Agilent Technologies E4350B, E4351B User Manual

OPERATING GUIDE for

SOLAR ARRAY SIMULATOR

AGILENT MODELS E4350B, E4351B

Agilent Model E4350B: US37410101 and Above *

Agilent Model E4351B: US37430101 and Above *

* For instruments with higher Serial Numbers, a change page may be included.

Agilent Part No. 5962-8206 |

Printed in USA: |

Microfiche 5962-8207 |

December, 1997 |

CERTIFICATION

Agilent Technologies Company certifies that this product met its published specifications at time of shipment from the factory. Agilent Technologies further certifies that its calibration measurements are traceable to the United States National Bureau of Standards, to the extent allowed by the Bureau’s calibration facility, and to the calibration facilities of other International Standards Organization members.

WARRANTY

This Agilent Technologies hardware product is warranted against defects in material and workmanship for a period of three years from date of delivery. Agilent software and firmware products, which are designated by Agilent for use with a hardware product and when properly installed on that hardware product, are warranted not to fail to execute their programming instructions due to defects in material and workmanship for a period of 90 days from date of delivery. During the warranty period Agilent Technologies Company will, at its option, either repair or replace products which prove to be defective. Agilent does not warrant that the operation of the software, firmware, or hardware shall be uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility designated by Agilent. Customer shall prepay shipping charges by (and shall pay all duty and taxes) for products returned to Agilent for warranty service. Except for products returned to Customer from another country, Agilent shall pay for return of products to Customer.

Warranty services outside the country of initial purchase are included in Agilent’s product price, only if Customer pays Agilent international prices (defined as destination local currency price, or U.S. or Geneva Export price).

If Agilent is unable, within a reasonable time to repair or replace any product to condition as warranted, the Customer shall be entitled to a refund of the purchase price upon return of the product to Agilent.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the Customer, Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the environmental specifications for the product, or improper site preparation and maintenance. NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER’S SOLE AND EXCLUSIVE REMEDIES. AGILENT SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contracts, product maintenance agreements and customer assistance agreements are also available. Contact your nearest Agilent Technologies Sales and Service office for further information on Agilent’s full line of Support Programs.

2

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair of this instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and intended use of the instrument. Agilent Technologies Company assumes no liability for the customer’s failure to comply with these requirements.

BEFORE APPLYING POWER.

Verify that the product is set to match the available line voltage and the correct fuse is installed.

GROUND THE INSTRUMENT.

This product is a Safety Class 1 instrument (provided with a protective earth terminal). To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical ground. The instrument must be connected to the ac power supply mains through a threeconductor power cable, with the third wire firmly connected to an electrical ground (safety ground) at the power outlet. For instruments designed to be hard-wired to the ac power lines (supply mains), connect the protective earth terminal to a protective conductor before any other connection is made. Any interruption of the protective (grounding) conductor or disconnection of the protective earth terminal will cause a potential shock hazard that could result in personal injury. If the instrument is to be energized via an external autotransformer for voltage reduction, be certain that the autotransformer common terminal is connected to the neutral (earthed pole) of the ac power lines (supply mains).

FUSES.

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be used. Do not use repaired fuses or short circuited fuseholders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made by qualified service personnel. Do not replace components with power cable connected. Under certain conditions, dangerous voltages may exist even with the power cable removed. To avoid injuries, always disconnect power, discharge circuits and remove external voltage sources before touching components.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is present.

DO NOT EXCEED INPUT RATINGS.

This instrument may be equipped with a line filter to reduce electromagnetic interference and must be connected to a properly grounded receptacle to minimize electric shock hazard. Operation at line voltages or frequencies in excess of those stated on the data plate may cause leakage currents in excess of 5.0 mA peak.

SAFETY SYMBOLS.

Instruction manual symbol: the product will be marked with this symbol when it is necessary for the user to refer to the instruction manual (refer to Table of Contents) .

Indicates hazardous voltages.

Indicate earth (ground) terminal.

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed beyond a CAUTION sign until the indicated conditions are fully understood and met.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modification to the instrument. Return the instrument to an Agilent Technologies Sales and Service Office for service and repair to ensure that safety features are maintained.

Instruments which appear damaged or defective should be made inoperative and secured against unintended operation until they can be repaired by qualified service personnel.

3

SAFETY SUMMARY (continued)

GENERAL

Any LEDs used in this product are Class 1 LEDs as per IEC 825-l.

ENVIRONMENTAL CONDITIONS

All instruments are intended for indoor use in an installation category II, pollution degree 2 environment. They are designed to operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the specifications tables for the ac mains voltage requirements and ambient operating temperature range.

SAFETY SYMBOL DEFINITIONS

Symbol |

Description |

Symbol |

Description |

Direct current

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal for Neutral conductor on permanently installed equipment

Terminal is at earth potential(Used for measurement and control circuits designed to be operated with one terminal at earth potential.)

Terminal for Line conductor on permanently installed equipment

Caution, risk of electric shock

Caution, hot surface

Caution (refer to accompanying documents)

In position of a bi-stable push control

Out position of a bi-stable push control

On (supply)

Off (supply)

Standby (supply)

Units with this symbol are not completely disconnected from ac mains when this switch is off. To completely disconnect the unit from ac mains, either disconnect the power cord or have a qualified electrician install an external switch.

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der Maschinenläminformationsverordnung vom 18 Januar 1991.

* Schalldruckpegel Lp <70 dB(A) * Am Arbeitsplatz * Normaler Betrieb * Nach EN 27779 (Typprufung).

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the German Sound Emission Directive, from 18 January 1991.

* Sound Pressure Lp <70 dB(A) *At Operator Position |

* Normal Operation |

* According to EN 27779 (Type |

Test). |

|

|

4

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: |

Agilent Technologies Company |

Manufacturer’s Address: |

150 Green Pond Road |

|

Rockaway, New Jersey 07866 |

|

U.S.A. |

declares that the Product |

|

Product Name: |

Solar Array Simulator |

Model Number: |

Agilent E4350A, E4350B, E4351B |

conforms to the following Product Specifications: |

|

Safety: |

IEC 1010-1:1990+A1(1992) / EN 61010-1: 1993 |

EMC: |

CISPR 11:1990 / EN 55011:1991 - Group 1 Class A |

|

IEC 801-2:1991 / EN 50082-1:1992 - 4 kV CD, 8 kV AD |

IEC 801-3:1984 / EN 50082-1:1992 - 3 V / m

IEC 801-4:1988 / EN 50082-1:1992 - 0.5 kV Signal Lines 1 kV Power Lines

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

New Jersey |

October 1997 |

|

|

Location |

Date |

|

Bruce Krueger / Quality Manager |

European Contact: Your local Agilent Technologies Sales and Service Office or Agilent Technologies GmbH,

Department TRE, Herrenberger Strasse 130, D-71034 Boeblingen (FAX:+49-7031-14-3143)

PRINTING HISTORY

The edition and current revision of this manual are indicated below. Reprints of this manual containing minor corrections and updates may have the same printing date. Revised editions are identified by a new printing date. A revised edition incorporates all new or corrected material since the previous printing date. Changes to the manual occurring between revisions are covered by change sheets shipped with the manual. In some cases, the manual change applies only to specific instruments. Instructions provided on the change sheet will indicate if a particular change applies only to certain instruments.

© Copyright 1997 Agilent Technologies Company Edition 1 - December, 1997

This document contains proprietary information protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated into another language without the prior consent of Agilent Technologies Company. The information contained in this document is subject to change without notice.

5

|

Table Of Contents |

|

1 |

General Information |

|

|

What’s In This Guide? .................................................................................................................................. |

13 |

|

Safety Considerations .................................................................................................................................... |

13 |

|

Options and Accessories................................................................................................................................ |

13 |

|

Operator Replaceable Parts ........................................................................................................................... |

14 |

|

Description .................................................................................................................................................... |

14 |

|

Key Features.................................................................................................................................................. |

14 |

|

Output Characteristic..................................................................................................................................... |

15 |

|

Fixed Mode ............................................................................................................................................. |

15 |

|

Simulator Mode....................................................................................................................................... |

15 |

|

Table Mode ............................................................................................................................................. |

17 |

2 |

Installation |

|

|

Inspection ...................................................................................................................................................... |

19 |

|

Damage.................................................................................................................................................... |

19 |

|

Packaging Material.................................................................................................................................. |

19 |

|

Items Supplied......................................................................................................................................... |

19 |

|

Location and Temperature............................................................................................................................. |

19 |

|

Bench Operation...................................................................................................................................... |

19 |

|

Rack Mounting ........................................................................................................................................ |

20 |

|

Temperature Performance ....................................................................................................................... |

20 |

|

AC Line Connection...................................................................................................................................... |

20 |

|

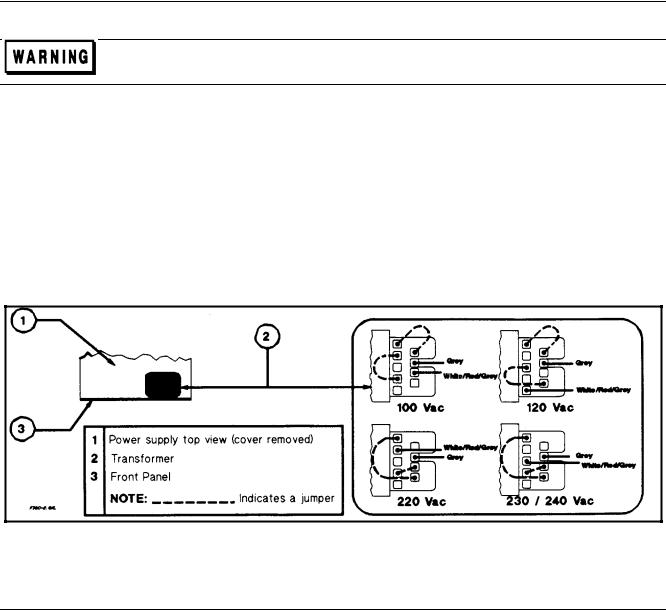

AC Voltage Conversion ................................................................................................................................ |

21 |

|

VXI plug&play Power Products Instrument Drivers ..................................................................................... |

21 |

|

Downloading and Installing the Driver ................................................................................................... |

22 |

|

Accessing Online Help ............................................................................................................................ |

22 |

3 |

Turn-on Checkout |

|

|

Introduction ................................................................................................................................................... |

23 |

|

Preliminary Checkout .................................................................................................................................... |

23 |

|

Power-on Checkout ....................................................................................................................................... |

23 |

|

Using the Keypad .......................................................................................................................................... |

24 |

|

Shifted Keys ............................................................................................................................................ |

24 |

|

Backspace Key ........................................................................................................................................ |

24 |

|

Output Checkout............................................................................................................................................ |

24 |

|

Checking the Voltage Function ............................................................................................................... |

24 |

|

Checking the Current Function................................................................................................................ |

25 |

|

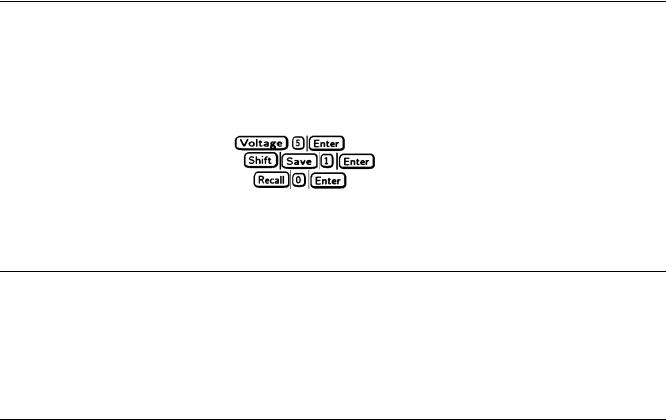

Checking the Save and Recall Functions....................................................................................................... |

27 |

|

Determining GPIB Address........................................................................................................................... |

27 |

|

In Case of Trouble......................................................................................................................................... |

27 |

|

Line Fuse ................................................................................................................................................. |

27 |

|

Error Messages........................................................................................................................................ |

27 |

|

Selftest Errors.......................................................................................................................................... |

27 |

|

Power-On Error Messages....................................................................................................................... |

27 |

|

Checksum Errors ..................................................................................................................................... |

28 |

|

Runtime Error Messages ......................................................................................................................... |

28 |

4 |

User Connections |

|

|

Rear Panel Connections................................................................................................................................. |

29 |

|

Wire Selection ......................................................................................................................................... |

29 |

|

Analog Connector.................................................................................................................................... |

29 |

|

Digital Connector .................................................................................................................................... |

30 |

|

Load Connections.......................................................................................................................................... |

30 |

|

Output Isolation....................................................................................................................................... |

30 |

6

|

Capacitive Loads ..................................................................................................................................... |

30 |

|

Inductive Loads ...................................................................................................................................... |

31 |

|

Connecting to an External Voltage Source.............................................................................................. |

31 |

|

Sense Connections......................................................................................................................................... |

31 |

|

Remote Voltage Sensing ......................................................................................................................... |

31 |

|

CV Regulation......................................................................................................................................... |

32 |

|

Overvoltage Protection Considerations ................................................................................................... |

32 |

|

Output Rating .......................................................................................................................................... |

32 |

|

Output Noise ........................................................................................................................................... |

32 |

|

Stability ................................................................................................................................................... |

32 |

|

Over Current Protection Considerations........................................................................................................ |

33 |

|

Hardware Overcurrent Circuit ................................................................................................................. |

33 |

|

Operating Configurations .............................................................................................................................. |

33 |

|

Connecting the Load to One Unit ........................................................................................................... |

33 |

|

Connecting Supplies in Parallel............................................................................................................... |

34 |

|

Connecting Supplies in Auto-Parallel...................................................................................................... |

35 |

|

Auto-Parallel Programming Cautions...................................................................................................... |

36 |

|

Connecting Supplies in Series ................................................................................................................. |

37 |

|

Analog Current Control ........................................................................................................................... |

38 |

|

Controller Connections.................................................................................................................................. |

38 |

|

Stand-Alone Connections ........................................................................................................................ |

38 |

|

Linked Connections................................................................................................................................. |

38 |

5 |

Front Panel Operation |

|

|

Introduction ................................................................................................................................................... |

41 |

|

Key Functions................................................................................................................................................ |

41 |

|

Programming the Output ......................................................................................................................... |

44 |

|

Establishing Initial Conditions. ............................................................................................................... |

44 |

|

Programming Voltage ............................................................................................................................. |

44 |

|

Programming Current. ............................................................................................................................. |

45 |

|

Programming Overvoltage Protection ........................................................................................................... |

45 |

|

Setting the OVP Level.............................................................................................................................. |

45 |

|

Checking OVP Operation......................................................................................................................... |

45 |

|

Clearing the OVP Condition .................................................................................................................... |

46 |

|

Programming Overcurrent Protection............................................................................................................ |

46 |

|

Setting the OCP Protection....................................................................................................................... |

46 |

|

Checking OCP Operation ......................................................................................................................... |

46 |

|

Clearing the OCP Condition..................................................................................................................... |

46 |

|

CV Mode vs. CC Mode................................................................................................................................. |

47 |

|

Unregulated Operation .................................................................................................................................. |

47 |

|

Saving and Recalling States .......................................................................................................................... |

47 |

|

Turn-on Conditions ....................................................................................................................................... |

47 |

|

Setting the GPIB Address.............................................................................................................................. |

48 |

|

Types of GPIB Addresses ....................................................................................................................... |

48 |

|

Changing the GPIB Address.................................................................................................................... |

48 |

6. |

Remote Programming |

|

|

GPIB Capabilities of the Power Supply ........................................................................................................ |

49 |

|

Introduction to SCPI...................................................................................................................................... |

49 |

|

Conventions............................................................................................................................................. |

49 |

|

Types of SCPI Commands ............................................................................................................................ |

50 |

|

Multiple Commands in a Message........................................................................................................... |

50 |

|

Moving Among Subsystems .................................................................................................................... |

51 |

|

Value Coupling........................................................................................................................................ |

51 |

|

Including Common Commands ............................................................................................................... |

51 |

|

SCPI Queries ........................................................................................................................................... |

51 |

7

|

Types of SCPI Messages .............................................................................................................................. |

51 |

|

The Message Unit.................................................................................................................................... |

52 |

|

Headers.................................................................................................................................................... |

52 |

|

Query Indicator ....................................................................................................................................... |

52 |

|

Message Unit Separator........................................................................................................................... |

52 |

|

Root Specifier.......................................................................................................................................... |

52 |

|

Message Terminator ................................................................................................................................ |

52 |

|

SCPI Data Formats........................................................................................................................................ |

53 |

|

Numerical Data........................................................................................................................................ |

53 |

|

Suffixes and Multipliers .......................................................................................................................... |

53 |

|

Character Data......................................................................................................................................... |

53 |

|

Examples ....................................................................................................................................................... |

54 |

|

Programming Voltage and Current.......................................................................................................... |

54 |

|

Programming Protection Circuits ............................................................................................................ |

54 |

|

Programming Units in Auto-Parallel ....................................................................................................... |

54 |

|

Changing Outputs by Trigger .................................................................................................................. |

55 |

|

Saving and Recalling States .................................................................................................................... |

55 |

|

Writing to the Display ............................................................................................................................. |

56 |

|

Programming Status ................................................................................................................................ |

56 |

|

Programming the Digital I/O Port ........................................................................................................... |

56 |

|

System Considerations .................................................................................................................................. |

56 |

|

Assigning GPIB Address in Programs..................................................................................................... |

57 |

|

Agilent 82335A Driver Considerations ................................................................................................... |

57 |

|

National Instruments GPIB Driver Considerations ................................................................................. |

57 |

|

BASIC Considerations ............................................................................................................................ |

57 |

7. |

Language Dictionary |

|

|

Introduction ................................................................................................................................................... |

61 |

|

Parameters ............................................................................................................................................... |

61 |

|

Related Commands.................................................................................................................................. |

61 |

|

Order of Presentation .............................................................................................................................. |

61 |

|

Common Commands ............................................................................................................................... |

61 |

|

Subsystem Commands............................................................................................................................. |

61 |

|

Description of Common Commands ............................................................................................................. |

62 |

|

*CLS........................................................................................................................................................ |

62 |

|

*ESE........................................................................................................................................................ |

62 |

|

*ESR?...................................................................................................................................................... |

63 |

|

*IDN? ...................................................................................................................................................... |

63 |

|

*OPC ....................................................................................................................................................... |

64 |

|

*OPC? ..................................................................................................................................................... |

64 |

|

*OPT? ..................................................................................................................................................... |

64 |

|

*PSC........................................................................................................................................................ |

65 |

|

*RCL ....................................................................................................................................................... |

65 |

|

*RST ....................................................................................................................................................... |

66 |

|

*SAV....................................................................................................................................................... |

66 |

|

*SRE ....................................................................................................................................................... |

67 |

|

*STB?...................................................................................................................................................... |

67 |

|

*TRG....................................................................................................................................................... |

68 |

|

*TST?...................................................................................................................................................... |

68 |

|

*WAI....................................................................................................................................................... |

68 |

|

Description of Subsystem Commands ........................................................................................................... |

69 |

|

Calibration Commands .................................................................................................................................. |

71 |

|

Display Subsystem ........................................................................................................................................ |

71 |

|

DISP ........................................................................................................................................................ |

71 |

|

DISP:MODE ........................................................................................................................................... |

71 |

|

DISP:TEXT............................................................................................................................................. |

72 |

8

Measure Subsystem ....................................................................................................................................... |

72 |

MEAS:CURR? ........................................................................................................................................ |

72 |

MEAS:VOLT? ........................................................................................................................................ |

72 |

Memory Subsystem ....................................................................................................................................... |

73 |

MEM:COPY:TABL ................................................................................................................................ |

73 |

MEM:DEL:ALL...................................................................................................................................... |

73 |

MEM:DEL[:NAME] ............................................................................................................................... |

73 |

MEM:TABL:SEL.................................................................................................................................... |

73 |

MEM:TABL:CURR ................................................................................................................................ |

73 |

MEM:TABL:VOLT ................................................................................................................................ |

73 |

MEM:TABL:CURR:POIN?.................................................................................................................... |

74 |

MEM:TABL:VOLT:POIN? .................................................................................................................... |

74 |

MEM:TABL:CAT? ................................................................................................................................. |

74 |

Output Subsystem.......................................................................................................................................... |

74 |

OUTP ...................................................................................................................................................... |

74 |

OUTP:PROT:CLE .................................................................................................................................. |

74 |

OUTP:PROT:DEL .................................................................................................................................. |

75 |

[SOUR:]CURR........................................................................................................................................ |

75 |

[SOUR:]CURR:TRIG ............................................................................................................................. |

75 |

[SOUR:]CURR:MODE........................................................................................................................... |

76 |

[SOUR:]CURR:PROT ............................................................................................................................ |

76 |

[SOUR:]CURR:PROT:STAT ................................................................................................................. |

76 |

[SOUR:]CURR:SAS:ISC ........................................................................................................................ |

77 |

[SOUR:]CURR:SAS:IMP ....................................................................................................................... |

77 |

[SOUR:]CURR:TABL:NAME ............................................................................................................... |

77 |

[SOUR:]CURR:TABL:OFFS.................................................................................................................. |

77 |

[SOUR:]DIG:DATA ............................................................................................................................... |

77 |

[SOUR:]VOLT........................................................................................................................................ |

78 |

[SOUR:]VOLT:TRIG ............................................................................................................................. |

78 |

[SOUR:]VOLT:PROT ............................................................................................................................ |

79 |

[SOUR:]VOLT:SAS:VOC ...................................................................................................................... |

79 |

[SOUR:]VOLT:SAS:VMP...................................................................................................................... |

79 |

[SOUR:]VOLT:TABL:OFFS.................................................................................................................. |

80 |

Status Subsystem ........................................................................................................................................... |

80 |

STAT:OPER?.......................................................................................................................................... |

80 |

STAT:OPER:COND? ............................................................................................................................. |

80 |

STAT:OPER:ENAB................................................................................................................................ |

81 |

STAT:OPER:PTR/NTR .......................................................................................................................... |

81 |

STAT:PRES ............................................................................................................................................ |

81 |

STAT:QUES? ......................................................................................................................................... |

82 |

STAT:QUES:COND? ............................................................................................................................. |

82 |

STAT:QUES:ENAB ............................................................................................................................... |

82 |

STAT:QUES:PTR/NTR.......................................................................................................................... |

83 |

System Commands ........................................................................................................................................ |

83 |

SYST:ERR? ............................................................................................................................................ |

83 |

SYST:VERS? .......................................................................................................................................... |

84 |

Trigger Subsystem......................................................................................................................................... |

84 |

ABOR...................................................................................................................................................... |

84 |

INIT84 |

|

INIT:CONT............................................................................................................................................. |

84 |

TRIG ....................................................................................................................................................... |

85 |

TRIG:SOUR............................................................................................................................................ |

85 |

9

8. |

Status Reporting |

|

|

Agilent SAS Status Structure......................................................................................................................... |

87 |

|

Operation Status Group ................................................................................................................................. |

87 |

|

Register Functions ................................................................................................................................... |

87 |

|

Register Commands................................................................................................................................. |

87 |

|

Questionable Status Group ............................................................................................................................ |

89 |

|

Register Functions ................................................................................................................................... |

89 |

|

Register Commands................................................................................................................................. |

89 |

|

Standard Event Status Group......................................................................................................................... |

89 |

|

Register Functions ................................................................................................................................... |

89 |

|

Register Commands................................................................................................................................. |

89 |

|

Status Byte Register ...................................................................................................................................... |

89 |

|

The RQS Bit ............................................................................................................................................ |

90 |

|

The MSS Bit............................................................................................................................................ |

90 |

|

Determining the Cause of a Service Interrupt.......................................................................................... |

90 |

|

Service Request Enable Register ................................................................................................................... |

90 |

|

Output Queue ................................................................................................................................................ |

90 |

|

Initial Conditions at Power-On...................................................................................................................... |

90 |

|

Status Registers ....................................................................................................................................... |

90 |

|

The PON (Power-On) Bit........................................................................................................................ |

91 |

|

Examples ....................................................................................................................................................... |

91 |

|

Servicing an Operation Status Mode Event............................................................................................. |

91 |

|

Adding More Operation Events............................................................................................................... |

91 |

|

Servicing Questionable Status Events ..................................................................................................... |

91 |

|

Monitoring Both Phases of a Status Transition ....................................................................................... |

92 |

|

SCPI Command Completion ......................................................................................................................... |

92 |

|

DFI (Discrete Fault Indicator) ....................................................................................................................... |

92 |

|

RI (Remote Inhibit) ....................................................................................................................................... |

93 |

|

Using Device Clear ....................................................................................................................................... |

93 |

A |

Specifications and Application Information |

|

|

Specifications and Supplemental Characteristics .......................................................................................... |

95 |

|

Output Impedance Graphs ............................................................................................................................. |

99 |

|

Simulator Mode....................................................................................................................................... |

99 |

|

Fixed Mode ........................................................................................................................................... |

101 |

|

Peak Power Tracker Application ................................................................................................................ |

102 |

|

Exponential Model Equations ............................................................................................................... |

103 |

|

Series Switching Regulation........................................................................................................................ |

104 |

|

Shunt Switching Regulation ........................................................................................................................ |

104 |

B |

Verification and Calibration |

|

|

Introduction ................................................................................................................................................. |

105 |

|

Test Equipment Required ............................................................................................................................ |

105 |

|

Current Monitoring Resistor.................................................................................................................. |

105 |

|

Verification.................................................................................................................................................. |

106 |

|

General Measurement Techniques ........................................................................................................ |

106 |

|

Programming the Agilent SAS .............................................................................................................. |

106 |

|

Order of Tests........................................................................................................................................ |

106 |

|

Turn On Checkout ................................................................................................................................. |

106 |

|

Voltage Programming and Readback Accuracy .................................................................................... |

106 |

|

Current Programming and Readback Accuracy..................................................................................... |

107 |

|

Calibration................................................................................................................................................... |

108 |

|

Test Equipment Required ...................................................................................................................... |

108 |

|

General Procedure ................................................................................................................................. |

108 |

|

Parameters Calibrated............................................................................................................................ |

108 |

|

Front Panel Calibration ............................................................................................................................... |

109 |

10

|

Entering the Calibration Values ............................................................................................................ |

109 |

|

Saving the Calibration Constants........................................................................................................... |

109 |

|

Disabling the Calibration Mode ............................................................................................................ |

109 |

|

Changing the Calibration Password....................................................................................................... |

109 |

|

Recovering From Calibration Problems ................................................................................................ |

111 |

|

Calibration Error Messages ................................................................................................................... |

111 |

|

Calibration over the GPIB ........................................................................................................................... |

111 |

|

Calibration Example.............................................................................................................................. |

111 |

|

Calibration Language Dictionary ................................................................................................................ |

112 |

|

CAL:CURR ........................................................................................................................................... |

112 |

|

CAL:CURR:LEV .................................................................................................................................. |

112 |

|

CAL:PASS ............................................................................................................................................ |

112 |

|

CAL:SAVE ........................................................................................................................................... |

112 |

|

CAL:STAT............................................................................................................................................ |

113 |

|

CAL:VOLT ........................................................................................................................................... |

113 |

|

CAL:VOLT:LEV .................................................................................................................................. |

113 |

|

CAL:VOLT:PROT ................................................................................................................................ |

113 |

|

Agilent Basic Calibration Program.............................................................................................................. |

114 |

C |

Digital Port Functions |

|

|

Digital Connector ........................................................................................................................................ |

117 |

|

Fault/Inhibit Operation ................................................................................................................................ |

117 |

|

Changing the Port Configuration................................................................................................................. |

119 |

|

Digital I/O Operation................................................................................................................................... |

119 |

D |

Error Messages |

|

|

Hardware Error Messages ........................................................................................................................... |

121 |

|

Calibration Error Messages ......................................................................................................................... |

121 |

|

System Error Messages ............................................................................................................................... |

121 |

|

Index .......................................................................................................................................................... |

123 |

|

Agilent Sales and Support Offices ..................................................................................................... |

128 |

11

1

General Information

What’s In This Guide?

This guide describes the Agilent Model E4350B/E4351B Solar Array Simulator (SAS). An overview of the unit is given in this chapter. Installation and user connections are discussed in chapters 2 and 4. Programming from the front panel and over the GPIB is discussed in chapters 5-7. If you just need to check that the unit is operating properly, read chapter 3.

The edition and current revision of this manual are indicated on the title page. Reprints of this manual containing minor corrections and updates may have the same printing date. Revised editions are identified by a new printing date. A revised edition incorporates all new or corrected material since the previous printing date.

Changes to the manual occurring between revisions are covered by change sheets shipped with the manual. In some cases, the manual change applies only to specific instruments. Instructions provided on the change sheet will indicate if a particular change applies only to certain instruments.

Safety Considerations

The Agilent Solar Array Simulator is a Safety Class 1 instrument, which means it has a protective earth terminal. That terminal must be connected to earth ground through a power source equipped with a 3-wire ground receptacle. Refer to the Safety Summary page at the beginning of this guide for general safety information. Before installation or operation, check the Agilent SAS and review this guide for safety warnings and instructions. Safety warnings for specific procedures are located at appropriate places in the guide.

Options and Accessories

|

Table 1-1 Options |

Option |

Description |

100 Input power 100 Vac, nominal

220 Input power 220 Vac, nominal

240 Input power 240 Vac, nominal (for 230 Vac operation, see table A-2 in appendix A)

Rack mount kit (Agilent 5062-3977) Support rails (E3663A) are required.

Rack mount kit (Agilent 5062-3977 & 5062-3974) Support rails (E3663A) are required.

909Rack mount kit with handles (Agilent 5062-3983) Support rails (E3663A) are required.

910Service manual with extra User’s guides

Table 1-2 Accessories |

|

Accessory Description |

Agilent No. |

GPIB cable (all models) |

|

0.5 meters (1.6 ft) |

10833D |

1.0 meter (3.3 ft) |

10833A |

2.0 meters (6.6 ft) |

10833B |

4.0 meters ( 13 .2 ft) |

10833C |

Serial link cable (all models) |

|

2.0 meters (6.6 ft) |

5080-2148 |

Slide mount kit |

1494-0059 |

General Information 13

Operator Replaceable Parts

Description

Cover, dc output Foot, cabinet Fuse, power

100 Vac line voltage, 15 A

120 Vac line voltage, 12 A 220/230/240 Vac line voltage, 7 A

Knob, rotary output control

Table 1-3 Operator Replaceable Parts

Agilent Part No.

0360-2191

5041-8801

2110-0054

2110-0249

21l0-06l4

0370-3238

Description

Plug, analog connector Plug, digital connector Screw, output bus bar Screw, terminal cover

Screw, carrying strap, M5x0.8x10 mm Standoff, GPIB

Agilent Part No.

1252-3698

1252-1488

0515-1085

0515-1085

0515-1132

0380-0644

Description

The Agilent E4350B/E4351B Solar Array Simulator (SAS) is a dc power source that simulates the output characteristics of a solar array. The Agilent SAS is primarily a current source with very low output capacitance. It is capable of simulating the I-V curve of a solar array under different conditions such as temperature and age. The I-V curve is programmable over the IEEE-488.2 bus and is automatically generated within the Agilent SAS. The Agilent SAS has three operating modes:

Fixed Mode: This is the default mode that occurs when the unit is first powered up. The I-V output has the rectangular characteristics of a standard power supply, but with excellent high speed constant current characteristics and low output capacitance. Fixed mode allows front panel programming and is convenient when, in certain applications, the I-V curve is not needed.

Simulator Mode: An internal algorithm is used to simulate a SAS I-V curve. One can easily approximate the curve through four input parameters: open circuit voltage (Voc), short circuit current (Isc), current at the approximate maximum power point on the curve (Imp), and voltage at the approximate maximum power point on the curve (Vmp).

Table Mode: The Agilent SAS provides a table mode for a fast and accurate I-V simulation of solar arrays. In this mode, a table of I-V points, often provided by the solar array manufacturer, specifies the curve. The Agilent SAS provides up to 60 tables with a total of 33,500 I-V points of storage and a maximum of 4,000 I-V points per table. The tables (I-V curves) are easily stored and recalled. A portion of table storage is allocated in non-volatile memory, with 30 possible tables totaling 3,500 points. These are retained when power is turned off. In table mode, current and voltage offsets can be applied to the selected table to simulate a change in the operating conditions of the solar array.

Key Features

■480 Watt output

■Auto-parallel capability for higher power

■Very low output capacitance

■Switching recovery time in less than 5 microseconds

■Programmable overvoltage and over-current protection which are independent of other circuits

■Overtemperature protection

■Fan speed control to minimize acoustic noise

■Extensive set of programming features

■Fast I-V curve change in both table and simulator modes

■Up to 60 volatile/non-volatile tables

■Self test at power-up or from an IEEE-488.2 command

■Serial link to connect up to 16 outputs to one IEEE-488.2 address

■Standard Commands for Programmable Instruments (SCPI)

14 General Information

Output Characteristic

The Agilent E4350B/E4351B Solar Array Simulator can be operated in three modes: fixed mode, simulator mode, and table mode. Mode switching on the Agilent SAS is accomplished over the GPIB bus via the SCPI CURRent:MODE command.

You cannot switch modes from the front panel.

Note: The Agilent SAS must be connected to a computer for you to be able to use the SAS functions that are available in simulator and table modes.

The front panel does not indicate which mode the Agilent SAS is presently operating in. If you are unsure which mode the unit is presently in, you can query the unit over the GPIB using the CURRent:MODE? command. If you cycle power to the unit, it will be in Fixed mode.

Fixed Mode

At power turn on, with *RST, or when executing a Device Clear, the operating state of the Agilent SAS is Fixed mode (see Figure 1-1). In Fixed mode, the output characteristic is similar to that of a standard power supply, except that the output capacitance is <100 nF on the Agilent E4350B, and <50 nF on the Agilent E4351B. This low output capacitance is ideal when using the unit as a constant current source. To use the unit as a low-impedance constant voltage source however, you can add an external output capacitor if so desired. The value of the external capacitor should not exceed 2,000 μF.

|

I |

|

||

E4351B = 4A |

|

MAXIMUM CURRENT |

480W MAX |

|

|

|

|

|

|

E4350B = 8A |

|

|

|

|

I set |

|

TYPICAL FIXED MODE OUTPUT |

|

|

|

|

|

MAXIMUM |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

VOLTAGE |

|

|

|

|

|

V

0 Vset 120V = E4351B

60V = E4350B

Figure 1-1. Fixed Mode Characteristic

Restrictions

■If the programmed values exceed the maximum current and voltage boundaries by more than 2 or 3 percent, an OUT OF RANGE error will be indicated.

Simulator Mode

Simulator mode uses an exponential model to approximate the I-V curve (see Figure 1-2). It is programmed in terms of its open circuit voltage (Voc), short circuit current (Isc), voltage point (Vmp), and current point (Imp) at approximately the peak power point (see page A-9 in appendix A for model equations). Simulator mode operation is achieved by sampling the output voltage, applying a low-pass filter, and continually adjusting the constant current loop by using the filtered voltage as an index into the exponential model.

General Information 15

|

I |

|

|

E4351B = 4A |

MAXIMUM CURRENT |

480W MAX |

|

E4350B = 8A |

|

|

|

I sc |

TYPICAL CURVE |

Pmp |

|

I mp |

|

MAXIMUM |

|

|

|

VOLTAGE |

|

|

|

V |

= 1Ω min (E4351B) |

|

POINTS UNDER |

I |

.25Ω min (E4350B) |

|

DASHED LINE |

|

|

|

ARE INVALID |

|

|

0 |

Vmp |

Voc |

|

|

V |

|

|

|

|||

|

|

120V |

130V = E4351B |

||

|

|

60V |

65V = E4350B |

||

|

|

|

|

|

|

Figure 1-2. Simulator Mode Characteristic

Note that under certain conditions, such as if Imp is significantly less than Isc, the model equation will exhibit a certain degree of inaccuracy in that the actual maximum power point (Pmp) and value may be somewhat different from the expected value of Pmp (Imp x Vmp). Thus the actual Pmp point may not occur at exactly the Imp x Vmp. This can be corrected by entering new values for Imp and Vmp (see Figure A-1 in appendix A).

Also note that the accuracy specifications in simulator mode are relative to the values given in the exponential equations, and not necessarily to the input parameters Imp and Vmp. However, the Isc and Voc values are always accurately given by the exponential equations.

Restrictions:

■Maximum Power £ 480 W

■Voc £ 130 V (E4351B) or 65 V (E4350B)

■Isc £ 4 A (E4351B) or 8 A (E4350B)

■Vmp < Voc

■Imp £ Isc

■DV/DI ³ .25 W for Agilent E4350B; ³ 1 W for Agilent E4351B

NOTE: When the unit detects invalid equation parameters, it will generate an error, light the ERR annunciator on the front panel, and will not use the new parameters. Instead, it will operate with the last valid settings. Therefore, although it may seem that the unit is operating correctly, it will NOT be using the values that you have programmed for simulator mode.

If simulator mode is entered with no parameters specified, |

|

E4350B |

E4351B |

the default values that will be used are: |

Voc |

61.5 V |

123 V |

|

Vmp |

49.2 V |

98.4 V |

|

Imp |

6.528 A |

3.264 A |

|

Isc |

8.16 A |

4.08 A |

|

Pmp |

321.2 W |

321.2 W |

|

|

|

|

16 General Information

Front panel operation:

You can use the front panel when the unit is operating in Simulator mode. To do this, press the Local key whenever the front panel RMT annunciator is on. Be aware however, that any voltage and current values that you enter from the front panel will have no effect on the unit while it is in Simulator mode. These front panel values will take effect as soon as the unit is placed in Fixed mode. Likewise, the OCP function only takes effect in Fixed mode. All other functions such as Local, Error, Output On/Off, Protect are active while the unit is operating in Simulator mode.

Table Mode

In Table mode, the output characteristic is determined by a user-defined table of voltage/current points (see Figure 1-3). Table mode operation is achieved by sampling the output voltage, applying a low-pass filter, and continually adjusting the constant current loop by using the filtered voltage as an index into the stored table of points. Linear interpolation is used to set the current when the filtered voltage does not have an exactly matching table entry. What this means is that the I-V curve is generated by connecting the points in the table by straight lines. The more points that you provide, the more accurate the curve will be when the points are connected.

|

|

I |

|

|

E4351B = 4A |

MAXIMUM CURRENT |

480W MAX |

||

E4350B = 8A |

|

|

|

|

I |

sc |

TYPICAL CURVE |

|

|

|

|

|

|

|

|

|

|

MAXIMUM |

|

|

|

|

VOLTAGE |

|

|

|

|

V |

= 1Ω min (E4351B) |

|

|

POINTS UNDER |

I |

|

|

|

.25Ω min (E4350B) |

||

|

|

|

||

|

|

DASHED LINE |

|

|

|

|

ARE INVALID |

|

|

|

V oc |

V |

0 |

130V = E4351B |

|

|

120V |

|

|

60V |

65V = E4350B |

Figure 1-3. Table Mode Characteristic

Each table can have a maximum of 4,000 output points (3,500 points if it will be stored in non-volatile memory). Each output point is defined by a voltage/current coordinate pair of values that define the location of the point on the curve. The first value is the voltage, the second value is the current. If no point is supplied for V=0, the current associated with the lowest voltage entry point is defined as Isc and the curve will be extended horizontally to the current axis. If no point is supplied for I=0, the slope that was determined by the last two current entry points will be extended to the voltage axis.

Multiple tables can be defined and saved in non-volatile memory (which is limited to 3500 points), or volatile memory (which is limited to 30,000 points). Up to 30 tables can be saved in each memory.

Restrictions

■The number of points in a table can vary from 3 to 4000, but an equal number of voltage and current values must be sent. Otherwise an error will occur when the table is selected with CURRent:TABLe:NAME. Use MEMory:TABLe:CURRent:POINts? and MEMory:TABLe:VOLTage:POINts? to find the length of an existing table.

■Points must be above dashed line shown in Figure 1-3.

General Information 17

■There is no restriction on the spacing between points in either voltage or current, but the points must be monotonic. Voltage values must be sent in increasing order of magnitude; current values must be sent in equal or decreasing order of magnitude. For an Agilent E4350B for example: (1,8) (50,7.8) (55,7.5) (56,7) (57, 6) (58, 4) (59,1).

■Each table point, when combined with the table offset, cannot exceed the unit’s maximum voltage, current, or power.

■A table cannot be deleted or redefined while it is selected with CURRent:TABLe:NAME.

■Maximum Power £ 480 W

■DV/DI ³ .25 W for Agilent E4350B; ³ 1 W for Agilent E4351B Voc £ 65V (Agilent E4350B); 130V (Agilent E4351B)

Isc £ 8A (Agilent E4350B); 4A (Agilent E4351B)

The Vmp and Imp points are calculated internally and need not be supplied.

NOTE: When the unit detects an invalid voltage/current point, it will generate an error, light the ERR annunciator on the front panel, and will not use the new parameters. Instead, it will operate with the last valid table settings. Therefore, although it may seem that the unit is operating correctly, it will NOT be using the values that you have programmed for table mode.

Table Offsets:

A new table can be generated by applying a limited voltage or current offset to an existing table. This can be helpful in simulating temperature, angular, rotational, or aging changes. Offset values are non-cumulative, they can be either positive or negative, and can be applied to any table. Each time a voltage or current offset is programmed, a new I-V curve is calculated based on the user-defined table that is presently active and the supplied offset values. Offset values affect the original I-V curve as follows:

Positive Voltage Offsets: The original curve is shifted to the right ( ) along the positive voltage axis, and the first point on the curve is extended horizontally at Isc until it intersects the current axis. Thus, the new Voc equals the original Voc plus the offset value. An error will be generated if the offset causes the maximum allowed Voc or the power limit to be exceeded.

Negative Voltage Offsets: The original curve is offset to the left ( ) along the positive voltage axis, and terminated at the current axis. The curve points that are not used because they extended beyond the current axis are not deleted; they will be valid once again if the negative voltage offset is reduced or eliminated.