siemens 840Dsl User Manual

SINUMERIK 840D sl

Detailed Maschine Data Description

Parameter Manual

Machine and

Setting Data 1

Index I

Valid for

Control

SINUMERIK 840D sl/ 840DE sl

Software Version

NCU Systemsoftware für 840D sl/ 840DE sl 2.6 SP1

03/2010

-

Legal information

Warning notice systemt

This manual contains notices you have to observe in order to ensure your personal safety, as well as to

prevent damage to property. The notices referring to your personal safety are highlighted in the manual

by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These

notices shown below are graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not

taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning

relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the

specific task in accordance with the relevant documentation for the specific task, in particular its warning

notices and safety instructions. Qualified personnel are those who, based on their training and experience,

are capable of identifying risks and avoiding potential hazards when working with these products/systems:

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be

recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning,

operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights

of the owner.

Copyright Siemens AG 2010 All Rights Reserved

The reproduction, transmission, or use of this document or its contents is not permitted without express written permission. Failure to

observe this rule will lead to damage claims. All rights reserved, especially those relating to granting patents or GM registration.

Siemens AG

Industry Sector

Postfach 4848

90327 NÜRNBERG

GERMANY

Siemens Aktiengesellschaft SINUMERIK 840D sl Detailed Maschine Data Description (AMDsl)

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency.

However, the information in this publication is reviewed regularly and

any necessary corrections are included in subsequent editions.

© Siemens AG 2010

Technical data subject to change.

03/2010

Preface

Structure of the documentation

The SINUMERIK documentation is available in three versions:

General Documentation

User Documentation

Manufacturer/Service Documentation

Information on the following topics is available at

http://www.siemens.com/motioncontrol/docu:

Ordering documentation

Here you can find an up-to-date overview of publications.

Downloading documentation

Links to more information for downloading files from Service & Support.

Researching documentation online

Information on DOConCD and direct access to the publications in

DOConWEB.

Compiling individual documentation on the basis of Siemens contents with the

My Documentation Manager (MDM), refer to http://www.siemens.com/mdm.

My Documentation Manager provides you with a range of features for generating your own machine documentation.

Target group

Benefits

Training and FAQs

Information on the range of training courses and FAQs (frequently asked

questions) are available via the page navigation.

This documentation is intended for project engineers, commissioning engineers,

machine operators, service and maintenance personnel.

The Parameter Manual enables the intended target group to evaluate error and

fault indications and to respond accordingly.

With the help of the Parameter Manual, the target group has an overview of the

various diagnostic options and diagnostic tools.

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

iii Siemens AG 2010 All Rights Reserved

Preface 03/2010

Standard version

This Parameter Manual only describes the functionality of the standard version.

Extensions or changes made by the machine tool manufacturer are documented

by the machine tool manufacturer.

Other functions not described in this documentation might be executable in the

control. This does not, however, represent an obligation to supply such functions

with a new control or when servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed

information about all types of the product and cannot cover every conceivable

case of installation, operation or maintenance.

Technical Support

If you have any questions, please contact the following hotline:

Europe / Africa

Phone

Fax

€0.14/min. from German landlines, max. 0.42 €/min for calls from a mobile phone.

Internet

Phone

Fax

Email

Phone

Fax

Email

+49 180 5050 222

+49 180 5050 223

http://www.siemens.de/automation/support-request

America

+1 423 262 2522

+1 423 262 2200

mailto:techsupport.sea@siemens.com

Asia / Pacific

+86 1064 757575

+86 1064 747474

mailto:support.asia.automation@siemens.com

Note

National phone numbers for technical support are provided under the following

Internet address: http://www.automation.siemens.com/partner

iv

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 Preface

Questions about this documentation

If you have any queries (suggestions, corrections) in relation to this documentation, please send a fax or email to the following address

Fax

Email

A fax form is available at the end of this document.

SINUMERIK Internet address

http://www.siemens.com/sinumerik

+49 9131 98 2176

mailto:docu.motioncontrol@siemens.com

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

v

Preface 03/2010

vi

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

Table of Contents

1 Machine and setting data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.1 Important information about the data tables . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.1.1 Structure of the data tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.1.2 Meaning of table fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.1.3 Overview of the data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.2 Display machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1.3 General machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.3.1 System settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

1.3.2 Override switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-169

1.3.3 System specific memory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-227

1.4 Channel-specific machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-294

1.4.1 Basic channel machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-294

1.4.2 Machine data for grinding function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-394

1.4.3 Channel auxiliary function settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-396

1.4.4 Transformation definitions in channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-425

1.4.5 Punching and nibbling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-480

1.4.6 Channel-specific memory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-494

1.5 Axis-specific machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-514

1.5.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-514

1.5.2 Encoder matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-532

1.5.3 Closed-loop control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-539

1.5.4 Reference point approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-583

1.5.5 Spindles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-600

1.5.6 Monitoring functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-624

1.5.7 Safety Integrated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-641

1.5.8 Travel to fixed stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-674

1.5.9 Axis-specific memory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-704

1.6 Setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-706

1.6.1 General setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-706

1.6.2 Channel-specific setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-722

1.6.3 Axis-specific setting data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-752

1.7 Machine data cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-770

1.7.1 General configuration machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-770

1.7.2 General cycle machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-782

1.7.3 Channel-specific configurations machine data . . . . . . . . . . . . . . . . . . . . . . 1-788

1.7.4 Channel-specific cycle machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-795

1.7.5 Axis-specific configuration machine data . . . . . . . . . . . . . . . . . . . . . . . . . . 1-797

1.7.6 General configuration setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-798

1.7.7 General cycle setting data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-798

1.7.8 Cannel-specific configuration setting data. . . . . . . . . . . . . . . . . . . . . . . . . . 1-817

1.7.9 Channel-specific cycle setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-820

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

vii Siemens AG 2010 All Rights Reserved

Table of Contents 03/2010

1.8 Machine data compile cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-837

1.8.1 General machine data compile cycles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-837

1.8.2 Channel-specific machine data compile cycles. . . . . . . . . . . . . . . . . . . . . . 1-839

1.8.3 Axis-specific machine data compile cycles . . . . . . . . . . . . . . . . . . . . . . . . . 1-859

IIndex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-863

viii

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

Machine and setting data 1

1.1 Important information about the data tables

This list manual provides information on all the machine and setting data in a concise table format. A functional description of the data is provided in the function

manual indicated in the cross reference.

You can also find more information in:

HMI Online Help directly on the control

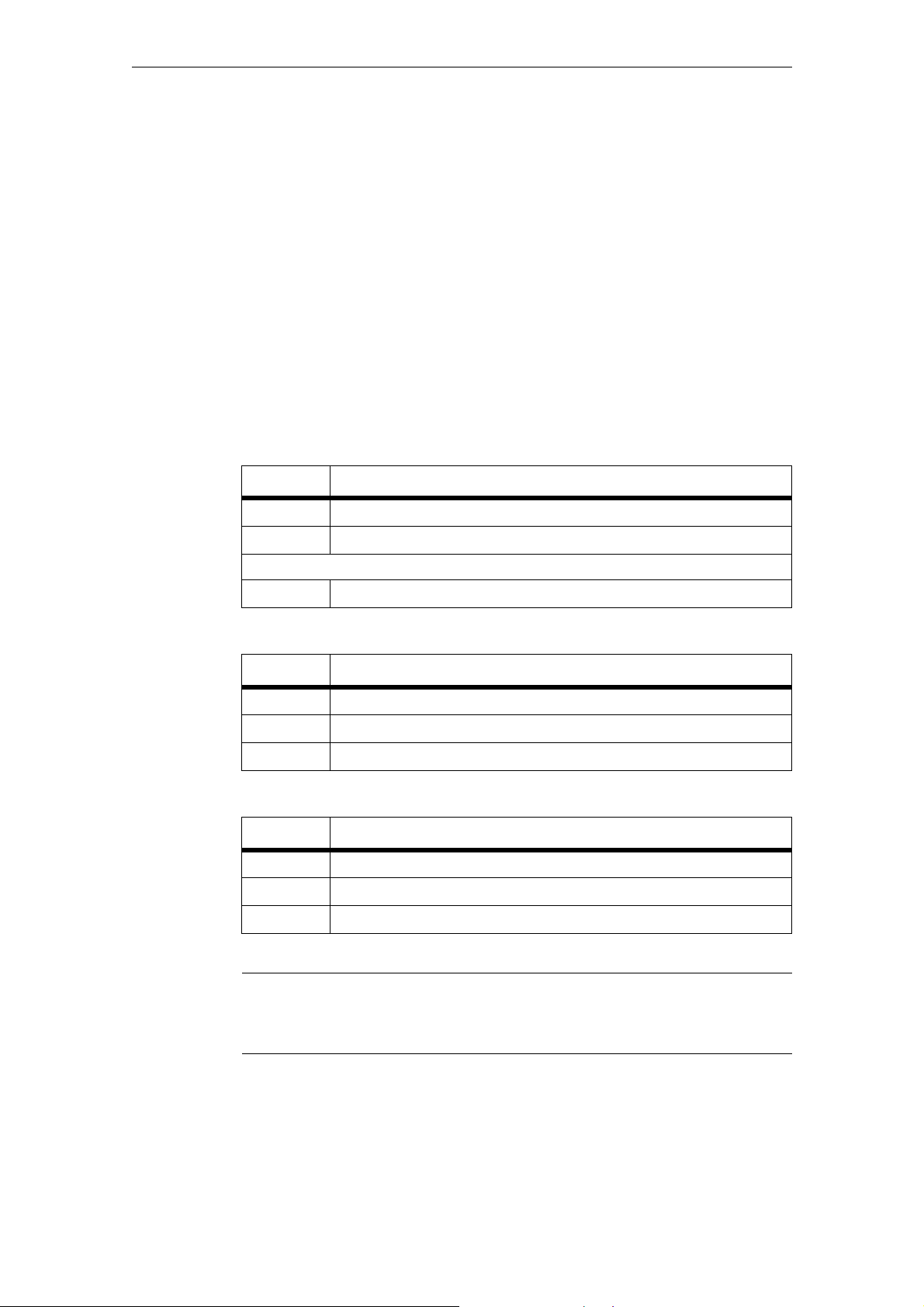

1.1.1 Structure of the data tables

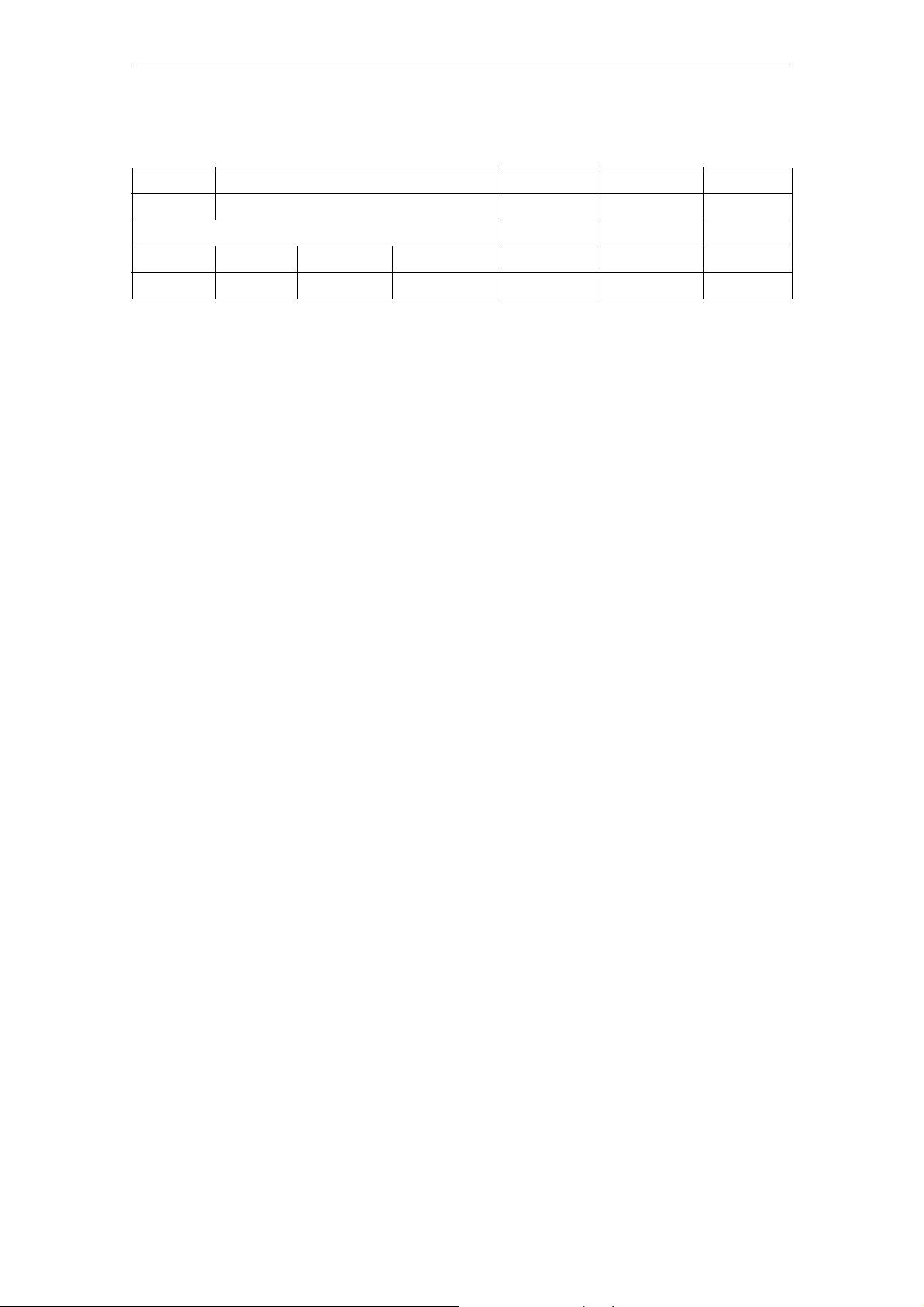

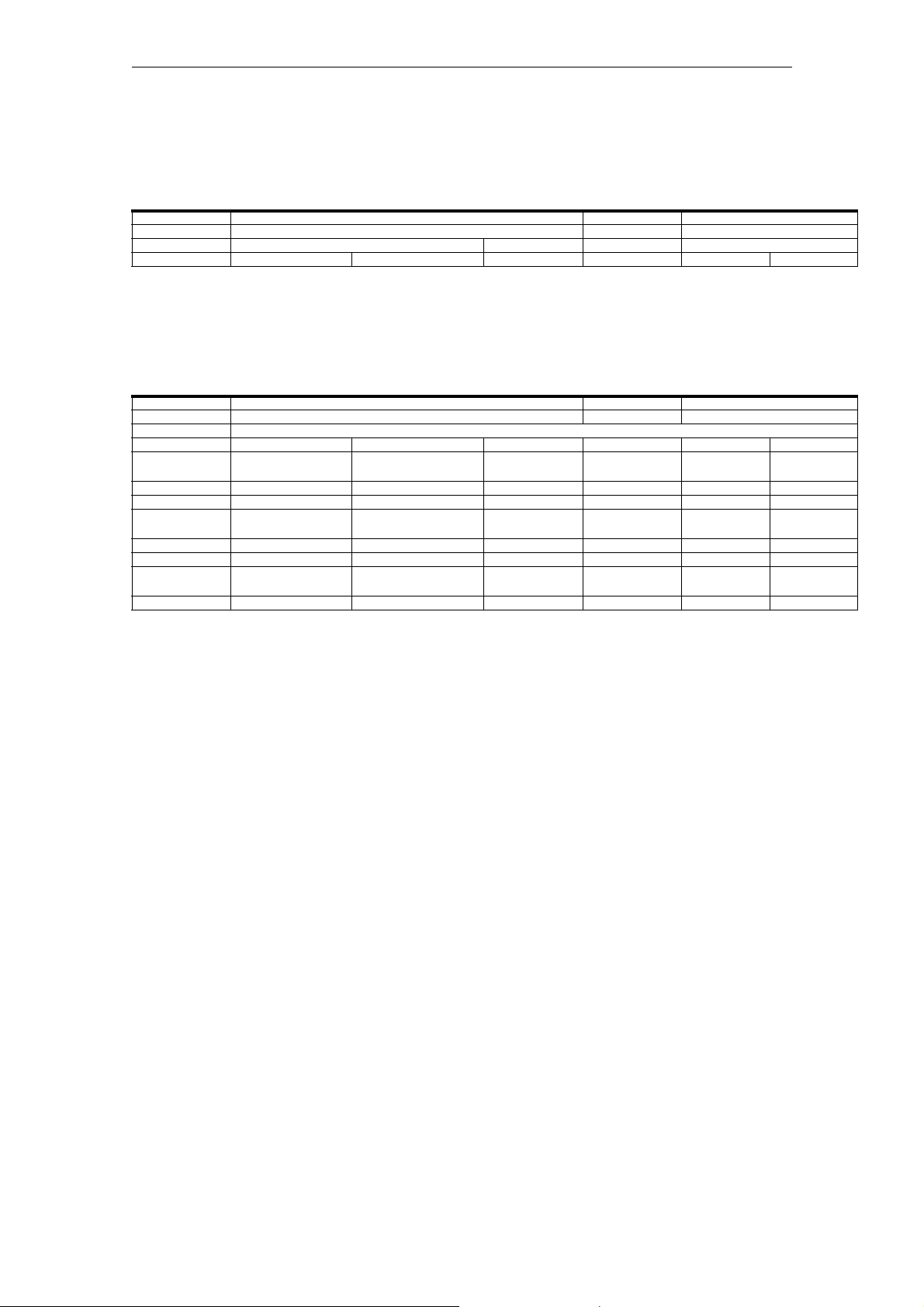

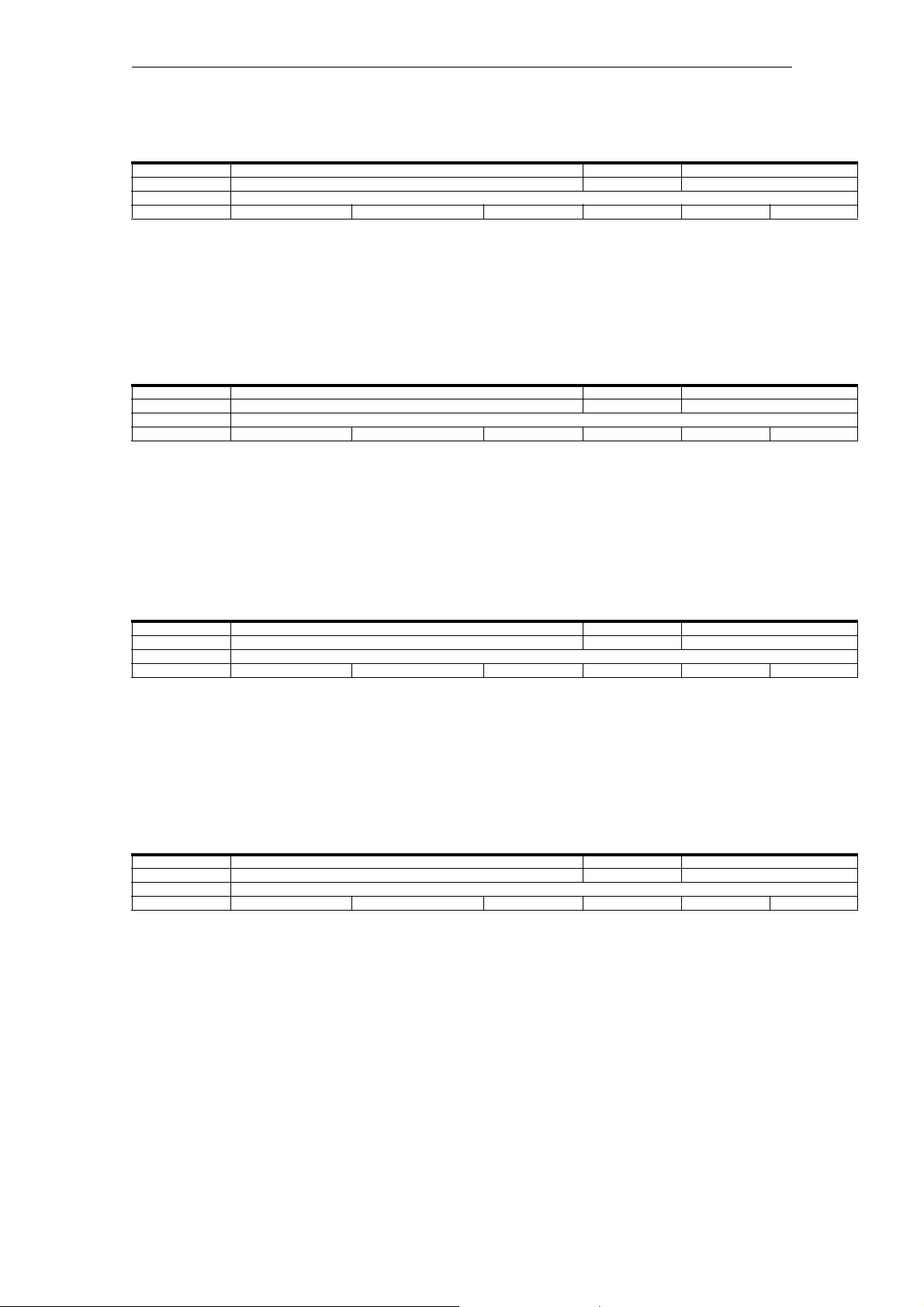

Standard table

The standard table contains all the important information about the data:

MD number Identifier Display filter Reference

Unit Name Data type Activation

Attributes

System Dimension Default value Minimum value Maximum value Protection Class

Expanded table

The expanded table includes data from the standard table plus additional rows

with system-specific values.

MD number Identifier Display filter Reference

Unit Name Data type Activation

Attributes

- Dimension Default value Minimum value Maximum value Protection Class

<System 1> - Default value - - -/-

<System 2> - - - - -1/-

A minus sign "-" in a field means that the same value as for System 1 applies for

the specified system.

The entry "-1/-" in the "Protection" field means that the machine data is not available for the specified system.

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-9

1 Machine and setting data 03/2010

1.1 Important information about the data tables

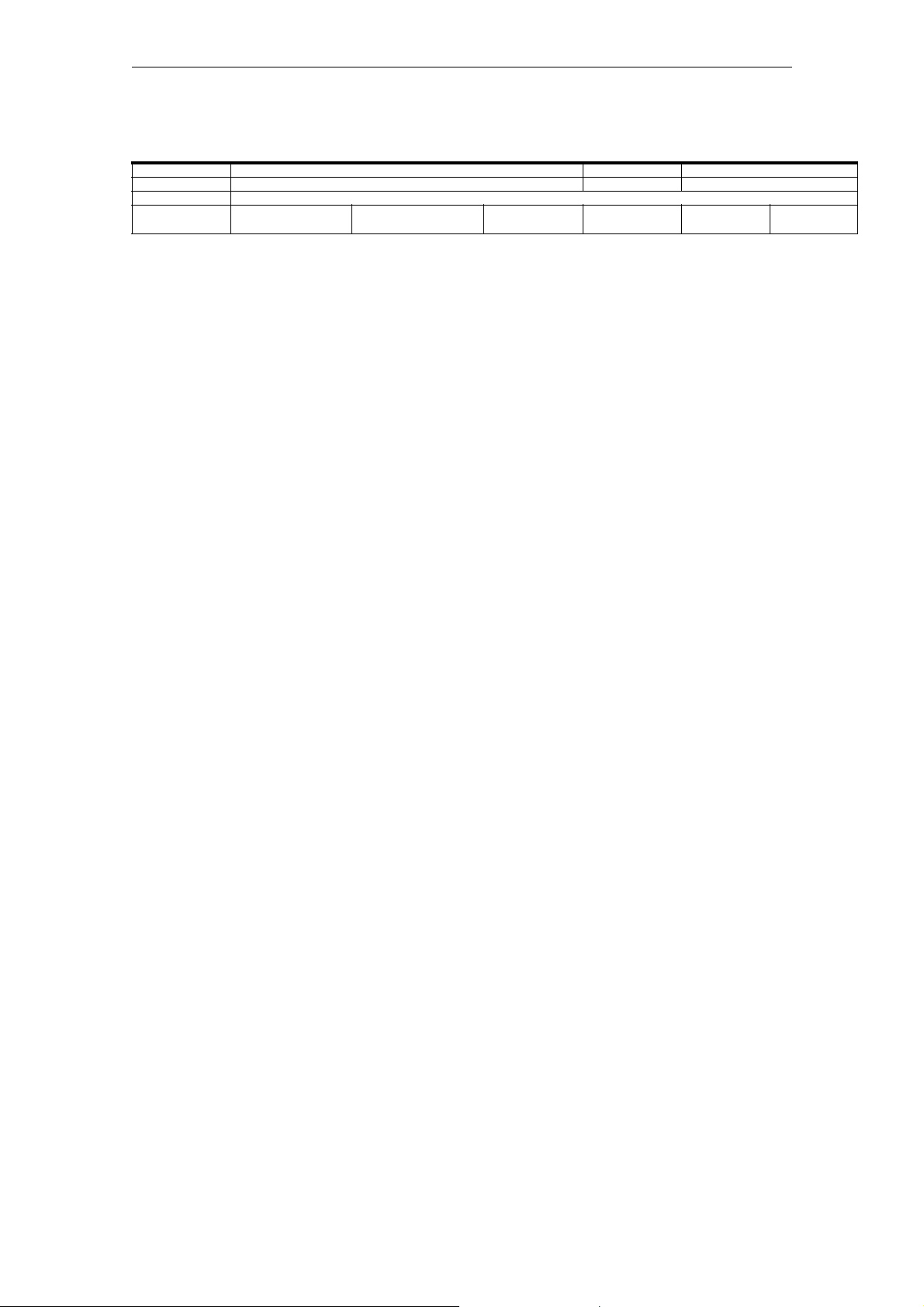

Example:

10050 SYSCLOCK.CYCLE_TIME N01, N05, N11 G3

s Basic system clock cycle DOUBLE POWER ON

SFCO

- - 0.004 0.000125 0.031 7/2 M

710-2a2c - 0.002 0.001 0.008 -/-

1.1.2 Meaning of table fields

MD number

The "MD number" field contains the machine data number. This number is displayed in the data lists on the user interface of the control.

Identifier

Reference

The "Identifier" field contains the unique alphanumeric identifier of the machine

data. The machine data is, for example, addressed by means of this identifier

(with an additional label) for programming in the part program.

This identifier is displayed in the data lists on the user interface of the control.

As a cross reference to the functional description of the data, the "Reference" field

contains the short designation of a supporting manual for a specific function manual.

Reference is made to the following documents:

Function Manual of basic machines, supporting manuals: A2, A3, B1, B2,

D1, F1, G2, H2, K1, K2, N2, P1, P3, R1, S1, V1, W1, Z1

Function Manual of expanded functions, supporting manuals: A4, B3, B4,

F3, H1, K3, K5, M1. M5, N3, N4, P2, P5, R2, S3, S7, T1, W3, W4, Z2

Function Manual of special functions, supporting manuals: F2, G1, G3, K6,

M3, S9, T3, TE01, TE02, TE1, TE3, TE4, TE6, TE7, TE8, TE9, V2, W5,

W6, Z3

Funktionshandbuch Antriebsfunktionen, Unterbücher, FBA: DB1, DD1,

DD2, DE1, DF1, DG1, DL1, DM1, DS1, DÜ1

1-10

Funktionshandbuch Antriebsfunktionen, Unterbücher, FBA: DB1, DD1,

DD2, DE1, DF1, DG1, DL1, DM1, DS1, DÜ1

Function Manual Safety Integrated, FBSI

Function Manual Turn, FBMA

Function Manuall of Tool Management, FBW

Function Manual of ISO-dialects for SINUMERIK, FBFA

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

03/2010 1 Machine and setting data

1.1 Important information about the data tables

Function Manual of Synchronized actions, FBSY

Programmiing Manual Fundamentals, PG

Programmiing Manual Job planing, PGA

Unit

The "Unit" field contains the physical unit of the data in the default setting. A minus

sign "-" means that the data does not have a physical unit.

Note

For machine data of the Performance 2 [P2] control module, the unit or units are

shown with a filter in row 2, column 1.

Name

The "Name" field contains the name of the data in plain text.

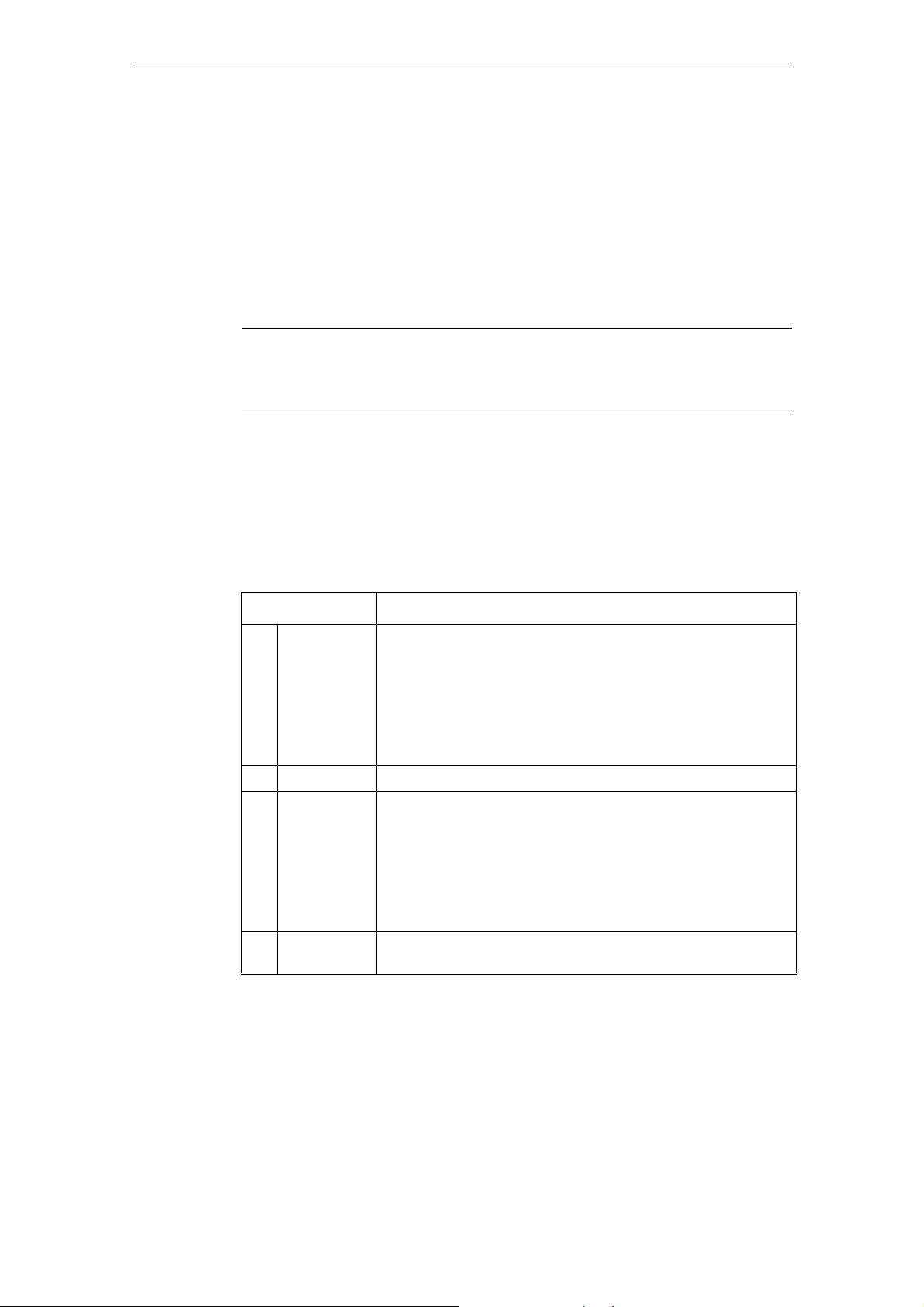

Activation

The "Activation" field contains the action that must be performed by the user in

order for a change to take effect.

Activation User action

po POWER ON Otherwise:

HMI softkey "Reset (po)" (SINUMERIK Operate/HMI-

Advanced SW 7.5 or higher)

HMI softkey "NCK-Reset" (HMI-Embedded)

Reset button on the front of the NCU module

Switch voltage off/on

cf NEW_CONF HMI softkey: "Activate MD"

re RESET Otherwise:

Channel reset: DBn.DBX 7.7 where n = 21, 22, 23, etc.

Mode group reset: DB11.DBX n.7 where n = 0, 20, 40, etc.

NCK reset: DB11.DBX n.7 where n = 0, 20, 40, etc. in all mode

groups of the control

Program end reset (M02/M30)

so IMMEDI-

ATELY

-

The activation levels are listed according to their priority.

po = highest priority

so = lowest priority

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-11

1 Machine and setting data 03/2010

1.1 Important information about the data tables

Axis-specific machine data with effectiveness criterion Reset.

To activate axis-specific machine data with effectiveness criterion RESET, trigger a channel reset in the channel in which the axis is currently located.

Note

Mode group reset generates a reset in all channels which have been combined

into one machining unit.

Notice

PLC-controlled axes always require an axial reset.

See Function Manual Extended Functions, Chapter "P2: Positioning Axes" >

"Influence of PLC" > "PLC-controlled Axes".

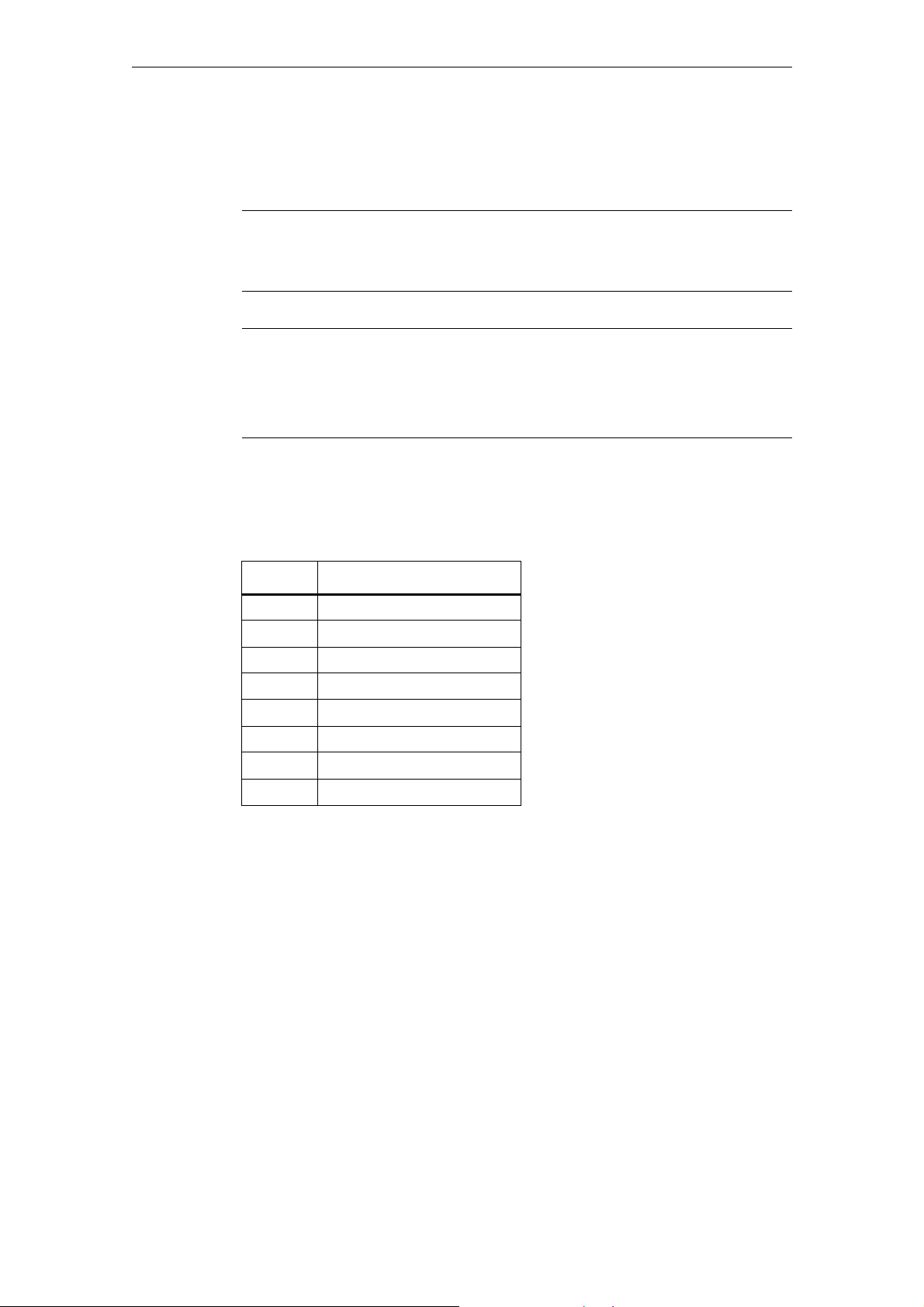

Protection

Protection

The "Protection" field contains the protection level for reading or writing to the

data in the format: Read / write.

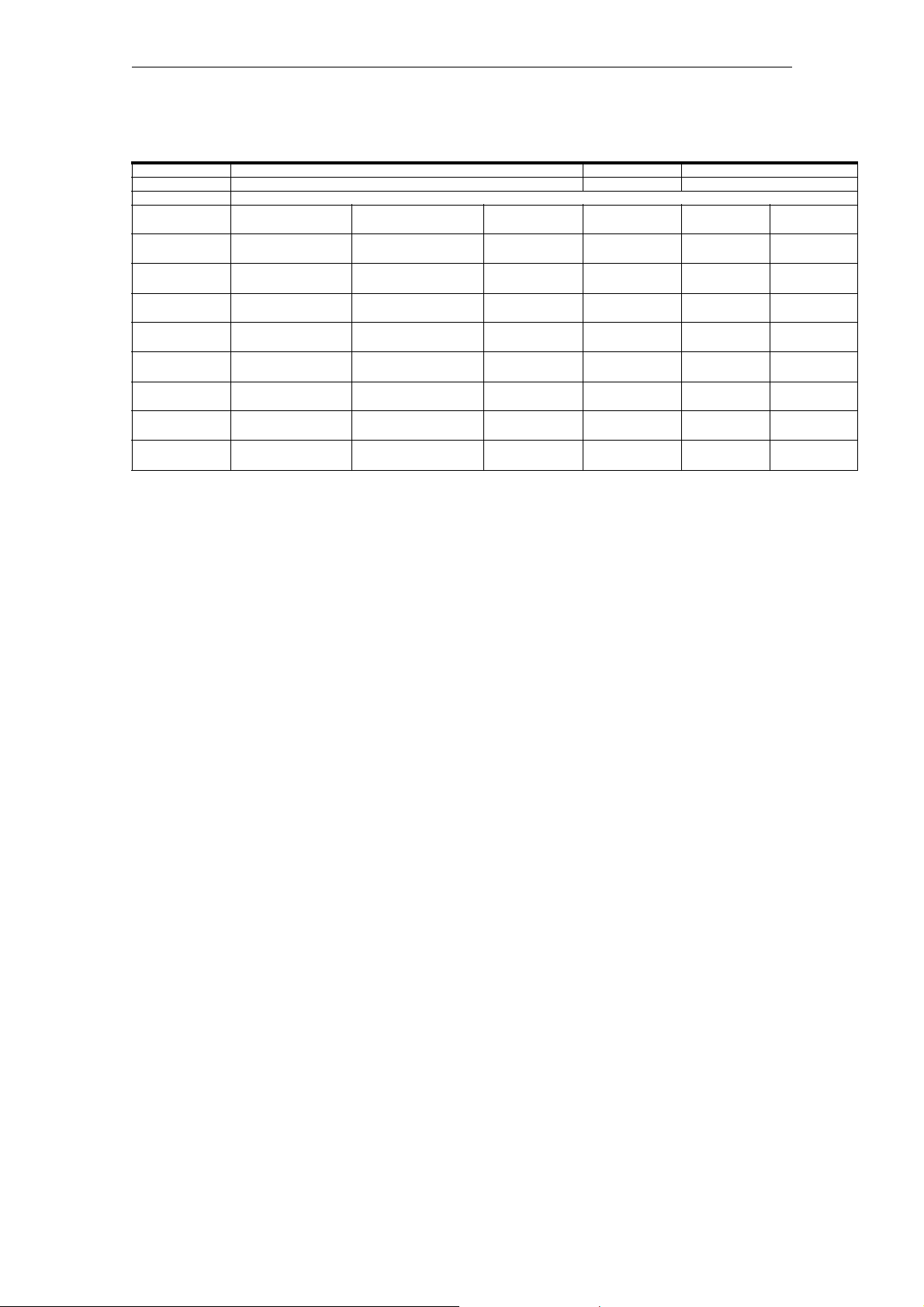

Value Protection level

0 or 10 System

1 or 11 Manufacturer

2 or 12 Service

3 or 13 User

4 or 14 Key-operated switch setting 3

5 or 15 Key-operated switch setting 2

6 or 16 Key-operated switch setting 1

7 or 17 Key-operated switch setting 0

The protection level for user data (GUD) is defined with the numbers 10 to 17.

1-12

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 1 Machine and setting data

1.1 Important information about the data tables

Class

The data class attribute of machines, setting and option data is usually derived

from the write authorization of the relevant data.

The following data classes are used:

Data class Write authorization Access authorization

S System Protection level 0 (password: System )

M Manufacturer/ Service Protection level 1 and 2 (password: Service)

U User Protection level 3 (password: User)

Protection level 4 to 7 (keyswitch)

Display filter

The "Display filter" field contains the identifier of the data filter setting that enables

the data to be seen. With the filter setting, the exact data areas needed at a given

time can be selected for display.

ID Data area

EXP Expert mode

Drive machine data

D00 Display signals

D01 Controller data

D02 Monitoring/limiting functions

D03 Message data

D04 Status data

D05 Motor/power unit

D06 Measuring system

D07 Safety Integrated

D08 Standard machine

General machine data

N01 Configuration/scaling

N02 Memory configuration

N03 PLC machine data

N04 Drive control

N05 Status data/diagnostics

N06 Monitoring/limiting functions

N07 Auxiliary functions

N08 Corrections/compensations

N09 Technological functions

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-13

1 Machine and setting data 03/2010

1.1 Important information about the data tables

ID Data area

N10 I/O configuration

N11 Standard machine

A12 External language

A13 Safety Integrated

A14 Selection for Safety Integrated

Channelspecific machine data

C01 Configuration

C02 Memory configuration

C03 Initial settings

C04 Auxiliary functions

C05 Speeds

C06 Monitoring/limiting functions

C07 Transformations

C08 Corrections/compensations

C09 Technological functions

C10 Standard machine

C11 External languages

Axis-specific machine data

A01 Configuration (including memory)

A02 Measuring system

A03 Machine geometry

A04 Speeds/accelerations

A05 Monitoring/limiting functions

A06 Spindle

A07 Controller data

A08 Status data

A09 Corrections/compensations

A10 Technological functions

A11 Standard machine

A12 External language

A13 Safety Integrated

A14 Selection for Safety Integrated

Display machine data

H01 ShopMill

1-14

H02 ShopTurn

H03 ManualTurn

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

03/2010 1 Machine and setting data

1.1 Important information about the data tables

ID Data area

H04 Access levels

H05 Standard machine

System

The "System" field contains the system for which the data is valid.

ID System

840Dsl 840D systems solution line

710 NCU 710

720 NCU 720

730 NCU 730

If this field is empty, the data is valid for all systems.

Dimension

Value range

Additional identifiers:

iajc i = number of axes

j = number of channels

For example: 6a2c = 6 axes, 2 channels

The "Dimension" field contains the number of elements of a data field.

The "Minimum value" and "Maximum value" fields contain the lower limit and

upper limit, respectively, of the permissible range of the data.

If the "Minimum value" and "Maximum value" fields contain the string " *** ", an

explicit range is not defined for this data. In this case, the range is determined by

the specified data type.

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-15

1 Machine and setting data 03/2010

1.1 Important information about the data tables

SINUMERIK data types

The "Data type" field contains the following data types:

Data type Value range

BOOLEAN Machine data bit (1 or 0)

BYTE Integer values ( -128 to 127 )

-308

DOUBLE Real values ( ± ( 2.2 * 10

to 1.8 * 10

DWORD Integer values ( -2147483648 to +2147483647 )

DWORD Hex values ( 0 to FFFF FFFF )

STRING Character string (max. 16 characters) consisting of upper-case

letters with digits and underscore

UNSIGNED WORD Integer values ( 0 to 65536 )

SIGNED WORD Integer values ( -32768 to 32767 )

UNSIGNED DWORD Integer values ( 0 to 4294967300 )

SIGNED DWORD Integer values ( -2147483650 to 2147483649 )

WORD Hex values ( 0000 to FFFF )

-37

FLOAT DWORD Real values ( ± ( 8.43 x 10

to "3.37 x 10

UBYTE Integer values ( 0 to 255 )

LONG Integer values ( 4294967296 to 4294967295 )

+308

38

) )

)

SIMATIC data types

The "Data type" field contains the following data types:

Data type Meaning Value range

I8 Integer8 8-bit integer

I16 Integer16 16-bit integer

I32 Integer32 32-bit integer

U8 Unsigned8 8 bits without sign

U16 Unsigned16 16 bits without sign

U32 Unsigned32 32 bits without sign

Float FloatingPoint32 32-bit floating point number

1-16

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 1 Machine and setting data

1.1 Important information about the data tables

Attributes

The "Attributes" field contains additional attributes of the data:

Attribute Meaning

NBUP No Back UP: The data is not backed up as part of the data

backup.

ODLD Only DownLoaD: The data can only be written to via an INI file,

archive, or from the part program.

NDLD No DownLoaD: The data can only be written to via the HMI

user interface.

SFCO SaFety COnfiguration: Component of the "Safety Integrated"

function

SCAL SCaling ALarm: Scaling data; when changed, alarm 4070 is

displayed

LINK LINK description: The data describes a link cluster, component

of the "NCU Link" function

CTEQ ConTainer EQual: The data must be the same for all axes in an

axis container, component of the "Axis container" function

CTDE ConTainer DEscription: The data describes an axis container,

component of the "Axis container" function

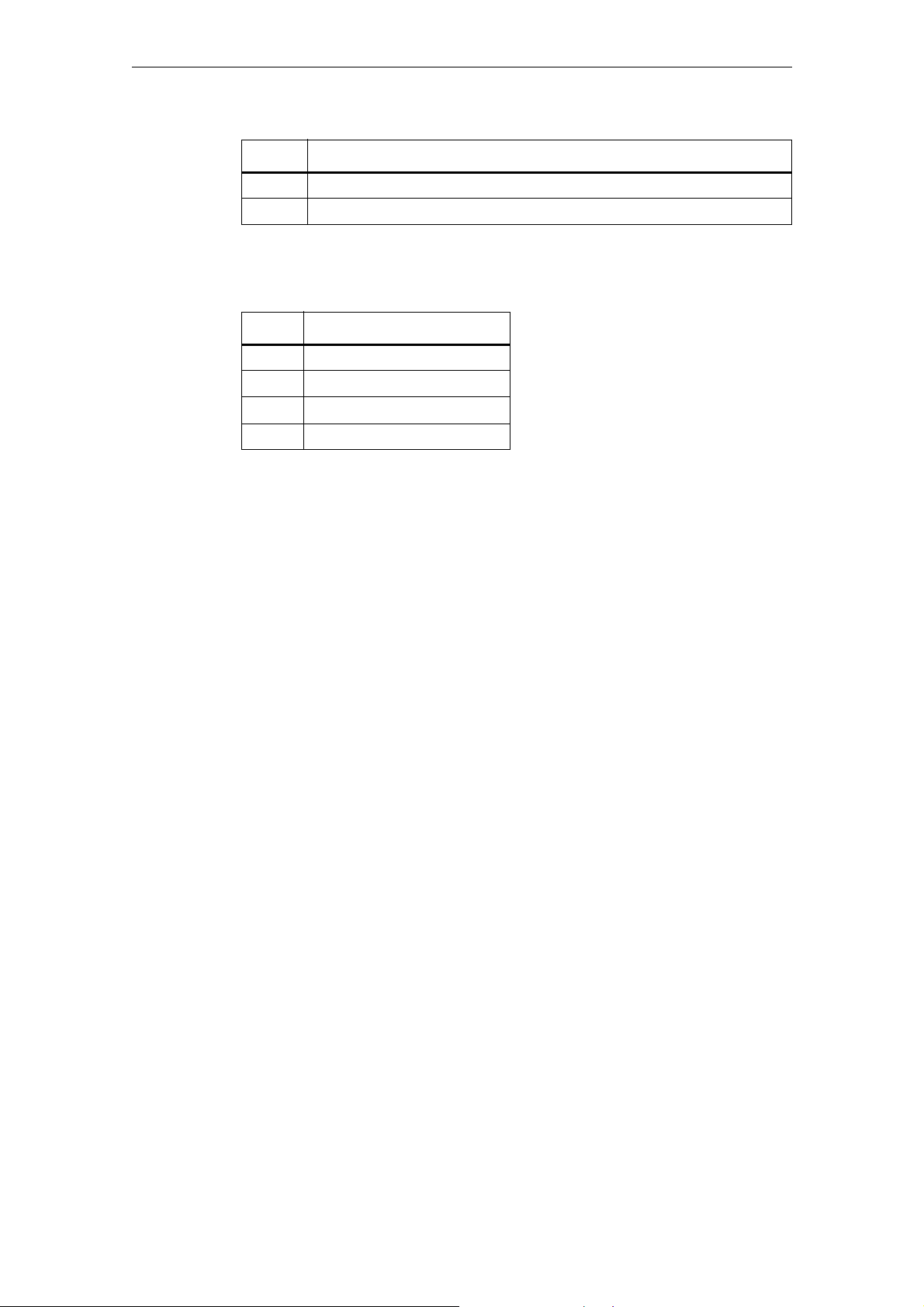

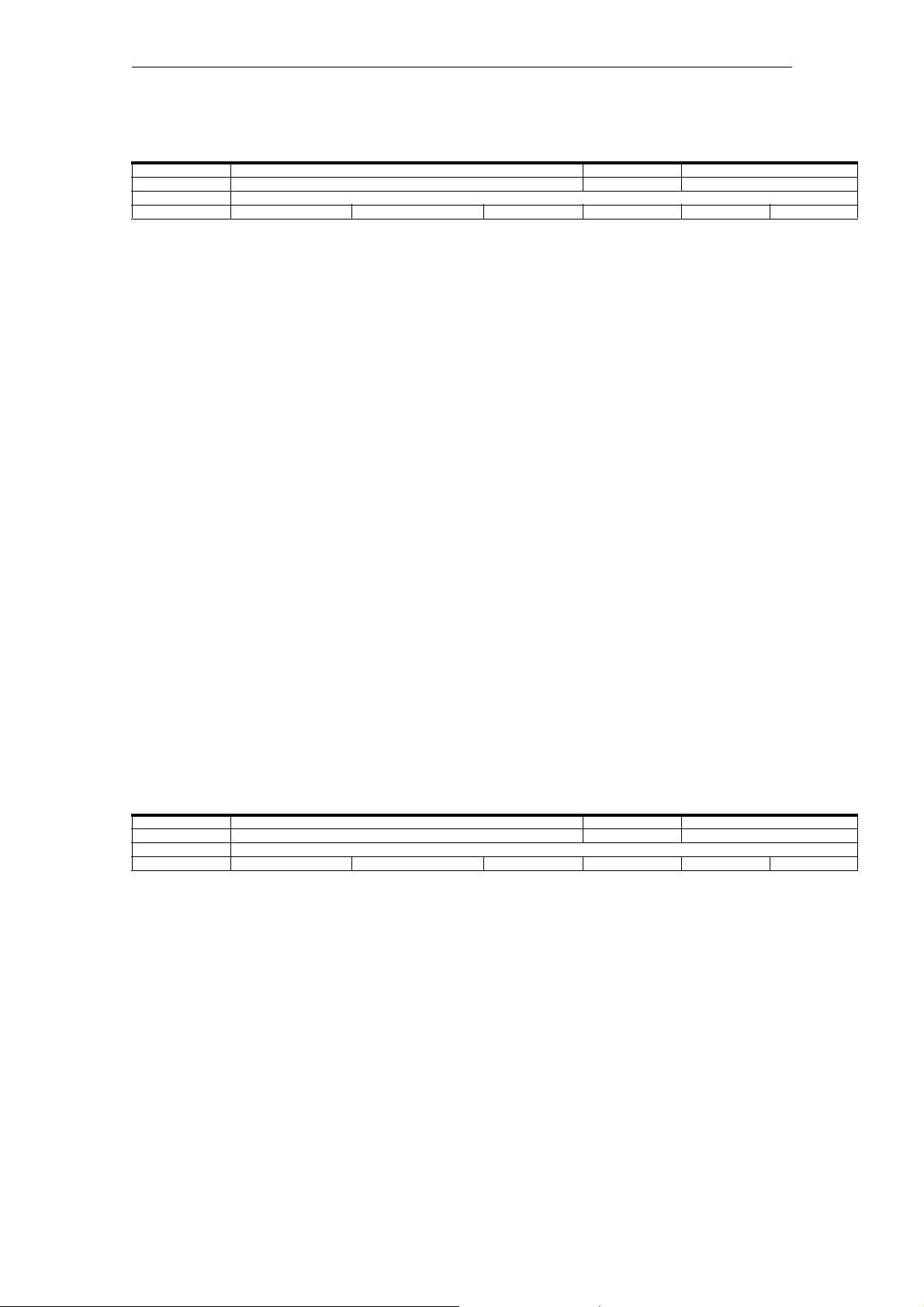

1.1.3 Overview of the data

Machine and setting data

The machine and setting data are divided into the following areas:

Range Designation

From 9000 to 9999 Display machine data

From 10000 to 18999 General NC machine data

From 19000 to 19999 Reserved

From 20000 to 28999 Channelspecific machine data

From 29000 to 29999 Reserved

From 30000 to 38999 Axis-specific machine data

From 39000 to 39999 Reserved

From 41000 to 41999 General setting data

From 42000 to 42999 Channel-specific setting data

From 43000 to 43999 Axis-specific setting data

From 51000 to 51299 General configuration machine data

From 51300 to 51999 General cycle machine data

From 52000 to 52299 Channel-specific configuration machine data

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-17

1 Machine and setting data 03/2010

1.1 Important information about the data tables

Range Designation

From 52300 to 52999 Channel-specific cycle machine data

From 53000 to 53299 Axis-specific configuration machine data

From 53300 to 53999 Axis-specific cycle machine data

From 54000 to 54299 General configuration setting data

From 54300 to 54999 General cycle setting data

From 55000 to 55299 Channel-specific configuration setting data

From 55300 to 55999 Channel-specific cycle setting data

From 56000 to 56299 Axis-specific configuration setting data

From 56300 to 56999 Axis-specific cycle setting data

From 61000 to 61999 General machine data for compile cycles

From 62000 to 62999 Channel-specific machine data for compile cycles

From 63000 to 63999 Axis-specific machine data for compile cycles

Data Identifiers

The identifier (designator) specified in the data description is displayed on the

HMI user interface. However, if the data is addressed in the parts program, for

example, the identifier of the relevant data area must precede the data identifier

(designator).

Identifier Data area

$MM_ Display machine data

$MN_/ $SN_

$MNS_/ $SNS_

$MC_/ $SC_

$MCS_/ $SCS_

$MA_/ $SA_

$MAS_/ $SAS_

Characters Meanings

$ System variables

M Machine data (first letter)

S Setting data (first letter)

M, N, C, A, D Subarea (second letter)

S Siemens data (third letter)

General machine/setting data

Channel-specific machine/setting data

Axis-specific machine/setting data

1-18

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 1 Machine and setting data

1.1 Important information about the data tables

Note:

Axis-specific data can also be addressed with the axis name as an index. The

internal axis identifier (AX1, AX2, AX3, etc.) or the identifier specified in

MD10000 $MA_AX_CONF_NAME_TAB can be used as the axis name.

Example: $MA_JOG_VELO[Y1]=2000

The JOG velocity of axis Y1 is 2000 mm/min.

If the content of a machine data is a STRING (e.g., X1) or a hexadecimal value

(e.g., H41), the content must be enclosed in single quotation marks (e.g., 'X1' or

'H41').

Example: $MN_DRIVE_INVERTER_CODE[0]='H14'

A FD module with performance data 9/18 A is present on the first slot of the drive

bus.

Example: $MA_FIX_POINT_POS[0,X1]=500.000

The value 500 is assigned to the first fixed point position on axis 1.

Examples:

$MN_AUXFU_GROUP_SPEC[2]='H41'

Output time of the auxiliary functions of the third auxiliary function group.

$MN_AXCONF_MACHAX_NAME_TAB[0]='X1'

The string "X1" is assigned to name the first machine axis.

$MA_REFP_SET_POS[0,X1]=100.00000

A value of 100 mm is assigned to the first reference point value of axis X1.

Examples:

Assignment to channel-specific machine data:

CHANDATA(1) ;Selection of the

first

;channel

$MC_CHAN_NAME='CHAN1' ;Name of the first

;channel

$MC_AXCONF_GEOAX_NAME_TAB[1]='Y' ;Name of the second

;geometry axis of the

;first channel is Y

R10 = 33.75

...

CHANDATA(2) ;Selection of the sec-

$MC_CHAN_NAME='CHAN2'

...

R10 = 96.88

...

;R10 of the first

channel

ond ;channel

;Name of the second

;channel

;R10 of the second

;channel

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-19

1 Machine and setting data 03/2010

1.1 Important information about the data tables

1-20

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 Machine and Setting Data

1.2 Display machine data

Product: Handbuch_Sinumerik, Version: V12.0, Language: eng

Objects:

1.2 Display machine data

Number Identifier Display filters Reference

Unit Name Data type Active

Attributes

System Dimension Default value Minimum value Maximum value Protection Class

Description: Description

9006 DISPLAY_SWITCH_OFF_INTERVAL --

- Time for screen saver DWORD PowerOn

-

- - 60 0 180 7/3 M

Description: This machine data defines the time in minutes after which the

screen automatically

switches to dark if no key has been pressed on the keyboard in the

meantime.

The value 0 disables automatic light/dark switching.

Note:

The screen is only switched light/dark automatically when IS

screen dark = 0.

Related to:

IS screen dark (DB19, ... DBX0.1)

9009 KEYBOARD_STATE --

- Keyboard shift behavior at booting BYTE PowerOn

-

-- 0 0 2 7/3 M

Description: This machine date defines the Shift behavior (SW-CAPSLOCK) of the

keyboard.

Basic configuration of the Shift behavior of the keyboard

0: SW-CAPSLOCK OFF

2: SW-CAPSLOCK ON

9032 HMI_MONITOR --

- Define PLC data for HMI screen info STRING PowerOn

-

- - - - 7/1 M

Description: Pointer, with offset, to a PLC data block. This is required to

report

HMI monitor information to the PLC, e.g active HMI task.

Format: PLC-specific format for specifying a data block with byte

offset,

e.g. DB60.DBB10 for data block 60, byte 10.

The monitor information reported by the HMI has a maximum length

of 8 bytes.

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl,, Detailed Maschine Data Description (AMDsl), 03/2010

1-21

Machine and Setting Data 03/2010

1.2 Display machine data

9056 ALARM_ROTATION_CYCLE --

- Rotation cycle time for alarm display DWORD PowerOn

-

- - 0 0 10000 7/3 M

Description: Rotation cycle time in the alarm display:

<500: no rotation in the alarm line

500 - 10000: cycle duration of alarm rotation in milliseconds

If a valid cycle time has been set, all alarms are displayed in the

alarm line one after the other.

Each alarm is displayed for the specified time until it is

replaced by the next alarm.

If no alarm is present, cycle alarms or program messages are dis-

played, if required. However, these do not rotate.

9100 CHANGE_LANGUAGE_MODE --

- Language selection mode BYTE Immediately

-

-- 1 1 2 7/3 I

Description: Language selection mode is defined:

1 = directly via selection list

2 = via setting of the 1st and 2nd language

9102 SHOW_TOOLTIP --

- Display tooltip BYTE Immediately

-

-- 1 0 1 7/3 U

Description: If the MD has been set to 1, tooltips will be displayed.

9103 TOOLTIP_TIME_DELAY -s Time delay tooltip display BYTE Immediately

-

- - 1 0 60 7/3 U

Description: Time delay for display of the tooltips in seconds.

9105 HMI_WIDE_SCREEN --

- Display of the HMI as wide screen with OEM area always

visible

-

-- 0 0 1 7/2 M

Description: Display of the HMI as wide screen. Above the HMI there is a sepa-

BYTE PowerOn

rate application field that is designed by the machine manufacturer.

9106 SERVE_EXTCALL_PROGRAMS --

- Process EXTCALL calls BYTE PowerOn

-

-- 1 0 1 7/3 M

Description: HMI processes reload requirements of the NC for EXTCALL calls.

1-22

SINUMERIK 840D sl,, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 Machine and Setting Data

1.2 Display machine data

9107 DRV_DIAG_DO_AND_COMP_NAMES --

- Expanded drive diagnostics: DO and components BYTE Immediately

-

-- 0 0 3 7/3 I

Description: 0: DO and component type names

1: Real DO names and component type names

2: DO type names and real component names

3: Reale DO names and real component names

9108 ENABLE_EPS_SERVICES --

- Activation of ePS Network services BYTE Immediately

-

-- 0 0 1 7/3 M

Description: If the machine data has been set to 1, the "ePS Network services"

softkey appears as the operating area.

9110 ACCESS_HMI_EXIT --

- Protection level of exit softkey BYTE PowerOn

-

-- 1 0 7 7/2 M

Description: Protection level for the exit softkey (HMI restart) in the operat-

ing area menu

9900 MD_TEXT_SWITCH --

- Plaintexts instead of MD identifier BOOLEAN Immediately

-

-- 0 - - 7/3 U

Description: If the MD has been set to 1, clear text is displayed on the opera-

tor panel instead of the machine data identifiers.

9990 SW_OPTIONS --

- Enable HMI software options DWORD Immediately

-

-- 0 - - 1/1 I

Description: Here you can enable the HMI software options

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl,, Detailed Maschine Data Description (AMDsl), 03/2010

1-23

Machine and Setting Data 03/2010

1.3 General machine data

1.3 General machine data

Number Identifier Display filters Reference

Unit Name Data type Active

Attributes

System Dimension Default value Minimum value Maximum value Protection Class

Description: Description

1.3.1 System settings

10000 AXCONF_MACHAX_NAME_TAB N01, N11 K2,F1,G2,F2,K5,M1

- Machine axis name STRING PowerOn

710-6a2c 31 X1,Y1,Z1,A1,B1,C1 - - 7/2 M

710-31a10c 31 X1,Y1,Z1,A1,B1,C1,U1...- - 7/2 M

710-31a10c6 31 X1,Y1,Z1,A1,B1,C1 - - 7/2 M

720-6a2c 31 X1,Y1,Z1,A1,B1,C1 - - 7/2 M

720-31a10c 31 X1,Y1,Z1,A1,B1,C1,U1...- - 7/2 M

720-31a10c6 31 X1,Y1,Z1,A1,B1,C1 - - 7/2 M

730-6a2c 31 X1,Y1,Z1,A1,B1,C1 - - 7/2 M

730-31a10c 31 X1,Y1,Z1,A1,B1,C1,U1...- - 7/2 M

730-31a10c6 31 X1,Y1,Z1,A1,B1,C1 - - 7/2 M

Description: List of the machine axis identifiers.

The name of the machine axis is entered in this MD.

In addition to the fixed, defined machine axis identifiers "AX1",

"AX2" ..., user-defined identifiers for the machine axes can also

be assigned in this data.

The identifiers defined here can be used parallel to the fixed,

defined identifiers for addressing axial data (e.g. MD) and

machine axis-related NC functions (reference point approach, axial

measurement, travel to fixed stop).

Special cases:

• The input machine axis name must not conflict with the names

and assignments of the geometry axes (MD20060

$MC_AXCONF_GEOAX_NAME_TAB, MD20050

$MC_AXCONF_GEOAX_ASSIGN_TAB) or channel axes (MD20080

$MC_AXCONF_CHANAX_NAME_TAB, MD20070 $MC_AXCONF_MACHAX_USED).

• The input machine axis name must not be the same as the names

for Euler angles (MD10620 $MN_EULER_ANGLE_NAME_TAB), names for

path-relevant orientation (MMD10624

$MN_ORIPATH_LIFT_VECTOR_TAB), names for normal vectors

(MD10630 $MN_NORMAL_VECTOR_NAME_TAB), names for directional

vectors (MD10640 $MN_DIR_VECTOR_NAME_TAB), names for rotation

vectors (MD10642 $MN_ROT_VECTOR_NAME_TAB), names for intermediate vector components (MD10644 $MN_INTER_VECTOR_NAME_TAB),

names for intermediate circle point coordinates with CIP

(MD10660 $MN_INTERMEDIATE_POINT_NAME_TAB) or the names for

interpolation parameters (MD10650 $MN_IPO_PARAM_NAME_TAB).

1-24

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 Machine and Setting Data

1.3 General machine data

• The input machine axis name must not include any of the following reserved address letters:

D Tool offset (D function) E Reserved

F Feedrate (F function) G Preparatory function

H Auxiliary function (H function) L Subroutine call

M Miscellaneous function (M function) N Subblock

P Subroutine number of passes R Arithmetic parameters

S Spindle speed (S function) T Tool (T function)

The name must not include any keywords (e.g. DEF, SPOS etc.) or

pre-defined identifiers (e.g. ASPLINE, SOFT).

The use of an axis identifier consisting of a valid address letter

(A, B, C, I, J, K, Q, U, V, W, X, Y, Z), followed by an optional

numerical extension (1-99) gives slightly better block cycle times

than a general identifier.

If no identifier is assigned to a machine axis, then the predefined name ("AXn") applies to the nth machine axis.

Related to:

MD20060 $MC_AXCONF_GEOAX_NAME_TAB (geometry axis name in the

channel [GEOAxisno.]

MD20080 $MC_AXCONF_CHANAX_NAME_TAB (channel axis name in the

channel [Channelaxisno.]

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-25

Machine and Setting Data 03/2010

1.3 General machine data

10002 AXCONF_LOGIC_MACHAX_TAB N01 B3,K2

- Logical NCK machine axis image STRING PowerOn

-

- 31 AX1,AX2,AX3,AX4,AX5

,AX6...

Description: List of machine axes available on an NCU. (Logical NCK machine

axis image)

MD10002 $MN_AXCONF_LOGIC_MACHAX_TAB creates another NCK global,

logical layer between the channel axis layer and the machine axes

in an NCU or NCU grouping. This layer is called the "Logic NckMachineAxImage", abbreviation: LAI ).

Axes can only be assigned between different NCUs via this new

intermediate layer!

The entry $MN_AXCONF_LOGIC_MACHAX_TAB[ n] = NCj_AXi assigns the

machine axis i on the NCU j to the axis index "n" in the LAI.

This makes the following assignments possible:

1. Local axes (default setting: AX1, AX2 ... AX31)

The entry $MN_AXCONF_LOGIC_MACHAX_TAB[n] = AX3 assigns the

local axis AX3 to axis index n. (Default setting AX3 is present

for n = 3 . Thus there is compatibility in software version 5

for MD blocks for software versions up to 4).

2. Link axes (axes that are physically connected to another

NCU). The entry $MN_AXCONF_LOGIC_MACHAX_TAB[n] = NCj_AXi assigns

axis AXi on NCU j to axis index n (link axis).

Limits:

n Machine axis address (of the local NCU)1 ... 31

j NCU number1 ... 16

i Machine axis address (of the local/remote NCU)1 ... 31

3. Axis container in which there are once again either local or

link axes. The entry $MN_AXCONF_LOGIC_MACHAX_TAB[n] = CTr_SLs

assigns container r and slot s to axis index n.

Limits:

n Machine axis address (of the local NCU)1 ... 31

r Container number1 ... 16

s Slot number (location) in the container1 ... 32

The channel layer is formed via the related machine data $MD20070

$MC_AXCONF_MACHAX_USED and no longer points (small P5) directly to

the machine axes but to the new LAI layer.

$MC_AXCONF_MACHAX_USED [k]=n assigns the LAI axis number "n" to

the axis index "k" in the channel layer.

The machine axis and the corresponding NCK can then be determined

from the LAI axis number.

If a number of NCUs point to the same machine axis in the cluster

as a result of MD10002 $MN_AXCONF_LOGIC_MACHAX_TAB, then the axial

machine data MD30554 $MA_AXCONF_ASSIGN_MASTER_NCU must define

which NCU generates the master NCU and the setpoint values for the

position controller after startup.

Related to:

MD12... $MN_AXCT_AXCONF_ASSIGN_TABi (make entries in containers

i)

- - 3/2 M

1-26

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 Machine and Setting Data

1.3 General machine data

10010 ASSIGN_CHAN_TO_MODE_GROUP N01, N02, N11 K1,K5

- Channel valid in mode group DWORD PowerOn

710-6a2c 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

710-31a10c 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

710-31a10c6 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

720-6a2c 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

720-31a10c 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

720-31a10c6 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

730-6a2c 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

730-31a10c 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

730-31a10c6 10 1,0,0,0,0,0,0,0,0,0,0,0,0

,0,0,0

Description: This MD assigns the channel to a mode group

Entry value 1 => Assigned to 1st mode group

Entry value 2 => Assigned to 2nd mode group

etc.

From software version 4, it is permissible not to assign a mode

group number to individual channels.

Channel gaps are allowed, in order to favor uniform configuration

in similar types of machines. In this case, the number 0 is

assigned to the channel instead of assigning a mode group number

equal to or greater than 1. The channel is not activated, however

it is handled like an active channel when counting the channels.

E.g.

ASSIGN_CHAN_TO_MODE_GROUP[0] = 1

ASSIGN_CHAN_TO_MODE_GROUP[1] = 1

ASSIGN_CHAN_TO_MODE_GROUP[2] = 0 ; gap

ASSIGN_CHAN_TO_MODE_GROUP[3] = 1

Application example:

Select desired channel via HMI and enter with MD10010

$MN_ASSIGN_CHAN_TO_MODE_GROUP = 1.

Note:

This MD must still be entered even when only one mode group is

present.

0 2 7/2 M

0 10 7/2 M

0 4 7/2 M

0 2 7/2 M

0 10 7/2 M

0 4 7/2 M

0 2 7/2 M

0 10 7/2 M

0 4 7/2 M

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-27

Machine and Setting Data 03/2010

1.3 General machine data

10050 SYSCLOCK_CYCLE_TIME N01, N05, N11, - G3,G2,R1

s System clock cycle DOUBLE PowerOn

SFCO

- - 0.002 0.001 0.008 7/2 M

Description: Basic cycle time of the system software

The cycle times settings of cyclical tasks (position controller/

IPO ) are multiples of this basic cycle. Apart from special applications in which POSCTRL_SYSCLOCK_TIME_RATIO is set greater than

1, the basic cycle corresponds to the position controller cycle.

For PROFIBUS/PROFINET:

In the case of systems with a PROFIBUS DP connection, this MD cor-

responds to the PROFIBUS DP cycle time. This time is read from the

configuration file (SDB-Type-2000) during startup and written to

the MD.

This MD can only be changed via the configuration file.

Note:

Reducing this MD can result in an automatic correction of

POSCTRL_CYCLE_DELAY that cannot be undone by a subsequent

increase!

Details:

The basic cycle is incremented in multiples (

SYSCLOCK_SAMPL_TIME_RATIO ) of units of the measured value sampling cycle. During system startup, the entered value is automatically rounded up to a multiple of this incrementation.

Note:

Discrete timer division ratios can give rise to the entered

value producing a value that is not an integer after a Power

OFF/ON.

For example:

Input = 0.005s

after Power OFF/ON =0.00499840

or

Input = 0.006s

after Power OFF/ON =0.0060032

10059 PROFIBUS_ALARM_MARKER N05 G3

- PROFIBUS/PROFINET alarm flag (internal only) BYTE PowerOn

NBUP, NDLD

-- 0 - - 0/0 S

Description: PROFIBUS/PROFINET alarm flag:

In this machine data, alarm requests for the PROFIBUS/PROFINET

layer are stored beyond a reboot.

If conflicts arise between machine data 10050, 10060, 10070 and

the data in the SDB on startup, the machine data are matched

according to SDB, and an alarm is output on the next start up.

These alarm requests are stored here.

Related to:

MD10050 $MN_SYSCLOCK_CYCLE_TIME,

MD10080 $MN_SYSCLOCK_SAMPL_TIME_RATIO

1-28

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

03/2010 Machine and Setting Data

1.3 General machine data

10060 POSCTRL_SYSCLOCK_TIME_RATIO N01, N05 G3

- Factor for position control cycle DWORD PowerOn

SFCO

- - 1 1 31 7/2 M

Description: The position-control cycle is stated as a multiple of the time

units of the system basic cycle SYSCLOCK_CYCLE_TIME.

The regular setting is 1. The position-control cycle then corre-

sponds to the system basic cycle SYSCLOCK_CYCLE_TIME.

Setting values > 1 costs computing time for the operating system

to calculate the additional timer interrupts, and should therefore

only be used in those cases in which there is a task in the system

that is to run faster than the position-control cycle.

For PROFIBUS/PROFINET:

In the case of systems with a PROFIBUS DP connection, this MD rep-

resents the ratio between the PROFIBUS DP cycle and the position

controller cycle.

10061 POSCTRL_CYCLE_TIME N01, N05 G3

- Position control cycle DOUBLE PowerOn

-

-- 0.0 - - 7/RO S

Description: Position controller cycle time:

Display of the position controller cycle time (not modifiable !).

It is compiled internally from the machine data

SYSCLOCK_CYCLE_TIME and POSCTRL_SYSCLOCK_TIME_RATIO.

10062 POSCTRL_CYCLE_DELAY N01, N05 G3

s Position control cycle offset DOUBLE PowerOn

-

- - 0.0 0.000 0.008 7/2 M

Description: For PROFIdrive only:

Only relevant to operation with PROFIBUS drives.

Position controller cycle offset in relation to the PROFIBUS DP

cycle.

Offsets that exceed the set DP cycle or are smaller than the maxi-

mum Tdx, are automatically corrected to a substitute value half

the size of the DP cycle.

MD10062 $MN_POSCTRL_CYCLE_DELAY > 0:Default for position controller offset

MD10062 $MN_POSCTRL_CYCLE_DELAY = 0:Automatic determination of the

position controller offset with max. Tdx from STEP7 project

Tdx_max is determined through all equidistant buses.

The actually active offset value is displayed in MD 10063[1].

Note:

MD10062 $MN_POSCTRL_CYCLE_DELAY > 0 can reduce MD10050

$MN_SYSCLOCK_CYCLE_TIME to the automatic correction of this MD

that cannot be undone by a subsequent increase.

Recommendation:

In this case set the original value or default value once again.

Siemens AG 2010 All Rights Reserved

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

1-29

Machine and Setting Data 03/2010

1.3 General machine data

10063 POSCTRL_CYCLE_DIAGNOSIS EXP, N01, N05 s Active timing DOUBLE PowerOn

-

- 3 0.0,0.0,0.0 - - 7/RO M

Description: Diagnostic data related to the PROFIBUS/PROFINET cycle.

[0]: Latest date at which the actual values must be available

(Tdx)

[1]: Actually active position controller cycle offset (Tm)

[2]: Latest date at which the setpoints were output by the posi-

tion controller

Diagnostic data are initialized with ZERO with each NCK power up

10065 POSCTRL_DESVAL_DELAY N01 B3

s Position setpoint delay DOUBLE PowerOn

-

- - 0.0 -0.1 0.1 7/2 M

Description: This MD can parameterize a delay of the setpoints in the position

contoller. The area of application is NCU-link when different

position control cycles are parameterized on the NCUs and if the

axes should nevertheless interpolate with one another. (Used for

example for non-circular turning.)

This MD is used to optimize the automatic setting.

Related to:

MD32990 $MA_POSCTRL_DESVAL_DELAY_INFO

10070 IPO_SYSCLOCK_TIME_RATIO N01, N05, N11, - G3,R1

- Factor for interpolation cycle DWORD PowerOn

SFCO

- - 4 1 100 7/2 M

Description: The interpolator cycle is stated as a multiple of the time units

of the system basic cycle SYSCLOCK_CYCLE_TIME.

Only integer multiples of the position control cycle can be set

(set in POSCTRL_SYSCLOCK_TIME_RATIO). Values that are not an integer multiple of the position control cycle are automatically

increased to the next integer multiple of the position control

cycle before they become active (on next power up).

This is accompanied by alarm 4102 "IPO cycle increased to [ ] ms".

10071 IPO_CYCLE_TIME N01, N05, N11, - G3

- Interpolator cycle DOUBLE PowerOn

-

-- 0.0 - - 7/RO S

Description: Interpolation time

Display of the interpolator cycle time (not modifiable !).

It is compiled internally from the machine data

SYSCLOCK_CYCLE_TIME and IPO_SYSCLOCK_TIME_RATIO.

1-30

SINUMERIK 840D sl, Detailed Maschine Data Description (AMDsl), 03/2010

Siemens AG 2010 All Rights Reserved

Loading...

Loading...