Flowserve E790 User Manual

McCANNA/MARPAC Valves |

MMAIM2002 |

(Part IM005) |

Petro Double Union End Ball Valve

Model E790: 1/4" – 2" Size

Installation, Operation and Maintenance Instructions

1. Installation

These valves may be installed in any position utilizing standard pipe fitting practices. With the ends installed, the body can be rotated before tightening the union nuts.

Welding Ends (Socket Weld)

To keep from destroying soft parts, loosen and slide away union nuts (12). Remove valve from line, taking care that the end and body seals (15 & 16) are not damaged, and then weld socket ends in position.

NOTE: Prior to removing valve from line, valve may be tack welded in line for line-up purposes.

The base material of valve covered by this procedure conforms to the following:

•Carbon Steel - ASTM A105 (Forged)

•316 Stainless Steel - ASTM A182 GRF316 (Forged)

Before welding, push pipe snugly into union ends and then back off approximately 1/16".

The socket and at least one inch of the pipe (at the joint) must be free of all foreign material which might prove detrimental to the weld.

Use the smallest electrode and minimum amperage consistent with efficient welding to minimize warpage. Tacks should be ground out before completing the root pass in that area. Weld stringer beads with no weaving and stagger all starts and stops.

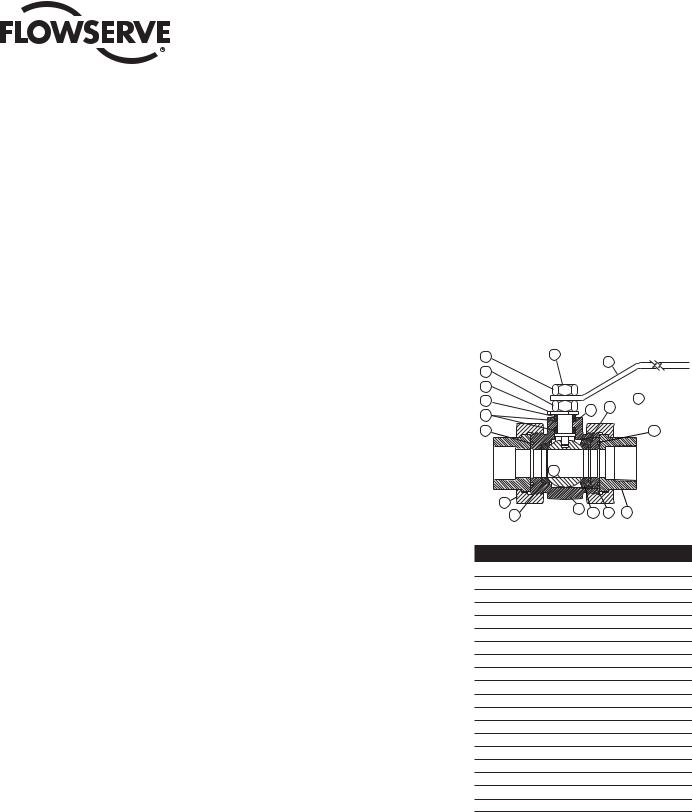

Figure 1

Valve Size |

Hex Size (Across Flats) |

1/4", 3/8", 1/2" |

5/8" |

3/4" |

13/16" |

1" |

1" |

11/4" |

11/4" |

11/2" |

11/2" |

2" |

111/16" |

Carbon steel ends should be allowed to cool slowly. The valve ends may be covered with a heat resisting blanket to promote slow cooling.

2. Stem Seal Adjustment

If leakage is evident in stem packing area, tighten the adjusting nut (18) 1/8 turn. If leak still persists, repeat above. Replacement of the stem seal (17) is indicated if the leak is still apparent after 1/2 turn.

3. Seal Replacement

There must be no line pressure on the valve at this time and ball should be partially open.

A.Loosen union nuts (12) and slide nuts out of the way. Now the valve body (14) can be removed from the line for servicing.

B.Remove end seal (15) and body seal (11). This may be done with a sharp instrument, such as a pocket knife. Care should be taken to avoid damage to the surfaces of the seal groove.

C.Remove threaded spacer (7) by using “allen” type wrench or hexagonal bar. (See Figure 1.)

D.To take out spacer seal (16), seat socket (8), one seat (10) and the ball (9) – rotate stem (2) so ball (9) is in fully closed position and insert wooden dowel (not metal) in port opposite threaded end and tap gently on ball (9) thereby forcing it out of body (14).

NOTE: Extreme caution should be taken to avoid damage to the ball (9).

E.Take out other seat (10).

F.Remove the handle retainer nut (4), handle (1), adjusting nut (18), travel stop (5) (part of the handle on sizes 1/2" and 3/4") and the gland ring (6). Push the stem (2)

Figure 2

4 |

|

2 |

|

1 |

|

|

|

|

|

|

|

18 |

|

|

|

|

|

5 |

|

|

|

|

NOT |

6 |

|

|

|

16 |

3 SHOWN |

17 |

|

|

19 |

|

|

|

|

|

|

||

|

|

|

|

|

|

11 |

|

|

|

|

15 |

|

|

9 |

|

|

|

|

12 |

14 |

|

|

|

|

10 |

8 |

7 |

13 |

|

|

|

||||

|

|

|

|

|

No. Description

1Handle

2Stem

3Stop Pin (not shown)

4Handle Retainer Nut

5Travel Stop (1" thru 2" sizes only)

6Gland Ring

7Threaded Spacer

8Seat Socket

9Ball

10Seat (2)

11Body Seal

12Union Nut (2)

13Union End (2)

14Body

15End Seal

16Spacer Seal

17Stem Seal

18Adjusting Nut

19Grounding Washer

down through the body and out the open end of the body (14). Remove the upper and lower stem seals (17) and the grounding washer (19). Grounding washer (19) is not used with the FIRE-GARD valves. Save the grounding washer (19) for reassembly.

Loading...

Loading...