Mitsubishi ME96SSHB-MB User Manual

Electronic Multi-Measuring Instrument

MODEL

ME96SSHB-MB

User's Manual: Detailed Edition

●Before use, you should read this user’s manual carefully to properly operate this instrument.

Be sure to forward the manual to the end user.

Check your delivery

The following table shows a list of the instrument accessories.

When unpacking your package, check all the contents.

Contents |

Quantity |

|

|

Specification |

||

User’s Manual |

1 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

||

(Digest version) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A3 size |

||

|

|

|

|

|

|

|

Attachment lug |

2 |

|

|

|

|

|

(with a screw) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Optional plug-in module

The following table shows a list of optional plug-in modules available for this product.

Installing the optional plug-in module enables various input or output. If you need it, consult with your supplier. ME-4201-NS96, ME-0052-NS96, and ME-0040C-NS96, which are optional plug-in modules for ME96NSR and ME96NSR-MB, are not available for ME96SSHB-MB.

|

|

|

|

|

|

|

|

|

|

I/O specifications |

|

|

|

|

|

|

|

|

||||

|

Model type |

|

|

Analog |

|

|

Pulse/Alarm |

|

|

Digital |

|

|

Digital |

|

|

Communication |

|

|

Logging |

|

|

|

|

|

|

|

output |

|

|

output |

|

|

input |

|

|

output |

|

|

|

|

function |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

ME-4210-SS96B |

|

4 ch |

|

2 ch |

|

1 ch |

|

|

|

|

|

|

|

|

|||||||

|

ME-0040C-SS96 |

|

|

|

|

|

4 ch |

|

|

|

|

CC-Link |

|

|

|

|||||||

|

ME-0052-SS96 |

|

|

|

|

|

5 ch |

|

2 ch |

|

|

|

|

|

|

|||||||

|

ME-0000MT-SS96 |

|

|

|

|

|

|

|

|

|

MODBUS |

|

|

|

||||||||

|

|

|

|

|

|

|

TCP |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

ME-0000BU-SS96 |

|

|

|

|

|

|

|

|

|

|

|

|

6 items |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

I/O parts |

|

|

|

|

Specifications |

|

|

|

|

|

Model type |

|

|||||||||

Analog output |

Output: 4 mA to 20 mA |

|

|

|

|

|

|

|

ME-4210-SS96B |

|

||||||||||||

Load resistance: 600 Ω or less |

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Pulse/Alarm output |

No-voltage a-contact |

|

|

|

|

|

|

|

ME-4210-SS96B |

|

||||||||||||

Contact capacity: 35 V DC, 0.1 A or less |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|||||||||||||||||

|

|

|

Contact capacity: 24 V DC (19 V DC to 30 V DC), 7 mA |

ME-4210-SS96B |

|

|||||||||||||||||

Digital input |

or less |

|

|

|

|

|

|

|

|

|

|

|

ME-0040C-SS96 |

|

||||||||

|

|

|

Input pulse width: 30 ms or more |

|

|

|

|

|

ME-0052-SS96 |

|

||||||||||||

Digital output |

No-voltage a-contact |

|

|

|

|

|

|

|

ME-0052-SS96 |

|

||||||||||||

Contact capacity: 35 V DC, 0.2 A or less |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In this manual, the operation is also explained when the optional plug-in module is installed.

1

Features

The instrument measures load status by wiring the secondary sides of VT (Voltage Transformer) and CT (Current Transformer) in the power receiving and distribution system and displays various measured values.

The instrument supports highly accurate measurement (accuracy of current/voltage: 0.1%; active energy: class 0.5S) and high-order harmonic measurement (1st to 31st).

Active energy can be measured by dividing into three time periods such as peak, off-peak, and shoulder. (Periodic Active Energy)

This instrument enables measurement of active energy/reactive energy/ apparent energy for any period (interval). (Rolling demand active power/Rolling demand reactive power/Rolling demand apparent power)

The password protection prevents undesired setting change and measured data deletion.

The transmission function (MODBUS RTU communication, CC-Link communication, or MODBUS TCP commination) transmits measured data to superior monitoring systems.

*CC-Link communication is available when ME-0040C-SS96 (optional plug-in module) is installed. *MODBUS TCP commination is available when ME-0040C-SS96 (optional plug-in module) is installed.

The logging function enables to back up measured values in a SD memory card even when a MODBUS RTU communication error occurs.

*It is available when ME-0000BU-SS96 (optional plug-in module) is installed.

This instrument itself can output key measuring elements such as current, voltage, active power, power factor, and active energy at the power receiving point by installing an optional plug-in module with analog output/pulse output function. It is ideal for remote monitoring.

*It is available when ME-4210-SS96B (optional plug-in module) is installed

The built-in logging function provides the logging of measured values, alarm logs, and system logs into this instrument.

The standard complies with the requirements of CE marking, UL standards, KC mark, and FCC/IC.

The support function for checking input wiring enables to determine the wiring condition in the test mode. When either a voltage input or current input are incorrectly wired, the incorrect wiring part is displayed on the screen and it also shows a current phase angle, a voltage phase angle, and each value of active power, voltage, and current.

Trademark

MODBUS is a trademark of Schneider Electric USA Inc.

Other company and product names herein are trademarks or registered trademarks of their respective owners. In the text, trademark symbols such as ‘TM’ and ‘®’ may not be written.

2

Table of Contents

Check your delivery ................................................................................................................................................ |

1 |

||||

Optional plug-in module.......................................................................................................................................... |

1 |

||||

Features.................................................................................................................................................................. |

|

|

|

2 |

|

Trademark .............................................................................................................................................................. |

|

|

|

2 |

|

Table of Contents ................................................................................................................................................... |

3 |

||||

Safety Precautions.................................................................................................................................................. |

5 |

||||

EMC Directive Instruction ....................................................................................................................................... |

9 |

||||

Table for measuring element code ....................................................................................................................... |

10 |

||||

1. |

Name and Function of Each Section............................................................................................................... |

11 |

|||

|

Name of Each Part ................................................................................................................................ |

11 |

|||

|

LCD Function......................................................................................................................................... |

13 |

|||

|

Function of Operation Buttons............................................................................................................... |

14 |

|||

|

LED Display of Optional Plug-in Module ............................................................................................... |

16 |

|||

2. |

Each Mode Function........................................................................................................................................ |

17 |

|||

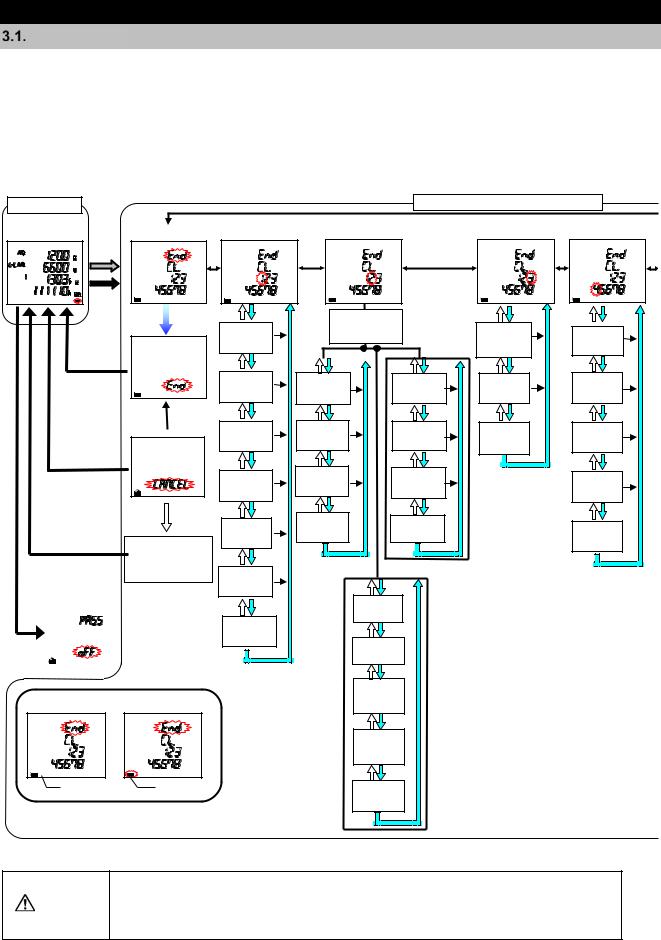

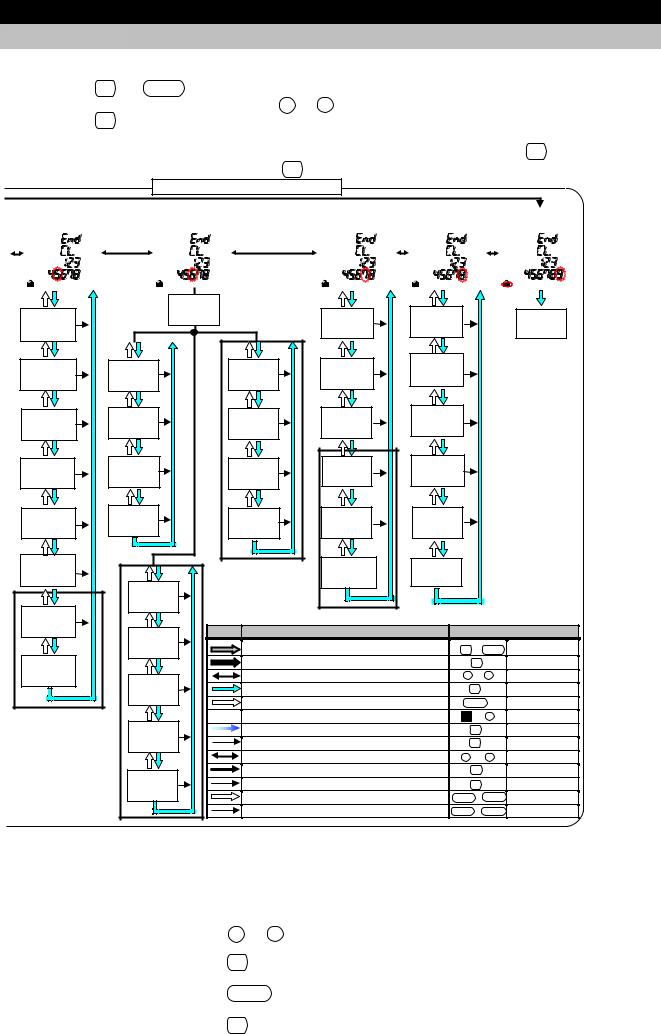

3. |

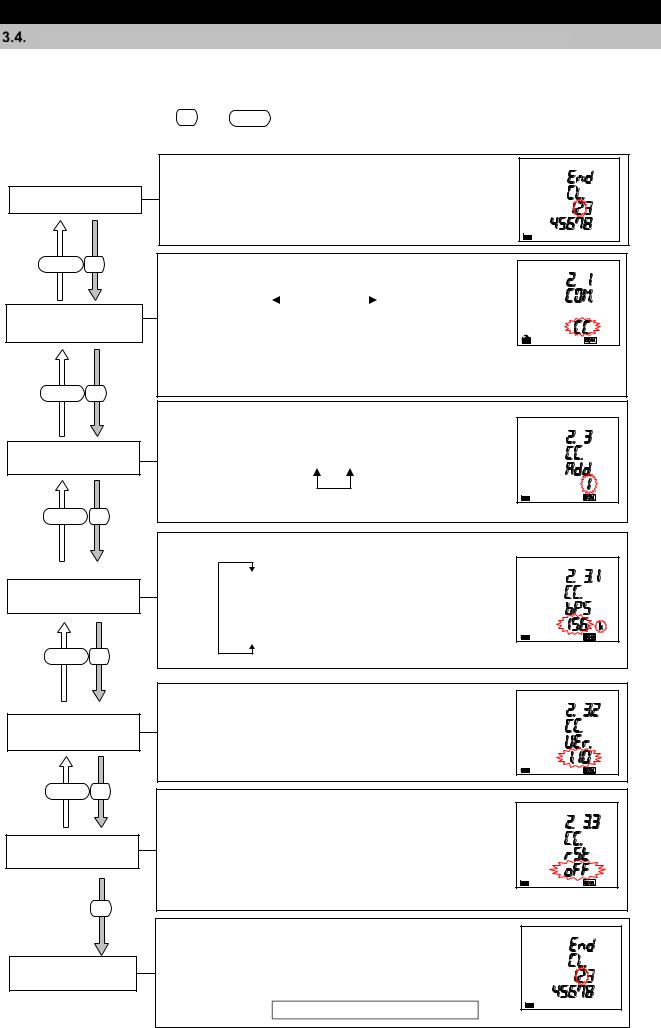

How to Set up .................................................................................................................................................. |

18 |

|||

|

Setting Flow........................................................................................................................................... |

18 |

|||

|

Setting Menu 1: Basic Setup (Settings for Phase Wire System, Display Pattern, VT/Direct Voltage, |

||||

|

and CT Primary Current) ....................................................................................................................... |

20 |

|||

|

Setting Menu 2: Communication Settings (MODBUS RTU Communication Settings) ......................... |

24 |

|||

|

Setting Menu 2: Communication Settings (CC-Link Communication Settings) .................................... |

25 |

|||

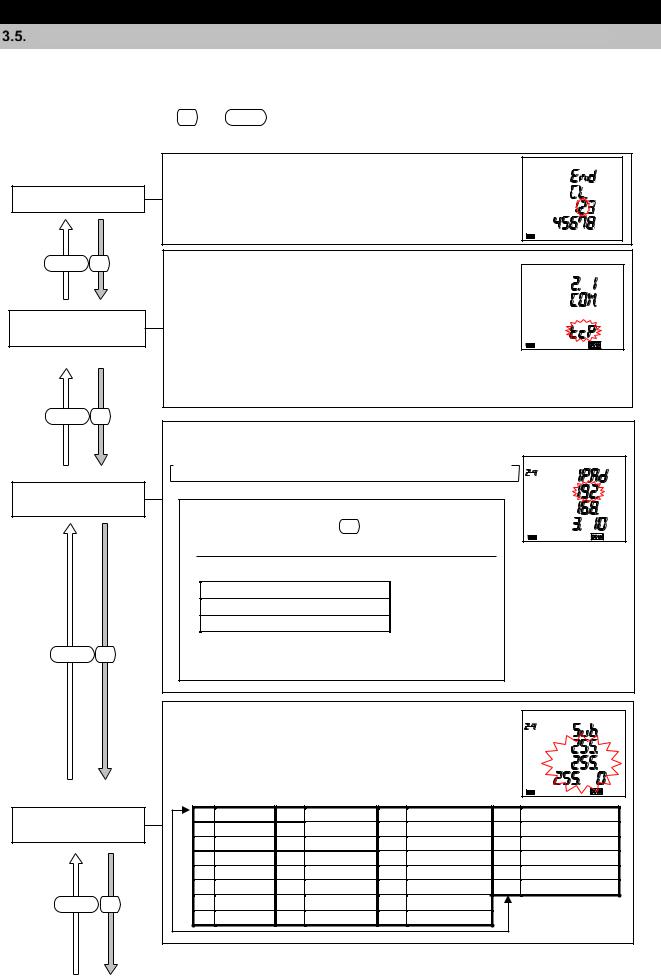

|

Setting Menu 2: Communication Settings (MODBUS TCP Communication Settings).......................... |

26 |

|||

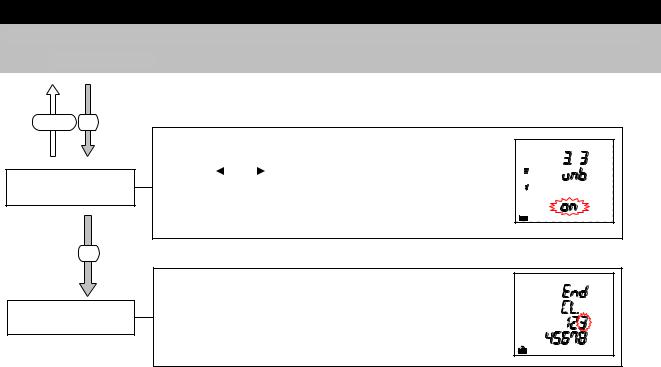

|

Setting Menu 3: Display Settings (Settings for Active/Reactive Energy and Harmonic Measurement)28 |

||||

|

Setting Menu 4: LCD Settings (Settings for Model Display, Version Display, Backlight, and Display |

|

|||

|

Update Time)......................................................................................................................................... |

30 |

|||

|

Setting Menu 5: Pulse/Alarm Settings (Settings for Upper/Lower Limit Alarm, Motor Starting Current |

|

|||

|

Mask Function, and Pulse Output) ........................................................................................................ |

31 |

|||

|

Setting Menu 6: Built-in Logging Settings ............................................................................................. |

36 |

|||

|

Setting Menu 6: Analog Output Settings ............................................................................................... |

39 |

|||

|

Setting Menu 6: Optional Logging settings............................................................................................ |

43 |

|||

|

Setting Menu 7: Settings for Periodic Active Energy, Rolling Demand, and Digital Input/Output......... |

45 |

|||

|

Setting Menu 8: Special Settings (Settings for Operating Time, IEC Mode, and CO2 equivalent)........ |

47 |

|||

|

Setting Menu CL: Present Time Settings .............................................................................................. |

49 |

|||

|

Setting Confirmation Menu 1 to 9: Confirming the Settings in the Setting Menu 1 to 8 and 9 Test |

|

|||

|

Mode...................................................................................................................................................... |

51 |

|||

|

Initialization of Related Items by Changing a Setting............................................................................ |

52 |

|||

|

Initialization of All Settings..................................................................................................................... |

53 |

|||

|

Settings for Special Display Pattern P00............................................................................................... |

54 |

|||

|

Example for Easy Setup ........................................................................................................................ |

56 |

|||

4. How to Use Test Mode .................................................................................................................................... |

58 |

||||

|

Test Menu 1: Communication Test ....................................................................................................... |

59 |

|||

|

Test Menu 2: Alarm Output/Digital Output Test .................................................................................... |

60 |

|||

|

Test Menu 3: Zero/Span Adjustment for Analog Output ....................................................................... |

61 |

|||

|

Test Menu 4: Analog Output Test ......................................................................................................... |

62 |

|||

|

Test Menu 5: Pulse Output Test............................................................................................................ |

63 |

|||

|

Test Menu 6: Function for Determining Incorrect Wiring....................................................................... |

64 |

|||

|

4.6.1. |

Incorrect Wiring Patterns Detected by |

Pattern display of incorrect wiring |

................................ |

67 |

5. |

.........................................................................................................................................................Operation |

|

|

|

70 |

|

Basic Operation ..................................................................................................................................... |

70 |

|||

|

5.1.1. |

How to Switch the Measurement Screen....................................................................................... |

70 |

||

|

5.1.2. |

How to Switch Phase Display ........................................................................................................ |

70 |

||

|

5.1.3. |

How to Display the Cyclic Mode .................................................................................................... |

71 |

||

|

5.1.4. |

Harmonics Display......................................................................................................................... |

72 |

||

|

5.1.5. |

Maximum/Minimum Value Display................................................................................................. |

73 |

||

|

5.1.6. |

How to Display Maximum/Minimum Value .................................................................................... |

73 |

||

|

5.1.7. |

How to Clear Maximum/Minimum Value........................................................................................ |

73 |

||

|

5.1.8. |

Active Energy/Reactive Energy/Apparent Energy Display ............................................................ |

74 |

||

|

5.1.9. |

How to Change the Display Digit of Active/Reactive/Apparent Energy......................................... |

74 |

||

|

5.1.10. How to Reset Active/Reactive/Apparent Energy to Zero............................................................... |

75 |

|||

|

5.1.11. How to Measure Reactive Energy (2 quadrant/4 quadrant measurement .................................. |

75 |

|||

|

5.1.12. Each Measuring Item Display during Power Transmission ........................................................... |

76 |

|||

|

5.1.13. |

Demand Time Period and Demand Value of Current demand...................................................... |

76 |

||

3

Table of Contents

|

Usage Depending on the Application (Alarm, Periodic Active Energy, Rolling Demand, Operating |

|

|

|

Time, Password, etc.)............................................................................................................................ |

77 |

|

|

5.2.1. |

Upper/Lower Limit Alarm Display and Action ................................................................................ |

77 |

|

5.2.2. |

How to Cancel the Upper/Lower Limit Alarm................................................................................. |

79 |

|

5.2.3. |

How to Stop Backlight Blinking Caused by the Upper/Lower Limit Alarm Generation.................. |

79 |

|

5.2.4. |

Upper/Lower Limit Alarm Item on the Alarm Contact .................................................................... |

79 |

|

5.2.5. |

Periodic Active Energy Display...................................................................................................... |

80 |

|

5.2.6. |

How to Reset Periodic Active Energy to Zero ............................................................................... |

80 |

|

5.2.7. |

Rolling Demand Display and Calculation....................................................................................... |

81 |

|

5.2.8. |

Rolling Demand Predict Value....................................................................................................... |

82 |

|

5.2.9. |

Rolling Demand Time Period Adjustment...................................................................................... |

82 |

|

5.2.10. |

How to Clear the Rolling Demand Peak Value.............................................................................. |

82 |

|

5.2.11. |

Operating Time Display ................................................................................................................. |

83 |

|

5.2.12. |

How to Reset Operating Time to Zero........................................................................................... |

83 |

|

5.2.13. |

CO2 Equivalent Display.................................................................................................................. |

83 |

|

5.2.14. |

How to Clear the CO2 Equivalent................................................................................................... |

83 |

|

5.2.15. |

Digital Input/Output Status Display and Action.............................................................................. |

84 |

|

5.2.16. |

How to Cancel the Latch for Digital Input ...................................................................................... |

84 |

|

5.2.17. |

How to Prevent Maximum Value Update by Motor Starting Current ............................................. |

84 |

|

5.2.18. |

Password Protection Setting.......................................................................................................... |

85 |

|

5.2.19. |

Built-in Logging Function ............................................................................................................... |

86 |

6. |

Others .............................................................................................................................................................. |

|

87 |

|

Display Pattern List................................................................................................................................ |

87 |

|

|

Standard Value...................................................................................................................................... |

90 |

|

|

Measuring Items and the Corresponding Display/Output ..................................................................... |

94 |

|

|

Instrument Operation............................................................................................................................. |

96 |

|

|

Troubleshooting..................................................................................................................................... |

97 |

|

7. |

Installation...................................................................................................................................................... |

|

100 |

|

Dimensions.......................................................................................................................................... |

100 |

|

|

How to Install ....................................................................................................................................... |

102 |

|

|

7.2.1. |

Mounting Hole Dimensions.......................................................................................................... |

102 |

|

7.2.2. |

Mounting Position ........................................................................................................................ |

102 |

|

7.2.3. |

Mounting and Fixing..................................................................................................................... |

102 |

|

7.2.4. |

Optional Plug-in Module Installation ............................................................................................ |

102 |

|

How to Connect Wiring........................................................................................................................ |

103 |

|

|

7.3.1. |

Specifications on the Applicable Electrical Wire.......................................................................... |

103 |

|

7.3.2. |

Wiring of this Instrument .............................................................................................................. |

103 |

|

7.3.3. |

Wiring of the Optional Plug-in Module ......................................................................................... |

103 |

|

7.3.4. |

Check the Connection.................................................................................................................. |

103 |

|

Wiring Diagram.................................................................................................................................... |

105 |

|

|

How to insert/remove SD memory card .............................................................................................. |

113 |

|

8. |

Specifications................................................................................................................................................. |

114 |

|

|

Product Specifications ......................................................................................................................... |

114 |

|

|

Compatible Standards ......................................................................................................................... |

117 |

|

|

MODBUS RTU Communication Specifications ................................................................................... |

117 |

|

|

CC-Link Communication Specifications for optional plug-in module .................................................. |

118 |

|

|

MODBUS TCP Communication Specifications for optional plug-in module ....................................... |

118 |

|

|

Logging Specifications for optional plug-in module............................................................................. |

119 |

|

|

Setting Table (Factory Default Settings and Customer’s Notes Settings) .......................................... |

120 |

|

9. |

Appendix........................................................................................................................................................ |

|

123 |

|

ME96SS Calculation Method (3-phase Unbalanced System with Neutral) ........................................ |

123 |

|

|

Optional parts ...................................................................................................................................... |

124 |

|

|

A List of Examples for Incorrect Wiring Display .................................................................................. |

125 |

|

|

9.3.1. |

3-phase 4-wire System ................................................................................................................ |

125 |

|

9.3.2. |

3-phase 3-wire System ................................................................................................................ |

134 |

|

9.3.3. |

1-phse 3-wire System .................................................................................................................. |

141 |

4

Safety Precautions

Before use, read these instructions carefully to properly operate the instrument. Be sure to follow the precautions described here for personnel and product safety. Keep this manual ready to hand and accessible for future use at all times.

Be sure to forward the manual to the end user.

If you consider using the instrument for a special purpose such as nuclear power plants, aerospace, medical care, or passenger vehicles, consult with our sales representative.

The instructional icon in the manual is described as follows.

The caution icon ( ) on the main unit indicates that incorrect handling may cause hazardous conditions. Always follow the subsequent instructions (

) on the main unit indicates that incorrect handling may cause hazardous conditions. Always follow the subsequent instructions ( ) because

) because

they are important to personal safety. Failure to follow them may result in an CAUTION electric shock, a fire, erroneous operation, or damage to the instrument. If the

instrument is used in a manner not specified by the manufacturer, the protection provided by the instrument may be impaired.

The terminals of auxiliary power (MA, MB) and voltage input (P1, P2, P3, PN) have

CAUTION hazards of electric shock, explosion, or arc flash. Turn off the power supply of auxiliary power and input circuit and then handle the instrument.

CAUTION hazards of electric shock, explosion, or arc flash. Turn off the power supply of auxiliary power and input circuit and then handle the instrument.

■Precautions on use environment and conditions Do not use the instrument in the following places:

Failure to follow the instruction may cause a malfunction or reduced product life time.

The ambient temperature exceeds the range -5°C to +55°C.

The average daily temperature exceeds +35°C.

The relative humidity exceeds the range 0 to 85% RH, or condensing.

The altitude exceeds 2000 m.

Pollution Degree: more than 2 *Note 1

Exposed to much dust, corrosive gas, salty environment, or oil mist

Transient over voltage: 4000 V *Note 1

Exposed to excessive vibration or impact

Exposed to rain or water drops

Exposed to direct sunlight

Pieces of metal or inductive substances are scattered.

Exposed to strong magnetic fields or large exogenous noise

Note1: For details about the Pollution Degree and the Transient over voltage category, refer to EN61010-1:2010.

Grit, dust, and small insects cause poor contact or a failure such as insulation decline that caused by deposition and moisture absorption. Furthermore, in the area where the air contains conductive dust, a failure such as a product malfunction or insulation deterioration occurs in a relatively short time. In this case, you must take measures against it such as putting the instrument in an enclosed board. In addition, if the temperature inside the board rises, the measures must be undertaken as well.

5

Safety Precautions

■Precautions on Installation and wiring

Be sure to read the instructions carefully before installation and wiring.

A qualified electrician must install and wire the instrument for safety.

Supply power to the instrument after completing its assembly work on a cabinet door.

The instrument is to be mounted on the cabinet door. All connections must be kept inside the cabinet.

The following table shows the specifications on the input/output terminal.

■Auxiliary power supply and measuring elements

|

Auxiliary power supply |

|

100 V AC to 240 V AC (±15%) 50 Hz to 60 Hz |

MA, MB |

|||||

|

|

100 V DC to 240 V DC (-30% 15%) |

|

|

terminal |

||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

3-phase 4-wire: max 277/480 V AC |

|

|

|

|

|

|

|

|

|

3-phase 3-wire: (DELTA) max 220 V AC |

|

|

||

|

|

|

Voltage |

|

|

(STAR) max 440 V AC |

|

Category |

P1, P2, P3, PN |

|

|

|

|

1-phase 3-wire: max 220/440 V AC |

|

|

terminals |

||

|

|

|

|

|

|

||||

|

Measuring |

|

|

|

1-phase 2-wire: (DELTA) max 220 V AC |

|

|

||

|

element |

|

|

|

(STAR) max 440 V AC |

|

|

|

|

|

|

|

|

|

5 A (CT secondary side), |

|

Category |

+C1, C1, +C2, |

|

|

|

|

Current |

|

|

C2, +C3, C3 |

|||

|

|

|

|

max 30 V AC |

|

|

|||

|

|

|

|

|

|

terminals |

|||

|

|

|

|

|

|

|

|

|

|

|

|

Frequency |

50 Hz or 60 Hz |

|

|

|

|||

|

The current |

input terminals must be connected to a CT, external equipment, with basic |

|||||||

|

insulation. |

|

|

|

|

|

|||

|

Be sure to continuously connect the terminals for voltage-measuring purpose and current- |

||||||||

|

measuring purpose during operation. |

|

|

|

|||||

|

■Others |

|

|

|

|

|

|||

|

MODBUS RTU communication |

T/R+, T/R-, SG terminals |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

MODBUS TCP communication |

Ethernet terminal |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

CC-Link communication |

|

DA, DB, DG terminals |

|

|

|

|||

|

|

|

|

|

|

|

|

||

|

Digital input |

|

DI1, DI2, DI3, DI4, DI COM, DI+, DI-, DI1+, DI1-, |

max 35 V DC |

|||||

CAUTION |

|

DI2+, DI2-, DI3+, DI3-k, DI4+, |

DI4-, DI5+, DI5- |

||||||

|

|

|

|

|

terminals |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital output |

|

DO1+, DO1-, DO2+, DO2terminals |

|

|||||

|

Analog output |

|

CH1+, CH1-, CH2+, CH2-, CH3+, CH3-, CH4+, CH4- |

|

|||||

|

|

terminals |

|

|

|

||||

|

Pulse/Alarm output |

|

C1A/A1, C1B/COM1, C2A/A2, C2B/COM2 terminals |

|

|||||

Keep the protection sheet affixed to the front of the instrument during installation and wiring.

Do not drop the instrument from high place. If it is dropped and the display cracks, do not touch the liquid leaking from the broken LCD or do not get it in your mouth. If you touched the liquid, rinse it off with soapy water at once.

Do not work under live-line condition. Otherwise, an instrument failure, an electric shock, or a fire may be caused.

When tapping or wiring, take care not to enter any foreign objects such as chips or wire pieces into the instrument.

If you pulled the wires with a strong force when connecting them to the terminals, the terminals might come off. (Tensile load: 39.2 N or less)

Check the wiring diagram carefully. Inappropriate wiring can cause a failure of the instrument, an electric shock, or a fire.

Use appropriate size wires. The use of an inappropriate size wire can cause a fire due to heat generation.

Use crimp-type terminals compatible with the wire size. For details, refer to 7.3.1 Specifications on Applicable Electrical Wire. The use of an inappropriate terminal

can cause a malfunction, failure, or burnout of the instrument or a fire due to damage to the terminal or poor contact.

Tighten the terminal screws with a specified torque and use a suitable pressure connector. For details, refer to 7.3.1Specifications on Applicable Electrical Wire.

Excessive tightening can cause damage to the terminals and screws.

Be sure to confirm the wiring connections strictly after the connection. Poor connection can cause a malfunction of the instrument, an electric shock, or a fire.

Continued to the next page.

6

Safety Precautions

|

In order to prevent invasion of noise, MODBUS RTU communication cables, auxiliary |

|||

|

power supply cables, and other signal cables must not be placed close to or bound |

|||

|

together with power lines or high voltage lines. When lying parallel to the power lines or |

|||

|

high voltage lines, refer to the following table for the separation distance. (Except the |

|||

CAUTION |

input part of the terminal block) |

|

|

|

|

|

Conditions |

Distance |

|

|

|

Power lines of 600 V or less |

300 mm or more |

|

|

|

Other power lines |

600 mm or more |

|

|

|

|

|

|

■Precautions on preparation before use

Observe the use conditions and environment requirements for installation place.

You must set up the instrument before use. Read the manual carefully to set it up correctly. If the setup is incorrectly done, the instrument will not be properly operated.

Check the power rating of the instrument and then apply proper voltage.

■Precautions on how to use

When operating the instrument, check that active bare wires do not exist around it. If any bare wire existed, stop the operation immediately and then take appropriate action such as insulation protection.

If a power outage occurred during the setup, the instrument would not be set up correctly. Set it up again after power recovery.

Do not disassemble or modify the instrument to use. Otherwise, a failure, an electric shock, or a fire can be caused.

Use the instrument within the rating specified in the manual. If you used it outside the rating, it might cause not only a malfunction or failure of the instrument but also ignition or burnout.

Do not open the CT secondary side while the primary current is energized. When the CT

secondary side circuit is open, the primary current flows. However, the secondary  CAUTION current does not flow. Therefore, a high voltage is generated at the CT secondary side and the temperature rises, resulting in insulation breakdown in the CT secondary

CAUTION current does not flow. Therefore, a high voltage is generated at the CT secondary side and the temperature rises, resulting in insulation breakdown in the CT secondary

winding. It may lead to burnout.

When external equipment is connected to the external terminals, the instrument and external equipment must not be powered and be used after the definitive assembly on a cabinet door.

The rating of the terminal of external equipment should satisfy that of the external terminal of the instrument.

■Precautions on maintenance

Wipe dirt off the surface with a soft dry cloth.

Do not leave a chemical cloth in contact with the instrument for a long time or do not wipe it with benzene, thinner, or alcohol.

In order to properly use the instrument for a long time, conduct the following inspections:

(1) Daily maintenance

No damage in the instrumentNo abnormality with LCD indicator

No abnormal noise, smell or heat generation

(2)Periodical maintenance

Inspect the following item every six months to once a year.

No looseness of installation and terminal block connection

Be sure to conduct periodic inspection under the electric outage condition. Failure to follow

CAUTION the instruction may cause a failure of the instrument, an electric shock, or a fire. Tighten the terminals regularly to prevent a fire.

CAUTION the instruction may cause a failure of the instrument, an electric shock, or a fire. Tighten the terminals regularly to prevent a fire.

7

Safety Precautions

■Precautions on storage

To store the instrument, turn off the power supplies of auxiliary power and input circuit, remove the wires from the terminals, and then put them in a plastic bag.

For long-time storage, avoid the following places. Otherwise, there is danger of an instrument failure or reduced product life time.

The ambient temperature exceeds the range -25°C to +75°C.

The average daily temperature exceeds +35°C.

The relative humidity exceeds the range 0 to 85% RH, or condensing.

Exposed to much dust, corrosive gas, salty environment, or oil mist.

Exposed to excessive vibration or impact.

Exposed to rain or water drops.

Exposed to direct sunlight.

Pieces of metal or inductive substances are scattered.

■Warranty

The warranty period is for one year from the date of your purchase or 18 months after the manufacturing date, whichever is earlier.

During the warranty period, if any failure occurred in standard use that the product is used in the condition, method, and environment followed by the conditions and precautions described in the catalog and user’s manual, we would repair the product without charge.

Even within the warranty period, non-free repair is applied to the following cases.

Failures caused by the customer’s improper storage, handling, carelessness, or fault.Failures caused by faulty workmanship

Failures due to faults in use or undue modification

Failures due to force majeure such as a fire or abnormal voltage or due to natural disasters such as earthquakes, windstorms, or floods.

Failures caused by the problem in question that could not be predicted with the technology available at the time the product was shipped.

Our company shall not be liable to compensate for any loss arising from events not attributable to our company, customers’ opportunity loss or lost earnings due to failure of the product, any loss, secondary loss, or accident caused by a special reason regardless of our company’s predictability, damage to other products besides our products, or other operations

■Replacement cycle of the product

It is recommend that you renew the product every ten years although it depends on your use condition. The long-term use of the product may cause discoloration of the LCD or a product malfunction.

■Disposal

Treat the product properly as industrial waste.

ME-0000BU-SS96 (optional plug-in module) is equipped with a lithium battery. The lithium battery is disposed of according to the local regulation.

In EU member states, there is a separate collection system for waste batteries. Dispose of batteries properly at the local community waste collection/recycling center.

For ME-0000BU-SS96, the following symbol mark is printed on the packaging.

Note: This symbol is for EU member states only.

The symbol is specified in Article 20 ‘Information for end-users’ of the new EU Battery Directive (2006/66/EC) and the Annex II.

The above symbol indicates that batteries need to be disposed of separately from other wastes.

ME-0000BU-SS96 (optional plug-in module) is equipped with a lithium battery. Therefore,

CAUTION if it is thrown in fire, heat generation, burst, or ignition may occur. The lithium battery is disposed of according to the local regulation.

■Packaging materials and user’s manual

For reduction of environment load, cardboard is used for packaging materials and the manual is printed with recycled papers.

8

EMC Directive Instruction

This section summarizes the precautions to have the cabinet constructed with the instrument conform to the EMC Directive.

However, the method of conformance to the EMC Directive and the judgment on whether or not the cabinet conforms to the EMC Directive must be determined finally by the manufacturer.

This instrument complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This instrument may not cause harmful interference, and (2) this instrument must accept any interference received, including interference that may cause undesired operation.

1 EMC Standards

EN 61326-1

EN 61000-3-2

EN 61000-3-3

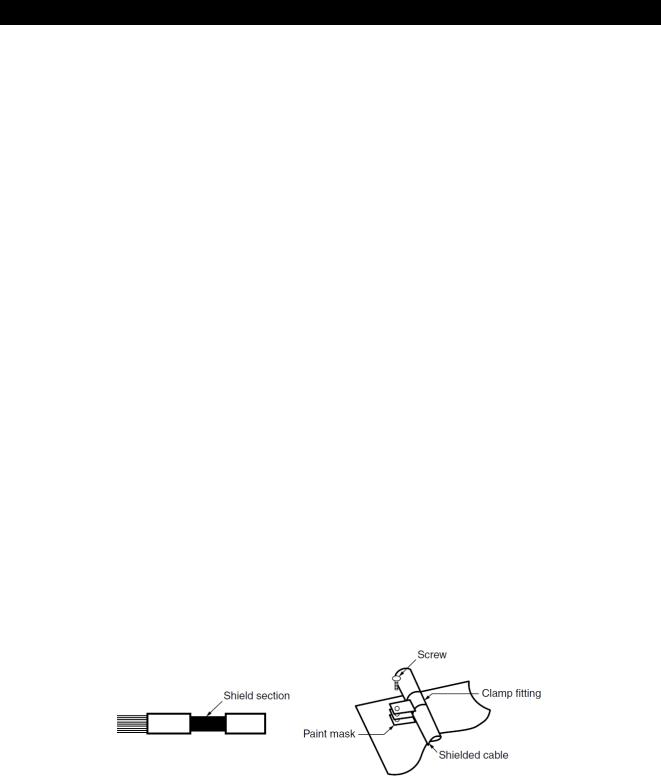

2 Installation (EMC directive)

The instrument is to be mounted on the panel of a cabinet.

Therefore, the installation to the cabinet is important not only for safety but also for conformance to EMC. The instrument is examined in the following conditions.

A conductive cabinet must be used.

The conductivity of the six surfaces of the cabinet must be all ensured.

The cabinet must be grounded by thick wires for low impedance.

The hole drilling dimensions on the cabinet must be 10 cm or less in diameter.

The terminals for protective earth and functional earth must be grounded by thick wires for low impedance. The use of the terminal for protective earth is important not only for safety but also for conformance to EMC.

The connecting part of the terminal must be all placed inside the cabinet.

Wiring outside the cabinet must be conducted with shielded cables, and the cables must be fixed to the panel with clamps. (Strip the covering of shielded cable by a portion of clamp installation and then mask the grounding part of the panel and clamp so as not to be painted.)

9

Table for measuring element code

The following table shows a list of measuring element codes used in the manual.

Measuring element code |

Measuring element name |

A1 |

Current, 1-phase |

A2 |

Current, 2-phase |

A3 |

Current, 3-phase |

AN |

Current, N-phase |

AAVG |

Current, average |

DA1 |

Current demand, 1-phase |

DA2 |

Current demand, 2-phase |

DA3 |

Current demand, 3-phase |

DAN |

Current demand, N-phase |

DAAVG |

Current demand, average |

V12 |

Voltage, between 1-2 lines |

V23 |

Voltage, between 2-3 lines |

V31 |

Voltage, between 3-1 lines |

VAVG (L-L) |

Voltage, average, line to line |

V1N |

Voltage, 1N-phase |

V2N |

Voltage, 2N-phase |

V3N |

Voltage, 3N-phase |

VAVG (L-N) |

Voltage, average, line to neutral |

W1 |

Active power, 1-phase |

W2 |

Active power, 2-phase |

W3 |

Active power, 3-phase |

ΣW |

Active power, total |

var1 |

Reactive power, 1-phase |

var2 |

Reactive power, 2-phase |

var3 |

Reactive power, 3-phase |

Σvar |

Reactive power, total |

VA1 |

Apparent power, 1-phase |

VA2 |

Apparent power, 2-phase |

VA3 |

Apparent power, 3-phase |

ΣVA |

Apparent power, total |

PF1 |

Power factor, 1-phase |

PF2 |

Power factor, 2-phase |

PF3 |

Power factor, 3-phase |

ΣPF |

Power factor, total |

Hz |

Frequency |

Wh |

Active energy |

varh |

Reactive energy |

VAh |

Apparent energy |

DW |

Rolling demand active power |

Dvar |

Rolling demand reactive power |

DVA |

Rolling demand apparent power |

HI |

Harmonic current |

HIN |

Harmonic current, N-phase |

HV |

Harmonic voltage |

THDi |

Harmonic current total distortion ratio |

THDv |

Harmonic voltage total distortion ratio |

Aunb |

Current unbalance rate |

Vunb |

Voltage unbalance rate |

DI |

Digital input |

DO |

Digital output |

10

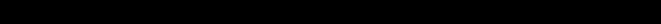

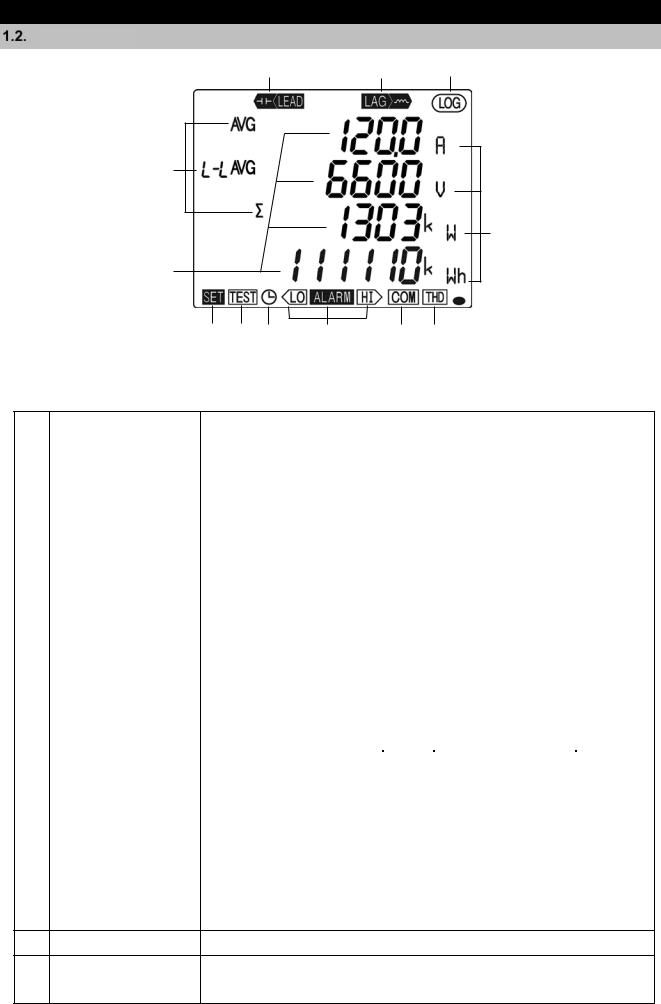

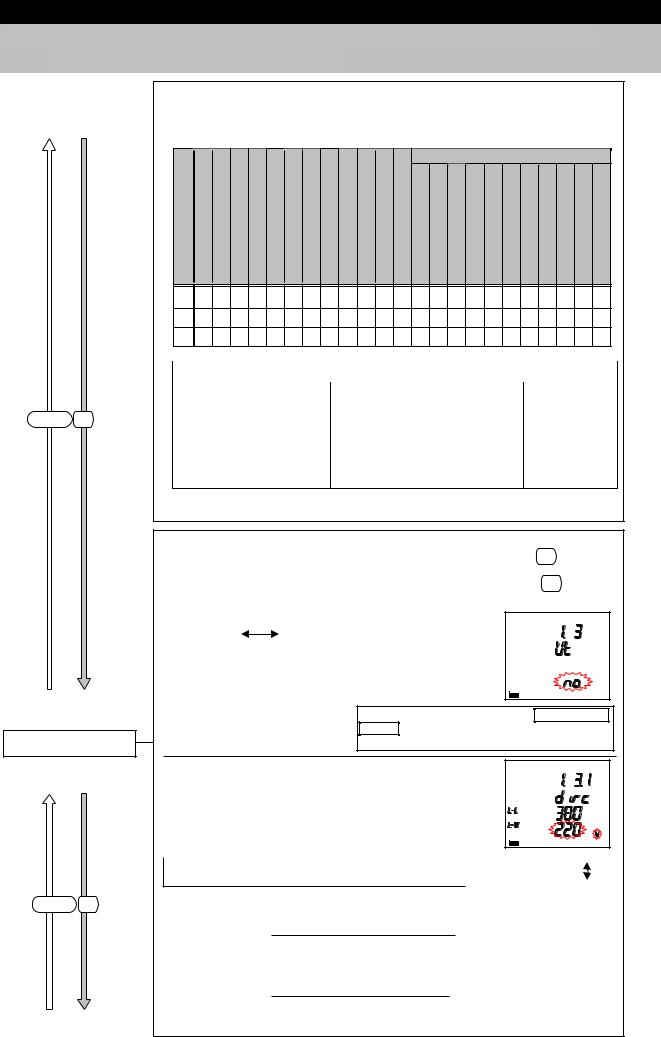

1. Name and Function of Each Section

Name of Each Part

<The instrument>

■The front of the unit

LCD with backlight

Operation buttons

*For details, refer to 1.3 Function of Operation Buttons.

■The back of the unit

MODBUS RTU communication terminals

T/R+: MODBUS RTU communication transmission terminal

T/R-: MODBUS RTU communication transmission terminal

SG: MODBUS RTU signal ground terminal

SLD: Shielded wire terminal (Ground resistance: 100 Ω or less)

Option cover

Remove the option cover to attach each optional plug-in module. For the terminal names of optional plug-in modules, refer to the next page.

Auxiliary power input terminals

MA, MB: Connect to an auxiliary power.

: Ground terminal (Ground resistance: 100 Ω or less)

Terminal covers

Voltage Input terminals

P1, P2, P3, PN (P1, NC, P3, P2): Circuit voltage is input.

Current Input terminals

+C1, C1: Input a circuit current. +C2, C2: Input a circuit current. +C3, C3: Input a circuit current.

11

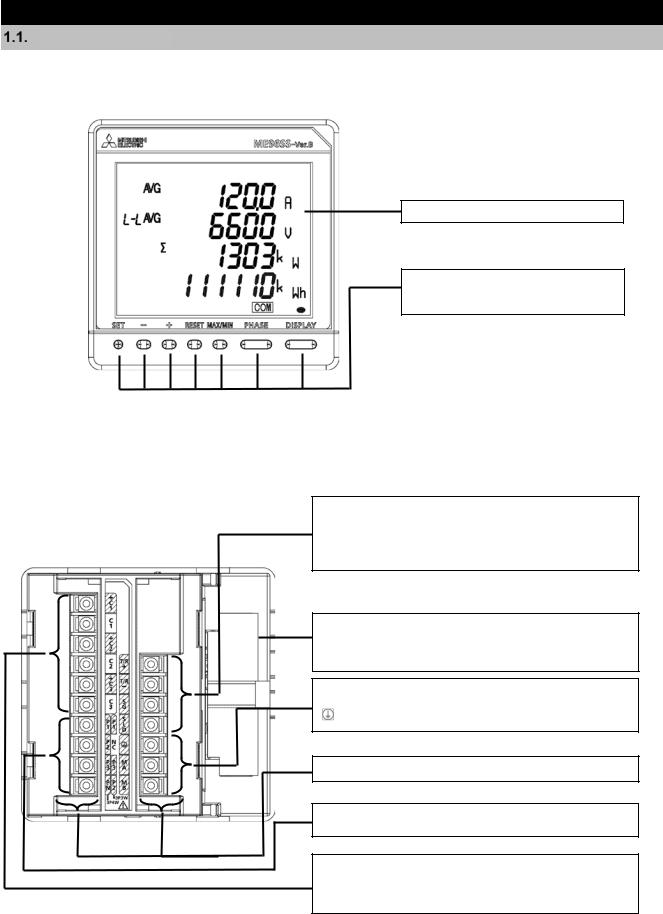

1.Name and Function of Each Section

1.1. Name of Each Part

<The optional plugs-in module>

■The back view (Model type: ME-4210-SS96B, ME-0040C-SS96, ME-0052-SS96)

|

Input/Output terminals (ME-4210-SS96B) |

|

|

Input/Output terminals (ME-0040C-SS96) |

|

CH1+, CH1-: Analog output terminal |

|

|

DA: CC-Link communication terminal |

|

CH2+, CH2-: Analog output terminal |

|

|

DB: CC-Link communication terminal |

|

CH3+, CH3-: Analog output terminal |

|

|

DG: CC-Link communication terminal |

|

CH4+, CH4-: Analog output terminal |

|

|

SLD: Shielded wire terminal |

|

C1A/A1, C1B/COM1: Pulse/Alarm output |

|

|

FG: Ground terminal |

|

C2A/A2, C2B/COM2: Pulse/Alarm output |

|

|

(Ground resistance: 100 Ω or less) |

|

DI+, DI-: Digital input terminal |

|

|

DI1, DI2, DI3, DI4, DI COM: Digital input |

|

|

|

|

terminal |

|

|

|

||

|

|

|

|

|

Input/Output terminals (ME-0052-SS96)

DI1+, DI1-: Digital input terminal

DI2+, DI2-: Digital input terminal

DI3+, DI3-: Digital input terminal

DI4+, DI4-: Digital input terminal

DI5+, DI5-: Digital input terminal

DO1+, DO1-: Digital output terminal

DO2+, DO2-: Digital output terminal

■The side/back view ((Model type: ME-0000MT-SS96)

LED indicators

(Refer to 1.4 LED display of optional plug-in module.)

ERR. Red

10/100 Green

LINK/ACT Green

10BASE-T/100BASE-TX

Connection connector (RJ45)

Connection connector (RJ45)

■The side/back view (Model type: ME-0000BU-SS96)

Slot for SD memory card

Slot for SD memory card

LED indicators

(Refer to 1.4 LED display of optional plug-in module.)

LOG. Red

SD C. Red

BAT. Red

12

1. Name and Function of Each Section

LCD Function

1 |

2 |

3 |

4

6

5

13

13

7 |

8 |

9 |

10 |

11 |

12 |

Note: The above display is an example for explanation.

No. |

|

Name of each part |

|

|

|

Function |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

LEAD status |

|

Light up on the reactive energy (imported lead)/ (exported lead) screen. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

LAG status |

|

Light up on the reactive energy (imported lag)/ (exported lag) screen. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

Built-in logging status |

|

Light up when the built-in logging function is operating |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

Digital element display |

|

Display measuring elements expressed in digital numbers |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

Digital display |

|

Display measured values in digital numbers |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

Unit |

|

Display the units of measured values |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

Setup status |

|

Light up in the setting mode |

|

|

|

|

|

|

|

|

|

Blink in the setting confirmation mode |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||

8 |

|

Test mode status |

|

Light up in the test mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

Clock status |

|

Light up when the present time is set. |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

Upper/lower limit alarm |

|

Blink when the upper/lower limit alarm is generating |

|

|

|

||||

|

|

status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specification |

ON |

|

Blink |

|

OFF |

|

|

|

|

|

|

|

|

|

CC-Link version |

|

Hardware |

|

|

|

|

|

|

CC-Link communication |

Normal |

|

mismatches |

|

|

|

|

|

|

|

|

|

abnormality |

|

||||

|

|

|

|

|

|

|

|

Hardware abnormality |

|

||

|

|

Communication/ |

|

|

|

|

|

|

|

|

|

11 |

|

|

|

MODBUS RTU communication |

Normal |

|

Communication error |

|

Hardware |

|

|

|

Option |

|

|

|

such as wrong |

|

|

||||

|

|

logging status display |

|

|

MODBUS TCP communication |

|

|

address*1 |

abnormality |

|

|

|

|

|

|

|

|

|

Error occurrence such |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

as setting abnormality, |

|

Hardware |

|

|

|

|

|

|

Option logging function |

Normal |

|

SD memory card error, |

|

|

|

|

|

|

|

|

|

abnormality |

|

||||

|

|

|

|

|

|

|

|

or battery voltage drop |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*1 |

|

|

|

|

*1. For details, refer to 6.5 Troubleshooting.

12 Harmonics |

Light up when harmonic is displayed |

13 Metering status

Blink when Imported active energy is measured *Note 1

*It appears on the imported active energy display screen only

Note 1: The blinking cycle is constant regardless of measuring input size.

13

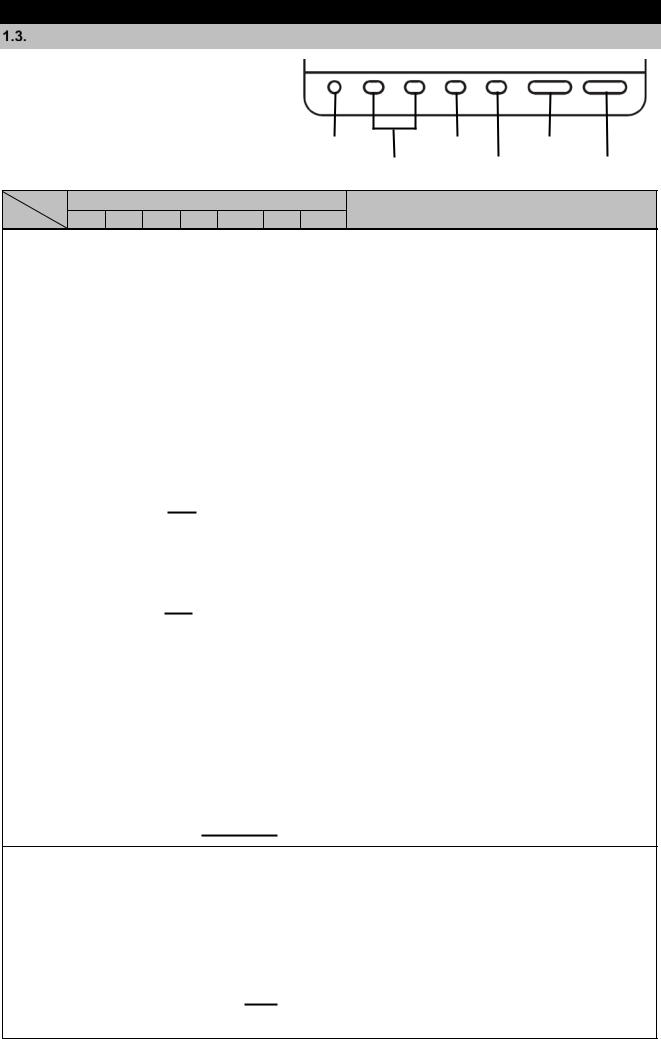

1. Name and Function of Each Section

Function of Operation Buttons

The function of each operation button varies |

SET |

RESET MAX/MIN-PHASE DISPLAY |

|

depending on how to press the button. |

|||

|

|

|

SET button |

|

|

RESET button |

|

Phase button |

|

||||

|

|

|

|

|

|

|

|

||||

<Meaning of marks> |

|

+/- button |

MAX/MIN button |

DISPLAY button |

|||||||

|

|

|

|

|

|

|

|

|

|

||

○: Press, □: Press for 1 second or more, : Press for 2 seconds or more, ――:Press simultaneously

Operation |

|

|

Button name |

Function |

|

Mode |

SET |

|

RESET MAX/MIN PHASE DISPLAY |

||

|

mode Operating

confirmation Setting |

mode/ Setting |

mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

Switch the measurement screen. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

Switch the measurement screen in the reverse direction. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch phase display. |

|

|

Display |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

|

|

Switch between the harmonic RMS value and distortion ratio. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Available on the harmonics display screen) |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

|

|

|

|

|

Enter/Exit the Max/Min value screen. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

switching |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter the cyclic display mode of measurement screen. Refer to |

|||

|

|

|

|

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

Switch the harmonic degree on the harmonics display screen. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.1.3. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter the cyclic display mode of phase. Refer to 5.1.3. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch between the harmonic RMS value and distortion ratio |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

screen in cyclic mode. (Available on the harmonics display) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Change the units of Wh, varh, and VAh or display the lower- |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

digit enlarged view. Refer to 5.1.9. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clear the Max/Min values displayed on |

|

They are available |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the screen. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

on the Max/Min |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clear Max/Min values for every item in |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

value screen. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

every screen. |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset Wh, varh, and VAh to zero. |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All measured values are reset to zero simultaneously. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset periodic active energy to zero. |

|

|||||

clear/valueMeasured resetAlarm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(The periodic active energy displayed on the screen only) |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Set the rolling demand time period on the rolling demand |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

screen. |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clear the rolling demand peak value on the rolling demand |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

screen. |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset operating time to zero. |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(The operating time displayed on the screen only) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset CO2 equivalent to zero on the CO2 equivalent screen. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

|

|

|

|

|

|

Reset the alarm. |

|

They are available |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(For the item displayed on the screen) |

|

only when set to |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset all alarms at once. |

|

manual alarm |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(For every item in every screen) |

|

cancellation. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

|

|

|

|

|

|

Stop the backlight blinking caused by alarm. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Available only when set to backlight blinking) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Release the latch for digital input at once on the digital input |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

screen. |

|

|||||

Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter the setting mode. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter the setting confirmation mode. |

|

||||

switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter the password protection screen. |

|

|||||

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Determine the settings and then shift to the next settings. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

Return to the previous setting item. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○ |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

Round up/down the setting value. |

|

||||||||

operation |

|

|

|

□ |

□ |

|

|

|

|

|

|

|

|

|

|

|

|

(Pressing for 1 second or more enables fast forward.) |

|||||||||

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reflect the setting change. (Available on the END screen) |

|||||

|

□ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Skip the settings and return to the setting menu screen. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cancel the setting change. (Available on the CANCEL screen) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Special operation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CANCEL screen) Refer to 3.16. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

□ |

|

□ |

|

|

Restart the instrument. (Available on the CANCEL screen) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Initialize to the factory default settings. (Available on the |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14

1. Name and Function of Each Section

1.3. Function of Operation Buttons

Note: During backlight off mode, pressing any operation button first turns on the backlight. In addition, pressing any button again enables the use of the functions in the above table.

|

When you execute a function such as ‘Reset Max/Min value’ or ‘Reset Wh, varh, and |

CAUTION |

VAh to zero’, past data is deleted. If you need to keep the data, record the data before |

the reset operation. |

|

When you execute ‘Restart the instrument’, the entire measurement function |

|

|

(measurement display, communication) will stop for a few seconds. |

|

|

15

1. Name and Function of Each Section

LED Display of Optional Plug-in Module

■LED (ME-0000MT-SS96

1. ERR.

1. ERR.

2. 10/100

2. 10/100

3. LINK/ACT

3. LINK/ACT

■LED (ME-0000BU-SS96

1. LOG.

1. LOG.

2. SD C.

2. SD C.  3. BAT.

3. BAT.

No. |

|

|

Name |

|

Function |

1 |

ERR. LED |

Indicate the communication status of |

|||

|

|

|

|

ME-0000MT-SS96. |

|

|

|

|

OFF |

Normal |

|

|

|

|

ON |

The following MODBUS TCP communication |

|

|

|

|

|