Mitsubishi MR-J4W3-222B, MR-J4W3-444B, MR-J4W2-44B, MR-J4W2-1010B, MR-J4W2-22B User Manual

...

General-Purpose AC Servo

SSCNET  /H Interface Multi-axis AC Servo

/H Interface Multi-axis AC Servo

MODEL

MR-J4W2-_B

MR-J4W3-_B

SERVO AMPLIFIER INSTRUCTION MANUAL

6DIHW\ ,QVWUXFWLRQV

6DIHW\ ,QVWUXFWLRQV

3OHDVH UHDG WKH LQVWUXFWLRQV FDUHIXOO\ EHIRUH XVLQJ WKH HTXLSPHQW

7R XVH WKH HTXLSPHQW FRUUHFWO\ GR QRW DWWHPSW WR LQVWDOO RSHUDWH PDLQWDLQ RU LQVSHFW WKH HTXLSPHQW XQWLO

\RX KDYH UHDG WKURXJK WKLV ,QVWUXFWLRQ 0DQXDO ,QVWDOODWLRQ JXLGH DQG DSSHQGHG GRFXPHQWV FDUHIXOO\ 'R QRW

XVH WKH HTXLSPHQW XQWLO \RX KDYH D IXOO NQRZOHGJH RI WKH HTXLSPHQW VDIHW\ LQIRUPDWLRQ DQG LQVWUXFWLRQV ,Q WKLV ,QVWUXFWLRQ 0DQXDO WKH VDIHW\ LQVWUXFWLRQ OHYHOV DUH FODVVLILHG LQWR :$51,1* DQG &$87,21

|

|

|

|

|

|

|

:$51,1* |

|

UHVXOWLQJ LQ GHDWK RU VHYHUH LQMXU\,QGLFDWHV WKDW LQFRUUHFW KDQGOLQJ PD\ FDXVH KD]DUGRXV FRQGLWLRQV |

|

|

|

|

|

|

|

&$87,21 |

|

UHVXOWLQJ LQ PHGLXP RU VOLJKW LQMXU\ WR SHUVRQQHO RU PD\ FDXVH SK\VLFDO,QGLFDWHV WKDW LQFRUUHFW KDQGOLQJ PD\ FDXVH KD]DUGRXV FRQGLWLRQV |

|

|

|

GDPDJH |

|

|

|

|

|

|

1RWH WKDW WKH &$87,21 OHYHO PD\ OHDG WR D VHULRXV FRQVHTXHQFH DFFRUGLQJ WR FRQGLWLRQV 3OHDVH IROORZ WKH LQVWUXFWLRQV RI ERWK OHYHOV EHFDXVH WKH\ DUH LPSRUWDQW WR SHUVRQQHO VDIHW\ :KDW PXVW QRW EH GRQH DQG ZKDW PXVW EH GRQH DUH LQGLFDWHG E\ WKH IROORZLQJ GLDJUDPPDWLF V\PEROV

,QGLFDWHV ZKDW PXVW QRW EH GRQH )RU H[DPSOH 1R )LUH LV LQGLFDWHG E\

,QGLFDWHV ZKDW PXVW QRW EH GRQH )RU H[DPSOH 1R )LUH LV LQGLFDWHG E\

,QGLFDWHV ZKDW PXVW EH GRQH )RU H[DPSOH JURXQGLQJ LV LQGLFDWHG E\

,QGLFDWHV ZKDW PXVW EH GRQH )RU H[DPSOH JURXQGLQJ LV LQGLFDWHG E\

,Q WKLV ,QVWUXFWLRQ 0DQXDO LQVWUXFWLRQV DW D ORZHU OHYHO WKDQ WKH DERYH LQVWUXFWLRQV IRU RWKHU IXQFWLRQV DQG VR

RQ DUH FODVVLILHG LQWR 32,17 $IWHU UHDGLQJ WKLV ,QVWUXFWLRQ 0DQXDO NHHS LW DFFHVVLEOH WR WKH RSHUDWRU

$

7R SUHYHQW HOHFWULF VKRFN QRWH WKH IROORZLQJ

:$51,1*

:$51,1*

%HIRUH ZLULQJ DQG LQVSHFWLRQV WXUQ RII WKH SRZHU DQG ZDLW IRU PLQXWHV RU PRUH XQWLO WKH FKDUJH ODPS WXUQV RII 7KHQ FRQILUP WKDW WKH YROWDJH EHWZHHQ 3 DQG 1 LV VDIH ZLWK D YROWDJH WHVWHU DQG RWKHUV 2WKHUZLVH DQ HOHFWULF VKRFN PD\ RFFXU ,Q DGGLWLRQ ZKHQ FRQILUPLQJ ZKHWKHU WKH FKDUJH ODPS LV RII RU QRW DOZD\V FRQILUP LW IURP WKH IURQW RI WKH VHUYR DPSOLILHU

%HIRUH ZLULQJ DQG LQVSHFWLRQV WXUQ RII WKH SRZHU DQG ZDLW IRU PLQXWHV RU PRUH XQWLO WKH FKDUJH ODPS WXUQV RII 7KHQ FRQILUP WKDW WKH YROWDJH EHWZHHQ 3 DQG 1 LV VDIH ZLWK D YROWDJH WHVWHU DQG RWKHUV 2WKHUZLVH DQ HOHFWULF VKRFN PD\ RFFXU ,Q DGGLWLRQ ZKHQ FRQILUPLQJ ZKHWKHU WKH FKDUJH ODPS LV RII RU QRW DOZD\V FRQILUP LW IURP WKH IURQW RI WKH VHUYR DPSOLILHU  *URXQG WKH VHUYR DPSOLILHU DQG VHUYR PRWRU VHFXUHO\

*URXQG WKH VHUYR DPSOLILHU DQG VHUYR PRWRU VHFXUHO\  $Q\ SHUVRQ ZKR LV LQYROYHG LQ ZLULQJ DQG LQVSHFWLRQ VKRXOG EH IXOO\ FRPSHWHQW WR GR WKH ZRUN

$Q\ SHUVRQ ZKR LV LQYROYHG LQ ZLULQJ DQG LQVSHFWLRQ VKRXOG EH IXOO\ FRPSHWHQW WR GR WKH ZRUN  'R QRW DWWHPSW WR ZLUH WKH VHUYR DPSOLILHU DQG VHUYR PRWRU XQWLO WKH\ KDYH EHHQ LQVWDOOHG 2WKHUZLVH LW PD\ FDXVH DQ HOHFWULF VKRFN

'R QRW DWWHPSW WR ZLUH WKH VHUYR DPSOLILHU DQG VHUYR PRWRU XQWLO WKH\ KDYH EHHQ LQVWDOOHG 2WKHUZLVH LW PD\ FDXVH DQ HOHFWULF VKRFN  'R QRW RSHUDWH VZLWFKHV ZLWK ZHW KDQGV 2WKHUZLVH LW PD\ FDXVH DQ HOHFWULF VKRFN

'R QRW RSHUDWH VZLWFKHV ZLWK ZHW KDQGV 2WKHUZLVH LW PD\ FDXVH DQ HOHFWULF VKRFN  7KH FDEOHV VKRXOG QRW EH GDPDJHG VWUHVVHG ORDGHG RU SLQFKHG 2WKHUZLVH LW PD\ FDXVH DQ HOHFWULF VKRFN

7KH FDEOHV VKRXOG QRW EH GDPDJHG VWUHVVHG ORDGHG RU SLQFKHG 2WKHUZLVH LW PD\ FDXVH DQ HOHFWULF VKRFN

7R SUHYHQW DQ HOHFWULF VKRFN DOZD\V FRQQHFW WKH SURWHFWLYH HDUWK 3( WHUPLQDO PDUNHG

7R SUHYHQW DQ HOHFWULF VKRFN DOZD\V FRQQHFW WKH SURWHFWLYH HDUWK 3( WHUPLQDO PDUNHG RI WKH VHUYR DPSOLILHU WR WKH SURWHFWLYH HDUWK 3( RI WKH FDELQHW

RI WKH VHUYR DPSOLILHU WR WKH SURWHFWLYH HDUWK 3( RI WKH FDELQHW

:KHQ XVLQJ D UHVLGXDO FXUUHQW GHYLFH 5&' VHOHFW WKH W\SH %

:KHQ XVLQJ D UHVLGXDO FXUUHQW GHYLFH 5&' VHOHFW WKH W\SH %

7R DYRLG DQ HOHFWULF VKRFN LQVXODWH WKH FRQQHFWLRQV RI WKH SRZHU VXSSO\ WHUPLQDOV

7R DYRLG DQ HOHFWULF VKRFN LQVXODWH WKH FRQQHFWLRQV RI WKH SRZHU VXSSO\ WHUPLQDOV

7R SUHYHQW ILUH QRWH WKH IROORZLQJ

&$87,21

&$87,21

,QVWDOO WKH VHUYR DPSOLILHU VHUYR PRWRU DQG UHJHQHUDWLYH UHVLVWRU RQ LQFRPEXVWLEOH PDWHULDO ,QVWDOOLQJ LW

GLUHFWO\ RU FORVH WR FRPEXVWLEOHV ZLOO OHDG WR D ILUH

$OZD\V FRQQHFW D PDJQHWLF FRQWDFWRU EHWZHHQ WKH SRZHU VXSSO\ DQG WKH PDLQ FLUFXLW SRZHU VXSSO\ / / DQG / RI WKH VHUYR DPSOLILHU LQ RUGHU WR FRQILJXUH D FLUFXLW WKDW VKXWV GRZQ WKH SRZHU VXSSO\ RQ WKH VLGH RI WKH VHUYR DPSOLILHU¶V SRZHU VXSSO\ ,I D PDJQHWLF FRQWDFWRU LV QRW FRQQHFWHG FRQWLQXRXV IORZ RI D ODUJH FXUUHQW PD\ FDXVH D ILUH ZKHQ WKH VHUYR DPSOLILHU PDOIXQFWLRQV

$OZD\V FRQQHFW D PDJQHWLF FRQWDFWRU EHWZHHQ WKH SRZHU VXSSO\ DQG WKH PDLQ FLUFXLW SRZHU VXSSO\ / / DQG / RI WKH VHUYR DPSOLILHU LQ RUGHU WR FRQILJXUH D FLUFXLW WKDW VKXWV GRZQ WKH SRZHU VXSSO\ RQ WKH VLGH RI WKH VHUYR DPSOLILHU¶V SRZHU VXSSO\ ,I D PDJQHWLF FRQWDFWRU LV QRW FRQQHFWHG FRQWLQXRXV IORZ RI D ODUJH FXUUHQW PD\ FDXVH D ILUH ZKHQ WKH VHUYR DPSOLILHU PDOIXQFWLRQV

:KHQ XVLQJ WKH UHJHQHUDWLYH UHVLVWRU VZLWFK SRZHU RII ZLWK WKH DODUP VLJQDO 1RW GRLQJ VR PD\ FDXVH D ILUH ZKHQ D UHJHQHUDWLYH WUDQVLVWRU PDOIXQFWLRQV RU WKH OLNH PD\ RYHUKHDW WKH UHJHQHUDWLYH UHVLVWRU

:KHQ XVLQJ WKH UHJHQHUDWLYH UHVLVWRU VZLWFK SRZHU RII ZLWK WKH DODUP VLJQDO 1RW GRLQJ VR PD\ FDXVH D ILUH ZKHQ D UHJHQHUDWLYH WUDQVLVWRU PDOIXQFWLRQV RU WKH OLNH PD\ RYHUKHDW WKH UHJHQHUDWLYH UHVLVWRU

3URYLGH DGHTXDWH SURWHFWLRQ WR SUHYHQW VFUHZV DQG RWKHU FRQGXFWLYH PDWWHU RLO DQG RWKHU FRPEXVWLEOH PDWWHU IURP HQWHULQJ WKH VHUYR DPSOLILHU DQG VHUYR PRWRU

3URYLGH DGHTXDWH SURWHFWLRQ WR SUHYHQW VFUHZV DQG RWKHU FRQGXFWLYH PDWWHU RLO DQG RWKHU FRPEXVWLEOH PDWWHU IURP HQWHULQJ WKH VHUYR DPSOLILHU DQG VHUYR PRWRU

$OZD\V FRQQHFW D PROGHG FDVH FLUFXLW EUHDNHU WR WKH SRZHU VXSSO\ RI WKH VHUYR DPSOLILHU

$OZD\V FRQQHFW D PROGHG FDVH FLUFXLW EUHDNHU WR WKH SRZHU VXSSO\ RI WKH VHUYR DPSOLILHU

&RQQHFWLQJ DQ HQFRGHU IRU GLIIHUHQW D[LV WR WKH &1$&1 % RU &1 & FRQQHFWRU PD\ FDXVH D ILUH

&RQQHFWLQJ DQ HQFRGHU IRU GLIIHUHQW D[LV WR WKH &1$&1 % RU &1 & FRQQHFWRU PD\ FDXVH D ILUH

7R SUHYHQW LQMXU\ QRWH WKH IROORZLQJ

&$87,21

&$87,21

2QO\ WKH YROWDJH VSHFLILHG LQ WKH ,QVWUXFWLRQ 0DQXDO VKRXOG EH DSSOLHG WR HDFK WHUPLQDO 2WKHUZLVH D EXUVW GDPDJH HWF PD\ RFFXU

2QO\ WKH YROWDJH VSHFLILHG LQ WKH ,QVWUXFWLRQ 0DQXDO VKRXOG EH DSSOLHG WR HDFK WHUPLQDO 2WKHUZLVH D EXUVW GDPDJH HWF PD\ RFFXU

&RQQHFW FDEOHV WR WKH FRUUHFW WHUPLQDOV 2WKHUZLVH D EXUVW GDPDJH HWF PD\ RFFXU

&RQQHFW FDEOHV WR WKH FRUUHFW WHUPLQDOV 2WKHUZLVH D EXUVW GDPDJH HWF PD\ RFFXU

(QVXUH WKDW SRODULW\ LV FRUUHFW 2WKHUZLVH D EXUVW GDPDJH HWF PD\ RFFXU

(QVXUH WKDW SRODULW\ LV FRUUHFW 2WKHUZLVH D EXUVW GDPDJH HWF PD\ RFFXU

7KH VHUYR DPSOLILHU KHDW VLQN UHJHQHUDWLYH UHVLVWRU VHUYR PRWRU HWF PD\ EH KRW ZKLOH SRZHU LV RQ RU IRU VRPH WLPH DIWHU SRZHU RII 7DNH VDIHW\ PHDVXUHV H J SURYLGH FRYHUV WR SUHYHQW DFFLGHQWDO FRQWDFW RI

7KH VHUYR DPSOLILHU KHDW VLQN UHJHQHUDWLYH UHVLVWRU VHUYR PRWRU HWF PD\ EH KRW ZKLOH SRZHU LV RQ RU IRU VRPH WLPH DIWHU SRZHU RII 7DNH VDIHW\ PHDVXUHV H J SURYLGH FRYHUV WR SUHYHQW DFFLGHQWDO FRQWDFW RI

KDQGV DQG SDUWV FDEOHV HWF ZLWK WKHP

$

$GGLWLRQDO LQVWUXFWLRQV

7KH IROORZLQJ LQVWUXFWLRQV VKRXOG DOVR EH IXOO\ QRWHG ,QFRUUHFW KDQGOLQJ PD\ FDXVH D PDOIXQFWLRQ LQMXU\

HOHFWULF VKRFN HWF

7UDQVSRUWDWLRQ DQG LQVWDOODWLRQ

&$87,21

&$87,21

|

7UDQVSRUW WKH SURGXFWV FRUUHFWO\ DFFRUGLQJ WR WKHLU PDVV |

|||

|

6WDFNLQJ LQ H[FHVV RI WKH VSHFLILHG QXPEHU RI SURGXFW SDFNDJHV LV QRW DOORZHG |

|||

|

,QVWDOO WKH VHUYR DPSOLILHU DQG WKH VHUYR PRWRU LQ D ORDG EHDULQJ SODFH LQ DFFRUGDQFH ZLWK WKH ,QVWUXFWLRQ |

|||

|

0DQXDO |

|

|

|

|

'R QRW JHW RQ RU SXW KHDY\ ORDG RQ WKH HTXLSPHQW |

|||

|

7KH HTXLSPHQW PXVW EH LQVWDOOHG LQ WKH VSHFLILHG GLUHFWLRQ |

|||

|

/HDYH VSHFLILHG FOHDUDQFHV EHWZHHQ WKH VHUYR DPSOLILHU DQG WKH FDELQHW ZDOOV RU RWKHU HTXLSPHQW |

|||

|

'R QRW LQVWDOO RU RSHUDWH WKH VHUYR DPSOLILHU DQG VHUYR PRWRU ZKLFK KDYH EHHQ GDPDJHG RU KDYH DQ\ |

|||

|

SDUWV PLVVLQJ |

|

|

|

|

:KHQ \RX NHHS RU XVH WKH HTXLSPHQW SOHDVH IXOILOO WKH IROORZLQJ HQYLURQPHQW |

|||

|

,WHP |

(QYLURQPHQW |

|

|

|

$PELHQW |

2SHUDWLRQ |

& WR & QRQ IUHH]LQJ |

|

|

WHPSHUDWXUH |

6WRUDJH |

& WR & QRQ IUHH]LQJ |

|

|

$PELHQW |

2SHUDWLRQ |

5+ RU OHVV QRQ FRQGHQVLQJ |

|

|

KXPLGLW\ |

6WRUDJH |

|

|

|

|

|||

|

$PELHQFH |

,QGRRUV QR GLUHFW VXQOLJKW IUHH IURP FRUURVLYH JDV IODPPDEOH JDV RLO PLVW GXVW DQG GLUW |

|

|

|

$OWLWXGH |

0D[ P DERYH VHD OHYHO |

|

|

|

9LEUDWLRQ |

P V RU OHVV DW +] WR +] GLUHFWLRQV RI ; < DQG = D[HV |

|

|

'R QRW EORFN WKH LQWDNH DQG H[KDXVW DUHDV RI WKH VHUYR DPSOLILHU 2WKHUZLVH LW PD\ FDXVH D PDOIXQFWLRQ

'R QRW EORFN WKH LQWDNH DQG H[KDXVW DUHDV RI WKH VHUYR DPSOLILHU 2WKHUZLVH LW PD\ FDXVH D PDOIXQFWLRQ

'R QRW GURS RU VWULNH WKH VHUYR DPSOLILHU DQG VHUYR PRWRU ,VRODWH WKHP IURP DOO LPSDFW ORDGV

'R QRW GURS RU VWULNH WKH VHUYR DPSOLILHU DQG VHUYR PRWRU ,VRODWH WKHP IURP DOO LPSDFW ORDGV

:KHQ WKH HTXLSPHQW KDV EHHQ VWRUHG IRU DQ H[WHQGHG SHULRG RI WLPH FRQWDFW \RXU ORFDO VDOHV RIILFH

:KHQ WKH HTXLSPHQW KDV EHHQ VWRUHG IRU DQ H[WHQGHG SHULRG RI WLPH FRQWDFW \RXU ORFDO VDOHV RIILFH

:KHQ KDQGOLQJ WKH VHUYR DPSOLILHU EH FDUHIXO DERXW WKH HGJHG SDUWV VXFK DV FRUQHUV RI WKH VHUYR DPSOLILHU

:KHQ KDQGOLQJ WKH VHUYR DPSOLILHU EH FDUHIXO DERXW WKH HGJHG SDUWV VXFK DV FRUQHUV RI WKH VHUYR DPSOLILHU

7KH VHUYR DPSOLILHU PXVW EH LQVWDOOHG LQ WKH PHWDO FDELQHW

7KH VHUYR DPSOLILHU PXVW EH LQVWDOOHG LQ WKH PHWDO FDELQHW

:LULQJ

&$87,21

&$87,21

:LUH WKH HTXLSPHQW FRUUHFWO\ DQG VHFXUHO\ 2WKHUZLVH WKH VHUYR PRWRU PD\ RSHUDWH XQH[SHFWHGO\

:LUH WKH HTXLSPHQW FRUUHFWO\ DQG VHFXUHO\ 2WKHUZLVH WKH VHUYR PRWRU PD\ RSHUDWH XQH[SHFWHGO\

'R QRW LQVWDOO D SRZHU FDSDFLWRU VXUJH NLOOHU RU UDGLR QRLVH ILOWHU )5 %,) RSWLRQ RQ WKH VHUYR DPSOLILHU RXWSXW VLGH 7R DYRLG D PDOIXQFWLRQ FRQQHFW WKH ZLUHV WR WKH FRUUHFW SKDVH WHUPLQDOV 8 9 DQG : RI WKH VHUYR

'R QRW LQVWDOO D SRZHU FDSDFLWRU VXUJH NLOOHU RU UDGLR QRLVH ILOWHU )5 %,) RSWLRQ RQ WKH VHUYR DPSOLILHU RXWSXW VLGH 7R DYRLG D PDOIXQFWLRQ FRQQHFW WKH ZLUHV WR WKH FRUUHFW SKDVH WHUPLQDOV 8 9 DQG : RI WKH VHUYR

DPSOLILHU DQG VHUYR PRWRU

$

&$87,21

&$87,21

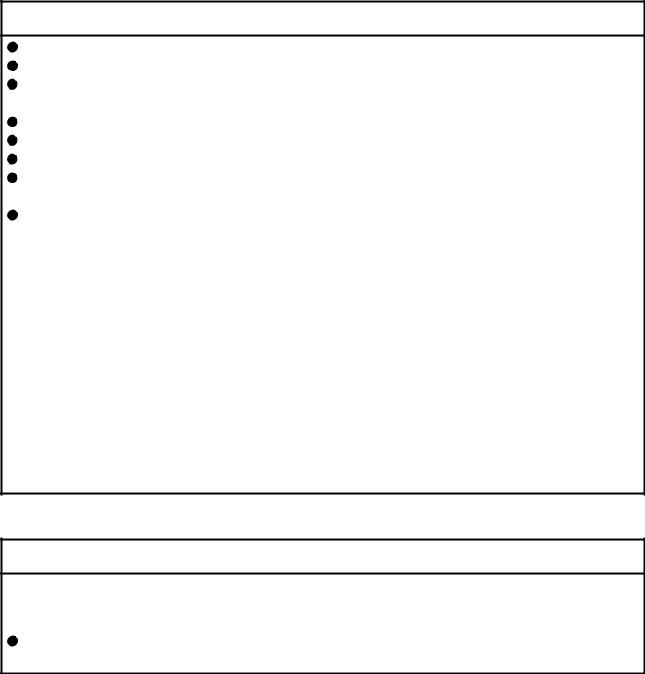

&RQQHFW WKH VHUYR DPSOLILHU SRZHU RXWSXW 8 9 DQG : WR WKH VHUYR PRWRU SRZHU LQSXW 8 9 DQG : GLUHFWO\ 'R QRW OHW D PDJQHWLF FRQWDFWRU HWF LQWHUYHQH 2WKHUZLVH LW PD\ FDXVH D PDOIXQFWLRQ

&RQQHFW WKH VHUYR DPSOLILHU SRZHU RXWSXW 8 9 DQG : WR WKH VHUYR PRWRU SRZHU LQSXW 8 9 DQG : GLUHFWO\ 'R QRW OHW D PDJQHWLF FRQWDFWRU HWF LQWHUYHQH 2WKHUZLVH LW PD\ FDXVH D PDOIXQFWLRQ

6HUYR DPSOLILHU |

8 |

6HUYR PRWRU |

6HUYR DPSOLILHU |

8 |

6HUYR PRWRU |

|

8 |

|

|

8 |

|

|

|

9 |

9 |

0 |

9 |

9 |

0 |

|

|

|

|

||||

: |

: |

|

: |

: |

|

|

|

|

|

|

|

7KH VXUJH DEVRUELQJ GLRGH LQVWDOOHG WR WKH '& UHOD\ IRU FRQWURO RXWSXW VKRXOG EH ILWWHG LQ WKH VSHFLILHG GLUHFWLRQ 2WKHUZLVH WKH HPHUJHQF\ VWRS DQG RWKHU SURWHFWLYH FLUFXLWV PD\ QRW RSHUDWH

7KH VXUJH DEVRUELQJ GLRGH LQVWDOOHG WR WKH '& UHOD\ IRU FRQWURO RXWSXW VKRXOG EH ILWWHG LQ WKH VSHFLILHG GLUHFWLRQ 2WKHUZLVH WKH HPHUJHQF\ VWRS DQG RWKHU SURWHFWLYH FLUFXLWV PD\ QRW RSHUDWH

6HUYR DPSOLILHU |

9 '& |

|

'2&20 |

||

|

||

&RQWURO RXWSXW |

5$ |

|

VLJQDO |

||

|

||

',&20 |

|

|

)RU VLQN RXWSXW LQWHUIDFH |

||

|

6HUYR DPSOLILHU |

9 '& |

|

|

'2&20 |

|

|

|

|

|

|

|

&RQWURO RXWSXW |

5$ |

|

|

VLJQDO |

|

|

|

|

|

|

|

',&20 |

|

|

|

)RU VRXUFH RXWSXW LQWHUIDFH |

|

|

:KHQ WKH FDEOH LV QRW WLJKWHQHG HQRXJK WR WKH WHUPLQDO EORFN WKH FDEOH RU WHUPLQDO EORFN PD\ JHQHUDWH

KHDW EHFDXVH RI WKH SRRU FRQWDFW %H VXUH WR WLJKWHQ WKH FDEOH ZLWK VSHFLILHG WRUTXH

7HVW UXQ DQG DGMXVWPHQW

&$87,21

&$87,21

%HIRUH RSHUDWLRQ FKHFN WKH SDUDPHWHU VHWWLQJV ,PSURSHU VHWWLQJV PD\ FDXVH VRPH PDFKLQHV WR SHUIRUP XQH[SHFWHG RSHUDWLRQ

%HIRUH RSHUDWLRQ FKHFN WKH SDUDPHWHU VHWWLQJV ,PSURSHU VHWWLQJV PD\ FDXVH VRPH PDFKLQHV WR SHUIRUP XQH[SHFWHG RSHUDWLRQ

1HYHU DGMXVW RU FKDQJH WKH SDUDPHWHU YDOXHV H[WUHPHO\ DV LW ZLOO PDNH RSHUDWLRQ XQVWDEOH

1HYHU DGMXVW RU FKDQJH WKH SDUDPHWHU YDOXHV H[WUHPHO\ DV LW ZLOO PDNH RSHUDWLRQ XQVWDEOH

8VDJH

&$87,21

&$87,21

3URYLGH DQ H[WHUQDO HPHUJHQF\ VWRS FLUFXLW WR HQVXUH WKDW RSHUDWLRQ FDQ EH VWRSSHG DQG SRZHU VZLWFKHG RII LPPHGLDWHO\

3URYLGH DQ H[WHUQDO HPHUJHQF\ VWRS FLUFXLW WR HQVXUH WKDW RSHUDWLRQ FDQ EH VWRSSHG DQG SRZHU VZLWFKHG RII LPPHGLDWHO\

'R QRW GLVDVVHPEOH UHSDLU RU PRGLI\ WKH HTXLSPHQW

'R QRW GLVDVVHPEOH UHSDLU RU PRGLI\ WKH HTXLSPHQW

%HIRUH UHVHWWLQJ DQ DODUP PDNH VXUH WKDW WKH UXQ VLJQDO RI WKH VHUYR DPSOLILHU LV RII LQ RUGHU WR SUHYHQW D VXGGHQ UHVWDUW 2WKHUZLVH LW PD\ FDXVH DQ DFFLGHQW

%HIRUH UHVHWWLQJ DQ DODUP PDNH VXUH WKDW WKH UXQ VLJQDO RI WKH VHUYR DPSOLILHU LV RII LQ RUGHU WR SUHYHQW D VXGGHQ UHVWDUW 2WKHUZLVH LW PD\ FDXVH DQ DFFLGHQW

8VH D QRLVH ILOWHU HWF WR PLQLPL]H WKH LQIOXHQFH RI HOHFWURPDJQHWLF LQWHUIHUHQFH (OHFWURPDJQHWLF LQWHUIHUHQFH PD\ EH JLYHQ WR WKH HOHFWURQLF HTXLSPHQW XVHG QHDU WKH VHUYR DPSOLILHU

8VH D QRLVH ILOWHU HWF WR PLQLPL]H WKH LQIOXHQFH RI HOHFWURPDJQHWLF LQWHUIHUHQFH (OHFWURPDJQHWLF LQWHUIHUHQFH PD\ EH JLYHQ WR WKH HOHFWURQLF HTXLSPHQW XVHG QHDU WKH VHUYR DPSOLILHU

%XUQLQJ RU EUHDNLQJ D VHUYR DPSOLILHU PD\ FDXVH D WR[LF JDV 'R QRW EXUQ RU EUHDN LW

%XUQLQJ RU EUHDNLQJ D VHUYR DPSOLILHU PD\ FDXVH D WR[LF JDV 'R QRW EXUQ RU EUHDN LW

8VH WKH VHUYR DPSOLILHU ZLWK WKH VSHFLILHG VHUYR PRWRU

8VH WKH VHUYR DPSOLILHU ZLWK WKH VSHFLILHG VHUYR PRWRU

7KH HOHFWURPDJQHWLF EUDNH RQ WKH VHUYR PRWRU LV GHVLJQHG WR KROG WKH PRWRU VKDIW DQG VKRXOG QRW EH XVHG IRU RUGLQDU\ EUDNLQJ

7KH HOHFWURPDJQHWLF EUDNH RQ WKH VHUYR PRWRU LV GHVLJQHG WR KROG WKH PRWRU VKDIW DQG VKRXOG QRW EH XVHG IRU RUGLQDU\ EUDNLQJ

)RU VXFK UHDVRQV DV VHUYLFH OLIH DQG PHFKDQLFDO VWUXFWXUH H J ZKHUH D EDOO VFUHZ DQG WKH VHUYR PRWRU DUH FRXSOHG YLD D WLPLQJ EHOW WKH HOHFWURPDJQHWLF EUDNH PD\ QRW KROG WKH PRWRU VKDIW 7R HQVXUH VDIHW\

)RU VXFK UHDVRQV DV VHUYLFH OLIH DQG PHFKDQLFDO VWUXFWXUH H J ZKHUH D EDOO VFUHZ DQG WKH VHUYR PRWRU DUH FRXSOHG YLD D WLPLQJ EHOW WKH HOHFWURPDJQHWLF EUDNH PD\ QRW KROG WKH PRWRU VKDIW 7R HQVXUH VDIHW\

LQVWDOO D VWRSSHU RQ WKH PDFKLQH VLGH

$

&RUUHFWLYH DFWLRQV

&$87,21

&$87,21

:KHQ LW LV DVVXPHG WKDW D KD]DUGRXV FRQGLWLRQ PD\ RFFXU GXH WR D SRZHU IDLOXUH RU SURGXFW PDOIXQFWLRQ XVH D VHUYR PRWRU ZLWK DQ HOHFWURPDJQHWLF EUDNH RU H[WHUQDO EUDNH WR SUHYHQW WKH FRQGLWLRQ

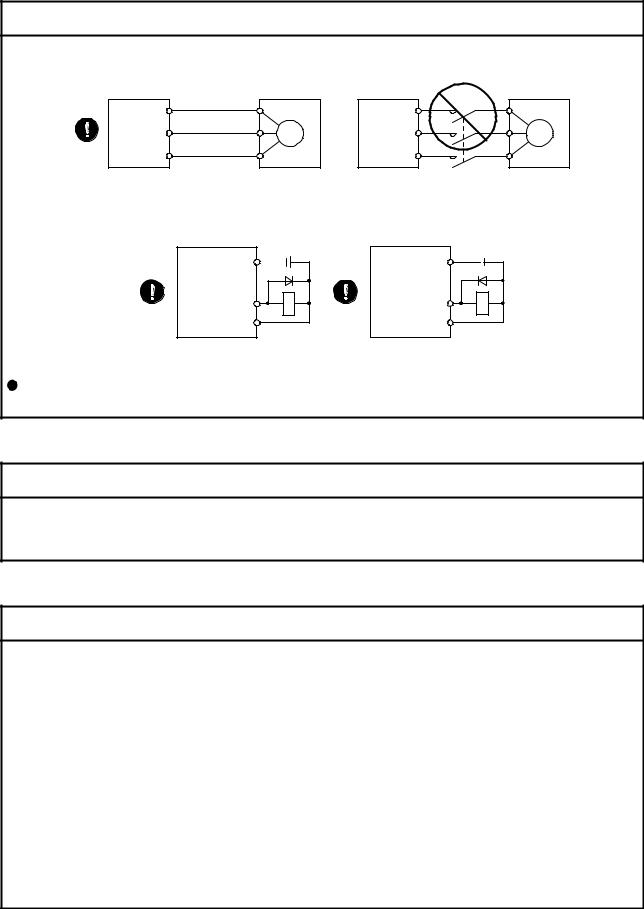

:KHQ LW LV DVVXPHG WKDW D KD]DUGRXV FRQGLWLRQ PD\ RFFXU GXH WR D SRZHU IDLOXUH RU SURGXFW PDOIXQFWLRQ XVH D VHUYR PRWRU ZLWK DQ HOHFWURPDJQHWLF EUDNH RU H[WHUQDO EUDNH WR SUHYHQW WKH FRQGLWLRQ  &RQILJXUH DQ HOHFWURPDJQHWLF EUDNH FLUFXLW VR WKDW LW LV DFWLYDWHG DOVR E\ DQ H[WHUQDO (0* VWRS VZLWFK

&RQILJXUH DQ HOHFWURPDJQHWLF EUDNH FLUFXLW VR WKDW LW LV DFWLYDWHG DOVR E\ DQ H[WHUQDO (0* VWRS VZLWFK

Contacts must be opened when CALM(And

&RQWDFWV PXVW EH RSHQHG ZKHQ$/0 &RQWDFWV PXVW EH RSHQHG malfunction)0DOIXQFWLRQor MBR(ElectromagneticU 0%5 B (OHFWURPDJQHWLFbrake ZLWK WKH (0* VWRS VZLWFK interlock)EUDNH LQWHUORFNB WXUQV RIIturns off.

6HUYR PRWRU |

|

5$ |

|

% |

9 '& |

(OHFWURPDJQHWLF EUDNH |

|

:KHQ DQ\ DODUP KDV RFFXUUHG HOLPLQDWH LWV FDXVH HQVXUH VDIHW\ DQG GHDFWLYDWH WKH DODUP EHIRUH UHVWDUWLQJ RSHUDWLRQ

:KHQ DQ\ DODUP KDV RFFXUUHG HOLPLQDWH LWV FDXVH HQVXUH VDIHW\ DQG GHDFWLYDWH WKH DODUP EHIRUH UHVWDUWLQJ RSHUDWLRQ

3URYLGH DQ DGHTXDWH SURWHFWLRQ WR SUHYHQW XQH[SHFWHG UHVWDUW DIWHU DQ LQVWDQWDQHRXV SRZHU IDLOXUH

3URYLGH DQ DGHTXDWH SURWHFWLRQ WR SUHYHQW XQH[SHFWHG UHVWDUW DIWHU DQ LQVWDQWDQHRXV SRZHU IDLOXUH

0DLQWHQDQFH LQVSHFWLRQ DQG SDUWV UHSODFHPHQW

&$87,21

&$87,21

:LWK DJH WKH HOHFWURO\WLF FDSDFLWRU RI WKH VHUYR DPSOLILHU ZLOO GHWHULRUDWH 7R SUHYHQW D VHFRQGDU\ DFFLGHQW GXH WR D PDOIXQFWLRQ LW LV UHFRPPHQG WKDW WKH HOHFWURO\WLF FDSDFLWRU EH UHSODFHG HYHU\ \HDUV

:LWK DJH WKH HOHFWURO\WLF FDSDFLWRU RI WKH VHUYR DPSOLILHU ZLOO GHWHULRUDWH 7R SUHYHQW D VHFRQGDU\ DFFLGHQW GXH WR D PDOIXQFWLRQ LW LV UHFRPPHQG WKDW WKH HOHFWURO\WLF FDSDFLWRU EH UHSODFHG HYHU\ \HDUV

ZKHQ LW LV XVHG LQ JHQHUDO HQYLURQPHQW 3OHDVH FRQWDFW \RXU ORFDO VDOHV RIILFH

*HQHUDO LQVWUXFWLRQ

7R LOOXVWUDWH GHWDLOV WKH HTXLSPHQW LQ WKH GLDJUDPV RI WKLV ,QVWUXFWLRQ 0DQXDO PD\ KDYH EHHQ GUDZQ ZLWKRXW FRYHUV DQG VDIHW\ JXDUGV :KHQ WKH HTXLSPHQW LV RSHUDWHG WKH FRYHUV DQG VDIHW\ JXDUGV PXVW EH LQVWDOOHG DV VSHFLILHG 2SHUDWLRQ PXVW EH SHUIRUPHG LQ DFFRUGDQFH ZLWK WKLV 6SHFLILFDWLRQV DQG

7R LOOXVWUDWH GHWDLOV WKH HTXLSPHQW LQ WKH GLDJUDPV RI WKLV ,QVWUXFWLRQ 0DQXDO PD\ KDYH EHHQ GUDZQ ZLWKRXW FRYHUV DQG VDIHW\ JXDUGV :KHQ WKH HTXLSPHQW LV RSHUDWHG WKH FRYHUV DQG VDIHW\ JXDUGV PXVW EH LQVWDOOHG DV VSHFLILHG 2SHUDWLRQ PXVW EH SHUIRUPHG LQ DFFRUGDQFH ZLWK WKLV 6SHFLILFDWLRQV DQG

,QVWUXFWLRQ 0DQXDO

',6326$/ 2) :$67(

',6326$/ 2) :$67(

3OHDVH GLVSRVH D VHUYR DPSOLILHU EDWWHU\ SULPDU\ EDWWHU\ DQG RWKHU RSWLRQV DFFRUGLQJ WR \RXU ORFDO ODZV DQG

UHJXODWLRQV

((3 520 OLIH

7KH QXPEHU RI ZULWH WLPHV WR WKH ((3 520 ZKLFK VWRUHV SDUDPHWHU VHWWLQJV HWF LV OLPLWHG WR ,I

WKH WRWDO QXPEHU RI WKH IROORZLQJ RSHUDWLRQV H[FHHGV WKH VHUYR DPSOLILHU PD\ PDOIXQFWLRQ ZKHQ WKH

((3 520 UHDFKHV WKH HQG RI LWV XVHIXO OLIH

:ULWH WR WKH ((3 520 GXH WR SDUDPHWHU VHWWLQJ FKDQJHV

:ULWH WR WKH ((3 520 GXH WR GHYLFH FKDQJHV

$

672 IXQFWLRQ RI WKH VHUYR DPSOLILHU

:KHQ XVLQJ WKH 672 IXQFWLRQ RI WKH VHUYR DPSOLILHU UHIHU WR FKDSWHU )RU WKH 05-' VDIHW\ ORJLF XQLW UHIHU WR DSSHQGL[

&203/,$1&( :,7+ &( 0$5.,1*

5HIHU WR$SSHQGL[ IRU WKH FRPSOLDQFH ZLWK &( PDUNLQJ

&203/,$1&( :,7+ 8/ &6$67$1'$5'

5HIHU WR$SSHQGL[ IRU WKH FRPSOLDQFH ZLWK 8/ &6$VWDQGDUG

$ERXW WKH PDQXDOV!!

<RX PXVW KDYH WKLV ,QVWUXFWLRQ 0DQXDO DQG WKH IROORZLQJ PDQXDOV WR XVH WKLV VHUYR (QVXUH WR SUHSDUH

WKHP WR XVH WKH VHUYR VDIHO\

5HOHYDQW PDQXDOV

|

|

|

0DQXDO QDPH |

0DQXDO 1R |

|

|

0(/6(592-6HULHV ,QVWUXFWLRQV DQG &DXWLRQV IRU 6DIH 8VH RI$& 6HUYRV |

,% 1$ 5 |

|

|

|

3DFNHG ZLWK WKH VHUYR DPSOLILHU |

|

|

|

|

0(/6(592-6(592$03/,),(5 ,16758&7,21 0$18$/ 7528%/(6+227,1* |

6+ 1$ |

|

|

|

0(/6(592 6HUYR 0RWRU ,QVWUXFWLRQ 0DQXDO 9RO 1RWH |

6+ 1$ |

|

|

|

0(/6(592 /LQHDU 6HUYR 0RWRU ,QVWUXFWLRQ 0DQXDO 1RWH |

6+ 1$ |

|

|

|

0(/6(592 'LUHFW 'ULYH 0RWRU ,QVWUXFWLRQ 0DQXDO 1RWH |

6+ 1$ |

|

|

|

0(/6(592 /LQHDU (QFRGHU ,QVWUXFWLRQ 0DQXDO 1RWH |

6+ 1$ |

|

|

|

(0& ,QVWDOODWLRQ *XLGHOLQHV |

,% 1$ |

|

1RWH |

,W LV QHFHVVDU\ IRU XVLQJ D URWDU\ VHUYR PRWRU |

|

||

|

|

|||

|

|

,W LV QHFHVVDU\ IRU XVLQJ D OLQHDU VHUYR PRWRU |

|

|

|

|

,W LV QHFHVVDU\ IRU XVLQJ D GLUHFW GULYH PRWRU |

|

|

|

|

,W LV QHFHVVDU\ IRU XVLQJ D IXOO\ FORVHG ORRS V\VWHP |

|

|

|

|

|

|

|

:LULQJ!! |

|

|

|

|

:LUHV PHQWLRQHG LQ WKLV ,QVWUXFWLRQ 0DQXDO DUH VHOHFWHG EDVHG RQ WKH DPELHQW WHPSHUDWXUH RI &

)

8 6 FXVWRPDU\ XQLWV!!

8 6 FXVWRPDU\ XQLWV DUH QRW VKRZQ LQ WKLV PDQXDO &RQYHUW WKH YDOXHV LI QHFHVVDU\ DFFRUGLQJ WR WKH

IROORZLQJ WDEOH

4XDQWLW\ |

6, PHWULF XQLW |

8 6 FXVWRPDU\ XQLW |

0DVV |

>NJ@ |

>OE@ |

/HQJWK |

>PP@ |

>LQ@ |

7RUTXH |

>1 P@ |

>R] LQ@ |

0RPHQW RI LQHUWLD |

> NJ P @ |

>R] LQ @ |

/RDG WKUXVW ORDG D[LDO ORDG |

>1@ |

>OEI@ |

7HPSHUDWXUH |

1 > &@ |

1 > )@ |

$

|

|

|

|

|

|

CONTENTS |

|

|

|

||||||

1. FUNCTIONS AND CONFIGURATION |

1- 1 to 1-12 |

||||||

1.1 |

Summary |

........................................................................................................................................... |

|

|

1- 1 |

||

1.2 |

Function |

block diagram..................................................................................................................... |

1- 2 |

||||

1.3 |

Servo amplifier standard specifications ............................................................................................ |

1- 3 |

|||||

1.3.1 |

Integrated |

2-axiservo amplifier................................................................................................ |

1- 3 |

||||

1.3.2 |

Integrated |

3-axiservo amplifier................................................................................................ |

1- 5 |

||||

1.3.3 |

Combinations of servo amplifier and servo motor ..................................................................... |

1- 7 |

|||||

1.4 |

Function list...................................................................................................................................... |

|

1- 8 |

||||

1.5 |

Model |

designation........................................................................................................................... |

1- 9 |

||||

1.6 |

Parts |

identification............................................................................................................................ |

1-10 |

||||

1.7 |

Configuration |

including auxiliary equipment.................................................................................... |

1-11 |

||||

|

|

|

|||||

2. INSTALLATION |

|

2- 1 to 2- 6 |

|||||

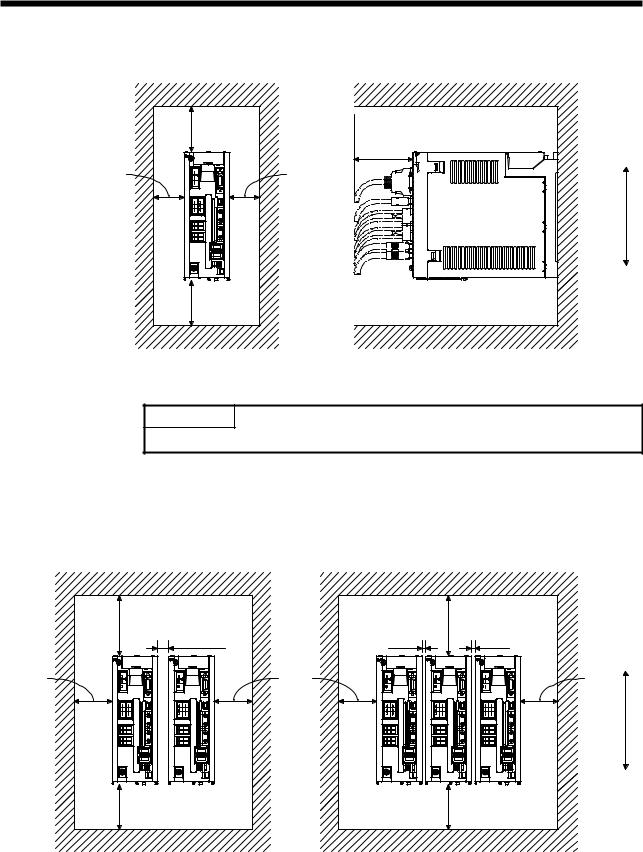

2.1 |

Installation |

direction and clearances ................................................................................................ |

2- 1 |

||||

2.2 |

Keep out foreign materials................................................................................................................ |

2- 3 |

|||||

2.3 |

Encoder ablec stress ........................................................................................................................ |

2- 3 |

|||||

2.4 |

SSCNET III cable laying ................................................................................................................... |

2- 3 |

|||||

2.5 |

Inspection items............................................................................................................................... |

2- 5 |

|||||

2.6 |

Parts |

havingservice lives ................................................................................................................. |

2- 6 |

||||

|

|

||||||

3. SIGNALS AND WIRING |

3- 1 to 3-38 |

||||||

3.1 |

Input |

powersupply circuit ................................................................................................................. |

3- 2 |

||||

3.2 |

I/O signal connection example.......................................................................................................... |

3- 5 |

|||||

3.2.1 |

For |

sinkI/O interface.................................................................................................................. |

3- 5 |

||||

3.2.2 |

For |

sourceI/O interface ............................................................................................................. |

3- 7 |

||||

3.3 |

Explanation of power supply system ................................................................................................ |

3- 8 |

|||||

3.3.1 |

Signalexplanations .................................................................................................................... |

3- 8 |

|||||

3.3.2 |

Power-on sequence .................................................................................................................. |

3-10 |

|||||

3.3.3 |

Wiring |

CNP1,CNP2, and CNP3 ............................................................................................... |

3-11 |

||||

3.4 |

Connectors |

andpin assignment ...................................................................................................... |

3-13 |

||||

3.5 |

Signal |

(device) explanations............................................................................................................ |

3-15 |

||||

3.5.1 |

Inputdevice............................................................................................................................... |

3-15 |

|||||

3.5.2 |

Outputdevice ............................................................................................................................ |

3-16 |

|||||

3.5.3 |

Output signal ............................................................................................................................. |

3-18 |

|||||

3.5.4 |

Power supply............................................................................................................................. |

3-19 |

|||||

3.6 |

Forced stop deceleration function ................................................................................................... |

3-20 |

|||||

3.6.1 Forced stop deceleration function (SS1)................................................................................... |

3-20 |

||||||

3.6.2 |

Base circuit shut-off delay time function ................................................................................... |

3-22 |

|||||

3.6.3 Vertical axis freefall prevention function ................................................................................... |

3-23 |

||||||

3.6.4 Residual risks of the forced stop function (EM2) ...................................................................... |

3-23 |

||||||

3.7 |

Alarm |

occurrenc timing chart......................................................................................................... |

3-24 |

||||

3.7.1 |

When you use the forced stop deceleration function................................................................ |

3-24 |

|||||

3.7.2 When you do not use the forced stop deceleration function..................................................... |

3-25 |

||||||

3.8 |

Interfaces ......................................................................................................................................... |

|

|

3-26 |

|||

3.8.1 |

Internal |

connectiondiagram...................................................................................................... |

3-26 |

||||

3.8.2 |

Detailed description of interfaces.............................................................................................. |

3-27 |

|||||

1

3.8.3 |

Source I/Ointerfaces ................................................................................................................ |

3-28 |

||

3.9 |

SSCNET III cable connection .......................................................................................................... |

3-29 |

||

3.10 |

Servo motor with an electromagnetic brake .................................................................................. |

3-31 |

||

3.10.1 |

|

Safetyprecautions .................................................................................................................. |

3-31 |

|

3.10.2 |

|

Timing chart ............................................................................................................................ |

3-33 |

|

3.11 |

Grounding ...................................................................................................................................... |

3-38 |

||

|

|

|||

4. STARTUP |

4- 1 to 4-22 |

|||

4.1 |

Switching power on for the first time................................................................................................. |

4- 1 |

||

4.1.1 |

Startup procedure ...................................................................................................................... |

4- 2 |

||

4.1.2 |

Wiring check............................................................................................................................... |

4- 3 |

||

4.1.3 |

Surrounding environment........................................................................................................... |

4- 4 |

||

4.2 |

Startup ............................................................................................................................................. |

4- 4 |

||

4.3 |

Switch setting and display of the servo amplifier.............................................................................. |

4- 7 |

||

4.3.1 |

Switches ..................................................................................................................................... |

4- 7 |

||

4.3.2 |

Scrolling display ........................................................................................................................ |

4-13 |

||

4.3.3 |

Status display of an axis ........................................................................................................... |

4-14 |

||

4.4 |

Test |

operation .................................................................................................................................. |

4-16 |

|

4.5 |

Test |

operation mode........................................................................................................................ |

4-16 |

|

4.5.1 |

Test operation mode in MR Configurator2................................................................................ |

4-17 |

||

4.5.2 |

Motor-less operation in controller.............................................................................................. |

4-19 |

||

|

|

|||

5. PARAMETERS |

5- 1 to 5-4 |

|||

5.1 |

Parameter list.................................................................................................................................... |

5- 1 |

||

5.1.1 Basic setting parameters ([Pr. PA_ _ ])...................................................................................... |

5- 2 |

|||

5.1.2 Gain/filter setting parameters ([Pr. PB_ _ ]) ............................................................................... |

5- 3 |

|||

5.1.3 Extension setting parameters ([Pr. PC_ _ ]) .............................................................................. |

5- 4 |

|||

5.1.4 I/O setting parameters ([Pr. PD_ _ ]) ......................................................................................... |

5- 6 |

|||

5.1.5 Extension setting 2 parameters ([Pr. PE_ _ ])............................................................................ |

5- 7 |

|||

5.1.6 Extension setting 3 parameters ([Pr. PF_ _ ])............................................................................ |

5- 9 |

|||

5.1.7 Linear servo motor/DD motor setting parameters ([Pr. PL_ _ ]) ............................................... |

5-10 |

|||

5.2 |

Detailed list of parameters ............................................................................................................... |

5-12 |

||

5.2.1 Basic setting parameters ([Pr. PA_ _ ])..................................................................................... |

5-12 |

|||

5.2.2 Gain/filter setting parameters ([Pr. PB_ _ ]) .............................................................................. |

5-21 |

|||

5.2.3 Extension setting parameters ([Pr. PC_ _ ]) ............................................................................. |

5-34 |

|||

5.2.4 I/O setting parameters ([Pr. PD_ _ ]) ........................................................................................ |

5-38 |

|||

5.2.5 Extension setting 2 parameters ([Pr. PE_ _ ])........................................................................... |

5-42 |

|||

5.2.6 Extension setting 3 parameters ([Pr. PF_ _ ])........................................................................... |

5-44 |

|||

5.2.7 Linear servo motor/DD motor setting parameters ([Pr. PL_ _ ]) ............................................... |

5-45 |

|||

|

|

|||

6. NORMAL GAIN ADJUSTMENT |

6- 1 to 6-18 |

|||

6.1 |

Different adjustment methods........................................................................................................... |

6- 1 |

||

6.1.1 Adjustment on a single servo amplifier ...................................................................................... |

6- 1 |

|||

6.1.2 |

Adjustment using MR Configurator2 .......................................................................................... |

6- 2 |

||

6.2 |

One-touch tuning .............................................................................................................................. |

6- 3 |

||

6.2.1 |

One-touch uningt flowchart ........................................................................................................ |

6- 3 |

||

6.2.2 |

Display transition and operation procedure of one-touch tuning ............................................... |

6- 4 |

||

6.2.3 |

Caution forone-touch tuning...................................................................................................... |

6- 8 |

||

2

6.3 |

Autotuning........................................................................................................................................ |

|

6- 9 |

|

6.3.1 |

Autotuning mode ....................................................................................................................... |

6- 9 |

||

6.3.2 |

Auto uningt mode basis............................................................................................................. |

6-10 |

||

6.3.3 |

Adjustment |

procedure by auto tuning ....................................................................................... |

6-11 |

|

6.3.4 Response level setting in auto tuning mode ............................................................................. |

6-12 |

|||

6.4 |

Manualmode ................................................................................................................................... |

|

6-13 |

|

6.5 |

2 gain adjustment mode .................................................................................................................. |

6-17 |

||

|

|

|||

7. SPECIAL ADJUSTMENT FUNCTIONS |

7- 1 to 7-28 |

|||

7.1 |

Filtersetting ...................................................................................................................................... |

|

7- 1 |

|

7.1.1 |

Machine resonanc suppression filter ....................................................................................... |

7- 1 |

||

7.1.2 |

Adaptivefilter II........................................................................................................................... |

7- 4 |

||

7.1.3 |

Shaft resonance suppressionfilter............................................................................................. |

7- 6 |

||

7.1.4 |

Low-pass filter ........................................................................................................................... |

7- 7 |

||

7.1.5 |

Advanced |

vibrationsuppression control II ................................................................................. |

7-7 |

|

7.1.6 |

Command |

notch filter ................................................................................................................ |

7-12 |

|

7.2 |

Gain switching function.................................................................................................................... |

7-14 |

||

7.2.1 |

Applications............................................................................................................................... |

7-14 |

||

7.2.2 |

Functionblock diagram............................................................................................................. |

7-15 |

||

7.2.3 |

Parameter.................................................................................................................................. |

|

7-16 |

|

7.2.4 |

Gain switching procedure ......................................................................................................... |

7-19 |

||

7.3 |

Tough drive function ........................................................................................................................ |

7-22 |

||

7.3.1 |

Vibration ought drive function.................................................................................................... |

7-22 |

||

7.3.2 |

Instantaneous power failure tough drive function ..................................................................... |

7-24 |

||

|

|

|||

8. TROUBLESHOOTING |

8- 1 to 8-10 |

|||

8.1 |

Alarm and warning list ...................................................................................................................... |

8- 1 |

||

8.2 |

Troubleshootingat power on ........................................................................................................... |

8-10 |

||

|

|

|||

9. OUTLINE DRAWINGS |

9- 1 to 9- 6 |

|||

9.1 |

Servo amplifier .................................................................................................................................. |

|

9- 1 |

|

9.2 |

Connector ......................................................................................................................................... |

|

9- 4 |

|

|

|

|||

10. CHARACTERISTICS |

10- 1 to 10-8 |

|||

10.1 |

Overload protection characteristics .............................................................................................. |

10- 1 |

||

10.2 |

Power supply capacity and generated loss .................................................................................. |

10- 2 |

||

10.3 |

Dynamic brake characterist cs...................................................................................................... |

10- 5 |

||

10.3.1 |

Dynamic |

brake operation ....................................................................................................... |

10- 5 |

|

10.3.2 Permissible load to motor inertia when the dynamic brake is used....................................... |

10- 6 |

|||

10.4 |

Cablebending life ......................................................................................................................... |

10- 7 |

||

10.5 Inrush currents at power-on of main circuit and control circuit..................................................... |

10- 7 |

|||

|

|

|||

11. OPTIONS AND AUXILIARY EQUIPMENT |

11- 1 to 11-34 |

|||

11.1 Cable/connector sets ..................................................................................................................... |

11- 1 |

|||

11.1.1 |

Combinations ofcable/connector sets................................................................................... |

11- 1 |

||

11.1.2 |

SSCNETIII cable ................................................................................................................... |

11- 4 |

||

3

11.1.3 |

Battery cable/junction battery cable ....................................................................................... |

11- 6 |

|||

11.1.4 |

MR-D05UDL3M-BSTO cable................................................................................................ |

11- 7 |

|||

11.2 |

Regenerative options.................................................................................................................... |

11- 7 |

|||

11.2.1 |

Combination andregenerative power.................................................................................... |

11- 7 |

|||

11.2.2 |

Selection ofregenerative option ............................................................................................ |

11- 8 |

|||

11.2.3 |

Parameter setting.................................................................................................................. |

11-10 |

|||

11.2.4 |

Selection ofregenerative option ........................................................................................... |

11-11 |

|||

11.2.5 |

Dimensions ........................................................................................................................... |

11-12 |

|||

11.3 |

MR-BT6VCASE battery case and MR-BAT6V1 battery .............................................................. |

11-13 |

|||

11.4 |

MR Configurator2 ........................................................................................................................ |

11-14 |

|||

11.5 |

Selection |

example of wires.......................................................................................................... |

11-16 |

||

11.6 |

Molded case circuit breakers, fuses, magnetic contactors (recommended) .............................. |

11-18 |

|||

11.7 |

Power factor improving AC reactors............................................................................................ |

11-19 |

|||

11.8 |

Relays |

(recommended)............................................................................................................... |

11-20 |

||

11.9 |

Noise |

reduction techniques ......................................................................................................... |

11-21 |

||

11.10 |

Leakage current breaker ........................................................................................................... |

11-27 |

|||

11.11 |

EMC |

filter(recommended) ........................................................................................................ |

11-30 |

||

11.12 |

Junction terminalblock MR-TB26A ........................................................................................... |

11-33 |

|||

|

|

||||

12. ABSOLUTE POSITION DETECTION SYSTEM |

12- 1 to 12-8 |

||||

12.1 |

Features........................................................................................................................................ |

|

12- 1 |

||

12.2 |

Specifications................................................................................................................................ |

12- 2 |

|||

12.3 |

Assembling battery unit ............................................................................................................. |

12- 5 |

|||

12.3.1 |

Required items ....................................................................................................................... |

12- 5 |

|||

12.3.2 Disassembly and assembly of the battery case MR-BT6VCASE.......................................... |

12- 5 |

||||

12.3.3 |

Battery ablec removal ............................................................................................................ |

12- 7 |

|||

12.4 |

Confirmation of absolute position detection data ......................................................................... |

12- 8 |

|||

|

|

||||

13. USING STO FUNCTION |

13- 1 to 13-12 |

||||

13.1 |

Introduction ................................................................................................................................... |

13- 1 |

|||

13.1.1 |

Summary................................................................................................................................ |

13- 1 |

|||

13.1.2 |

Terms related to safety .......................................................................................................... |

13- 1 |

|||

13.1.3 |

Cautions ................................................................................................................................. |

13- 1 |

|||

13.1.4 Residual risks of the STO function......................................................................................... |

13- 2 |

||||

13.1.5 |

Specifications ......................................................................................................................... |

13- 3 |

|||

13.1.6 |

Maintenance........................................................................................................................... |

13- 4 |

|||

13.2 |

STO I/O signal connector (CN8) and pin assignment.................................................................. |

13- 4 |

|||

13.2.1 |

Pin |

assignment................................................................................................................... |

13- 4 |

||

13.2.2 |

Signal (device) explanations .................................................................................................. |

13- 5 |

|||

13.2.3 |

How to pull out the STO cable ............................................................................................... |

13- 5 |

|||

13.3 |

Connectionexample ..................................................................................................................... |

13- 6 |

|||

13.3.1 |

Connection examplefor CN8 connector................................................................................ |

13- 6 |

|||

13.3.2 External I/O signal connection example using an MR-J3-D05 safety logic unit..................... |

13- 7 |

||||

13.3.3 External I/O signal connection example using an external safety relay unit ......................... |

13- 8 |

||||

13.3.4 External I/O signal connection example using a motion controller........................................ |

13- 9 |

||||

13.4 |

Detailed |

description of interfaces ................................................................................................ |

13-10 |

||

13.4.1 |

Sink |

I/O interface................................................................................................................... |

13-10 |

||

13.4.2 |

Source I/Ointerface .............................................................................................................. |

13-11 |

|||

4

14. USING A LINEAR SERVO MOTOR |

14- 1 to 14-30 |

|||

14.1 |

Functions and configuration ......................................................................................................... |

14- 1 |

||

14.1.1 |

Summary................................................................................................................................ |

|

14- 1 |

|

14.1.2 Servo system with auxiliary equipment.................................................................................. |

14- 2 |

|||

14.2 |

Signalsand wiring......................................................................................................................... |

14- 3 |

||

14.3 |

Operationand functions................................................................................................................ |

14- 5 |

||

14.3.1 |

Startup.................................................................................................................................... |

|

14- 5 |

|

14.3.2 |

Magnetic |

pole detection ......................................................................................................... |

14- 7 |

|

14.3.3 |

Home position return............................................................................................................. |

14-15 |

||

14.3.4 |

Test operation mode in MR Configurator2............................................................................ |

14-19 |

||

14.3.5 |

Operation |

omfr controller ...................................................................................................... |

14-21 |

|

14.3.6 |

Function................................................................................................................................. |

|

14-23 |

|

14.3.7 |

Absolute |

position detection system....................................................................................... |

14-25 |

|

14.4 |

Characteristics |

............................................................................................................................. |

14-26 |

|

14.4.1 |

Overload |

protection characteristics ...................................................................................... |

14-26 |

|

14.4.2 Power supply capacity and generated loss .......................................................................... |

14-27 |

|||

14.4.3 |

Dynamic |

brake characterist cs.............................................................................................. |

14-29 |

|

14.4.4 Permissible load to motor mass ratio when the dynamic brake is used............................... |

14-30 |

|||

|

|

|||

15. USING A DIRECT DRIVE MOTOR |

15- 1 to 15-20 |

|||

15.1 |

Functions and configuration ......................................................................................................... |

15- 1 |

||

15.1.1 |

Summary................................................................................................................................ |

|

15- 1 |

|

15.1.2 Servo system with auxiliary equipment.................................................................................. |

15- 2 |

|||

15.2 |

Signalsand wiring......................................................................................................................... |

15- 3 |

||

15.3 |

Operationand functions................................................................................................................ |

15- 4 |

||

15.3.1 |

Startup procedure .................................................................................................................. |

15- 5 |

||

15.3.2 |

Magnetic |

pole detection ......................................................................................................... |

15- 6 |

|

15.3.3 |

Operation |

omfr controller ...................................................................................................... |

15-13 |

|

15.3.4 |

Function................................................................................................................................. |

|

15-15 |

|

15.4 |

Characteristics |

............................................................................................................................. |

15-17 |

|

15.4.1 |

Overload |

protection characteristics ...................................................................................... |

15-17 |

|

15.4.2 Power supply capacity and generated loss .......................................................................... |

15-18 |

|||

15.4.3 |

Dynamic |

brake characterist cs.............................................................................................. |

15-19 |

|

|

|

|||

16. FULLY CLOSED LOOP SYSTEM (available in the future) |

16- 1 to 16-24 |

|||

16.1 |

Functions and configuration ......................................................................................................... |

16- 1 |

||

16.1.1 |

Functionblock diagram.......................................................................................................... |

16- 1 |

||

16.1.2 |

Selecting |

procedur of control mode ..................................................................................... |

16- 3 |

|

16.1.3 |

System onfigurationc.............................................................................................................. |

16- 4 |

||

16.2 |

Load-side encoder ........................................................................................................................ |

16- 5 |

||

16.2.1 |

Linearencoder ....................................................................................................................... |

16- 5 |

||

16.2.2 |

Rotary encoder....................................................................................................................... |

16- 5 |

||

16.2.3 |

Configuration diagram of encoder cable................................................................................ |

16- 5 |

||

16.2.4 |

MR-J4FCCBL03M branchablec............................................................................................ |

16- 7 |

||

16.3 |

Operationand functions................................................................................................................ |

16- 8 |

||

16.3.1 |

Startup.................................................................................................................................... |

|

16- 8 |

|

16.3.2 |

Home position return............................................................................................................. |

16-14 |

||

16.3.3 |

Operation |

omfr controller ...................................................................................................... |

16-17 |

|

5

16.3.4 Fully closed loop control error detection functions................................................................ |

16-19 |

|

16.3.5 |

Absolute position detection system under fully closed loop system..................................... |

16-21 |

16.3.6 |

About MRConfigurator 2 ...................................................................................................... |

16-22 |

|

|

|

APPENDIX |

App.- 1 to App.-34 |

|

App. 1 Auxiliary equipment manufacturer (for reference)................................................................... |

App.- 1 |

|

App. 2 Handling of AC servo amplifier batteries for the United Nations Recommendations on the Transport

of Dangerous Goods........................................................................................................................... |

App.- 1 |

||

App. 3 Symbol for the new EU Battery Directive ................................................................................ |

App.- 3 |

||

App. 4 Compliance with the CE marking ............................................................................................ |

App.- 3 |

||

App. 5 Compliance with UL/CSA standard ......................................................................................... |

App.- 6 |

||

App. 6 Compliance with KC mark ....................................................................................................... |

App.- 9 |

||

App. 7 |

MR-J3-D05 Safety logic unit.................................................................................................... |

App.- 9 |

|

App. 8 |

EC declaration of conformity .................................................................................................. |

App.-28 |

|

App. 9 |

How to replace servo amplifier without magnetic pole detection ........................................... |

App.-29 |

|

App. 10 |

Two-wire type encoder cable for HG-MR/HG-KR ................................................................ |

App.-31 |

|

App. 11 |

SSCNET III cable (SC-J3BUS_M-C) manufactured by Mitsubishi Electric System & Service App.- |

||

31 |

|

|

|

App. 12 |

CNP_ crimping connector .................................................................................................... |

App.-32 |

|

App. 13 |

Recommended cable for servo amplifier power supply ....................................................... |

App.-33 |

|

6

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Summary

The MELSERVO-J4 series of multi-axis servo amplifiers inherits the high performance, sophisticated functions, and usability of the MR-J4-B servo amplifiers, and ensures space saving, reduced wiring, and energy saving.

The MR-J4W_-B servo amplifier is connected to controllers, including a servo system controller, on the fast synchronization network, SSCNET III/H. The servo amplifier directly receives a command from a controller to drive a servo motor.

One MR-J4W_-B servo amplifier can drive two or three servo motors. The footprint of one MR-J4W_-B servo amplifier is considerably smaller than that of two or three MR-J4-B servo amplifiers. You can install MR- J4W_-B servo amplifiers without clearance between them. This makes your system more compact.

The multi-axis structure enables multiple axes to share the SSCNET III cable, control circuit power supply cable, and main circuit power supply cable. This ensures reduced wiring.

For the MR-J4W_-B servo amplifier, the parameter settings allows you to use a rotary servo motor, linear servo motor, and direct drive motor for each axis. The axes can be connected to a rotary servo motor, linear servo motor, and direct drive motor, which have different capacity. Using a linear servo motor or direct drive motor simplifies the system, and using the MR-J4W_-B servo amplifier downsizes the equipment, enhances the equipment performance, and ensures space saving.

Using regenerative energy generated when a servo motor decelerates ensures energy saving. Depending on the operating conditions, the regenerative option is not required.

As the MR-J4-B servo amplifier, the MR-J4W_-B servo amplifier supports the one-touch adjustment and the real-time auto tuning. This enables you to easily adjust the servo gain according to the machine.

The tough drive function and the drive recorder function, which are well-received in the MELSERVO-JN series, have been improved. The MR-J4W_-B servo amplifier supports the improved functions. Additionally, the preventive maintenance support function detects an error in the machine parts. This function provides strong support for the machine maintenance and inspection.

On the SSCNET III/H network, the stations are connected with a maximum distance of 100 m between them. This allows you to create a large system.

The MR-J4W_-B servo amplifier supports the Safe Torque Off (STO) function for safety. When the MR- J4W_-B servo amplifier is connected to a SSCNET III/H-compatible motion controller, in addition to the STO function, the servo amplifier also supports the Safe Stop 1 (SS1), Safe Stop 2 (SS2), Safe Operating Stop (SOS), Safely-Limited Speed (SLS), Safe Brake Control (SBC), and Safe Speed Monitor (SSM) functions. The MR-J4W_-B servo amplifier has a USB communication interface. Therefore, you can connect the servo amplifier to the personal computer with MR Configurator2 installed to perform the parameter setting, test operation, gain adjustment, and others.

1 - 1

1. FUNCTIONS AND CONFIGURATION

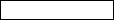

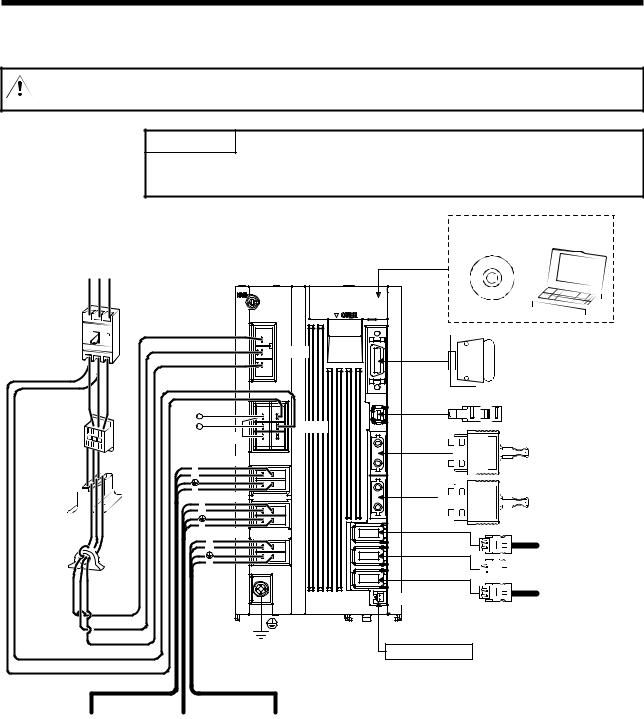

1.2 Function block diagram

The function block diagram of this servo is shown below.

MCCB

(Note 2) Power supply

STO switch

Controller or servo amplifier

Servo amplifier or cap

|

|

|

|

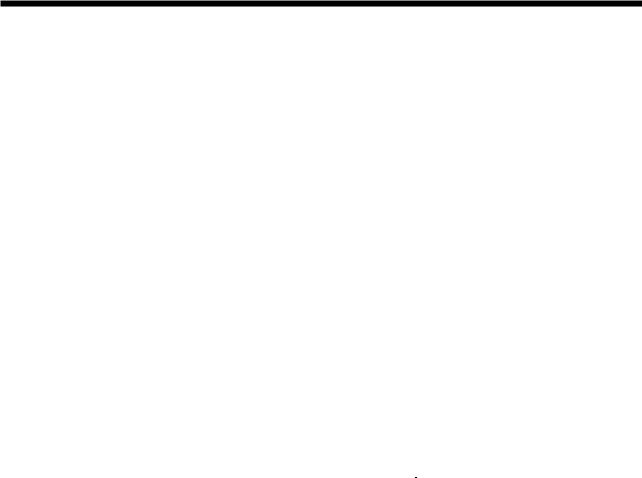

|

|

Regenerative |

|

|

|

|

||

|

|

|

|

|

|

option |

|

|

|

|

|

|

|

|

|

|

|

|

P+ |

C |

D |

|

|

|

|

|

|

|

|

|

|

CNP2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Built-in |

|

|

|

|

|

|

|

|

|

|

|

|

regenerative |

TRM(A) |

|

|

|

MC |

L1 |

|

|

|

|

|

|

resistor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Regene- |

|

|

|

|

|

||

CNP1 |

|

U |

U |

|

+ |

|

|

Current |

A-axis |

|||

L3 U |

|

TR |

|

|

|

|||||||

|

L2 |

|

|

|

rative |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

detector |

output |

|

|

|

|

|

|

CHARGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

lamp |

|

|

|

|

Dynamic |

|

|

|

|

|

|

Cooling fan |

|

|

|

|

|

brake circuit (A) |

A-axis |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

(Note 1) |

|

STO circuit |

|

|

|

F/B |

|

|

|

|

|

|

|

|

|

|

|

|

||

CNP2 |

L11 |

|

|

Control |

|

|

|

|

|

|

|

|

L21 |

|

+ |

circuit |

|

|

Base |

|

|

Current |

|

||

|

power |

|

|

Overvoltage |

Overcurrent |

|

||||||

|

|

|

|

detection |

|

|||||||

|

|

|

|

|

supply |

|

|

amplifier |

|

(A) |

(A) |

B-axis |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

output |

CN8 |

|

|

|

|

|

|

|

|

Control (A-axis) |

|

Virtual |

|

|

|

|

|

|

|

|

|

|

motor |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Model position |

Model speed |

|

B-axis |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

control (A) |

control (A) |

|

|

|

|

|

|

|

|

|

|

|

|

F/B |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

CN1A |

|

|

|

|

|

Control (B-axis) |

|

|

|

|

||

|

|

|

|

|

Control (C-axis) |

|

|

Virtual |

|

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I/F |

|

|

|

|

|

|

encoder |

C-axis |

|

|

|

|

Control |

|

|

|

|

|

|

|

output |

CN1B |

|

|

|

|

|

|

|

|

Actual position |

Actual speed |

Current |

|

|

|

|

|

|

|

|

|

control (A) |

control (A) |

control (A) |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

C-axis |

|

|

|

|

|

|

|

|

|

|

|

|

F/B |

|

U |

A-axis Servo motor |

|

CNP3A |

V |

M |

|

W |

|||

|

|||

|

|

CN2A |

|

E |

|

|

|

||

|

U |

B-axis Servo motor |

|

CNP3B |

V |

M |

|

W |

|||

|

|||

|

|

||

CN2B |

|

E |

|

|

|

|

U |

C-axis Servo motor |

|

CNP3C |

V |

M |

|

W |

|||

|

|||

|

|

||

CN2C |

|

E |

|

|

|

Step-down

circuit

Note 1. The MR-J4W2-22B has no cooling fan.

2.For 1-phase 200 V AC to 240 V AC, connect the power supply to L1 and L3. Leave L2 open. For the power supply specifications, refer to section 1.3.

1 - 2

1. FUNCTIONS AND CONFIGURATION

1.3 Servo amplifier standard specifications 1.3.1 Integrated 2-axis servo amplifier

Model MR-J4W2- |

|

22B |

|

44B |

|

77B |

|

1010B |

|||

|

|

Rated voltage |

|

|

|

3-phase 170 V AC |

|

|

|

||

Output |

|

Rated current |

|

1.5 |

|

2.8 |

|

5.8 |

|

6.0 |

|

|

(each axis) |

[A] |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||

|

|

Power supply |

|

3-phase or 1-phase 200 V AC to 240 V AC, 50/60 Hz |

|

3-phase 200 V AC to |

|||||

|

|

/Frequency |

|

|

240 V AC, 50/60 Hz |

||||||

|

|

|

|

|

|

|

|

|

|||

|

|

Rated current |

[A] |

2.9 |

|

5.2 |

|

7.5 |

|

9.8 |

|

Main circuit |

|

Permissible voltage |

|

3-phase or 1-phase 170 V AC to 264 V AC |

|

|

3-phase 170 V AC to |

||||

|

fluctuation |

|

|

|

|

264 V AC |

|||||

power supply |

|

|

|

|

|

|

|

|

|||

|

Permissible frequency |

|

|

|

|

|

|

|

|||

input |

|

|

|

Within ±5% |

|

|

|

||||

|

fluctuation |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

Power supply |

|

|

|

Refer to section 10.2. |

|

|

|||

|

|

capacity |

[kVA] |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||

|

|

Inrush current |

[A] |

|

|

Refer to section 10.5. |

|

|

|||

|

|

Power supply |

|

|

|

1-phase 200 V AC to 240 V AC, 50/60 Hz |

|

|

|||

|

|

/Frequency |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

Rated current |

[A] |

|

0.4 |

|

|

|

|||

Control circuit |

|

Permissible voltage |

|

|

1-phase 170 V AC to 264 V AC |

|

|

||||

|

fluctuation |

|

|

|

|

|

|||||

power supply |

|

|

|

|

|

|

|

|

|

|

|

|

Permissible frequency |

|

|

|

|

|

|

|

|||

input |

|

|

|

Within ±5% |

|

|

|

||||

|

fluctuation |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

Power consumption |

|

55 |

|

|

|

||||

|

|

|

|

[W] |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inrush current |

[A] |

|

|

Refer to section 10.5. |

|

|

|||

Interface |

|

Voltage/Frequency |

|

|

24 V DC ± 10% |

|

|

|

|||

|

Power supply |

|

|

|

|

|

|

|

|

||

power supply |

|

|

|

|

0.35 A (Note 1) |

|

|

|

|||

|

capacity |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

Reusable regenerative |

17 |

|

21 |

|

|

44 |

|||

|

|

energy (Note 2) |

[J] |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

|

|

Moment of inertia J |

|

|

|

|

|

|

|

||

|

|

equivalent to the |

|

|

|

|

|

|

|

||

|

|

permissible charging |

3.45 |

|

4.26 |

|

|

8.92 |

|||

|

|

amount (Note 3) |

|

|

|

|

|

|

|

||

Capacitor |

|

[× 10-4 kg • m2] |

|

|

|

|

|

|

|

||

regeneration |

|

Mass |

|

LM-H3 |

3.8 |

|

4.7 |

|

|

9.8 |

|

|

|

equivalent to |

|

|

|

|

|

|

|

|

|

|

|

the |

|

LM-F |

|

|

|

|

|

|

|

|

|

permissible |

|

|

|

|

|

|

|

|

|

|

|

|

LM-K2 |

8.5 |

|

10.5 |

|

|

22.0 |

||

|

|

charging |

|

|

|

|

|||||

|

|

|

LM-U2 |

|

|

|

|

|

|

|

|

|

|

amount |

|

|

|

|

|

|

|

|

|

|

|

(Note 4) [kg] |

|

|

|

|

|

|

|

|

|

Control method |

|

|

|

|

|

Sine-wave PWM control, current control method |

|||||

Built-in regenerative resistance |

[W] |

|

20 |

|

|

100 |

|||||

Dynamic brake |

|

|

|

|

|

Built-in |

|

|

|

||

Fully-closed loop control |

|

|

|

Available in the future |

|

|

|||||

Load-side encoder interface |

|

|

|