Flowserve 93 User Manual

19860-C

Worcester Controls

Series 93 PULSAIR III

Digital Electronic Positioner

Installation, Operation and Maintenance Instructions

The Pulsair III is a digital positioner designed primarily for controlling adjustable valves. The positioner can be used with single or double action 39 series actuators.

The Pulsair III Watertight Positioner (L93W) can be equipped with modules for feedback, limit switches, sensors, and a pressure gauge block.

The Pulsair III Hazardous Location Positioner (4L93Z) does not allow for switch/sensor options. However, the feedback (4–20 mA output) option is included as standard.

For the L93W, modules can be factory assembled before delivery or fitted later.

The modules for feedback (4–20 mA output) and limit switches/sensors can contain the following:

Feedback (4–20 mA output) and/or one of the following functions:

•Two mechanical switches (code M2)

•Two proximity (reed) switches (code R2)

•Two Namur sensors (code P2)

Storage Instructions

PULSAIR III positioners are precision instruments which should be stored and handled accordingly to avoid problems or damage.

Electro-pneumatic positioners contain electronic components which can be damaged by exposure to excessive water. Appropriate precautions should be taken to protect units while in storage.

Warehouse Storage

Stored in original shipping containers, units should be stored in an environmentally controlled area, i.e., clean, cool (15–26°C, 60–80°F) and dry, out of direct sunlight or weather exposure.

Field Storage

NOTE: Once the air supply to the positioner is connected and turned on, internal air bleed will prevent the ingress of moisture and protect the unit from corrosion. It is recommended that the air supply be left on at all times.

•If units are installed immediately, turn, and leave on, the air supply.

•If positioners must be stored outdoors, tighten all covers which may have loosened in shipment and make sure all open enclosure points are sealed.

Positioners should be wrapped and sealed, air and watertight with desiccant inside the plastic, units should be securely covered with an opaque cover and not exposed to direct sunlight, rain or snow.

Units should have all ports sealed and be protected from direct exposure to weather. For long term storage (>1 month) or overseas shipment, units should be protected with plastic and desiccant.

Potential Damage to Mechanism

When units are stored in hot, humid climates, the daily heating/cooling cycle will cause air to expand/contract and be drawn in and out of the positioner housing. Dependent on the local temperature variations, humidity, dew points and time in storage, condensation could occur and accumulate inside causing erratic operation or failure due to water and corrosion. The potential for condensation damage is especially high in southern climates and aggravated if units are exposed to direct sunlight.

For further assistance, please contact you nearest Worcester distributor.

Installation

Flow Control Division

Worcester Controls

If not already plumbed, plumb the Positioner to the Actuator

If Positioner is not already mounted to the 39 Series Actuator, mount per part 1:

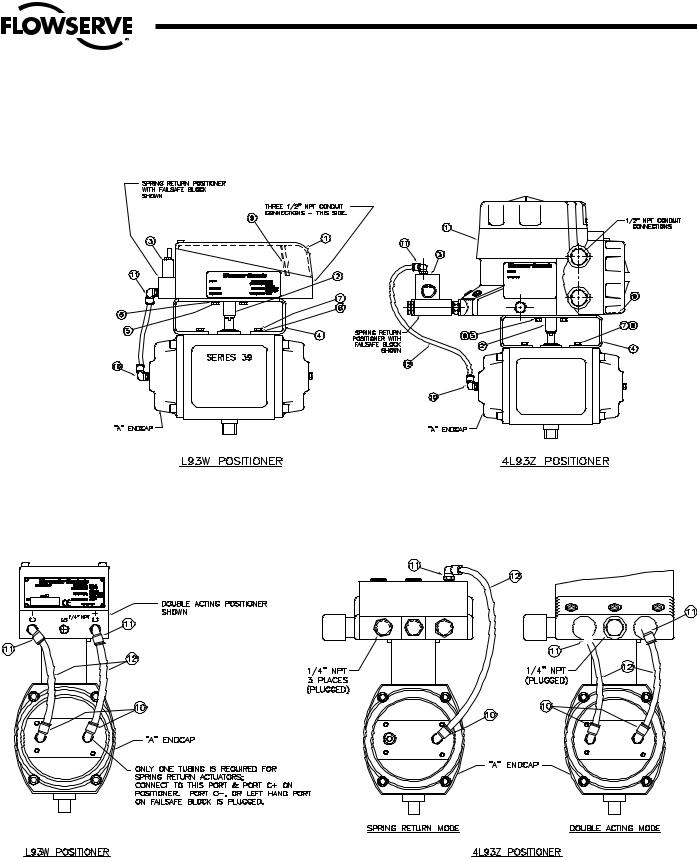

1.Attaching the Positioner to the 39 Series Actuator (refer to Figure 1)

Remove positioner (1) from the box. Coupling (spindle adapter) (2), and failsafe block (3) (used with spring return only) are loose inside the box.

Insert the round end of the coupling (2) into the bottom of the positioner making sure that the spline seats properly, and that the coupling is firmly seated in the positioner shaft. There is a spring loaded ring on the coupling which must fit into a groove inside the positioner shaft.

Install the mounting bracket (4) onto the bottom of the positioner using four M6 X 12 mm screws (5) and lock washers

(6) included in the bracket kit. Align the bracket with the positioner.

Rotate the coupling to align the coupling tang with the slot in the output shaft on top of the actuator. Attach the positioner/bracket/ coupling assembly to the actuator using four M5 x 12 mm screws (7) and lock washers (8). The air inlet porting on the positioner must be on the same end as the “A” endcap (air inlet end) of the actuator.

Using an indelible marker, mark the 39 actuator model number and output torque (as found on 39 actuator nameplate) on the white mylar label supplied with the positioner and attach it to the side of the actuator opposite the nameplate side.

2.If not already attached, attach the Failsafe Block to the Positioner (for spring return only)

Refer to figure 1.

Install three O-rings (for L93W only) into the failsafe block (3).

Mount the failsafe block (3) to the end of the positioner (1) with the ‘C+’ port to the right using the two screws provided with the L93W, or three each of fittings and bushings and six grommets with the 4L93Z.

3.Air Connections (Refer to Figures 1 and 2)

Connect the elbow air fitting(s) (10) to the actuator “A” end cap.

|

|

|

|

|

ACTUATOR SIZE |

PORT THREAD (NPT) |

|

|

10–20 |

1/8" |

|

|

25–42 |

1/4" |

|

Connect 1/4" NPT straight or elbow air fitting(s) (11) into the positioner.

For spring return, use ‘C+’ port on the failsafe block, and make sure that there is a plug in the unidentified port on the failsafe block (far left position).

For double acting actuator, use the ‘C+’ and ‘C-’ ports on the positioner. Note that no failsafe block is necessary.

Cut the tubing (12) provided to as short a length as possible that will still reach comfortably from the positioner to the actuator. Connect the tube(s) to their respective actuator and positioner port fittings.

4.Connect 80 psig Supply Air to Positioner (Refer to Figure 2)

Remove plastic plug from the positioner (or failsafe block) port ‘S’ and discard.

Connect an air supply line to the 1/4" NPT ‘S’ port.

5.Installation of M2, R2, or P2 Switch/Sensor and/or 4-20 mA Output Options (for L93W Positioner only)

1.If not already installed, install optional switches/sensors and/or 4–20 mA output into the positioner (if applicable):

2.The option kit includes a circuit board with switches mounted, two mounting screws, and a cam assembly with two mounting screws installed.

3.Refer to the PULSAIR III Technical Reference Manual (Part No. 19990) for assembly illustrations.

4.Remove the outside positioner cover.

5.Remove the plastic, yellow and black, position indicator. The indicator is a press fit and can be removed by prying up using fingers or small screwdrivers.

IMPORTANT: Use industrial air (or other non-flammable gas), Which must be dry and oil free. See PULSAIR III Technical Reference Manual (Part No. 19990) for other air supply requirements and technical data.

Series 93 PULSAIR III mounting kits contain two elbow fittings for actuator, two elbow and two straight fittings for positioner, and one length of 1/4" O.D. tubing. The length of tubing will be cut to suit the assembly.

Note: Pipe thread sealant may be used on the threads of the fittings (do not allow thread sealant to contaminate the internal air passages of the positioner). Fluoropolymer tape thread sealant should not be used.

6.Remove the two inside cover attachment screws located at the terminal strip end of the inside positioner cover.

7.Carefully lift the inside cover to clear the yellow push button switches, and slide the inside cover towards the terminal strip to remove. The inside cover has a lip which is under the clear filter cover.

8.Install the circuit board over the positioning shaft, and align the board socket with the twelve pins on the positioner motherboard. Press firmly to seat the contacts.

9.Install the two mounting screws to hold the circuit board to the positioner motherboard.

2 |

Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance |

19860-C |

Flow Control Division

Worcester Controls

Figure 1

|

|

|

|

|

|

|

$ |

|

|

% '( ) |

% |

|

% & '( ) |

% & |

! ! " #

*

Figure 2

19860-C |

Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance |

3 |

Loading...

Loading...