KEYENCE LV-SB User Manual

1

E LV-S-IM

Ultra-small Digital Laser Sensor

LV-S Series (Type B)

Instruction Manual

■ Symbols

The following warning symbols are used to alert you to safety precautions and

to prevent human injury and/or damage to property when using this product.

Note

Provides additional information on proper operations that can be easily mistaken.

Safety Information for LV-S series

Safety precautions on laser products

* The classification is implemented based on IEC60825-1 following the

requirements of Laser Notice No.50 of FDA (CDRH).

Safety Measures for the Laser

■ Laser emission stop input

The laser emission can be stopped by selecting the “Laser emission stop” signal

(20 ms or more) from the input functions and inputting it externally.

The emission stops while the signal is being input. The laser beam is emitted in 20 ms

after the signal input is canceled. The control output functions according to the

received light intensity even while laser emission stop is input.

Note

When the power is turned on, even when the laser emission stop signal is

input, the laser is emitted for about 60 ms for self-diagnostic purpose.

Accessories

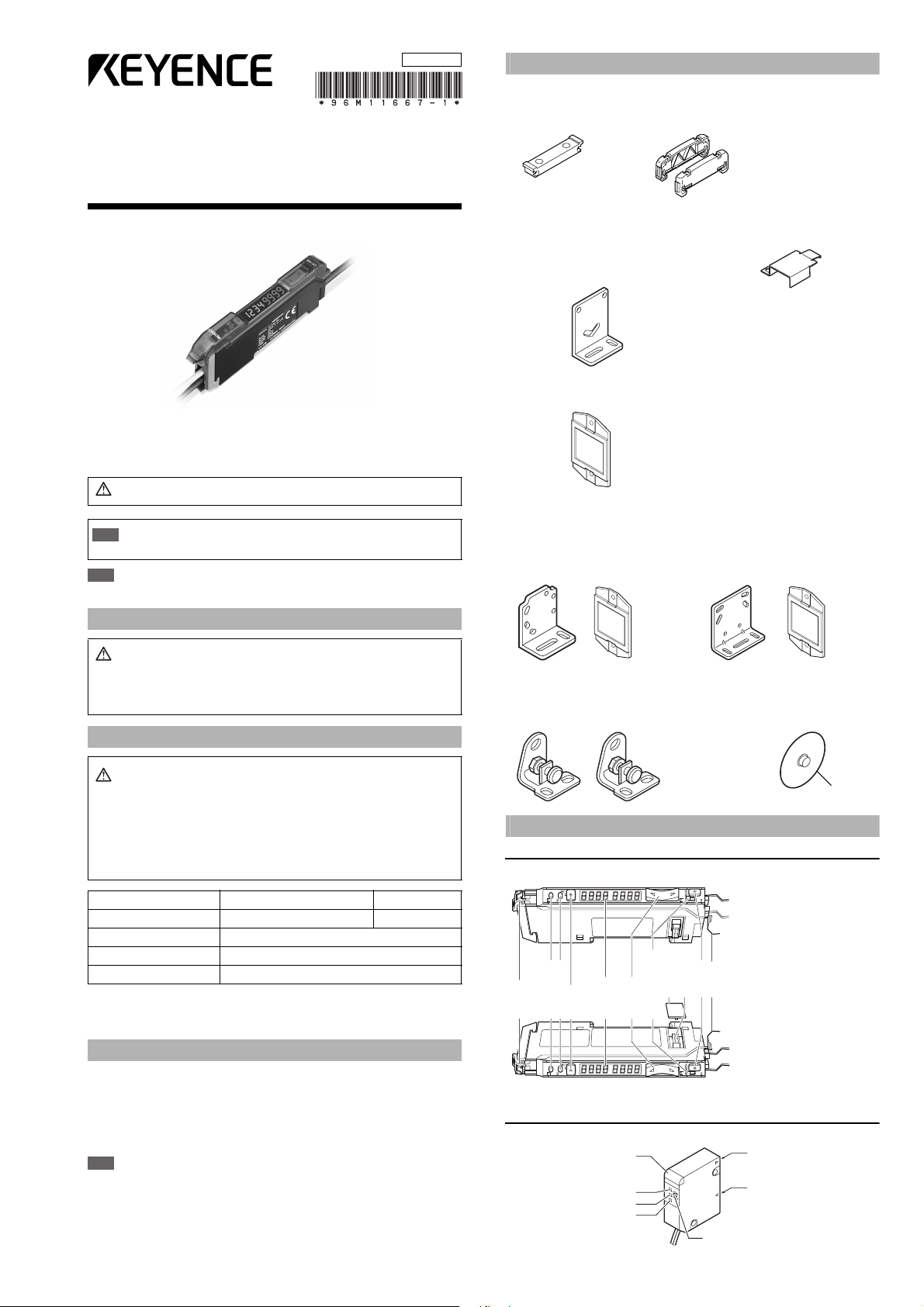

■ Amplifier

Mounting bracket: 1 End unit: 2 Instruction Manual: 1

Supplied with LV-11SB (P) Supplied with LV-12SB (P)

■

LV-S31 dedicated accessories

■

LV-S62 dedicated accessories

Reflector (R-6L): 1

■

LV-S61 dedicated accessories

Mounting bracket: 1

Plate nut: 1

M2 x 12 screw: 2

Reflector (R-6): 1

■ LV-S71/S72 dedicated accessories

Mounting bracket: 2 Nut: 4

Beam axis adjustment cap: 1

Facing ring: 2

Washer: 2

Identifying Part Names

Amplifier

■ LV-12SB (P) (Expansion unit)

■ LV-11SB (P) (Main unit)

Sensor head

■ LV- S3 1

Warning

Failure to follow instructions may lead to injury.

Important

Indicates warnings and restrictions that must be followed during

operations.

Warning

•

This product is just intended to detect the object(s). Do not use this

product for the purpose to protect a human body or a part of human

body.

•

This product is not intended for use as explosion-proof product. Do not

use this product in hazardous location and/or potentially explosive

atmosphere.

Warning

• U se of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radia-

tion exposure.

• This product employs a semiconductor laser for its light source.

• Follow the instructions mentioned in this manual. Otherwise, injury

to the human body (eyes and skin) may result.

Precautions on class 1 laser products

•

Do not disassemble this product. Laser emission from this product

is not automatically stopped when it is disassembled.

•

Do not stare into the beam.

Sensor head LV-S31/S41/S41L/S61/S71/S72 LV-S62/S63

Wavelength 655 nm 660 nm

Output 290 μW

FDA(CDRH) Part 1040.10* Class 1 Laser Product

IEC 60825-1 Class 1 Laser Product

■

LV-S41/S41L dedicated accessories

Mounting bracket: 1

Mounting bracket: 1

Plate nut: 1

M3 x 15 screw: 2

Adjustment screwdriver: 1

■

LV-S63 dedicated accessories

L-shaped mounting bracket: 1

M4 nut: 3

M4 x 30 screw: 3

Reflector (R-9): 1

ø30

Output indicator lamp

(for control output 2)

SET button

Digital monitor

Manual button

Channel selection switch

(display settings)

Connector protection

cover

Extension connector

MODE button

Dust cover

Output indicator lamp

(for control output 1)

Hold lock bar

Receiving section

Transmitting section

Operation indicator (red)

FAR indicator (red)

J

U

S

T

i

n

d

i

c

a

t

o

r

(

g

r

e

e

n

)

NEAR indicator (red)

F

F

N

J

N

Adjustment trimmer

96M11667

2

E LV-S-IM

■ LV- S 41

■ LV- S 61

■ LV- S 62

■ LV- S 63

■ LV-S71

The operation indicator works in conjunction with the Output selected at the

channel selection switch. (It does with Output 1 in area detection mode.)

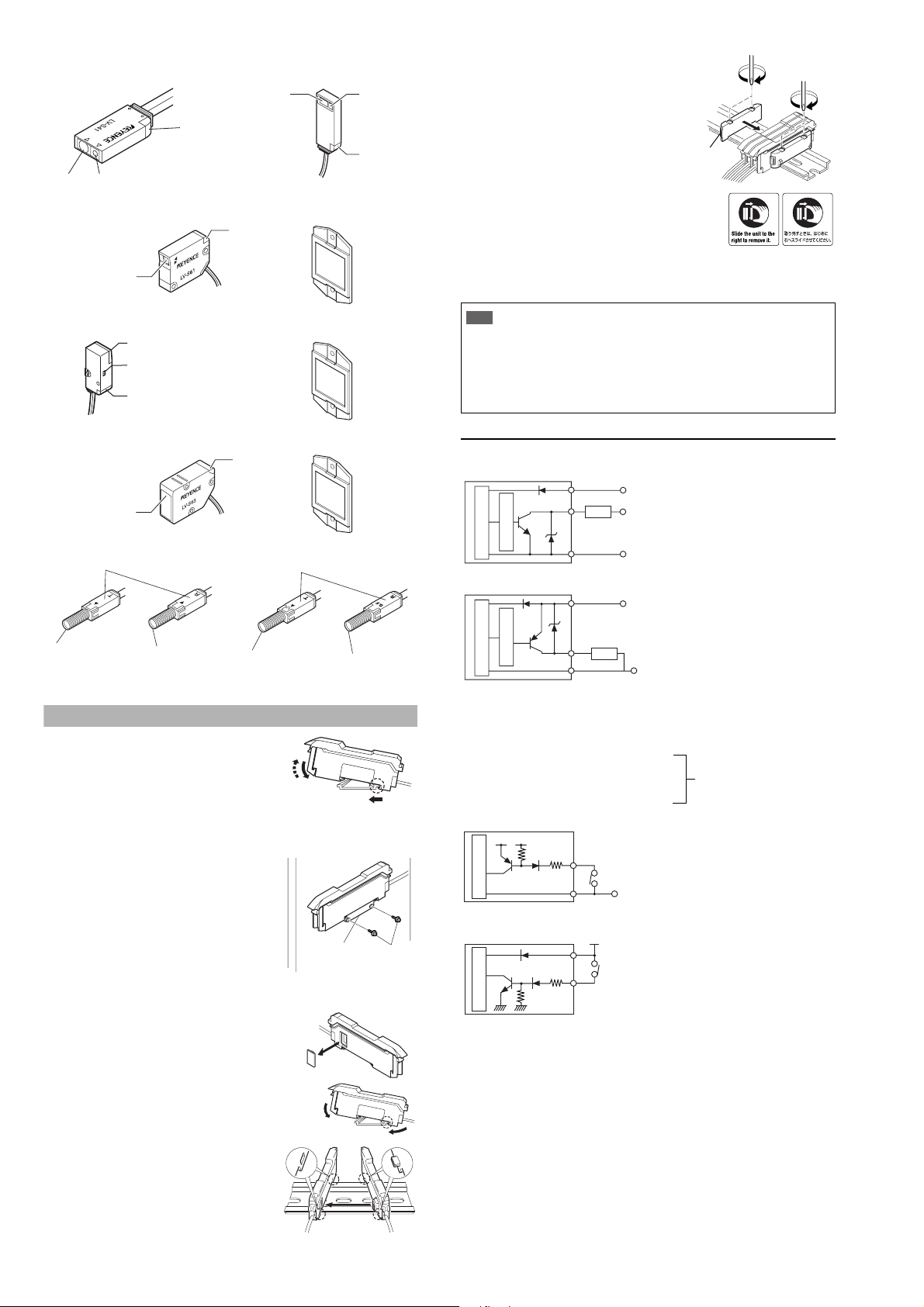

Mounting the Amplifier Unit

■ Mounting on a DIN rail

1)

Align the claw at the bottom of the main body with the

DIN rail. While pushing the main body in the direction

of the arrow 1, slant it in the direction of the arrow 2

.

2)

To dismount the sensor, raise the main body

in the direction of the arrow 3 while pushing

the main body in the direction of the arrow 1.

■

Installation using the mounting bracket (accessory) (LV-11SB/11SBP only)

Mount the amplifier unit using the supplied

mounting bracket as shown in the figure.

■ Connecting several amplifier units

Up to 16 expansion units LV-12SB can be installed to the main unit LV-11SB.

1 Remove the protection cover on the side of the

main unit.

2 Install the amplifier one by one on the DIN rail.

3 Engage the two claws of the expansion

unit with the recesses on the main unit

side until you hear a click sound.

4 Install the end units on both ends of

the amplifier unit.

Fasten the screws on the top of the

end units (at two positions on both

end units) with the Philips screw-

driver.

* The stickers on the right are provided. Attach

the sticker on the place near the amplifier unit.

■ Removing the amplifier unit

1 Remove the end units.

2 Slide the expansion unit and remove it one by one.

Input/Output Circuit Schematic

■ Output circuit

LV-11SB/12SB (NPN output type)

LV-11SBP/12SBP (PNP output type)

The power of the expansion unit LV-12SB (P) is supplied by the Extension connec-

tor on the side of the main unit LV-11SB (P). The power wires (brown and blue) of

the main unit and those of the expansion unit are unified inside by the connector.

■ Input circuit

LV-11SB/12SB (NPN output type)

LV-11SBP/12SBP (PNP output type)

Receiving

section

Transmitting section

Operation

indicator

(red)

■ LV- S4 1 L

Transmitting

section

Receiving

section

Operation

indicator

(red)

Transmitting section,

Receiving section

Operation

indicator (red)

Reflector (accessory)

Reflector (accessory)

Transmitting section,

Receiving section

Spot selection switch

Operation indicator

(red)

Transmitting section,

Receiving section

Operation

indicator (red)

Reflector (accessory)

Operation indicator (red)

Transmitting section

Receiving section

Tra ns mi t te r

Receiver

■ LV- S7 2

Operation indicator (red)

Transmitting section

Receiving section

Tra ns m it te r

Receive

r

(1)

(2)

(3)

M3 screw

Mounting bracket

(OP-25431)

(1)

(2)

Important

•

When installing additional expansion unit, be sure to use the DIN rail and the end units.

• Turn off the power when installing or removing the unit.

• Do not remove the protective cover of the extension connector on the

amplifier expansion unit that is added at the end.

•

Do not remove the amplifier unit with all added units attached, from the DIN rail.

•

Verify the operation ambient temperature after addi tional installati on. (“Specifications” page 11)

•

Do not use full calibration functions or stability output when the expansion unit of

the LV-S Series is connected to a device with full calibration functions (such as

FST or PS-T) via external input. Doing so may lead to product malfunctions.

Two end units are

supplied with an

expansion unit.

OP-26751

DC5-40V

DC12-24V

Load

Black/white (control output 1/2)

Brown *

Blue *

Sensor main circuit

Overcurrent protection circuit

0V

* LV-11SB only

DC12-24V

Load

Black/white (control output 1/2)

Brown *

Blue *

Sensor main circuit

Overcurrent protection circuit

0V

* LV-11SBP only

• Not to be used

• Light emission stop input

• External calibration input

• Setting value bank selection input

• Received light intensity shift input

Select either one.

(switched by the amplifier

function selection)

(Short-circuit current 1 mA max.)

PLC etc.

Pink (input)

Sensor main circuit

Blue *

DC3.3V

0V

* LV-11SB only

PLC etc.

Pink (input)

Sensor main circuit

Brown *

DC12-24V

* LV-11SBP only

(Short-circuit

current 2 mA max.)

3

E LV-S-IM

Connecting the Sensor Head and the Amplifier Unit

■ How to connect the amplifier unit and the connector

1 Open the dust cover, and tilt the

hold-lock lever.

2 Raise the hook, and insert the

connector to the very end.

3

Lower the hook and

hook the part shown

in the figure, and

then raise the hold-

lock lever.

Note

When shortening the sensor head cable, follow the instructions given in the

“Sensor Head Connector Assembly Procedures” included with the sensor

head.

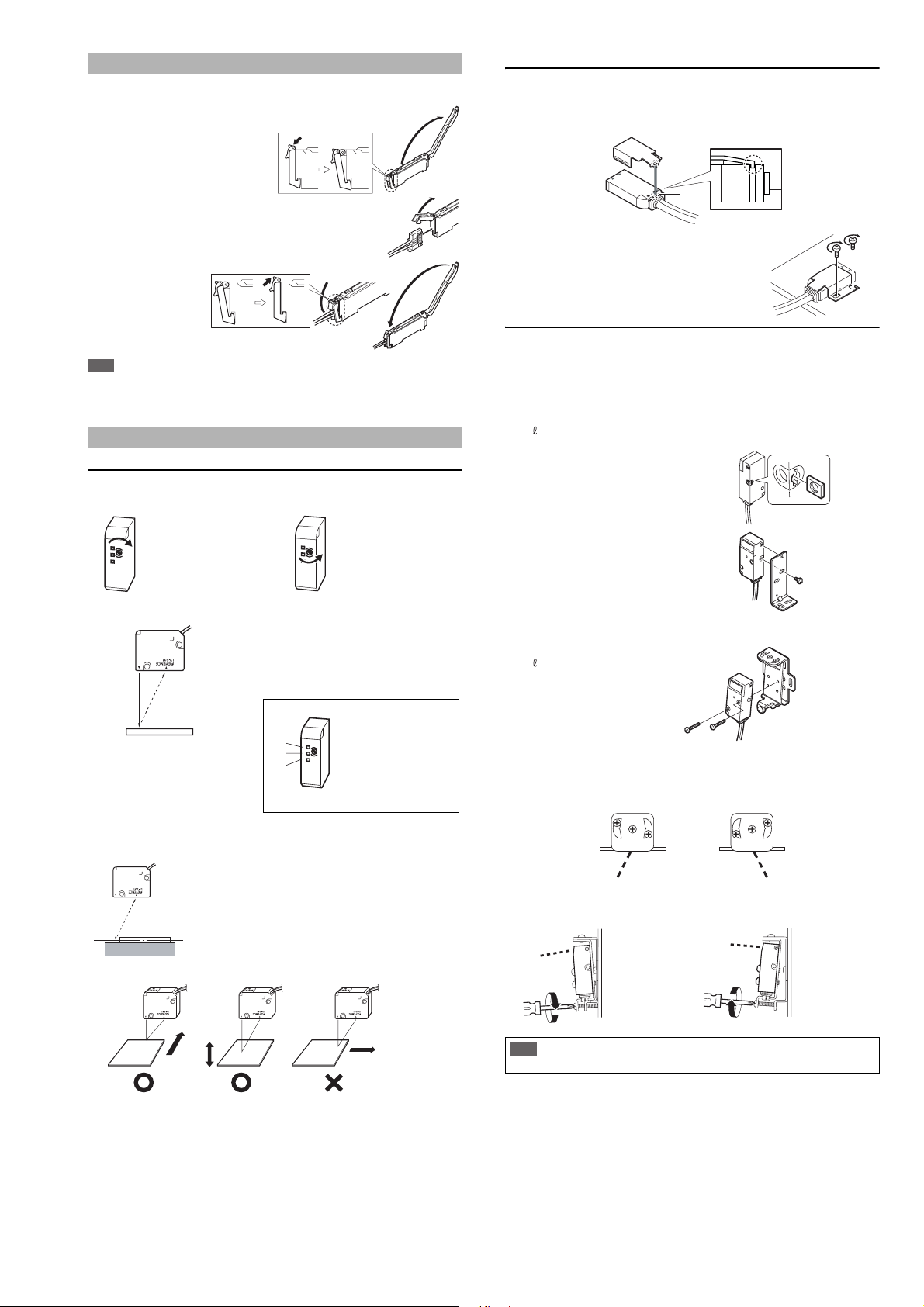

Mounting and Adjusting the Sensor Head

LV- S3 1

■ Adjusting the trimmer (detection position)

The detection range can be selected as desired by adjusting the trimmer.

■ Adjusting the center of detection

1

Place the workpiece at the position you

want to set as the center of detection.

2 Turn the trimmer until JUST

indicator (2) illuminates in green.

Finer adjustment is possible by looking at the display on the amplifier (page 9).

■ Detecting a height difference

A stable detection is made possible by

adjusting the trimmer so that the middle

point of the height comes to the center of

detection.

■ Movement directions of the workpiece

LV-S41/S41L

Be sure to use the supplied mounting bracket.

1 Press the mounting bracket on the sensor head.

Be sure to hook the A portion of the mounting bracket on the B portion of

the sensor head.

2 Install the sensor head on the flat surface with the

M3 screws as shown in the following figure.

(The M3 screw is not an accessory.)

LV-S62

Mount the sensor head using either L-shaped mounting bracket (OP-84350),

rear mounting bracket (OP-84349), side mounting bracket (OP-84351) sold

separately.

■ L-shaped mounting bracket (sold separately: OP-84350)

Mounting bracket 1

Plate nut 1

M3 x 7.3 screw 1

1 Insert the plate nut to the head.

2 Insert the protrusion on the amplifier for

securing the bracket into the hole at the

upper part of the bracket.

■ Rear mounting bracket (sold separately: OP-84349)

Mounting bracket 1

M3 x 18 screw 2

• Adjusting the beam axis

(1) The beam axis angle can be adjusted horizontally by swinging the

bracket to the left and right with screws (a), (b) and (c) loosened. In order

to tighten the screws, be sure to tighten screw (b) first.

(2) The angle of the beam axis can be changed downward if the screw indi-

cated by the arrow is tightened, and upward if loosened.

When detecting the target

from a long distance, turn the

trimmer clockwise to adjust.

When detecting the target

from a short distance, turn the

trimmer counterclockwise to

adjust.

F

J

N

F

N

F

J

N

F

N

When (1) illuminates, turn the

trimmer clockwise until (2)

illuminates.

When (2) illuminates, the

adjustment is complete.

When (3) illuminates, turn the

trimmer counterclockwise

until (2) illuminates.

F

J

N

F

N

(1)

(2)

(3)

Middle point

Movement

direction

Detecting

object

Detecting

object

Detecting

object

Movement

direction

Movement

direction

Important

Be sure to adjust the beam axis in the order of (1) and (2).

If the order is reversed, the screws in (1) may be damaged.

A

B

Limit the tight-

ening torque

up to 0.5Nm

Limit the tightening

torque up to 0.5Nm

(a)

(b)

(c)

(a)

(b)

(c)

When you want to lower the beam axis. When you want to raise the beam axis.

4

E LV-S-IM

■ Side mounting bracket (sold separately: OP-84351)

Mounting bracket 1

M3 x 18 screw 2

Note

When mounting the sensor head in the opposite direction as described previ-

ously, set the spot toggle switch before mounting.

• Adjusting the beam axis

The angle of the beam axis can be changed upward if the screw indicated by

the arrow is tightened, and downward if loosened.

LV-S71/S72

Mount the sensor head such

that the letter “T” (on the

transmitter) or “R” (on the

receiver) faces upward. The

side where the operation indi-

cator illuminates should face

upward.

• Adjusting the beam axis

The angle of the beam axis can be changed downward if the screw indicated

by the arrow is tightened, and upward if loosened.

Adjust the spot to be emitted at the

center on the receiver.

The adjustment is facilitated by

attaching the beam-axis adjustment

cap supplied with the sensor head to

the tip of the receiver

. Once the

adjustment is complete, remove the

beam-axis adjustment cap.

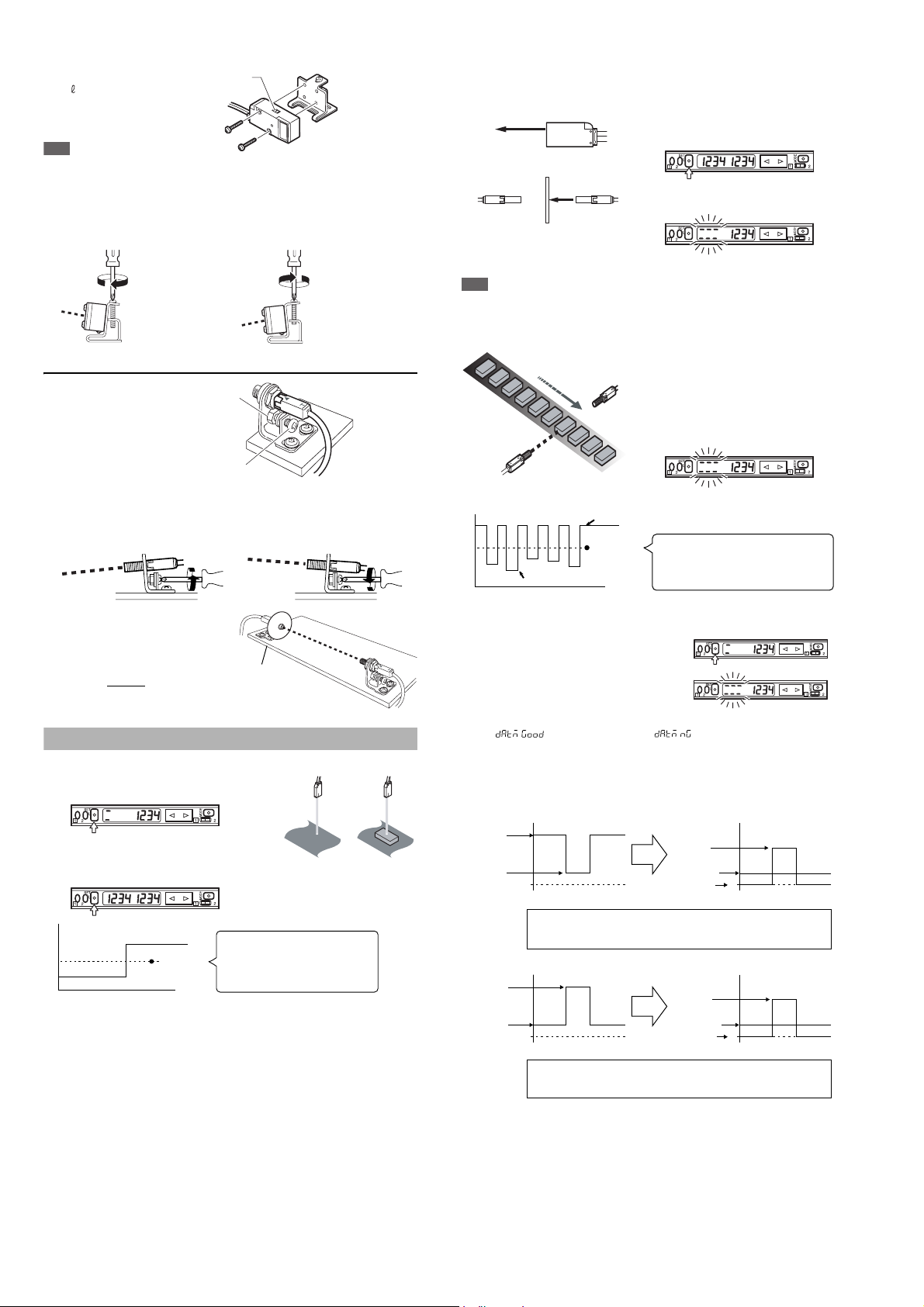

Setting Sensitivity

■ 2-point calibration

1 Press the SET button once without a

workpiece being placed.

2 Place a workpiece at the designated

position, and quickly press the SET

button once again.

*

If the sensitivity difference does not have enough room, “

++++

” flashes after

the calibration is complete. The setting value is changed at this time, too.

■ Maximum sensitivity setting

Set the sensitivity without a workpiece in the case of the reflective type, and with

a workpiece in the case of the transmission type.

1 Press the SET button for three

seconds in the state as shown in

the figure on the left.

The indication flashes when the setting

is complete.

2 Release the SET button.

Note

In the transmission type, if the value for the maximum sensitivity setting is the same as

DSC, the device will not operate correctly, so do not use the same value.

■ Full-auto calibration (not available for the LV-S31)

1

Let the workpiece pass while the SET

button is being pressed for three

seconds. (The sensitivity is set

according to the received light intensity

while the SET button is pressed.)

2

The indication flashes when the

setting is complete.

3 Release the SET button.

Perform 2-point calibration if the setting cannot be configured as desired.

■ Zero datum calibration (not available for the LV-S31)

1 Press the SET button quickly without a

workpiece being placed.

2 Press the SET button for at least three

seconds. When the indication flashes,

release the button.

3 The calibration is complete when

" " is displayed. When " " is displayed, switch the

channel toggle switch to "2" and check the contents of the alarm.

*The alarm contents are only displayed when "Auto" is selected for "ALrt",

the operation of control output 2 in "4. Detection mode selection". (For

information about the display, see "Toggling the display" on page 9.)

Transmission/retro-reflective types

Reflective type

Spot toggle

switch

Limit the tightening

torque up to 0.5Nm

When you want to raise the beam axis. When you want to lower the beam axis.

Fixing nut

Beam axis

adjusting screw

Limit the tightening

torque up to 1.2 Nm.

When you want to lower the beam axis When you want to raise the beam axis

Beam axis

adjustment cap

12

Received light intensity

Setting value

Time

The value set at the intermediate point

between the received light intensity

measured when the SET button is pressed

for the first time and that measured when it

is pressed for the second time.

1

2

Reflective type

Transmission type

With no workpiece

With workpiece

Received light intensity

Setting value

Time

MAX

MIN

The value is set at the intermediate point

between the MAX value and the MIN value

of the received light intensity measured

while the SET button is pressed.

Received light

intensity without

workpiece

0 0

Received light

intensity with

workpiece

(Blocked light)

Received light

intensity without

workpiece

Blocked light

Setting value

In the transmission or retro-reflective type, when zero datum calibration is performed

without a workpiece, the received light intensity without a workpiece is used as zero and

the value indicates the amount of blocked light. The setting value is set automatically.

0 0

Received light

intensity without

workpiece

Received light

intensity with

workpiece

(Entered light)

Received light

intensity without

workpiece

Entered light

Setting value

In the reflective type, when zero datum calibration is performed without a

workpiece, the received light intensity without a workpiece is used as zero and the

value indicates the amount of entered light. The setting value is set automatically.

Loading...

Loading...