siemens 802S Programming Manual

Operating and Programming 01/2002 Edition

Milling

SINUMERIK 802S/802C

SINUMERIK 802S

Introduction 1

Power ON 2

SINUMERIK 802C

Operation and Programming

Milling

Setup 3

Manually Controlled

Operation

Automatic Mode 5

Part Programming 6

4

Valid for

Control System Software Version

SINUMERIK 802S 3

SINUMERIK 802C 3

01.2002 Edition

Services and Diagnosis 7

Programming 8

Cycles 9

3ls

SINUMERIKDocumentation

Printing history

Brief details of this edition and previous editions are listed below.

IThe status of each edition is shown by the code in the ”Remarks” column.

Status code in the “Remarks” column:

A New documentation.. . . . .

B Unrevised reprint with new Order No.. . . . .

C Revised edition with new status. . . . . .

If actual changes have been made on the page since the last edition,

this is indicated by a new edition coding in the header on the page.

Edition Order–No. Remark

02.99 6FC5598–2AA10–0BP1 A

04.00 6FC5598–3AA10–0BP1 C

01.02 6FC5598–3AA10–0BP2 C

This Manual is included on the documentation on CD–ROM (DOCONCD)

Edition Order–No. Remark

11.02 6FC5298–6CA00–0BG3 C

Trademarks

SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr and SIMODRIVEr are registered

trademarks of Siemens. Third parties using for their own purposes any other names in this document which

refer to trademarks might infringe upon the rights of trademark owners.

This publication was produced with Interleaf V 7

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for demages. All rights, including rights created by patent

grant or registration of utility model or design, are reserved.

Siemens AG 2002. All rights reserved.

Printed in the Federal Republic of Germany

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this document correspond to

the hardware and software described. Nonetheless, differences might

exist and therefore we cannot guarantee that they are completely

identical. The information contained in this document is, however,

reviewed regularly and any necessary changes will be included in the

next edition. We welcome suggestions for improvement.

Subject to change without prior notice.

Siemens–AktiengesellschaftBestell–Nr. 6FC5598–3AA10–0BP2

Safety notices

!

!

!

This Manual contains notices intended to ensure your personal safety and to avoid material damage. The notices

are highlighted by a warning triangle and, depending on the degree of hazard, represented as shown below:

Danger

indicates that loss of life, severe personal injury or substantial material damage will result if the appropriate pre-

cautions are not taken.

Warning

indicates that loss of life, severe personal injury or substantial material damage may result if the appropriate pre-

cautions are not taken.

Caution

indicates that minor personal injury or material damage may result if the appropriate precautions are not taken.

Caution

without a warning triangle means that a material damage can occur if the appropriate precau-

tions are not taken.

Attention

means that an undesirede event or status can occur if the appropriate note is not observed.

Note

is used to draw your special attention to an important information on the product, the handling of the product or the

corresponding part of the documentation.

Qualified personnel

Start–up and operation of a device may only be carried out by qualified personnel. Qualified personnel as referred to in the safety notices provided in this Manual are persons who are authorized to start up, ground and tag

devices, systems and circuits according to the relevant safety standards.

Usage as per intended purpose

Please observe the following:

Warning

!

The device may only be used for the cases of application, as intended by the Catalog, and only in conjunction with

third–party devices and components recommended or approved by Siemens.

The proper and safe operation of the product requires transport, storage and installation according to the relevant

instructions and qualified operation and maintenance at the prescribed intervals.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

v

Table of Contents

1 Introduction 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Screen Layout 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Operating areas 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Overview of the most important softkey functions 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Pocket calculator 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Basic principles 1-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Turning On and Reference Point Approach 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Setup 3-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Entering tools and tool offsets 3-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Creating a new tool 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Tool compensation data 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Determining the tool offsets 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Entering/modifying zero offsets 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Determining the zero offset 3-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Programming the setting data – “Parameters” operating area 3-36. . . . . . . . . . . . . . . . . . . . . . . .

3.8 R parameters - “Parameters” operating area 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Manually Operated Mode 4-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Jog mode - ”Machine” operating area 4-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Assigning handwheels 4-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 MDA Mode (Manual Data Input) - “Machine” operating area 4-43. . . . . . . . . . . . . . . . . . . . . . . . .

5 Automatic Mode 5-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Selecting/starting a part program - “Machine” operating area 5-48. . . . . . . . . . . . . . . . . . . . . . . .

5.2 Block search - “Machine” operating area 5-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Stopping/cancelling a part program - “Machine” operating area 5-49. . . . . . . . . . . . . . . . . . . . . .

5.4 Repositioning after interruption 5-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Program execution from external (V.24 interface) 5-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Teach In 5-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Part Programming 6-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Entering a new program - “Program” operating area 6-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Editing part programs - “Program” operating area 6-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Programming support 6-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Vertical menu 6-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Cycles 6-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Contour 6-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.4 Free softkey assignment 6-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Services and Diagnosis 7-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Data transfer via the V24 Interface 7-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Interface parameters 7-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Special functions 7-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Interface parameterization 7-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

7.2 Diagnosis and start–up - ”Diagnostics” operating area 7-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Programming 8-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Fundamentals of NC programming 8-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Program structure 8-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Word structure and address 8-100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Block structure 8-100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.4 Character set 8-102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.5 Overview of instructions 8-104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Position data 8-114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Plane selection: G17 to G19 8-114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Absolute/incremental dimensions: G90, G91 8-115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Metric/inch dimensions: G71, G70 8-116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Programmable zero offset and rotation: G158, G258, G259 8-117. . . . . . . . . . . . . . . . . . . . . . . . .

8.2.5 Workpiece clamping – settable zero offset:

G54 to G57, G500, G53 8-119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Axis movements 8-121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Linear interpolation at rapid traverse: G0 8-121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Linear interpolation at feedrate: G1 8-122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Circular interpolation: G2, G3 8-123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.4 Circular interpolation via intermediate point: G5 8-126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.5 Thread cutting with constant lead: G33 8-127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.6 Tapping with compensating chuck: G63 8-128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.7 Thread interpolation: G331, G332 8-129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.8 Fixed–point approach: G75 8-131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.9 Reference point approach: G74 8-131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.10 Feedrate F 8-131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.11 Feed overrride for circles: G900, G901 8-132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.12 Exact stop / continuous–path operation: G9, G60, G64 8-133. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.13 Dwell time: G4 8-136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Spindle movements 8-137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Spindle speed S, directions of rotation 8-137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Spindle speed limitation: G25, G26 8-137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Spindle positioning: SPOS 8-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Rounding, chamfer 8-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Tool and tool offset 8-141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 General notes 8-141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 Tool T 8-142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.3 Tool offset number D 8-142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.4 Selection of tool radius offset: G41, G42 8-146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.5 Behavior at corners: G450, G451 8-148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.6 Tool radius compensation OFF: G40 8-149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.7 Special cases of tool radius compensation 8-151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.8 Example of tool radius compensation 8-153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Miscellaneous function M 8-154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 Arithmetic parameters R 8-155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 Program branches 8-157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.1 Labels – destination for program branches 8-157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.2 Unconditional program branches 8-157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.3 Conditional branches 8-158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.4 Example of program with branches 8-160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10 Subroutine technique 8-161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Cycles 9-165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 General information about standard cycles 9-165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 Overview of cycles 9-165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

vii

9.1.2 Error messages and error handlingin cycles 9-166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Drilling cycles 9-168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Drilling, spot facing – LCYC82 9-168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Deep hole drilling – LCYC83 9-170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.3 Tapping without compensating chuck – LCYC84 9-174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.4 Tapping with compensating chuck – LCYC840 9-176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.5 Boring – LCYC85 9-179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Drilling patterns 9-181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 Drilling a row of holes – LCYC60 9-181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 Hole circle – LCYC61 9-185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Milling cycles 9-187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 Cutting square pockets, slots and circular pockets – LCYC75 9-187. . . . . . . . . . . . . . . . . . . . . . . .

viii

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

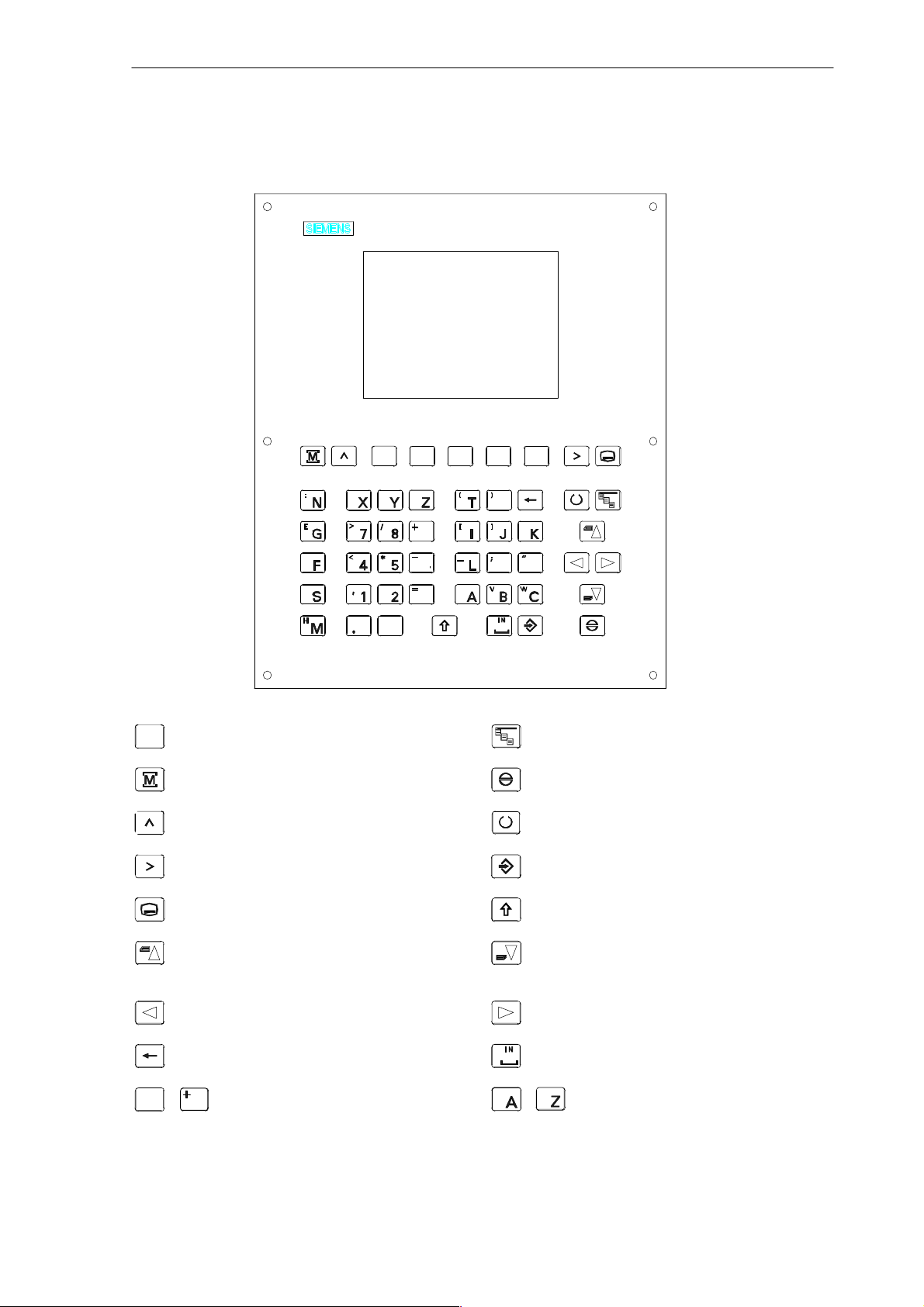

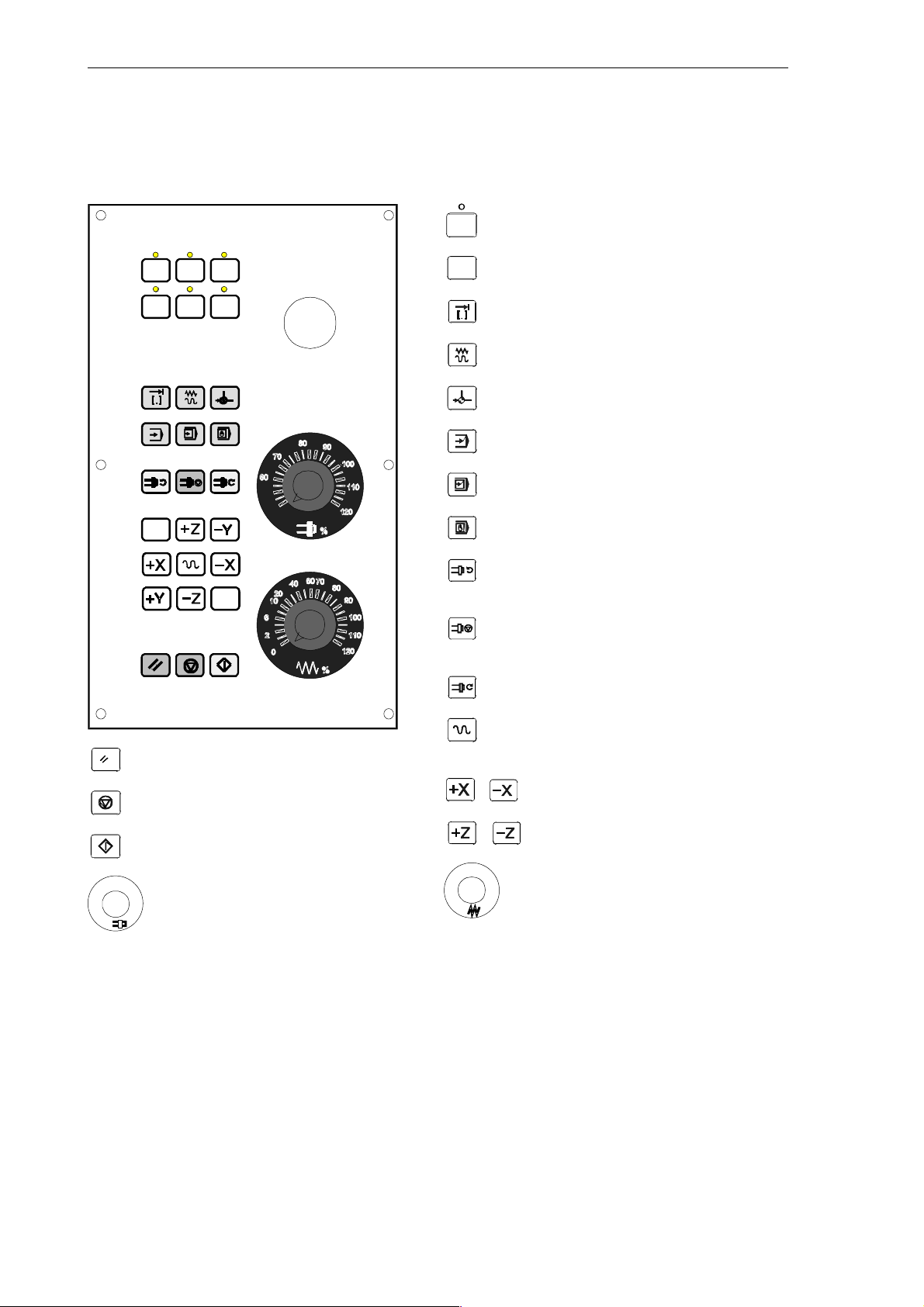

SINUMERIK 802S Slimline Operator Panel OP

D

9

O

Q

6

3

$

0

P

R

U

S

Softkey

Machine area key

Recall key

ETC key

Area switchover key

Cursor UP

with shift: page up

Cursor LEFT

S

Delete key (backspace)

$

0

9

Numerical keys

shift for alternative assignment

U

Alphanumeric keys

Vertical menu

Acknowledge alarm

Selection key/toggle key

ENTER / input key

Shift key

Cursor DOWN

with shift: page down

Cursor RIGHT

SPACE (INSERT)

shift for alternative assignment

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

ix

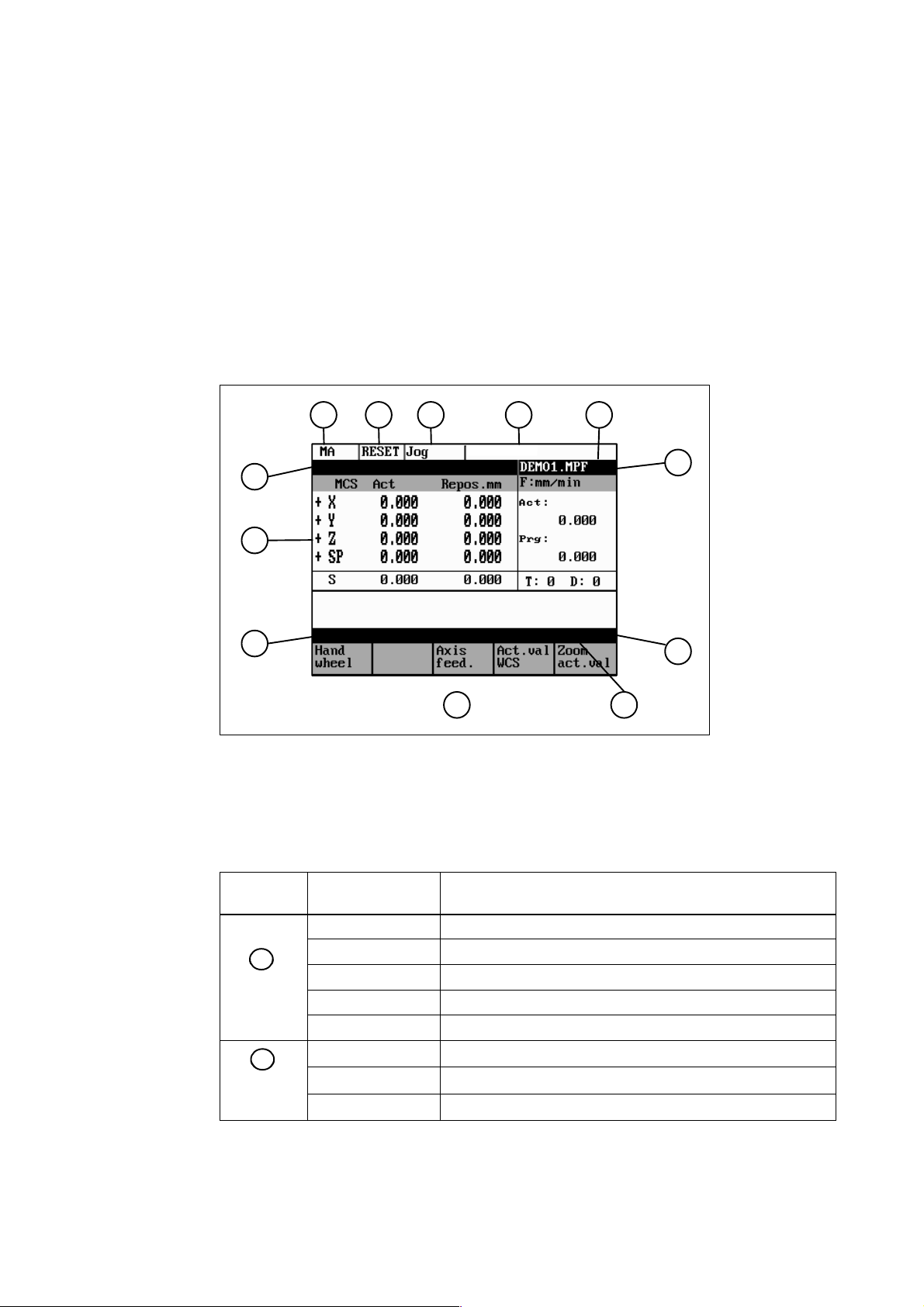

External Machine Control Panel

User–defined key with LED

User–defined key without LED

INCREMENT

JOG

REFERENCE POINT

AUTOMATIC

SINGLE BLOCK

MANUAL DATA

SPINDLE START LEFT

Counterclockwise direction

SPINDLE START RIGHT

Clockwise direction

SPINDLE STOP

RAPID TRAVERSE OVERLAY

RESET

NC STOP

X axis

NC START

Z axis

%

%

Spindle Speed Override

Feed Rate Override

(optional)

x

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Introduction

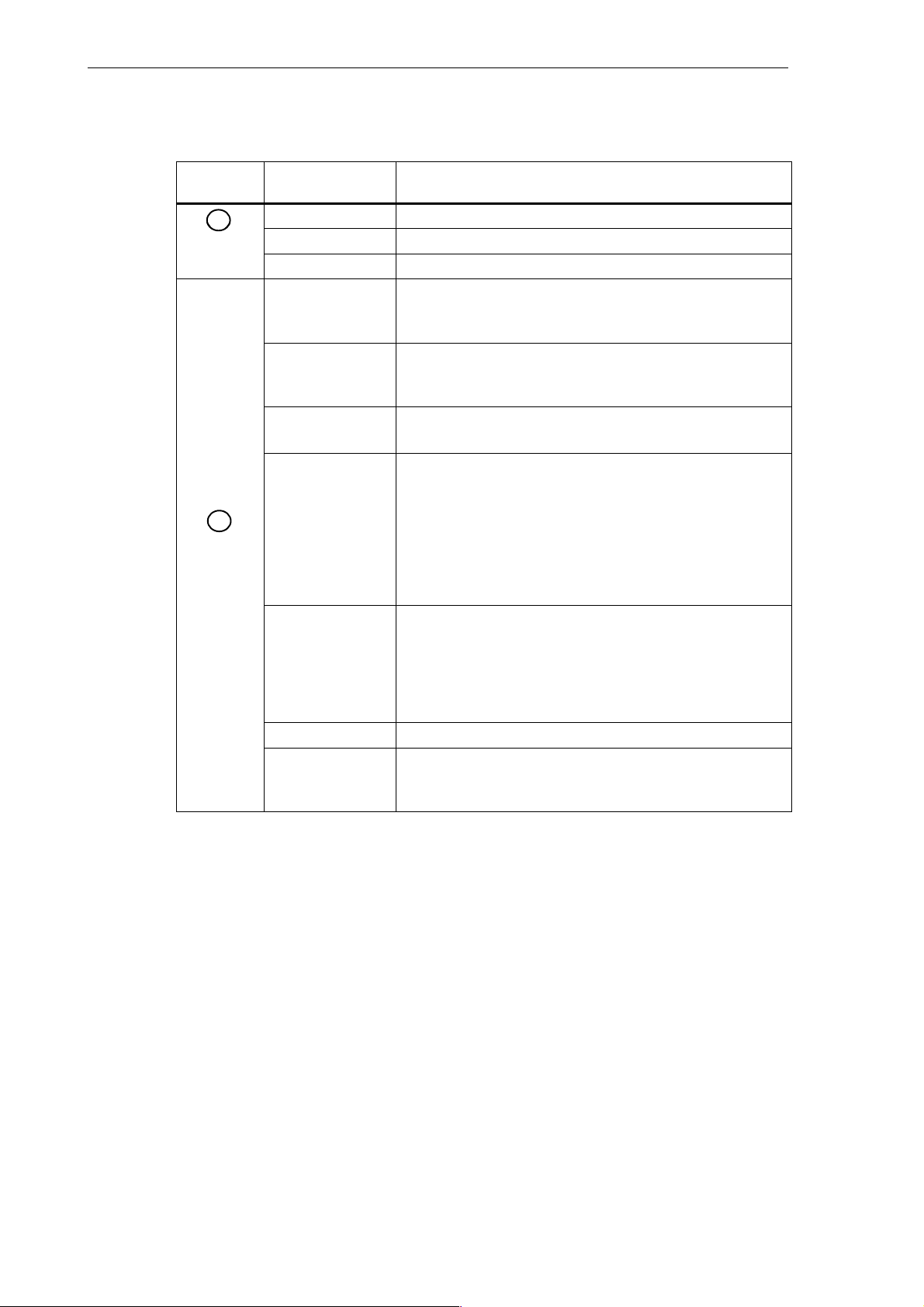

1.1 Screen Layout

1

1 2 3 4

5

8

9

11

Fig. 1-1 Screen layout

The abbreviations on the screen stand for the following:

Table 1-1 Explanation of display elements

7

6

10

12

Display

Element

1

1

Active operating area

2

2

Program

status

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

Abbreviation Meaning

MA Machine

PA Parameter

PR Programming

DI Services

DG Diagnosis

STOP Programm stopped

RUN Program running

RESET Program aborted

1-11

Introduction

1.1 Screen Layout

Table 1-1 Explanation of display elements

Display

Element

3

3

Operating

mode

4

Status

display

MeaningAbbreviation

Jog Manual traverse

MDA Manual input with automatic function

Auto Automatic

SKP Skip block

Program blocks marked by a slash in front of the block

number are ignored during program execution.

DRY Dry run feed

Traversing movements are executed at the feed specified

in the Dry Run Feed setting data.

ROV Rapid traverse override

The feed override also applies to rapid feed mode.

SBL Single block with stop after each block

When this function is active, the part program blocks are

processed separately in the following manner:

Each block is decoded separately, the program is stopped

at the end of each block. The only exception are thread

blocks without dry run feed. In this case, the program is

stopped only when the end of the current thread block is

reached. SBL can only be selected in the RESET state.

M1 Programmed stop

When this function is active, the program is stopped at

each block in which the miscellaneous function M01 is

programmed.

In this case, the message “5 stop M00/M01 active“ appears on the screen.

PRT Program test

1...1000 INC Incremental mode

If the control is in the Jog mode, incremental dimension is

displayed instead of the active program control function.

1-12

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Table 1-1 Explanation of display elements

Introduction

1.1 Screen Layout

Display

Element

5

Operational

messages

6

10

11

12

13

14

15

16

17

18

19

20

21

22

23

MeaningAbbreviation

1

2

3

4

5

6

7

8

9

Stop: No NC Ready

Stop: EMERGENCY STOP active

Stop: Alarm active with stop

Stop: M0/M01 sctive

Stop: Block ended in SBL mode

Stop: NC STOP active

Wait: Read–in enable missing

Wait: Feed enable missing

Wait: Dwell time active

Wait: Auxiliary function acknowl. missing

Wait: Axis enable missing

Wait: Exact stop not reached

Wait: For spindle

Wait: Feed override to 0%

Stop: NC block incorrect

Wait: Block search active

Wait: No spindle enable

Wait: Axis feed value 0

Program

name

7

Alarm line

8

Working

window

9

Recall

symbol

10

Menu

extension

11

Softkey bar

12

Vertical

menu

The alarm line is only displayed if an NC or PLC alarm is active. The alarm line contains the alarm number and reset criterion of the most recent alarm.

Working window and NC display

This symbol is displayed above the softkey bar when the operator is in a lower–level menu.

When the Recall key is pressed, you can return to the next–

higher menu without saving data.

ETC is possible

If this symbol appears above the softkey bar, further menu

functions are provided. These functions can be activated

by the ETC key.

If this symbol is displayed above the softkey bar, further menu

functions are provided. When the VM key is pressed, these

functions appear on the screen and can be selected by Cursor UP and Cursor DOWN.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

1-13

Introduction

1.2 Operating areas

1.2 Operating areas

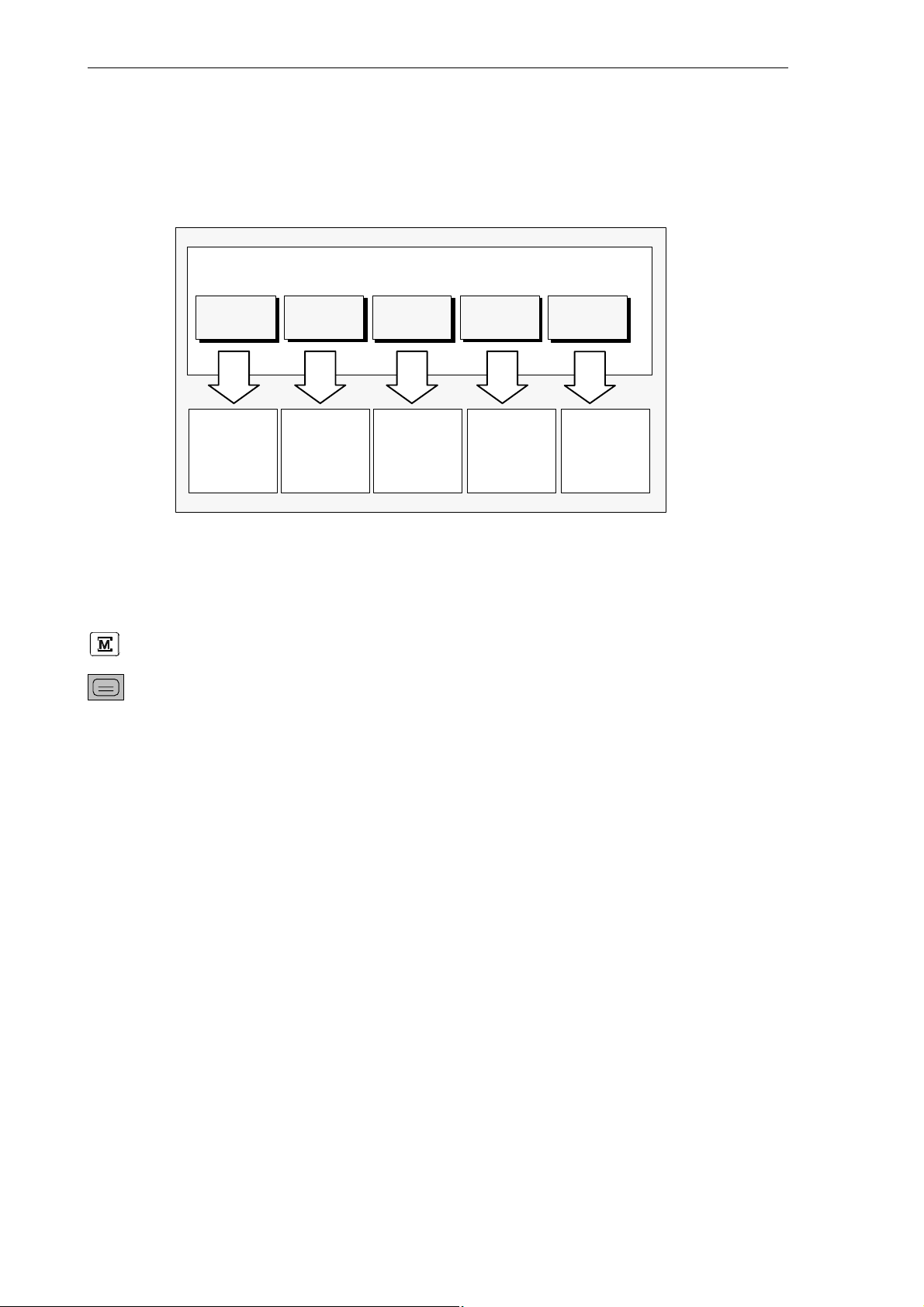

The basic functions are grouped in the CNC into the following operating areas:

Operating areas

Machine Parameter Program Services

Executing

part programs

Manual

control

Fig. 1-2 SINUMERIK 802S operating areas

Editing program data

Switching between the operating areas

Press the “Machine area” key for direct access to the “Machine” operating area.

Use the area switching key to return from any operating area to the main menu.

Press the area switching key twice to return to the previous operating area.

After turning on the control system, you will always find yourself in the

Machine operating area.

Creating

part programs

Data

import /

export

Diagnosis

Alarm display

Start–up

Protection levels

Sensible points of the control system are password–protected against entering and modifying

data.

However, the operator can alter the classes of protection in the “Machine data display” menu

in the “Diagnosis” operating area.

Default: protection level 3.

In the following menus, entering and modifying data depends on the set protection class:

S tool offsets

S zero offsets

S setting data

S V24 setting

1-14

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

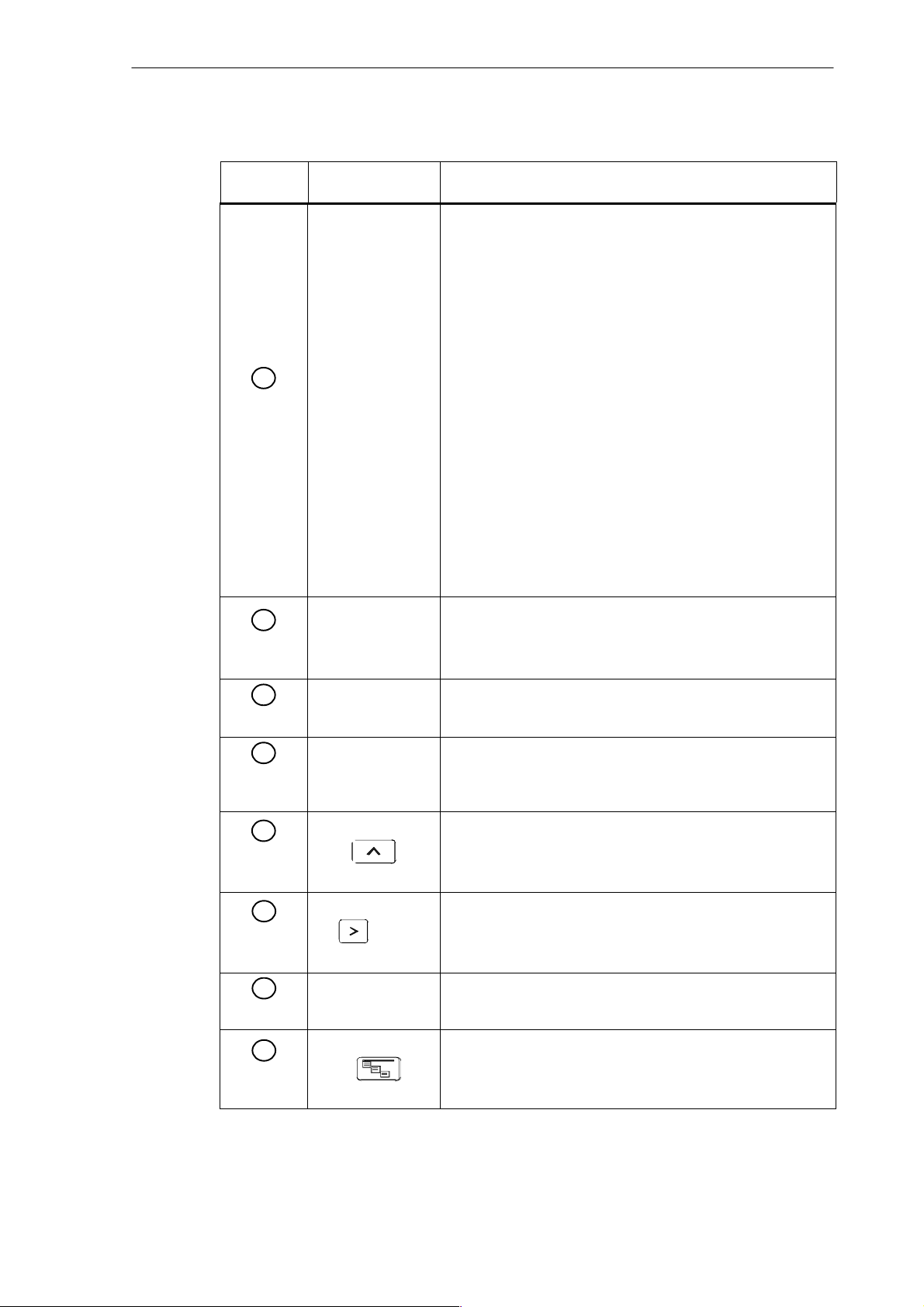

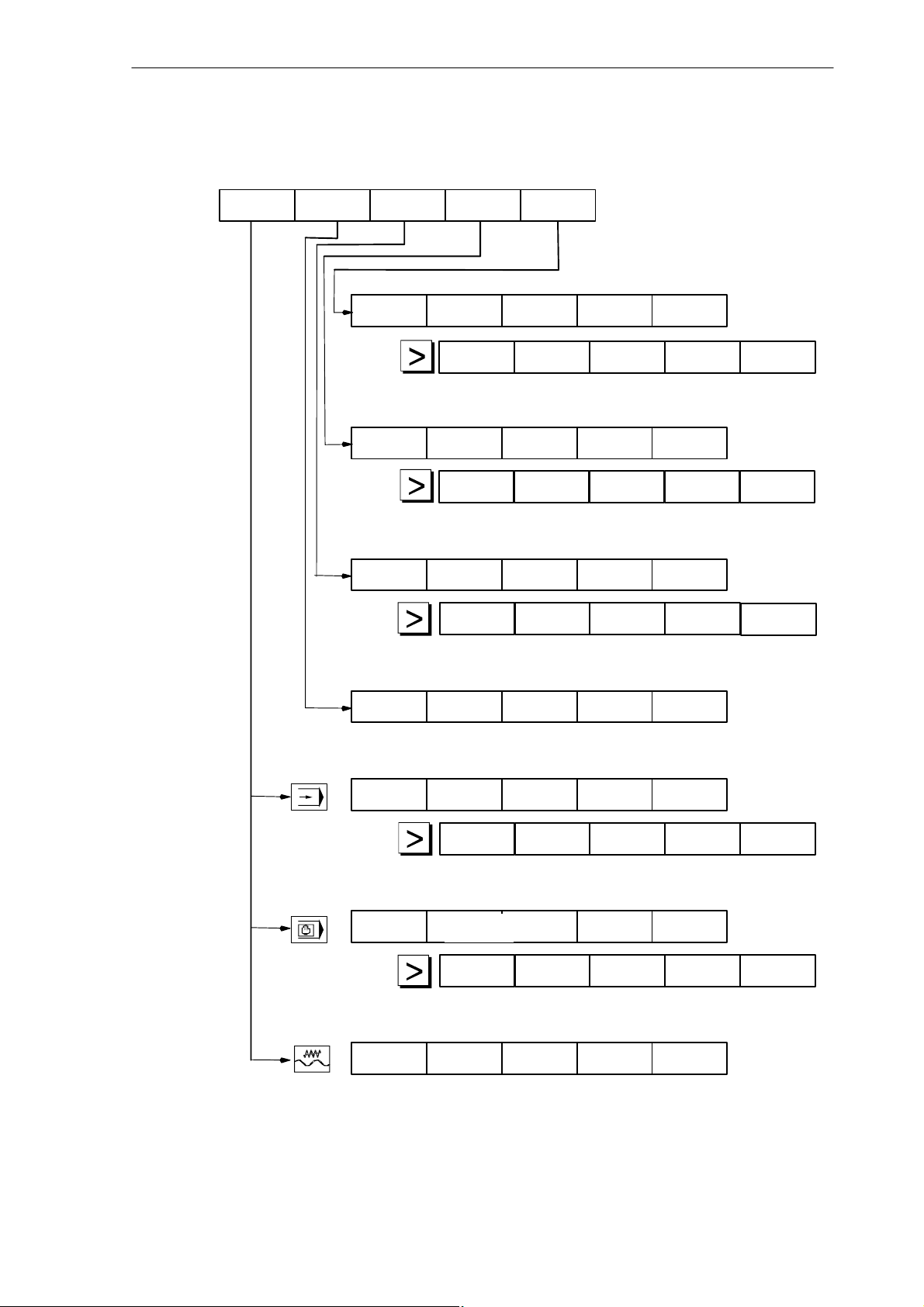

1.3 Overview of the most important softkey functions

1.3 Overview of the most important softkey functions

Introduction

Machine

Parameters Program

Alarms

Data Data

in out

Progr.

Services

Service

display

Display Display

bright. darker

RS232

setting

Execut

f. ext.

Cycles

New Copy

Diagnosis

Start–up

Change

lang.

Error

log

Selection

Delete Rename

Machine

data

Show

Open

Memory

info

R Tool Setting Zero

parameters offset data

Program

control WCS act.val.

Zoom

block

Axis

feed

Block

search

Zoom

block

Axis

feed

Handwheel

Axis

feed

Execut

f. ext.

offset

Act.val. Zoom

Zoom

G funct.

Act.val.

WCS

Zoom

act. val.

Zoom

G funct.

Act.val.

WCS/MCS

Zoom

act.val.

Zoom

M funct.

Zoom

M funct.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

1-15

Introduction

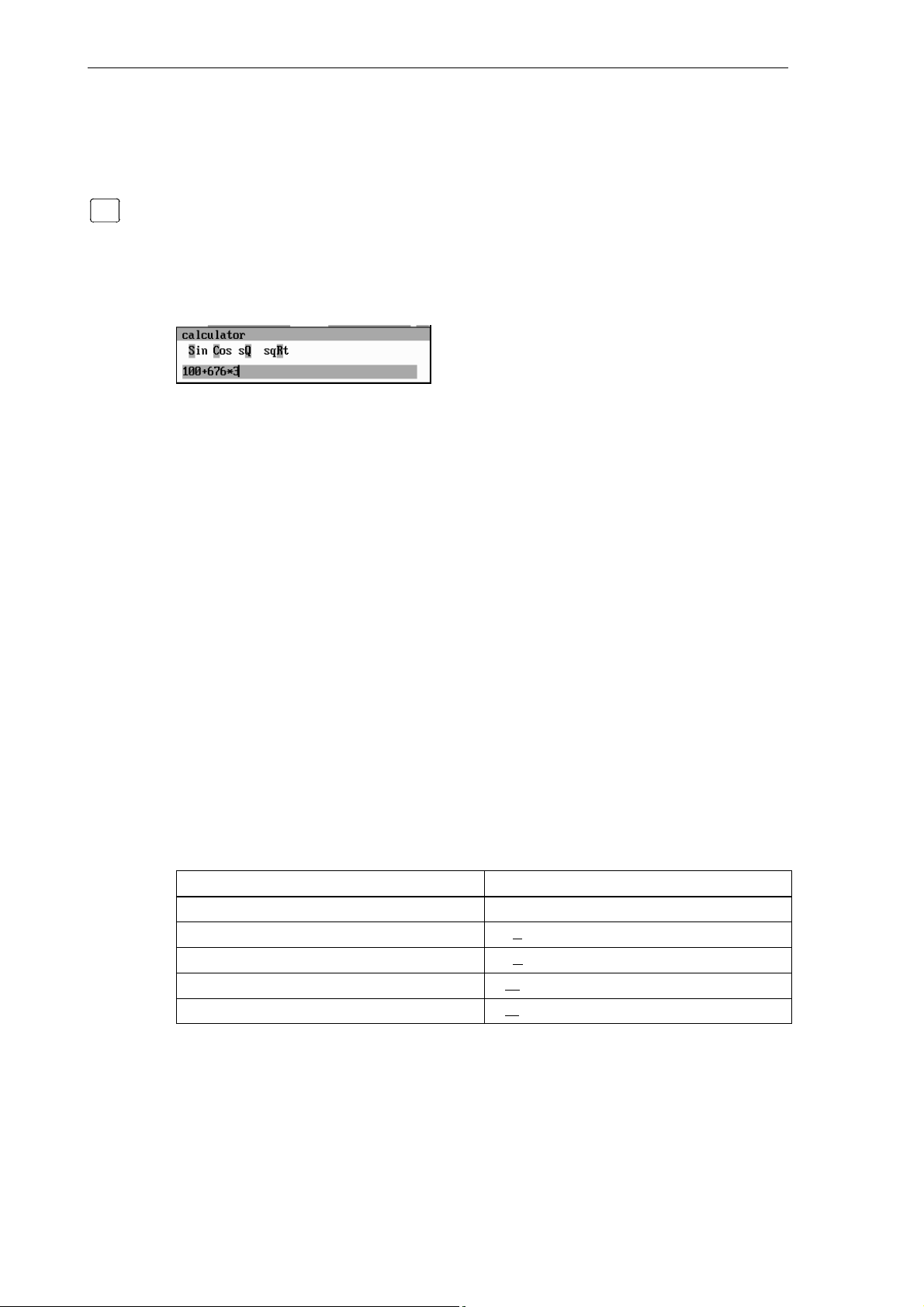

1.4 Pocket calculator

1.4 Pocket calculator

=

3

This function can be activated for all input fields intended for entry of numerical values by means of

the “=” character. To calculate the required value, you can use the four basic arithmetic operations,

and the functions sine, cosine, squaring, as well as the square root function.

If the input field is already loaded with a value, this function writes the value in the input line of

the pocket calculator.

Fig. 1-3 Pocket calculator

Permissible character

The following characters are permitted for input:

+ Value X plus value Y

– Value X minus value Y

* Value X multiplied with value Y

/ Value X divided by value Y

S Sine function

The value X in front of the input cursor is replaced by the value sin(X).

C Cosine function

The value X in front of the input cursor is replaced by the value cos(X).

Q Square function

The value X in front of the input cursor is replaced by the value X

R Square root function

The value X in front of the input cursor is replaced by the value √X.

Calculation examples

100 + (67*3) 100+67*3

sin(45_) 45 S –> 0.707107

cos(45_) 45 C –> 0.707107

2

4

√4 4 R –> 2

The calculation is carried out when the Input key is pressed. The function writes the result to

the input field and automatically closes the pocket calculator.

2.

Task Input

4 Q –> 16

1-16

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Softkeys

Introduction

1.4 Pocket calculator

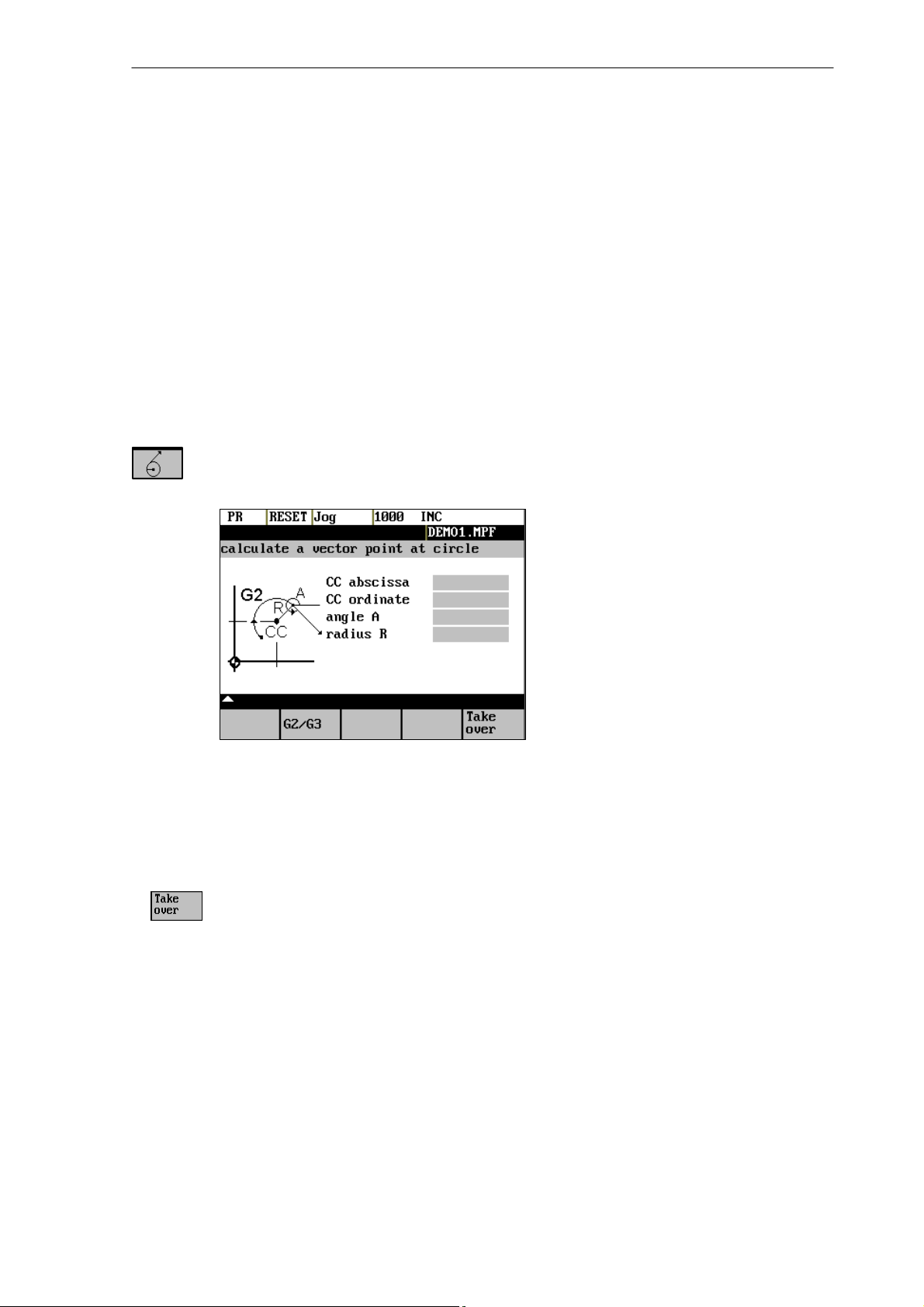

To calculate auxiliary points on a contour, the pocket calculator provides the following functions:

S calculating the tangential transition between a circle sector and a straight line

S moving a point in a plane

S converting polar coordinates into Cartesian coordinates

S adding the second end point of a contour section ’straight line – straight line’ given via an-

gular interrelation.

These functions are directly linked with the input fields of the programming support. Any values in this input field are written by the pocket calculator into the input line, and the result is

automatically copied into the input fields of the programming support.

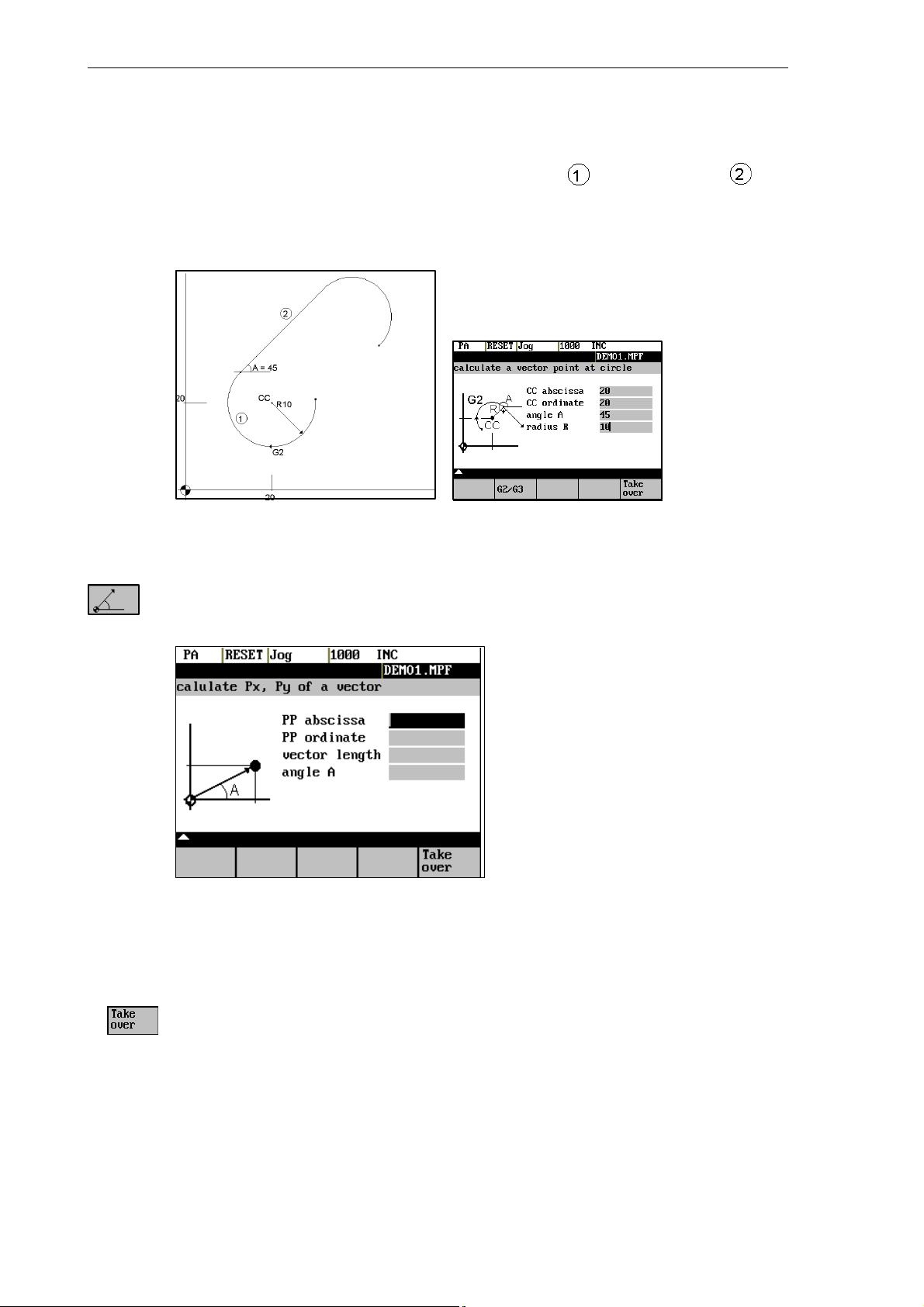

This function is used to calculate a point on a circle. The point results from the angle of the created

tangent and the direction of rotation of the circle.

Fig. 1-4 Calculation of a point on a circle

Enter the circle center, the angle of the tangent and the radius of the circle.

Use the softkeys G2 / G3 to define the direction of rotation of the circle.

The values of abscissa and ordinate are calculated. The abscissa is the first axis of the plane, and

the ordinate the second axis of the plane.

Example

If plane G17 is active, the abscissa is the X axis, and the ordinate the Y axis.

The value of the abscissa is copied into that input field from which the pocket calculator function has been called, and the ordinate value into the next following input field.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

1-17

Introduction

1.4 Pocket calculator

Example

Calculating the intersection point between the circle sector and the straight line .

Given: Radius: 10

Circle center point: X 20 Y20

Ongoing angle of the straight line: 45°

Result: X = 12.928

Y = 27.071

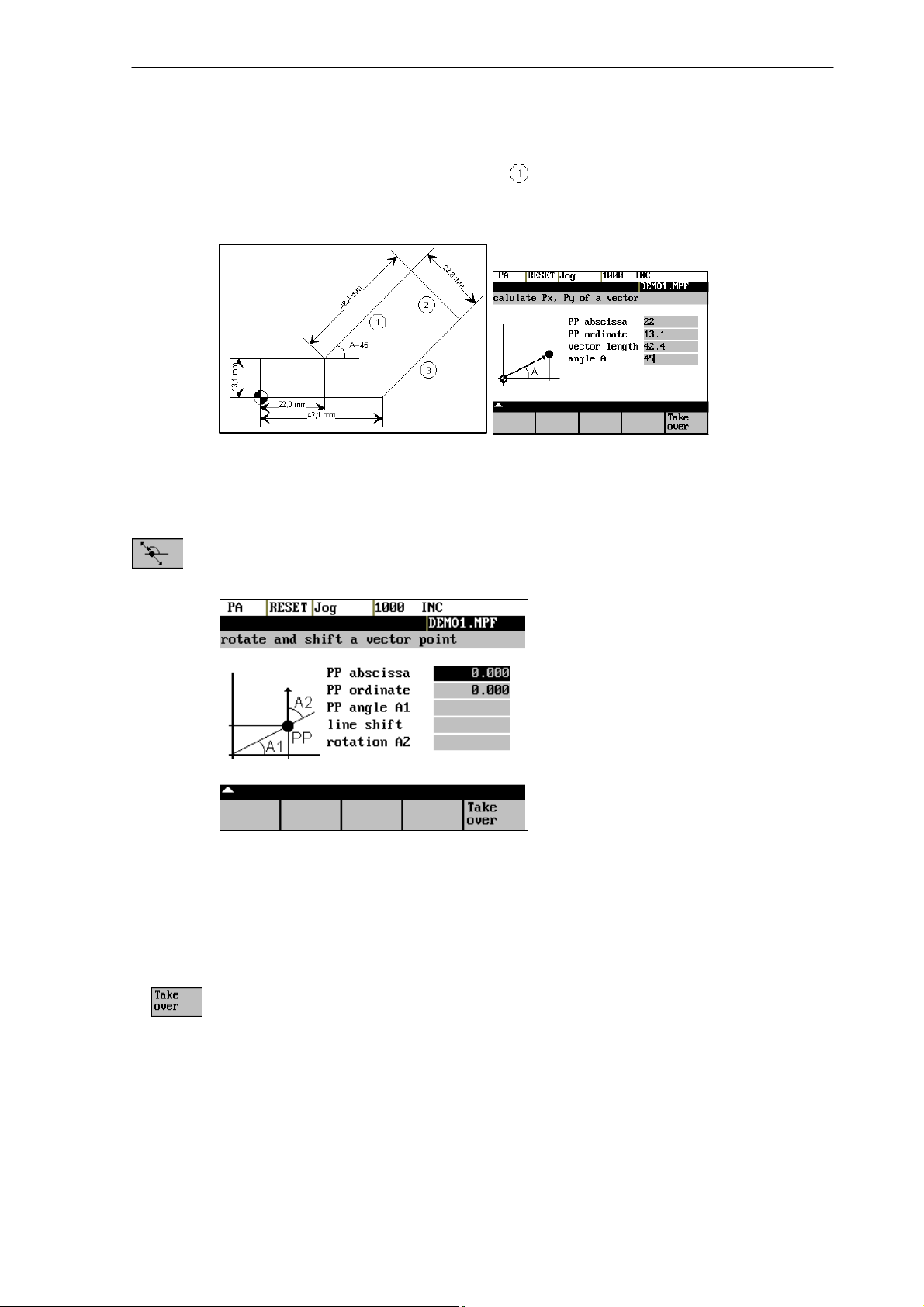

The function calculates the Cartesian coordinates from a straight line specified by length and rise

angle.

Fig. 1-5 Conversion of the polar coordinates into Cartesian coordinates

Enter the pole point (PP) as both an abscissa and ordinate value, the length and the rise angle of the straight line.

1-18

The values of abscissa and ordinate are calculated.

The abscissa value is copied into the input field from which the pocket calculator function has

been called, and the ordinate value into the next following input field.

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Example

Introduction

1.4 Pocket calculator

Calculating the end point of the straight line . The straight line is defined by the angle

° uand its length..

A=45

Result: X = 51.981

Y = 43.081

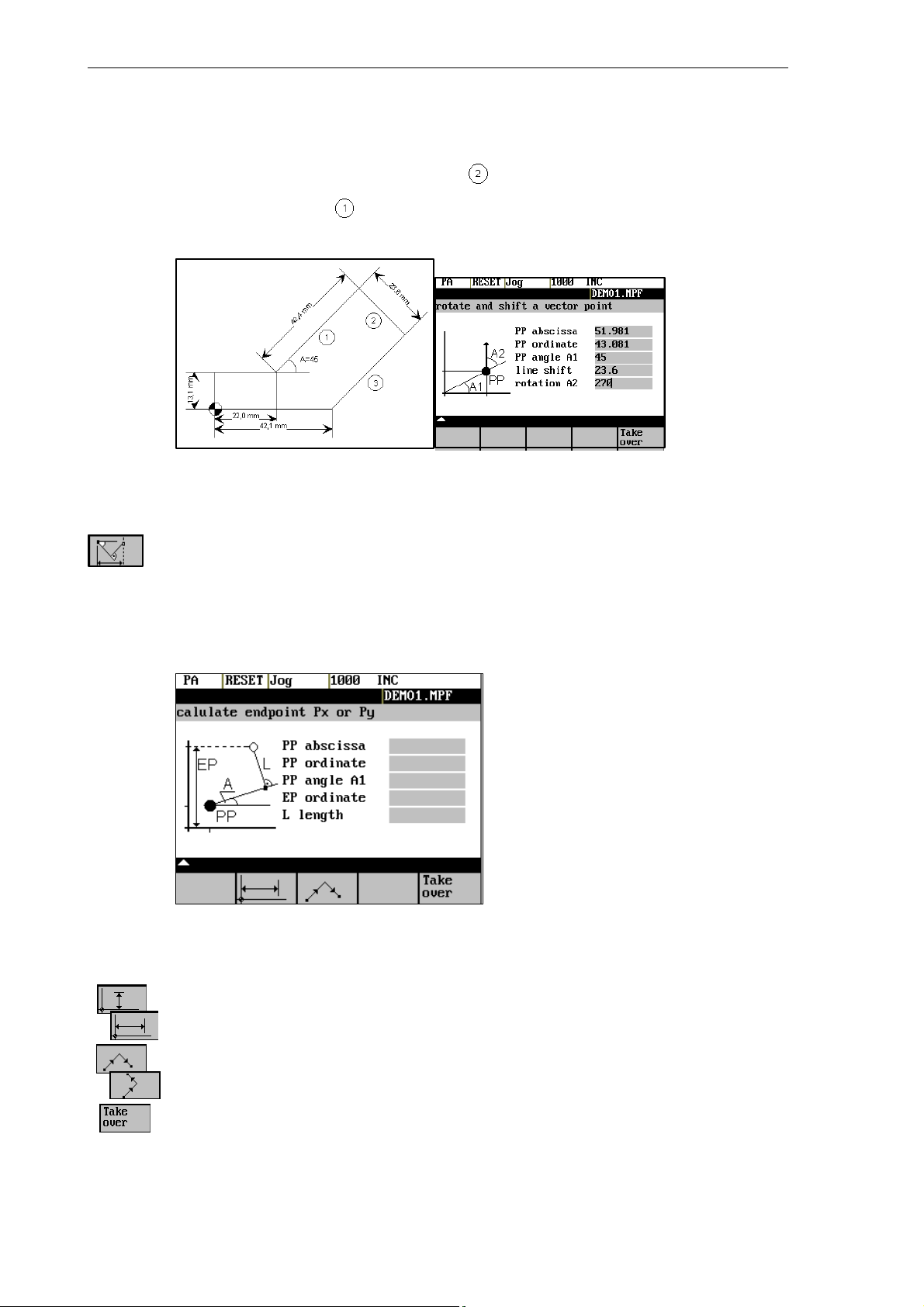

This function can be used to move a point in the plane. The point is on a straight line defined by its

rise angle.

Fig. 1-6 Moving a point in the plane

Enter the rise angle of the straight line and the coordinates of the point.

Enter line shift and rotation of the point with refer to the straight line in the fields “line shift” and

“rotation”.

The values of abscissa and ordinate are calculated.

The pocket calculator copies the abscissa value into the input field from which the pocket calculator function has been called, and the ordinate value into the next following input field.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

1-19

Introduction

1.4 Pocket calculator

Example

Calculating the end point of the straight line . The straight line stands vertical on the end

point of the straight line (coordinates: X = 51.981, Y = 43.081). The length of the straight

line is also given.

Result: X = 68.668

Y = 26.393

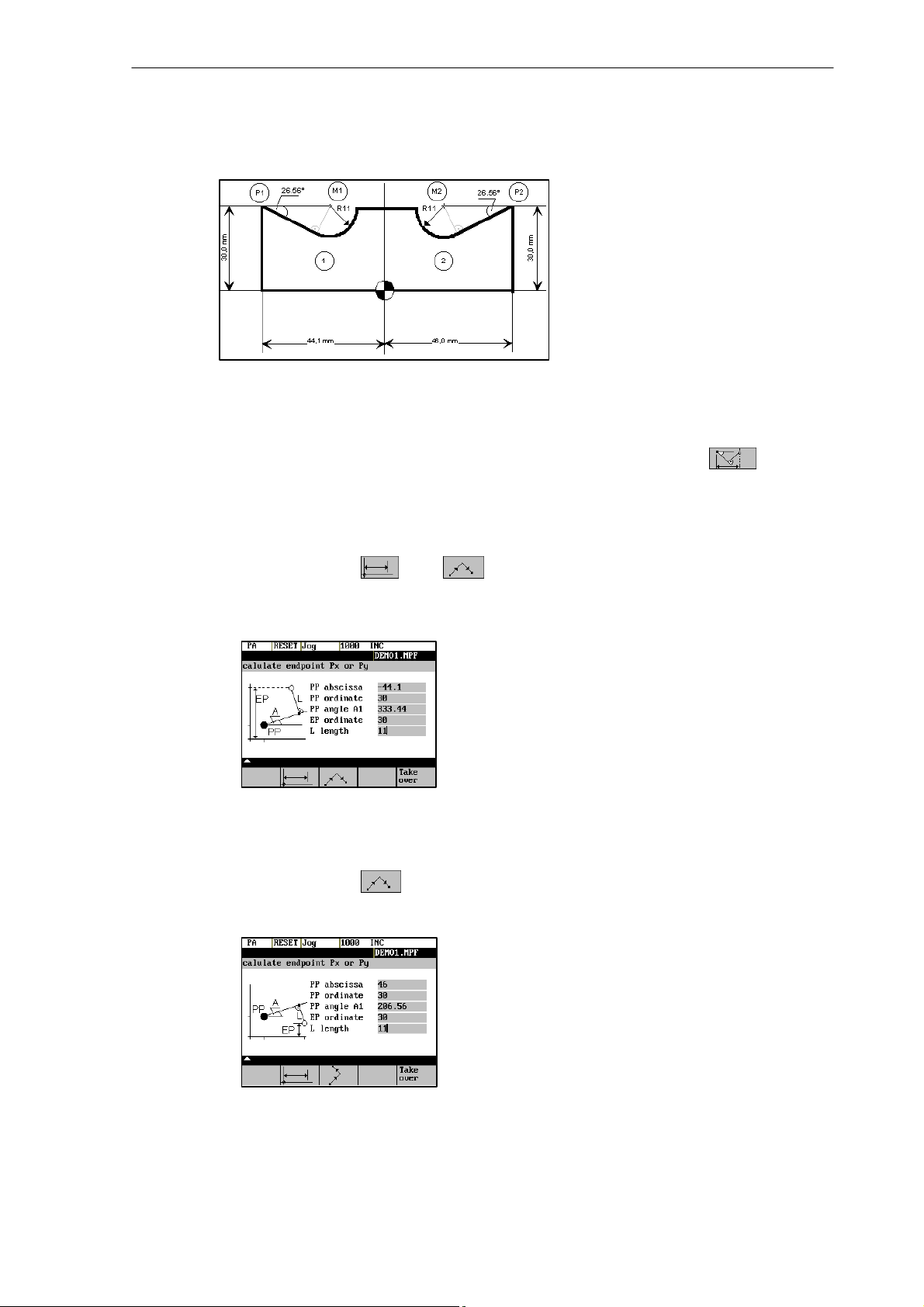

This function calculates the missing end point of the contour section straight line – straight line,

with the second straight line standing vertically on the first straight line.

The following values of the straight line are known:

Straight line 1: Starting point and rise angle

Straight line 2: Length and one end point in the Cartesian coordinate system

Fig. 1-7

1-20

This function chooses the given coordinate of the end position.

The value of ordinate and/or abscissa is given.

The second straight line is rotated in clockwise direction or, with refer to the first straight line, rotated

by 90 degrees in counter–clockwise direction. The function chosses the appropriate setting.

The missing end position is calculated. The value of the abscissa is copied into that input field from

which the pocket calculator function has been called, and the ordinate value into the next following

input field.

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Example

Introduction

1.4 Pocket calculator

The drawing above must be added by the values of the of the circle center points to be able to

calculate the intersection points between the contour sections. Calculating the missing coordi-

nates of the center points is carried out with the pocket calculator function , since the

radius in the tangential transition stands vertical on the straight line.

Calculating M1 in section 1:

In this section, the radius stands on the straight line section in counter–clockwise direction.

Use the softkeys and to select the given constellation.

Enter the coordinates, the pole point P1, the rise angle of the straight line, the given ordinate value and the circle radius as the length.

Result: X = –19.449

Y = 30

Calculating M2 in section 2:

In this section, the radius stands on the straight line section rotated in clockwise direction.

Use the softkeys to select the given constellation.

Enter the parameters in the screen form.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

Result X = 21.399

Y = 30

1-21

Introduction

1.5 Basic principles

1.5 Basic principles

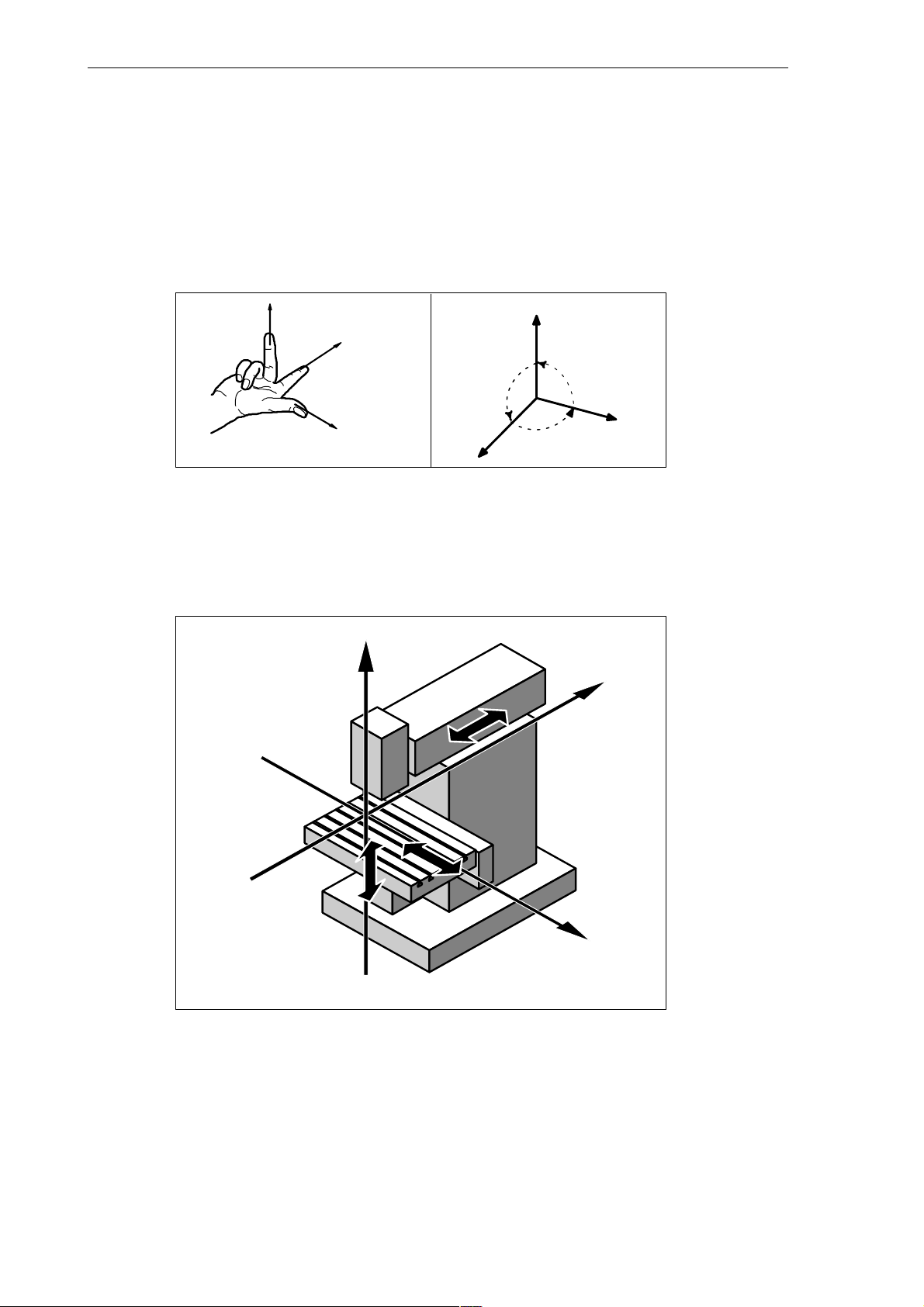

Coordinate sytems

Right–handed, rectangular coordinate systems are used for machine tools.

Such systems describe the movements on the machine as a relative motion between tool and

workpiece.

+Z

Fig. 1-8 Specification of mutual relationship between axis directions;

+X

+Y

+ Z

90°

90°

+Y

90°

+ X

Machine coordinate system (MCS)

The orientation of the coordinate system on the machine tool depends on the particular machine type. It can be turned to various positions.

+Z

+Y

+X

1-22

Fig. 1-9 Example of machine coordinates/axes

The origin of the coordinate system is the machine zero.

All axes are in zero position at this point. This point is merely a reference point determined by

the machine manufacturer. It need not to be approachable.

The traversing range of the machine axes can be negative.

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

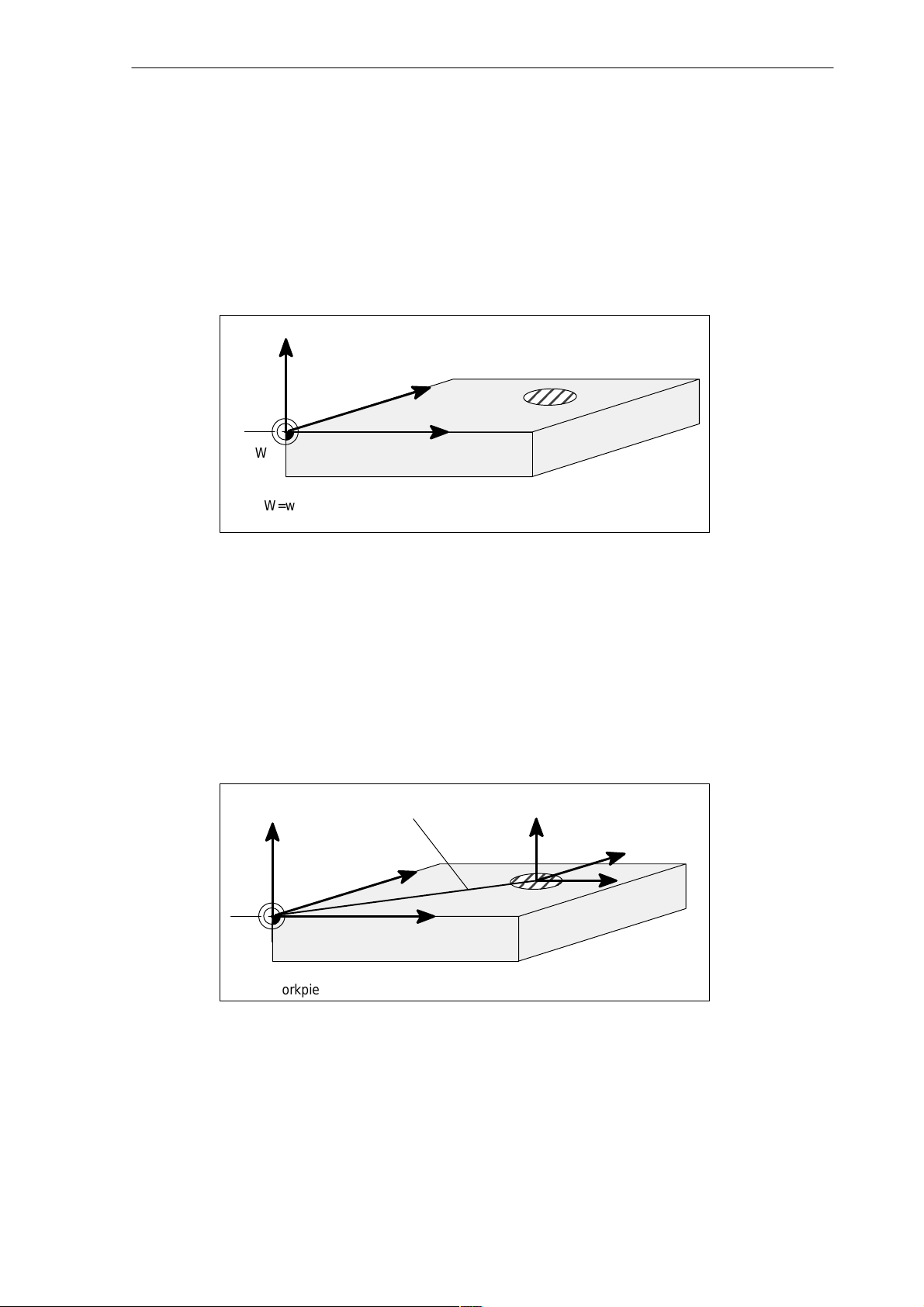

Workpiece coordinate system (WCS)

The workpiece coordinate system described above (see Fig. 1-8) is also used to describe the

geometry of a workpiece in the workpiece program.

The workpiece zero can be freely selected by the programmer. The programmer need not

know the real movement conditions on the machine, i.e. whether the workpiece or the tool

moves; this can be different in the individual axes.

The definition of the directions is based on the assumption that the workpiece does not move

and the tool moves.

Z

Y

Introduction

1.5 Basic principles

W

W=workpiece zero

Fig. 1-10 Workpiece coordinate system

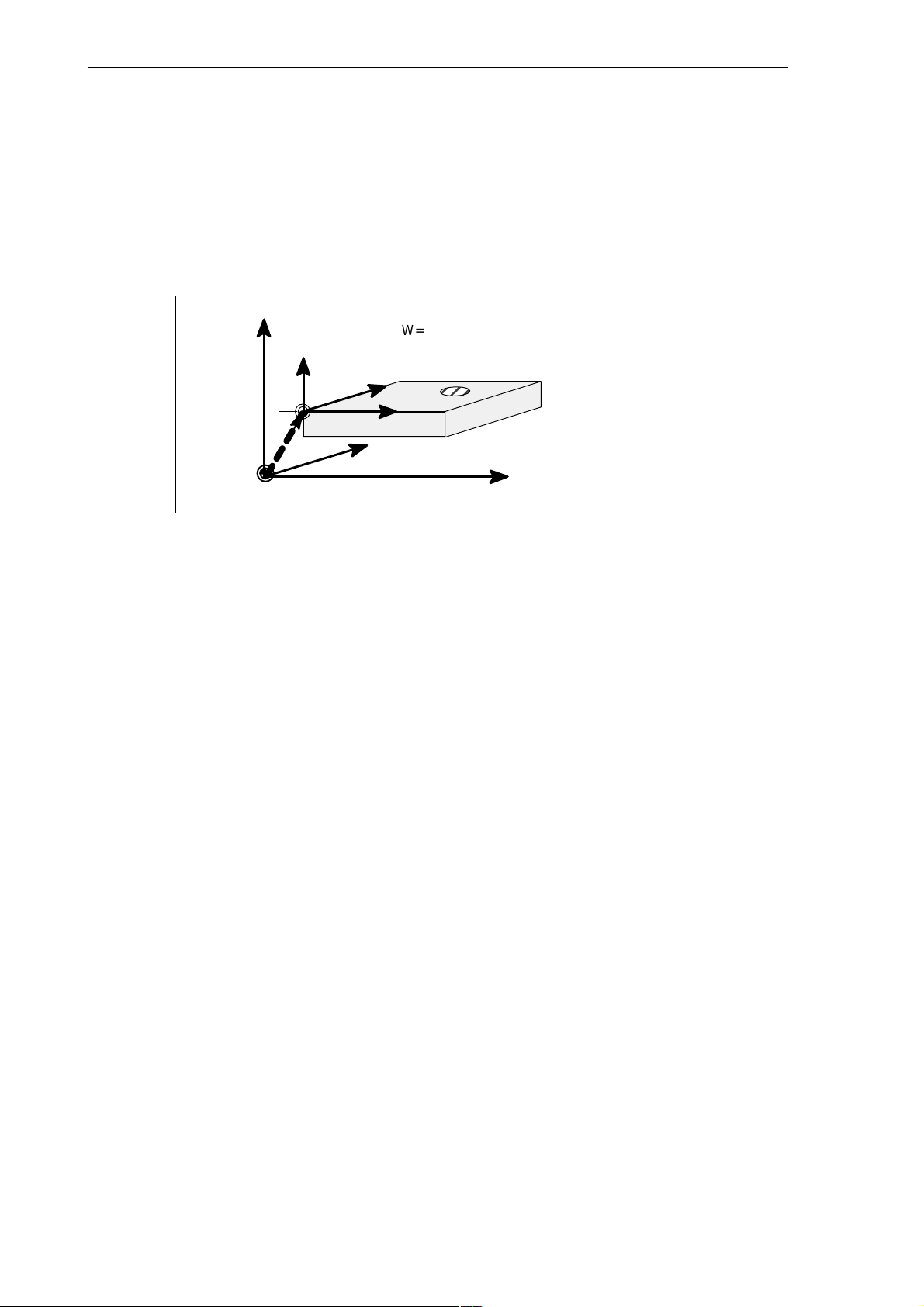

Current workpiece coordinate system

If the programmer feels that it is better to continue his geometrical descriptions from another

zero than the initially selected zero (workpiece zero), he can define a new zero using the programmable zero offset. Reference is always made to the original zero.

The use of the programmable zero offset provides a completely new current workpiece coordinate system. The current workpiece coordinate system can also be turned to the original

workpiece coordinate system (see Section “Programmable Zero Offset and Rotation”).

Programmable offset

Z

Y

X

G158

Z Current

Y

X

W

W=workpiece zero

Fig. 1-11 Coordinates on the workpiece, current workpiece coordinate sy-

stem

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

X

1-23

Introduction

1.5 Basic principles

Workpiece clamping

To machine the workpiece, it is clamped on the machine. The workpiece must be aligned such

that the axes of the workpiece coordinate system run in parallel with the machine axes. Any

resultant offset of the machine zero is determined for each axis and entered into the intended

data areas for the settable zero offset. This offset is activated during the NC program execution by means, for example, of a programmable G54 (see Section ”Workpiece Clamping –

Settable Zero Offset ...”).

Z

Machine

Z

Workpiece

W=workpiece zero

M=machine zero

Y

W

z.B.

G54

M

Fig. 1-12 Workpiece on the machine

X

Y

Machine

X

Machine

1-24

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

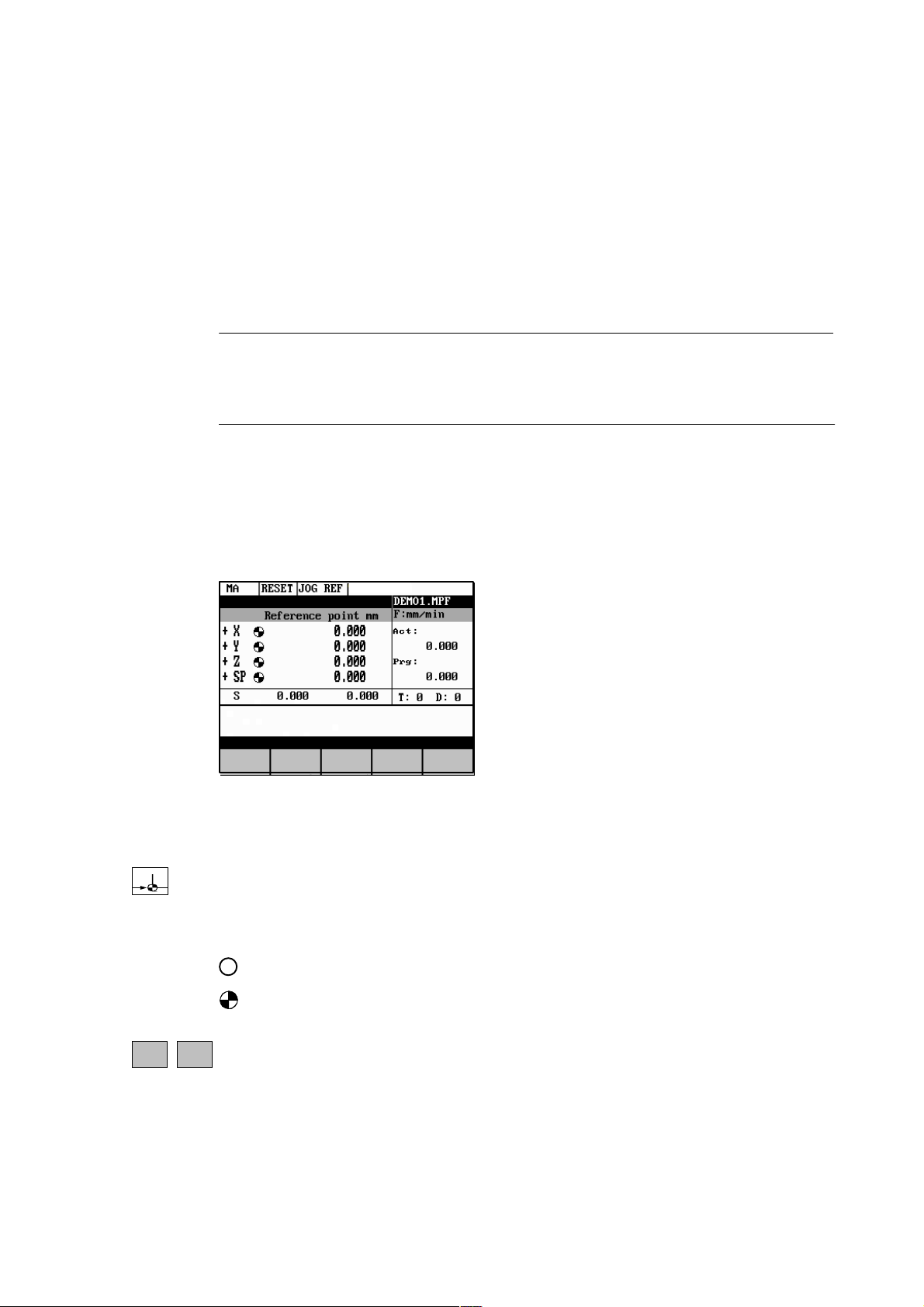

Turning On and Reference Point Approach

Note

Before you switch on the SINUMERIK and the machines, you should also have read the machine documentation, since turning on and reference point approach are machine–dependent

functions.

Operating sequence

First switch on the power supply of the CNC and of the machine. After the control system has

booted, you are in the “Machine” operating area, in the Jog operating mode.

The Reference point approach window is active.

2

+X

Fig. 2-1 Jog Ref basic screen

Reference–point approach can only be executed in the Jog mode.

Activate the “Approach reference point” function by selecting the Ref key on the machine control

panel.

In the “Reference point approach” window (Fig. 2-1), it is displayed whether or not the axes

have to be referenced.

Axis has to be referenced

Axis has reached the reference point

...

Press the direction keys.

-Z

The axis does not move if you select the wrong direction.

Approach the reference point in each axis successively.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

2-25

Turning On and Reference Point Approach

You can quit the function by selecting another operating mode (MDA, Automatic or Jog).

2-26

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Setup

Preliminary remarks

S Before you can use the CNC, set up the machine, tools, etc. on the CNC by:

S entering the tools and tool offsets

S entering/modifying the zero offset

S entering the setting data

3.1 Entering tools and tool offsets

Functionality

The tool offsets consist of several data that describe the geometry, wear and tool type.

Each tool has a defined number of parameters depending on the tool type.

Each tool is identified by its own tool number (T number).

3

See also Section 8.6 “Tool and Tool Offset“.

Operating sequences

Parameter

Tool

Corr.

This function opens the Tool Compensation Data window, which contains the offset values of the

currently active tool. If you select another tool using the <<T or T>> softkeys, the setting remains

when you quit the window.

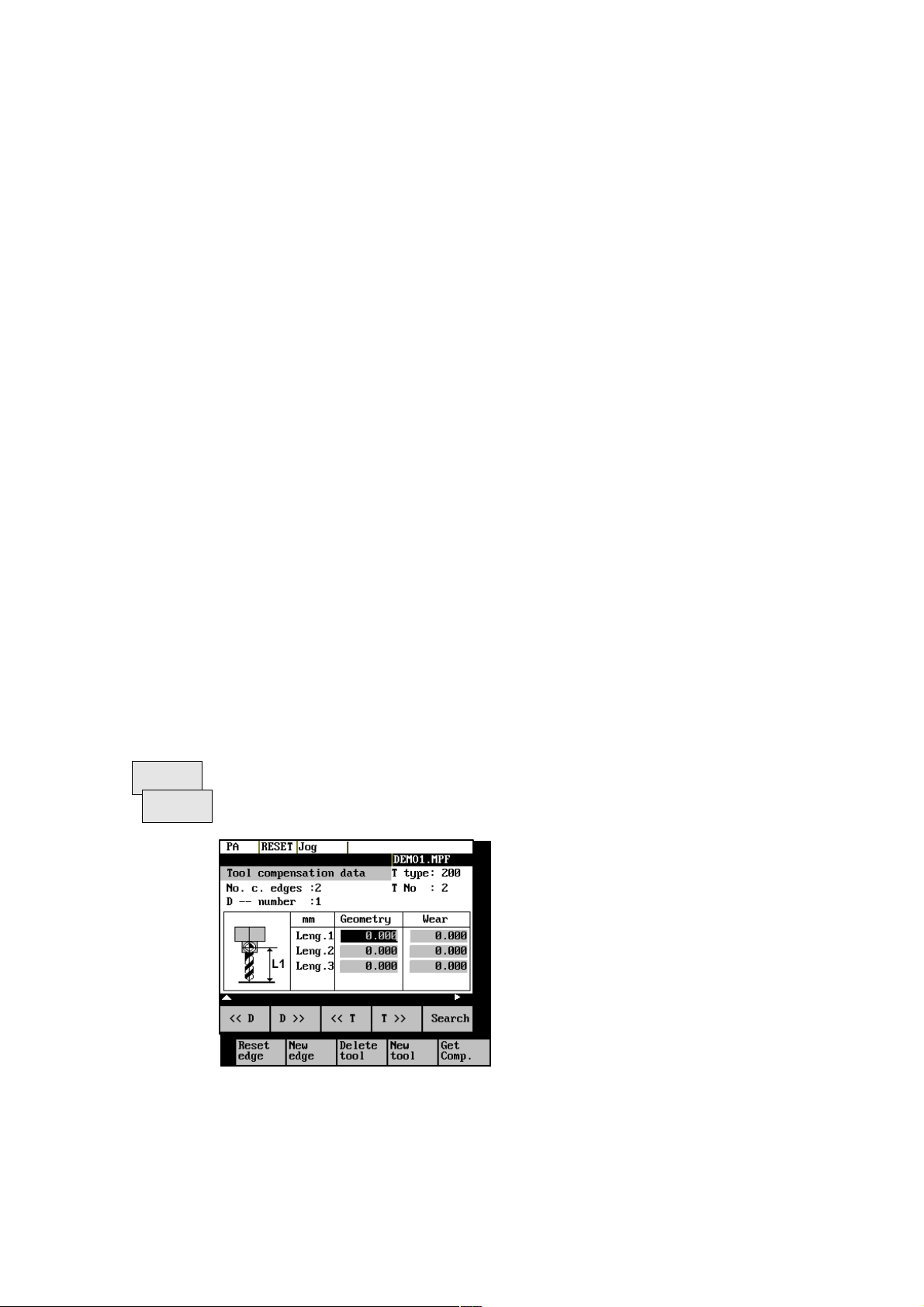

Fig. 3-1 Tool list

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

3-27

Setup

3.2 Creating a new tool

Softkeys

<< D

D >>

<< T

T >>

Search

Reset

edge

New

edge

Delete

tool

New

tool

Select next lower or next higher edge number.

Select next lower or next higher tool.

Pressing this softkey opens the dialog box and the overview of the tool numbers assigned. Enter the

tool number you search for in the input window and start search with OK. If the searched tool exists,

the search function opens the tool offset data box.

Press the ETC key to extend the softkey functions.

All edge compensation values are reset to zero.

Creates a new edge and loads it with the appropriate parameters.

The new edge is created for the currently displayed tool; it is automatically assigned the next

higher edge number (D1 - D9).

Max. 30 edges (in total) can be stored in the memory.

Deletes the tool compensation data of all edges of the selected tool.

Creates new tool compensation data for a new tool.

Note: Max. 20 tools can be created.

Get

Comp.

Determines the length compensation values.

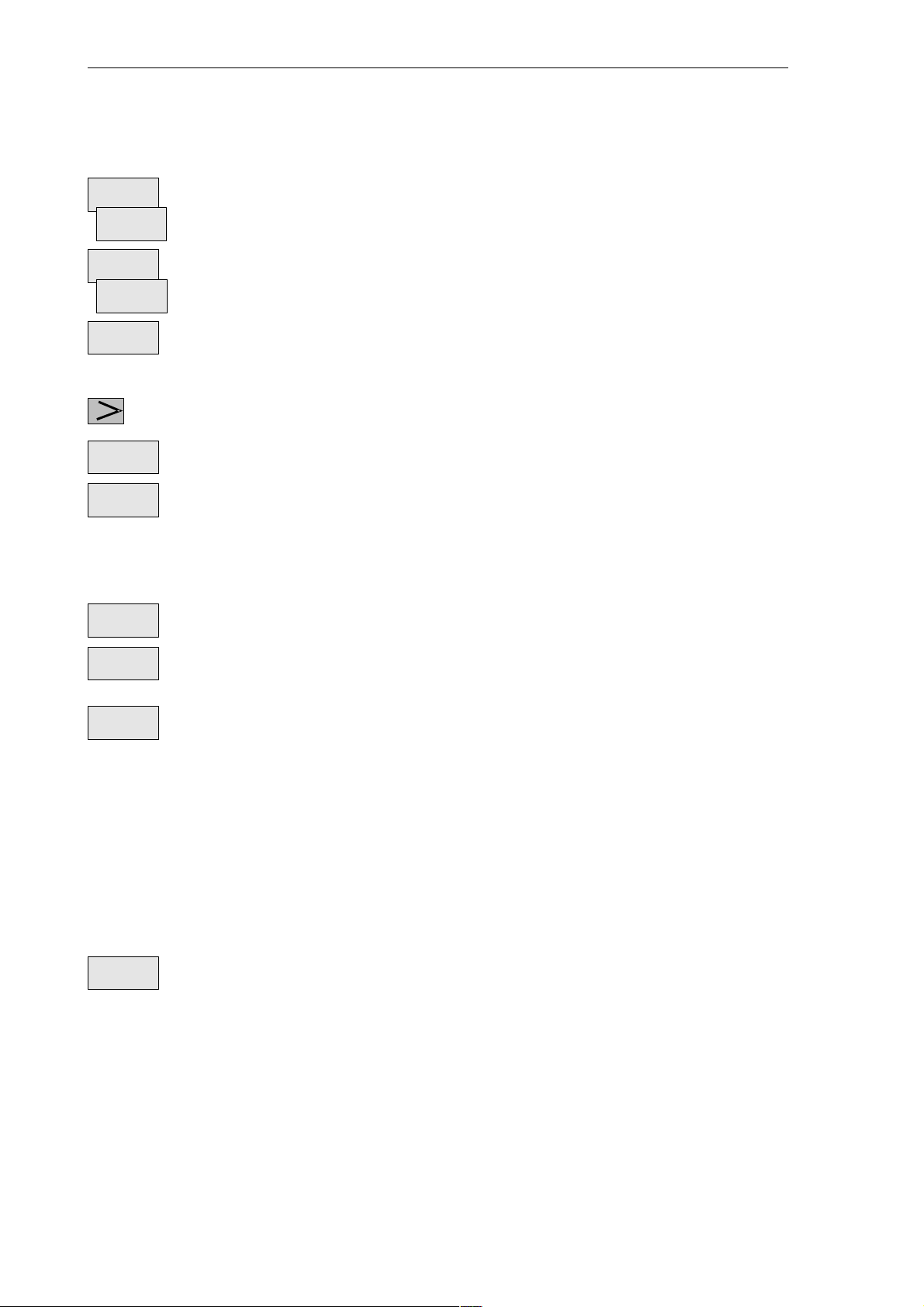

3.2 Creating a new tool

Operating sequence

Press this softkey to create a new tool.

New

tool

Pressing this softkey opens the input window and an overview of the tool numbers assigned.

3-28

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Fig. 3-2 New Tool window

Setup

3.3 Tool compensation data

$

0

. . .

Enter the new T number (in the range from 1 to 32000) and specify the tool type.

9

Press OK to confirm your entry; the Tool Compensation Data window is opened.

OK

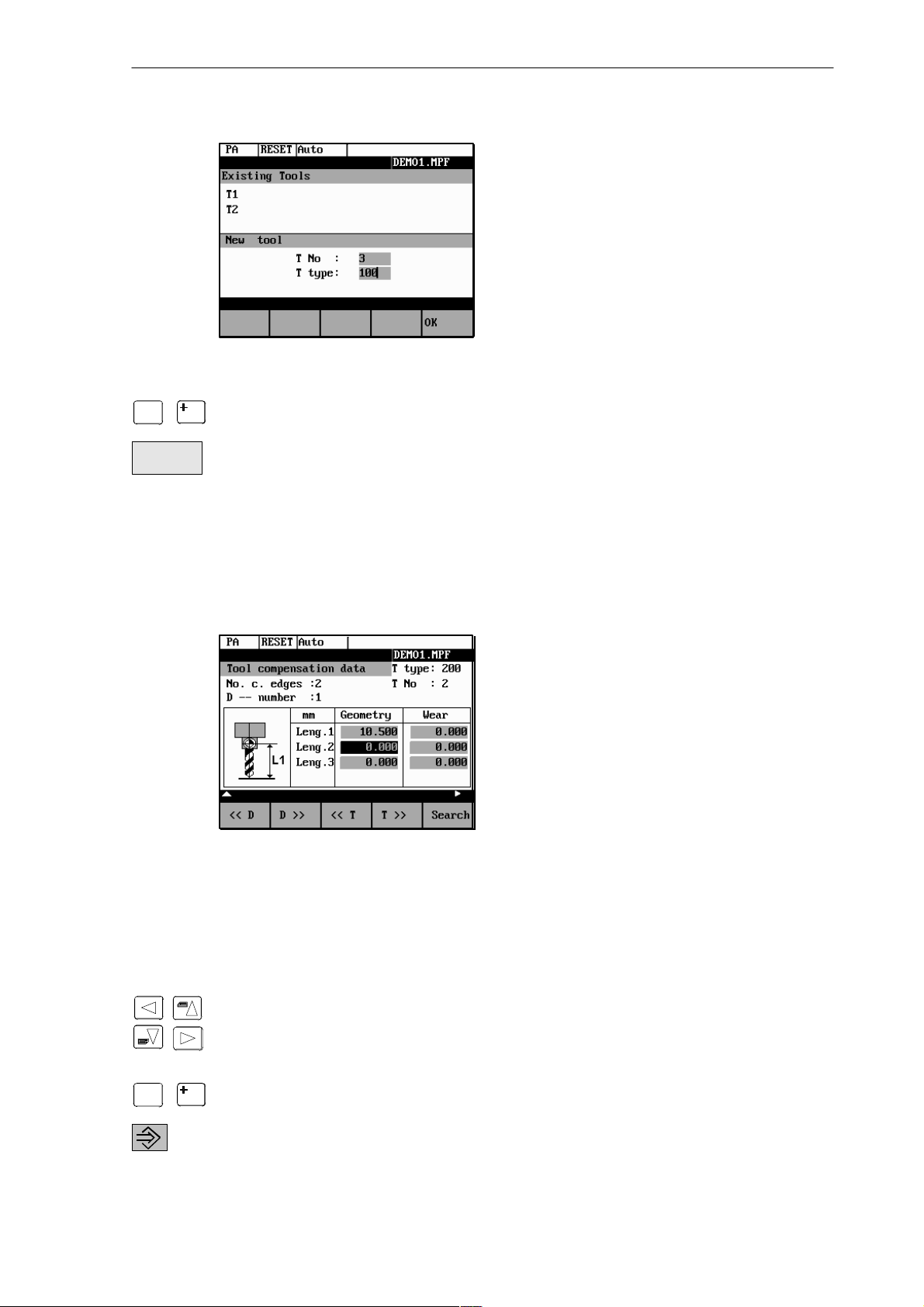

3.3 Tool compensation data

The tool compensation data are divided into length and radius compensation data.

The list is structured according to the tool type.

Fig. 3-3 Tool compensation data

Operating sequence

Enter the offsets by

positioning the cursor on the input field to be modified,

$

0

. . .

entering value(s)

9

and confirming your entry by pressing Input or a cursor selection.

SINUMERIK 802S/802C

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

3-29

Setup

3.4 Determining the tool offsets

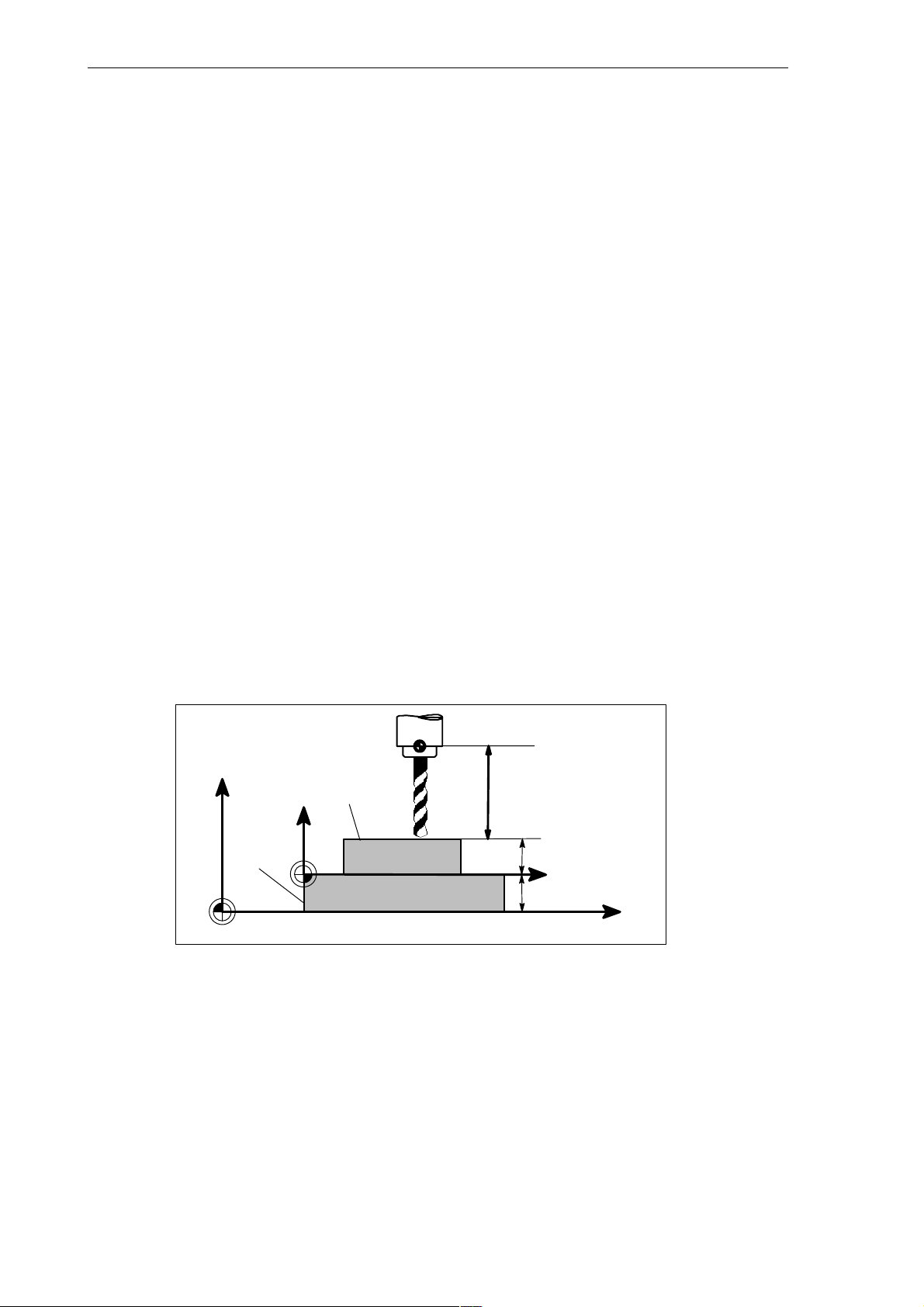

3.4 Determining the tool offsets

Functionality

This function can be used to determine the unknown geometry of a tool T.

Prerequisite

The appropriate tool has been changed. In JOG mode, approach a point on the machine, from

which you knw the machine coordinates, with the edge of the tool. This can be a workpiece

with a knwon position. The machine coordinate value can be split into two components: stored

zero offset and offset.

Procedure

Enter the offset value in the intended Offset field. Then select the required zero offset (e.g.

G54) or G500 if no zero offset is to be calculated. These entries must be made for each selected axis (see Fig. 3–5).

Please note the following: For milling tools, length 1 and the radius must be determined, and

for drilling tools only length 1.

Using the actual position of point F (machine coordinate), the offset entry and the selected

zero offset Gxx (position of the edge), the control system can calculate the assigned compensation value of length 1 or the tool radius.

Note: You can also use a zero offset already determined (e.g. G54 value) as the known machine coordinate. In this case, approach the workpiece zero with the edge of the tool. If the

edge stands directly at the workpiece zero, the offset value is zero.

F–tool carrier reference point

M–machine zero

W–workpiece zero

Z

Machine

Workpiece

M

Fig. 3-4 Determination of length compensation using the example of a drill: length 1/Z

axis

Interm. layer

W

F

Length 1=?

Actual position Z

Known machine

coordinate value Z

Offset

Gxx, z.B. G54

X

Machine

3-30

6FC5 598–3AA10–0BP2 (01.02) (OP–M)

SINUMERIK 802S/802C

Loading...

Loading...