Agilent Technologies 66311D, 66311B, 66309B, 66111A User Manual

USER’S GUIDE

Agilent Model 66111A

Fast Transient DC Source

Agilent Model 66311B/D, 66309B/D

Mobile Communications DC Source

NOTE: Refer to page 23 for a brief description of the model differences.

Agilent Part No. 5964-8125

Microfiche No. 5964-8126

Printed in USA: June 2000

Warranty Information

CERTIFICATION

Agilent Technologies certifies that this product met its published specifications at time of shipment from the factory. Agilent Technologies further certifies that its calibration measurements are traceable to the United States National Bureau of Standards, to the extent allowed by the Bureau’s calibration facility, and to the calibration facilities of other International Standards Organization members.

WARRANTY

This Agilent Technologies hardware product is warranted against defects in material and workmanship for a period of three years from date of delivery. Agilent Technologies software and firmware products, which are designated by Agilent Technologies for use with a hardware product and when properly installed on that hardware product, are warranted not to fail to execute their programming instructions due to defects in material and workmanship for a period of 90 days from date of delivery. During the warranty period Agilent Technologies will, at its option, either repair or replace products which prove to be defective. Agilent Technologies does not warrant that the operation for the software firmware, or hardware shall be uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility designated by Agilent Technologies. Customer shall prepay shipping charges by (and shall pay all duty and taxes) for products returned to Agilent Technologies for warranty service. Except for products returned to Customer from another country, Agilent Technologies shall pay for return of products to Customer.

Warranty services outside the country of initial purchase are included in Agilent Technologies’ product price, only if Customer pays Agilent Technologies international prices (defined as destination local currency price, or U.S. or Geneva Export price).

If Agilent Technologies is unable, within a reasonable time to repair or replace any product to condition as warranted, the Customer shall be entitled to a refund of the purchase price upon return of the product to Agilent Technologies.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the Customer, Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the environmental specifications for the product, or improper site preparation and maintenance. NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER’S SOLE AND EXCLUSIVE REMEDIES. AGILENT TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contacts, product maintenance agreements and customer assistance agreements are also available. Contact your nearest Agilent Technologies Sales and Service office for further information on Agilent Technologies’ full line of Support Programs.

2

Safety Summary

The following general safety precautions must be observed during all phases of operation of this instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and intended use of the instrument. Agilent Technologies assumes no liability for the customer’s failure to comply with these requirements.

GENERAL

This product is a Safety Class 1 instrument (provided with a protective earth terminal). The protective features of this product may be impaired if it is used in a manner not specified in the operation instructions.

Any LEDs used in this product are Class 1 LEDs as per IEC 825-1.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use in an installation category II, pollution degree 2 environment. It is designed to operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the specifications tables for the ac mains voltage requirements and ambient operating temperature range.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage, the correct fuse is installed, and all safety precautions are taken. Note the instrument’s external markings described under "Safety Symbols".

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cover must be connected to an electrical ground. The instrument must be connected to the ac power mains through a grounded power cable, with the ground wire firmly connected to an electrical ground (safety ground) at the power outlet. Any interruption of the protective (grounding) conductor or disconnection of the protective earth terminal will cause a potential shock hazard that could result in personal injury.

ATTENTION: Un circuit de terre continu est essentiel en vue du fonctionnement sécuritaire de l’appareil. Ne jamais mettre l'appareil en marche lorsque le conducteur de mise … la terre est d‚branch‚.

FUSES

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be used. Do not use repaired fuses or short-circuited fuseholders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

DO NOT REMOVE THE INSTRUMENT COVER

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made only by qualified service personnel.

Instruments that appear damaged or defective should be made inoperative and secured against unintended operation until they can be repaired by qualified service personnel.

3

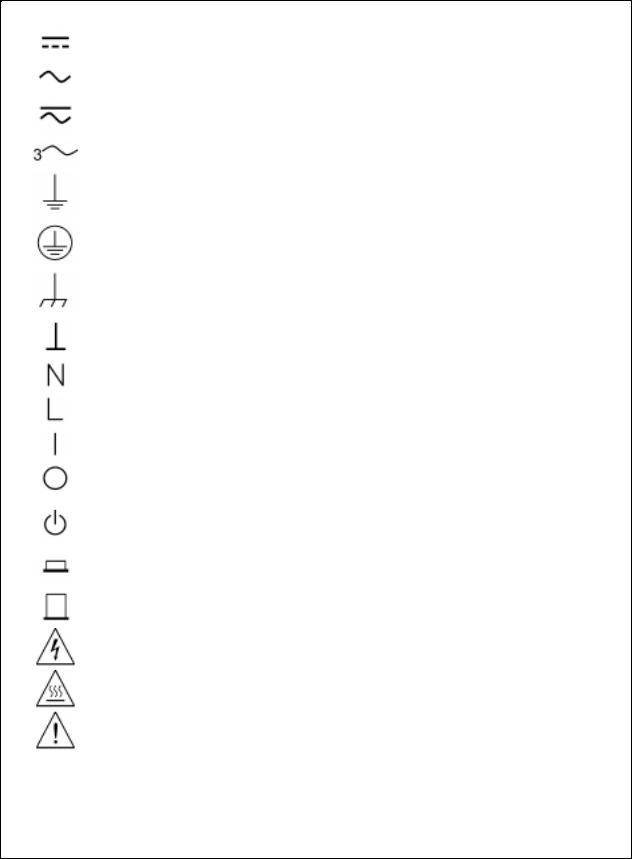

SAFETY SYMBOLS

WARNING

Caution

Direct current

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal is at earth potential. Used for measurement and control circuits designed to be operated with one terminal at earth potential.

Terminal for Neutral conductor on permanently installed equipment

Terminal for Line conductor on permanently installed equipment

On (supply)

Off (supply)

Standby (supply). Units with this symbol are not completely disconnected from ac mains when this switch is off. To completely disconnect the unit from ac mains, either disconnect the power cord or have a qualified electrician install an external switch.

In position of a bi-stable push control

Out position of a bi-stable push control

Caution, risk of electric shock

Caution, hot surface

Caution (refer to accompanying documents)

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed beyond a CAUTION sign until the indicated conditions are fully understood and met.

4

Declaration Page

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: |

Agilent Technologies |

Manufacturer’s Address: |

140 Green Pond Road |

|

Rockaway, New Jersey 07866 |

|

U.S.A. |

declares that the Product |

|

Product Name: |

a) Dynamic Measurement DC Source |

|

b) System DC Power Supply |

|

c) Remote Front Panel |

Model Number: |

a) Agilent 66311A, 66311B, 66312A, 66111A |

|

b) Agilent 6612B, 6611C, 6612C, 6613C, 6614C |

|

c) Agilent 14575A |

conforms to the following Product Specifications: |

|

Safety: |

IEC 1010-1:1990+A1(1992)/EN61010-1:1993 |

EMC: |

CISPR 11:1990 / EN 55011:1991 - Group 1 Class B |

|

IEC 801-2:1991 / EN 50082-1:1992 - 4 kV CD, 8 kV AD |

|

IEC 801-3:1984 / EN 50082-1:1992 - 3 V / m |

IEC 801-4:1988 / EN 50082-1:1992 - 0.5 kV Signal Lines

1 kV Power Lines

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC//93/68/EEC and the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

New Jersey |

December 1, 1998 |

______ |

Location |

Date |

Bruce Krueger / Quality Manager |

European Contact: Your local Agilent Technologies Sales and Service Office or Agilent Technologies GmbH, Department TRE, Herrenberger Strasse 130, D-71034 Boeblingen (FAX:+49-7031-14-3143)

5

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: |

Agilent Technologies |

Manufacturer’s Address: |

140 Green Pond Road |

|

Rockaway, New Jersey 07866 |

|

U.S.A. |

declares that the Product |

|

Product Name: |

a) Mobile Communication DC Source-Dual Output |

Model Number: |

a) Agilent 66309B, 66309D |

conforms to the following Product Specifications: |

|

Safety: |

IEC 1010-1:1990+A1(1992)/EN61010-1:1993 |

EMC: |

CISPR 11:1990 / EN 55011:1991 - Group 1 Class B |

|

IEC 801-2:1991 / EN 50082-1:1992 - 4 kV CD, 8 kV AD |

IEC 801-3:1984 / EN 50082-1:1992 - 3 V / m

IEC 801-4:1988 / EN 50082-1:1992 - 0.5 kV Signal Lines 1 kV Power Lines

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC//93/68/EEC and the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

New Jersey |

February, 1999 |

______ |

Location |

Date |

Bruce Krueger / Quality Manager |

European Contact: Your local Agilent Technologies Sales and Service Office or Agilent Technologies GmbH, Department TRE, Herrenberger Strasse 130, D-71034 Boeblingen (FAX:+49-7031-14-3143)

6

Acoustic Noise Information

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenläminformationsverordnung vom 18 Januar 1991.

*Schalldruckpegel Lp <70 dB(A)

*Am Arbeitsplatz

*Normaler Betrieb

*Nach EN 27779 (Typprüfung).

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the German Sound Emission Directive, from 18 January 1991.

*Sound Pressure Lp <70 dB(A)

*At Operator Position

*Normal Operation

*According to EN 27779 (Type Test).

Printing History

The edition and current revision of this manual are indicated below. Reprints of this manual containing minor corrections and updates may have the same printing date. Revised editions are identified by a new printing date. A revised edition incorporates all new or corrected material since the previous printing date.

Changes to the manual occurring between revisions are covered by change sheets shipped with the manual. In some cases, the manual change applies only to specific instruments. Instructions provided on the change sheet will indicate if a particular change applies only to certain instruments.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated into another language without the prior consent of Agilent Technologies. The information contained in this document is subject to change without notice.

© Copyright 1999 Agilent Technologies Inc. |

Edition 1 __________February, 1999 |

|

Update 1 __________January, 2000 |

|

Update 2 __________June, 2000 |

7

Table of Contents

Warranty Information |

2 |

Safety Summary |

3 |

Declaration Page |

5 |

Acoustic Noise Information |

7 |

Printing History |

7 |

Table of Contents |

8 |

1 - QUICK REFERENCE |

15 |

The Front Panel - At a Glance |

15 |

The Rear Panel - At a Glance |

16 |

Instrument Configuration |

16 |

Front Panel Number Entry |

17 |

Front Panel Annunciators |

18 |

Immediate Action Keys |

18 |

Front Panel Menus - At a Glance |

19 |

SCPI Programming Commands - At a Glance |

20 |

2 - GENERAL INFORMATION |

21 |

Document Orientation |

21 |

Safety Considerations |

22 |

Options and Accessories |

22 |

Description and Model Differences |

23 |

Common Capabilities |

24 |

Front Panel Controls |

24 |

Remote Programming |

24 |

Output 1 Characteristic |

25 |

Output 2 Characteristic |

26 |

Option 521 Description (Agilent 66309B/D only) |

27 |

3 - INSTALLATION |

29 |

Installation and Operation Checklist |

29 |

Inspection |

30 |

Damage |

30 |

Packaging Material |

30 |

Items Supplied |

30 |

Cleaning |

30 |

Location |

30 |

Bench Operation |

31 |

Rack Mounting |

31 |

Input Connections |

31 |

Connect the Power Cord |

31 |

Output Connections |

32 |

Output 1 |

32 |

Output 2 |

32 |

Current Ratings |

32 |

Voltage Drops and Lead Resistance |

32 |

Remote Sense Connections |

33 |

Load Regulation and Voltage Drop in the Remote Sense Leads |

35 |

Maintaining Stability while Remote Sensing |

35 |

Open Sense Lead Protection |

36 |

Local Sensing |

37 |

Output Compensation |

38 |

OVP Considerations |

39 |

8

DVM Connections |

39 |

Measuring Circuits that are Not Powered by the Main Output |

40 |

Measuring Circuits that are Floating with Respect to the Main Output |

41 |

External Protection Connections |

42 |

Digital I/O Connections |

43 |

Computer Connections |

43 |

GPIB Interface |

43 |

RS-232 Interface |

44 |

4 - TURN-ON CHECKOUT |

45 |

Checkout Procedure |

45 |

In Case of Trouble |

47 |

Selftest Error Messages |

47 |

Runtime Error Messages |

48 |

Line Fuse |

48 |

5 - FRONT PANEL OPERATION |

49 |

|

Introduction |

49 |

|

Front Panel Description |

49 |

|

System Keys |

51 |

|

Function Keys |

52 |

|

Immediate Action Keys |

52 |

|

Scrolling Keys |

52 |

|

Metering Keys |

53 |

|

Output Control Keys |

54 |

|

Entry Keys |

55 |

|

Examples of Front Panel Programming |

56 |

|

1 |

- Using the Front Panel Display |

56 |

2 |

- Setting the Output Voltage, Current, Compensation, and Relay Mode |

57 |

3 |

- Setting the Output 2 Voltage and Current (Agilent 66309B/D only) |

58 |

4 |

- Querying and Clearing Output Protection and Errors |

59 |

5 |

– Making Basic Front Panel Measurements |

60 |

6 |

– Making Enhanced Front Panel Measurements |

61 |

7 |

– Making DVM Measurements (Agilent 66311D/66309D only) |

62 |

8 |

- Programming External Protection and the Digital Port Functions |

63 |

9 |

- Setting the GPIB Address and Programming Language |

63 |

10 - Storing and Recalling Instrument States |

64 |

|

6 - INTRODUCTION TO PROGRAMMING |

65 |

External References |

65 |

GPIB References |

65 |

SCPI References |

65 |

VXIplug&play Power Products Instrument Drivers |

66 |

Supported Applications |

66 |

System Requirements |

66 |

Downloading and Installing the Driver |

66 |

Accessing Online Help |

67 |

GPIB Capabilities of the DC Source |

67 |

GPIB Address |

67 |

RS-232 Capabilities of the DC Source |

67 |

RS-232 Data Format |

67 |

RS-232 Flow Control |

68 |

Introduction to SCPI |

68 |

Conventions Used in This Guide |

69 |

Types of SCPI Commands |

69 |

Multiple Commands in a Message |

70 |

Moving Among Subsystems |

70 |

9

Including Common Commands |

70 |

Using Queries |

71 |

Types of SCPI Messages |

71 |

The Message Unit |

71 |

Headers |

71 |

Query Indicator |

72 |

Message Unit Separator |

72 |

Root Specifier |

72 |

Message Terminator |

72 |

SCPI Data Formats |

72 |

Numerical Data Formats |

72 |

Suffixes and Multipliers |

73 |

Response Data Types |

73 |

SCPI Command Completion |

73 |

Using Device Clear |

74 |

SCPI Conformance Information |

74 |

SCPI Conformed Commands |

74 |

Non-SCPI Commands |

74 |

7 - PROGRAMMING THE DC SOURCE |

75 |

Introduction |

75 |

Programming the Output |

75 |

Power-on Initialization |

75 |

Enabling the Output |

75 |

Output Voltage |

76 |

Output Current |

76 |

Triggering Output Changes |

77 |

SCPI Triggering Nomenclature |

77 |

Output Trigger Model |

77 |

Setting the Voltage or Current Transient Levels |

77 |

Enabling the Output Trigger System |

78 |

Selecting the Output Trigger Source |

78 |

Generating Triggers |

78 |

Making Basic Measurements |

79 |

Average Measurements |

79 |

Controlling Measurement Samples |

79 |

Window Functions |

80 |

Measuring Output 2 Voltage and Current (Agilent 66309B/D only) |

80 |

Making Enhanced Measurements |

80 |

Current Ranges and Measurement Detector |

81 |

RMS Measurements |

81 |

Pulse Measurements |

82 |

Returning All Measurement Data From the Data Buffer |

83 |

Making DVM Measurements |

83 |

Average Measurements |

83 |

RMS Measurements |

83 |

Triggered Measurements |

84 |

SCPI Triggering Nomenclature |

84 |

Measurement Trigger Model |

84 |

Enabling the Measurement Trigger System |

85 |

Selecting the Measurement Trigger Source |

85 |

Selecting the Sensing Function |

85 |

Generating Measurement Triggers |

86 |

Pre-trigger and Post-trigger Data Acquisition |

88 |

Programming the Status Registers |

88 |

Power-On Conditions |

89 |

Operation Status Group |

90 |

10

Questionable Status Group |

91 |

Standard Event Status Group |

91 |

Status Byte Register |

91 |

Determining the Cause of a Service Interrupt |

92 |

Servicing Operation Status and Questionable Status Events |

92 |

Monitoring Both Phases of a Status Transition |

93 |

Inhibit/Fault Indicator |

93 |

Remote Inhibit (RI) |

93 |

Discrete Fault Indicator (DFI) |

94 |

Using the Inhibit/Fault Port as a Digital I/O |

94 |

8 - LANGUAGE DICTIONARY |

95 |

Introduction |

95 |

Subsystem Commands |

95 |

Common Commands |

99 |

Programming Parameters |

99 |

Calibration Commands |

100 |

CALibrate:CURRent |

100 |

CALibrate:CURRent2 |

100 |

CALibrate:CURRent:MEASure:LOWRange |

100 |

CALibrate:CURRent:MEASure:AC |

100 |

CALibrate:DATA |

101 |

CALibrate:DATE |

101 |

CALibrate:DVM |

101 |

CALibrate:LEVel |

101 |

CALibrate:PASSword |

101 |

CALibrate:SAVE |

102 |

CALibrate:STATe |

102 |

CALibrate:VOLTage |

102 |

CALibrate:VOLTage2 |

102 |

CALibrate:VOLTage:PROTection |

102 |

Display Commands |

103 |

DISPlay |

103 |

DISPlay:CHANnel |

103 |

DISPlay:MODE |

103 |

DISPlay:TEXT |

103 |

Measurement Commands |

104 |

FORMat |

104 |

FORMat:BORDer |

105 |

MEASure:ARRay:CURRent? FETCh:ARRay:CURRent? |

105 |

MEASure:ARRay:VOLTage? FETCh:ARRay:VOLTage? |

105 |

MEASure:CURRent? FETCh:CURRent? |

106 |

MEASure:CURRent2? |

106 |

MEASure:CURRent:ACDC? FETCh:CURRent:ACDC? |

106 |

MEASure:CURRent:HIGH? FETCh:CURRent:HIGH? |

107 |

MEASure:CURRent:LOW? FETCh:CURRent:LOW? |

107 |

MEASure:CURRent:MAXimum? FETCh:CURRent: MAXimum? |

107 |

MEASure:CURRent:MINimum? FETCh:CURRent:MINimum? |

108 |

MEASure:DVM? FETCh:DVM? |

108 |

MEASure:DVM:ACDC? FETCh:DVM:ACDC? |

108 |

MEASure:VOLTage? FETCh:VOLTage? |

108 |

MEASure:VOLTage2 |

109 |

MEASure:VOLTage:ACDC? FETCh:VOLTage:ACDC? |

109 |

MEASure:VOLTage:HIGH? FETCh:VOLTage:HIGH? |

109 |

MEASure:VOLTage:LOW? FETCh:VOLTage:LOW? |

110 |

MEASure:VOLTage:MAXimum? FETCh:VOLTage:MAXimum? |

110 |

MEASure:VOLTage:MINimum? FETCh:VOLTage:MINimum? |

110 |

11

SENSe:CURRent:DETector |

111 |

SENSe:CURRent:RANGe |

111 |

SENSe:FUNCtion |

112 |

SENSe:PROTection:STATe |

112 |

SENSe:SWEep:OFFSet:POINts |

112 |

SENSe:SWEep:POINts |

112 |

SENSe:SWEep:TINTerval |

113 |

SENSe:WINDow |

113 |

Output Commands |

114 |

INSTrument:COUPle:OUTPut:STATe |

114 |

OUTPut[1 | 2] |

114 |

OUTPut[1 | 2]:RELay:MODE |

114 |

OUTPut:DFI |

115 |

OUTPut:DFI:SOURce |

115 |

OUTPut:PON:STATe |

115 |

OUTPut:PROTection:CLEar |

116 |

OUTPut:PROTection:DELay |

116 |

OUTPut:RI:MODE |

116 |

OUTPut:TYPE |

116 |

[SOURce:]CURRent |

117 |

[SOURce:]CURRent2 |

117 |

[SOURce:]CURRent:PROTection:STATe |

118 |

[SOURce:]CURRent:TRIGger |

118 |

[SOURce:]CURRent2:TRIGger |

118 |

[SOURce:]DIGital:DATA |

119 |

[SOURce:]DIGital:FUNCtion |

119 |

[SOURce:]VOLTage |

119 |

[SOURce:]VOLTage2 |

120 |

[SOURce:]VOLTage:PROTection |

120 |

[SOURce:]VOLTage:PROTection:STATe |

120 |

[SOURce:]VOLTage:TRIGger |

121 |

[SOURce:]VOLTage2:TRIGger |

121 |

Status Commands |

121 |

STATus:PRESet |

121 |

STATus:OPERation? |

122 |

STATus:OPERation:CONDition? |

122 |

STATus:OPERation:ENABle |

122 |

STATus:OPERation:NTR STATus:OPERation:PTR |

123 |

STATus:QUEStionable? |

123 |

STATus:QUEStionable:CONDition? |

124 |

STATus:QUEStionable:ENABle |

124 |

STATus:QUEStionable:NTR STATus:QUEStionable:PTR |

124 |

System Commands |

125 |

SYSTem:ERRor? |

125 |

SYSTem:LANGuage |

125 |

SYSTem:VERSion? |

125 |

Trigger Commands |

126 |

ABORt |

126 |

INITiate:SEQuence INITiate:NAME |

126 |

INITiate:CONTinuous:SEQuence1 INITiate:CONTinuous:NAME TRANsient |

127 |

TRIGger |

127 |

TRIGger:SOURce |

127 |

TRIGger:SEQuence2 TRIGger:ACQuire |

128 |

TRIGger:SEQuence2:COUNt:CURRent TRIGger:ACQuire:COUNt:CURRent |

128 |

TRIGger:SEQuence2:COUNt:DVM TRIGger:ACQuire:COUNt:DVM |

128 |

TRIGger:SEQuence2:COUNt:VOLTage TRIGger:ACQuire:COUNt:VOLTage |

129 |

TRIGger:SEQuence2:HYSTeresis:CURRent TRIGger:ACQuire:HYSTeresis:CURRent |

129 |

12

TRIGger:SEQuence2:HYSTeresis:DVM TRIGger:ACQuire:HYSTeresis:DVM |

130 |

TRIGger:SEQuence2:HYSTeresis:VOLTage TRIGger:ACQuire:HYSTeresis:VOLTage |

130 |

TRIGger:SEQuence2:LEVel:CURRent TRIGger:ACQuire:LEVel:CURRent |

131 |

TRIGger:SEQuence2:LEVel:DVM TRIGger:ACQuire:LEVel:DVM |

131 |

TRIGger:SEQuence2:LEVel:VOLTage TRIGger:ACQuire:LEVel:VOLTage |

132 |

TRIGger:SEQuence2:SLOPe:CURRent TRIGger:ACQuire:SLOPe:CURRent |

132 |

TRIGger:SEQuence2:SLOPe:DVM TRIGger:ACQuire:SLOPe:DVM |

133 |

TRIGger:SEQuence2:SLOPe:VOLTage TRIGger:ACQuire:SLOPe:VOLTage |

133 |

TRIGger:SEQuence2:SOURce TRIGger:ACQuire:SOURce |

134 |

TRIGger:SEQuence1:DEFine TRIGger:SEQuence2:DEFine |

134 |

Common Commands |

135 |

*CLS |

135 |

*ESE |

135 |

*ESR? |

136 |

*IDN? |

136 |

*OPC |

136 |

*OPT? |

137 |

*PSC |

137 |

*RCL |

137 |

*RST |

138 |

*SAV |

138 |

*SRE |

139 |

*STB? |

139 |

*TRG |

140 |

*TST? |

140 |

*WAI |

140 |

Additional Commands |

141 |

INSTrument:STATe |

141 |

OUTPut:PROTection:TRIPped? |

141 |

CURRent:LIMit:HIGH? |

141 |

CURRent:LIMit:LOW? |

141 |

CURRent:PROTection:TRIPped? |

142 |

VOLTage:LIMit:HIGH? |

142 |

VOLTage:LIMit:LOW? |

142 |

VOLTage:PROTection:TRIPped? |

142 |

A - SPECIFICATIONS |

143 |

Specifications |

143 |

Supplemental Characteristics |

144 |

B - VERIFICATION AND CALIBRATION |

147 |

Introduction |

147 |

Equipment Required |

147 |

Test Setup |

147 |

Performing the Verification Tests |

148 |

Turn-On Checkout |

148 |

Voltage Programming and Measurement Accuracy |

149 |

Current Programming and Measurement Accuracy |

149 |

DVM Measurement Accuracy |

151 |

Performing the Calibration Procedure |

154 |

Front Panel Calibration Menu |

154 |

Front Panel Calibration Procedure |

155 |

Calibration Error Messages |

159 |

Changing the Calibration Password |

159 |

Calibration Over the GPIB |

159 |

13

C - ERROR MESSAGES |

161 |

Error Number List |

161 |

D - EXAMPLE PROGRAMS |

165 |

Introduction |

165 |

Assigning the GPIB Address in Programs |

165 |

National Instruments GPIB Driver |

165 |

BASIC |

168 |

Pulse Measurements |

169 |

DFI Programming Example |

173 |

E - LINE VOLTAGE CONVERSION |

175 |

Open the Unit |

175 |

Configure the Power Transformer |

175 |

Install the Correct Line Fuse |

175 |

Close the Unit |

175 |

F - COMPATIBILITY LANGUAGE |

177 |

Introduction |

177 |

INDEX |

183 |

14

1

Quick Reference

The Front Panel - At a Glance

1 A 14-character display |

2 Annunciators indicate |

shows output measurements |

operating modes and status |

and programmed values. |

conditions. |

3 Rotary control sets voltage, current, and menu parameters.

Use Æ and Ç

to set the resolution; then adjust the value with the knob.

1 |

2 |

3 |

|

66309D |

DUAL OUTPUT |

|

|

|

|

|

|

Mobile Communications DC Source |

|

|

|

|

||

CV |

CC |

Unr Dis |

OCP Prot Cal |

Shift Rmt Addr Err |

SRQ |

|

|

|

SYSTEM |

|

|

FUNCTION |

|

|

ENTRY |

Channel |

Error |

Input |

OV |

|

Res |

Cir Entry |

|

Local |

Address |

Meter |

Voltage |

. |

Output |

Enter |

|

LINE |

|

|

|

|

|

Number |

|

1 |

2 |

3 |

4 |

5 |

|

- |

|

|

|

|

|||||

|

|

Save |

Prot Cir |

OCP |

|

Cal |

|

Off |

|

Recall |

Protect |

Current |

|

Output |

Enter |

On |

6 |

7 |

8 |

9 |

0 |

On/Off |

|

|

|

|

|||||

Backspace

4 |

|

5 |

6 |

|

|

|

|

|

7 |

|

|

|

|

|

|

4 Turns the dc |

5 System keys: |

6 Function keys: |

7 Entry keys: |

|

|

||||||||||

source on and off. |

♦ |

return to Local mode |

♦ |

enable/disable the |

♦ |

enter values |

|

|

|||||||

|

♦ |

select output channel |

|

output |

♦ |

increment or |

|||||||||

|

♦ |

set GPIB address |

♦ |

select metering |

|

decrement values |

|||||||||

|

♦ |

set RS-232 interface |

|

functions |

♦ |

|

|

and |

|

|

|

||||

|

|

É |

|

|

È |

|

|||||||||

|

♦ |

display SCPI error |

♦ |

program voltage and |

|

|

front |

|

|

||||||

|

|

select |

panel |

|

|||||||||||

|

|

codes |

|

current |

|

menu parameters. |

|||||||||

|

♦ |

save and recall |

♦ set and clear protection |

♦ |

Æ |

|

and |

|

Ç |

|

|||||

|

♦ |

instrument states |

♦ |

functions |

|

select |

a digit in |

||||||||

|

display firmware |

|

|

and |

|

|

|

the numeric entry |

|||||||

|

|

ó |

€ |

|

|||||||||||

|

|

revision and serial |

|

|

|

|

|

|

|

field. |

|

|

|

|

|

|

|

|

|

scroll |

through the front |

|

|

|

|

|

|||||

|

|

number. |

|

panel menu commands. |

|

|

|

|

|

|

|

||||

15

1 - Quick Reference

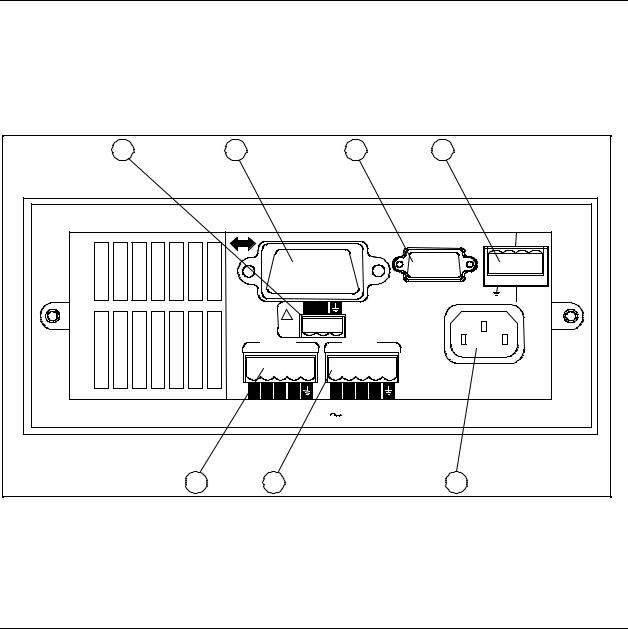

The Rear Panel - At a Glance

1 DVM inputs. |

2 GPIB (IEEE-488) |

3 Remote front panel |

4 INH/FLT (remote |

Connector plug is |

interface connector. |

display connector. |

INHibit / internal FauLT) |

removable. |

|

RS-232 interface for |

connector. Connector plug |

|

|

Agilent 66111A, |

is removable. |

|

|

66311B/D only. |

|

1 |

2 |

3 |

4 |

WARNING: |

NO OPERATOR SERVICEABLE PARTS |

REFER SERVICING TO SERVICE TRAINED |

INH FLT

+ - +

|

- |

+ |

|

! |

|

|

DVM |

|

|

OUTPUT 2 |

OUTPUT 1 |

|

0 - 12V / 0 - 1.5A |

0 - 15V / 0 - 3A |

|

-S - + +S |

-S - + +S |

WARNING: |

FOR CONTINUED FIRE PROTECTION, USE SPECIFIED LINE |

|

5 |

6 |

7 |

5 Output 2 connector |

6 Output 1 connector. |

7 Power cord |

(Agilent 66309B/D only). |

Connector plug is removable. |

connector (IEC 320) |

Connector plug is removable. |

IMPORTANT: Install this connector with |

|

|

its supplied sense jumpers before applying |

|

|

power to the unit. |

|

Instrument Configuration

Use the front panel Address key to configure the interface

Refer to “Front Panel Menus - At a Glance”

♦Select either the GPIB or RS-232 interface.

♦Enter the GPIB bus address.

♦Configure the RS-232 baud rate, parity, and flow control.

♦Select either the SCPI or COMPatibility programming language.

♦Enable the optional Agilent 14575A remote front panel.

16

Quick Reference - 1

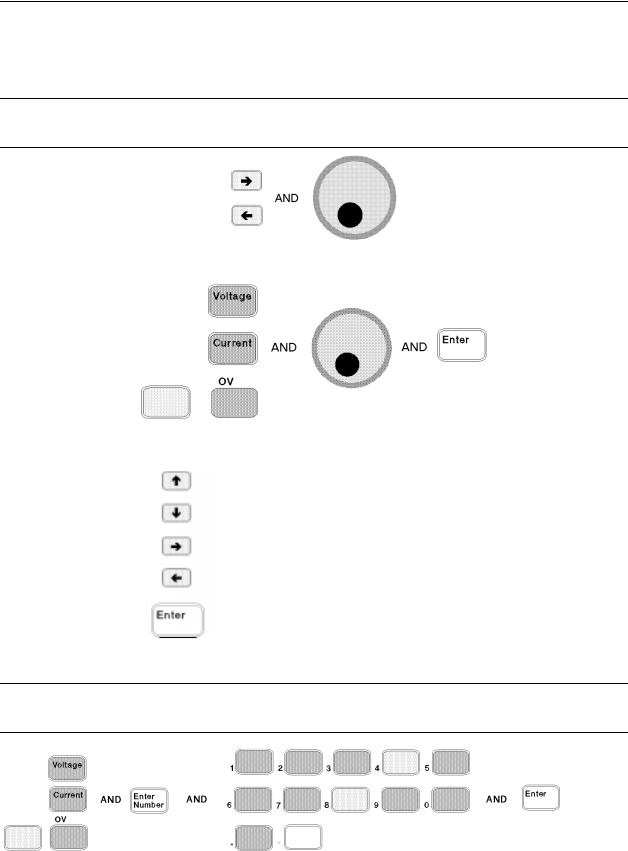

Front Panel Number Entry

Enter numbers from the front panel using one the following methods:

Use the arrow keys and knob to change voltage or current settings

NOTE: The output must be ON to see the displayed values change in Meter mode. With the output enabled, this method changes the output voltage or current immediately.

Use the Function keys and knob to change the displayed settings

Use the arrow keys to edit individual digits in the displayed setting

Increments the flashing digit

Decrements the flashing digit

Moves the flashing digit to the right

Moves the flashing digit to the left

Enters the value when editing is complete

Use the Function keys and Entry keys to enter a new value

NOTE: If you make a mistake, use the Backspace key to delete the number, or press the Meter key to return to meter mode.

17

1 - Quick Reference

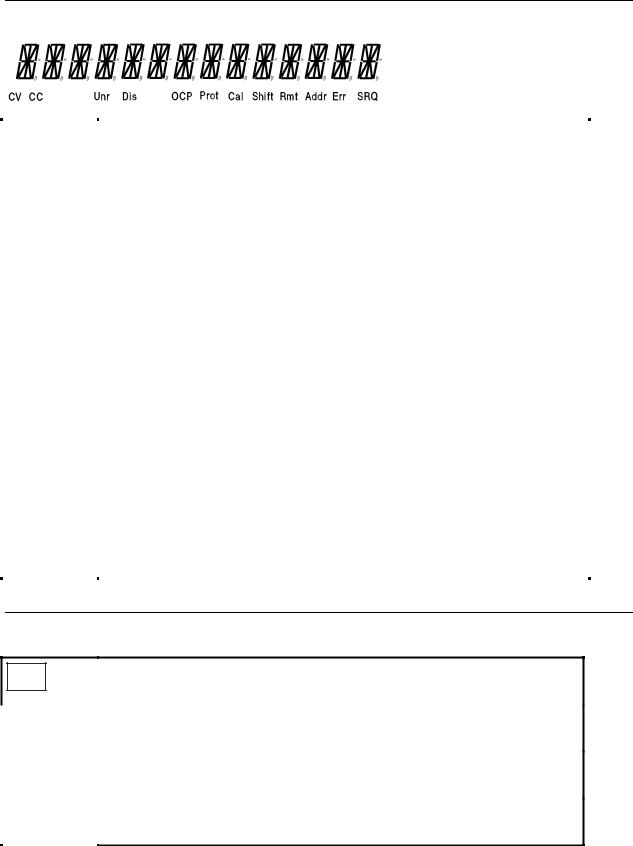

Front Panel Annunciators

CV |

|

Output 1 or output 2 is operating in constant voltage mode. |

CC |

|

Output 1 or output 2 is operating in constant current mode. |

Unr |

|

Output 1 or output 2 is unregulated. |

Dis |

|

The output is OFF. Press the Output On/Off key to turn the output on. |

OCP |

|

The over-current protection state is ON. Press the OCP key to turn over-current |

|

|

protection off. |

Prot |

|

Indicates that the output has been disabled by one of the protection features. |

|

|

Press the Prot Clear key to clear the protection condition. |

Cal |

|

Calibration mode is ON. Scroll to the Cal Off command and press the Enter key |

|

|

to exit the calibration mode. |

Shift |

|

The Shift key has been pressed. |

Rmt |

|

The remote programming interface (GPIB or RS-232) is active. Press the Local |

|

|

key to return the unit to front panel control. |

Addr |

|

The interface is addressed to talk or listen. |

Err |

|

There is an error in the SCPI error queue. Press the Error key to view the error |

|

|

code. |

SRQ |

|

The interface is requesting service. |

|

|

|

Immediate Action Keys

Output

On/Off

|

|

|

|

|

|

|

Local |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shift |

|

Prot Clr |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Shift |

|

OCP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Toggles the output of the selected output between the ON and OFF states. When coupled, turns both output channels ON or OFF.

Activates front panel control when the unit is in remote mode (unless a Lockout command is in effect).

Resets the protection circuit and allows the unit to return to its last programmed state.

A toggle switch that enables or disables overcurrent protection.

18

Quick Reference - 1

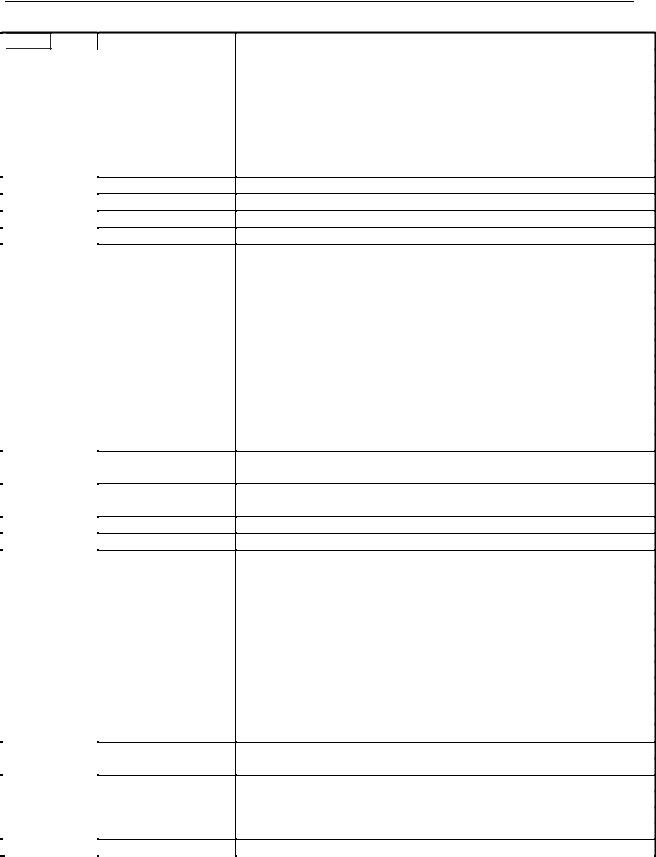

Front Panel Menus - At a Glance

Address

Address

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

|

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

Recall |

|

|

|

|

|

|

Shift |

|

|

Save |

|

|

|

Shift |

|

|

Error |

|

|

|

Shift |

|

|

Channel |

|

|

|

Meter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

|

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

Voltage |

|

|

|

|

|

|

|

|

|

|

|

|

|

Current |

|

|

|

|

|

|

|

|

|

|

|

|

|

Shift |

|

Res |

|

|

|

|

Protect |

|

|

|

|

|

|

Output |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

Shift |

|

OV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ó |

|

|

|

Shift |

|

|

Input |

|

|

|

|

|

|

|

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

|

|

|

ó |

|

|

|

Shift |

|

Cal |

|

|

|

|

|

|

|

|

|

|

ADDRESS 7

INTF GPIB BAUDRATE 300 PARITY NONE FLOW NONE LANG SCPI REMOTE FP OFF ROM: A.00.00 SN: US12345678

*RCL 0

*SAV 0

ERROR 0

2 5.000V 0.104A

1 |

12.000V |

1 0.204A |

1 |

12.500V |

MAX |

1 |

1.000V |

MIN |

1 |

12.330V |

HIGH |

1 |

0.080V |

LOW |

1 |

12.000V |

RMS |

1 |

0.350A |

MAX |

1 |

0.050A |

MIN |

1 |

0.400A |

HIGH |

1 |

0.012A |

LOW |

1 |

0.210A |

RMS |

1 |

12.000V DC:DVM |

|

112.000V RMS:DVM

1VOLT 12.000

2VOLT 2.000

1CURR 2.000

2CURR 1.000

OVERCURRENT

*RST COUPLING ALL TYPE:CAP LOW PON:STATE RST PROT:DLY 0.08 RI LATCHING DFI OFF DFI:SOUR OFF PORT RIDFI DIGIO 7

SENSE:PROT OFF 1 REL:MODE DD

VOLT:PROT 22 PROT:STAT ON

CURR:RANG HIGH CURR:DET ACDC TINT 46.8

POINT 2048

CAL ON

Sets the GPIB Address

Selects an interface (GPIB | RS232) 1

Selects baud rate (300 | 600 | 1200 | 2400 | 4800 | 9600) 1 Selects message parity (NONE | EVEN | ODD | MARK | SPACE) 1 Selects flow control (XON-XOFF | RTS-CTS | DTR-DSR | NONE) 1 Selects language (SCPI | COMP) 1

Enables or disables Agilent 14575A remote front panel (ON | OFF) Displays the firmware revision of the instrument

Displays the serial number of the instrument

Recalls the instrument state

Saves the present instrument state

Displays the number of errors in the SCPI error queue

Toggles the display between output 1 and output 2 (output 2 shown)

Measures the output voltage and current (output 1 shown)

Measures the peak output voltage 2

Measures the minimum output voltage 2

Measures the high level of a voltage pulse waveform 2

Measures the low level of a voltage pulse waveform 2

Measures the rms voltage 2

Measures the peak output current 2

Measures the minimum output current 2

Measures the high level of a current pulse waveform 2

Measures the low level of a current pulse waveform 2

Measures the rms current 2

Measures the dc voltage on the DVM input 3

Measures the rms voltage on the DVM input 3

Sets the voltage of output 1 on all models

Sets the voltage of output 2 4

Sets the current limit of output 1 on all models

Sets the current limit of output 2 4

Not available

Protection status (example shows overcurrent tripped)

Places the dc source in the factory-default state

Couples or decouples output 1 and output 2 (NONE or ALL) 3 Sets the output capacitance compensation (HIGH, H2, or LOW) Select the power-on state command (RST or RCL0)

Sets the output protection delay in seconds

Sets the remote inhibit mode (LATCHING, LIVE, or OFF) Sets the discrete fault indicator state (ON or OFF)

Selects the DFI source (QUES, OPER, ESB, RQS, or OFF) Sets the output port functions (RIDFI or DIGIO)

Sets and reads the I/O port value (0 through 7)

Enables or disables the open sense lead detect circuit (ON or OFF)

Sets the relay mode for Option 521 units (DD, HD, DH, or HH) (output 1 shown)

Sets the overvoltage protection level

Enables or disables overvoltage protection (ON or OFF)

Sets the current range (HIGH, LOW, or AUTO) 2

Sets the current measurement detector (ACDC or DC) 2

Sets the time interval for a front panel measurement in seconds Sets the buffer size for a front panel measurement

Accesses calibration menu (See Appendix B).

|

|

|

|

|

|

|

|

|

|

|

|

Use |

É |

and |

È |

|

to select parameters (table shows factory defaults). |

Use |

Meter |

to exit any menu. |

|||

1Not |

valid for Agilent Model 66309B |

2Not valid for Agilent Model 66111A |

|

|

|||||||

3Only valid for Agilent Model 66309B/D |

4Only valid for Agilent Model 66311D/66309D |

||||||||||

19

1 - Quick Reference

SCPI Programming Commands - At a Glance

NOTE: Some [optional] commands have been included for clarity. Refer to chapter 8 for a complete description of all programming commands.

ABORt CALibrate

:CURRent [:POSitive] :NEGative

:MEASure :LOWRange 1 :AC 1

:CURRent2 2 :DATA <n> :DATE <date> :DVM 3 :LEVel P1 | P2

:PASSword <n> :SAVE

:STATe <bool> [, <n>] :VOLTage [:DC]

:PROTection :VOLTage2 2

DISPlay

<bool>

:CHANnel <channel> 2 :MODE NORMal | TEXT :TEXT <display_string>

FORMat

[:DATA] ASCII | REAL [,length] :BORDer NORM | SWAP

INITiate

:SEQuence[1|2]

:NAME TRANsient | ACQuire :CONTinuous :SEQuence[1], <bool>

:NAME TRANsient, <bool>

INSTrument

:COUPling:OUTPut:STATe NONE | ALL 2

MEASure

:CURRent2 [:DC]? 2 :VOLTage2 [:DC]? 2

MEASure | FETCh

:ARRay :CURRent? :VOLTage?

[:CURRent] [:DC]? :ACDC? 1 :HIGH? 1 :LOW? 1 :MAX? 1 :MIN? 1

:DVM [:DC]? 3 :ACDC? 3

:VOLTage [:DC]? :ACDC? 1 :HIGH? 1 :LOW? 1 :MAX? 1 :MIN? 1

OUTPut [1|2]

<bool> :DFI <bool>

:SOURce QUES | OPER | ESB | RQS | OFF :PON :STATe RST | RCL0

:PROTection :CLEar :DELay <n>

:RELay :MODE DD | HD | DH | HH 2

:RI :MODE LATCHing | LIVE | OFF :TYPE [:CAPacitance] HIGH | H2 | LOW

SENSe

:CURRent :RANGe <n>1 :DETector ACDC | DC1

:FUNCtion “VOLT” | “CURR” | "DVM" :PROTection :STATe <bool> :SWEep :OFFSet :POINts <n>

:POINts <n> :TINTerval <n>

:WINDow :TYPE “HANN” | “RECT”

[SOURce:]

CURRent <n> :TRIGgered <n>

:PROTection :STATe <bool> CURRent2 <n> 2

:TRIGgered <n> 2 DIGital :DATA <n>

:FUNCtion RIDF | DIG VOLTage <n>

:TRIGgered <n> :PROTection <n>

:STATe <bool>

VOLTage2 <n> 2 :TRIGgered <n> 2

STATus

:PRESet

:OPERation [:EVENt]? :CONDition? :ENABle <n> :NTRansition <n> :PTRansition <n>

:QUEStionable [:EVENt]? :CONDition? :ENABle <n> :NTRansition <n> :PTRansition <n>

SYSTem

:ERRor?

:LANGuage SCPI | COMPatibility :VERSion?

TRIGger

:SEQuence2| :ACQuire [:IMMediate] :COUNt :CURRent <n>

:DVM <n> 3 :VOLTage <n>

:HYSTeresis:CURRent <n> :DVM <n> 3 :VOLTage <n>

:LEVel :CURRent <n> :DVM <n> 3 :VOLTage <n>

:SLOPe :CURRent POS | NEG | EITH :DVM POS | NEG | EITH 3 :VOLTage POS | NEG | EITH

:SOURce BUS | INTernal [:SEQuence1| :TRANsient][:IMMediate]

:SOURce BUS :SEQuence1 :DEFine TRANsient :SEQuence2 :DEFine ACQuire

1Not valid for Agilent 66111A

2Only valid for Agilent 66309B/D

3Only valid for Agilent 66311D/66309D

20

2

General Information

Document Orientation

This manual describes the operation of the Agilent Model 66111A Fast Transient, the Agilent Model 66311B/D Mobile Communications, and the Agilent Model 66309B/D Dual Output DC Source. Agilent Models 66311D and 66309D have an additional DVM measurement input on the rear panel. Unless otherwise noted, these models will be referred to by the description "dc source" throughout this manual.

The following Getting Started Map will help you find the information you need to complete the specific task that you want to accomplish. Refer to the table of contents or index of each guide for a complete list of the information contained within.

Getting Started Map

Task

Quick Reference Section

General information

Model differences Capabilities and characteristics

Where to find information

Chapter 1

Chapter 2

Installing the unit |

Chapter 3 |

Line connections |

|

Computer connections |

|

Load connections |

|

Checking out the unit |

Chapter 4 |

Verifying proper operation |

|

Using the front panel |

|

Calibrating the unit |

|

Using the front panel

Front panel keys

Front panel examples

Using the programming interface

GPIB interface

RS-232 interface

Programming the unit using SCPI (and

COMPatibility) commands

SCPI commands

SCPI programming examples

SCPI language dictionary

Installing the VXIplug&play instrument driver

NOTE: The driver must be installed on your pc to access the on-line information. Drivers are available on the web at www.agilent.com/find/drivers.

Chapter 5

Chapter 6

Chapters 7 and 8 for SCPI commands. Appendix D for SCPI examples Appendix F for COMPatibility commands

Chapter 6

21

2 - General Information

Safety Considerations

This dc source is a Safety Class 1 instrument, which means it has a protective earth terminal. That terminal must be connected to earth ground through a power source equipped with a ground receptacle. Refer to the Safety Summary page at the beginning of this guide for general safety information. Before installation or operation, check the dc source and review this guide for safety warnings and instructions. Safety warnings for specific procedures are located at appropriate places in the guide.

Options and Accessories

|

Table 2-1. Options |

Option |

Description |

100 |

87−106 Vac, 47−63 Hz |

220 |

191−233 Vac, 47−63 Hz |

230 |

207−253 Vac, 47−63 Hz |

8ZJ |

Delete instrument feet option |

004Output compensation is factory set to High mode for best transient response. (Refer to chapter 3, under "Output Compensation" for more information)

AXS1 |

Rack mount kit for two side-by-side units of equal depth. Consists of: |

|

Lock-link kit (p/n 5061-9694) and Flange kit (p/n 5062-3974) |

1CM1 |

Rack mount kit for one unit (p/n 5062-3972) |

521 |

Solid state relays to connect and disconnect the output (Models 66309B/D only) |

052 |

Device characterization software for current measurements and display |

|

(available for Agilent Model 66311B only) |

1Support rails are required when rack mounting units. Use E3663A support rails for Agilent rack cabinets. If you are using non-Agilent rack cabinets, contact the rack manufacturer to obtain support rails for your cabinet.

Table 2-2. Accessories

Item

GPIB cables 1.0 meter (3.3 ft)

2.0 meters (6.6 ft)

4.0 meters (13.2 ft)

0.5 meters (1.6 ft)

Rack mount with slide - for two side-by-side units of different depths

Rack mount - for two side by side units of different depths

Rack mount with slide - for one unit

Remote Front Panel - for viewing up to six units that are installed in a remote location where the front panels is not visible. Includes an ac/dc adapter for powering up to 3 remote panels

Part Number

Agilent 10833A

Agilent 10833B

Agilent 10833C

Agilent 10833D

5062-3996; 1494-0015

5062-3996

5062-3996; 1494-0015;

5062-4022

Agilent 14575A

22

General Information - 2

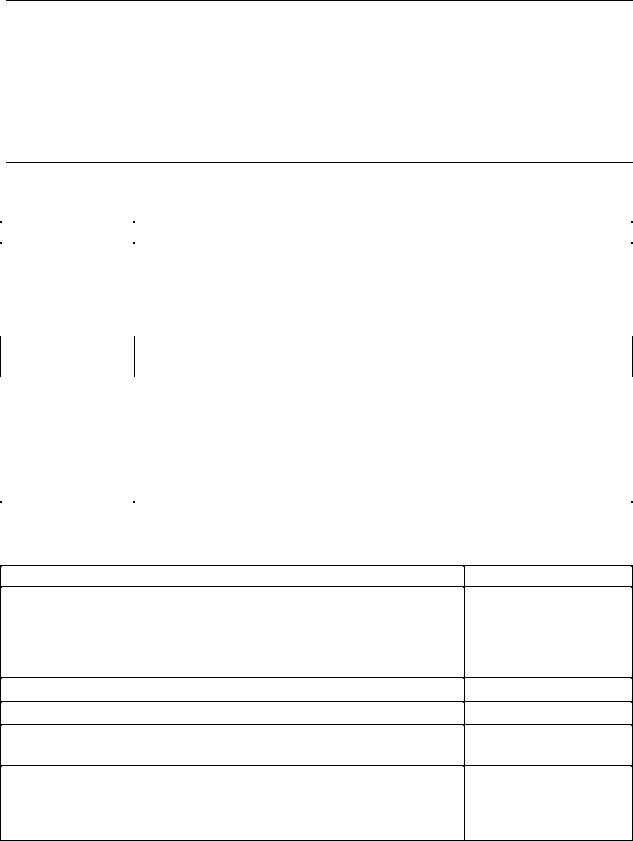

Description and Model Differences

The Agilent 66111A Fast Transient DC Source is a high performance dc power source that provides peak current sourcing and rapid, basic measurements in a compact, half-rack box. It is designed to simplify the testing of digital wireless communications products. Excellent voltage transient response characteristics prevent test interruptions due to triggering of low voltage phone shutdown. The 15 volt source and 5A peak current capability provides compatibility with a number of communications standards, including: GSM, CDMA, TDMA, PCS, DECT, TERA, PHS, NADC, PHS, and others. Figure 2-1 describes the output characteristic of the dc source.

The Agilent 66311B Mobile Communications DC Source is a high performance dc power source that provides all of the capabilities of the Agilent 66111A plus fast dynamic measurement and analysis of voltage and current waveforms. Dynamic measurement and analysis of current waveforms combined with precision current measurement let you characterize cellular phone current requirements under all operating conditions.

The Agilent 66309B Mobile Communications DC Source includes all of the capabilities of the Agilent 66311B with the addition of a second, electrically-isolated output. Figure 2-2 describes output characteristic of this second output, which is primarily used to provide voltage or current for a charger input on the device under test. The second output has all of the basic programmable features as the main output, with the exception of the waveform measurement capability, the open sense lead detect capability, overvoltage protection, and low current range.

The Agilent 66311D and 66309D Mobile Communications DC Sources also contain an auxiliary DVM, with input terminals located on the rear panel. This provides limited, low voltage dc and ac measurement capability, which can be used to monitor test point voltages on the unit under test as well as on the test fixture. The common mode voltage range is from −4.5 Vdc to +25 Vdc relative to the minus terminal of output 1. The DVM is programmable from the front panel of the instrument as well as remotely using SCPI programming commands.

|

Table 2-3. Model Differences |

|

|

||

Item |

Agilent |

Agilent |

Agilent |

Agilent |

Agilent |

|

66111A |

66311B |

66311D |

66309B |

66309D |

Waveform measurements |

NO |

YES |

YES |

YES1 |

YES1 |

Low range current |

NO |

YES |

YES |

YES1 |

YES1 |

measurements |

|

|

|

|

|

ACDC measurement |

NO |

YES |

YES |

YES1 |

YES1 |

detector |

|

|

|

|

|

Output compensation |

YES |

YES |

YES |

YES1 |

YES1 |

Open sense lead protection |

YES |

YES |

YES |

YES1 |

YES1 |

Auxiliary output (output |

NO |

NO |

NO |

YES |

YES |

2) |

|

|

|

|

|

External DVM input |

NO |

NO |

YES |

NO |

YES |

Adjustable measurement |

YES |

YES |

YES |

YES |

YES |

buffer |

|

|

|

|

|

Compatibility commands |

YES |

YES |

YES |

NO |

NO |

RS-232 interface |

YES |

YES |

YES |

NO |

NO |

1Applies to the main output (output 1) only.

23

2 - General Information

Common Capabilities

♦Voltage and current control with 12-bit programming resolution on output 1.

ê3 ampere current source capability (up to 5 amperes for 7 milliseconds)

♦Extensive measurement capability on output 1

êdc voltage and current.

êrms and peak voltage and current.

êCurrent measurement capability up to approximately 7.0 amperes

ê16-bit measurement resolution.

êTriggered acquisition of digitized current and voltage waveforms (all models except Agilent 66111A)

♦Front panel control with 14-character vacuum fluorescent display, keypad, and rotary control for voltage and current settings.

♦Built-in GPIB interface programming with SCPI command language.

♦Non-volatile state storage and recall with SCPI command language.

♦Over-voltage, over-current, over-temperature, and RI/DFI protection features.

♦Extensive selftest, status reporting, and software calibration.

Front Panel Controls

The front panel has both rotary and keypad controls for setting the output voltage and current. The panel display provides digital readouts of a number of output measurements. Annunciators display the operating status of the dc source. System keys let you perform system functions such as setting the GPIB address and recalling operating states. Front panel Function keys access the dc source function menus. Front panel Entry keys let you select and enter parameter values. Refer to chapter 5 for a complete description of the front panel controls.

Remote Programming

NOTE: When shipped, all dc sources are set to the SCPI programming language.

On Agilent 66111A and Agilent 66311B/D units you can change the programming language from SCPI to COMPatibility language. Press the front panel Address key, use ⌠to scroll to the LANG command, press É to select COMP, then press Enter. The language setting is saved in non-volatile memory.

The dc source may be remotely programmed via the GPIB bus, and on Agilent 66111A and 66311B/D units, from an RS-232 serial port. GPIB programming is with SCPI commands (Standard Commands for Programmable Instruments), which make dc source programs compatible with those of other GPIB instruments. Dc source status registers allow remote monitoring of a wide variety of dc source operating conditions. A Compatibility language mode is also included on Agilent 66311A and 66311B/D units to make the dc source compatible with the Agilent 6632A, 6633A, and 6634A Series dc power supplies (refer to appendix E). Note that the compatibility features of this unit are limited to the features that were originally available on Agilent 6632A, 6633A, and 6634A units.

24

General Information - 2

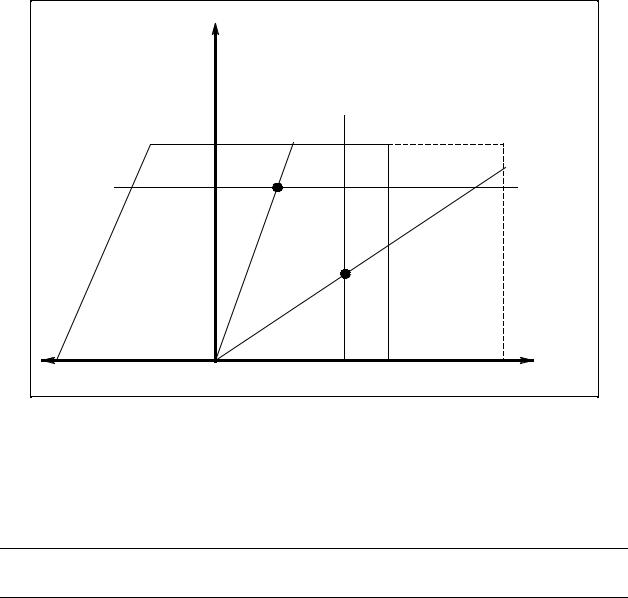

Output 1 Characteristic

The dc source’s main output (output 1) characteristic is shown in the following figure. The main output of the dc source may be adjusted to any value within the boundaries shown.

Output

Voltage

|

|

|

|

|

|

|

ISET |

|

|

|

|

15V |

|

|

|

|

|

|

|

|

|

|

-1.2A |

|

|

|

|

|

|

|

|

|

|

VSET |

|

|

|

1 |

|

|

|

|

|

|

|

|

ne |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

load |

l |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

|

v |

|

|

|

|

2 |

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

t |

|

|

|

|

|

|

|

|

|

|

s |

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

line |

Peak Current |

|

|

|

|

es |

|

|

|

|

|

|

|

||

|

r |

|

|

|

|

|

d |

|

|

|

|

V |

|

|

|

|

|

a |

capability for up |

|

|

|

|

|

|

|

|

lo |

|

|

||

|

C |

|

|

|

|

v |

|

|

|

|

|

|

|

|

|

i |

e |

to 7 ms shown |

|

|

|

|

|

|

|

s |

|

|

|

|

||

|

|

|

|

i |

t |

|

|

|

|

|

|

|

|

s |

|

|

|

by dotted lines |

|

|

|

|

|

e |

|

|

|

|

|

|||

|

|

r |

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

- |

C |

|

|

|

|

|

|

+ |

|

|

|

|

|

|

|

|

|

|

Output |

||

|

|

|

|

|

|

|

|

|

|

|

-2.8A |

0 |

|

|

|

|

|

3A |

5A |

|

Current |

|

|

|

|

|

|

|

||||

Figure 2-1. Dc Source Output 1 Characteristic

The dc source is capable of providing a constant dc output of 15 volts with up to 3 amperes of current. It is capable of sourcing peak currents of up to 5 amperes -- provided the peak current pulse does not exceed 7 milliseconds, and the average current requirement does not exceed 3 amperes. If the unit attempts to draw current for longer than seven milliseconds, the current limit amplifier will limit the current to a maximum of 3.0712 amps. The peak current capability is illustrated by the dotted line in Figure 2-1.

NOTE: To source up to 5 amperes of current for up to 7 milliseconds, the current limit must be programmed for greater than 3 amperes (up to a maximum of 3.0712 A).

The dc source can operate in either constant voltage (CV) or constant current (CC) over the rated output voltage and current. Although the dc source can operate in either mode, it is designed as a constant voltage source. This means that the unit turns on in constant voltage mode with the output voltage rising to its Vset value. There is no command for constant current operation. The only way to turn the unit on in constant current mode is by placing a short across the output and then enabling or turning the output on.

Note that the dc source cannot be programmed to operate in a specific mode. After inital turn-on, the operating mode of the unit will be determined by the voltage setting, current setting, and the load resistance. In figure 2-1, operating point 1 is defined by the load line traversing the positive operating quadrant in the constant voltage region. Operating point 2 is defined by the load line traversing the positive operating quadrant in the constant current region.

25

2 - General Information

Figure 2-1 also shows a single range − two quadrant capability. This means that the dc source is capable of sourcing as well as sinking current over the output voltage range from zero volts to the rated voltage. This negative current sinking capability provides fast downprogramming of the output of the dc source. It can also be used to sink current from a battery charger, thus providing battery charger test capability. The negative current is not programmable, and varies linearly from approximately 1.2 amperes at the full rated voltage, to approximately 2.8 amperes at zero output voltage.

NOTE: If you attempt to operate the dc source beyond its output ratings, the output of the unit may become unregulated. This is indicated by the UNR annunciator on the front panel. The output may also become unregulated if the ac line voltage drops below the minimum rating specified in Appendix A.

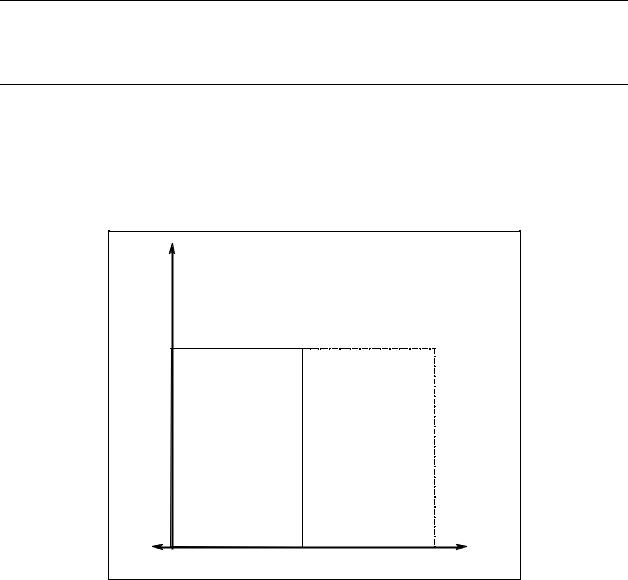

Output 2 Characteristic

As shown in the following figure, Agilent 66309B/D units have a second output rated at 12 V and 1.5A. The second output has all of the primary programmable features as the main output, with the exception of the waveform measurement capability, the open sense lead detect capability, overvoltage protection, and low current range.

Output

Voltage

+12V

-

0

Peak Current capability for up to 1 ms shown by dotted lines

|

+ Output |

|

1.5A |

3.0A |

Current |

|

||

Figure 2-2. Output 2 Characteristic

Tables A-1 through A-3 document the specifications and supplemental characteristics of the Agilent dc sources documented in this manual.

26

General Information - 2

Option 521 Description (Agilent 66309B/D only)

Option 521 consists of the following enhancements to the output capabilities of Agilent models 66309B/66309D:

♦Solid-state relays to connect and disconnect the output of the dc source.

The relays are available on the output and sense terminals of outputs 1 and 2. When the solid state relays are open, the output impedance is effectively raised to about 500k ohms for output 1, and about 200k ohms for output 2. Note that the relays open only in response to an Output OFF command.

♦The ability to either Hot switch or Dry switch the solid state relays.

With Hot switching, the relays control the on/off characteristics of the voltage at the output terminals. With Dry switching, the power mesh controls the on/off characteristics of the voltage at the output terminals. In general, Hot switching activates the relays when current is flowing through them. Dry switching activates the relays when no current is flowing through them. You can specify different relay options for the Output ON and Output OFF commands. The following table describes the actions that occur based on the relay mode selection in response to the ON or OFF commands.

|

|

Table 2-5. Option 521 Relay Modes |

||

Relay Mode |

|

Output ON |

|

Output OFF |

Dry (D) |

1. Closes the output relay |

1. |

Downprograms the output |

|

|

2. |

Closes the sense relay |

2. |

Opens the sense relay |

|

3. |

Programs the output |

3. |

Opens the output relay |

Hot (H) |

1. Programs the power mesh |

1. |

Opens the sense relay |

|

|

2. |

Closes the output relay |

2. |

Opens the output relay |

|

3. |

Closes the sense relay |

3. |

Downprograms the power mesh |

The relay modes are stored in non-volatile memory. The last selected mode will be restored when the unit is turned on. When shipped from the factory, the relay mode for both output 1 and output 2 is set to Output ON Hot, Output OFF Hot (HH). The *RST command has no effect on the relay mode.

NOTES: Even with open sense lead detection enabled, the dc source does not check for open sense leads when output 1 is enabled if the Output ON relay mode is set to Hot.

On output 1 and output 2, with the Output OFF relay mode set to Hot, any external output capacitors will not be downprogrammed or discharged. This is because the output relay opens prior to the downprogramming of the power mesh.

With either output 1 or output 2 disabled, the output voltage readback will not be correct. This is because the sense relay is open, effectively breaking the readback path. The voltage readback will be a small negative number.

Table 2-6. Option 521 Factory Settings

Output Coupling |

None |

|

(outputs not coupled) |

Output Sense Protection |

Off |

Output Compensation |

High |

Output 1 Relay Mode |

HH |

Output 2 Relay Mode |

HH |

27

3

Installation

Installation and Operation Checklist

Check the Output Compensation

Check that the output compensation of the dc source is appropriate for your application. Refer to “Output Compensation” in this chapter.

High mode provides the best transient response and can be used with phones having input capacitances from 5 to 12000μF. Note that if the last two digits on the front panel display are fluctuating when the phone is in standby, you may want to set the output compensation to Low mode.

Low mode is used when testing phones having input capacitances from 0 to 12000μF. Standard dc sources are factory-set to Low mode.

Check the Phone Connections

If you ARE remote sensing, are the + and − sense leads connected ONLY at the test fixture and within 20 inches of the phone contacts? For best performance, the distance from sense lead termination to the phone contacts should be as short as possible. Refer to “Lead Resistance” in this chapter. If your unit has a remote sense switch on the back, make sure it is set to the Remote position (out).

If you are NOT remote sensing, are the sense jumpers installed in the output connector? Ensure that the output connector plug is installed in the unit with its supplied sense jumpers in place. Without sense jumpers, the unit goes into a protect state with the output disabled. If your unit has a remote sense switch on the back, you don't need sense jumpers. Make sure the switch is set to the Local position (in).

Check the Operating Settings and Conditions

Are you able to communicate remotely with the dc source? If not, check that the address is set correctly. Refer to “GPIB Address” in the User’s Guide. If your unit has both SCPI and COMP language settings, check that the programming language is set correctly. Refer to “Language setting” in chapter 5.

Is the Prot or Err annunciator on the front panel on? If yes, clear the fault condition before continuing. Refer to “Clearing Protection” in chapter 5.

Is the Overvoltage circuit shutting the unit down? If yes, you can disable the overvoltage circuit. Refer to “Clearing Protection” in chapter 5.

Are the front panel readings unstable? If yes, check that the front panel sampling rate is correct. Also check the setting of the output compensation. Refer to “Front Panel Measurements” in chapter 5 and “Output Compensation” in this chapter.

Additional Agilent 66311/66309 Operating Settings Checks

Are you measuring dynamic output currents? If yes, check that the current detector is set to ACDC. Refer to “Front Panel Measurements” in chapter 5.

Are you measuring output currents under 20 mA? If yes, check that the current range is set to LOW. Refer to “Front Panel Measurements” in chapter 5.

29

3 - Installation

Inspection

Damage

When you receive your dc source, inspect it for any obvious damage that may have occurred during shipment. If there is damage, notify the shipping carrier and the nearest Agilent Sales and Support Office immediately. The list of Agilent Sales and Support Offices is at the back of this guide. Warranty information is printed in the front of this guide.

Packaging Material

Until you have checked out the dc source, save the shipping carton and packing materials in case the unit has to be returned. If you return the dc source for service, attach a tag identifying the model number and the owner. Also include a brief description of the problem.

Items Supplied

The following user-replaceable items are included with your dc source. Some of these items are installed in the unit.

Table 3-1. Items Supplied

Item

Power Cord

Part Number

contact the nearest Agilent Sales and Support Office

Description

A power cord appropriate for your location.

Digital I/O |

1252-1488 |

4-terminal digital plug for connecting digital I/O |

connector |

|

leads. The connector installs in the back of the unit. |

Output connector |

0360-2604 |

5-terminal output plug for connecting load and sense |

|

|

leads. This connector installs in the back of the unit. |

DVM connector |

1252-8670 |

3-terminal plug for DVM connections (66309B/D) |

Sense jumpers |

8120-8821 |

Jumpers that insert into output connector for local |

|

|

sensing. Connect +s to +, and −s to −. |

Line Fuse |

2110-0638 |

3.15 AT (time delay) for 100/120 Vac operation |

|

2110-0773 |

1.6 AT (time delay) for 220/230 Vac operation |

Feet |

5041-8801 |

feet for bench mounting |

User’s Guide |

5964-8125 |

This manual. Contains installation, checkout, front |

|

|

panel, and programming information. |

Cleaning

Use a dry cloth or one slightly dampened with water to clean the external case parts. Do not attempt to clean internally.

WARNING: To prevent electric shock, unplug the unit before cleaning.

Location

Figure 3-1 gives the dimensions of your dc source. The dc source must be installed in a location that allows sufficient space at the sides and back of the unit for adequate air circulation (see Bench Operation).

30

Loading...

Loading...