Flowserve LRG 16-40 User Manual

GESTRA

GESTRA Steam Systems |

|

LRG 16-40 |

|

LRG 17-40 |

|

Installation Instructions 818524-01

Conductivity Electrode LRG 16-40

Conductivity Electrode LRG 17-40

|

Contents |

|

|

Page |

Important Notes |

|

Usage for the intended purpose............................................................................................................... |

4 |

Safety note.............................................................................................................................................. |

4 |

Danger.................................................................................................................................................... |

4 |

PED (Pressure Equipment Directive)........................................................................................................ |

4 |

ATEX (Atmosphère Explosible).................................................................................................................. |

4 |

Explanatory Notes |

|

Scope of supply....................................................................................................................................... |

5 |

Description.............................................................................................................................................. |

5 |

Function.............................................................................................................................................. |

5, 6 |

System components................................................................................................................................ |

6 |

Design..................................................................................................................................................... |

6 |

Technical Data |

|

LRG 16-40, LRG 17-40...................................................................................................................... |

7 – 9 |

Corrosion resistance................................................................................................................................ |

9 |

Sizing...................................................................................................................................................... |

9 |

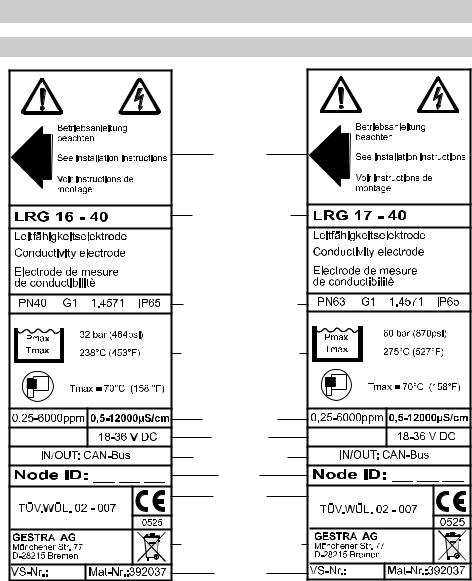

Name plate / marking............................................................................................................................ |

10 |

Dimensions LRG 16-40 ........................................................................................................................ |

11 |

Dimensions LRG 17-40 ........................................................................................................................ |

12 |

Key........................................................................................................................................................ |

14 |

Functional Elements |

|

LRG 16-40 / LRG 17-40......................................................................................................................... |

13 |

Key........................................................................................................................................................ |

14 |

Installation |

|

Installation notes................................................................................................................................... |

15 |

Mounting conductivity electrode............................................................................................................ |

15 |

Terminal box......................................................................................................................................... |

16 |

Opening terminal box............................................................................................................................ |

16 |

Aligning terminal box............................................................................................................................. |

16 |

Removing terminal box.......................................................................................................................... |

16 |

Mounting terminal box........................................................................................................................... |

17 |

Closing terminal box.............................................................................................................................. |

17 |

Tools .................................................................................................................................................... |

17 |

Example of Installation |

|

Conductivity metering............................................................................................................................ |

18 |

Conductivity metering and continuous boiler blowdown................................................................... |

18, 19 |

Key........................................................................................................................................................ |

19 |

Contents – continued – |

|

|

Page |

Wiring |

|

Bus cable ............................................................................................................................................. |

20 |

Note...................................................................................................................................................... |

20 |

Assigning the connector and jack.......................................................................................................... |

20 |

Wiring diagram of conductivity electrode LRG 16-40, LRG 17-40..................................................... |

21, 22 |

Attention............................................................................................................................................... |

22 |

Basic Settings |

|

Factory settings..................................................................................................................................... |

22 |

Commissioning |

|

Check wiring......................................................................................................................................... |

23 |

Apply mains voltage.............................................................................................................................. |

23 |

Setting parameters................................................................................................................................ |

23 |

Operation |

|

Start...................................................................................................................................................... |

23 |

System Malfunctions |

|

Causes.................................................................................................................................................. |

24 |

Note...................................................................................................................................................... |

24 |

Systematic malfunction analysis............................................................................................................ |

25 |

Malfunctions |

|

Fault finding list for troubleshooting................................................................................................. |

26, 27 |

Cleaning measuring electrode .............................................................................................................. |

27 |

Replacing electronic circuit board.......................................................................................................... |

27 |

Note...................................................................................................................................................... |

27 |

Decommissioning |

|

Replacing conductivity electrode........................................................................................................... |

28 |

Danger / Attention................................................................................................................................. |

28 |

Disposal................................................................................................................................................ |

28 |

Annex |

|

CAN bus................................................................................................................................................ |

29 |

Factory set node IDs.............................................................................................................................. |

29 |

Node ID................................................................................................................................................. |

29 |

Establishing / changing node ID............................................................................................................. |

30 |

Attention............................................................................................................................................... |

30 |

Table “Node ID”..................................................................................................................................... |

31 |

Declaration of conformity...................................................................................................................... |

32 |

Important Notes

Usage for the intended purpose

Use conductivity electrodes LRG 16-40/LRG 17-40 only for measuring the electrical conductivity of liquid fluids.

For conductivity limiting or continuous boiler blowdown the conductivity electrodes LRG 16-40/

LRG 17-40 must only be used in conjunction with TDS controller LRR 1-40 and an operating terminal & display unit type URB or SPECTORcontrol.

To guarantee a trouble-free operation observe the requirements made on water quality as specified in the pertinent TRD and EN regulations.

Safety note

The equipment must only be installed and commissioned by qualified staff.

Maintenance and service work must only be performed by adequately trained persons who have a recognized level of competence.

Danger

When loosening the electrode steam or hot water might escape.

This presents the danger of severe scalding. It is therefore essential not to remove or install the electrode unless the boiler pressure is verified to be zero.

The electrode is hot during operation. This presents the danger of severe burns to hands and arms. Installation and maintenance work should only be carried out when the system is cold.

PED (Pressure Equipment Directive)

The equipment fulfills the requirements of the Pressure Equipment Directive (PED) 97/23/EC. Applicable in fluids of group 1 and 2. With CE marking (apart from equipment according to section 3.3).

ATEX (Atmosphère Explosible)

According to the European Directive 94/9/EC the equipment must not be used in explosion-risk areas.

Explanatory Notes

Scope of supply

LRG 16-40

1 Level electrode type LRG 16-40

1 S. S. joint ring 33 x 39, form D, DIN 7603 (made of 1.4301), bright annealed 1 Terminating resistor 120 Ω

1 Installation manual

LRG 17-40

1 Level electrode type LRG 17-40

1 S. S. joint ring 33 x 39, form D, DIN 7603 (made of 1.4301), bright annealed 1 Terminating resistor 120 Ω

1 Installation manual

Description

The conductivity electrode LRG 1x-40 consists of a TDS (= Total Dissolved Solids) monitoring electrode for conductivity measurement, a temperature sensor for detecting the fluid temperature and a conductivity transmitter that is fully integrated in the terminal box.

The equipment is of the two electrode type and works according to the conductometric measurement principle, measuring the electrical conductivity of electrically conductive fluids.

Together with the TDS controller LRR 1-40 and an operating device type URB or SPECTORcontrol the conductivity electrode LRG 1x-40 can be used as conductivity limiter and continuous blowdown controller in steam boilers and (pressurized) hot water plants.

The data exchange between the conductivity electrode LRG 1x-40, the control and operating equipment and other devices is effected by the CAN-Bus to ISO 11898, using the CANopen protocols.

Function

A measuring current of variable frequency flows through the fluid and creates a potential gradient between the measuring electrode and the measuring tube. The potential gradient is evaluated as measuring voltage UU.

The electrical conductivity is a function of temperature. To relate the measured values to a reference temperature the resistance thermometer integrated in the electrode measures the fluid temperature.

The electrical conductivity is calculated from the measuring voltages UU and UI and – through temperature compensation – is based on a reference temperature of 25°C.

The electrical conductivity is a non-linear function of temperature. For the compensation of the measured values one of the following three procedures can be applied:

nTemperature compensation Auto: The conductivity electrode records the specific conductivity/ temperature curve of the respective fluid and based on the data obtained, performs the compen sation.

The auto-curve temperature compensation is suitable for boilers operating with variable pressure, which means that the boiler does not have a fixed working pressure (e. g. low load 10 bar, full load 15 bar). The system detects in steps of 10°C all temperatures and conductivity values from 100°C to the service temperature. For this purpose the boiler must reach its working pressure (with variable

pressure operation: max. allowable working pressure). If the standard curve is not suitable for variable pressure operation, use can be made of the recorded curve.

Explanatory Notes – continued –

Function – continued –

nTemperature compensation NORM: The conductivity/temperature curves of 11 normally used conditioning agents are stored in the electrode and can be selected.

The standard curve temperature compensation is suitable for boilers operating with variable pressure, which means that the boiler does not have a fixed working pressure (e.g. low load 10 bar, full load

15 bar). The standard curves of feedwater conditioning agents with different basic conductivities compensate for the influence of the temperature on readings within the operating range.

nTemperature compensation LINEAR: A fixed temperature coefficient (Tk) is used to correct the measured conductivity value linearly.

The gradient (default setting: 2.1 % / °C) is normally used for steam boilers operating with constant pressure. The conductivity is ascertained at an ambient temperature of 25°C. The cell constant can be modified in order to calibrate the value measured by the electrode. The gradient can be verified at operating pressure with the aid of a calibrated conductivity meter.

At regular intervals the conductivity electrode LRG 1x-40 sends a data telegram via CAN-bus to the controller with the following information:

nMeasured conductivity value, referred to 25°C as actual value (X),

nMeasuring range / adaptation of actual value output,

nAlarm: self-monitoring of electrode supply cables,

nAlarm: temperature sensor defective,

nAlarm: excessively high temperature in terminal box.

A short circuit in the cables leading to the measuring electrode, the measuring tube and the resistance thermometer or the interruption of the data transmission via CAN bus will be indicated by a malfunction message.

A sensor monitors the temperature in the terminal box and indicates a malfunction if the limit value is exceeded.

System components

LRR 1-40

Digital switching controller for conductivity electrode LRG 1x-40

Functions: Conductivity limiter, continuous blowdown controller

Data exchange via CAN bus to ISO 11898 using CANopen protocol

URB 1, URB 2

Operating & display unit

Functions: Parameterization, indication via LCD display

Data exchange via CAN bus to ISO 11898 using CANopen protocol

Design

LRG 1x-40

Screwed 1", ISO 228-1. Fig. 3, Fig. 4

Technical Data

LRG 16-40, LRG 17-40

Type approval no.

TÜV.WÜL.02-007

EG BAF-MUC 02 05 103881 003

Service pressure

LRG 16-40: 32 bar at 238°C LRG 17-40: 60 bar at 275°C

Connection

Screwed 1" BSP (to ISO 228-1)

Materials

Screw-in enclosure: 1.4571, X6CrNiMoTi17-12-2

Measuring electrode/reference tube/screw: 1.4571, X6CrNiMoTi17-12-2 Electrode insulation: PTFE

Terminal box: 3.2161 G AlSi8Cu3 Spacer disc: LRG 16-40: PEEK Spacer disc: LRG 17-40: PEEK HT

Length of installation / measuring length

200, 300, 400, 500, 600, 800 and 1000 mm

Temperature sensor

Resistance thermometer PT 1000

Cell constant C

0.2 cm-1

Conductivity measuring range

0.5 – 12000 μS/cm at 25°C

0.25 – 6000 ppm (parts per million)

Note

The electrical conductivity is measured in μS/cm. For ppm (parts per million) use the following conversion: 1 μS/cm = 0.5 ppm.

Technical Data – continued –

LRG 16-40, LRG 17-40 – continued –

Measuring cycle

1 sec.

Accuracy

5 %, referred to conductivity readings without temperature compensation

Temperature compensation

Type of temp. compensation can be adjusted with URB or SPECTORcontrol :

nTemperature compensation AUTO:

with conductivity/temperature curve characteristic of the installation.

nTemperature compensation NORM:

with standard conductivity/temperature curve.

nTemperature compensation LINEAR: with set temperature coefficient (Tk).

Time constant T (measured as specified in DIN 3440)

Temperature: 9 sec. Conductivity: 14 sec.

Input/Output

CAN bus interface with power supply 18 – 36 V DC, short circuit protected

Data exchange

CAN-bus to ISO 11898, CANopen protocol

Power consumption

3.8 W

Fuse

Electronic thermal fuse Tmax 85°C, hysteresis -2K.

Indicators and adjustors

Two LEDs for internal status messages.

One 10-pole code switch for node-ID and baud rate settings.

Electric connection

M 12 sensor connector, 5 poles, A coded M 12 sensor jack, 5 poles, A coded

Protection

IP 65 to EN 60529

Ambient temperature

Max. 70°C

Weight

Approx. 2.5 kg

Technical Data – continued –

LRG 16-40, LRG 17-40 – continued –

The standard conductivity-/temperature curves can be adjusted using the operating & display devices SPECTORcontrol and URB.

Standard curve |

Conditioning agent |

Basic conductivity at 25°C |

|

|

|

1 |

NaOH (caustic soda) |

260 μS/cm |

|

|

|

2 |

NaOH (caustic soda) |

1080 μS/cm |

|

|

|

3 |

NaOH (caustic soda) |

5400 μS/cm |

|

|

|

4 |

NaOH (caustic soda) |

11000 μS/cm |

|

|

|

5 |

Na3PO4 (trisodiumphosphate) |

190 μS/cm |

6 |

Na3PO4 (trisodiumphosphate) |

1100 μS/cm |

7 |

Na3PO4 (trisodiumphosphate) |

5900 μS/cm |

8 |

Na3PO4 (trisodiumphosphate) |

11200 μS/cm |

9 |

Na2SO3 (sodium sulfite) |

980 μS/cm |

10 |

Dipolique 444 |

200 μS/cm |

|

|

|

11 |

Levoxin |

195 μS/cm |

|

|

|

Corrosion resistance

If the conductivity electrode LRG 1x-40 is used for its intended purpose, its safety is not impaired by corrosion.

Sizing

The electrode body must not be subjected to sharp increases/decreases in pressure. The dimensional allowances for corrosion reflect the latest state of technology.

Technical Data – continued –

Name plate / Marking

|

Safety note |

|

Equipment designation |

|

Pressure rating, thread type, |

|

material number, protection |

|

Pressure/temperature rating |

|

Measuring range |

|

Power rating |

|

Output characteristics |

|

Node ID |

|

CE marking |

|

Manufacturer / Disposal note |

|

Spare part |

|

specification |

Fig. 1 |

Fig. 2 |

10 |

|

Technical Data |

– continued – |

|

|

|

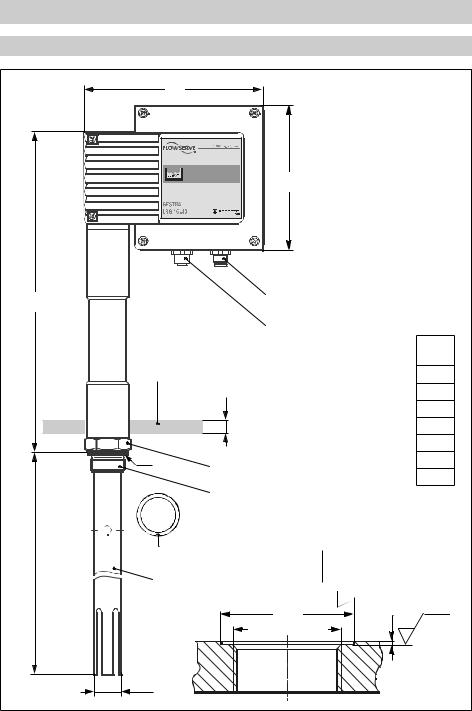

Dimensions LRG 16-40 |

|

|

|

|

|

|

173 |

|

|

|

|

140 |

|

|

|

|

b = 68 |

|

|

336 |

|

A |

|

|

|

|

B |

|

G |

|

|

|

|

|

|

|

|

|

[mm] |

|

C |

|

|

200 |

|

|

|

300 |

|

|

|

20 |

|

|

|

|

|

400 |

|

|

|

|

|

|

|

|

|

|

500 |

|

|

|

|

600 |

|

D |

A. F. 41 |

|

800 |

|

|

1000 |

||

|

|

|

|

|

|

|

1" BSP (ISO 228-1) |

|

|

|

E |

Ra 12.5 |

|

|

G |

F |

|

|

|

|

|

|

||

|

|

40 |

0.5 |

Ra 3.2 |

|

|

1" BSP (ISO 228-1) |

||

|

|

|

||

|

|

|

|

|

|

28 |

|

|

|

Fig. 3 |

|

|

|

|

|

|

|

|

11 |

Loading...

Loading...