KEYENCE LS-7000 User Manual

96M12219

User’s Manual

High-speed, High-precision Digital Micrometer

LS-7000 Series

Preface

This instruction manual provides necessary information on the operation and maintenance of the LS-7000 Series along with precautions. Please read the manual carefully and be sure you understand the information provided before attempting to install and operate the LS-7000 Series. Keep this manual handy for future reference.

Please make sure that the end users are provided with this manual.

Symbols

The following symbols are used for the list of precautions to ensure safety and to prevent personal injury and/or property damage when using the LS-7000 Series.

The following symbols alert you to important messages. Be sure to read these messages carefully.

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

Important:

Note:

Tips

Reference:

Failure to follow instructions may lead to death or serious injury.

Failure to follow instructions may lead to injury.

Failure to follow instructions may lead to product damage (product malfunctions, etc.).

Provides important precautions and restrictions on proper operation.

Provides additional information on proper operation.

Provides useful information on proper operation.

Provides reference pages.

General precautions

1.No part of this manual may be reprinted or reproduced in any form or by any means without the prior written permission of KEYENCE CORPORATION.

2.The content of this manual is subject to change without notice.

3.KEYENCE has thoroughly checked and reviewed this manual. Please contact the sales office listed at the end of this manual if you have any questions or comments regarding this manual, or if you find an error.

4.KEYENCE assumes no liability for damages resulting from the use of the information in this manual, item 3 above notwithstanding.

5.KEYENCE will replace any incomplete or incorrectly collated manual.

6.All company names and product names in this manual are registered trademarks or trademarks of their respective owners.

Safety Precautions

■General precautions

•At startup and during operation, be sure to monitor the functions and performance of the LS-7000 Series.

•Take sufficient safety measures to prevent damage to the human body and/or equipment that may be caused if this product should fail to operate properly.

•Do not modify the LS-7000 Series or use it in any way other than as described in the specifications. Its functions and performance are not guaranteed under said conditions.

•When the LS-7000 Series is used in combination with other instruments, its functions and performance may be degraded, depending on the operating conditions and surrounding environment.

•Do not use the LS-7000 Series for the purpose of protecting the human body.

•Do not expose the LS-7000 Series and peripheral devices to sudden temperature change, as this may cause condensation.

■Precautions

WARNING |

■ Operation |

|

• Always use the LS-7000 Series at 24 VDC, otherwise a fire, |

|

|

|

electric shock or product failure may result. |

|

• Prepare the applicable AC power supply cable if you use LS- |

|

S11. |

|

• Secure the GND line of the power cable of the AC power |

|

supply stand to protective ground, otherwise an electric shock |

|

or product failure may result. |

|

• Do not disassemble or modify the LS-7000 Series. |

|

This may cause fire or electric shock. |

|

■ When abnormal conditions are encountered |

|

If the following conditions are encountered, immediately turn off |

|

the power. Continuing to use the LS-7000 Series. under abnor- |

|

mal conditions may cause fire, electric shock or equipment |

|

failure. |

|

Contact your nearest KEYENCE sales office for repairs. |

|

• When water or foreign matter enters the controller. |

|

• When the LS-7000 Series. is dropped or the housing is |

|

damaged. |

|

• When the controller produces smoke or an abnormal smell. |

96M12219 |

i |

CAUTION |

■ Usage |

• Be sure to turn off the power to the LS-7000 Series and any |

|

|

connected devices before connecting or disconnecting the |

|

cables. Otherwise, the camera and connected devices may be |

|

damaged. |

•Do not turn off the power while setting a parameter. Otherwise, the settings may be partially or completely lost.

•Do not block the ventilation slots on the LS-7000 Series and peripheral devices. A rise in inner temperature may cause equipment failure.

■ Proper environment and conditions

To use the LS-7000 Series properly and safely, do not install the LS-7000 Series in locations with the following conditions. Use of this equipment in an improper environment may cause fire, electric shock, or equipment failure.

•Locations with high humidity, a large amount of dust, or poor ventilation

•Locations where the temperature rises excessively due to direct sunlight, etc.

•Locations where corrosive or flammable gas exists

•Locations where the LS-7000 Series is directly subjected to vibration or impact

•Locations where water, oil or chemicals may splash the LS7000 Series

•Locations where static electricity is easily built up

■ Countermeasures against Noise

The LS-7000 Series may malfunction or fail to operate due to noise generated from power lines or high-tension lines. If the LS7000 Series is operated close to such noise sources, use a noise filter, wire the cable of the LS-7000 Series in an independent conduit, or locate the LS-7000 Series in an area with proper insulation from noise.

ii

Note: |

■ Influence of Ambient Operating Temperature |

|

|

Ensure that the ambient operating temperature is constant. A |

|

|

change in the ambient operating temperature may result in |

|

|

measurement errors. If the ambient operating temperature |

|

|

changes by 10°C, it will take approximately 60 minutes for the |

|

|

interior temperature distribution of the LS-7000 Series to be |

|

|

uniform. |

|

|

■ Warming Up |

|

|

Do not operate the LS-7000 Series for approximately 30 minutes |

|

|

after it is turned on. The internal circuitry of the LS-7000 Series is |

|

|

not stable immediately after it is turned on. The measured value |

|

|

drifts gradually as a result. |

|

|

■ Influence of Dust and Dirt |

|

|

A measurement error may result due to dirt, dust, water, or oil in |

|

|

any of the following cases. |

|

|

• Cover glass: Blow off the dirt, dust, water or oil on the cover |

|

|

|

glass with clean air. If the cover glass is excessively dirty, wipe |

|

|

the glass with a soft cloth moistened with isopropyl alcohol. |

|

• |

Target surface: Blow off the dirt, dust, water or oil on the sur- |

|

|

face with clean air or wipe the surface. |

|

• |

Intrusion of dirt, dust, water or oil blown or sprayed into optical |

|

|

sensing area: Install a protection cover or perform air purging. |

■ Influence of Vibration

The measured value of an object may fluctuate if the object is vibrating. If that happens, increase the averaging number. This will ensure highly accurate measurement.

■ Targets

The measured value of an object may have an error due to the shape and surface condition. Locate a reference object within the measuring area and use the calibration function of the LS-7000 Series to correct the error if that happens.

■ Influence of Air Flow

The measured value of an object may fluctuate due to a slow flow of air. In that case, the following countermeasures are effective.

• Protect the measuring head with a cover.

• Use a fan to mix the air vigorously between the transmitter and receiver.

■ Maintenance

Do not wipe the LS-7000 Series with a damp cloth or a cloth moistened with benzine or paint thinner. This may cause the discoloration or deformation of the LS-7000 Series. If the LS7000 Series is excessively dirty, use a tightly squeezed cloth moistened with thin neutral detergent. Then wipe the LS-7000 Series with a soft dry cloth.

■ Precautions for LED

The LS-7010/LS-7030/LS-7070 Measuring Head uses an LED light source. Abide by the following precautions when using the unit.

|

• Do not look at the LED light source for a long time. |

|

CAUTION |

|

|

The LED used as the light source is classified into class 1 |

|

|

|

according to IEC60825-1 standards. Basically the light beam of |

|

|

|

|

|

the LED is safe, but do not look at the LED for a long time. |

|

|

• Do not disassemble the unit. |

|

|

The unit does not incorporate a mechanism to stop the emission |

|

|

of the LED when the unit is disassembled. Never attempt to |

|

|

disassemble the unit, otherwise you will be exposed to LED light. |

iii |

|

|

Precautions for CE Markings

Keyence confirms that the LS-7000 Series meets EC directive requirements. The LS-7000 Series bears CE markings. Keep the following conditions if the LS-7000 Series is used in European countries.

■ EMC Directives

Keep the following condition so that the LS-7000 Series will satisfy EN61326-1 requirements.

•The power cable and I/O cable connected to the controller are both less than 30m in length.

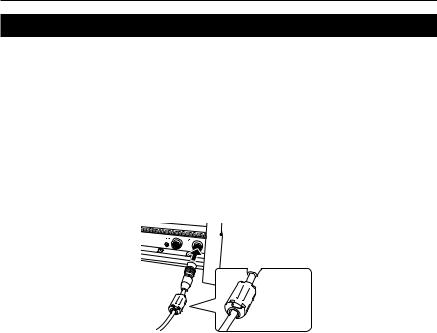

•Attach the OP-31973 Clamp-type Ferrite Core to the cable between the controller and measuring head. The attaching position is as close as possible to the cable end on the controller side, where the core must be snapped onto the cable to form a one-turn loop.

Ferrite core

OP-31973

■ Low-voltage Directives

When using the LS-S11 AC Power Supply Stand as a dedicated power supply to the LS7000 Series, keep the following conditions so that the LS-S11 will satisfy EN61010-1 requirements. The LS-S11 satisfies EN60825-1 (LED Class 1) requirements with no conditions attached.

Environment Conditions

Installation category (Overvoltage category): II (see note 1)

Pollution degree: 2 (see note 2)

Operation and Installation Conditions

•The LS-S11 AC Power Stand is a dedicated power supply for the LS-7000 Series. Never use the LS-S11 for other purposes.

•When using the LS-7000 Series in European countries, check that the AC power supply cable satisfies EC directive requirements certified by an authorized third party. Consult your Keyence representative for the AC power supply cable in detail.

•Before turning the LS-7000 Series on, connect the ground terminal of the AC power supply cable to the protective ground terminal of the power supply.

•Be sure to use a time lag fuse rated 250 V, 3.15 A for the replaceable fuse of the LSS11.

Note 1: Installation categories (overvoltage categories) include impulse overvoltage regulations at transient overvoltage levels specified by EC directives.

Installation category II indicates a level where power is provided from fixed installations, such as distribution panels.

Note 2: The pollution degree refers to the level of solid, liquid, or gas contamination that deteriorates the dielectric strength or surface resistance of the LS-7000 Series. Pollution degree 2 indicates the normal indoor environment (free of non-con-

ductive contamination).

iv

About this Manual

The following section provides information on the configuration of each page of this manual along with symbols and terms used in this manual.

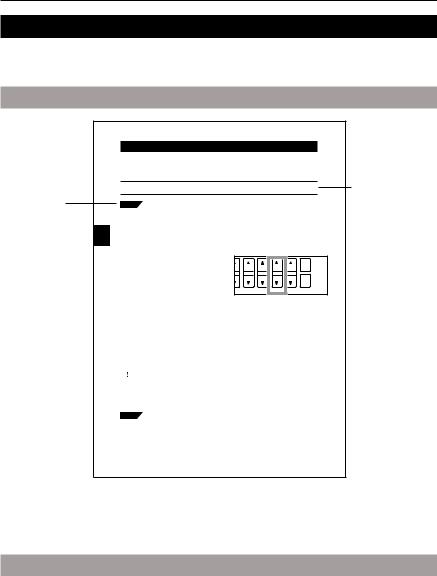

Page Configuration and Symbols

|

|

Chapter 3 |

Operation Control |

|

|

|

Automatic Zero Function |

|

|

|

|

The automatic zero function sets measuring values to zero (0.00000) instantly. This func- |

||

|

|

tion is convenient for zero-point calibration for a variety of target. Furthermore, |

||

|

|

master calibration is possible by using this function in combination with the offset function. |

||

|

|

Note: |

This function will not be available while the controller is awaiting the result of |

|

|

|

|

measurement, during which the LCD monitor will display “– – –. – – – –.”) |

|

Tips: Describes |

|

Tips |

The automatic zero value will not be lost after the LS-7500 Series is turned |

|

information that will |

|

|

off. The automatic zero value for each program will be stored. |

|

|

Automatic zero settings are made through the following functional components. |

|||

deepen the user’s |

|

|||

3 |

• Control panel |

|

||

comprehension of |

• External terminal |

|

||

• RS-232C interface |

|

|||

the manual along |

|

■ Control Panel |

|

|

with other useful |

|

|

||

|

If a single measuring value is displayed, an |

|

||

information. |

|

automatic zero setting will be made for the |

HOLD |

|

|

corresponding OUT number only. |

|

||

|

|

If both measuring values are displayed, an |

|

|

|

|

automatic zero setting will be made for the |

ZERO |

|

|

|

selected OUT number on the screen. |

|

|

|

|

|

AREA |

DISP |

|

|

1 Press the [ZERO] key once. Automatic |

|

|

|

|

zero will be set. |

|

|

|

|

To cancel the setting, press the [ZERO] |

|

|

|

|

key again. |

|

|

|

|

■ External I/O Terminal |

|

|

|

|

Automatic zero will be set by short-circuiting the I/O, ZERO, and COM terminals on the |

||

|

|

rear panel of the controller together. |

|

|

|

|

Refer to Section 7 I/O Terminals on page 7-1 for details. |

|

|

Caution: Indicates |

|

|

|

|

• Do not look at the LED light source for a long time. |

information that, if |

|

|

CAUTION |

The LED used as the light source is classified into class 1 |

|

|

|

|

according to IEC60825-1 standards. Basically the light beam of |

||

not heeded, could |

|

|

|

the LED is safe, but do not look at the LED for a long time |

|

|

|

|

|

||

result in relatively |

|

|

|

|

|

serious or minor |

|

Tips |

Master Calibration with Offset Function (Automatic Offset Function) |

||

injury, damage to |

|

Set the size of a master workpiece to an offset value and make an automatic |

|||

|

|

||||

|

|

zero setting while measuring the master workpiece. Then the size of the |

|||

the LS-7000 Series, |

|

|

master workpiece will be displayed as an offset value. Refer to 3-3 Measure- |

||

|

|

ment of Outer Diameter and Width (with Two Measuring Heads) on page 3-4 |

|||

or faulty operation. |

|

|

for an application example. |

||

|

|

Refer to Offset on page 5-43 for the offset function in detail. |

|||

Note: Describes items that need the user’s attention in order to prevent mistakes in the operation of the LS-7000 Series.

3-10

The above page sample is for your reference only. It does not coincide with any of the actual pages of this manual.

Definition of Terms

This manual uses the following terms.

Term |

Description |

LS-7000 Series |

Refers to the LS-7001 controller and the measuring head as a set. |

Controller |

Refers to the LS-7001 controller. |

Measuring head |

Refers to the LS-7010/LS-7030/LS-7070 measuring head. |

v

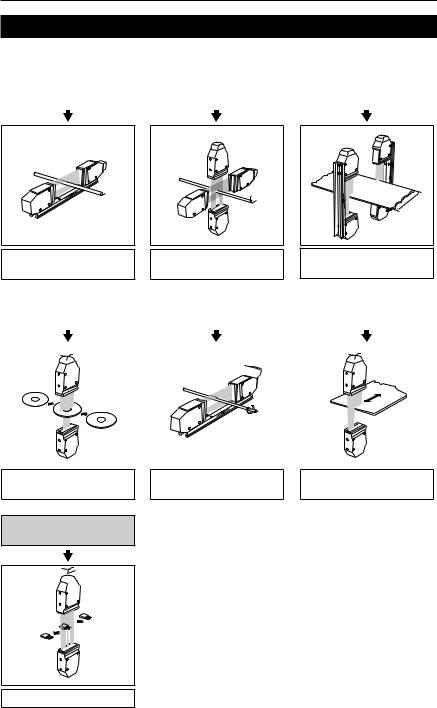

Optimum Measurement Methods

Refer to the following methods, and select the optimum measurement method according to the type of target.

Measurement of Outer Diameter |

|

Measurement of Average Outer |

|

Measurement of Sheet Width |

of a Round Bar or Wire |

|

Diameter of Round Bar or Wire |

|

|

|

|

|

||

|

|

|

|

|

D

D

Measurement of outer diameter and width (with single measuring head) (Page 2-2)

Y

X

X

Measurement of outer diameter and width (with two measuring heads in X and Y directions) (Page 2-3)

L |

Measurement of outer diameter and width (with two measuring heads for larger objects) (Page 2-4)

Measurement of Inner |

|

Measurement of Outer Diameter |

|

Measuring Robot Movement |

Diameter of a Disc |

|

and Eccentricity of a Roller |

|

and Positioning of LCD Plate |

|

|

|

|

|

|

|

|

|

|

Measurement of inner diameter and clearance (Page 2-5)

Measurement of Connector

Pins and IC Pins

Measurement of outer diameter and eccentricity (Page 2-6)

Measurement of movement and positioning (Page 2-7)

Measurement of pitch (Page 2-8)

vi

Configuration of Manual

Chapter 1 Getting Started

Provides information on precautions and necessary preparations required.

Chapter 2 Easy Setting Guide

Provides information on targets and settings for typical applications respectively.

Chapter 3 Operation Control

Provides information on setting control items on the control panel while the LS-7000 Series is in measurement operation.

Chapter 4 Function Settings

Provides information on the overview of program settings and setting methods.

Chapter 5 Environment Settings

Provides information on basic operation settings.

Chapter 6 I/O Terminals

Provides information on the specifications of the I/O terminals and timing charts.

Chapter 7 RS-232C

Provides information on how to connect external devices and the communications function to operate the LS-7000 Series through the external devices.

Chapter 8 Specifications

Provides the specifications, characteristics, and external dimensions of the LS-7000 Series.

Chapter 9 Troubleshooting

Provides information on troubleshooting and error messages.

Appendix

Provides a list of options and the index of the manual.

1

2

3

4

5

6

7

8

9

Appendix

vii

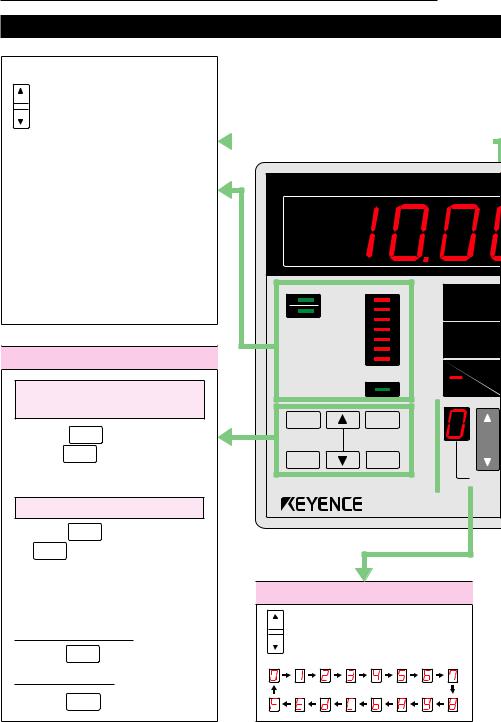

LS-7001 Operation Map

Select the area (See page 3-4)

Press the Up or Down key to select the area.

AREA

The selected area appears on the AREA display.

POSITION monitor

The POSITION monitor is lit according to the position and size of the target.

FOCUS monitor

The FOCUS monitor is lit according to the distance between the transmitter and receiver.

To make lit range changes, refer to page 4-14.

Program Settings

Area, calibration, output, or option setting:

Press the PROG key and select the

item with FUNC key.

Environment setting:

Press the PROG key while pressing

the FUNC key.

Set item selection:

Press the or

or  key.

key.

Set item cancellation:

Press the ESC key.

Entering set item:

Press the ENT key.

AREA |

POSITION |

1 |

|

2 |

|

|

FOCUS |

PROG |

ESC |

|

|

FUNC |

ENT |

|

PROG No |

Program selection

Press the Up or Down key.

PROG No.

viii

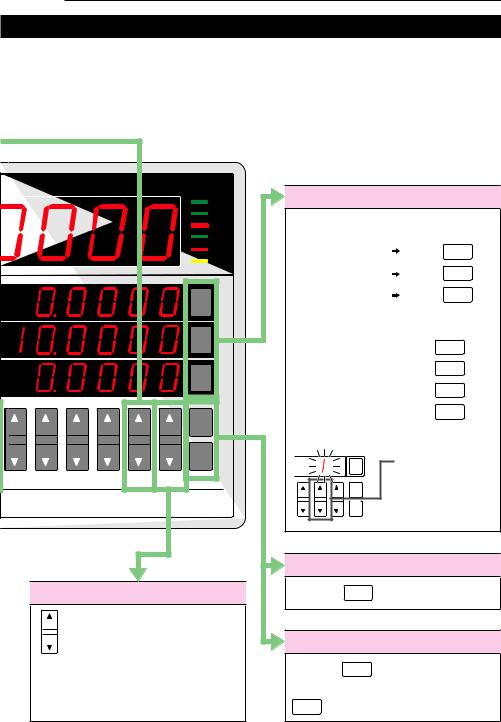

|

|

OUT 1 |

|

|

OUT 2 |

|

|

HI |

|

|

GO |

|

|

LO |

|

|

TIM |

|

|

HI |

|

|

GO |

|

|

LO |

|

|

HOLD |

|

|

ZERO |

. |

AREA |

DISP |

|

|

LS-7000 |

Measured value display selection

Press the Up or Down key.

DISP

Measured value display varies between the reference value mode and threshold mode for tolerance setting. (See page 3-2)

Tolerance setting (See page 4-50)

Reference value mode

Upper limit setting: |

Press the |

Reference value setting: |

Press the |

Lower limit setting: |

Press the |

Threshold setting |

|

HI

GO

LO

key.

key.

key.

HI value setting:  Press the HH value setting:

Press the HH value setting: Press the LO value setting:

Press the LO value setting: Press the LL value setting:

Press the LL value setting:  Press the

Press the

HI

HI

LO

LO

key. key 2X. key. key 2X.

Value change while setting

Press the key

LO

below the value HOLD flashing.

ZERO

Hold function (See page 3-5)

Press the HOLD key.

Auto zero function (See page 3-6)

Press the ZERO key.

To cancel the function, press the

ZERO key again.

ix

Contents

Safety Precautions .............................................................................................................. |

i |

Precautions for CE Markings ........................................................................................... |

iv |

About this Manual .............................................................................................................. |

v |

Page Configuration and Symbols .................................................................................... |

v |

Definition of Terms .......................................................................................................... |

v |

Optimum Measurement Methods .................................................................................... |

vi |

Configuration of Manual .................................................................................................. |

vii |

LS-7001 Operation Map .................................................................................................. |

viii |

Contents.............................................................................................................................. |

x |

Chapter 1 Getting Started

Outline and Features of LS-7000 Series ....................................................................... |

1-2 |

System Applications ....................................................................................................... |

1-3 |

Package Checks .............................................................................................................. |

1-4 |

LS-7001 ....................................................................................................................... |

1-4 |

LS-7010 ....................................................................................................................... |

1-4 |

LS-7030 ....................................................................................................................... |

1-4 |

LS-7070 ....................................................................................................................... |

1-5 |

LS-C A ..................................................................................................................... |

1-5 |

LS-S11 ......................................................................................................................... |

1-6 |

Functions and Nomenclature ......................................................................................... |

1-7 |

Controller ..................................................................................................................... |

1-7 |

Measuring Head ........................................................................................................... |

1-9 |

Mounting and Connection ............................................................................................ |

1-11 |

Mounting the Measuring Head ................................................................................... |

1-11 |

Mounting the Controller .............................................................................................. |

1-13 |

Connection ................................................................................................................. |

1-17 |

Turning AC Power Supply Stand On and Off .............................................................. |

1-19 |

Measurement and Setting Overview ........................................................................... |

1-20 |

Resetting to Initial Status ............................................................................................. |

1-21 |

Chapter 2 Easy Setting Guide

Measurement of Outer Diameter and Width (with Single Measuring Head) .............. |

2-2 |

Measurement of Outer Diameter and Width (with Two Measuring Heads)................. |

2-3 |

Measurement of Outer Diameter and Width |

|

(with Two Measuring Heads for Larger Objects) .......................................................... |

2-4 |

Measurement of Inner Diameter and Clearance ........................................................... |

2-5 |

Measurement of Outer Diameter and Eccentricity ....................................................... |

2-6 |

Measurement of Movement and Positioning ................................................................ |

2-7 |

Measurement of Pitch ..................................................................................................... |

2-8 |

Chapter 3 Operation Control

Selection of Measured Value Display ............................................................................ |

3-2 |

Area Monitor .................................................................................................................... |

3-4 |

Hold Function .................................................................................................................. |

3-5 |

Automatic Zero Function................................................................................................ |

3-6 |

Panel Lock Function ....................................................................................................... |

3-7 |

Program Changes ........................................................................................................... |

3-8 |

x

Chapter 4 Function Settings

Flow of Program Settings ............................................................................................... |

4-2 |

Default Values and Possible Setting Ranges ............................................................... |

4-4 |

Copying Program Setting Details and Initialization ..................................................... |

4-6 |

Area Settings ................................................................................................................... |

4-7 |

Area Selection .............................................................................................................. |

4-9 |

Focus Monitor ............................................................................................................ |

4-14 |

Area Check ................................................................................................................ |

4-15 |

Difference Check ........................................................................................................ |

4-16 |

Function Output Selection .......................................................................................... |

4-17 |

Change of Edge Detection Threshold ........................................................................ |

4-18 |

Calibration Settings ...................................................................................................... |

4-20 |

Calibration Type Selection ......................................................................................... |

4-23 |

Logic Calibration Settings .......................................................................................... |

4-23 |

Two-point Calibration Settings ................................................................................... |

4-25 |

One-point Calibration Settings ................................................................................... |

4-26 |

Initialization of Calibration .......................................................................................... |

4-26 |

Output Settings ............................................................................................................. |

4-28 |

Area Calculation ......................................................................................................... |

4-30 |

Number of Averaging Measurements ......................................................................... |

4-31 |

Measuring Mode ........................................................................................................ |

4-33 |

Offset ......................................................................................................................... |

4-43 |

Analog Output Settings .............................................................................................. |

4-44 |

Comparator Output Setting ........................................................................................ |

4-47 |

Tolerance (LIMIT) Settings ........................................................................................... |

4-50 |

Limit Range ................................................................................................................ |

4-50 |

Limit Settings ............................................................................................................. |

4-51 |

Hold Value Elimination ............................................................................................... |

4-52 |

Option Settings ............................................................................................................. |

4-54 |

Tolerance Mode (LIMITS)........................................................................................... |

4-56 |

Timing Mode .............................................................................................................. |

4-56 |

Display Unit ................................................................................................................ |

4-57 |

Minimum Display Unit ................................................................................................ |

4-58 |

I/O Mode .................................................................................................................... |

4-59 |

Units, Default Minimum Values, and Setting Ranges ................................................. |

4-60 |

Chapter 5 Environment Settings

Possible Environment Settings ...................................................................................... |

5-2 |

Default Settings ............................................................................................................ |

5-2 |

Changing Environment Settings .................................................................................. |

5-3 |

Flow of Environment Setting Display ........................................................................... |

5-4 |

Details of Environment Settings .................................................................................... |

5-5 |

Program ....................................................................................................................... |

5-5 |

RS-232C ...................................................................................................................... |

5-7 |

Head .......................................................................................................................... |

5-10 |

Beep ........................................................................................................................... |

5-12 |

Panel Lock ................................................................................................................. |

5-13 |

xi

Chapter 6 I/O Terminals

Nomenclature and Functions of I/O Terminals |

............................................................. 6-2 |

Terminal Block .............................................................................................................. |

6-2 |

Connector I/O ............................................................................................................... |

6-4 |

Functions ..................................................................................................................... |

6-7 |

Electrical Specifications ............................................................................................... |

6-9 |

Timing Chart .................................................................................................................. |

6-11 |

Chapter 7 RS-232C

Specifications .................................................................................................................. |

7-2 |

Communication using Serial Commands ..................................................................... |

7-4 |

Connecting to a PC/PLC Link Unit ............................................................................... |

7-4 |

Connecting to KV Series .............................................................................................. |

7-5 |

Outline of Command Formats ...................................................................................... |

7-6 |

Measurement Serial Commands ................................................................................. |

7-7 |

Setup Serial Commands ............................................................................................ |

7-12 |

Serial Commands to check the LS Settings ............................................................... |

7-19 |

Batch Commands ...................................................................................................... |

7-20 |

Timing Chart .............................................................................................................. |

7-21 |

ASCII Table ................................................................................................................ |

7-22 |

Communication using an External Synchronous Trigger ......................................... |

7-23 |

Chapter 8 Specifications

Specifications .................................................................................................................. |

8-2 |

Controller ..................................................................................................................... |

8-2 |

Measuring Head ........................................................................................................... |

8-3 |

Optional Accessories ................................................................................................... |

8-3 |

Characteristics ................................................................................................................ |

8-4 |

Measurement Range and Accuracy ............................................................................. |

8-4 |

Temperature Characteristics ........................................................................................ |

8-5 |

Response Delay Time .................................................................................................. |

8-6 |

Focus Characteristics................................................................................................... |

8-6 |

Mode Specifications ....................................................................................................... |

8-7 |

External Dimensions....................................................................................................... |

8-8 |

Chapter 9 Troubleshooting

Troubleshooting Guide ................................................................................................... |

9-2 |

Error Messages ............................................................................................................... |

9-6 |

Appendix

List of Optional Accessories........................................................................... |

Appendix-2 |

Setting Record Sheet ....................................................................................... |

Appendix-3 |

Environment Setting Record Sheet ................................................................ |

Appendix-5 |

Index ................................................................................................................. |

Appendix-6 |

xii

Chapter 1

Getting Started

This section provides information on the configuration of the LS-7000 Series, precautions, and necessary preparations required before operating the LS-7000 Series. Familiarize yourself with this section before using the LS-7000 Series.

Outline and Features of LS-7000 Series |

.............................. 1-2 |

System Applications ............................................................. |

1-3 |

Package Contents ................................................................ |

1-4 |

Functions and Nomenclature ............................................... |

1-7 |

Mounting and Connection .................................................. |

1-11 |

Supply Stand On and Off ................................................... |

1-19 |

Setting Overview ................................................................ |

1-20 |

Resetting to Initial Status ................................................... |

1-21 |

1-1

Chapter 1 Getting Started

Outline and Features of LS-7000 Series

The LS-7000 Series is a high-speed, high-accuracy digital micrometer used for the dimen- 1 sional measurement of objects without coming into contact with the objects. It is such a

versatile model that it has a wide range of applications including in-line measurement and offline measurement.

■ Special Features

High-speed Sampling of 2400 Times per Second

Ensures high-speed sampling that is twice as fast as the sampling speed of conventional models. The continuous measurement of extruded products and the in-line measurement of moving workpieces are possible.

Repeat Accuracy of ±0.15μm

Incorporates the latest optical system, thus ensuring excellent repeat accuracy that is twice as high as the accuracy of conventional models, thus supporting the manufacture of high-precision products.

Connecting Two Measuring Heads for two-channel Simultaneous Measurement

Two measuring heads can be used in combination for the simultaneous measurement of two targets.

Stable Detection of Transparent Objects with Threshold Change

The threshold change function supported by the DE processor makes it possible to detect transparent objects stably.

■ Principle of Measurement

The high-intensity GaN green LED radiates light, which will be changed into uniform parallel light through the special diffusion unit and collimator lens and emitted to the target in the measuring range. Then the shadow image of the target will appear on the HL-CCD (high-speed linear CCD) through the telecentric optical system. The output incident signal of the HL-CCD will be processed by the DE (digital edge-detection) processor in the controller and CPU. As a result, the dimensions of the target will be displayed and output.

HL-CCD for |

Telecentric optical |

High-intensity GaN |

measurement use |

system |

green LED |

|

Special diffusion unit |

|

|

Target |

Collimator lens |

Receiver |

|

Transmitter |

A/D |

DE |

Control input |

conversion |

processor |

Control output |

|

CPU |

BCD output |

|

|

Analog output |

|

|

RS-232C interface |

|

Controller |

|

1-2

Chapter 1 Getting Started

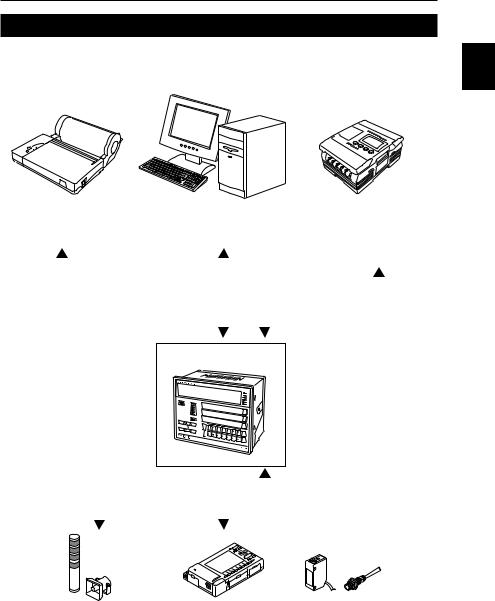

System Applications

The LS-7000 Series has a wide range of applications when used in combination with |

1 |

commercially available peripheral devices. |

Printer |

PC |

Programmable Logic |

||||

The results of measurement |

Control values or measuring |

Controller |

||||

are printed. |

values are retrieved over RS- |

Control output and measured |

||||

|

|

232C. |

values are retrieved and |

|||

|

|

|

|

|

programs for measurement |

|

|

|

|

|

|

timing control are changed. |

|

|

RS-232C |

|

RS-232C |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Comparator output |

|

|

|

|

|

|

BCD output |

|

|

|

|

|

|

RS-232C |

|

|

|

|

|

|

Timing input |

|

|

|

LS-7001 |

Auto zero input |

|||

|

|

Reset input |

||||

|

|

|

|

|

||

|

|

|

|

|

Program number selection |

|

|

|

|

|

|

|

|

|

|

|

Comparator output |

Analog output |

Timing input |

||

|

|

|

|

|

|

|

|

|

|

Indicator Light and Buzzer |

Recorder |

Photoelectric Sensor or |

Alarms are generated according to |

The results of |

Proximity Sensor |

the output of discrimination |

measurement are |

Timing input signals are sent |

results. |

recorded. |

whenever objects are detected. |

1-3

Chapter 1 Getting Started

Package Checks

1 |

|

Check that nothing is missing from the LS-7000 Series package before use. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

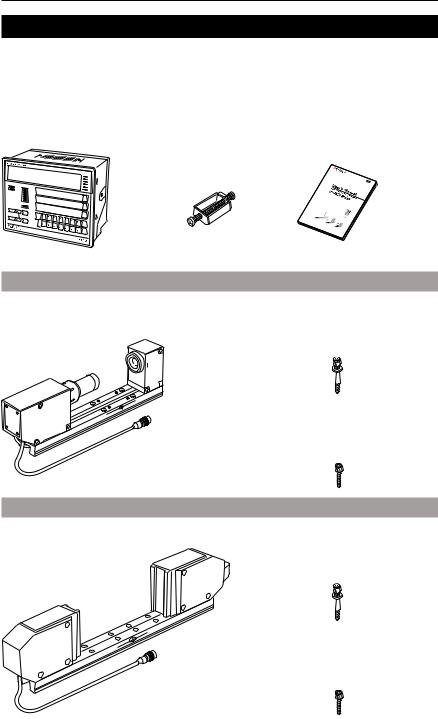

LS-7001 |

|

|

|

|

Controller |

Four Panel Mounting |

LS-7000 Series |

|

|

|

Brackets |

User’s Manual |

`

LS-7010

Measuring Head

Allen-head bolt

(Five, M3 x 45 with a washer)

Allen-head bolt (Four, M4 x 20)

LS-7030

Measuring Head

Allen-head bolt

(Six, M5 x 45 with a washer)

Allen-head bolt (Four, M4 x 20)

1-4

Chapter 1 Getting Started |

|

||

|

|

|

|

|

|

||

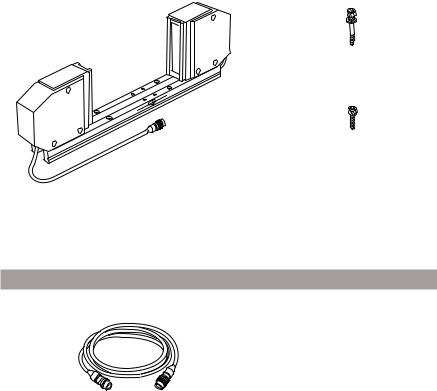

LS-7070 |

|

|

|

Measuring Head |

|

||

|

|||

Allen-head bolt |

1 |

||

(Six, M4 x 50 with a washer) |

|||

|

|||

|

|

|

|

Allen-head bolt (Four, M5 x 20)

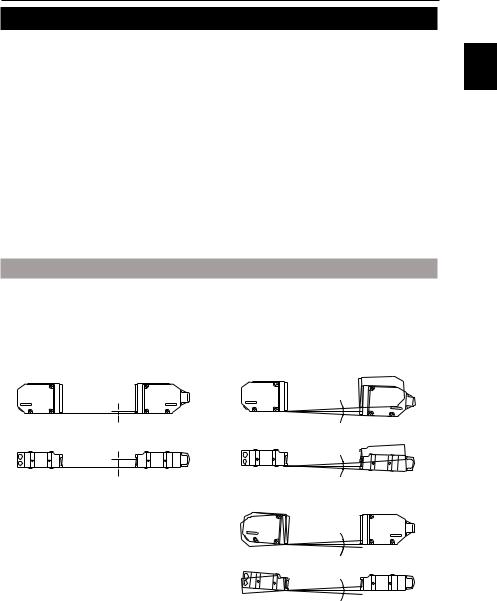

LS-C A

Extension Cable (Cable between the controller and measuring head)

LS-C3A: 3-m cable

LS-C10A: 10-m cable

LS-C30A: 30-m cable

Up to two cables are connectable, provided that the total length of the cables does not exceed 40 m.

1-5

Chapter 1 Getting Started

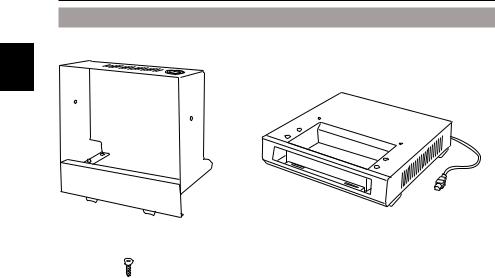

LS-S11

Stand Unit |

Base Unit |

1

Screws (Four, M4 x 8)

Keyence ships each package with utmost care and attention. If there should be any improper or damaged product, contact your Keyence representative.

1-6

Chapter 1 Getting Started

Functions and Nomenclature

The following section provides information on the functions and nomenclature of the |

1 |

controller and measuring head. |

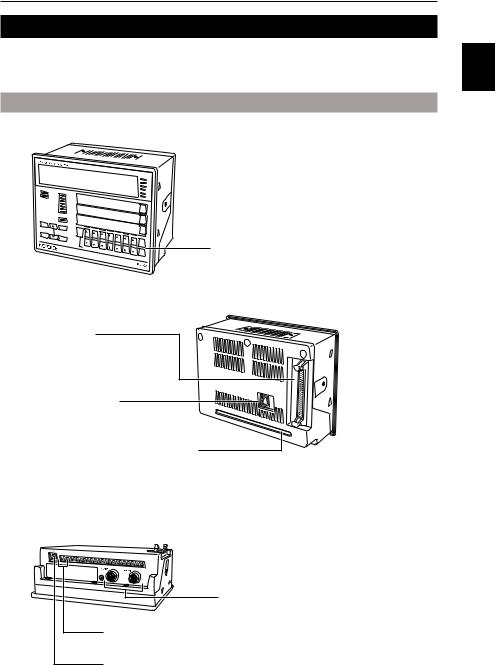

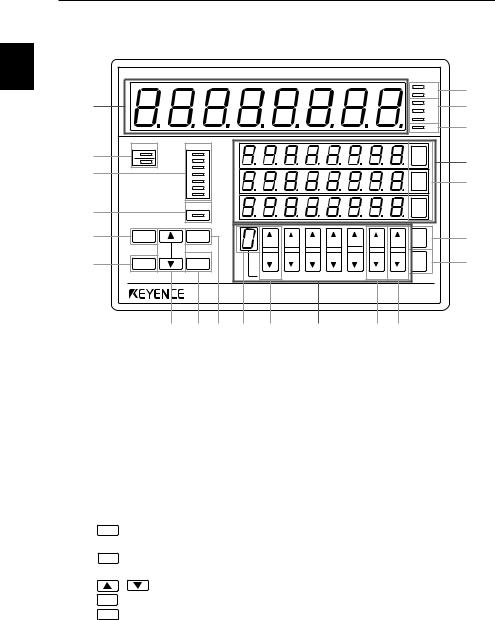

Controller

Control Panel

(Page 1-8, Control Panel)

Controller (Rear Side)

Connector I/O

Used for signal I/O

(Page 6-2, Section 6 I/O Pin)

Modular Connector

Used to connect the console connector or RS-232C cable connector.

(Page 7-4, 7-5, Section 7 RS-232C)

Terminal Block

Used for signal I/O

(Page 6-2, Section 6 I/O Terminals)

Controller (Bottom)

Extension Cable

Connect the cable between the controller and the measuring head.

Power Input Pins (24 VDC)

Provide 24 VDC power supply.

DC IN

Connect the LS-S11 AC Power Supply

Cable.

1-7

Chapter 1 Getting Started

■ Control Panel

1

|

|

|

|

|

|

|

|

OUT 1 |

(19) |

|

|

|

|

|

|

|

|

OUT 2 |

|

(1) |

|

|

|

|

|

|

|

HI |

(20) |

|

|

|

|

|

|

|

GO |

||

|

|

|

|

|

|

|

|

LO |

(21) |

|

|

|

|

|

|

|

|

TIM |

|

(3) |

AREA |

POSITION |

|

|

|

|

|

HI |

|

1 |

|

|

|

|

|

|

(2) |

||

|

|

|

|

|

|

|

|

||

|

2 |

|

|

|

|

|

|

|

|

(4) |

|

|

|

|

|

|

|

|

(17) |

|

|

|

|

|

|

|

|

GO |

|

(5) |

|

FOCUS |

|

|

|

|

|

LO |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

(6) |

PROG |

ESC |

|

|

|

|

|

HOLD |

(16) |

(7) |

FUNC |

|

|

|

|

|

|

(15) |

|

ENT |

|

|

|

|

|

ZERO |

|||

|

|

|

|

|

PROG No. |

|

AREA |

DISP |

|

|

|

|

|

|

|

|

|

LS-7000 |

|

|

(8) |

(10) |

(9) |

(11) |

(12) |

(18) |

(13) (14) |

|

|

(1) |

Main display: |

The measured value is displayed. Refer to Selection |

||

|

|

|

|

of Measured Value Display on page 3-2. |

(2) |

Sub display: |

Used to display tolerance or measured values while |

||

|

|

|

|

the LS-7000 Series is in measuring operation. The set |

|

|

|

|

value is displayed while in value setting. Refer to |

|

|

|

|

Selection of Measured Value Display on page 3-2. |

(3) |

Area monitor display: |

The number of the selected area is displayed. Refer |

||

|

|

|

|

to Area Monitor on page 3-4. |

(4) |

Position display: |

The position of the target in the selected area is |

||

|

|

|

|

displayed. Refer to Area Monitor on page 3-4. |

(5) |

Focus display: |

The focus status of the selected area is displayed. |

||

|

|

|

|

Refer to Area Monitor on page 3-4. |

(6) |

PROG (Setting) key: |

Press this key to set program details. Refer to |

||

|

|

|

|

Program Changes on page 3-8. |

(7) |

FUNC |

(Function) key: |

Press this key to set the setting item. Refer to Section |

|

|

|

|

|

4 Function Settings. |

(8) |

|

/ |

key: |

Press the Up or Down key to select the set item. |

(9) |

ESC |

key: |

|

Press this key to finish the present setting. |

(10) |

ENT |

key: |

|

Press this key to enter the set item or print the meas- |

|

|

|

|

ured value from the printers. |

(11) Program number display: |

The selected program number is displayed. |

|||

(12) Program selection key: |

Press this key to select the program number when |

|||

|

|

|

|

measuring. (Page 3-8, Program Change) |

(13) Area monitor selection key: |

Press this key to select the area number when |

|||

|

|

|

|

measuring. (Page 3-4, Area Monitor) |

1-8

|

|

|

Chapter 1 Getting Started |

|

|

|

|

|

|

||

(14) Display selection key: |

Press this key to select the main display or sub |

|

|||

|

|

|

display when measuring. (Page 3-2, Switching |

|

|

|

|

|

Display Screen) |

|

|

(15) |

ZERO key: |

|

Press this key to select the auto zero function. (Page |

1 |

|

|

|

|

3-6, Automatic Zero Function) |

||

|

|

|

|

||

(16) |

HOLD key: |

|

Press this key to select the hold function. (Page 3-5, |

|

|

(17) |

|

|

Hold Function) |

|

|

HI , GO |

, and LO keys: |

Press these keys to make tolerance settings. (Page 4- |

|

||

|

|

|

50, Limit Setting) |

|

|

(18) |

and |

keys: |

Press these keys to select the set value or item. |

|

|

(19) |

Output selection display: |

Indicates whether the measured value on the main |

|

||

|

|

|

display is OUT1 or OUT2. |

|

|

(20) |

Comparator result display: |

Displays the comparator result of the main display. |

|

||

(21) Timing display: |

Lit when timing input into the main display turns ON. |

|

|||

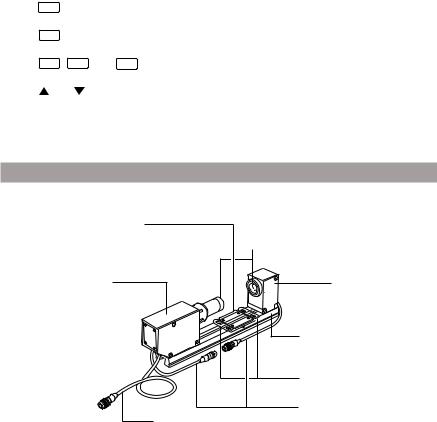

Measuring Head

LS-7010

Multi-purpose Mounting Holes

A fixture for targets can be attached.

Receiver (R Head)

Receives light from the transmitter.

Cover Glass

Transmitter (T Head)

Emits light for measurement.

TR Base

Used to mount the transmitter and receiver.

TR Cables

Used to connect the transmitter

Mounting Holes

Extension Cable

Used to mount the

Connected to the controller.

measuring head.

1-9

Chapter 1 Getting Started

LS-7030

|

Multi-purpose |

|

|

Mounting Holes |

|

|

||

1 |

A fixture for targets can |

|

be attached. |

||

|

||

|

|

Cover Glass

Transmitter (T Head)

Emits light for measurement.

Receiver (R Head)

Receives light from the transmitter.

TR Base

Used to mount the transmitter and receiver.

TR Cables

Used to connect the transmitter and receiver.

Mounting Holes

Used to mount the measuring head.

Extension Cable

Connected to the controller.

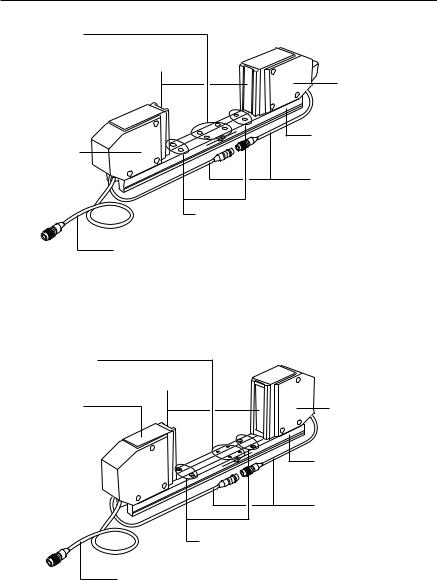

LS-7070 |

|

|

Multi-purpose |

|

|

Mounting Holes |

|

|

A fixture for targets can |

Cover Glass |

|

be attached. |

|

|

|

|

|

Receiver (R Head) |

|

Transmitter (T Head) |

Receives light from |

|

Emits light for |

the transmitter. |

|

measurement. |

|

|

TR Base |

|

|

Used to mount the |

|

|

transmitter and receiver. |

|

|

TR Cables |

|

|

Used to connect the |

|

|

transmitter and receiver. |

|

|

Mounting Holes |

|

|

Used to mount the measuring head. |

|

Extension Cable |

|

|

Connected to the controller. |

|

1-10

Chapter 1 Getting Started

Mounting and Connection

Mount the measuring head and the controller, and connect them with the cables. |

1 |

■ Mounting the Measuring Head |

The measuring head can be mounted with or without the TR base employed, according to the type of targets and operating environment.

The following section provides information on how to mount the measuring head with or without the TR base employed, along with mounting conditions required.

■ Mounting the Controller

Mount the controller to panels, such as control or operation panels, or to the LS-S11 AC Power Supply Stand. The LS-S11 Power Supply Stand is sold separately.

■ Connection

After the measuring head and the controller are mounted, connect them with the cables.

Mounting the Measuring Head

■ Mounting Restrictions

The transmitter and receiver must abide by the following restrictions when the measuring head is mounted.

Vertical Position Mismatching

Receiver |

±1 mm max. Transmitter |

Receiver |

±1 mm max. Transmitter |

The values are the same for LS-7010, LS-7030, and LS-7070.

Angle Mismatching

Receiver |

±0.25° max |

Transmitter |

|

|

|

Receiver |

±0.25° max |

Transmitter |

Receiver |

Transmitter |

|

±0.25° max |

Receiver |

Transmitter |

|

±0.25° max |

1-11

Chapter 1 Getting Started

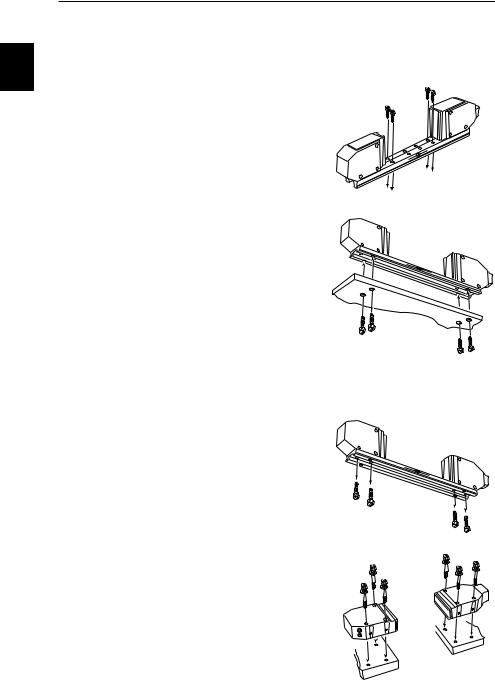

■ With TR Base

The transmitter and receiver are mounted to the TR base at the time of shipment. This section provides how to install the transmitter and receiver (LS-7030 in this case) that

1 are mounted on the TR base.LS-7010 and LS-7070 can also be installed in the same way.

Use the four, M4x20 Allen-head bolts, which are provided with the package, to mount the TR base. To mount the TR base with the bolts on the surface of the TR base, use the mounting holes on the surface.

To mount the TR base with the bolts on the back of the TR base, use the 10-mm-deep M4 (10-mm-deep M5 for LS-7070) mounting holes on the back.

■ Without TR Base

Take the following steps to use the transmitter and receiver (LS-7030 in this case) after dismounting them from the TR base. LS-7010 and LS-7070 can also be used in the same way.

1 Loosen the bolts on the back of the TR base and remove the measuring head.

2 Mount the measuring head.

Use the side mounting holes on the transmitter and receiver as shown in the illustration. Mount them with the Allenhead bolts provided with the package.

1-12

Chapter 1 Getting Started

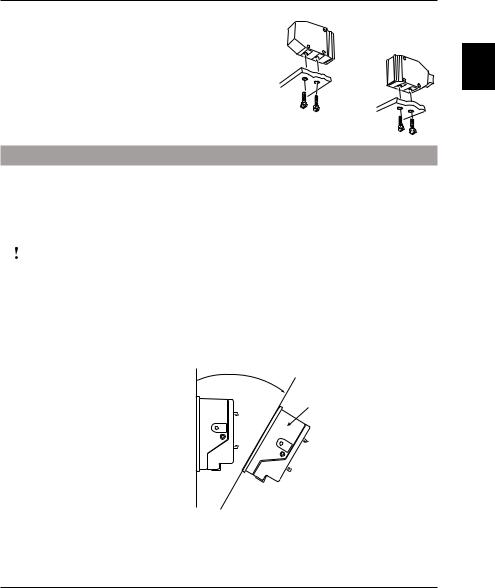

Use the 5-mm-deep M4 bottom mounting holes of the transmitter and receiver as shown in the illustration.

1

Mounting the Controller

■ Mounting Restrictions

Be aware of the following items when mounting the controller.

|

CAUTION |

• Do not install the controller upside down. |

|

• Do not block the ventilation louver. Otherwise, the interior heat |

|

|

|

may cause the controller to malfunction. |

|

|

|

Note: |

• For the maintenance, operability, and ventilation of the LS-7000 |

|

|

|

Series, separate the controller as far as possible from periph- |

|

|

eral structures or parts. |

|

|

• The mounting angle must abide by the following restrictions. |

|

|

30˚ |

Side

Display  panel

panel

•Check that the controller will not be exposed to the heat radiation of peripheral devices.

•Separate the controller as much as possible from devices with arc generation, such as electromagnetic switches or non-fuse breakers.

1-13

Chapter 1 Getting Started

■ Mounting to Panel

The controller can be mounted to control panels with the mounting brackets provided with the package. Arrange the following panel mounting dimensions.

1

207

169 +10

124 +10

200

Unit: mm

1 Mount the controller from the front side of the panel.

2 Attach resin caps to the mounting brackets.

3 Insert the mounting brackets to the four mounting holes on the side of the controller respectively.

Mounting holes

Mounting holes

1-14

Chapter 1 Getting Started

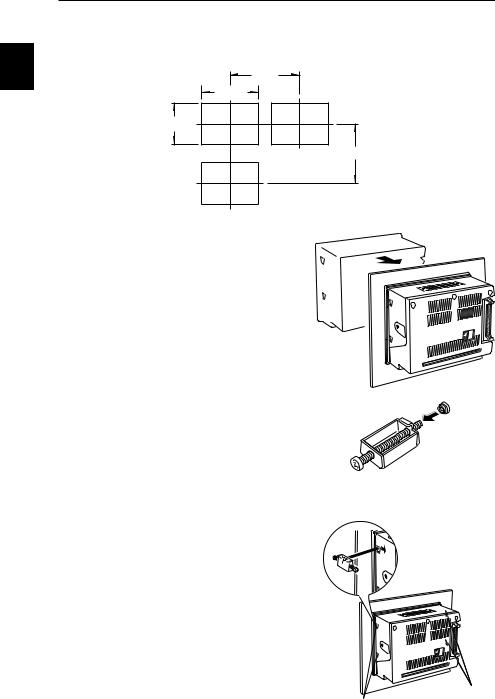

4 Secure the mounting brackets with a Phillips screwdriver.

1

• Tighten the mounting screws to a maximum torque of 0.4 Nm. CAUTION Do not tighten up the mounting screws excessively, otherwise

the panel or controller casing may be deformed.

•Do not remove the gasket, otherwise the controller will not satisfy IP64 conditions.

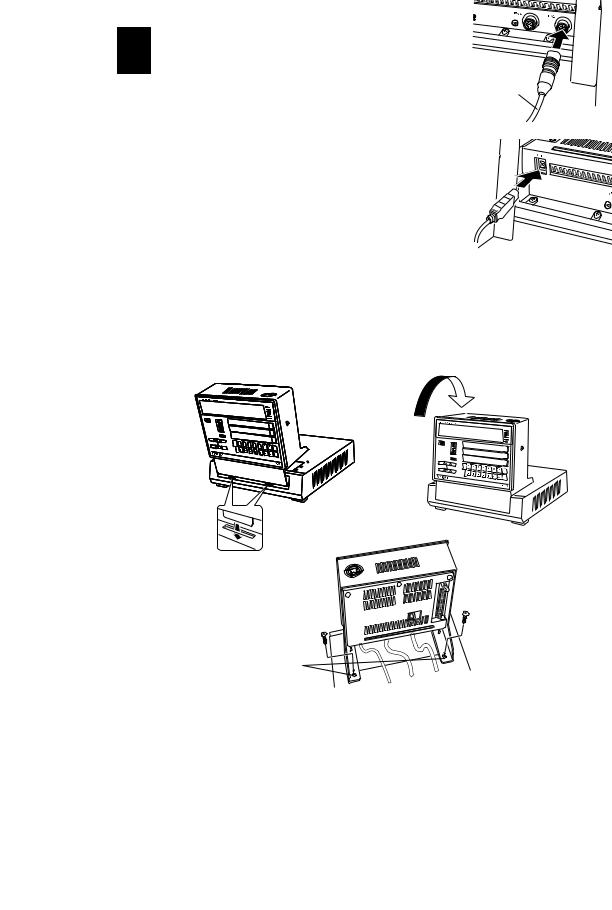

■Mounting to AC Power Supply Stand

The following section provides information on how to mount the controller to the AC power supply stand (sold separately). The AC power supply stand consists of a stand unit and base unit. Mount the controller to the stand unit first. Connect the power supply cable and extension cable (i.e., the cable between the controller and measuring head). Then mount them to the base unit.

1 Remove the gasket around the controller.

Gasket

2 Mount the controller to the stand.

Use the two screws provided with the package and secure the controller on the side.

The stand must be located on the groove from which the gasket was removed.

Secure these potions with screws.

1-15

|

Chapter 1 Getting Started |

|

|

|

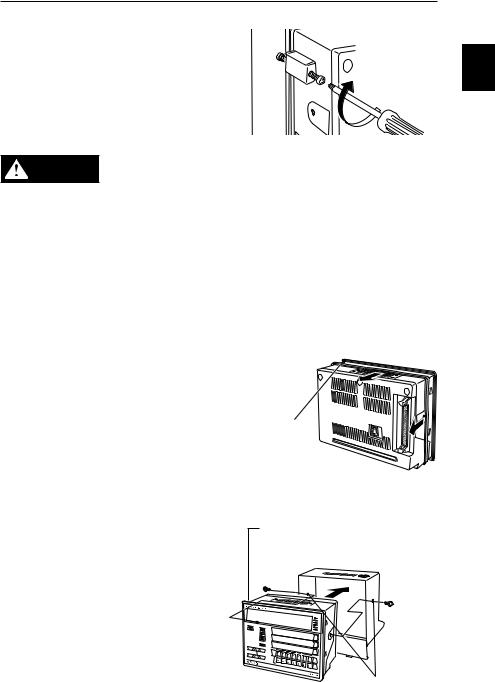

3 Connect the cable between the con- |

|

troller and measuring head. |

|

If only a single measuring head is used, |

1 |

connect the cable to the HEAD1 connec- |

tor. |

Cable between controller and measuring head

4 Connect the power supply cable of the AC power supply stand to the controller.

5 Mount the stand unit to the base unit.

Mount the stand unit with the two screws provided with the package.

(2) Lean the stand unit in the direction indicated by the arrow. Pay utmost attention so that the connected cable will not be caught by the stand unit.

(1) Lean the stand unit in the front direction and insert the tab.

(3) Secure these portions with screws.

1-16

Loading...

Loading...