KEYENCE SJ-F036 User Manual

96M00225

High-speed, High-precision

Built-in-Controller Type

Static Elimination Blower

Instruction Manual

Before using this Built-in-Controller Type Static Elimination Blower, be sure to thoroughly read this Instruction Manual.

After you are finished with this Instruction Manual, be sure to store it in a safe place for quick reference.

Preface

This document describes handling, method of operation and precautions when using the High-speed, High-precision Built-in-Controller Type Static Elimination Blower SJ-F031/036. Before you start to use the SJ-F031/036, be sure to thoroughly read this document in order to make full use and safely use the functions of the SJ-F031/036.

Store this document in a safe place so that you can retrieve it whenever necessary.

■ Symbols

This manual uses the following symbols to alert you to important information.

Be sure to read below.

DANGER |

Failure to follow these instructions may lead to death or serious injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

Failure to follow these instructions may lead to injury. |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION |

Failure to follow these instructions may lead to physical damage (product |

|

|

|

malfunction, etc.). |

|

|

|

|

|

|

|

|

|

Important

Provides additional information on precautions and restrictions that must be followed in operation.

Note

Provides additional information on proper operation.

Tip Indicates useful information or information that aids understanding of text descriptions.

Indicates a reference item or page to be referred to in this manual and a separate manual.

Safety Precautions

■ General Precautions

CAUTION • At startup and during operation, be sure to monitor the functions and performance of the SJ-F031/036.

•We recommend that you take substantial safety measures to avoid any damage in the event that a problem occurs.

•Do not modify the SJ-F031/036 or use it in any way other than described in the specifications. The functions and performance of products used or modified in this way cannot be assured.

•When the SJ-F031/036 is used in combination with other instruments, functions and performance may be degraded, depending on operating conditions and the surrounding environment.

•Do not use the SJ-F031/036 for the purpose of protecting the human body.

■SJ-F031/036 Handling Precautions

The SJ-F031/036 is a high-voltage product that is not designed in an explosion-proof structure. Pay attention to the following when using the SJ-F031/036.

WARNING |

• To prevent electric shock and to ensure accurate static elimination, be sure |

|

to connect a Class D ground (maximum resistance of 100 Ohms). |

||

|

•Do not use this product in locations where there is the risk of ignition or explosion from flammable solvents or dirt and dust.

•High voltage is applied to this product. Prevent it from being splashed with water, oil, or flammable solvents. Failure to do so may cause insulation breakdown, which will result in electric shock or malfunction.

•Do not bring your fingers or tools, wire or other metallic objects near this product. Doing so may cause electric shock or malfunction.

•Do not use this product in a non-ventilated location. The ozone generated from this product may become toxic. Be sure to ventilate the installation site when this product is used in a non-ventilated location.

•Do not use this product in locations where sudden changes in temperature or condensation are likely to occur. Doing so may cause accidents or malfunction.

•Do not operate this product with wet hands. Doing so may cause electric shock.

•Before starting maintenance, be sure to turn the power OFF. Failure to do so may result in electric shock or accidents.

•During maintenance, do not directly touch the electrode needles. Doing so may cause personal injury.

•If any malfunction is observed in this product, immediately turn it OFF, and contact your nearest agent. You should never repair this product yourself. Doing so may cause electric shock or malfunction.

CAUTION Do not touch the electrode needles with a tool or other hard object. Damage to the electrode needles will prevent static elimination performance from being fully demonstrated, and cause accidents or malfunction.

CAUTION • When this product is used for a long period of time, the electrode needles become dirty due to the adhesion of dust and dirt. If the ion level alarm

indicator or condition alarm indicator blinks in red clean the electrode needles. If the electrode needles are used in a dirty or dusty state, the static elimination performance can no longer be fully demonstrated, resulting in accidents or malfunction. We recommend periodically cleaning the electrode needles (as a guideline, once every two weeks in a regular operating environment though this depends on the installation conditions).

•Do not drop or subject this product to shock. Doing so may result in accidents or malfunction.

•Use this product for static elimination only. Do not use it for other purposes.

■Power Supply Precautions

CAUTION • Use a DC power supply with rated 24 V output.

•Noise applied to the power supply may cause this product to malfunction. If this happens, install an insulated transformer.

•When using a switching regulator, be sure to connect a Class D ground to the Frame Ground terminal.

■Grounding Precautions

CAUTION • To ensure safety and appropriate static elimination, be sure to ground this product.

•Be sure to connect a Class D ground (maximum resistance of 100 Ohms).

■SJ-F031/036 Warning Label

A WARNING label is affixed on the SJ-F031/036 to ensure safety.

Read the description on this WARNING label to ensure correct use of the SJ-F031/036.

Be sure to turn the power off when replacing |

the electrode probes. Otherwise, electric shock may occur. |

WARNING |

Do not touch electrode probes with your hands |

or fingers, as this may cause injury. |

* WARNING labels in Japanese, German, French, Italian and Chinese: SC are provided.

Use them as necessary.

1

1

1

■ Installation Precautions

CAUTION Avoid installing the SJ-F031/036 in the following locations as this may cause accidents.

•Locations directly subject to vibration and shock

•Locations subject to ambient temperature out of the 0°C to +50°C range

•Locations subject to ambient humidity out of the 35 to 65%RH range (condensation not allowed)

•Locations subject to sudden changes in temperature

•Locations subject directly from blasts from air conditioners

•Locations subject to volatile or flammable substance, solvents or corrosive gases

•Locations subject to large amounts of dirt, and dust, salt, iron and oil smoke

•Locations that may be splashed with water, oil or chemical mist

•Locations where strong magnetic and electrical fields are generated

■About Warming Up the SJ-F031/036

Note

Leave the SJ-F031/036 for about 20 minutes after turning the power on. Otherwise, the ion balance may not be stable.

■ Other Precautions

CAUTION • Be sure to read the WARNINGS and CAUTIONS described in each of the items in this Instruction Manual.

CAUTION • Be sure to read the WARNINGS and CAUTIONS described in each of the items in this Instruction Manual.

•The Static Elimination Blower has a built-in EEPROM. Do not turn the Static Elimination Blower OFF during the setup.

CAUTION Refer to the following diagram when installing the SJ-F031/036.

CAUTION Refer to the following diagram when installing the SJ-F031/036.

•Install the Static Elimination Blower away from the wall or surrounding objects.

50 mm or more

50 mm or more

•Install the Static Elimination Blower so that the Electrode Unit can be removed for replacement.

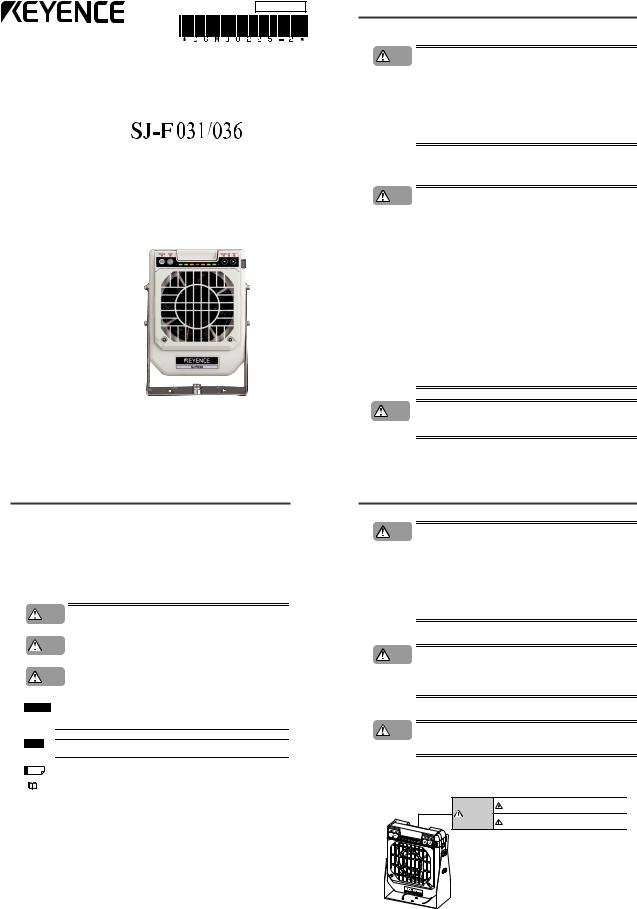

1-1 System Configuration |

1ABOUT THE STATIC ELIMINATION BLOWER UNIT SJ-F031/036 |

This section describes the system configuration of the Static Elimination Blower SJ-F031/036.

System Configuration

to AC power

AC adapter

I/O, DC power supply

I/O cable

I/O cable  1

1

* One of the AC and DC power supplies is used.

Precautions on Regulations and Standards

■ CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of the applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in the Member State of European Union.

● EMC Directive(2004/108/EC)

• Applicable standard EN61326-1

•Be sure to provide a ground when installing the SJ-F031/036.

•The length of cable (power lead and I/O leads) must be less than or equal to 30m. Remarks:

These specifications do not give any guarantee that the end-product with this product incorporated complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely responsible for the compliance on the end-product itself according to EMC Directive.

●Low-Voltage Directive (2006/95/EC)

•Applicable Standard : EN61010-1

•Overvoltage category I

•Use this product under pollution degree 2.

•Use the power supply for the SJ-F031/036, that satisfies the requirements of the Limited

Power Source specifications stipulated in EN60950-1 and certified by European third-party certification organization, or a Keyence Corporation AC adapter (SJ-U2). The specifications of the AC adapter (SJU2) are as follows.

When connecting to an SJ-U2, be sure to use a power cable compliant with European standards. Applicable standard: EN60950-1

Overvoltage category II Pollution degree 2

• Be sure to provide a ground when installing the SJ-F031/036.

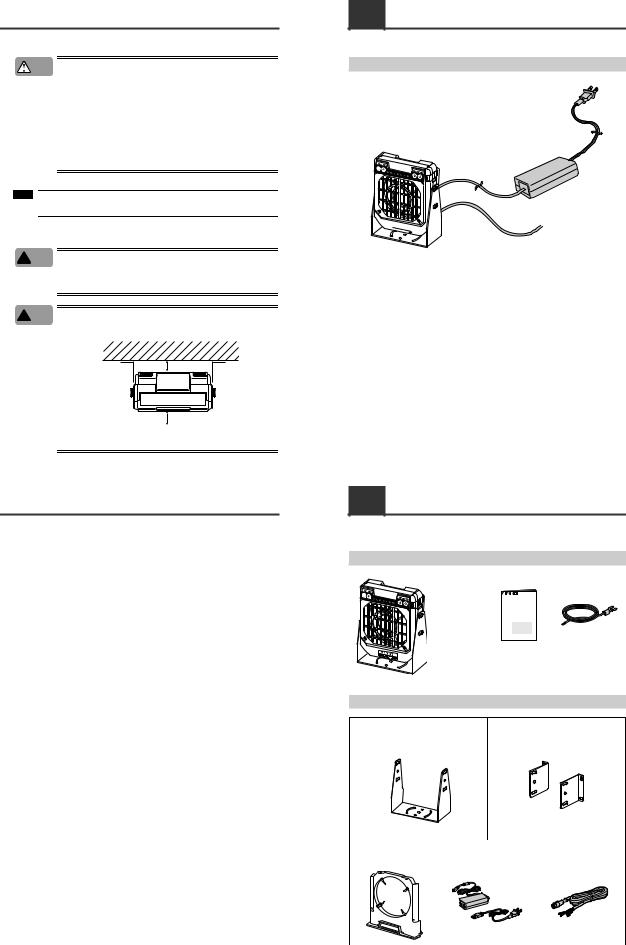

1-2 Checking the Contents of the Package

The package contains the following components and accessories. Before getting started, make sure that the package contains everything that it is supposed to contain.

Package Contents

• |

Instruction Manual |

• Ground lead |

|

High-speed, High-precision |

|

|

Built-in-Controller Type Static |

|

|

Elimination Blower |

|

|

SJ-F 031/036 |

|

|

Instruction Manual |

|

• Warning label (Japanese, German, French, Italian, |

||

|

Chinese: SC) |

|

|

* Use as necessary. |

|

Options |

|

|

Mounting fixture (OP-84374) |

Ceiling-mounting fixtures (OP-78477) |

|

Accessory: M4 screw for fixing the Static |

Accessory: M4 screw for fixing the Static |

|

Elimination Blower x 4 |

Elimination Blower x 4 |

|

Electrode Unit for exchanging |

AC adapter (SJ-U2) |

I/O cable (SJ-FC5) |

||

(OP-51407) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

1-3 Names and Functions of Parts

■ Front view

Operation panel |

Lock switch |

|

Electrode Unit |

Fan guard

Electrode needle

Electrode Unit

Provided with the electrode needles. Remove the Electrode Unit before attempting maintenance and servicing work.

Refer to  "Performing Maintenance on the Electrode Needles" (page 7) for details about how to remove the Electrode Unit.

"Performing Maintenance on the Electrode Needles" (page 7) for details about how to remove the Electrode Unit.

Electrode needle

Generates ions from its tip.

Lock switch

Affixes the Electrode Unit.

Fan guard

SJ-F031: Metal

SJ-F036: Resin

■ Operation panel

|

[1] |

|

|

[2] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[3] [4] [5] |

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[7] |

|

|

[8] |

|

|

|

[6] |

|

|

|

|

|

|

|

|

|

|

|

[9] |

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[1] |

Ion level alarm indicator |

Lit OFF |

Normal |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||

Blinking in red |

Ion level alarm has occurred. |

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

[2] |

|

Condition alarm indicator |

Lit OFF |

Normal |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

Blinking in red |

Condition alarm has occurred. |

|

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

[3] |

|

Ion balance indicator |

|

|

|

|

When lit, the indicator displays the ion balance. |

||||||||||||||||||||||||||||||||||||

[4] |

|

Ion level indicator |

|

|

|

|

When lit, the indicator displays the ion level. |

|

|

|

|

||||||||||||||||||||||||||||||||

[5] |

|

Blow rate indicator |

|

|

|

|

When lit, the indicator displays the blow rate setting value. |

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The monitor displays the ion balance, ion level, blow rate setting value in |

||||||||||||||||||||||||||||

[6] |

|

Monitor |

|

|

|

|

seven indication levels. |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lights in red when the Static Elimination Blower needs cleaning. |

||||||||||||||||||||||||||||

[7] |

|

START/STOP key |

|

|

|

|

Used for switching start/stop. |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

[8] |

|

ENTER key |

|

|

|

|

Used for selecting various setups. |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

[9] |

|

UP/DOWN key |

|

|

|

|

Used for selecting and adjusting various setups. |

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-3 |

Names and Functions of Parts |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

■ Rear view |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

I/O cable connector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCI |

N |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power supply connector |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground terminal |

|

|

|

|

|||||||

■ I/O cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wire color |

|

|

|

|

|

|

|

Description |

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brown |

DC power supply (Rating: 24 V) |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Blue |

Power GND |

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Static elimination stop input signal |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pink |

(Static elimination can be turned on or off by |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

shorting this wire and the orange wire.) |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Orange |

Output signal GND |

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Black |

Ion level alarm output signal |

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

White |

Condition alarm output signal |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gray |

Alarm output signal |

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shielded wire |

Ground lead (Connect to a Class D ground.) |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Thick black wire) |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* The blue and orange wires are connected internally. |

||||||||||||||||||||||||||

■ Input circuit diagram |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

+24V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input zero-voltage contact (relay, etc.) or NPN open |

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

collector to INPUT. |

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

470Ω |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

INPUT* |

|

|

3kΩ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

0V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

*Static elimination stop input |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

■ Output circuit diagram |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

Open collector output |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

OUTPUT* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

DC40V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

100mA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

0V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

0V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|||||||||

|

*Alarm output, Condition/Ion level alarm output |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

2-1 Before Installation |

2CONNECTION AND INSTALLATION |

Before you install this product, examine carefully the distance between the Static Elimination Blower and the target object and the time required for static elimination.

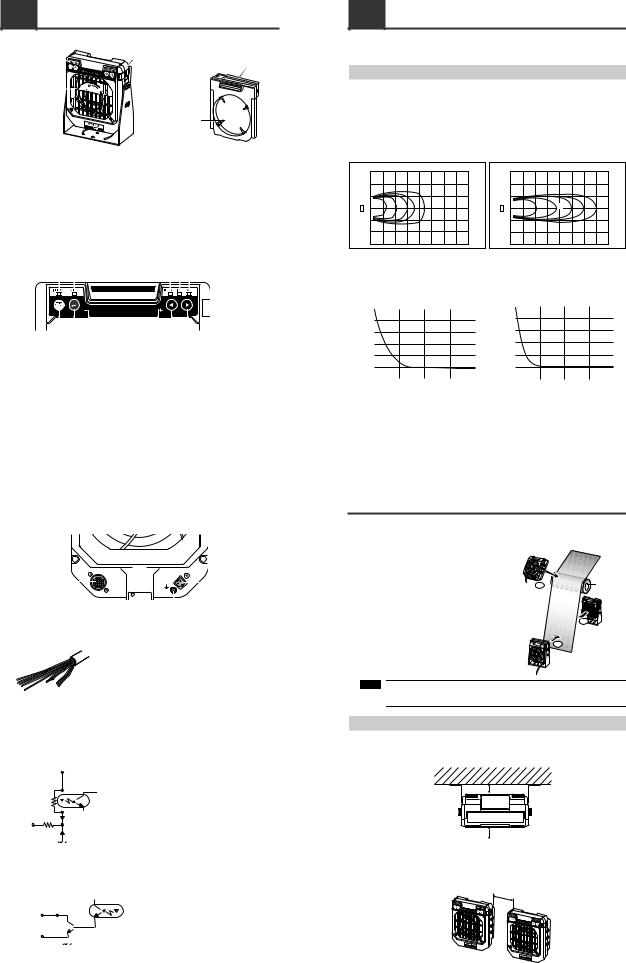

About Static Elimination Performance

The following shows a typical example where static is eliminated from an aluminum plate (20 pF) 150 mm x 150 mm square charged to +1000 V by this product.

The blow rate of the blower is set at maximum (FAST).

■ Static elimination area

The following graphs show the relationship between the time required for eliminating static from a target object charged from +1000 V to +100 V and the distance from the charged object up to the Static Elimination Blower.

200 |

400 |

600 |

|

800 |

1000 |

1200 |

1400 |

1600mm |

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600mm |

600mm |

|

|

|

|

|

|

|

|

600mm |

|

|

|

|

|

|

|

1s |

2s |

3s |

4s |

5s |

|

|

|

|

|

1s |

|

2s |

3s |

4s |

5s |

|

0 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

SJ-F031 |

|

|

|

|

|

|

|

|

SJ-F036 |

|

|

|

|

|

|

|

600mm |

|

|

|

|

|

|

|

|

600mm |

|

|

|

|

|

|

|

■ Static elimination time

The following graphs show the relationship between the time required for eliminating static at the maximum blow rate from a target object charged at +1000 V positioned 300 mm apart from the Static Elimination Blower and the charged level.

|

1 |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

(kV) |

0.8 |

|

SJ-F031 |

|

|

|

|

(kV) |

0.8 |

|

SJ-F036 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||

0.6 |

|

|

|

|

|

|

0.6 |

|

|

|

|

|

||

level |

0.4 |

|

|

|

|

|

|

level |

0.4 |

|

|

|

|

|

Charged |

0.2 |

|

|

|

|

|

|

Charged |

0.2 |

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

-0.2 |

|

|

|

|

|

|

|

-0.2 |

|

|

|

|

|

|

0 |

1 |

2 |

3 |

4 |

|

|

0 |

1 |

2 |

3 |

4 |

||

|

|

Time required for static elimination (sec) |

|

|

|

|

|

Time required for static elimination (sec) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-1 Before Installation

■ Appropriate static elimination method

Pay attention to the following points to ensure that static elimination is performed appropriately.

Static elimination cannot be performed accurately at locations where the target object is touching a metallic body (grounded body).

Eliminate static from the target body at locations where it is not directly touching metallic bodies (grounded body).

Static will be eliminated from only the surface of the insulated body (film, sheet, etc.) that is facing the Static Elimination Blower.

When eliminating static from both sides of a target body, install two Static Elimination Blowers as one unit must be installed on either side of the target body.

Film, sheet or other electrically charged object

NG |

Metal roller |

|

OK |

|

OK |

Note

Install the Static Elimination Blower so that it can be easily accessed, for example, for replacement of parts and cleaning.

Installation Precautions

■ Installation site

Refer to the following diagram when installing the SJ-F031/036.

• Install the Static Elimination Blower away from the wall or surrounding objects.

50 mm or more

50 mm or more

•Install the Static Elimination Blower so that the Electrode Unit can be removed for replacement.

■Interference

The Static Elimination Blower may not function properly if two or more units are used close to each other.

In such an installation, refer to the following diagram and maintain the indicated distance between units.

15 mm |

or more |

Loading...

Loading...