Quick Guide 10.2015 QG EVE0105 B-(en)

SRD991 Intelligent Positioner

These instructions are to be used as a guide for quick start-up. For more detailed information, please refer

to the standard documents “Master Instructions” and “Product Specification Sheet”. These can be found

on our Website.

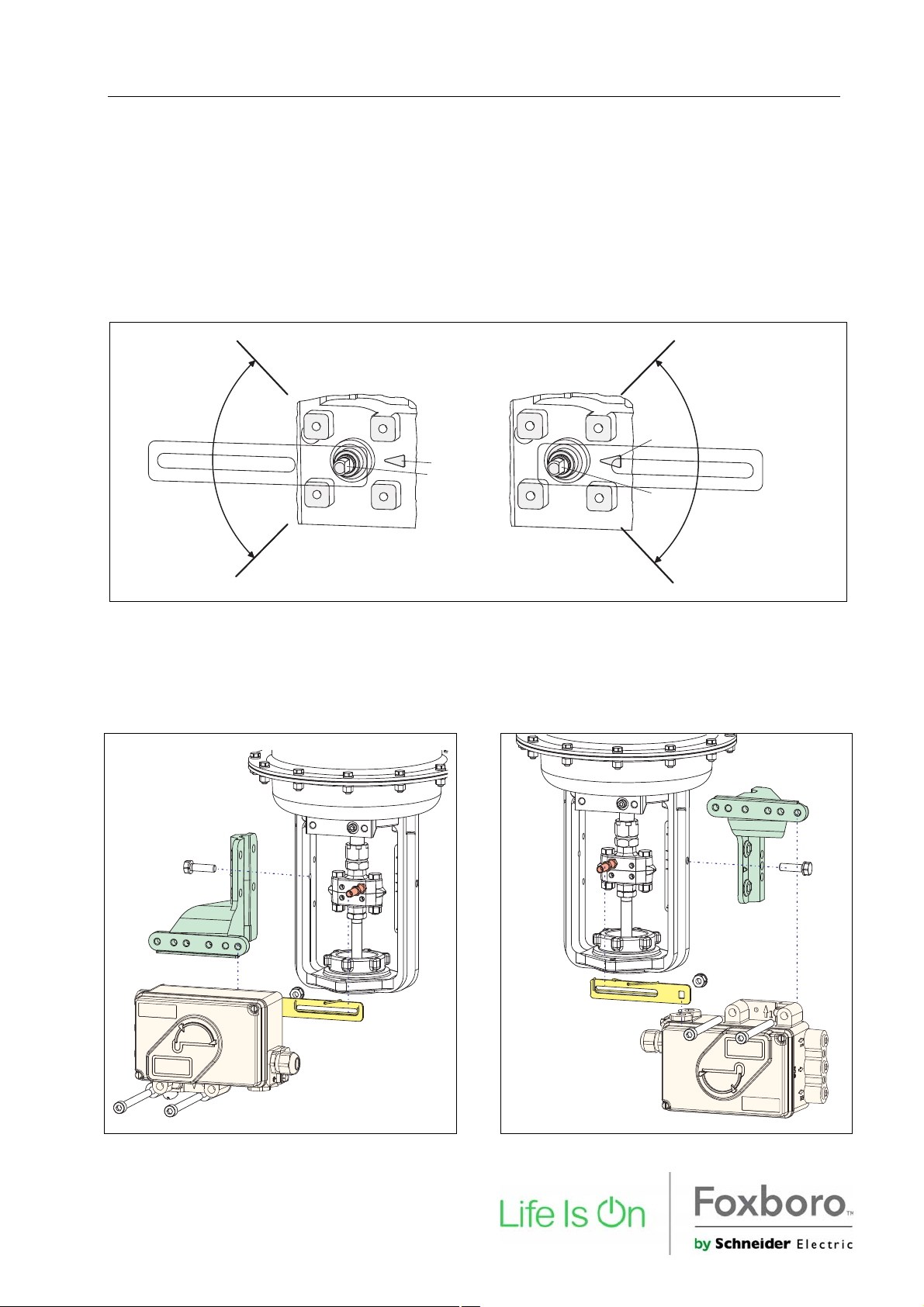

1. MOUNTING TO ACTUATORS

During operation, the flat side of the spindle 9 on the back of the positioner must always point towards

the arrow 26. The working angle around this position is ±45º.

2 6

2 6

9

9

Any mechanical backlash may be source of poor control, oscillation and hunting as well as long duration of

Autostart. Please use only original mounting parts and ensure that they are correctly mounted and tighten.

By not using the original feedback lever or by using them in an inappropriate way, the performance of the

positioner may be compromised.

MOUNTING TO LINEAR ACTUATORS

NAMUR Mounting - left hand -

NAMUR Mounting - right hand -

2 SRD991 QG EVE0105 B-(en)

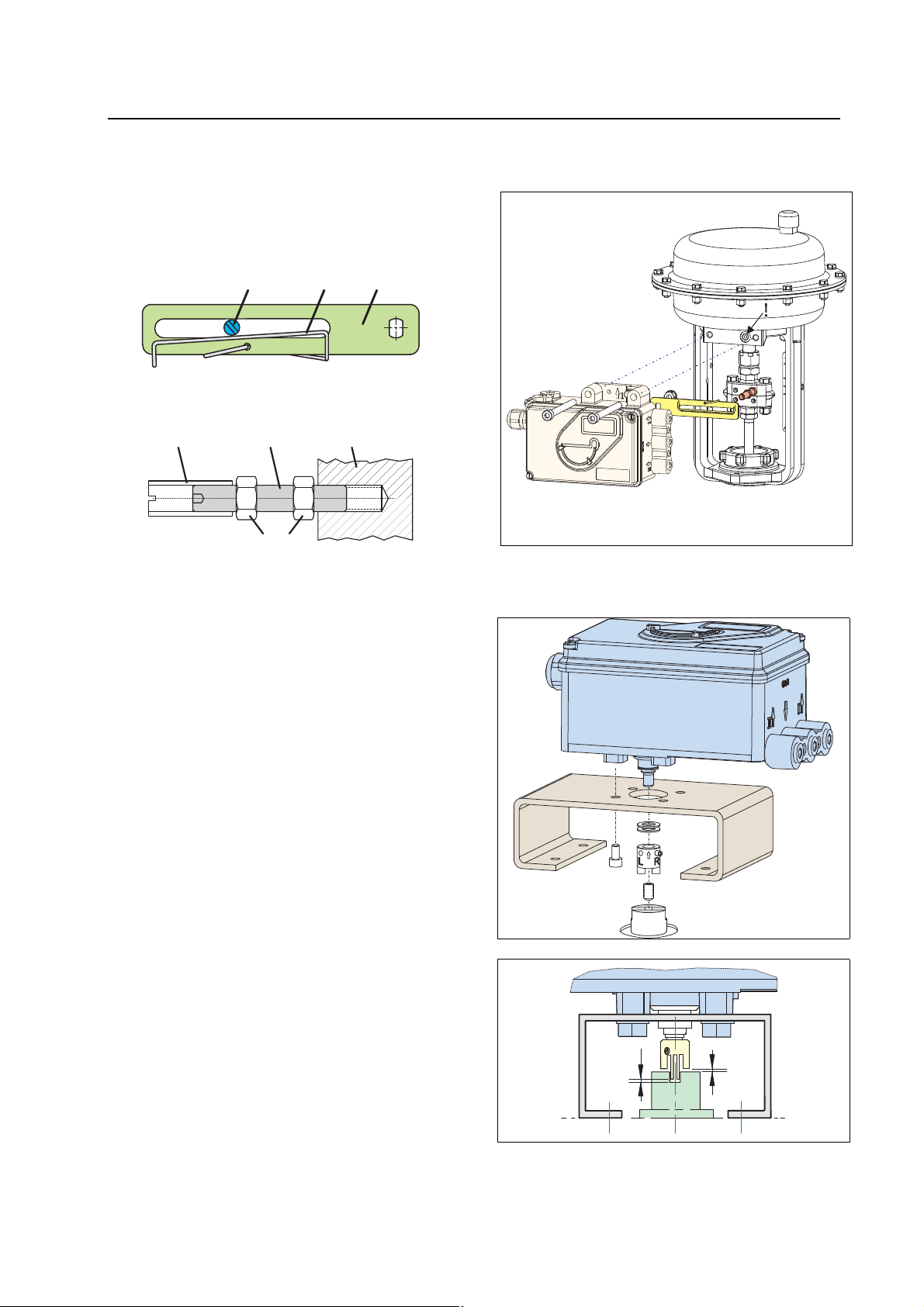

MOUNTING TO LINEAR ACTUATORS (cont’d)

Feedback lever for linear actuators :

The carrier bolt B is in the slot of the feedback

lever A and the compensating spring F touches

the carrier bolt.

AB F

Carrier bolt B:

1 threaded sleeve 2 Stud 3 coupling piece

1 2 3

M 6

MOUNTING TO ROTARY ACTUATORS

• Do not tighten grub screw 4 against the thread

of spindle 9 ! (see next page).

• When in use the flat side of the spindle 9 must

move ( 0 ↔ 100%) in front of the arrow 26.

Direct Mounting

• When the product temperature rises, the drive

shaft 1 increases in length. Therefore, the rotary

adapter 3 must be mounted so that approx. 1

mm (0.04 in.) of clearance results between the

drive shaft 1 and the rotary adapter 3. This is

achieved by placing an appropriate number of

washers 5 on the feedback spindle 9 before

attaching the rotary adapter. Two washers

should result in a clearance of 1 mm.

> 1

> 1

QG EVE0105 B-(en) SRD991 3

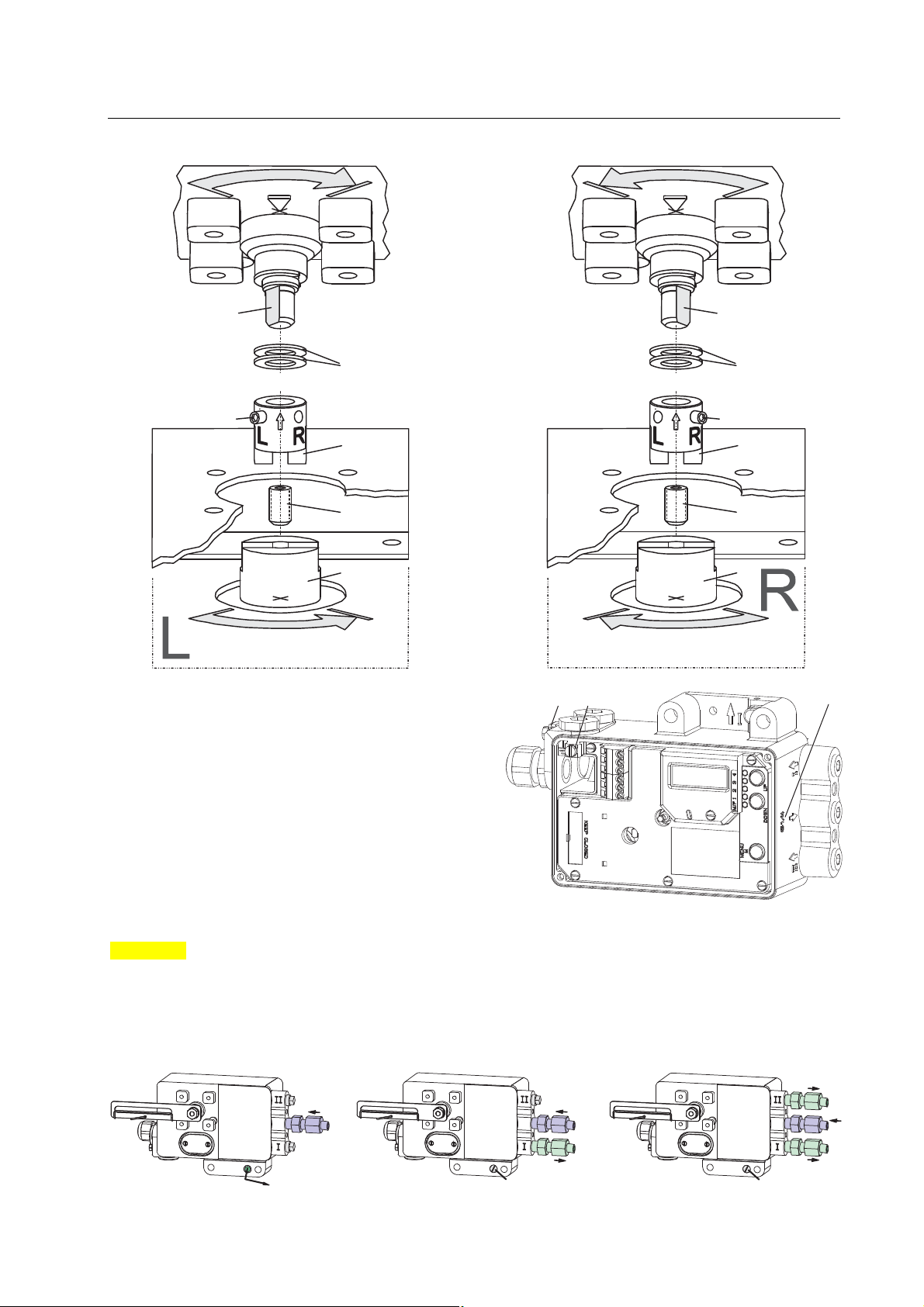

Actuator, left turning Actuator, right turning

9

5

4

3

2

1

2. CONNECTIONS

Check before mounting fittings and cable glands

that the threads are matching; otherwise the

housing can be damaged. The letter “G” on the

housing marks where the pneumatic connections

are in G 1/4 (otherwise NPT).

Ground

Connect earth cable to screw #1 (or screw #2 in

the electrical connection compartment).

9

5

4

3

2

1

# 1 # 2

" G "

PNEUMATIC CONNECTIONS

WARNING

To avoid any personal injury resulting from bursting of parts, do not exceed maximum supply pressure of

positioner and actuator. To avoid any personal injury or property damage from sudden or fast movement,

during air connection: Do not put your finger or other part at any time inside the valve or in any

moving part of the actuator or in the feedback lever mechanism. Do not touch the rear part of the

positioner at any time. Connect air supply only after connections y1 (and y2 for double acting) are done.

Air supply (s): 1.4 to 6 bar (but not more than the max. pressure of actuator), free of oil, dust and water

( - - )

s

( - - )

y 1

( - - )

( - - )

s

y 1

( - - )

!

Single acting, Direct mounting Single acting Double acting

s supply y1, y2 pneumatic outputs (--) closed

y 2

s

y 1

4 SRD991 QG EVE0105 B-(en)

A

3. ELECTRICAL CONNECTIONS

The safety requirements of document EX EVE0001 as well as the requirements of PSS EVE0105 and

MI EVE0105 for SRD991 must be observed!

3.1 Setpoint Electric Terminal A

3.1.1 SRD991-xD (w/o communication)

SRD991-xH (HART)

1 1 + 1 2

3.1.3 SRD991-xP (PROFIBUS PA)

SRD991-xQ (FIELDBUS FF)

1 1 1 2

3.2 Inductive Limit Switch Electric Terminal C

3.2.1 SRD991-xxxT or U

3.2.3 SRD991-xxxV

Warning: For connection of micro switches please refer to MI (Master Instruction) and obey the

safety requirements described in document EX EVE0001.

3.3 Option Board Electric Terminal B

3.3.1 Two binary outputs (SRD991-xxP)

3.3.2 Two binary inputs (SRD991-xxB)

3.3.3 Position feedback 4 to 20 mA and 1 Alarm

3.3.4 Two binary in-/outputs (SRD991-xxE)

*

For intrinsically safe circuits please refer to certificate / data label for

max. operating voltages etc.

Input 4 to 20 mA

Bus connection acc. to IEC 1158-2

Supply voltage 9 to 32 V DC *

Two-wire proximity sensors, 3.2.2 SRD991-xxxR

acc. to DIN 19234 or NAMUR

5 1 + 5 2 4 1 + 4 2

Switching amplifier with

intrinsically safe control circuit

Switching amplifier with

intrinsically safe control circuit

4 2 5 24 1 + 4 3

Contact 2

Contact 1

Supply voltage 10 to 30 V DC

8 3 + 8 4 8 1 + 8 2

Two-wire system, acc. to DIN 19234

or switched output.

External power supply (e.g.

intrinsically safe control circuit

External power supply (e.g.

intrinsically safe control circuit

Binary inputs with internal supply for connection

1 5 + 1 6 1 3 + 1 4

of sensors or switches (switch closed for a

normal operation!)

3 1 + 3 2 8 1 + 8 2

(SRD991-xxQ ou SRD991-xxF)

Analog output 4-20 mA and Binary output Twowire system acc. to DIN 19234 or switched.

Two-wire system, supplied with

external power supply

External power supply (e.g.

intrinsically safe control circuit

8 1 + 8 2 8 3 + 8 4

Two-wire system acc. to DIN 19234 or

switched in-/output.

Binary in-/ output 4 to 20 mA,

Two-wire system, supplied with

external power supply

Binary in-/ output 4 to 20 mA,

Two-wire system, supplied with

external power supply

nalog output 4 to 20 mA,

QG EVE0105 B-(en) SRD991 5

4. START UP (Setting by means of local keys and LCD)

After mounting the positioner on the actuator, air

and electrical input connected, you can start-up

the SRD. The positioner can be adjusted by means

of a local key-pad and LCD.

WARNING

To avoid any personal injury or property damage

from sudden or fast movement, d uring conf iguratio n:

Do not put your finger or other part at any time

inside the valve or in any moving part of the

actuator or in the feedback lever mechanism.

Do not touch the rear part of the positioner at

any time.

IN OPERATION:

An already configurated device may show the

following display:

87.5 %

Valve position

For configuration press (M) and Main menu

appears.

CONFIGURATION with push buttons and LCD:

If the SRD wasn’t configurated yet, the Main

menu*) appears automatically after power-up:

SRD Main Menu

1 Mounting

2 Autostart

3 Valve Action

(The selected item is displayed with dark background.)

In menu 1 you select the type of mounting: Press

keys (UP)+(DOWN) simultaneously to enter this

menu.

*) On delivery the menu language in the display is English.

The menu language can be changed over to another stored

language. For this select 9.8.2 [German] or 9.8.3 [as ordered]

and confirm with keys (UP)+(DOWN) (simultaneously).

Leave menu by repeated pressing of (M) key.

Process variable

Push buttons

(M)

Enter or

exit Main

menu

|-both simultaneously:-|

Enter / store

Select your ‘Type of mounting’ by pressing (UP) or

(DOWN).

1 Mounting

1.1 Lin left

1.2 Lin right

1.3 rot cclockw

Press keys (UP)+(DOWN) simultaneously to

confirm and save. The SRD moves back to Main

menu again.

SRD Main Menu

1 Mounting

2 Autostart

3 Valve Action

To enter next menu (= menu 2, Autostart) press

(UP) once:

SRD Main Menu

1 Mounting

2 Autostart

3 Valve Action

Now press keys (UP)+(DOWN) simultaneously to

enter menu ‘Autostart’.

(Continued on next page.)

(DOWN)

Previous

menu or

Parameter

(UP)

Next

menu or

Parameter

6 SRD991 QG EVE0105 B-(en)

Several Autostart options are available . Select relevant Autostart by pressing (UP) or (DOWN):

2 Autostart

2.1 Endpoints

2.2 Standard

2.3 Enhanced

2.4 Smooth resp.

2.5 Fast resp.

Press keys (UP)+(DOWN) simultaneously to confirm and to launch Autostart. The automatic adaptation to

the actuator is composed of a sequence of steps indicated on the LCD.

With the last step the device is IN OPERATION:

87.5 %

Valve position

5 TROUBLE SHOOTING (For more details see MI EVE0105 E)

Autostart err 1

Description of message / LCD text Remedy

Air supply too low Check air supply

Feedback lever (linear actuator) or Coupling (rotary

actuator) incorrectly linked. Potentiometer moves

out of operating range of ± 47° of 0° position

Coupling (rotary actuator) incorrectly linked

(R and L interchanged)

Pneumatic output to actuator closed or untight.

When direct mounting onto FlowTop or FlowPak,

the screw plug y1-d is not removed

Mechanical stops not determinable Check spring movement of actuator /

When using a booster or spool valve, no control

parameters can be determined, since air capacity

is too high

Control parameter too high since air capacity is too

high (in general, oscillation in valve movement)

Possibly incomprehensible configuration data Reset configuration, see Menu 9.1

Optionboard err

Description of message / LCD text Remedy

Configured status of the SRD deviates from

existing version (e.g. Option board has been

inserted subsequently)

Bad contact Connections to terminals interchanged

Defective Exchange option board

Ctrl diff error

Description of message / LCD text Remedy

Actuator problems (high friction or blocked) Check actuator

Insufficient air supply Check air supply / air filter

Insufficient parametes for position controls,

for example, amplification too small

IP module or pneumatic amplifier defect Check with Menu 7; replace if necessary

Determines only the mechanical stops of actuator/ valve

Recommended for standard applications

Optimized control behaviour compared to Standard Autostart

Dampened control behaviour for e.g. smaller actuators

Undampened control behaviour for e.g. larger actuators

Process variable

87.5 %

Valve position

Ctrl diff error

Check mounting. Flat area points to arrow on

housing

Check mounting

Check pneumatic connections

check air supply / Check mounting

Device version is not suitable for this actuator;

select version with smaller air capacity or remove

booster

Use a booster or the version with spool valve.

Reduce control parameter prop.-gain (Menu 6.1

and 6.2) to Code 10 = value 26.6.

Check if correct option board has been connected

Confirm message by pressing keys (UP)+(DOWN)

simultaneously

Check connections

Tighten electronics

Check control paramter,

check pneumatic components

Diagnostic messages

see following table.

QG EVE0105 B-(en) SRD991 7

y

6 MENU STRUCTURE FOR SRD991 / SRD960

SRD Main Menu

Menu Factory

configuration

1 Mounting

1.1 Lin left

1.2 Lin right

1.3 Rot cclockw

1.4 Rot clockw

1.5 Linear

2 Autostart

2.1 Endpoints

2.2 Standard

2.3 Enhanced

2.4 Smooth resp.

2.5 Fast resp.

3 Valve Action

3.1 SRD

3.1.1 Direct

3.1.2 Reverse

3.2 Feedback

3.2.1 Direct

3.2.2 Reverse

Description

Linear actuator, left-hand or direct mounting

Linear actuator, right-hand mounting

Rotary actuator, opening counter-clockwise

Rotary actuator, opening clockwise

For Top Mounting (only for SRD991)

Adaptation of the mechanical stops onl

Autostart recommended for standard application

Enh. Autostart. Optimized control behaviour compared to Standard Autostart

Enh. Autostart. Dampened control behaviour for e.g. smaller actuators

Enh. Autostart. Undampened control behaviour for e.g. larger actuators

Action of Positioner:

Valve opens with increasing setpoint value

Valve closes with increasing setpoint value

Action of Feedback Unit:

Increasing Current with increasing valve position

Decreasing Current with increasing valve position

4 Character

4.1 Linear

4.2 Eq Perc 1:50

4.3 Quick open

4.4 Customer

5 Limits/alarms

5.1 Lower limit 0 %

5.2 Cutoff low 1 %

5.3 Cutoff high 100 %

5.4 Upper limit 100 %

5.5 Splitr 0 % 4 mA

5.6 Splitr 100 % 20 mA

5.7 Lower Alarm -10 %

5.8 Upper Alarm 110 %

5.9 Valve 0% 4 mA

5.10 Valve 100% 20 mA

5.11 Stroke Range x° / 20 mm

5.12 Units SI

6 Parameters

6.1 Gain closing 15

6.2 Gain opening 2

6.3 Res time cl 7.5

6.4 Res time op 2.4

6.5 Rate lim cl 0.35

6.6 Rate lim op 0.35

6.7 Control gap 0.1

Linear characteristic

Equal percentage characteristic 1:50

Inverse equal percentage characteristic 1:50 (quick opening)

Custom characteristic (Configuration via DTM)

(Not locally available with LED versions of communication FF and Profibus)

Closing limit is set to input value

0%-tight sealing point is set to input value

100%-tight sealing point is set to input value

Opening limit is set to input value

Split range 0 %: input value corresponds to 0 %

Split range 100 %: input value corresponds to 100 %

Lower position alarm on output 1 is set to input value

Upper position alarm on output 2 is set to input value

Configuration of rated-stroke of 0% at 4 mA

Configuration of rated-stroke of 100% at 20 mA

Configuration of nominal travel

Configuration of temperature and pressure unit SI or Anglo US

P: Proportional gain for ‘close valve’

P: Proportional gain for ‘open valve’

I: Integration time for ‘close valve’

I: Integration time for ‘open valve’

T63: Setting time for ‘close valve’

T63: Setting time for ‘open valve’

Permitted dead band for control difference

7 Output

8 Setpoint

8.1 12.5% Steps Setpoint changes of 12.5% steps by using push buttons Up or Down

8.2 1% Steps Setpoint changes of 1% steps by using push buttons Up or Down

8.3 Do PST Start Partial Stroke Test

Continued on the next page

Manual setting of IP-Module for testing of pneumatic output

Manual setting of valve position

8 SRD991 QG EVE0105 B-(en)

A

A

9 Workbench

9.1 Reset Config

9.2 Calib. 4 mA

9.3 Calib. 20 mA

9.4 Calib. -45°

9.5 Calib. +45°

9.6 Reset all 1 Resetting of configuration and Calibration (!) to “ex factory” setting for

9.7 Reset all 2 Resetting of configuration and Calibration (!) to “ex factory” setting for

9.8 Go Online

9.9 Menu Lang

9.9.1 English

9.9.2 Deutsch

9.9.3 Français

9.10 LCD orient

9.10.1 Normal

9.10.2 Flipped

9.11 Cal. Feedbk Calibration of output current of position transmitter

9.11.1 Cal. 4 mA Calibration of 0% at 4 mA

9.11.2 Cal 20mA Calibration of 100% at 20 mA

Resetting of configuration to setting “ex factory”

Calibrate input current to 4 m

Calibrate input current to 20 m

Calibrate position measuring value to –45°

Calibrate position measuring value to +45°

single-acting

double-acting

Setting position into mode Online (Service function only)

Language on LCD:

Standard English

Standard German

Preselected / freely definable

LCD Orientation:

Normal orientation of writing on LCD

Reverse orientation of writing on LCD

output

output

10 Profibus PA - Bus Address

10.1 Address LSB

10.2 Address MSB

10.3 Address 126

10 FOUNDATION Fieldbus H1

10.1 Simulate

Disabled

Enabled

10.2 Profile

Link Master

Basic Device

Profibus only.

Ratio from Dec. 0 / Hex 00 to Dec. 15 / Hex 0F

Ration from Dec. 0 / Hex 00 to Dec. 112 / Hex 70

Display of Bus Address from Dec. 1 to 127 (Hex 00 to 7F)

FF only.

Simulate disabled

Simulate enabled

Link Master active

Link Master de-activated

Invensys Systems, Inc.

38 Neponset Street

Foxboro, MA 02035

United States of America

Global Customer Support

Toll free: 1-866-746-6477

Global: 1-508-549-2424

Website:

http://support.ips.invensys.com

Copyright 2010-2016 Invensys Systems, Inc.

All rights reserved.

Invensys, Foxboro, and I/A Series are trademarks of Invensys Limited, its subsidiaries,

and affiliates. All other trademarks are the

property of their respective owners.

DOKT 534 022 302

FD-QG-PO-002-EN 0316

Loading...

Loading...