |

This section gives, as information required by the CE at the site (or at the customer's premise), a rough outline of the service schedule and its details, maintenance steps, the object and role of each adjustment, error codes and supplementary information.

The details of items with an asterisk "*" are described only in the service manual of

the main body.

Confidential – for internal use only, do not distribute |

C-1 |

Notation of the service manual

A. Product name

In this manual, each of the products is described as follows:

(1) |

IC board: |

Standard printer |

(2) |

bizhub 500/420/360: |

Main body |

(3) |

Microsoft Windows 95: |

Windows 95 |

|

Microsoft Windows 98: |

Windows 98 |

|

Microsoft Windows Me: |

Windows Me |

|

Microsoft Windows NT 4.0: |

Windows NT 4.0 or Windows NT |

|

Microsoft Windows 2000: |

Windows 2000 |

|

Microsoft Windows XP: |

Windows XP |

When the description is made in combination of the OS's mentioned above: Windows 95/98/Me

Windows NT 4.0/2000

Windows NT/2000/XP Windows 95/98/Me/NT/2000/XP

B. Brand name

The company names and product names mentioned in this manual are the brand name or the registered trademark of each company.

C. Electrical parts and signals

Those listed by way of example below are not exhaustive, but only some instances among many.

Classification |

Load symbol |

Ex. of signal name |

Description |

|

|

|

|

|

|

IN |

|

|

|

|

|

|

|

PS |

|

|

|

|

|

Sensor |

PS |

Door PS1 |

Sensor detection signal |

|

|

|

|

|

|

SIG |

|

|

|

|

|

|

|

102 PS |

|

|

|

|

|

|

|

24V |

Power to drive the solenoid |

|

|

|

|

Solenoid |

SD |

DRV |

Drive signal |

|

|

|

|

|

|

SOL |

|

|

|

|

|

|

|

|

|

|

|

24V |

Power to drive the clutch |

|

|

|

|

Clutch |

CL |

DRV |

Drive signal |

|

|

|

|

|

|

SOL |

|

|

|

|

|

|

|

|

|

C-2 |

Confidential – for internal use only, do not distribute |

Classification |

Load symbol |

Ex. of signal name |

Description |

|||

|

|

|

|

|||

|

|

24V |

Power to drive the motor |

|||

|

|

|

|

|||

|

|

CONT |

Drive signal |

|||

|

|

|

|

|||

Motor |

M |

DRV1 |

|

|||

|

|

|

|

|||

DRV2 |

Drive signals of two kinds |

|||||

|

|

|||||

|

|

|

|

|

||

|

|

D1 |

||||

|

|

|

||||

|

|

|

|

|||

|

|

D2 |

|

|||

|

|

|

|

|||

|

|

_U |

|

|||

|

|

|

|

|||

|

|

_V |

|

|||

|

|

|

|

|||

|

|

_W |

Drive signals (control signals) of three kinds |

|||

|

|

|

|

|

||

|

|

DRV1 |

||||

|

|

|

||||

|

|

|

|

|||

|

|

DRV2 |

|

|||

|

|

|

|

|||

|

|

DRV3 |

|

|||

|

|

|

|

|||

|

|

D1 |

|

|||

|

|

|

|

|||

|

|

D2 |

|

|||

|

|

|

|

|||

|

|

D3 |

|

|||

|

|

|

|

|||

|

|

D4 |

|

|||

|

|

|

|

|||

|

|

DRV A |

|

|||

|

|

|

|

|

|

|

|

|

DRV |

|

|

|

|

|

|

A |

|

|||

|

|

|

|

|||

|

|

DRV B |

Drive signals (control signals) of four kinds |

|||

|

|

|

|

|

Motor, phases A and B control signals |

|

|

|

DRV |

|

|

||

|

|

B |

||||

|

|

|

|

|||

|

|

A |

|

|||

Motor |

M |

|

|

|||

/A |

|

|||||

|

|

|

|

|||

|

|

B |

|

|||

|

|

|

|

|||

|

|

/B |

|

|||

|

|

|

|

|||

|

|

AB |

|

|||

|

|

|

|

|||

|

|

BB |

|

|||

|

|

|

|

|||

|

|

CLK, PLL |

PLL control signal |

|||

|

|

|

|

|||

|

|

LCK, Lock, LD |

PLL lock signal |

|||

|

|

|

|

|||

|

|

FR |

Forward/reverse rotation signal |

|||

|

|

|

|

|||

|

|

EM, Lock, LCK, LD |

Motor lock abnormality |

|||

|

|

|

|

|||

|

|

BLK |

Drive brake signal |

|||

|

|

|

|

|||

|

|

P/S |

Power/stop |

|||

|

|

|

|

|||

|

|

S/S |

Operating load start/stop signal |

|||

|

|

|

|

|

||

|

|

SS |

||||

|

|

|

||||

|

|

|

|

|||

|

|

CW/CCW, F/R |

Rotational direction switching signal |

|||

|

|

|

|

|||

|

|

ENB |

Effective signal |

|||

|

|

|

|

|||

|

|

TEMP_ER |

Motor temperature abnormality detection signal |

|||

|

|

|

|

|||

|

|

24V |

Power to drive the fan motor |

|||

|

|

|

|

|||

Fan |

FM |

CONT, DRIVE |

Drive signal |

|||

|

|

|

|

|||

HL |

Speed control signal (2 speeds) |

|||||

|

|

|||||

|

|

|

|

|||

|

|

EM, Lock, LCK, FEM |

Detection signal |

|||

|

|

|

|

|||

Others |

|

TH1.S, ANG |

Analog signal |

|||

|

|

|

|

|

|

|

Confidential – for internal use only, do not distribute |

C-3 |

Classification |

Load symbol |

Ex. of signal name |

Description |

|

|

|

|

Ground |

|

SG, S.GND, S_GND |

Signal ground |

|

|

|

|

|

PG, P.GND |

Power ground |

|

|

|

||

|

|

|

|

|

|

DCD |

Data carrier detection |

|

|

|

|

|

|

SIN |

Serial input |

|

|

|

|

|

|

SOUT |

Serial output |

|

|

|

|

|

|

DTR |

Data terminal operation available |

|

|

|

|

Serial com- |

|

GND |

Signal ground (earth) |

|

|

|

|

|

DSR, DSET |

Data set ready |

|

munication |

|

||

|

|

|

|

|

|

RTS |

Transmission request signal |

|

|

|

|

|

|

CTS |

Consent transmission signal |

|

|

|

|

|

|

RI |

Ring indicator |

|

|

|

|

|

|

TXD |

Serial transmission data |

|

|

|

|

|

|

RXD |

Serial reception data |

|

|

|

|

D. Paper feed direction

When the direction in which paper is fed is in parallel with the longer side of paper, the paper feed direction like this is referred to as the longitudinal feed.

And the paper feed direction that is perpendicular to the longitudinal feed is referred to as the transverse feed.

When specifying the longitudinal feed, "S (abbreviation for Short Edge Feeding)" is added to the paper size. For the transverse feed, no specific notation is employed.

However, when only the longitudinal feed is specified for one and the same paper size with no specification made for the transverse feed, "S" is not added even when being fed longitudinally.

<Example>

Paper size |

Feed direction |

Notation |

|

|

|

|

|

A4 |

Transverse feed |

A4 |

|

|

|

||

Longitudinal feed |

A4S |

||

|

|||

|

|

|

|

A3 |

Longitudinal feed |

A3 |

|

|

|

|

C-4 |

Confidential – for internal use only, do not distribute |

SERVICE MANUAL

Theory of Operation

500/420/360

Main body

Confidential – for internal use only, do not distribute

2007.01 Ver. 2.0

Revision history

After publication of this service manual, the parts and mechanism may be subject to change for improvement of their performance.

Therefore, the descriptions given in this service manual may not coincide with the actual machine.

When any change has been made to the descriptions in the service manual, a revised version will be issued with a revision mark added as required.

Revision mark: |

|

|

|

|

|

• |

To indicate clearly a section revised, show |

1 |

to the left of the revised section. |

||

|

A number within |

1 |

represents the number of times the revision has been made. |

||

• |

To indicate clearly a section revised, show |

1 |

in the lower outside section of the correspond- |

||

|

ing page. |

|

|

|

|

|

A number within |

1 |

represents the number of times the revision has been made. |

||

NOTE

Revision marks shown in a page are restricted only to the latest ones with the old ones deleted.

•When a page revised in Ver. 2.0 has been changed in Ver. 3.0:

The revision marks for Ver. 3.0 only are shown with those for Ver. 2.0 deleted.

•When a page revised in Ver. 2.0 has not been changed in Ver. 3.0: The revision marks for Ver. 2.0 are left as they are.

2007/01 |

2.0 |

|

Revision in relation to launching of bizhub 360 |

|

|

|

|

2006/02 |

1.0 |

— |

Issue of the first edition |

|

|

|

|

Date |

Service manual Ver. |

Revision mark |

Descriptions of revision |

|

|

|

|

Confidential – for internal use only, do not distribute

Theory of Operation Ver.2.0 Jan. 2007 |

CONTENTS |

|

|

CONTENTS

bizhub 500/420/360

OUTLINE

1. SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2. PRODUCT SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 3. UNIT CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 4. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

COMPOSITION/OPERATION

5. OVERALL CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 5.1 Time chart when the power is turned ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 5.2 Control block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 6. SCANNER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 6.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 6.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 6.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 6.3.1 Scan/exposure lamp control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 6.3.2 Original size detection control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 6.3.3 AE control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 6.3.4 Image processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 7. WRITE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 7.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 7.2.1 Laser beam path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 7.2.2 Write control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 7.2.3 Image stabilization control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 7.2.4 Image processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 8. PHOTO CONDUCTOR SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 8.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 8.2.1 Drum drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 8.2.2 Drum claw drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 8.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 8.3.1 Image creation control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 8.3.2 Drum claw control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 8.3.3 Image stabilization control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9. CHARGING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 9.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 9.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 9.2.1 Charging control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 9.2.2 Erase lamp (EL) control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 10. TRANSFER/SEPARATION SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 10.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 10.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 10.2.1 Transfer guide control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 10.2.2 Transfer/separation control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

bizhub 500/420/360

Confidential – for internal use only, do not distribute |

i |

|

bizhub 500/420/360

CONTENTS |

Theory of Operation Ver.2.0 Jan. 2007 |

|

|

10.2.3 Transfer exposure lamp (TSL) control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 11.DEVELOPING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 11.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 11.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 11.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 11.3.1 Developer conveyance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 11.3.2 Developing bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 11.3.3 Developing suction control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 11.3.4 Image stabilization control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 12.TONER SUPPLY SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 12.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 12.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 12.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 12.3.1 Toner level detection control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 12.3.2 Toner supply control to the toner hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 12.3.3 Toner supply control to the developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 12.3.4 Toner conveyance control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

13.CLEANING/TONER RECYCLE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 13.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 13.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 13.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 13.3.1 Cleaning operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 13.3.2 Toner collection mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 13.3.3 Toner conveyance operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 14.PAPER FEED SECTION (Tray 1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 14.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 14.1.1 Tray 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 14.1.2 Tray 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 14.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 14.2.1 Paper feed drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 14.2.2 Tray lift drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 14.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 14.3.1 Up/down control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 14.3.2 Paper size detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 14.3.3 Paper feed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 14.3.4 Paper empty control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 14.3.5 Paper remaining detection mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

15.BYPASS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 15.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 15.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 15.2.1 Paper feed drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 15.2.2 Tray lift drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 15.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 15.3.1 Up/down control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 15.3.2 Paper size detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 15.3.3 Paper feed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 15.3.4 Paper empty control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 16.REGISTRATION SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 16.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 16.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ii |

Confidential – for internal use only, do not distribute |

|

Theory of Operation Ver.2.0 Jan. 2007 |

CONTENTS |

|

|

16.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 16.3.1 Loop control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 17. ADU SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 17.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 17.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 17.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 17.3.1 Conveyance path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 17.3.2 Conveyance control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

18. FUSING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 18.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 18.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 18.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 18.3.1 Fusing roller drive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 18.3.2 Web drive control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 18.3.3 Fusing temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 18.3.4 Fusing roller edge cooling control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 18.3.5 Envelope conveyance mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 18.3.6 Protection against abnormality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 18.3.7 Jam detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 19. REVERSE/EXIT SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 19.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 19.2 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 19.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 19.3.1 Conveyance control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 19.3.2 Reverse control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

20. INTERFACE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 20.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 20.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 21. IMAGE STABILIZATION CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 21.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 21.2 Operation flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 21.2.1 Image stabilization control flow when the power switch (SW2) is turned ON . . . . . . . . . . . . . . . 83 21.2.2 Image stabilization control flow while in the print and the idle . . . . . . . . . . . . . . . . . . . . . . . . . . 86 22. IMAGE PROCESSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 22.1 Image processing in the scanner section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 22.1.1 Shading correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 22.1.2 AE control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 22.1.3 Area discrimination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 22.1.4 Brightness/density conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 22.1.5 Filter/magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 22.1.6 Scanner gamma correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 22.1.7 Halftone processing (error diffusion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 22.1.8 Compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 22.1.9 Storage of image data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 22.2 Image processing in the write section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

23. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 23.1 Fan control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 23.1.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 23.1.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 23.2 Counter control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

bizhub 500/420/360

Confidential – for internal use only, do not distribute |

iii |

|

bizhub 500/420/360

CONTENTS |

Theory of Operation Ver.2.0 Jan. 2007 |

|

|

23.2.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 23.2.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 23.3 Parts that operate when the power switch is turned ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 23.3.1 Parts that operate when the main power switch (SW1) is turned ON . . . . . . . . . . . . . . . . . . . 103 23.3.2 Parts that operate when the power switch (SW2) is turned ON. . . . . . . . . . . . . . . . . . . . . . . . 104

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

iv |

Confidential – for internal use only, do not distribute |

|

|

|

|

|

Theory of Operation Ver.2.0 Jan. 2007 |

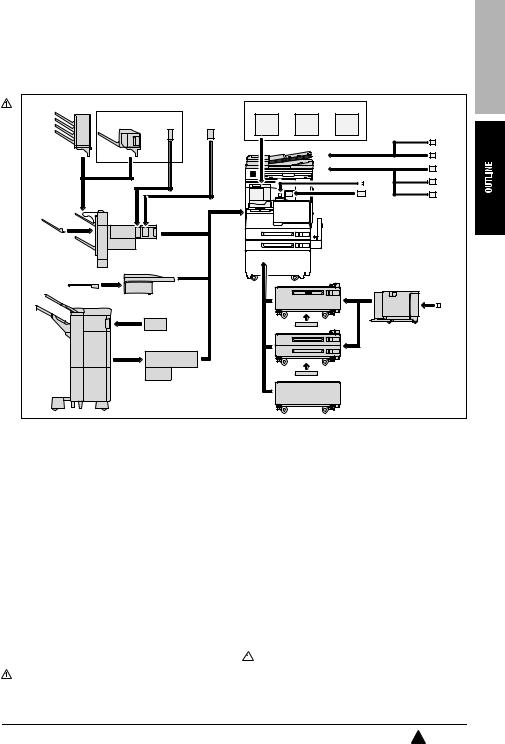

1. SYSTEM CONFIGURATION |

|

|

OUTLINE |

|

|

|

|

500/420/360 |

|

1. SYSTEM CONFIGURATION |

|

|

||||

|

|

|

|

|

|

|

A. |

System configuration |

|

|

|

|

bizhub |

|

|

|

|

|

|

|

|

[23] |

|

[27] |

[28] |

[29] |

|

|

[24] |

[25] |

[26] |

|

|

|

|

|

|

|

|

|

[5] |

|

|

|

|

|

[1] |

[6] |

|

|

|

|

|

[2] |

[7] |

|

|

|

|

|

[3] |

[8] |

|

|

|

|

|

[4] |

[9] |

|

[22] |

|

|

|

|

|

|

[21] |

|

|

|

|

|

|

[20] |

|

|

|

|

|

|

[19] |

|

|

|

[11] |

[14] |

|

|

|

|

|

|

|

|

[17] |

|

|

|

|

[15] |

|

|

[18] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[10] |

[12] |

|

|

|

[16] |

|

|

|

|

|

|

|

|

[10] |

[13] |

|

|

|

|

|

|

|

50gat1e001nb |

[1]Reverse automatic document feeder (DF-607) (standard equipment)

[2]Main body

[3]Image controller (IC-204)

[4]Hard disk (HD-505)

[5]Stamp unit (SP-501)

[6]Spare TX marker stamp 2

[7]Key counter kit 4 *1

[8]Key counter *1

[9]Key counter mount kit *1

[10]Dehumidifier heater 1C

[11]Paper feed cabinet (PC-402)

[12]Paper feed cabinet (PC-202)

[13]Desk (DK-501)

[14]Large capacity unit (LU-201)

[15]Dehumidifier heater *2

[16]Relay unit (RU-502)

[17]Finisher (FS-511)

[18]Swedish punch kit G *3

[19]Job separator (JS-502)

[20]Output tray kit (OT-501)

[21]Output tray (OT-601)

[22]Finisher (FS-510)

[23]Mail bin kit (MT-501)

[24]Saddle stitcher (SD-502)

[25]Folding unit (included in SD-502)

[26]Punch unit (PU-501)

[27]FAX kit (FK-502)

[28]Mount kit (MK-708)

[29]FAX multi line (ML-503)

*1 See "6.4 Option counter" in Field Service bizhub 500/420/360 main body for details. *2 Dehumidifier heater is set up as service part.

*3 Swedish punch kit G is for Europe only.

Confidential – for internal use only, do not distribute |

1 |

1 |

Loading...

Loading...