HP sx2000 User Manual

User Service Guide

HP Integrity Superdome/sx2000 and HP 9000

Superdome/sx2000 Servers

HP Part Number: A9834-9001D_ed6

Published: September 2009

Edition: 6

Legal Notices

© Copyright 2009 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Intel and Itanium are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other countries.

Microsoft and Windows are U.S. registered trademarks of Microsoft Corporation.

UNIX is a registered trademark of The Open Group.

Table of Contents |

|

About This Document....................................................................................................... |

13 |

Intended Audience................................................................................................................................ |

13 |

Document Organization....................................................................................................................... |

13 |

Typographic Conventions..................................................................................................................... |

13 |

Related Information.............................................................................................................................. |

14 |

Publishing History................................................................................................................................ |

14 |

HP Encourages Your Comments.......................................................................................................... |

15 |

1 Overview....................................................................................................................... |

17 |

Server History and Specifications......................................................................................................... |

17 |

Server Components............................................................................................................................... |

18 |

Power Subsystem.................................................................................................................................. |

19 |

AC Power......................................................................................................................................... |

20 |

DC Power......................................................................................................................................... |

20 |

Power Sequencing............................................................................................................................ |

21 |

Enabling 48 Volts............................................................................................................................. |

21 |

Cooling System..................................................................................................................................... |

21 |

Utilities Subsystem................................................................................................................................ |

22 |

Platform Management..................................................................................................................... |

22 |

UGUY.............................................................................................................................................. |

23 |

CLU Functionality........................................................................................................................... |

23 |

PM3 Functionality........................................................................................................................... |

23 |

System Clocks.................................................................................................................................. |

24 |

Management Processor.................................................................................................................... |

24 |

Compact Flash................................................................................................................................. |

25 |

HUCB............................................................................................................................................... |

25 |

Backplane.............................................................................................................................................. |

26 |

Crossbar Chip.................................................................................................................................. |

26 |

Switch Fabrics.................................................................................................................................. |

27 |

Backplane Monitor and Control...................................................................................................... |

27 |

I2C Bus Distribution........................................................................................................................ |

27 |

Clock Subsystem.............................................................................................................................. |

27 |

System Clock Distribution......................................................................................................... |

27 |

Hot-Swap Oscillator................................................................................................................... |

28 |

sx2000 RCS Module.................................................................................................................... |

28 |

Cabinet ID........................................................................................................................................ |

29 |

Cell ID.............................................................................................................................................. |

29 |

Backplane Power Requirements and Power Distribution............................................................... |

29 |

CPUs and Memories............................................................................................................................. |

30 |

Cell Controller................................................................................................................................. |

31 |

Processor Interface........................................................................................................................... |

31 |

Processors........................................................................................................................................ |

32 |

Cell Memory System....................................................................................................................... |

32 |

Memory Controller .................................................................................................................... |

33 |

DIMM Architecture.................................................................................................................... |

33 |

Memory Interconnect................................................................................................................. |

33 |

Mixing Different Sized DIMMs.................................................................................................. |

34 |

Memory Interleaving................................................................................................................. |

34 |

Memory Bank Attribute Table.............................................................................................. |

34 |

Cell Map................................................................................................................................ |

35 |

Table of Contents |

3 |

Link Interleaving................................................................................................................... |

35 |

Memory Error Protection........................................................................................................... |

35 |

DRAM Erasure........................................................................................................................... |

36 |

PDC Functional Changes................................................................................................................. |

36 |

Platform Dependent Hardware....................................................................................................... |

36 |

Reset................................................................................................................................................. |

37 |

Cell OL*........................................................................................................................................... |

37 |

I/O Subsystem....................................................................................................................................... |

37 |

PCI-X Backplane Functionality........................................................................................................ |

38 |

SBA Chip CC-to-Ropes.............................................................................................................. |

38 |

Ropes-to-PCI LBA Chip............................................................................................................. |

39 |

PCI Slots..................................................................................................................................... |

40 |

Mixed PCI-X and PCI Express I/O Chassis........................................................................... |

40 |

PCI Hot-Swap Support......................................................................................................... |

41 |

System Management Station................................................................................................................ |

41 |

User Accounts.................................................................................................................................. |

42 |

New Server Cabling.............................................................................................................................. |

42 |

m-Link Cable................................................................................................................................... |

42 |

e-Link Cable..................................................................................................................................... |

42 |

Clock Cable...................................................................................................................................... |

44 |

Firmware............................................................................................................................................... |

44 |

Itanium Firmware for HP Integrity Superdome/sx2000................................................................. |

44 |

Itanium System Firmware Functions......................................................................................... |

46 |

PA-RISC Firmware for HP 9000/sx2000 Servers.............................................................................. |

46 |

PA-RISC System Firmware Functions........................................................................................ |

47 |

Server Configurations........................................................................................................................... |

47 |

Server Errors......................................................................................................................................... |

48 |

2 System Specifications................................................................................................... |

49 |

Dimensions and Weights...................................................................................................................... |

49 |

Component Dimensions.................................................................................................................. |

49 |

Component Weights........................................................................................................................ |

49 |

Shipping Dimensions and Weights................................................................................................. |

50 |

Electrical Specifications......................................................................................................................... |

50 |

Grounding....................................................................................................................................... |

51 |

Circuit Breaker................................................................................................................................. |

51 |

Power Options................................................................................................................................. |

51 |

System Power Requirements........................................................................................................... |

52 |

Component Power Requirements................................................................................................... |

53 |

IOX Cabinet Power Requirements................................................................................................... |

53 |

IOX Cabinet Power Cords............................................................................................................... |

53 |

Environmental Requirements............................................................................................................... |

54 |

Temperature and Humidity Specifications..................................................................................... |

54 |

Power Dissipation............................................................................................................................ |

54 |

Acoustic Noise Specification........................................................................................................... |

56 |

Airflow............................................................................................................................................. |

56 |

3 Installing the System..................................................................................................... |

59 |

Introduction ......................................................................................................................................... |

59 |

Communications Interference ........................................................................................................ |

59 |

Electrostatic Discharge ................................................................................................................... |

59 |

Public Telecommunications Network Connection.......................................................................... |

60 |

Unpacking and Inspecting the System................................................................................................. |

60 |

4Table of Contents

Verifying Site Preparation............................................................................................................... |

60 |

Gathering LAN Information...................................................................................................... |

60 |

Verifying Electrical Requirements.............................................................................................. |

60 |

Checking the Inventory................................................................................................................... |

60 |

Inspecting the Shipping Containers for Damage............................................................................ |

61 |

Inspection Precautions............................................................................................................... |

62 |

Claims Procedures ..................................................................................................................... |

62 |

Unpacking and Inspecting Hardware Components....................................................................... |

62 |

Tools Required............................................................................................................................ |

63 |

Unpacking the Cabinet............................................................................................................... |

63 |

Unpacking the PDCA...................................................................................................................... |

71 |

Returning Equipment...................................................................................................................... |

71 |

Setting Up the System........................................................................................................................... |

72 |

Moving the System and Related Equipment to the Installation Site .............................................. |

72 |

Unpacking and Installing the Blower Housings and Blowers........................................................ |

72 |

Attaching the Side Skins and Blower Side Bezels........................................................................... |

75 |

Attaching the Side Skins............................................................................................................ |

75 |

Attaching the Blower Side Bezels............................................................................................... |

77 |

Attaching the Leveling Feet and Leveling the Cabinet................................................................... |

79 |

Installing the Front Door Bezels and the Front and Rear Blower Bezels ....................................... |

79 |

Installing the Front Door Bezels................................................................................................. |

79 |

Installing the Rear Blower Bezel................................................................................................ |

81 |

Installing the Front Blower Bezel............................................................................................... |

82 |

Wiring Check................................................................................................................................... |

83 |

Installing and Verifying the PDCA................................................................................................. |

84 |

Checking Voltage............................................................................................................................. |

88 |

Removing the EMI Panels............................................................................................................... |

89 |

Connecting the Cables..................................................................................................................... |

91 |

Routing the I/O Cables.................................................................................................................... |

91 |

Installing the Support Management Station......................................................................................... |

93 |

Installing the SMS Support Shelf.......................................................................................................... |

93 |

Connecting the SMS to the Superdome................................................................................................ |

94 |

SMS Software and Superdome Firmware Downloading Procedure.................................................... |

94 |

Configuring the Event Information Tools............................................................................................. |

95 |

Turning On Housekeeping Power........................................................................................................ |

96 |

Connecting the MP to the Customer LAN........................................................................................... |

98 |

Connecting the MP to the Network................................................................................................. |

98 |

Setting the Customer IP Address.................................................................................................... |

99 |

Booting and Verifying the System...................................................................................................... |

101 |

Connecting to the MP.................................................................................................................... |

101 |

Powering On the System 48 V Power Supply................................................................................ |

104 |

Booting the HP Integrity Superdome/sx2000 to an EFI Shell........................................................ |

104 |

Booting an HP 9000 sx2000 Server to BCH.................................................................................... |

106 |

Verifying the System...................................................................................................................... |

106 |

Running JET Software......................................................................................................................... |

108 |

Running JUST ............................................................................................................................... |

108 |

Power Cycling After Using JET..................................................................................................... |

109 |

Offline Diagnostic Environment......................................................................................................... |

109 |

Attaching the Rear Kick Plates............................................................................................................ |

109 |

Performing a Visual Inspection and Completing the Installation...................................................... |

110 |

Conducting a Post-Installation Check................................................................................................. |

112 |

4 Booting and Shutting Down the Operating System............................................... |

113 |

Operating Systems Supported on Cell-based HP Servers.................................................................. |

113 |

Table of Contents |

5 |

System Boot Configuration Options................................................................................................... |

114 |

HP 9000 Boot Configuration Options............................................................................................ |

114 |

HP Integrity Boot Configuration Options..................................................................................... |

114 |

Booting and Shutting Down HP-UX................................................................................................... |

118 |

HP-UX Support for Cell Local Memory........................................................................................ |

118 |

Adding HP-UX to the Boot Options List....................................................................................... |

118 |

Booting HP-UX.............................................................................................................................. |

119 |

Standard HP-UX Booting......................................................................................................... |

120 |

Single-User Mode HP-UX Booting........................................................................................... |

123 |

LVM-Maintenance Mode HP-UX Booting............................................................................... |

126 |

Shutting Down HP-UX.................................................................................................................. |

127 |

Booting and Shutting Down HP OpenVMS I64................................................................................. |

128 |

HP OpenVMS I64 Support for Cell Local Memory....................................................................... |

129 |

Adding HP OpenVMS to the Boot Options List............................................................................ |

129 |

Booting HP OpenVMS................................................................................................................... |

131 |

Shutting Down HP OpenVMS....................................................................................................... |

132 |

Booting and Shutting Down Microsoft Windows.............................................................................. |

133 |

Microsoft Windows Support for Cell Local Memory.................................................................... |

133 |

Adding Microsoft Windows to the Boot Options List................................................................... |

134 |

Booting Microsoft Windows.......................................................................................................... |

135 |

Shutting Down Microsoft Windows.............................................................................................. |

137 |

Booting and Shutting Down Linux..................................................................................................... |

138 |

Linux Support for Cell Local Memory.......................................................................................... |

138 |

Adding Linux to the Boot Options List......................................................................................... |

139 |

Booting Red Hat Enterprise Linux................................................................................................ |

140 |

Booting SuSE Linux Enterprise Server ......................................................................................... |

141 |

Shutting Down Linux.................................................................................................................... |

142 |

A sx2000 LEDs.............................................................................................................. |

145 |

B Management Processor Commands........................................................................ |

149 |

BO Command ..................................................................................................................................... |

149 |

CA Command..................................................................................................................................... |

149 |

CC Command...................................................................................................................................... |

150 |

CP Command...................................................................................................................................... |

151 |

DATE Command................................................................................................................................. |

152 |

DC Command..................................................................................................................................... |

152 |

DF Command...................................................................................................................................... |

153 |

DI Command....................................................................................................................................... |

154 |

DL Command...................................................................................................................................... |

155 |

EL Command...................................................................................................................................... |

155 |

HE Command..................................................................................................................................... |

156 |

ID Command....................................................................................................................................... |

157 |

IO Command....................................................................................................................................... |

158 |

IT Command....................................................................................................................................... |

159 |

LC Command...................................................................................................................................... |

159 |

LS Command....................................................................................................................................... |

160 |

MA Command.................................................................................................................................... |

160 |

ND Command..................................................................................................................................... |

161 |

PD Command...................................................................................................................................... |

161 |

PE Command...................................................................................................................................... |

162 |

PS Command....................................................................................................................................... |

163 |

RE Command...................................................................................................................................... |

164 |

6Table of Contents

RL Command...................................................................................................................................... |

165 |

RR Command...................................................................................................................................... |

166 |

RS Command...................................................................................................................................... |

166 |

SA Command...................................................................................................................................... |

167 |

SO Command...................................................................................................................................... |

167 |

SYSREV Command............................................................................................................................. |

168 |

TC Command...................................................................................................................................... |

169 |

TE Command...................................................................................................................................... |

169 |

VM Command..................................................................................................................................... |

170 |

WHO Command................................................................................................................................. |

170 |

XD Command..................................................................................................................................... |

171 |

C Powering the System On and Off ........................................................................... |

173 |

Shutting Down the System................................................................................................................. |

173 |

Checking System Configuration.................................................................................................... |

173 |

Shutting Down the Operating System........................................................................................... |

175 |

Preparing the Partitions for Shutdown.......................................................................................... |

176 |

Powering Off the System............................................................................................................... |

177 |

Turning On Housekeeping Power...................................................................................................... |

178 |

Powering On the System Using the PE Command............................................................................. |

180 |

D Templates.................................................................................................................... |

183 |

Templates............................................................................................................................................ |

183 |

Equipment Footprint Templates.................................................................................................... |

185 |

Computer Room Layout Plan........................................................................................................ |

185 |

Index............................................................................................................................... |

197 |

Table of Contents |

7 |

List of Figures

1-1 |

Superdome History....................................................................................................................... |

17 |

1-2 |

Superdome Cabinet Components................................................................................................. |

19 |

1-3 |

UGUY............................................................................................................................................ |

23 |

1-4 |

Management Processor................................................................................................................. |

25 |

1-5 |

HUCB............................................................................................................................................. |

26 |

1-6 |

HSO and RCS Locations................................................................................................................ |

29 |

1-7 |

Backplane Power Supply Module................................................................................................. |

30 |

1-8 |

Backplane (Rear View).................................................................................................................. |

30 |

1-9 |

Cell Board...................................................................................................................................... |

31 |

1-10 |

Cell Memory.................................................................................................................................. |

33 |

1-11 |

PCI-X I/O Rope Mapping.............................................................................................................. |

39 |

1-12 |

PCIe I/O Rope Mapping................................................................................................................ |

41 |

1-13 |

e-Link Cable................................................................................................................................... |

43 |

1-14 |

Backplane Cables........................................................................................................................... |

44 |

1-15 |

Itanium Firmware Interfaces......................................................................................................... |

45 |

1-16 |

PA-RISC Firmware Interfaces........................................................................................................ |

47 |

2-1 |

PDCA Locations............................................................................................................................ |

52 |

2-2 |

Airflow Diagram........................................................................................................................... |

57 |

3-1 |

Normal Tilt Indicator.................................................................................................................... |

61 |

3-2 |

Abnormal Tilt Indicator ................................................................................................................ |

62 |

3-3 |

Front of Cabinet Container............................................................................................................ |

64 |

3-4 |

Cutting the Polystrap Bands.......................................................................................................... |

64 |

3-5 |

Removing the Ramps from the Pallet............................................................................................ |

65 |

3-6 |

Power Supply Mounting Screws Location.................................................................................... |

66 |

3-7 |

I/O Chassis Mounting Screws....................................................................................................... |

66 |

3-8 |

Shipping Strap Location................................................................................................................ |

68 |

3-9 |

Removing the Mounting Brackets................................................................................................. |

69 |

3-10 |

Positioning the Ramps................................................................................................................... |

70 |

3-11 |

Rolling the Cabinet Down the Ramp............................................................................................ |

70 |

3-12 |

Blower Housing Frame.................................................................................................................. |

72 |

3-13 |

Removing Protective Cardboard from the Housing..................................................................... |

73 |

3-14 |

Installing the Rear Blower Housing.............................................................................................. |

73 |

3-15 |

Installing the Front Blower Housing............................................................................................. |

74 |

3-16 |

Installing the Blowers.................................................................................................................... |

75 |

3-17 |

Attaching the Rear Side Skin......................................................................................................... |

76 |

3-18 |

Attaching the Front Side Skins...................................................................................................... |

77 |

3-19 |

Attaching the Side Bezels.............................................................................................................. |

78 |

3-20 |

Attaching the Leveling Feet........................................................................................................... |

79 |

3-21 |

Installing the Lower Front Door Assembly................................................................................... |

80 |

3-22 |

Installing the Upper Front Door Assembly................................................................................... |

81 |

3-23 |

Installing the Rear Blower Bezel.................................................................................................... |

82 |

3-24 |

Installing the Front Blower Bezel.................................................................................................. |

83 |

3-25 |

PDCA Assembly for Options 6 and 7............................................................................................ |

85 |

3-26 |

A 4-Wire Connector....................................................................................................................... |

85 |

3-27 |

A 5-Wire Connector....................................................................................................................... |

86 |

3-28 |

Installing the PDCA....................................................................................................................... |

86 |

3-29 |

Checking PDCA Test Points (5-Wire)............................................................................................ |

87 |

3-30 |

Wall Receptacle Pinouts................................................................................................................ |

88 |

3-31 |

Power Supply Indicator LED........................................................................................................ |

89 |

3-32 |

Removing Front EMI Panel Screw................................................................................................ |

90 |

3-33 |

Removing the Back EMI Panel...................................................................................................... |

90 |

3-34 |

Cable Labeling............................................................................................................................... |

91 |

8List of Figures

3-35 |

Routing I/O Cables........................................................................................................................ |

92 |

3-36 |

Front Panel with HKP and Present LEDs...................................................................................... |

97 |

3-37 |

BPS LEDs....................................................................................................................................... |

98 |

3-38 |

MP LAN Connection Location...................................................................................................... |

99 |

3-39 |

LAN Configuration Screen.......................................................................................................... |

100 |

3-40 |

The ls Command Screen.............................................................................................................. |

101 |

3-41 |

Logging In.................................................................................................................................... |

102 |

3-42 |

Main MP Menu............................................................................................................................ |

102 |

3-43 |

MP Command Option................................................................................................................. |

103 |

3-44 |

MP Virtual Front Panel................................................................................................................ |

103 |

3-45 |

Example of Partition State—Cabinet Not Powered Up............................................................... |

103 |

3-46 |

MP Console Option..................................................................................................................... |

104 |

3-47 |

HP Integrity Superdome/sx2000 EFI Boot Manager................................................................... |

105 |

3-48 |

EFI Shell Prompt.......................................................................................................................... |

105 |

3-49 |

HP Integrity Superdome/sx2000 Partitions at System Firmware Console.................................. |

106 |

3-50 |

Power Status First Window......................................................................................................... |

107 |

3-51 |

Power Status Window................................................................................................................. |

107 |

3-52 |

Power Status Showing State of UGUY LEDs .............................................................................. |

108 |

3-53 |

Attaching Rear Kick Plates.......................................................................................................... |

110 |

3-54 |

Cell Board Ejectors....................................................................................................................... |

111 |

3-55 |

Front EMI Panel Flange and Cabinet Holes................................................................................ |

111 |

3-56 |

Reinstalling the Back EMI Panel.................................................................................................. |

112 |

A-1 |

Utilities ........................................................................................................................................ |

147 |

A-2 |

PDH Status.................................................................................................................................. |

147 |

C-1 |

Connecting to the Host................................................................................................................ |

173 |

C-2 |

Main MP Menu............................................................................................................................ |

173 |

C-3 |

Checking for Other Users............................................................................................................ |

174 |

C-4 |

Checking Current System Configuration.................................................................................... |

174 |

C-5 |

MP Virtual Front Panel................................................................................................................ |

174 |

C-6 |

Example of Partition State........................................................................................................... |

175 |

C-7 |

Partition Consoles Menu............................................................................................................. |

175 |

C-8 |

Entering the rr Command........................................................................................................... |

176 |

C-9 |

Using the de -s Command........................................................................................................ |

177 |

C-10 |

Power Entity Command.............................................................................................................. |

177 |

C-11 |

Power Status First Window......................................................................................................... |

178 |

C-12 |

Power Status Second Window..................................................................................................... |

178 |

C-13 |

Front Panel Display with Housekeeping (HKP) Power and Present LEDs On.......................... |

179 |

C-14 |

BPS LEDs..................................................................................................................................... |

180 |

C-15 |

Power Entity Command.............................................................................................................. |

181 |

C-16 |

Power Status First Window......................................................................................................... |

181 |

C-17 |

Power Status Window................................................................................................................. |

182 |

D-1 |

Cable Cutouts and Caster Locations........................................................................................... |

183 |

D-2 |

SD16 and SD32 Space Requirements........................................................................................... |

184 |

D-3 |

SD64 Space Requirements........................................................................................................... |

185 |

D-4 |

Computer Floor Template........................................................................................................... |

186 |

D-5 |

Computer Floor Template........................................................................................................... |

187 |

D-6 |

Computer Floor Template........................................................................................................... |

188 |

D-7 |

Computer Floor Template........................................................................................................... |

189 |

D-8 |

Computer Floor Template........................................................................................................... |

190 |

D-9 |

SD32, SD64, and IOX Cabinet Templates.................................................................................... |

191 |

D-10 |

SD32, SD64, and IOX Cabinet Templates.................................................................................... |

192 |

D-11 |

SD32, SD64, and IOX Cabinet Templates.................................................................................... |

193 |

D-12 |

SD32, SD64, and IOX Cabinet Templates.................................................................................... |

194 |

D-13 |

SD32, SD64, and IOX Cabinet Templates.................................................................................... |

195 |

D-14 |

SD32, SD64, and IOX Cabinet Templates.................................................................................... |

196 |

9

List of Tables

1-1 |

HSO LED Status Indicator Meaning............................................................................................. |

28 |

1-2 |

Supported Processors and Minimum Firmware Versions............................................................ |

32 |

1-3 |

SMS Lifecycles............................................................................................................................... |

42 |

2-1 |

Server Component Dimensions.................................................................................................... |

49 |

2-2 |

I/O Expansion Cabinet Component Dimensions.......................................................................... |

49 |

2-3 |

System Component Weights......................................................................................................... |

49 |

2-4 |

IOX Cabinet Weights..................................................................................................................... |

50 |

2-5 |

Miscellaneous Dimensions and Weights....................................................................................... |

50 |

2-6 |

Available Power Options............................................................................................................... |

51 |

2-7 |

Option 6 and 7 Specifics................................................................................................................ |

51 |

2-8 |

Power Requirements (Without SMS)............................................................................................ |

52 |

2-9 |

Component Power Requirements (Without SMS)........................................................................ |

53 |

2-10 |

I/O Expansion Cabinet Power Requirements (Without SMS)....................................................... |

53 |

2-11 |

I/O Expansion Cabinet Component Power Requirements............................................................ |

53 |

2-12 |

I/O Expansion Cabinet ac Power Cords........................................................................................ |

54 |

2-13 |

Operational Physical Environment Requirements........................................................................ |

54 |

2-14 |

Nonoperational Physical Environment Requirements................................................................. |

54 |

2-15 |

HP Integrity Superdome/sx2000 Dual-Core CPU Configurations............................................... |

55 |

2-16 |

HP Integrity Superdome/sx2000 Single-Core CPU Configurations............................................. |

55 |

2-17 |

Physical Environmental Specifications......................................................................................... |

57 |

3-1 |

Available Power Options............................................................................................................... |

71 |

3-2 |

Power Cord Option 6 and 7 Details............................................................................................... |

71 |

3-3 |

4- and 5-Wire Voltage Ranges....................................................................................................... |

87 |

A-1 |

Front Panel LEDs......................................................................................................................... |

145 |

A-2 |

Power and OL* LEDs................................................................................................................... |

146 |

A-3 |

OL* LED States............................................................................................................................ |

147 |

A-4 |

PDH Status and Power Good LED States.................................................................................... |

148 |

10 List of Tables

List of Examples

3-1 |

Directory Example......................................................................................................................... |

95 |

3-2 |

Directory Example......................................................................................................................... |

95 |

4-1 |

Single-User HP-UX Boot.............................................................................................................. |

124 |

B-1 |

BO command............................................................................................................................... |

149 |

B-2 |

CA Command.............................................................................................................................. |

150 |

B-3 |

CC Command.............................................................................................................................. |

151 |

B-4 |

CP Command.............................................................................................................................. |

152 |

B-5 |

DATE Command......................................................................................................................... |

152 |

B-6 |

DC Command.............................................................................................................................. |

153 |

B-7 |

DF Command.............................................................................................................................. |

154 |

B-8 |

DI Command............................................................................................................................... |

155 |

B-9 |

DL Command.............................................................................................................................. |

155 |

B-10 |

EL Command............................................................................................................................... |

156 |

B-11 |

HE Command.............................................................................................................................. |

157 |

B-12 |

ID Command............................................................................................................................... |

158 |

B-13 |

Example: ..................................................................................................................................... |

159 |

B-14 |

IT Command................................................................................................................................ |

159 |

B-15 |

LC Command.............................................................................................................................. |

160 |

B-16 |

LS Command............................................................................................................................... |

160 |

B-17 |

MP Main Menu............................................................................................................................ |

161 |

B-18 |

ND Command............................................................................................................................. |

161 |

B-19 |

PD Command.............................................................................................................................. |

162 |

B-20 |

PE Command for a Compute Cabinet......................................................................................... |

163 |

B-21 |

PS Command............................................................................................................................... |

164 |

B-22 |

Re-key lock for partition 3........................................................................................................... |

166 |

B-23 |

RR Command.............................................................................................................................. |

166 |

B-24 |

RS Command............................................................................................................................... |

167 |

B-25 |

SA Command.............................................................................................................................. |

167 |

B-26 |

SO Command.............................................................................................................................. |

168 |

B-27 |

SYSREV Command...................................................................................................................... |

169 |

B-28 |

TC Command.............................................................................................................................. |

169 |

B-29 |

TE Command............................................................................................................................... |

170 |

B-30 |

VM Command............................................................................................................................. |

170 |

B-31 |

WHO Command.......................................................................................................................... |

171 |

B-32 |

XD Command.............................................................................................................................. |

172 |

11

12

About This Document

Thisdocumentcontainsthesystemoverview,system-specificparameters,installationprocedures of the system, operating system specifics, and procedures for components in the system.

Intended Audience

This document is intended for HP trained Customer Support Consultants.

Document Organization

This document is organized as follows:

Chapter 1 This chapter presents an historical view of the Superdome server family, describes the various server components, and describes how the server components function together.

Chapter 2 This chapter contains the dimensions and weights for the server and various components.Electricalspecifications,environmentalrequirements,andtemplates are also included.

Chapter 3 Thischapterdescribeshowtounpackandinspectthesystem,setupthesystem, connect the MP to the customer LAN, and how to complete the installation.

Chapter 4 Thischapterdescribeshowtobootandshutdowntheserveroperatingsystem

(OS) for each OS supported.

Appendix A ThisappendixcontainstablesthatdescribethevariousLEDstatesforthefront panel, power and OL* states, and OL* states for I/O chassis cards.

Appendix B This appendix provides a summary for each management processor (MP) command. Screen output is provided for each command so you can see the results of the command.

Appendix C Thisappendixprovidesprocedurestopoweroffandpoweronthesystemwhen the removal and replacement of a component requires it.

Appendix D This appendix contains templates for cable cutouts and caster locations; SD16, SD32, SD64, and I/O expansion cabinets; and the computer room floor.

Typographic Conventions

The following typographic conventions are used in this document.

WARNING! Lists requirements that you must meet to avoid personal injury.

WARNING! Lists requirements that you must meet to avoid personal injury.

CAUTION: Provides information required to avoid losing data or to avoid losing system functionality.

IMPORTANT: Provides essential information to explain a concept or to complete a task.

IMPORTANT: Provides essential information to explain a concept or to complete a task.

NOTE: Highlights useful information such as restrictions, recommendations, or important details about HP product features.

• Commands and options are represented using this font.

•Text that you type exactly as shown is represented using this font.

Intended Audience |

13 |

•Text to be replaced with text that you supply is represented using this font.

Example:“Enterthels -l filenamecommand”meansyoumustreplacefilenamewithyour own text.

•Keyboard keys and graphical interface items (such as buttons, tabs, and menu items) are represented using this font.

Examples: The Control key, the OK button, the General tab, the Options menu.

•Menu —> Submenu represents a menu selection you can perform.

Example: “Select the Partition —> Create Partition action” means you must select the

Create Partition menu item from the Partition menu.

•Example screen output is represented using this font.

Related Information

FurtherinformationonHPserverhardwaremanagement,Microsoft®Windows®,anddiagnostic support tools are available through the following website links.

WebsiteforHPTechnicalDocumentation ThefollowinglinkisthemainwebsiteforHPtechnical documentation.ThissiteofferscomprehensiveinformationaboutHPproductsavailableforfree. See http://docs.hp.com.

Server Hardware Information The following link is the systems hardware section of the docs.hp.com website. It provides HP nPartition server hardware management information, includinginformationonsitepreparation,installation,andsoon. See http://docs.hp.com/hpux/ hw/.

Diagnostics and Event Monitoring: Hardware Support Tools The following link contains comprehensive information about HP hardware support tools, including online and offline diagnostics and event monitoring tools. This website has manuals, tutorials, FAQs, and other reference material. See http://docs.hp.com/hpux/diag.

Website for HP Technical Support The following link is the HP IT resource center website and provides comprehensive support information for IT professionals on a wide variety of topics, including software, hardware, and networking. See http://us-sup port2.external.hp.com.

Publishing History

The document printing date and edition number indicate the document’s current edition and areincludedinthefollowingtable.Theprintingdatewillchangewhenaneweditionisproduced. Documentupdatesmaybeissuedbetweeneditionstocorrecterrorsordocumentproductchanges. The latest version of this document is available on line at:

docs.hp.com.

First Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

March 2006 |

Second Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

September 2006 |

Third Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

February 2007 |

Fourth Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

November 2007 |

Fifth Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

March 2009 |

Sixth Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

September 2009 |

14

HP Encourages Your Comments

HP welcomes your feedback on this publication. Direct your comments to http://docs.hp.com/ en/feedback.html and note that you will not receive an immediate reply. All comments are appreciated.

HP Encourages Your Comments 15

16

1 Overview

Server History and Specifications

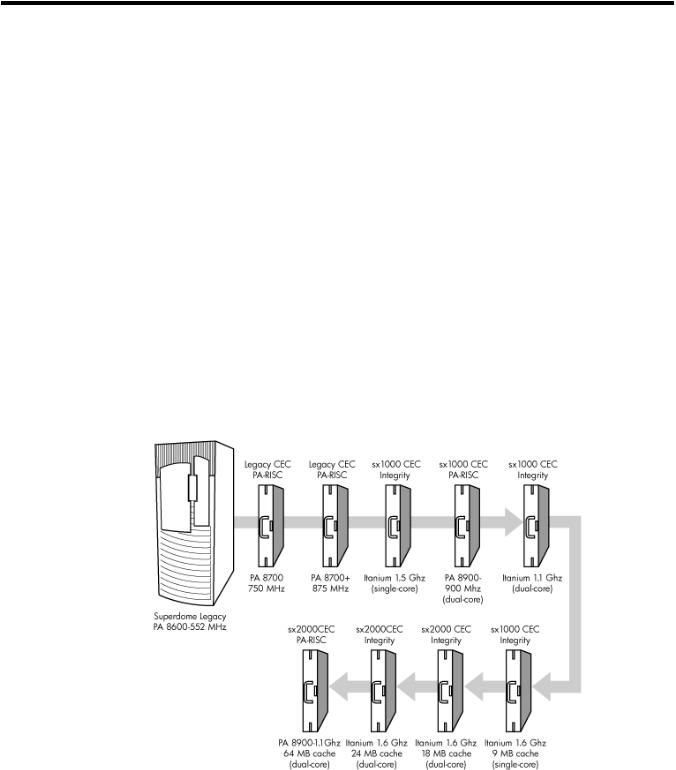

Superdome was introduced as the new platform architecture for high-end HP servers between the years 2000 and 2004. Superdome represented the first collaborative hardware design effort between traditional HP and Convex technologies. Superdome was designed to replace T- and

V-Class servers and to prepare for the transition from PA-RISC to Intel® Itanium® processors. The new design enabled the ability of running different operating systems on the same server. Thedesignalsoincludedseveralnew,high-availabilityfeatures.Initially,Superdomewasreleased with the legacy core electronics complex (CEC) and a 552 MHz PA-8600 processor. The Legacy CEC supported two additional speeds; a 750 MHz PA-8700 followed by an 875 MHz PA-8700 processor.

The HP Integrity server project consisted of four projects based on the sx1000 CEC chipset and the Integrity cell boards. The first release was the sx1000 chipset, Integrity cell boards, Itanium

firmware and a 1.2 MHz Intel® processor. This release included PCI-X and PCI I/O mixes. The Integrity systems were compatible with the legacy Superdome IOX.

The second release, based on the sx1000 CEC, included Integrity cell boards, but used PA-RISC firmware, and a dual-core PA-RISC processor. The release also included a 2 GB DIMM and a newHP-UXversion.Componentssuchasprocessors,processorpowerpods,memory,firmware, and operating system all changed for this release.

Figure 1-1 Superdome History

The third release, also based on the sx1000 chipset, included the Integrity cell boards, Itanium firmware,anda1.5MHzItaniumCPU.TheCPUmoduleconsistedofadual-coreprocessorwith a new cache controller. The firmware allowed for mixed cells within a system. All three DIMM sizes were supported. Firmware and operating system changes were minor compared to their earlier versions.

ThefourthandfinalreleaseistheHPsuperscalablesx2000processorchipset. Itisalsobasedon the new CEC that supports up to 128 PA-RISC or Itanium processors. It is the last generation of Superdome servers to support the PA-RISC family of processors. Modifications to the server components include:

Server History and Specifications |

17 |

•the new CEC chipset

•board changes including cell board

•system backplane

•I/O backplane

•associated power boards

•interconnect

•a redundant, hot-swappable clock source

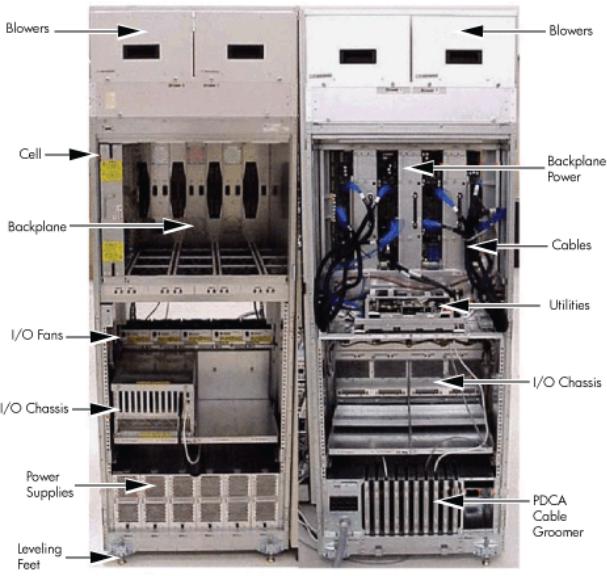

Server Components

A Superdome system consists of the following types of cabinet assemblies:

•MinimumofoneSuperdomeleft-sidecabinet.TheSuperdomecabinetcontainstheprocessors, the memory, and the core devices of the system. They also house the system's PCI cards. Systemscanincludebothleftandrightcabinetassembliescontainingaleftorrightbackplane (SD64) respectively.

•One or more HP Rack System/E cabinets. These rack cabinets are used to hold the system peripheral devices such as disk drives.

•Optionally, one or more I/O expansion cabinets (Rack System/E). An I/O expansion cabinet is required when a customer requires more PCI cards than can be accommodated in the Superdome cabinets.

The width of the cabinet assemblies accommodates moving them through standard-sized doorways. The intake air to the main (cell) card cage is filtered. This air filter is removable for cleaning and replacement while the system is fully operational.

Astatusdisplayislocatedontheoutsideofthefrontandreardoorsofeachcabinet.Thisfeature enables you to determine the basic status of each cabinet without opening any cabinet doors.

The Superdome is a cell-based system. Cells communicate with others utilizing the crossbar on the backplane. Every cell has its own I/O interface, which can be connected to one 12-slot I/O card cage using two System Bus Adapter (SBA) link cables. Not all SBA links are connected by default, due to a physical limitation of four I/O card cages per cabinet or node. In addition to these components, each system consists of a power subsystem and a utility subsystem. Three types of Superdome are available:

•SD16

•SD32

•SD64, a two-cabinet system with single-CPU cell board sockets

The SD## represents the maximum number of available CPU sockets.

An SD16 contains the following components:

•Up to four cell boards

•Four I/O card cages

•Five I/O fans

•Four system cooling fans

•Four bulk power supplies (BPS)

•Two power distribution control assemblies (PDCA)

TwobackplaneN+1powersuppliesprovidepowertotheSD16.Thefourcellboardsareconnected to one pair of crossbar chips (XBC). The backplane of an SD16 is the same as a backplane of an SD32. On the HUCB utility PCB is a switch set to TYPE= 1.

An SD32 has up to eight cell boards. All eight cell boards are connected to two pairs of XBCs. TheSD32backplaneisdesignedforasystemupgradetoanSD64. OnanSD32,fouroftheeight connectorsuseU-Turncables.TheU-Turncablesdoublethenumberoflinksandthebandwidth betweentheXBCsandarerecommendedtoachievebestperformance.AnSD64hasupto16cell boards and requires two cabinets. All 16 cell boards are connected to four pairs of XBCs. The

18 Overview

SD64 consists of left backplane and right backplane cabinets, which are connected using 12 m-Link cables.

When the PA-RISC dual-core or the Itanium dual-core processors are used, the CPU counts are

doubledbytheuseofthedual-dieprocessors,assupportedontheIntel® Itanium® cellboards. Up to 128 processors can be supported.

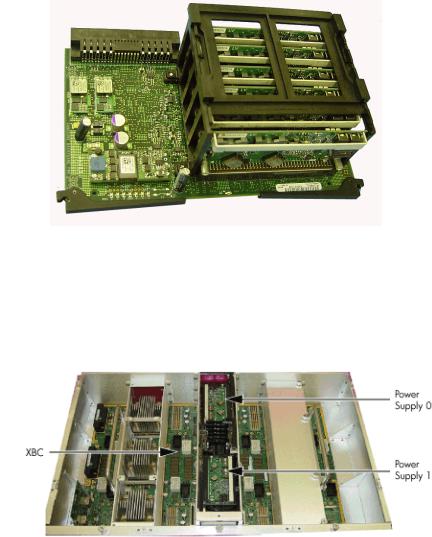

Figure 1-2 Superdome Cabinet Components

Power Subsystem

The power subsystem consists of the following components:

•One or two PDCAs

•One Front End Power Supply (FEPS)

•Up to six BPS

•One power board per cell

•An HIOB power system

•Backplane power bricks

•Power monitor (PM) on the Universal Glob of Utilities (UGUY)

•Local power monitors (LPM) on the cell, the HIOB, and the backplanes

Power Subsystem 19

AC Power

The ac power system includes the PDCA, one FEPS, and up to six BPS.

The FEPS is a modular, 2n+2 shelf assembly power system that can consume up to 17 KVA of power from ac sources. The purpose of the FEPS chassis is to provide interconnect, signal and voltage busing between the PDCAs and BPSs, between the BPSs and utility subsystem, and betweentheBPSandthesystempowerarchitecture.TheFEPSsubsystemcomprisesthreedistinct modular assemblies: six BPS, two PDCAs, and one FEPS chassis.

At least one 3-phase PDCA per Superdome cabinet is required. For redundancy, you can use a second PDCA. The purpose of the PDCA is to receive a single 3-phase input and output three 1-phase outputs with a voltage range of 200 to 240 volts regardless of the ac source type. The PDCAalsoprovidesaconveniencedisconnectswitch/circuitbreakerforservice,testpoints,and voltage present LED indicators. The PDCA is offered as a 4-wire or a 5-wire PDCA device. Separate PDCAs (PDCA-0 and PDCA-1) can be connected to 4-wire and 5-wire input source simultaneously as long as the PDCA internal wiring matches the wiring configuration of the ac source.

The 4-wire PDCA is used in a phase to phase voltage range of 200 to 240 volts at 50/60 Hz. This PDCA is rated for a maximum input current of 44 Amps per phase. The ac input power line to thePDCAisconnectedwithpowerplugsorishardwired.Whenusingpowerplugs,useapower cord [OLFLEX 190 (PN 6008044) four conductor 6-AWG (16 mm), 600 V, 60 Amp, 90˚C, UL and CSA approved, conforms to CE directives GN/YW ground wire].

When installing cables in locations that have been designated as “air handling spaces” (under raised flooring or overhead space used for air supply and air return), advise the customer to specifytheuseofdatacablesthatcontainaplenumrating.Datacableswiththisratinghavebeen certified for FLAMESPREAD and TOXICITY (low smoke emissions). Power cables do not carry aplenumrating,theycarryadataprocessing(DP)rating. Powercablesinstalledinairhandling spacesshouldbespecifiedwithaDPrating.DetailsonthevariouslevelsoftheDPratingsystem are found in the National Electric Code (NEC) under Article 645.

The following recommend plugs for the 4-wire PDCA:

•In-lineconnector:MennekesME460C9,3-phase,4-wire,60Amp,250V,ULapproved,color blue, IEC309-1 grounded at 9:00 o'clock.

•Panel-mountreceptacle:MennekesME460R9,3-phase,4-wire,60Amp,250V,ULapproved, color blue, IEC309-1 grounded at 9:00 o'clock.

The 5 wire PDCA is used in a phase-to-neutral voltage range of 200 to 240 V ac 50/60Hz. This PDCA is rated for a maximum input current of 24 Amps per phase. The ac input power line to the PDCA is connected with power plugs or is hardwired. When using power plugs, a power cord [five conductors, 10-AWG (6 mm), 450/475 V, 32 Amps, <HAR< European wire cordage, GN/YW ground wire]. Alternatively the customer can provide the power plug including the power cord and the receptacle. Recommended plugs are as follows:

•Inlineconnector:MennekesME532C6-16,3-phase,5-wire,32Amps,450/475V,VDEcertified, color red, IEC309-1, IEC309-2, grounded at 6:00 o'clock.

•Panel-mountreceptacle:MennekesME532R6-1276,3-phase,5-wire,32Amp,450/475V,VDE certified, color red, IEC309-1, IEC309-2, grounded at 6:00 o'clock.

•FUSE per phase: 25 Amp (valid for Germany).

DC Power

Each power supply output provides 48 V dc up to 60 A (2.88 kVA) and 5.3 V dc housekeeping. NormallyanSD32SuperdomecabinetcontainssixBPSindependentfromtheinstallednumber of cells and I/O. An SD16 normally has four BPS installed.

20 Overview

Power Sequencing

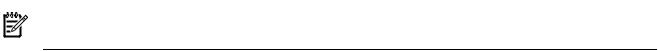

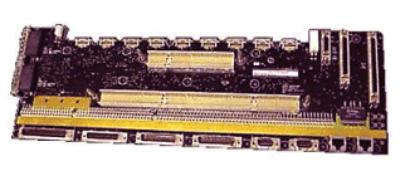

The power on sequence is as follows: