Motorola MPX10GP, MPX10GS, MPX10GSX, MPX10D, MPX10DP Datasheet

...

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

Order this document by MPX10/D

10 kPa Uncompensated

Silicon Pressure Sensors

The MPX10 series device is a silicon piezoresistive pressure sensor providing a very accurate and linear voltage output Ð directly proportional to the applied pressure. This standard, low cost, uncompensated sensor permits manufacturers to design and add their own external temperature compensating and signal conditioning networks. Compensation techniques are simplified because of the predictability of Motorola's single element strain gauge design.

Features

•Low Cost

•Patented Silicon Shear Stress Strain Gauge Design

•Ratiometric to Supply Voltage

•Easy to Use Chip Carrier Package Options

•Differential and Gauge Options

Application Examples

•Air Movement Control

•Environmental Control Systems

•Level Indicators

•Leak Detection

•Medical Instrumentation

•Industrial Controls

•Pneumatic Control Systems

•Robotics

Figure 1 shows a schematic of the internal circuitry on the stand±alone pressure sensor chip.

PIN 3  + VS

+ VS

PIN 2

+ Vout

+ Vout

X±ducer

PIN 4

± Vout

± Vout

PIN 1

MPX10

SERIES

0 to 10 kPa (0 ± 1.45 psi)

35 mV FULL SCALE SPAN (TYPICAL)

BASIC CHIP

CARRIER ELEMENT

CASE 344±15, STYLE 1

DIFFERENTIAL

PORT OPTION

CASE 344C±01, STYLE 1

NOTE: Pin 1 is the notched pin.

PIN NUMBER

1 |

Gnd |

3 |

VS |

2 |

+Vout |

4 |

±Vout |

Figure 1. Uncompensated Pressure Sensor Schematic

VOLTAGE OUTPUT versus APPLIED DIFFERENTIAL PRESSURE

The differential voltage output of the X±ducer is directly proportional to the differential pressure applied.

The output voltage of the differential or gauge sensor increases with increasing pressure applied to the pressure side (P1) relative to the vacuum side (P2). Similarly, output voltage increases as increasing vacuum is applied to the vacuum side (P2) relative to the pressure side (P1).

Senseon and X±ducer are trademarks of Motorola, Inc.

REV 5

Motorola Sensor Device Data |

1 |

Motorola, Inc. 1997 |

|

MPX10 SERIES

MAXIMUM RATINGS

Rating |

|

Symbol |

|

|

|

Value |

|

Unit |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Overpressure(8) (P1 > P2) |

|

Pmax |

|

|

75 |

|

|

kPa |

|

||

Burst Pressure(8) (P1 > P2) |

|

P |

|

|

100 |

|

|

kPa |

|

||

|

|

burst |

|

|

|

|

|

|

|

|

|

Storage Temperature |

|

Tstg |

|

|

± 40 to +125 |

|

°C |

|

|||

Operating Temperature |

|

TA |

|

|

± 40 to +125 |

|

°C |

|

|||

OPERATING CHARACTERISTICS (VS = 3.0 Vdc, TA = 25°C unless otherwise noted, P1 > P2) |

|

|

|

|

|||||||

Characteristic |

|

Symbol |

|

Min |

|

Typ |

|

Max |

|

Unit |

|

|

|

|

|

|

|

|

|

|

|

||

Differential Pressure Range(1) |

|

POP |

0 |

|

Ð |

|

10 |

|

kPa |

||

Supply Voltage(2) |

|

VS |

Ð |

|

3.0 |

|

6.0 |

|

Vdc |

||

Supply Current |

|

Io |

Ð |

|

6.0 |

|

Ð |

|

mAdc |

||

Full Scale Span(3) |

|

V |

20 |

|

35 |

|

50 |

|

mV |

||

|

|

FSS |

|

|

|

|

|

|

|

|

|

Offset(4) |

|

Voff |

0 |

|

20 |

|

35 |

|

mV |

||

Sensitivity |

|

V/ P |

Ð |

|

3.5 |

|

Ð |

|

mV/kPa |

||

|

|

|

|

|

|

|

|

|

|

||

Linearity(5) |

|

Ð |

±1.0 |

|

Ð |

|

1.0 |

|

%VFSS |

||

Pressure Hysteresis(5) (0 to 10 kPa) |

|

Ð |

Ð |

|

± 0.1 |

|

Ð |

|

%V |

|

|

|

|

|

|

|

|

|

|

|

|

FSS |

|

Temperature Hysteresis(5) (± 40°C to +125°C) |

|

Ð |

Ð |

|

± 0.5 |

|

Ð |

|

%V |

|

|

|

|

|

|

|

|

|

|

|

|

FSS |

|

Temperature Coefficient of Full Scale Span(5) |

|

TCV |

± 0.22 |

|

Ð |

|

± 0.16 |

|

%V |

/°C |

|

|

|

FSS |

|

|

|

|

|

|

|

FSS |

|

Temperature Coefficient of Offset(5) |

|

TCV |

Ð |

|

±15 |

|

Ð |

|

μV/°C |

||

|

|

off |

|

|

|

|

|

|

|

|

|

Temperature Coefficient of Resistance(5) |

|

TCR |

0.21 |

|

Ð |

|

0.27 |

|

%Z |

/°C |

|

|

|

|

|

|

|

|

|

|

|

in |

|

Input Impedance |

|

Zin |

400 |

|

Ð |

|

550 |

|

Ω |

|

|

Output Impedance |

|

Zout |

750 |

|

Ð |

|

1250 |

|

Ω |

|

|

Response Time(6) (10% to 90%) |

|

tR |

Ð |

|

1.0 |

|

Ð |

|

ms |

||

Warm±Up |

|

Ð |

Ð |

|

20 |

|

Ð |

|

ms |

||

|

|

|

|

|

|

|

|

|

|

|

|

Offset Stability(9) |

|

Ð |

Ð |

|

± 0.5 |

|

Ð |

|

%V |

|

|

|

|

|

|

|

|

|

|

|

|

FSS |

|

MECHANICAL CHARACTERISTICS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Characteristic |

|

Symbol |

|

Min |

|

Typ |

|

Max |

|

Unit |

|

|

|

|

|

|

|

|

|

|

|

||

Weight (Basic Element, Case 344±15) |

|

Ð |

Ð |

|

2.0 |

|

Ð |

|

Grams |

||

|

|

|

|

|

|

|

|

|

|

||

Common Mode Line Pressure(7) |

|

Ð |

Ð |

|

Ð |

|

690 |

|

kPa |

||

NOTES: |

|

|

|

|

|

|

|

|

|

|

|

1.1.0 kPa (kiloPascal) equals 0.145 psi.

2.Device is ratiometric within this specified excitation range. Operating the device above the specified excitation range may induce additional error due to device self±heating.

3.Full Scale Span (VFSS) is defined as the algebraic difference between the output voltage at full rated pressure and the output voltage at the minimum rated pressure.

4.Offset (Voff) is defined as the output voltage at the minimum rated pressure.

5.Accuracy (error budget) consists of the following:

• |

Linearity: |

Output deviation from a straight line relationship with pressure, using end point method, over the specified |

|

|

pressure range. |

• |

Temperature Hysteresis: |

Output deviation at any temperature within the operating temperature range, after the temperature is |

|

|

cycled to and from the minimum or maximum operating temperature points, with zero differential pressure |

|

|

applied. |

• |

Pressure Hysteresis: |

Output deviation at any pressure within the specified range, when this pressure is cycled to and from the |

|

|

minimum or maximum rated pressure, at 25°C. |

• |

TcSpan: |

Output deviation at full rated pressure over the temperature range of 0 to 85°C, relative to 25°C. |

• |

TcOffset: |

Output deviation with minimum rated pressure applied, over the temperature range of 0 to 85°C, relative |

|

|

to 25°C. |

• |

TCR: |

Zin deviation with minimum rated pressure applied, over the temperature range of ± 40°C to +125°C, |

|

|

relative to 25°C. |

6.Response Time is defined as the time for the incremental change in the output to go from 10% to 90% of its final value when subjected to a specified step change in pressure.

7.Common mode pressures beyond specified may result in leakage at the case±to±lead interface.

8.Exposure beyond these limits may cause permanent damage or degradation to the device.

9.Offset stability is the product's output deviation when subjected to 1000 hours of Pulsed Pressure, Temperature Cycling with Bias Test.

2 |

Motorola Sensor Device Data |

TEMPERATURE COMPENSATION

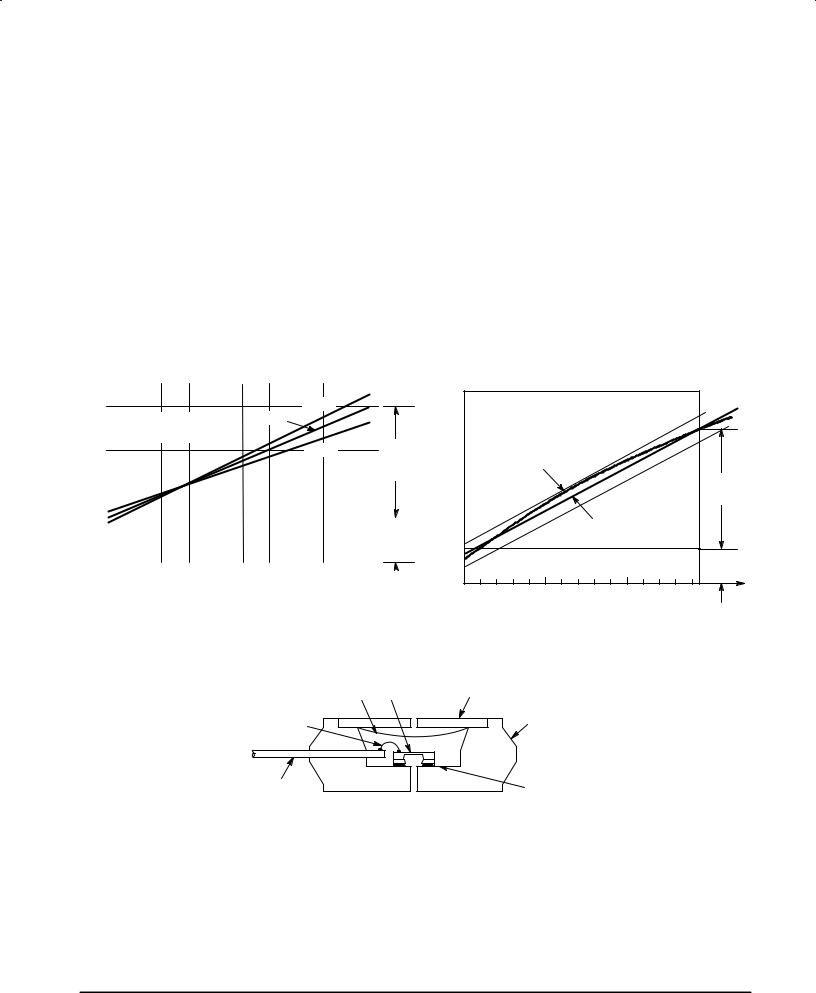

Figure 2 shows the typical output characteristics of the MPX10 series over temperature.

The X±ducer piezoresistive pressure sensor element is a semiconductor device which gives an electrical output signal proportional to the pressure applied to the device. This device uses a unique transverse voltage diffused semiconductor strain gauge which is sensitive to stresses produced in a thin silicon diaphragm by the applied pressure.

Because this strain gauge is an integral part of the silicon diaphragm, there are no temperature effects due to differences in the thermal expansion of the strain gauge and the diaphragm, as are often encountered in bonded strain gauge pressure sensors. However, the properties of the strain gauge itself are temperature dependent, requiring that the device be temperature compensated if it is to be used over an extensive temperature range.

Temperature compensation and offset calibration can be achieved rather simply with additional resistive components,

MPX10 SERIES

or by designing your system using the MPX2010D series sensor.

Several approaches to external temperature compensation over both ±40 to +125°C and 0 to +80°C ranges are presented in Motorola Applications Note AN840.

LINEARITY

Linearity refers to how well a transducer's output follows the equation: Vout = Voff + sensitivity x P over the operating pressure range (Figure 3). There are two basic methods for calculating nonlinearity: (1) end point straight line fit or (2) a least squares best line fit. While a least squares fit gives the ªbest caseº linearity error (lower numerical value), the calculations required are burdensome.

Conversely, an end point fit will give the ªworst caseº error (often more desirable in error budget calculations) and the calculations are more straightforward for the user. Motorola's specified pressure sensor linearities are based on the end point straight line method measured at the midrange pressure.

|

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

± 40 |

°C |

|

|

|

|

|

|

||

|

70 |

|

|

VS = 3 Vdc |

|

|

|

+ 25°C |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

(mVdc) |

|

|

|

P1 > P2 |

|

|

|

|

|

|

|

|

|

|

|

|

SPAN |

||||

50 |

|

|

|

|

|

|

|

|

|

+ 125°C |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

OUTPUT |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RANGE |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(TYP) |

||||

|

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OFFSET |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(TYP) |

|||

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PSI |

0 |

0.3 |

|

0.6 |

0.9 |

|

|

1.2 |

|

1.5 |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

kPa |

|

|

2.0 |

|

4.0 |

6.0 |

|

8.0 |

|

10 |

|

|

|

|

|||||||

|

|

|

|

|

|

PRESSURE DIFFERENTIAL |

|

|

|

|

|

|

|

|

|

||||||

Figure 2. Output versus Pressure Differential

|

70 |

|

|

|

60 |

LINEARITY |

|

|

|

|

|

(mVdc) |

50 |

|

|

40 |

ACTUAL |

|

|

|

SPAN |

||

OUTPUT |

|

|

|

30 |

(VFSS) |

||

|

|

||

|

THEORETICAL |

|

|

|

20 |

|

|

|

|

|

|

|

10 |

OFFSET |

|

|

0 |

(VOFF) |

|

|

0 |

MAX |

POP |

PRESSURE (kPA)

Figure 3. Linearity Specification Comparison

SILICONE |

|

|

STAINLESS STEEL |

DIE COAT |

DIE |

|

|

|

METAL COVER |

||

|

|

P1 |

|

|

|

EPOXY |

|

WIRE BOND |

|

|

|

|

|

CASE |

|

LEAD FRAME |

|

|

RTV DIE |

|

|

BOND |

|

|

|

P2 |

|

|

|

|

Figure 4. Cross±Sectional Diagram (not to scale)

Figure 4 illustrates the differential or gauge configuration in the basic chip carrier (Case 344±15). A silicone gel isolates the die surface and wire bonds from the environment, while allowing the pressure signal to be transmitted to the silicon diaphragm.

The MPX10 series pressure sensor operating characteris-

tics and internal reliability and qualification tests are based on use of dry air as the pressure media. Media other than dry air may have adverse effects on sensor performance and long term reliability. Contact the factory for information regarding media compatibility in your application.

Motorola Sensor Device Data |

3 |

Loading...

Loading...